Electromagnetic Design and Losses Analysis of a High-Speed Permanent Magnet Synchronous Motor with Toroidal Windings for Pulsed Alternator

Abstract

:1. Introduction

2. Electromagnetic Design

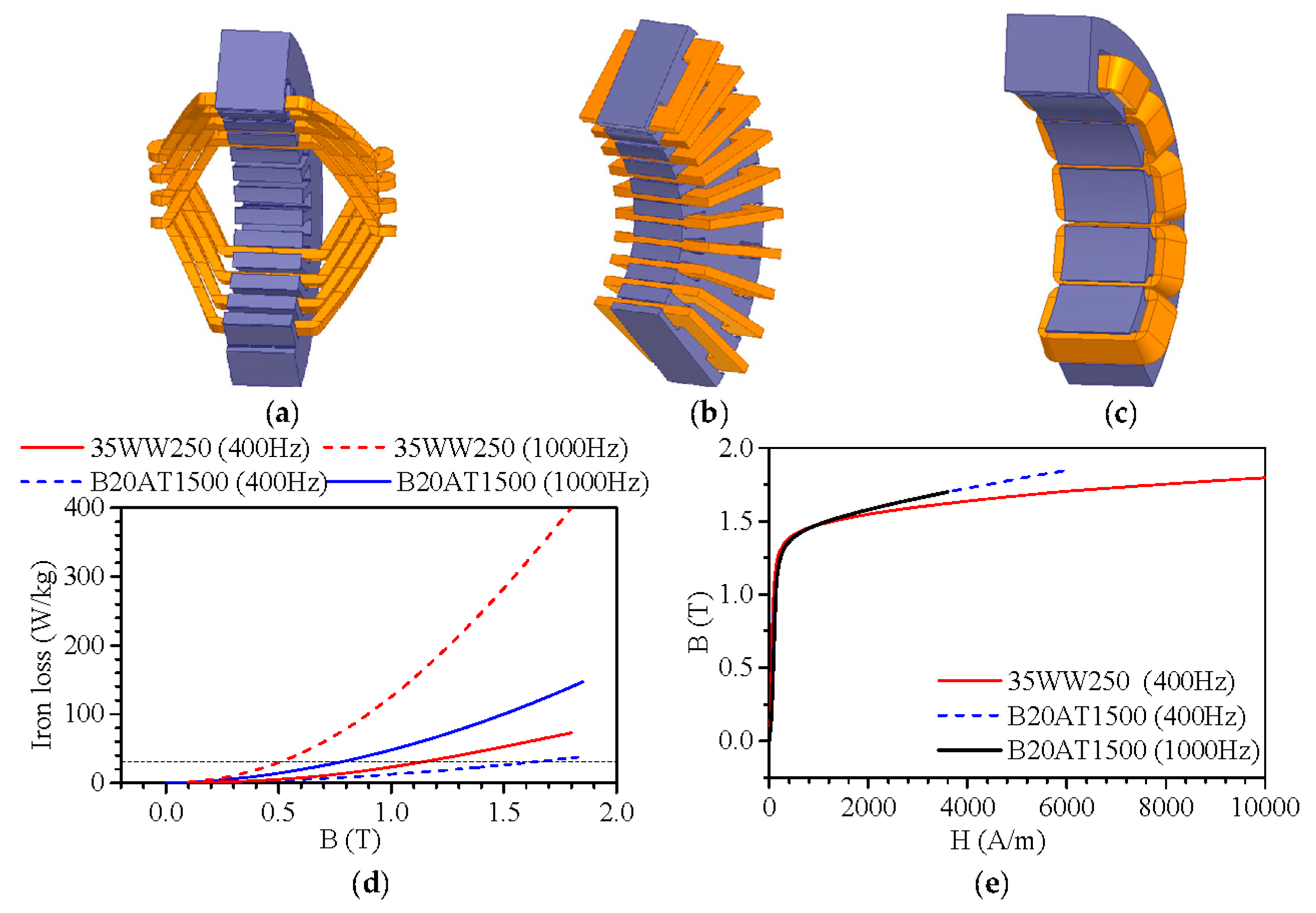

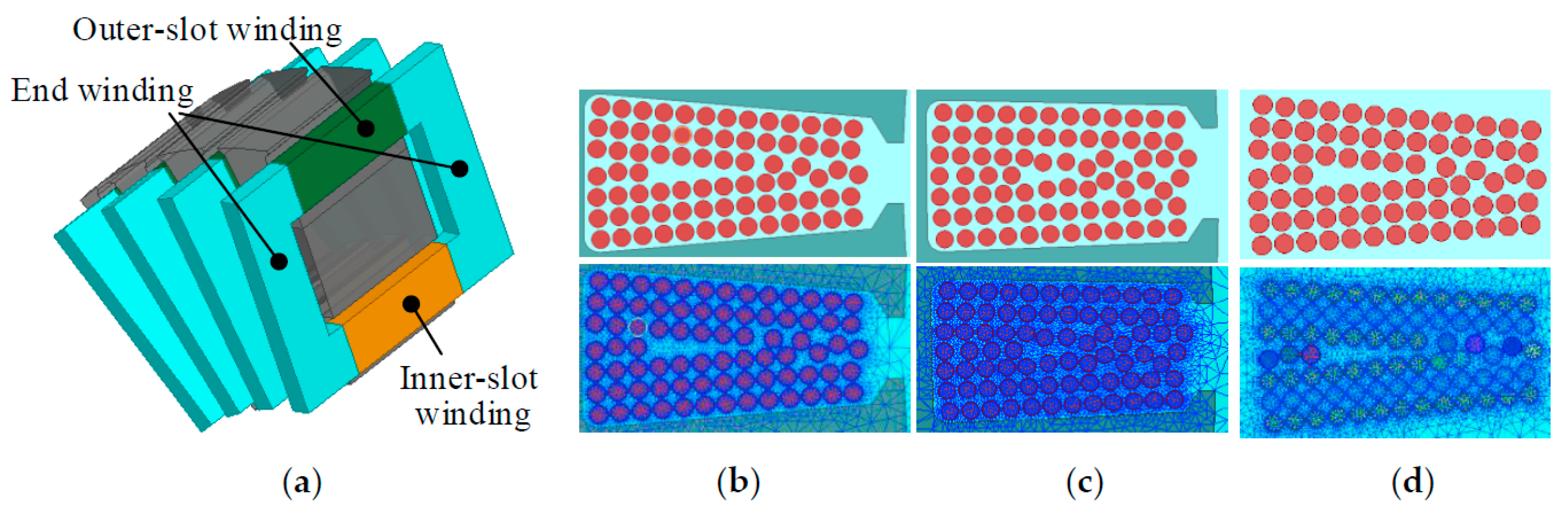

2.1. Windings

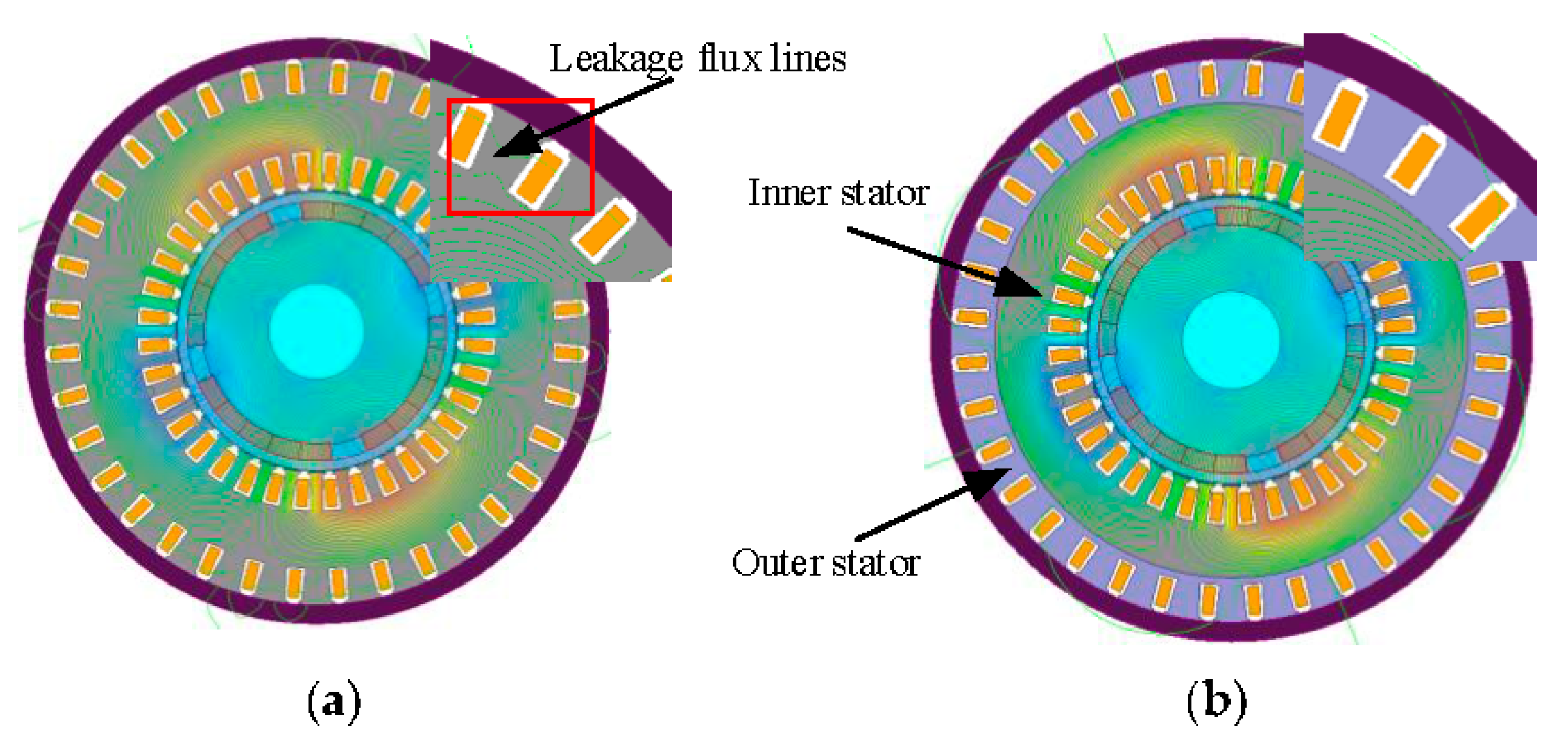

2.2. Stator Structure

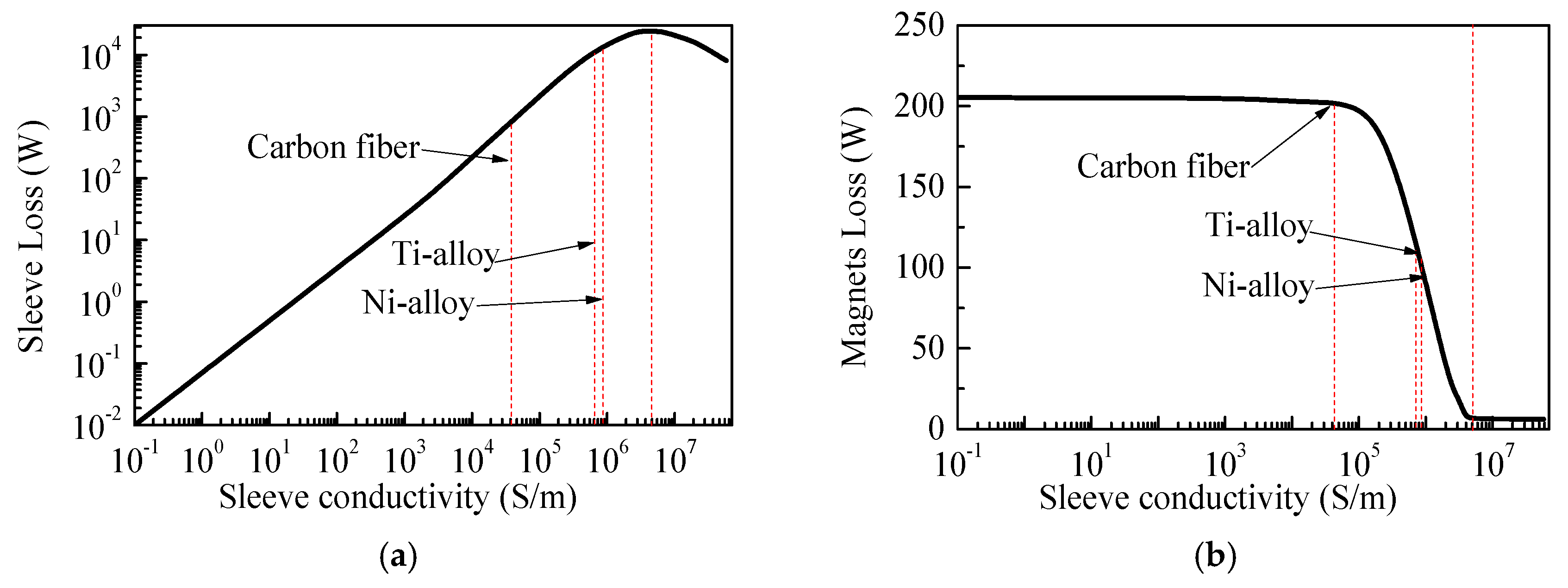

2.3. Retaining Sleeve

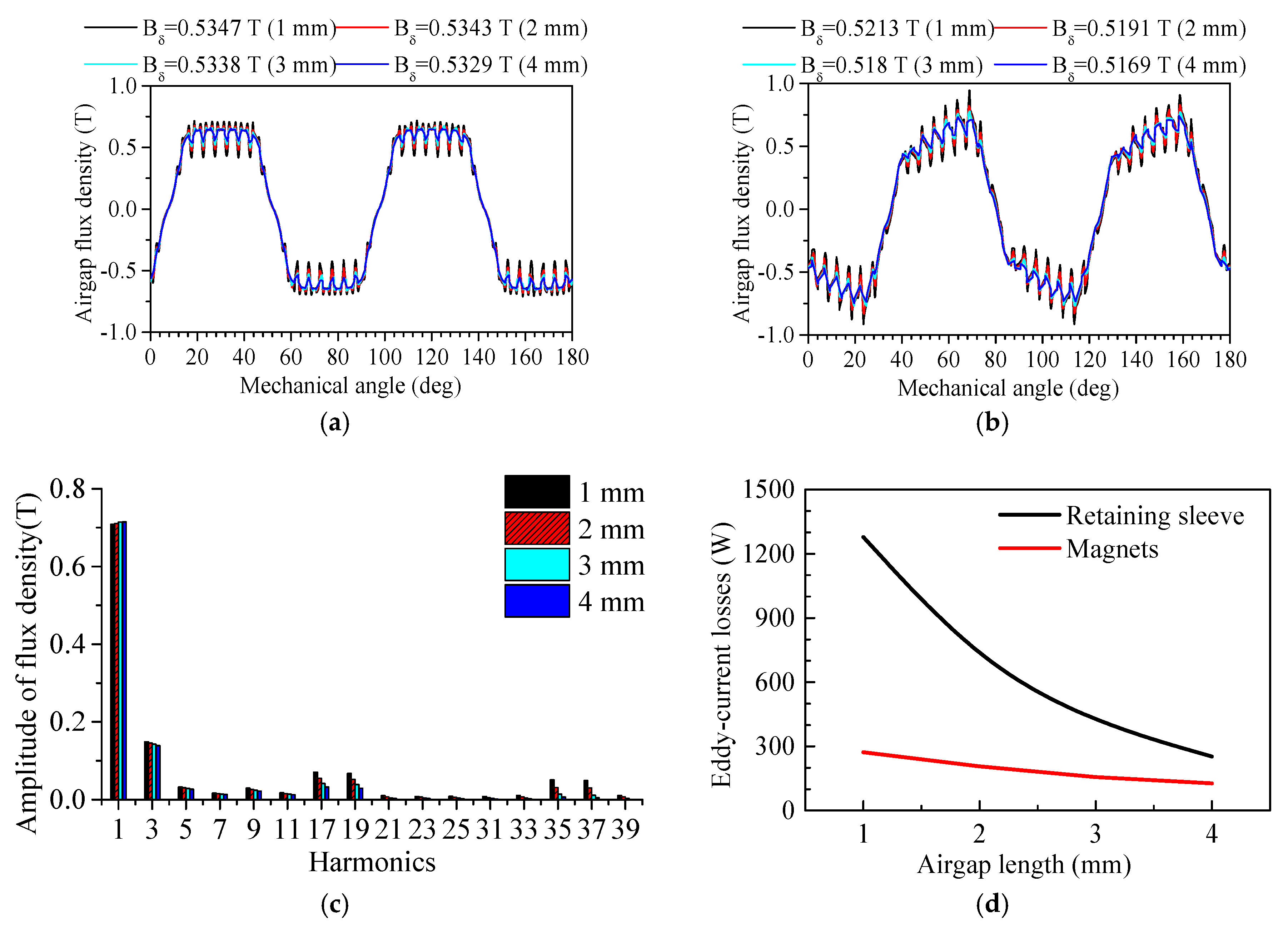

2.4. Airgap

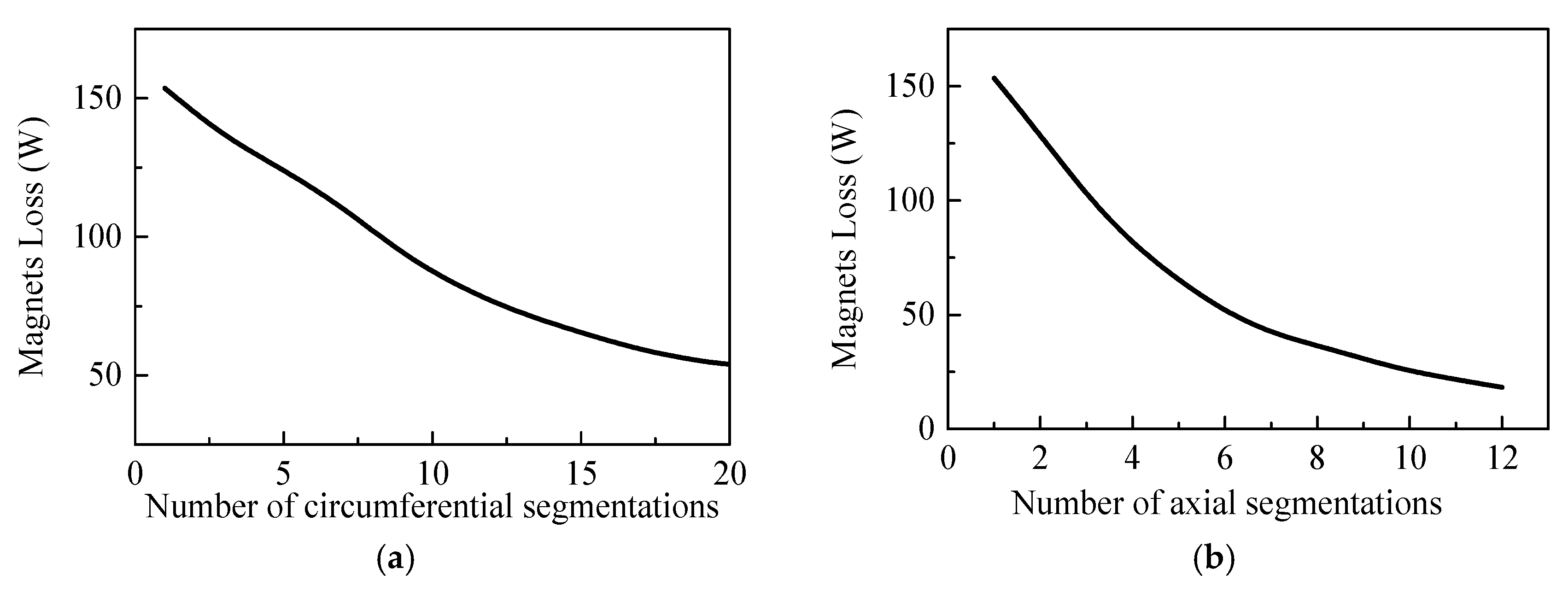

2.5. Segmentation of Magnets

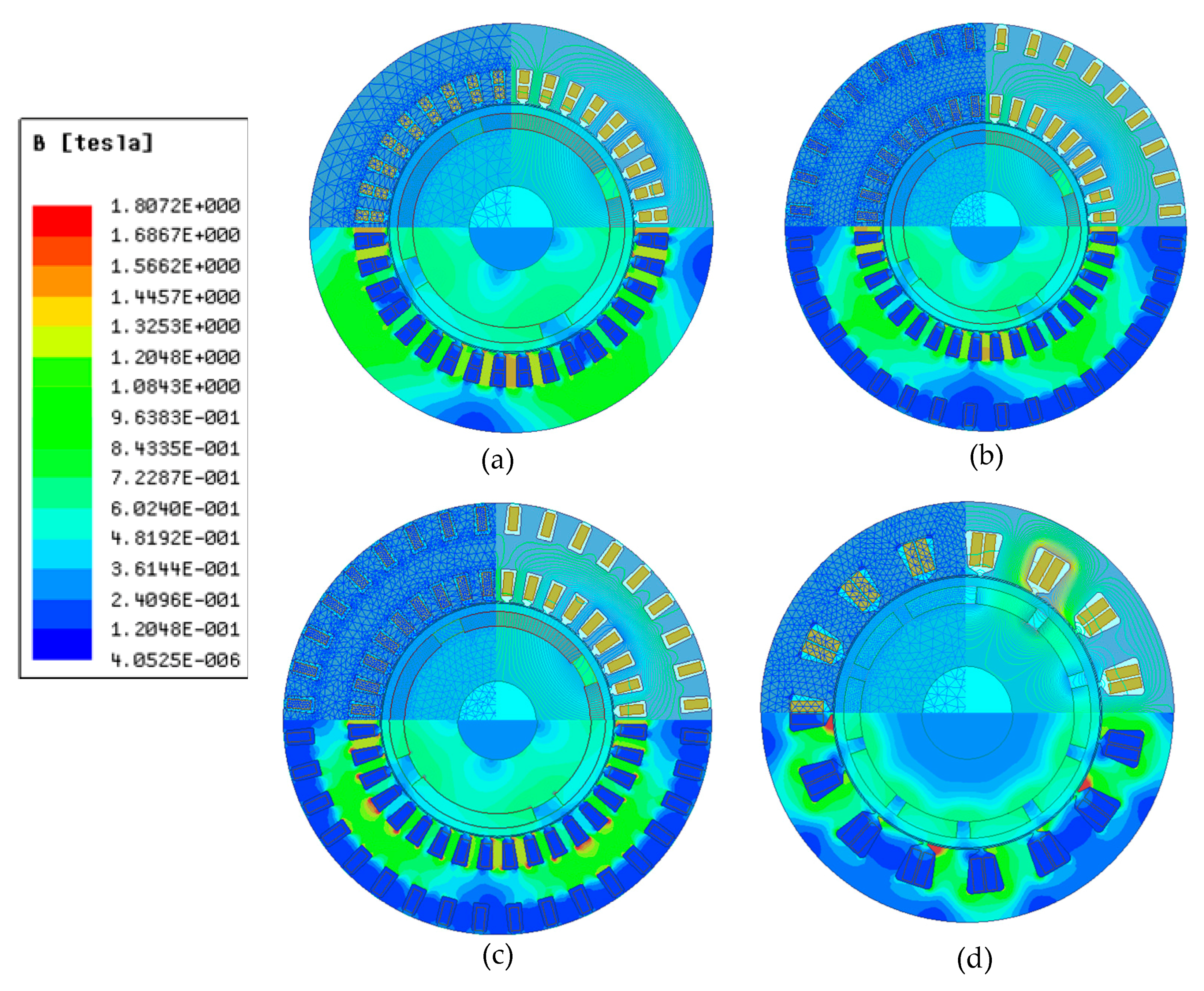

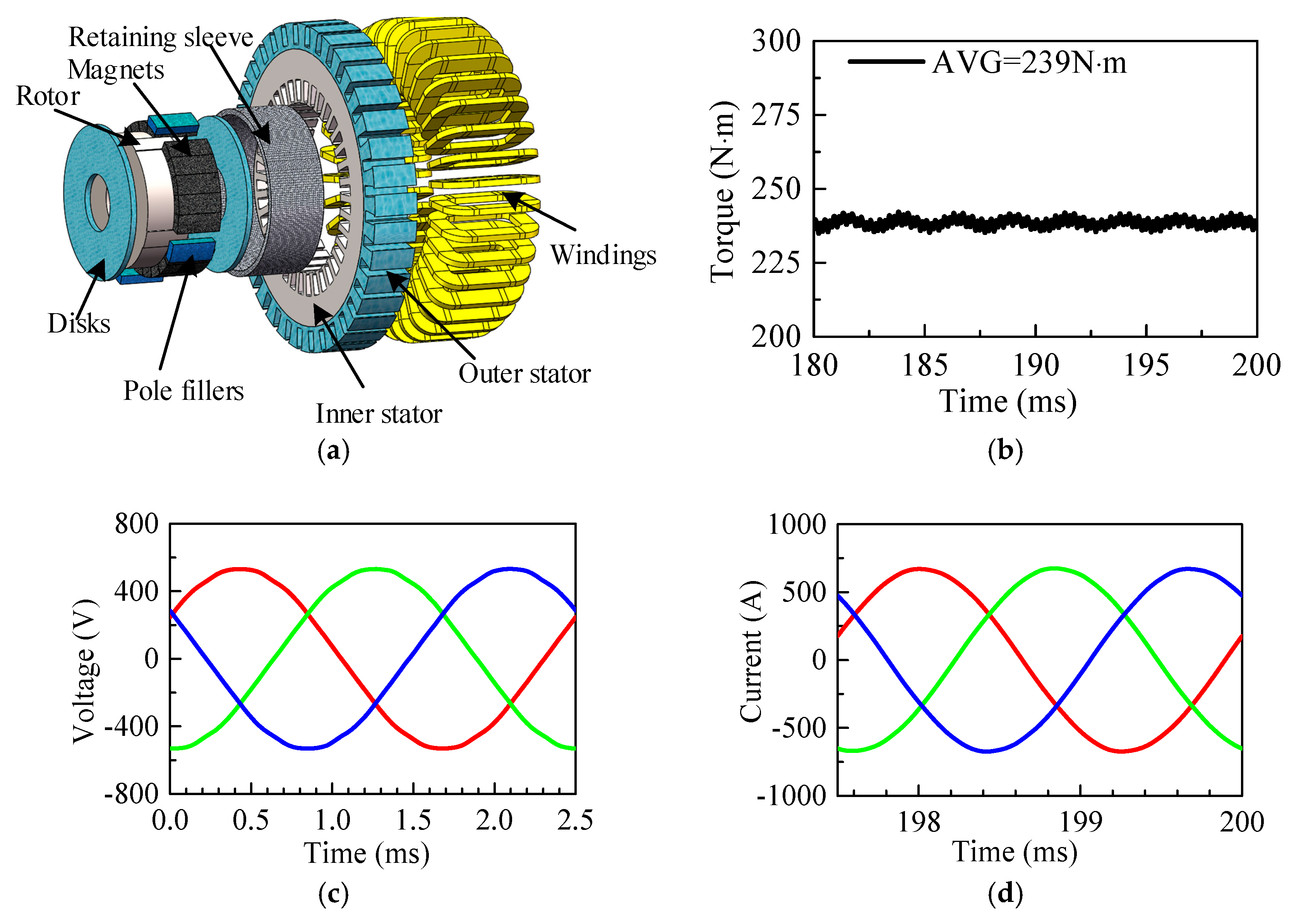

2.6. Electromagnetic Performances

3. Analysis of Losses and Evaluation of Effects of Influencing Factors

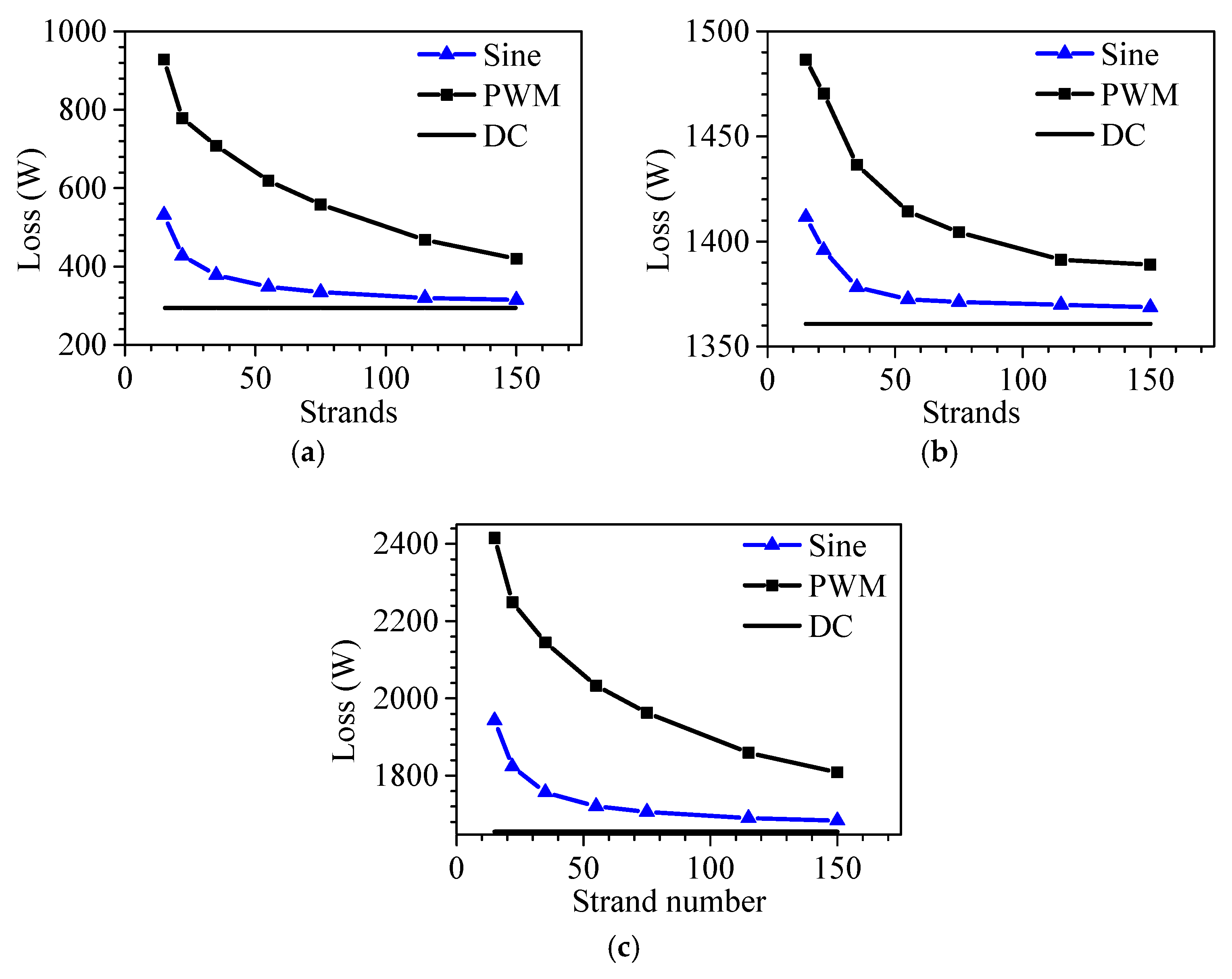

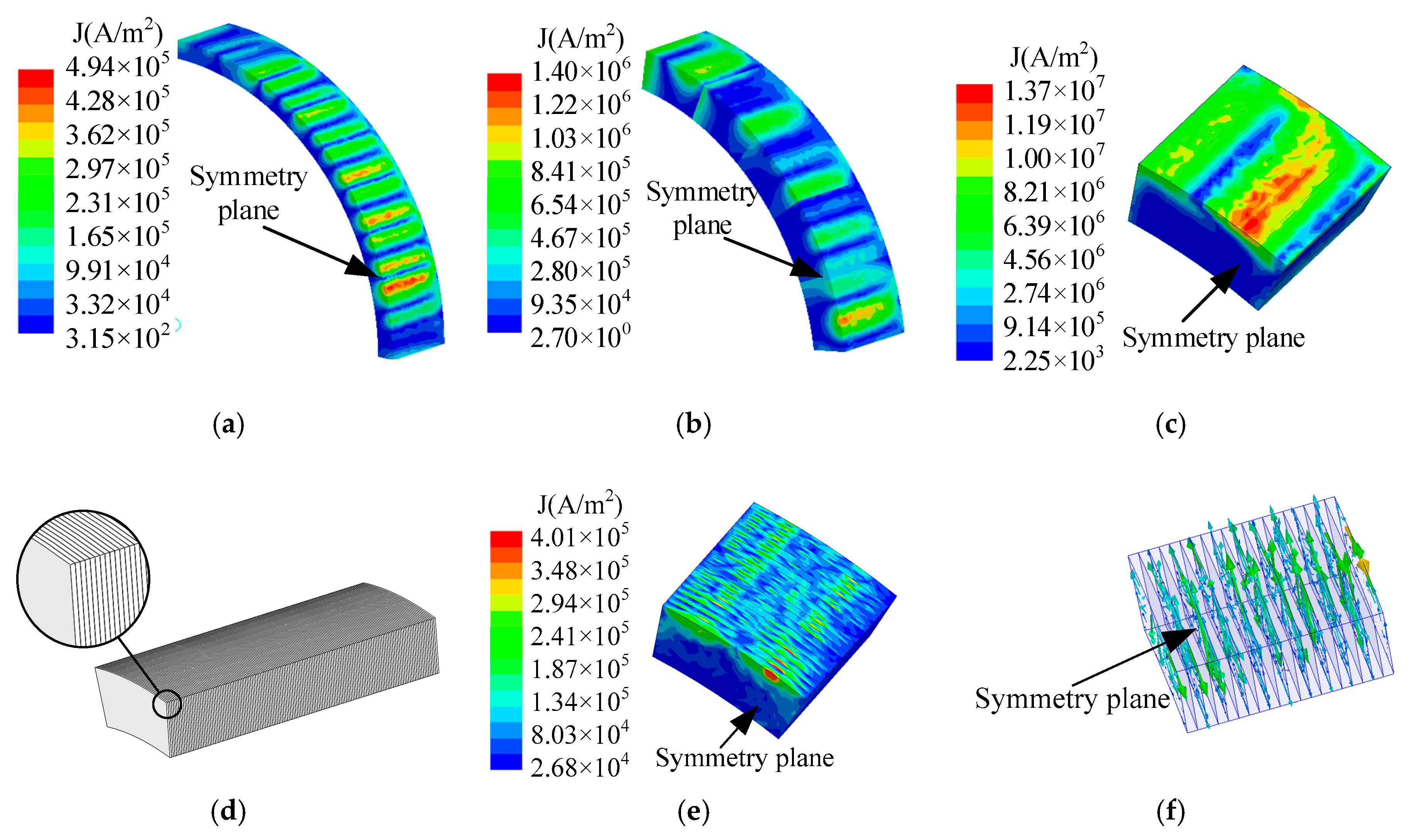

3.1. Copper Loss

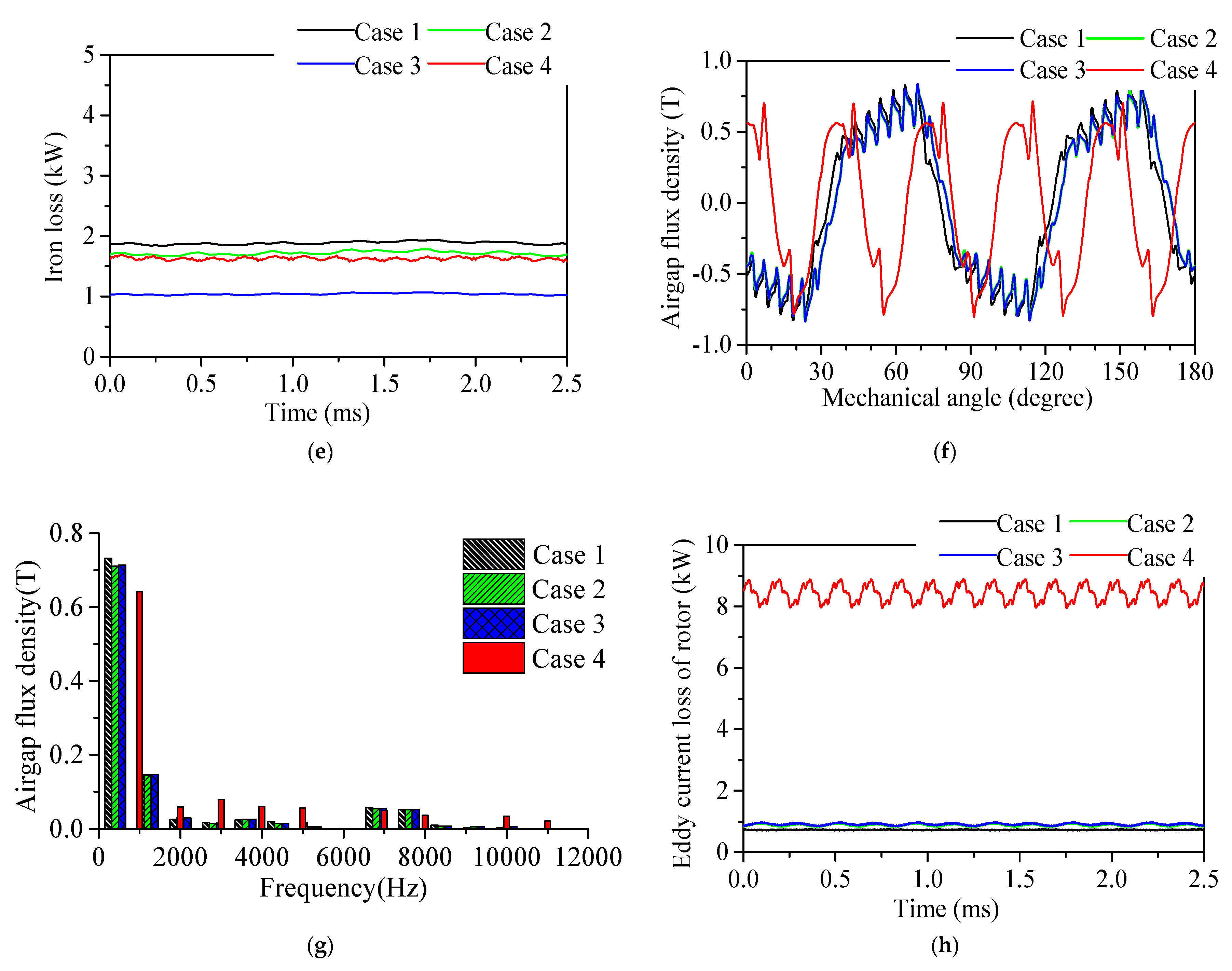

3.2. Iron Loss

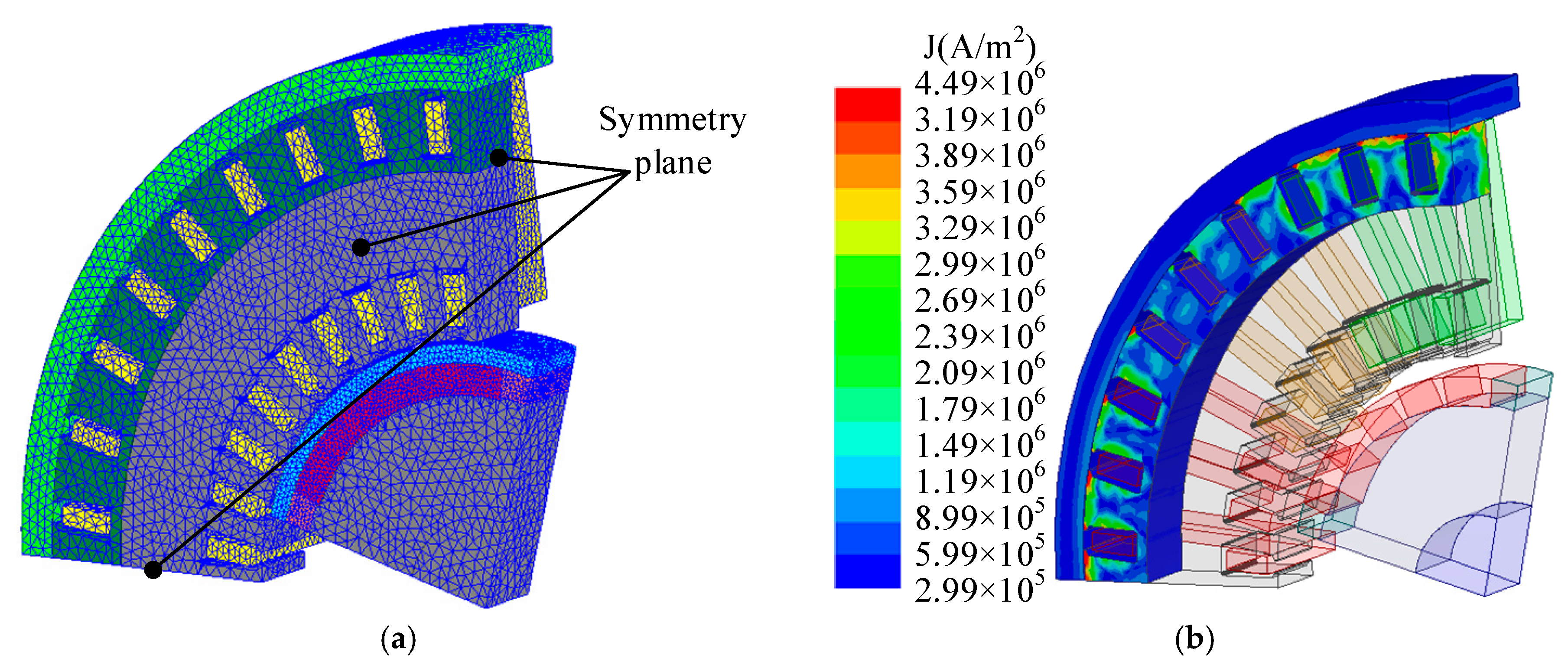

3.3. Eddy-Current Loss of the Rotor

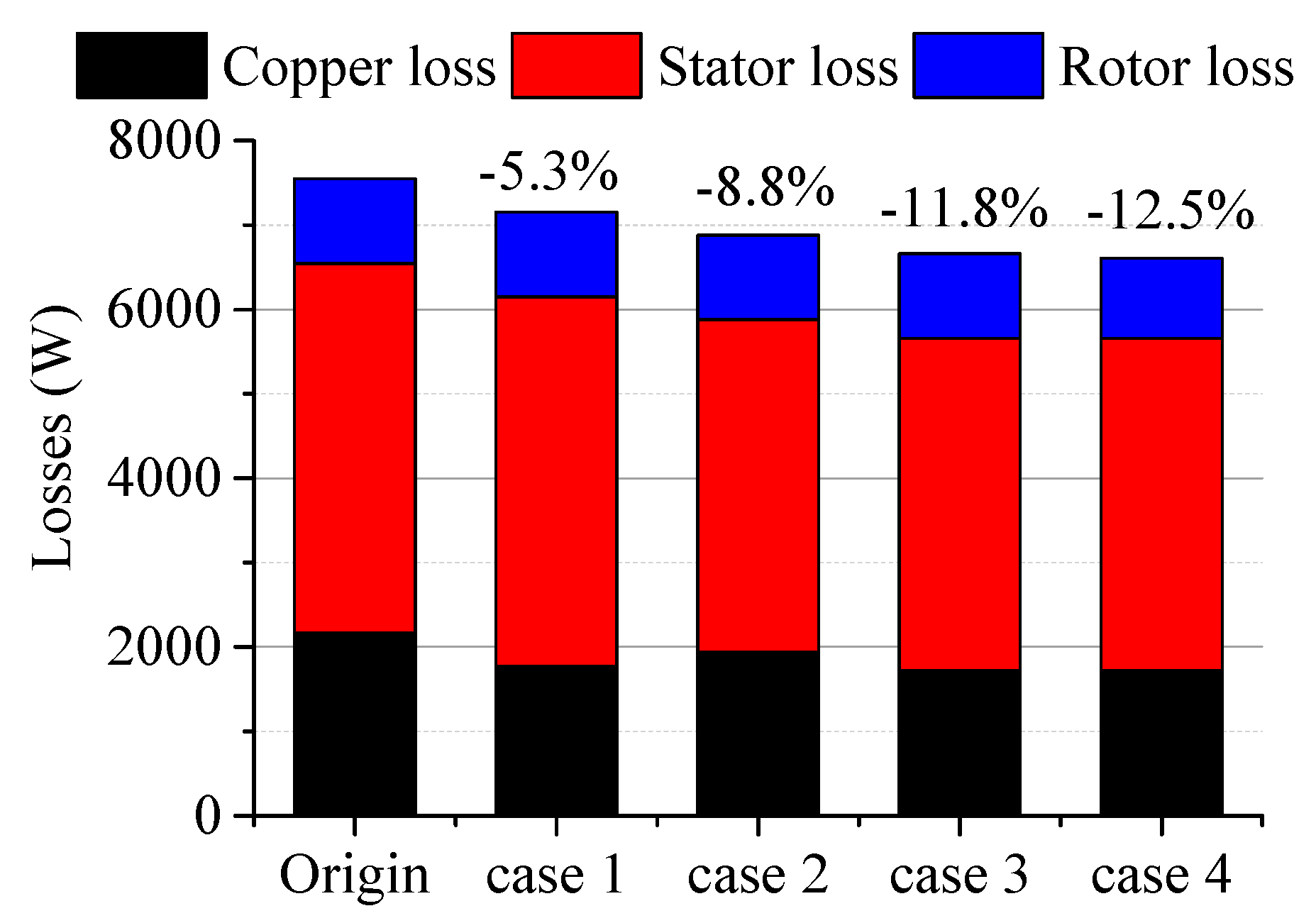

3.4. Evaluation of Influencing Factors on Total Loss

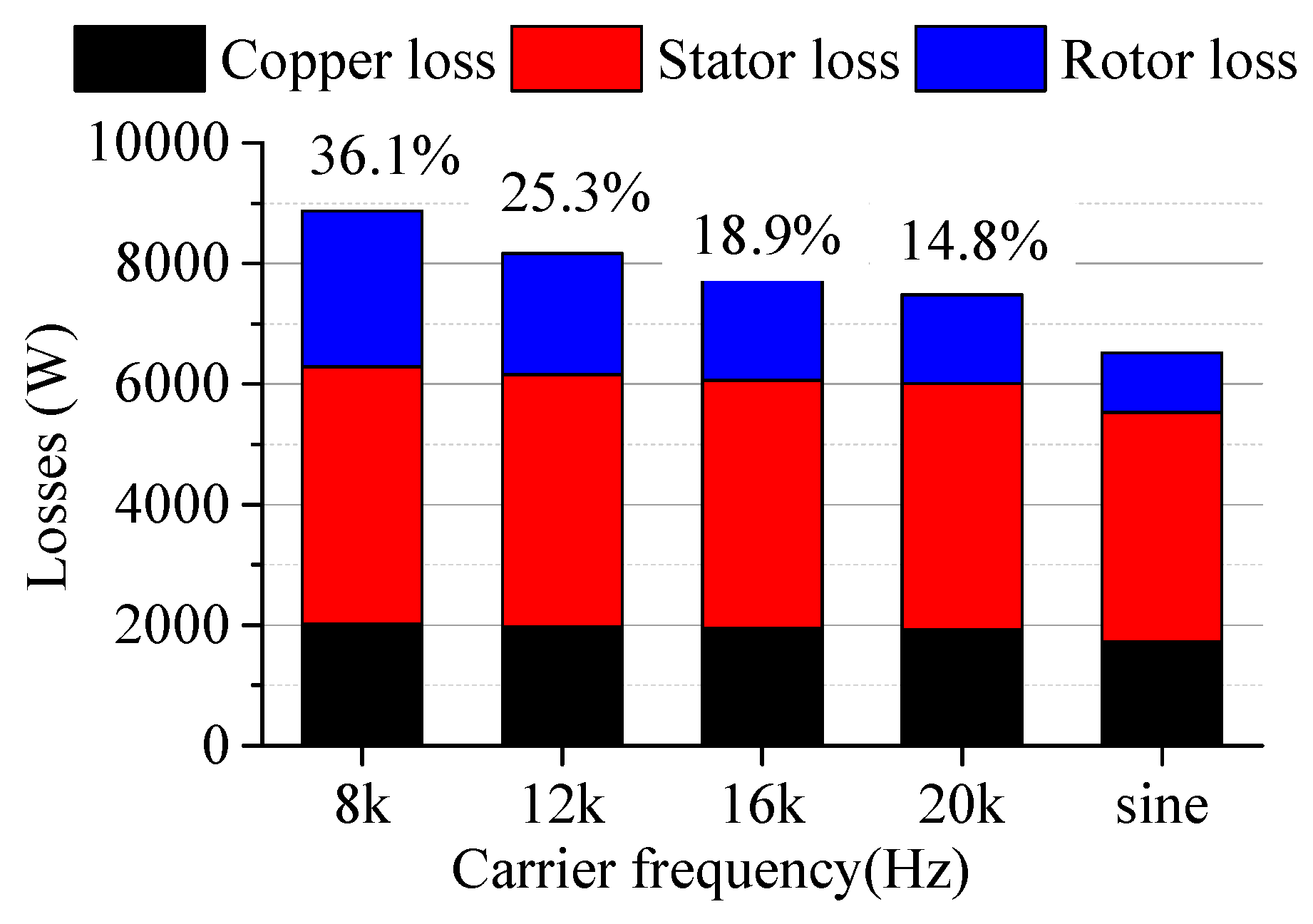

3.5. Influences of Carrier Frequency of PWM Inverter on the Losses

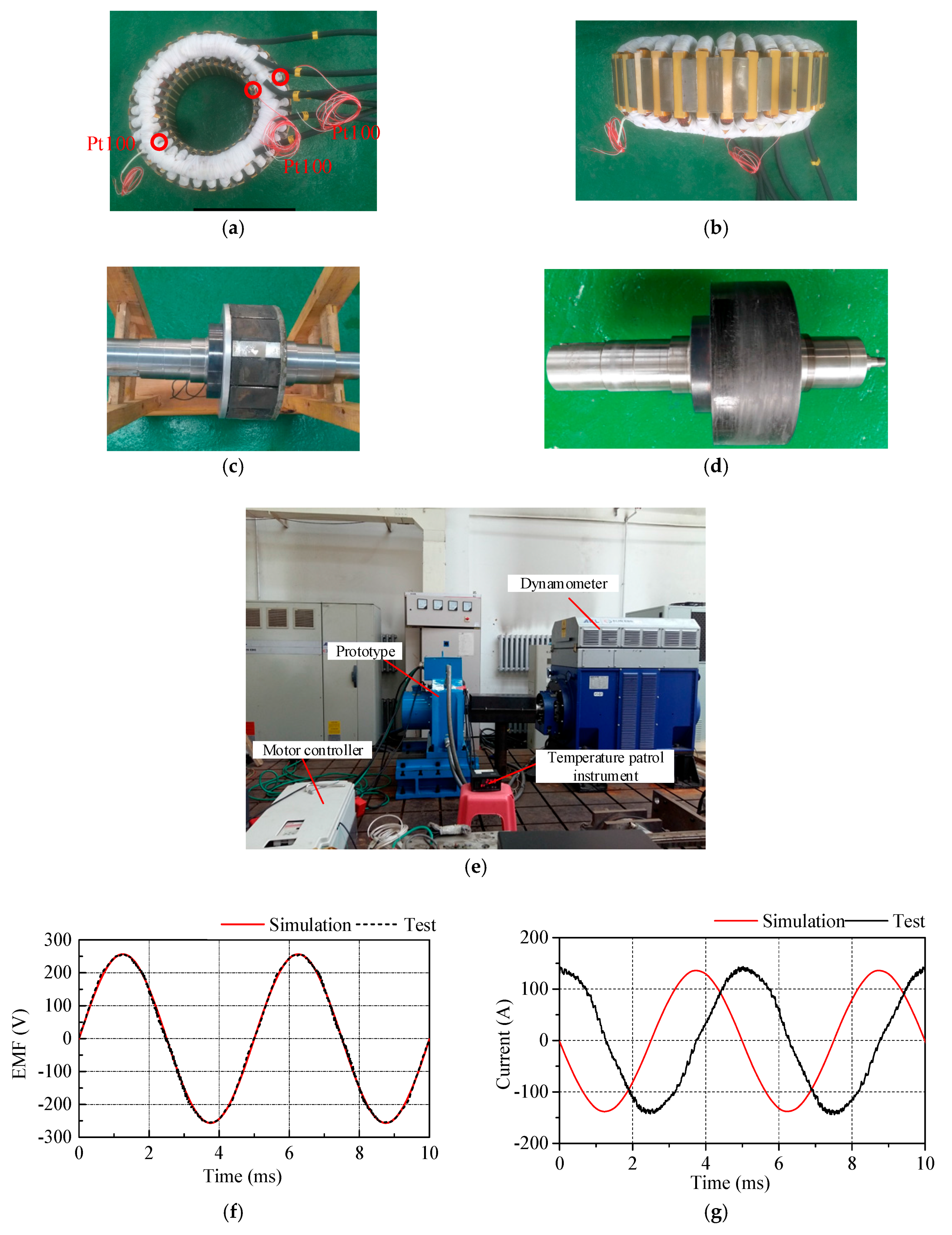

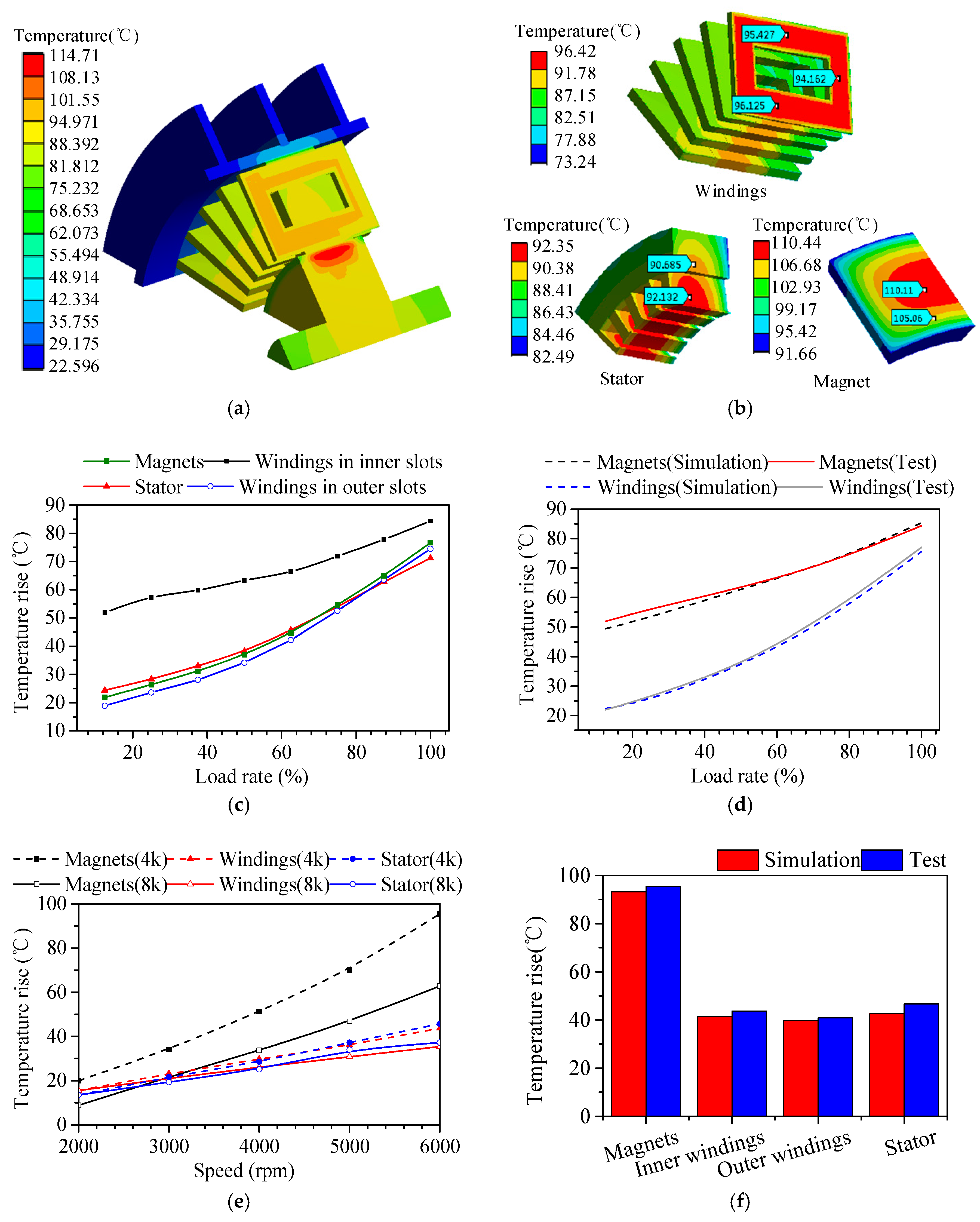

4. Experiments

5. Conclusions

Author Contributions

Conflicts of Interest

References

- McNab, R. Large-Scale Pulsed Power Opportunities and Challenges. IEEE Trans. Plasma Sci. 2014, 42, 1118–1127. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, D.; Liu, Q.; Cui, S. Sensitivity Analysis and Regulation Strategy of Current Waveform for Two-Axis-Compensated Compulsators. IEEE Trans. Plasma Sci. 2013, 41, 1254–1259. [Google Scholar] [CrossRef]

- Wan, Y.; Cui, S.; Wu, S.; Song, L.; Milyaev, I.M.; Yuryevich, S.O. Shock-Resistance Rotor Design of A High-Speed PMSM for Integrated Pulsed Power System. IEEE Trans. Plasma Sci. 2017, 45, 1399–1405. [Google Scholar] [CrossRef]

- Gerada, D.; Mebarki, A.; Brown, N.L.; Gerada, C.; Cavagnino, A.; Boglietti, A. High-Speed Electrical Machines: Technologies, Trends, and Developments. IEEE Trans. Ind. Electron. 2014, 61, 2946–2959. [Google Scholar] [CrossRef]

- Binder, A.; Schneider, T.; Klohr, M. Fixation of buried and surface-mounted magnets in high-speed permanent-magnet synchronous machines. IEEE Trans. Ind. Appl. 2006, 42, 1031–1037. [Google Scholar] [CrossRef]

- Zhang, F.; Du, G.; Wang, T.; Wang, F.; Cao, W.; Kirtley, J.L. Electromagnetic Design and Loss Calculations of a 1.12-MW High-Speed Permanent-Magnet Motor for Compressor Applications. IEEE Trans. Energy Convers. 2016, 31, 132–140. [Google Scholar] [CrossRef]

- Ede, J.D.; Zhu, Z.Q.; Howe, D. Rotor resonances of high-speed permanent-magnet brushless machines. IEEE Trans. Ind. Appl. 2002, 38, 1542–1548. [Google Scholar] [CrossRef]

- Hong, D.K.; Woo, B.C.; Koo, D.H. Rotordynamics of 120000 r/min 15 kW Ultra high speed motor. IEEE Trans. Magn. 2009, 45, 2831–2834. [Google Scholar] [CrossRef]

- King, J.E.; Kobuck, R.M.; Repp, J.R. High speed water-cooled permanent magnet motor for pulse alternator-based pulse power systems. In Proceedings of the 2008 14th Symposium on Electromagnetic Launch Technology (EML), Victoria, BC, Canada, 10–13 June 2008; pp. 1–6. [Google Scholar]

- Spann, M.; Pratap, S.; Brinkman, W.; Perkins, D.; Thelen, R. A rapid fire, compulsator-driven railgun system. IEEE Trans. Magn. 1986, 22, 1753–1756. [Google Scholar] [CrossRef]

- Walls, W.A.; Spann, M.L.; Pratap, S.B.; Bresie, D.; Brinkman, W.; Kitzmiller, J.; Herbst, J.; Hsieh, K.; Liu, H.; Manifold, S.; et al. Design of a self-excited, air-core compulsator for a skid-mounted repetitive fire 9 MJ railgun system. IEEE Trans. Magn. 1989, 25, 574–579. [Google Scholar] [CrossRef]

- Atkinson, G.J.; Mecrow, B.C.; Jack, A.G.; Atkinson, D.J.; Sangha, P.; Benarous, M. The Analysis of Losses in High-Power Fault-Tolerant Machines for Aerospace Applications. IEEE Trans. Ind. Appl. 2006, 42, 1162–1170. [Google Scholar] [CrossRef]

- Li, W.; Qiu, H.; Zhang, X.; Cao, J.; Yi, R. Analyses on Electromagnetic and Temperature Fields of Superhigh-Speed Permanent-Magnet Generator with Different Sleeve Materials. IEEE Trans. Ind. Electron. 2014, 61, 3056–3063. [Google Scholar] [CrossRef]

- Reddy, P.B.; Zhu, Z.Q.; Han, S.H.; Jahns, T.M. Strand-level proximity losses in PM machines designed for high-speed operation. In Proceedings of the 2008 18th International Conference on Electrical Machines (ICEM), Vilamoura, Portugal, 6–9 September 2008; pp. 1–6. [Google Scholar]

- Iwasaki, S.; Deodhar, R.P.; Liu, Y.; Pride, A.Z.; Zhu, Q.; Bremner, J.J. Influence of PWM on the Proximity Loss in Permanent-Magnet Brushless AC Machines. IEEE Trans. Ind. Appl. 2009, 45, 1359–1367. [Google Scholar] [CrossRef]

- Thomas, A.S.; Zhu, Z.Q.; Jewell, G.W. Proximity Loss Study in High Speed Flux-Switching Permanent Magnet Machine. IEEE Trans. Magn. 2009, 45, 4748–4751. [Google Scholar] [CrossRef]

- Marcic, T.; Stumberger, B.; Stumberger, G.; Hadziselimovic, M.; Zagradisink, I. The impact of different stator and rotor slot number combinations on iron losses of a three-phase induction motor at no-load. J. Magn. Magn. Mater. 2008, 320, e891–e895. [Google Scholar] [CrossRef]

- Zhu, J.G.; Ramsden, V.S. Improved Formulations for Rotational Core Losses in Rotating Electrical Machines. IEEE Trans. Magn. 1998, 34, 2234–2242. [Google Scholar] [CrossRef]

- Stumberqer, B.; Hamler, A.; Gorican, V.; Jesenik, M. Accuracy of iron loss estimation in induction motors by using different iron loss models. J. Magn. Magn. Mater. 2004, 272, e1723–e1725. [Google Scholar] [CrossRef]

- Wan, Y.; Wu, S.; Cui, S. Choice of Pole Spacer Materials for a High-Speed PMSM Based on the Temperature Rise and Thermal Stress. IEEE Trans. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Miyama, Y.; Hazeyama, M.; Hanioka, S.; Watanabe, N.; Daikoku, A.; Inoue, M. PWM Carrier Harmonic Iron Loss Reduction Technique of Permanent-Magnet Motors for Electric Vehicles. IEEE Trans. Ind. Appl. 2016, 52, 2865–2871. [Google Scholar] [CrossRef]

- Yon, J.M.; Mellor, P.H.; Wrobel, R.; Booker, J.D.; Burrow, S.G. Analysis of Semipermeable Containment Sleeve Technology for High-Speed Permanent Magnet Machines. IEEE Trans. Energy Convers. 2012, 27, 646–653. [Google Scholar] [CrossRef]

- Lazzari, M.; Miotto, A.; Tenconi, A.; Vaschetto, S. Analytical prediction of eddy current losses in retaining sleeves for surface mounted PM synchronous machines. In Proceedings of the 2010 XIX International Conference on Electrical Machines (ICEM), Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Cho, H.W.; Jang, S.M.; Choi, S.K. A Design Approach to Reduce Rotor Losses in High-Speed Permanent Magnet Machine for Turbo-Compressor. IEEE Trans. Magn. 2006, 42, 3521–3523. [Google Scholar] [CrossRef]

- Li, W.; Qiu, H.; Zhang, X.; Cao, J.; Zhang, S.; Yi, R. Influence of Rotor-Sleeve Electromagnetic Characteristics on High-Speed Permanent-Magnet Generator. IEEE Trans. Ind. Electron. 2014, 61, 3030–3037. [Google Scholar] [CrossRef]

- Kawase, Y.; Tadashi, Y.; Tomohiro, U. Effects of carrier frequency of multilevel PWM inverter on electrical loss of interior permanent magnet motor. In Proceedings of the 2009 International Conference on Electrical Machines and Systems (ICEMS), Tokyo, Japan, 15–18 November 2009; pp. 1–15. [Google Scholar]

- Rezzoug, A.; Zaïm, M.E. High-Speed Electric Machines: Non-Conventional Electrical Machines; John Wiley and Sons: Eastbourne, UK, 2011; pp. 127–133. ISBN 978-1-84821-300-5. [Google Scholar]

- Saari, J. Thermal Analysis of High-Speed Induction Machines; Helsinki University of Technology: Helsinki, Finland, 1998; pp. 2–17. ISBN 951-22-5576-6. [Google Scholar]

| Cases | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Poles number | 4 | 4 | 4 | 10 |

| Slot number | 36 | 36 | 36 | 15 |

| Rated Frequency (Hz) | 400 | 400 | 400 | 1000 |

| Winding type | Double-layer lap windings | Toroidal windings | Toroidal windings | Concentrated windings |

| Do of stator (mm) | 490 | 560 | 520 | 450 |

| Di of stator (mm) | 294 | 294 | 294 | 294 |

| Materials of stator | 35WW250 | 35WW250 | B20AT1500 | B20AT1500 |

| Effective length (mm) | 80 | 80 | 80 | 98 |

| Axial length (mm) | 290 | 180 | 180 | 180 |

| Heat loading (A2/m3) | 175.3 | 178.3 | 179.3 | 178.68 |

| EMF (V) | 216.4 | 220.1 | 220.8 | 220 |

| Rated power (kW) | 300 | 300 | 300 | 300 |

| Rated current (A) | 472.1 | 480.2 | 474.5 | 496 |

| Efficiency | 98.45% | 98.44% | 98.77% | 96.36% |

| Power factor | 0.9822 | 0.9672 | 0.9763 | 0.9554 |

| Power density (kW/kg) | 2.1914 | 1.8841 | 2.2605 | 2.5884 |

| Iron loss density (W/kg) | 30.59 | 29.14 | 26.88 | 30.14 |

| Cases | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Airgap length (mm) | 1 | 2 | 3 | 4 |

| Magnet thickness (mm) | 16 | 18 | 20 | 22 |

| EMF (V) | 220.9 | 220 | 219.3 | 217.6 |

| Power (kW) | 300 | 300 | 300 | 300 |

| Rated current (A) | 477.4 | 475.2 | 474.2 | 475 |

| Torque ripple | 3.8 | 3.5 | 3.1 | 2.5 |

| Efficiency | 98.06% | 98.28% | 98.40% | 98.46% |

| Power factor | 0.9733 | 0.9753 | 0.9767 | 0.9741 |

| Loss density of magnets (W/m3) | 314.88 | 213.46 | 149.65 | 111.85 |

| Loss density of sleeve (W/m3) | 1803.68 | 976.03 | 582.53 | 364.77 |

| Intensity of PM utilization (kg/kW) | 0.022 | 0.0243 | 0.0266 | 0.0288 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Poles number | 4 | Thickness of sleeve (mm) | 10 |

| Slots Number | 36 | Thickness of Magnet (mm) | 18 |

| Do of outer stator (mm) | 570 | Effective length (mm) | 80 |

| Di of outer stator (mm) | 490 | Material of inner stator | 35WW250 |

| Di of inner stator (mm) | 294 | Material of outer stator | Al-alloy |

| Airgap length (mm) | 2 | Material of retaining sleeve | Carbon fiber |

| Material of Outer Stator | Silicon Steel Sheet | Al-Alloy/Epoxy Glass Cloth Laminate |

|---|---|---|

| Inner-slot-wingdings loss (W) | 531.5 | 531.5 |

| Outer-slot-wingdings loss (W) | 531.5 | 305.1 |

| End-windings loss (W) | 1106 | 1106 |

| Total copper loss (W) | 2169 | 1942.6 |

| Outer Stator Material | Silicon Steel Sheet | Al-Alloy | Epoxy Glass Cloth Laminate |

|---|---|---|---|

| Iron loss (W) | 1795 | 1901 | 1909 |

| Outer stator loss (W) | / | 1083 | 0 |

| Shell loss (W) | 2583 | 953 | 1366 |

| Total loss (W) | 4378 | 3937 | 3275 |

| Material of Pole Fillers | Sleeve Loss (W) | Magnet Loss (W) | Filler Loss (W) | Total (W) |

|---|---|---|---|---|

| Al-alloy | 491.2 | 130.3 | 43.2 | 664.7 |

| Ti-alloy | 504.7 | 133.9 | 42.1 | 680.7 |

| S-steel | 500.3 | 128.6 | 58.1 | 687 |

| Epoxy resin | 504.7 | 126.2 | 0 | 630.9 |

| 2-mm s-steel stack | 499.3 | 128.5 | 0.64 | 628.4 |

| 1-mm al-alloy stack | 499.1 | 128.4 | 1.7 | 629.2 |

| 2-mm al-alloy stack | 498.6 | 128.6 | 7.6 | 634.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Y.; Cui, S.; Wu, S.; Song, L. Electromagnetic Design and Losses Analysis of a High-Speed Permanent Magnet Synchronous Motor with Toroidal Windings for Pulsed Alternator. Energies 2018, 11, 562. https://doi.org/10.3390/en11030562

Wan Y, Cui S, Wu S, Song L. Electromagnetic Design and Losses Analysis of a High-Speed Permanent Magnet Synchronous Motor with Toroidal Windings for Pulsed Alternator. Energies. 2018; 11(3):562. https://doi.org/10.3390/en11030562

Chicago/Turabian StyleWan, Yuan, Shumei Cui, Shaopeng Wu, and Liwei Song. 2018. "Electromagnetic Design and Losses Analysis of a High-Speed Permanent Magnet Synchronous Motor with Toroidal Windings for Pulsed Alternator" Energies 11, no. 3: 562. https://doi.org/10.3390/en11030562