Hydration of Magnesium Carbonate in a Thermal Energy Storage Process and Its Heating Application Design †

Abstract

:1. Introduction

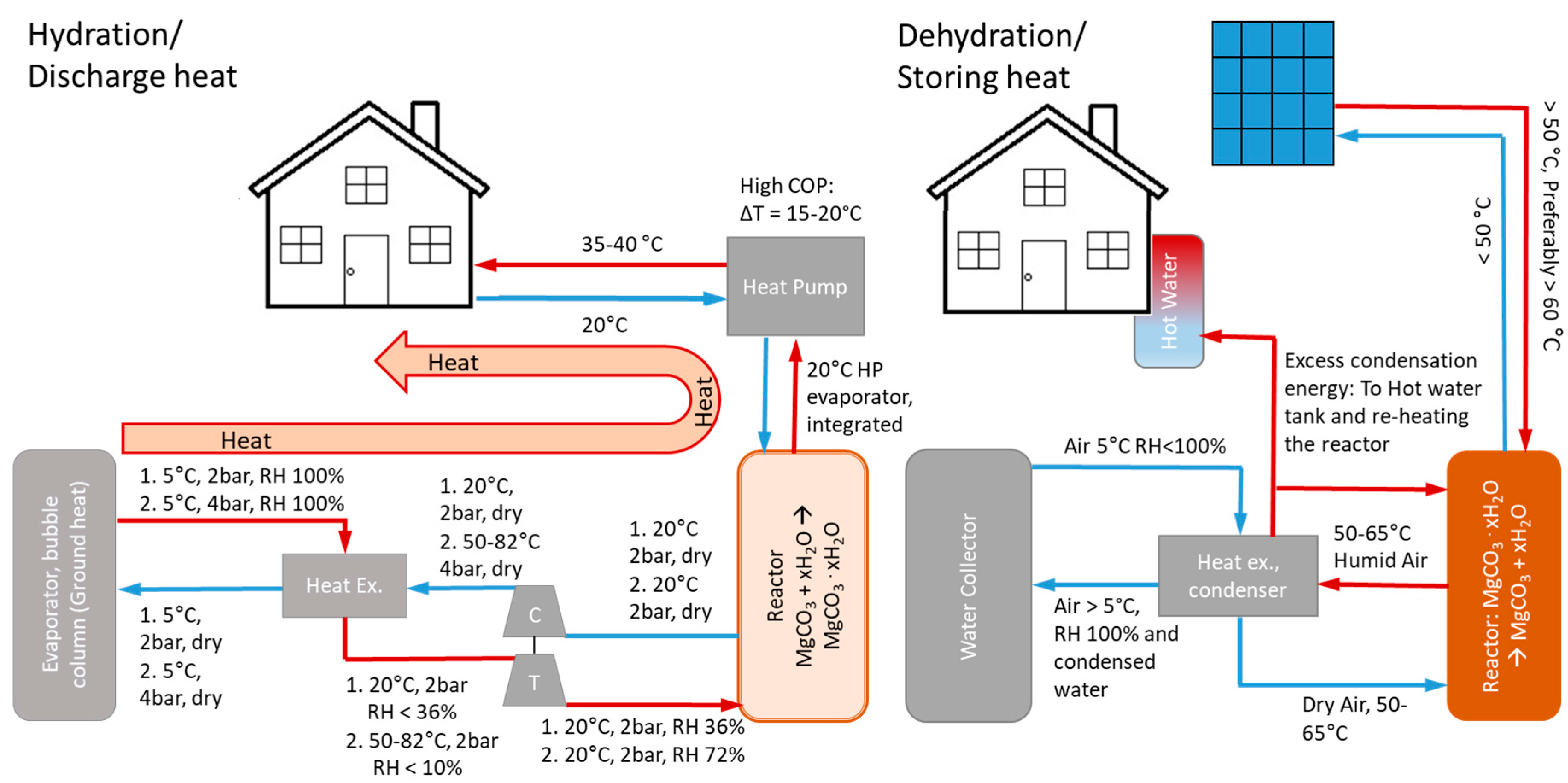

2. Conceptual Design

2.1. Heat Storage and Heating System Concept Using Ground Heat

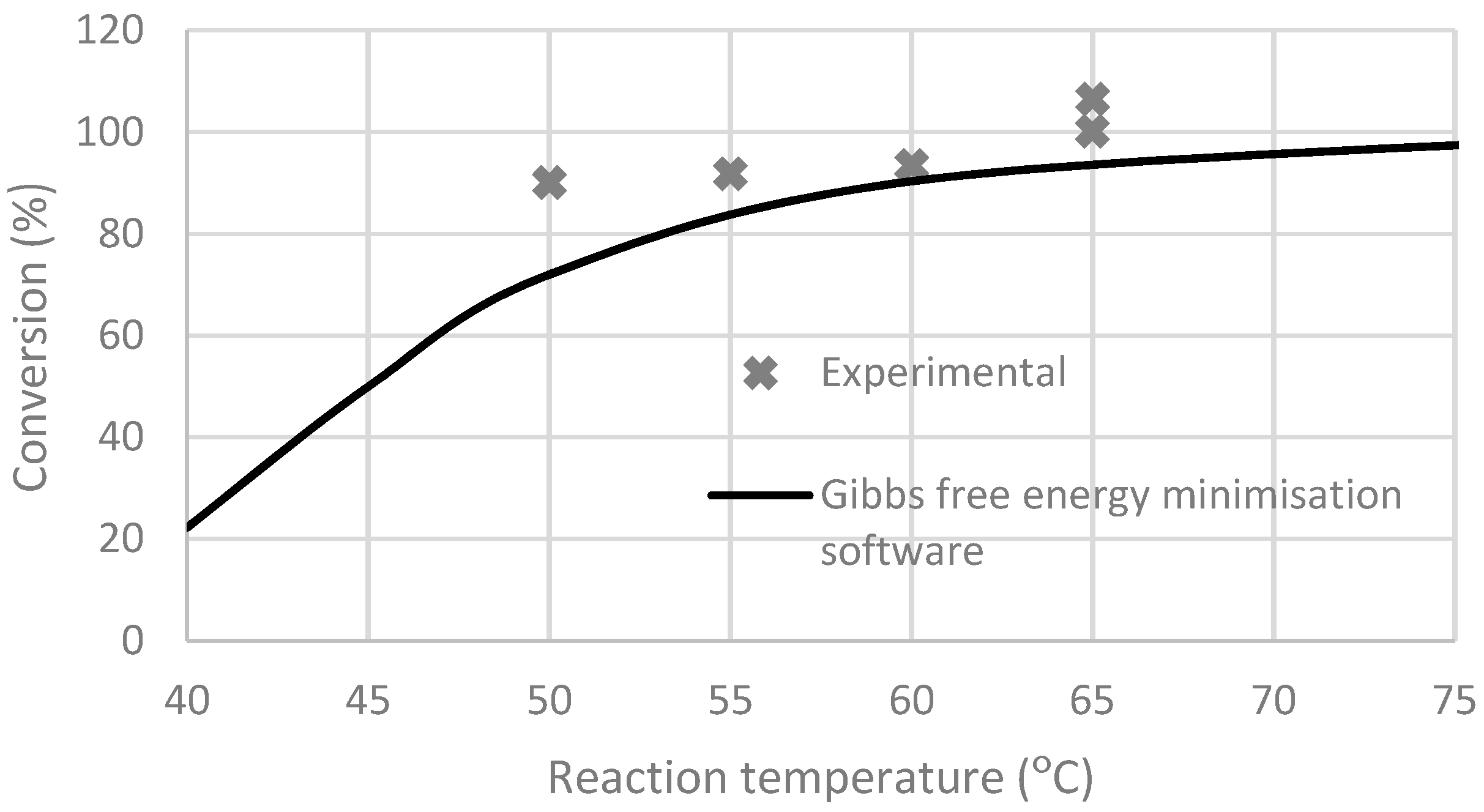

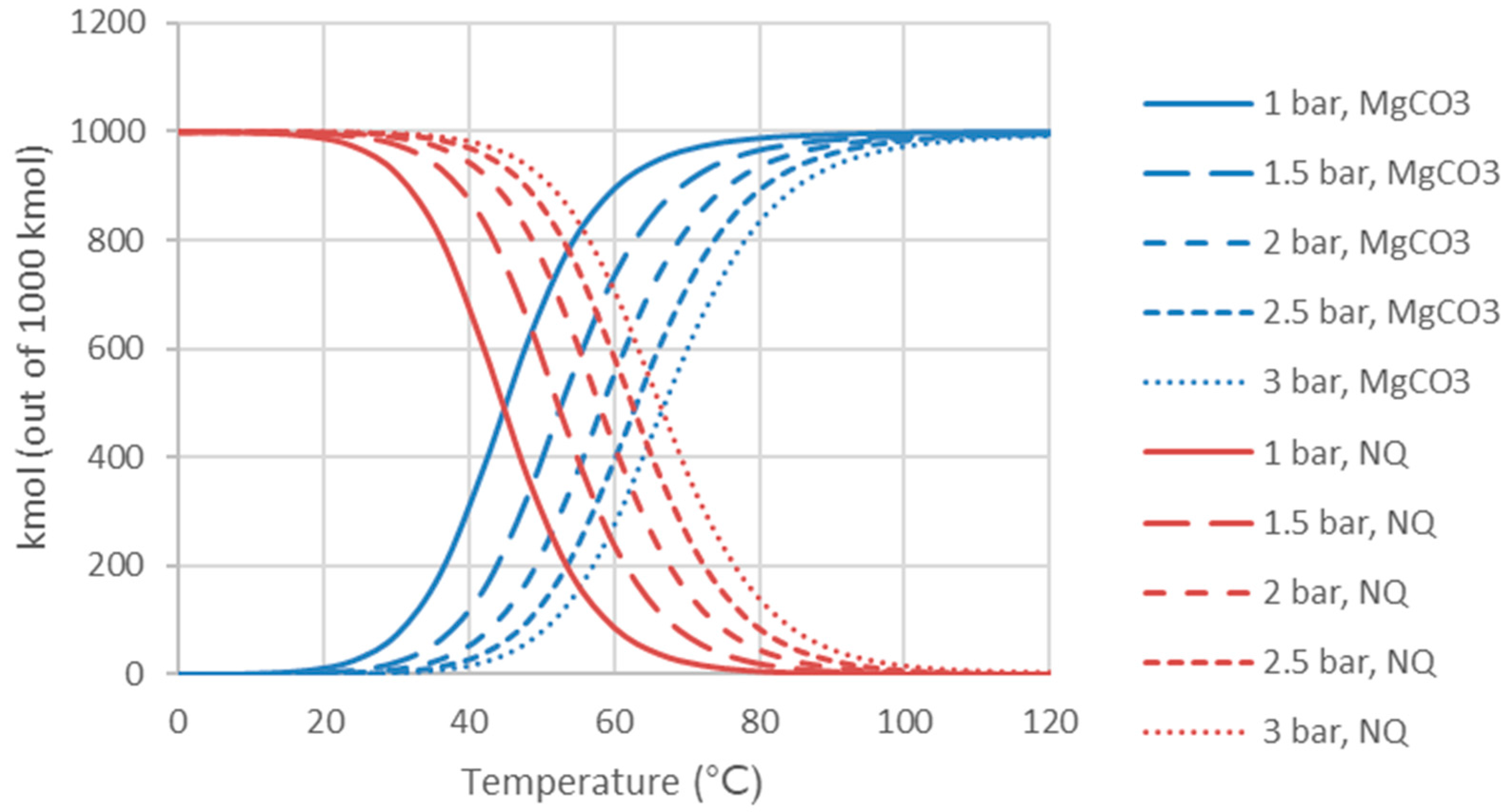

2.1.1. Design of Heat Storage Process

2.1.2. Charging Process

2.2. TES Combined with Exhaust Air Heat Pump

3. Experimental Design and Procedure

3.1. Production of Nesquehonite

3.2. Preparation of Nesquehonite and Silica Gel Granule Mixture Samples

3.3. Hydration Experiments

4. Results

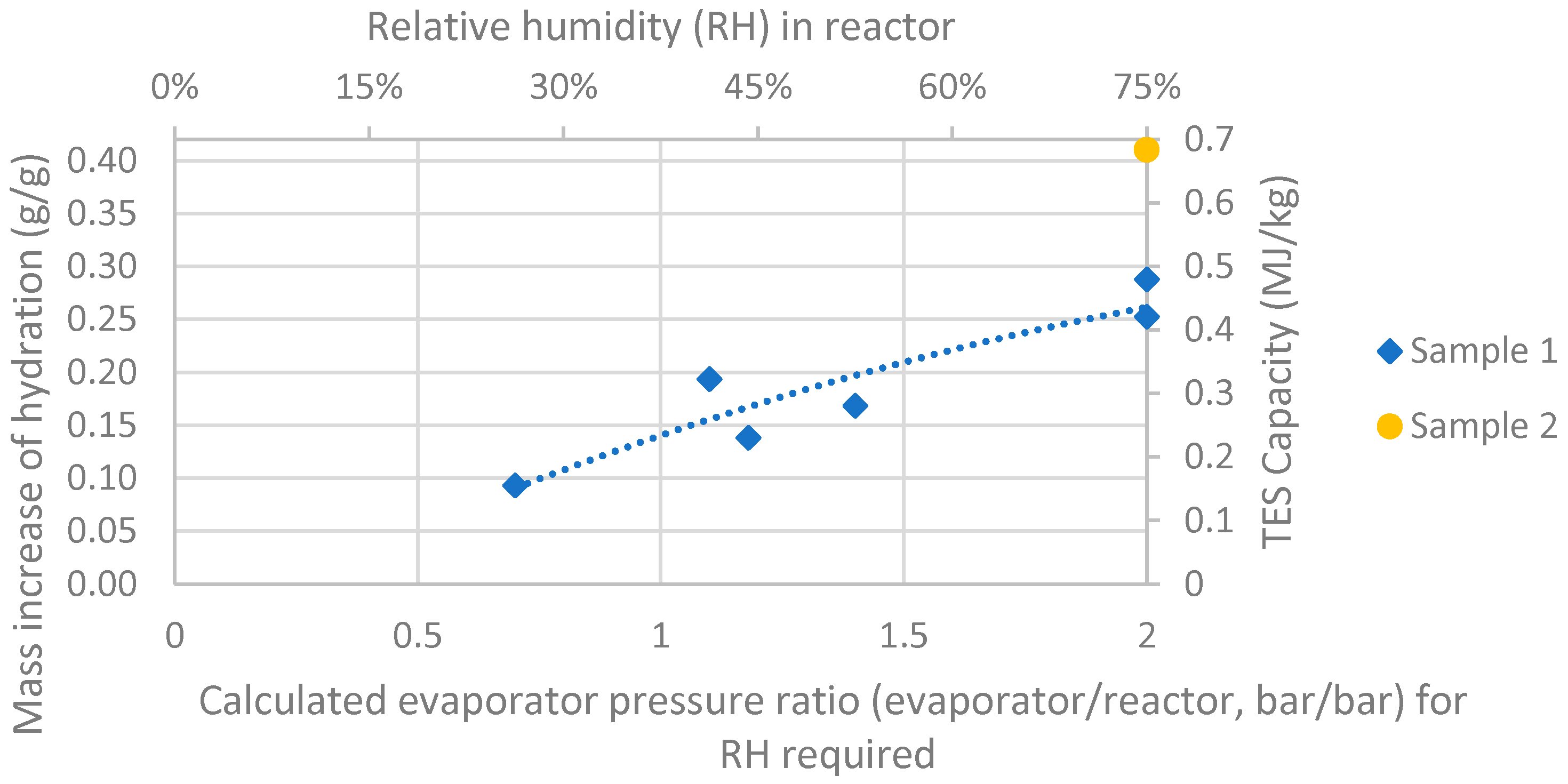

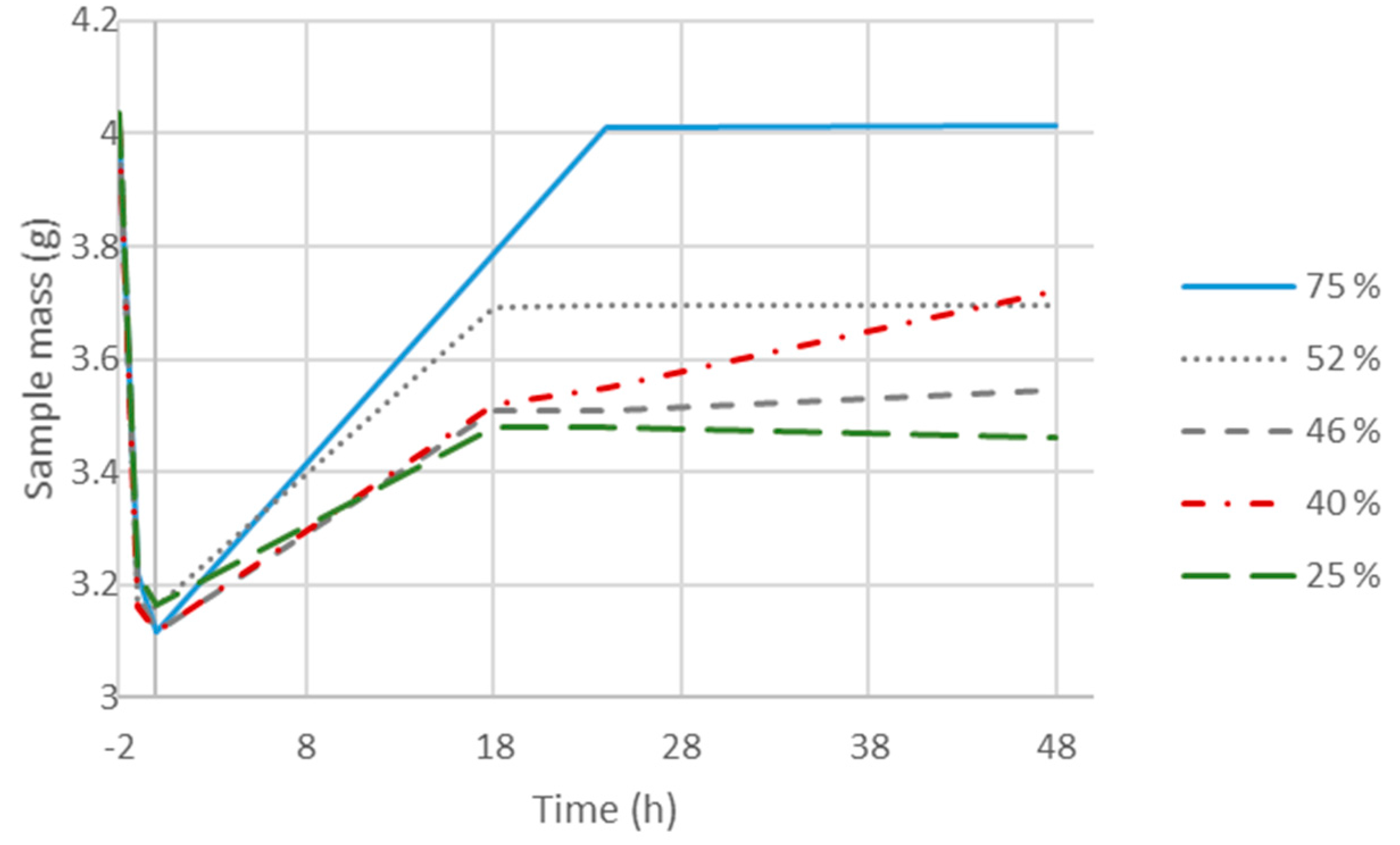

4.1. Relative Humidity Dependent Hydration

4.2. Heat Storage Efficiency and Operational Opportunities

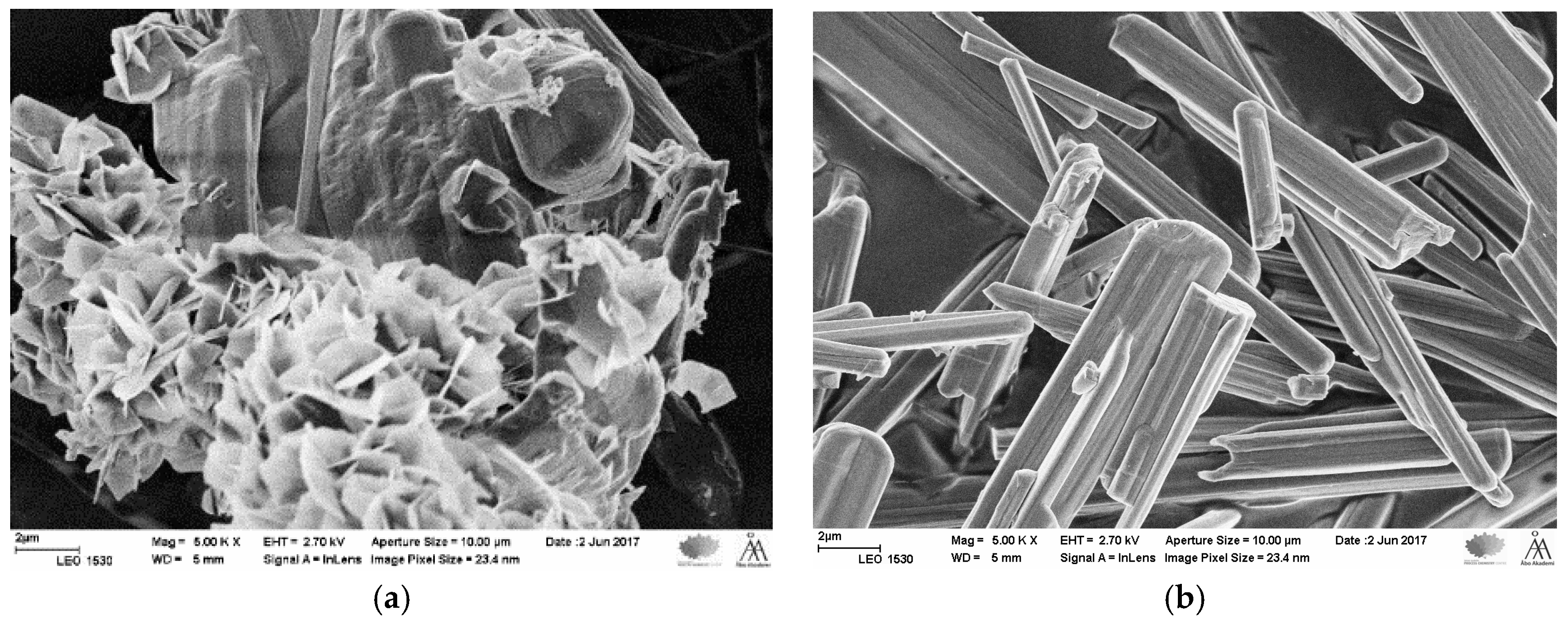

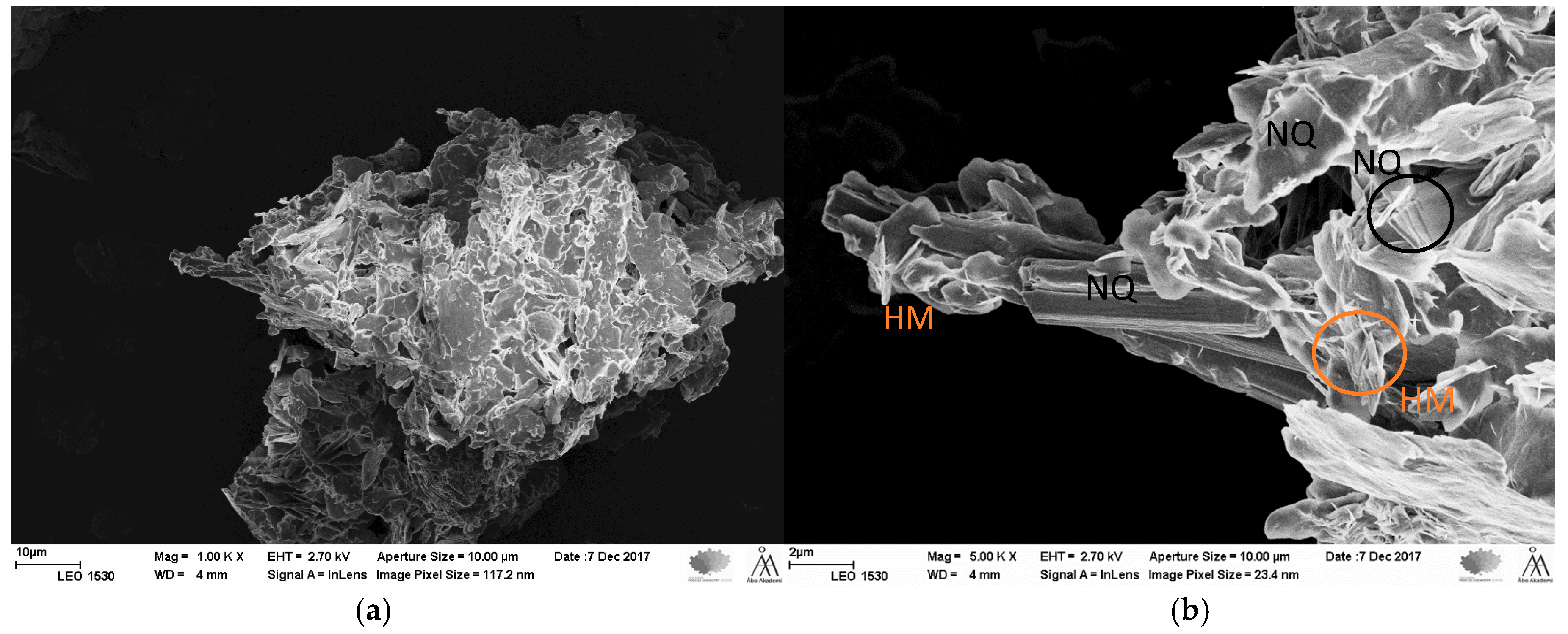

4.3. Sample Morphology, Crystal and Efficiency

4.4. Efficiency Calculations and Improvements

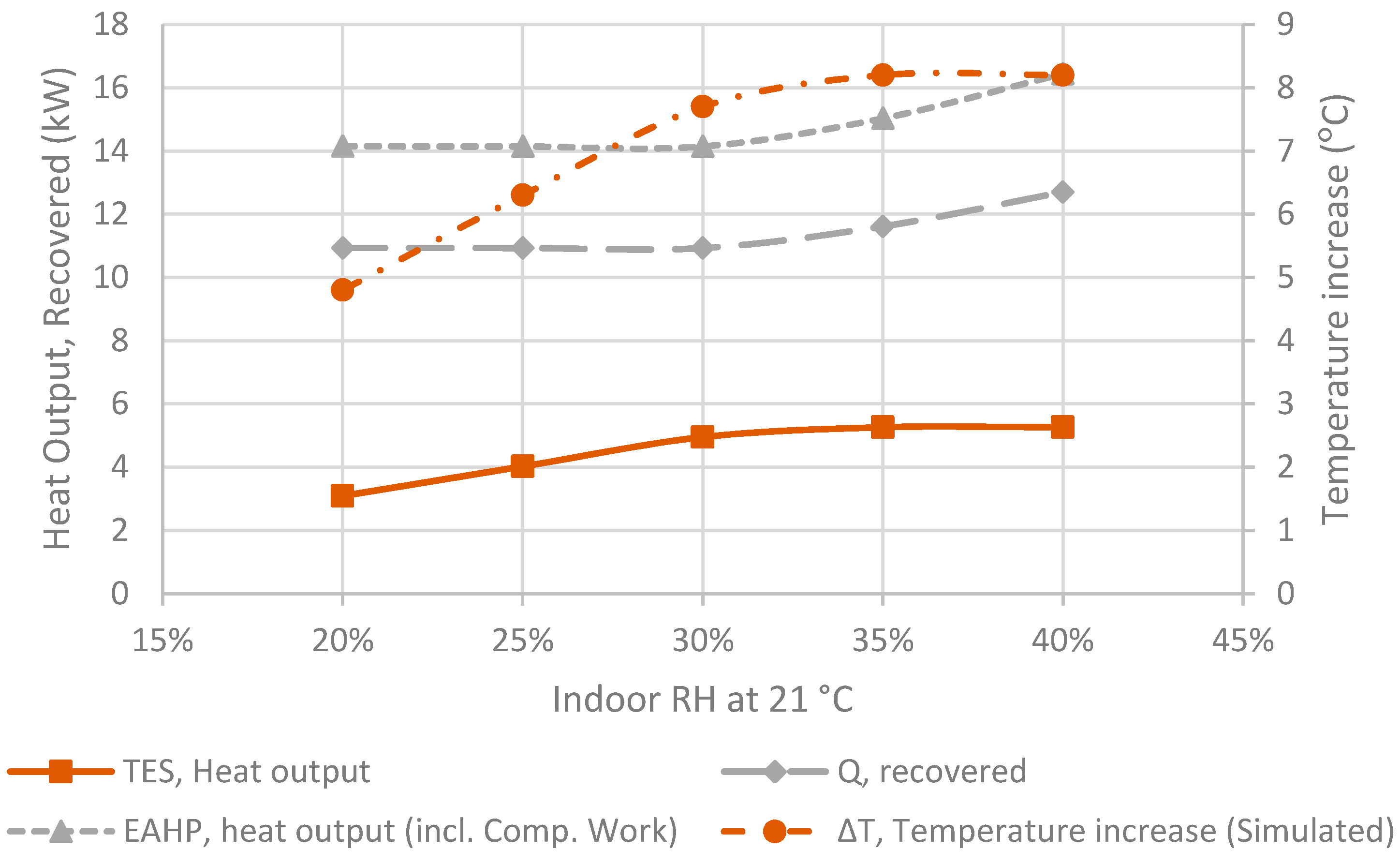

4.5. Output of Reactor Coupled with Exhaust Air Heat Pump (EAHP)

4.6. Silica Gel/Nesquehonite Mass Ratio

5. Conclusions

- -

- increased absolute humidity by operating the hydration reactor at slightly elevated pressure.

- -

- using a two (instead of one) circuit system decreasing the temperature difference in the system, decreasing the pressure difference between the evaporator and reactor.

- -

- sufficiently high compressor and turbine efficiency.

- -

- exhaust air heat pump (EAHP) chilled outlet air, with high RH, eliminating the compressor reqirement.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AH | Absolute humidity |

| COP | Coefficient of performance |

| COPTES | Coefficient of performance for the TES system |

| EAHP | Exhaust air heat pump |

| HM | Hydromagnesite |

| NQ | Nesquehonite |

| pevaprator | Pressure in the evaporator/bubble column |

| preactor | Pressure in the adsorption reactor |

| Qtot | Total heat effect of the TES system, including heat from the reactor and waste heat from compressor work |

| RH | Relative humidity |

| SEM | Scanning electron microscope |

| SG | Silica gel |

| TES | Thermal energy storage |

| Tevaporator | Temperature in the evaporator/bubble column |

| Treactor | Temperature in the adsorption reactor |

References

- Edem N’Tsoukpoe, K.; Liu, H.; Le Pierrès, N.; Luo, L. A review on long-term sorption solar energy storage. Renew. Sustain. Energy Rev. 2009, 13, 2385–2396. [Google Scholar] [CrossRef]

- Bauer, D.; Marx, R.; Nußbicker-Lux, J.; Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. German central solar heating plants with seasonal heat storage. Sol. Energy 2010, 84, 612–623. [Google Scholar] [CrossRef]

- Whiting, G.; Grondin, D.M.; Bennici, S.; Auroux, A. Heats of water sorption studies on zeolite–MgSO4 composites as potential thermochemical heat storage materials. Sol. Energy Mater. Sol. Cells 2013, 112, 112–119. [Google Scholar] [CrossRef]

- Hongois, S.; Kuznik, F.; Stevens, P.; Roux, J.-J. Development and characterization of a new MgSO4-zeolite composite for long-term thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 1831–1837. [Google Scholar] [CrossRef]

- Zondag, H.; Kikkert, B.; Smeding, S.; de Boer, R.; Bakker, M. Prototype thermochemical heat storage with open reactor system. Appl. Energy 2013, 109, 360–365. [Google Scholar] [CrossRef]

- HSC Chemistry, version 8.1.1; Reaction Equations; Outotec: Pori, Finland, 2014.

- Hill, R.J.; Canterford, J.H.; Moyle, F.J. New data for lansfordite. Miner. Soc. 1982, 46, 453–457. [Google Scholar] [CrossRef]

- Zevenhoven, R.; Slotte, M.; Åbacka, J.; Highfield, J. A comparison of CO2 mineral carbonation processes involving a dry or wet carbonation step. Energy 2016, 177, 604–611. [Google Scholar] [CrossRef]

- Zevenhoven, R.; Slotte, M.; Koivisto, E.; Erlund, R. Serpentine carbonation process routs using ammonium sulphate and integration in industry. Energy Technol. 2017, 5, 945–954. [Google Scholar] [CrossRef]

- Koivisto, E.; Erlund, R.; Zevenhoven, R. Extraction of magnesium from four Finnish magnesium silicate rocks for CO2 mineralisation—Part 1: Thermal solid/solid extraction. Hydrometallurgy 2016, 166, 222–228. [Google Scholar] [CrossRef]

- Erlund, R.; Koivisto, E.; Zevenhoven, R. Extraction of magnesium from four Finnish magnesium silicate rocks for CO2 mineralisation—Part 2: Aqueous solution extraction. Hydrometallurgy 2016, 166, 229–236. [Google Scholar] [CrossRef]

- Morgan, B.; Wilson, S.; Madsen, I.; Gozukara, J. Increased thermal stability of nesquehonite (MgCO3·H2O) in the presence of humidity and CO2: Implications for low-temperature CO2 storage. Int. J. Greenh. Gas Control 2015, 39, 366–376. [Google Scholar] [CrossRef]

- Erlund, R.; Zevenhoven, R. Thermal storage of (solar) energy by sorption of water in magnesium (hydro) carbonates. Int. J. Thermodyn. 2017, 20, 102–109. [Google Scholar] [CrossRef]

- Hollingbery, L.A.; Hull, T.R. The fire retardant behaviour of huntite and hydromagnesite—A review. Polym. Degrad. Stabil. 2010, 95, 2213–2225. [Google Scholar] [CrossRef]

- Tahat, M.A. Heat-pump/energy-store using silica gel and water as a working pair. Appl. Energy 2001, 69, 19–27. [Google Scholar] [CrossRef]

- Lim, K.; Che, J.; Lee, J. Experimental study on adsorption characteristics of a water and silica-gel based thermal energy storage (TES) system. Appl. Therm. Eng. 2017, 110, 80–88. [Google Scholar] [CrossRef]

- Statens Energimyndigheten, Sweden. Available online: http://www.energimyndigheten.se/tester/tester-a-o/bergvarmepumpar/bergvarmepumpar/ (accessed on 5 December 2017). (In Swedish).

- Johannes, K.; Kuznik, F.; Hubert, J.-L.; Durier, F.; Obrecht, C. Design and characterisation of a high powered energy dense zeolite thermal energy storage system for buildings. Appl. Energy 2015, 159, 80–86. [Google Scholar] [CrossRef]

- Aydin, D.; Casey, S.P.; Riffat, S. The latest advancements on thermochemical heat storage systems. Renew. Sustain. Energy Rev. 2015, 41, 356–367. [Google Scholar] [CrossRef]

- Jauffret, G.; Morrison, J.; Glasser, F.P. On the thermal decomposition of nesquehonite. J. Therm. Anal. Calorim. 2015, 122, 601–609. [Google Scholar] [CrossRef]

- Morrison, J.; Jauffret, G.; Galvez-Martos, J.K.; Glasser, F.P. Magnesium-based cements for CO2 capture and utilization. Cem. Concr. Res. 2016, 85, 183–191. [Google Scholar] [CrossRef]

- Teir, T.; Kuusik, R.; Fogelholm, C-J.; Zevenhoven, R. Production of magnesium carbonates from serpentinite for long-term storage of CO2. Int. J. Miner. Process. 2007, 85, 1–15. [Google Scholar] [CrossRef]

- Fracastoro, G.V.; Serraino, M. Energy analyses of buildings equipped with exhaust air heat pumps (EAHP). Energy Build. 2010, 42, 1283–1289. [Google Scholar] [CrossRef]

- Mikola, A.; Kõiv, T-A. The Efficiency Analysis of the Exhaust Air Heat Pump System. Engineering 2014, 6, 1037–1045. [Google Scholar] [CrossRef]

- Ren, H.-S. Construction of a generalized psychrometric chart for different pressures. Int. J. Mech. Eng. Educ. 2004, 32, 212–222. [Google Scholar] [CrossRef]

- How to Estimate Compressor Efficiency? Available online: http://www.jmcampbell.com/tip-of-the-month/2015/07/how-to-estimate-compressor-efficiency/ (accessed on 5 December 2017).

| Reaction | Hydration Temp. (°C) | T (ΔG = 0) (°C) | 90% Dehydr. (°C) | Dehydr. Temp. (°C) | Specific Capacity (MJ/kg) |

|---|---|---|---|---|---|

| MgCO3 + 3H2O(g) = MgCO3·3H2O | ~20 | 45 | 61 | 60–65 | 1.0 |

| MgCO3 + xH2O(l) = MgCO3· xH2O | Irrev. | Irrev. | |||

| MgCO3 + 5H2O(g) = MgCO3·5H2O | 5–10 | 55 | 66 | 65–70 | 1.41 |

| MgSO4 + 7H2O(g) = MgSO4·7H2O | ~20 | 145 | 153 | 122 1) | 1.7 |

| 2H2O (20 °C) = 2H2O (60 °C) | 20 2) | - | - | 60 2) | 0.17 |

| Silica gel | ~20 | - | 65 3) | 100 | 0.62 |

| (Silica gel dehydrated at 65 °C) | ~20 | - | - | 65 | 0.52 |

| Zeolite HY [4] | ~20 | - | ~110 | 110 | 0.8 |

| Zeolite Na-Y (dehydrated) = Zeolite Na-Y (hydrated) [4] | ~20 | - | ~140 | 140 | 1.0 |

| MgCl2·6H2O = MgCl2·2H2O + 4H2O [5] | 60 | 100 | - | 150 |

| Relative Humidity in Reactor | Hydration Mass Increase (g/gsample) | TDewpoint at 1 bar (°C) | pevaporator for 100% RH (bar) | Absolute Humidity (g/kg) | Specific Capacity (MJ/kg) | Sample Nr. |

|---|---|---|---|---|---|---|

| 25% | 0.093 | 0 | 0.7 | 3.7 | 0.16 | 1 |

| 36% | - | 5 | 1 | 5.3 | - | |

| 40% | 0.194 | 7 | 1.1 | 6.3 | 0.32 | 1 |

| 46% | 0.138 | 8 | 1.2 | 6.7 | 0.23 | 1 |

| 52% | 0.169 | 10 | 1.4 | 7.7 | 0.28 | 1 |

| 75% | 0.288 | 15 | 2 | 11.0 | 0.48 | 1 |

| 75% | 0.253 | 15 | 2 | 11.0 | 0.42 | 1 |

| 75% | 0.293 | 15 | 4 * | 22.0 | 0.49 | 1 |

| 75–80% | 0.410 ** | 14 | 2 | 11.0 | 0.68 | 2 |

| Tevaporator (°C) | pevaprator (bar) | Treactor (°C) | preactor (bar) | Relative Humidity, Reactor (%) | Storage Capacity (MJ/kg) | COPTES | System Circuits |

|---|---|---|---|---|---|---|---|

| 5 | 2 | 20 | 1 | 75% | 0.48 | 2.2 | 1 |

| 5 | 1.41 | 20 | 1 | 55% | 0.32 | 2.8 | 1 |

| 5 | 1 | 20 | 1 | 36% | 0.22 | No Comp. | 1 |

| 5 | 1.41 | 15 | 1 | 75% | 0.48 1) | 3.0 | 2 |

| 15 | 1.41 | 25 | 1 | 75% | 0.48 1) | 4.3 | 2 |

| 5 | 4 | 20 | 2 | 75% | 0.49 | 3.3 | 1 |

| 5 | 2.82 | 20 | 2 | 55% | 0.32 | 4.6 | 1 |

| 5 | 4.32 | 20 | 3 | 55% | 0.32 | 6.4 | 1 |

| 5 | 4.32 | 15 | 3 | 75% | 0.49 3) | 7.0 (4.5) 2) | 2 |

| 15 | 4.32 | 25 | 3 | 75% | 0.49 3) | 11 (4.5) 2) | 2 |

| 5 | 6 | 20 | 3 | 75% | 0.49 3) | 4.5 | 1 |

| Relative Humidity in Reactor | Hydration Mass Increase (g/gsample) | Temperature (°C) | Reactions Time until Stagnation | Absolute Humidity (g/kg) | Specific Capacity (MJ/kg) | Sample Nr. |

|---|---|---|---|---|---|---|

| 65–75% | 0.214 | 8–11 | 4 days | 0.053 | 0.36 | 2 |

| 95% | 0.422 | 20 | 2 weeks | 0.14 | 0.70 | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erlund, R.; Zevenhoven, R. Hydration of Magnesium Carbonate in a Thermal Energy Storage Process and Its Heating Application Design. Energies 2018, 11, 170. https://doi.org/10.3390/en11010170

Erlund R, Zevenhoven R. Hydration of Magnesium Carbonate in a Thermal Energy Storage Process and Its Heating Application Design. Energies. 2018; 11(1):170. https://doi.org/10.3390/en11010170

Chicago/Turabian StyleErlund, Rickard, and Ron Zevenhoven. 2018. "Hydration of Magnesium Carbonate in a Thermal Energy Storage Process and Its Heating Application Design" Energies 11, no. 1: 170. https://doi.org/10.3390/en11010170