Smart Integrated Renewable Energy Systems (SIRES): A Novel Approach for Sustainable Development

Abstract

:1. Introduction

1.1. Literature Review

1.2. Scope and Structure of this Paper

- Introducing the concept of “Energization”

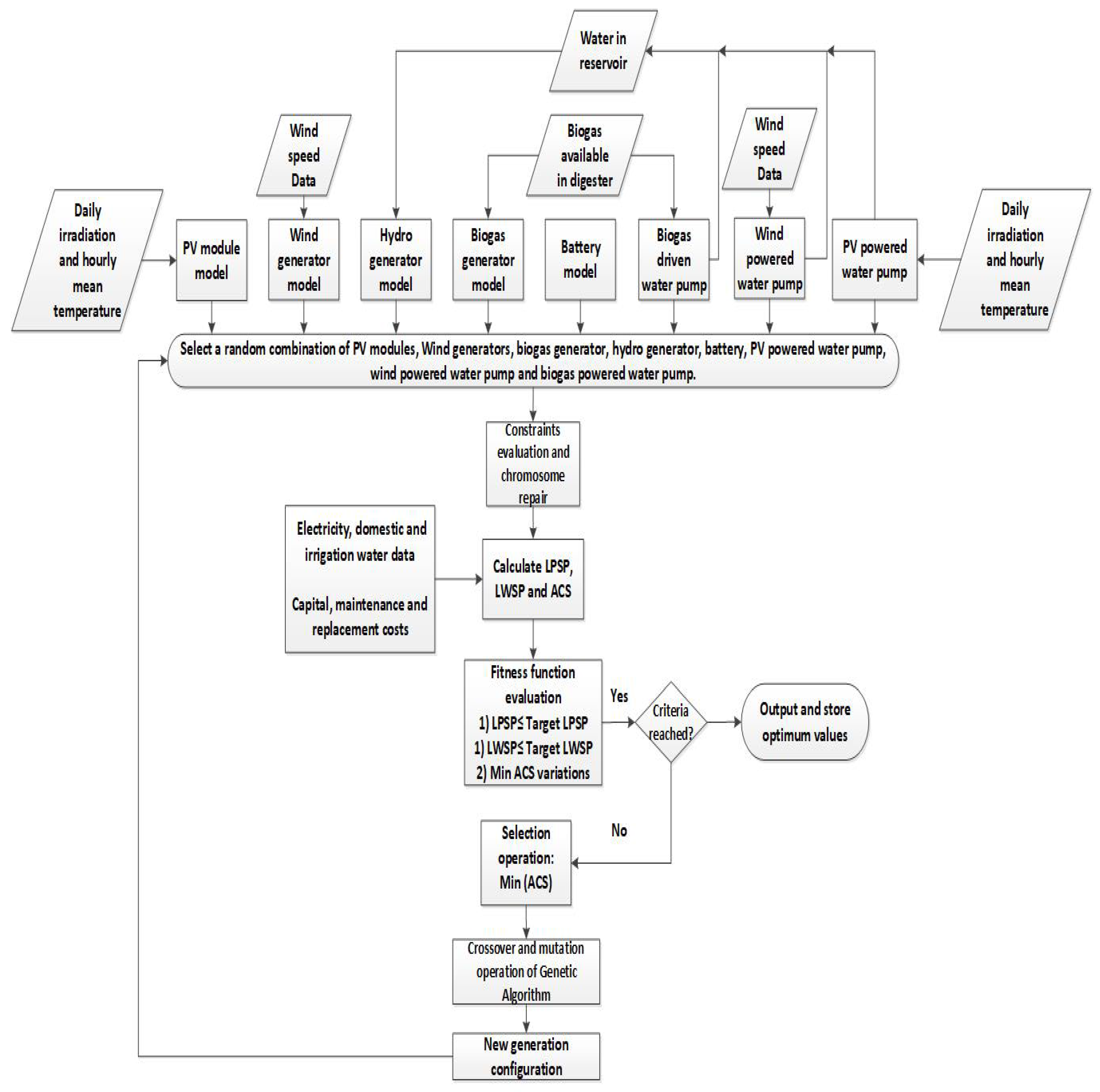

- Development of a genetic algorithm for optimal sizing to minimize cost and maximize reliability for SIRES (multi resource-multi need system)

- Collection of data for parameters, such as weather (insolation, wind speed, rainfall, humidity, temperature), domestic water consumption and electricity

- Comparison of cost (ACS, Net Present Cost (NPC) and installation cost) with existing methods, such as grid extension, microgrid (with and without diesel generator)

2. Electrification vs. Energization

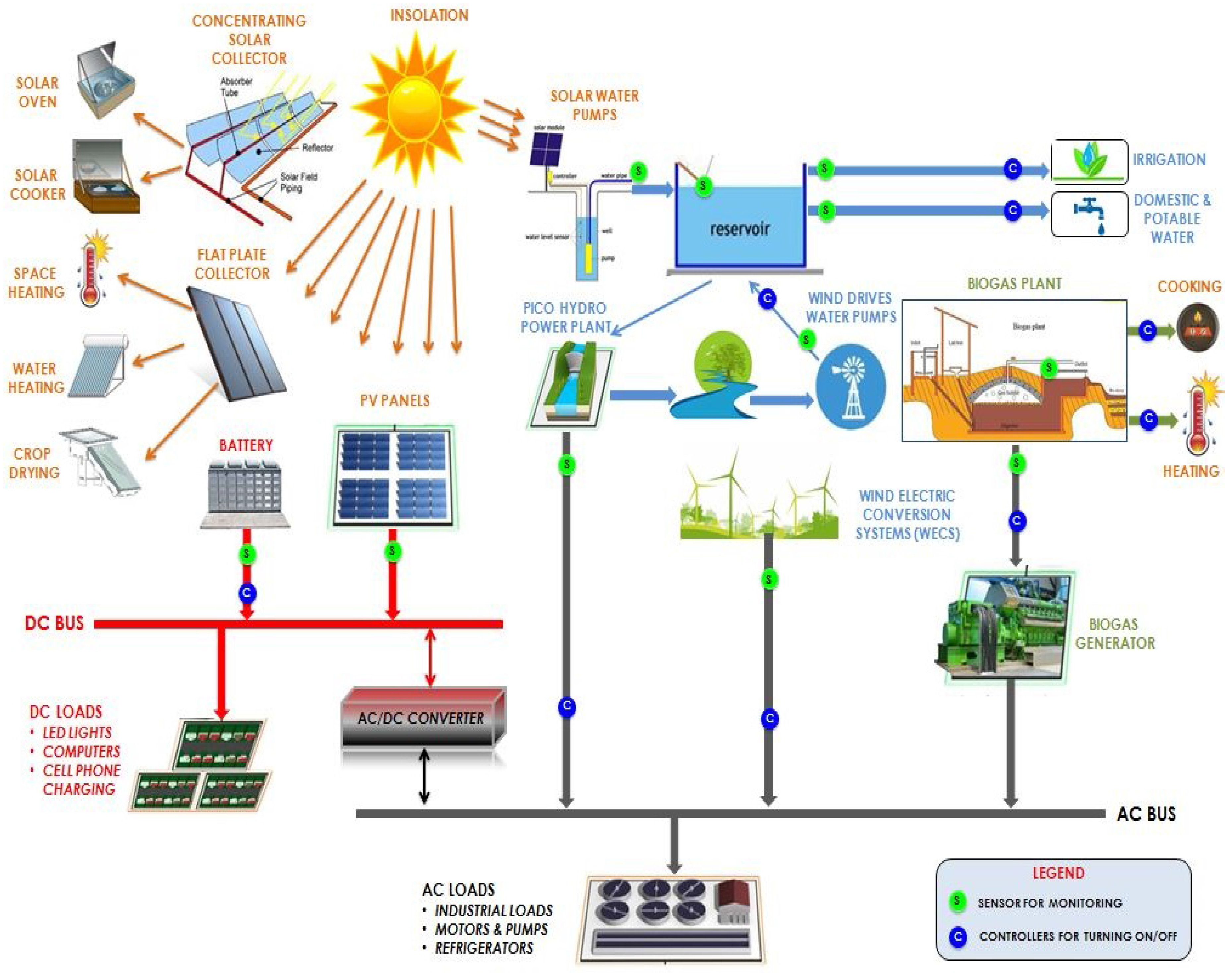

3. Smart Integrated Renewable Energy Systems (SIRES)

3.1. Operation of SIRES

3.2. What Is “Smart” about This Approach?

- SIRES maximizes the impact by “energization” as compared to “electrification”, which is not efficient and cost-effective for demands such as cooking, water pumping etc.

- Needs are prioritized based on necessities of daily life. For example, cooking would be on a higher priority when compared to electricity, and water for domestic purpose would be on a higher priority when compared to irrigation water

- Use of Genetic Algorithm (GA), which optimizes the operation of system components to minimize annualized cost of system and maximize reliability

- Operation and resiliency are enhanced by using smart sensors and intelligent controllers

4. Analysis and Modeling

4.1. Initial Analysis

4.1.1. Determination of Energy Requirements

4.1.2. Analysis of Availability and Conditions

4.1.3. Priortization and Selection of Technologies

4.2. Modeling of System Components

4.3. Modeling of System Reliability and Annualized Cost of System

4.3.1. System Reliability

4.3.2. Annualized Cost of System

4.4. Application of GA to SIRES

5. Results and Discussion

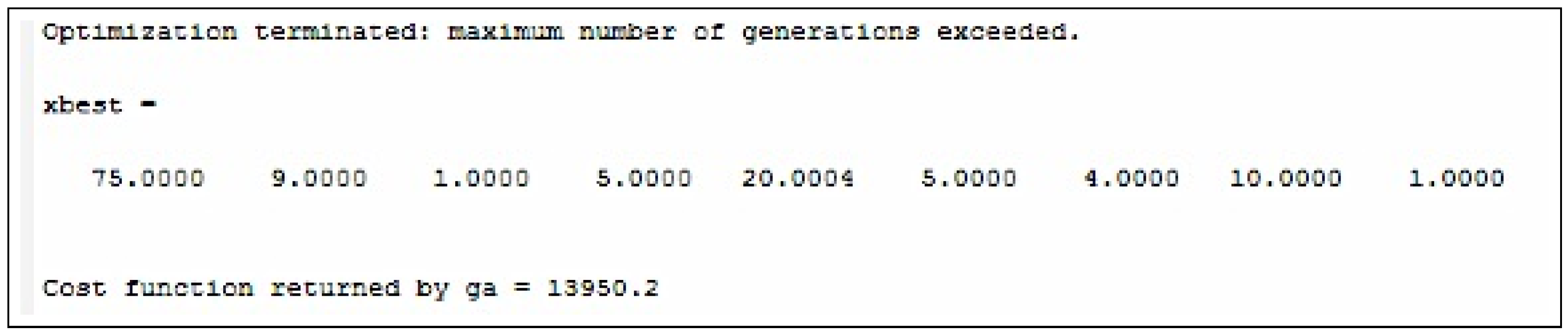

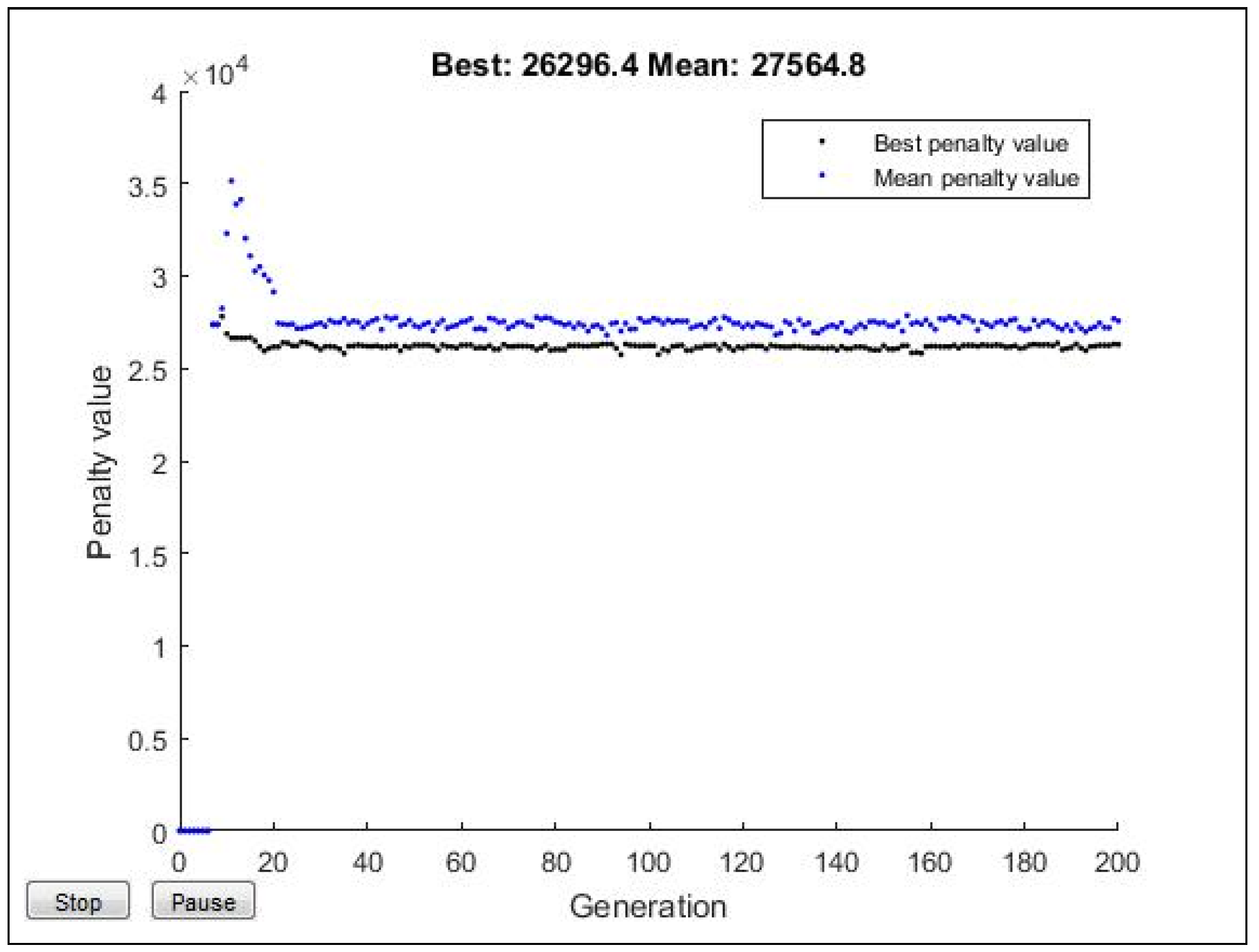

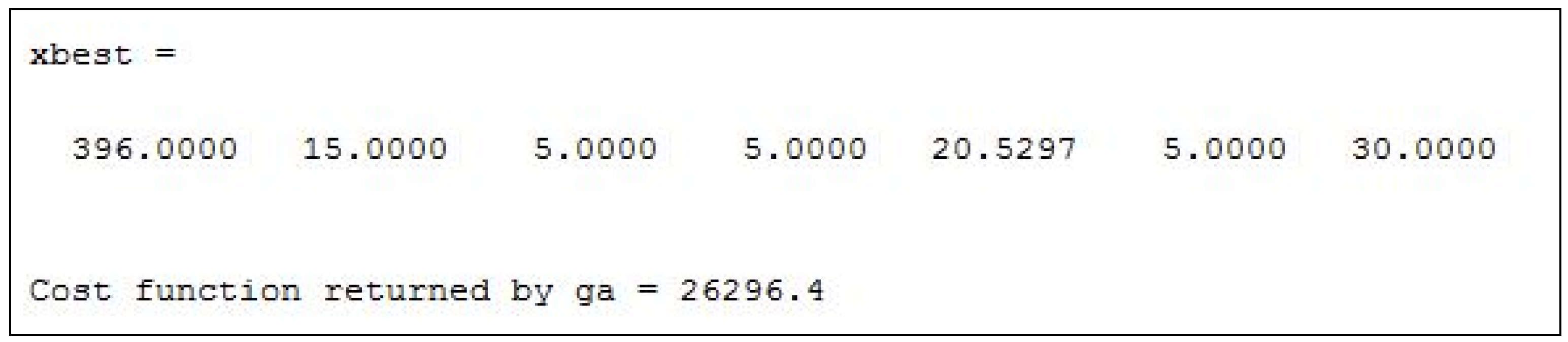

5.1. Optimal Sizing and Cost Analysis

5.2. Cost Comparison for Various Approaches of Rural Development

5.2.1. SIRES

5.2.2. Grid Extension

5.2.3. Microgrid with Diesel Generator(MDG)

5.2.4. Microgrid Without Diesel Generator(MWDG)

6. Concluding Remarks

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SIRES | Smart Integrated Renewable Energy Systems |

| ACS | Annualized Cost of System |

| LPSP | Loss of Power Supply Probability |

| LWSP | Loss of Water Supply Probability |

| GA | Genetic Algorithm |

| NPC | Net Present Cost |

| NPV | Net Present Value |

| PV | Photovoltaic |

| CRF | Capital Recovery Factor |

| SFF | Sinking Fund Factor |

| IRR | Internal Rate of Return |

References

- Rolland, S. Rural Electrification with Renewable Energy; ARE Publication: Brussels, Belgium, 2010. [Google Scholar]

- Energy for Cooking in Development Countries. International Energy Agency (IEA). Available online: https://www.iea.org/publications/freepublications/publication/cooking.pdf (accessed on 15 September 2015).

- Reddy, A.K.N.; Subramanian, D.K. In the design of rural energy centers. In Rural Technology; Indian Academy of Sciences; Macmillann India Press: Bangalore, India, 1979; pp. 109–131. [Google Scholar]

- Progress on Drinking Water and Sanitation. World Health Organization and UNICEF Joint Monitoring Programme (JMP), May 2014. Available online: http://www.unicef.org/publications/files/JMP_{}report_{}2014_{}webEng.pdf (accessed on 15 September 2015).

- Gates, B.; Gates, M. Two Superpowers We Wish We Had. 2016 Annual Letter. 22 February 2016. Available online: https://www.gatesnotes.com/2016-Annual-Letter (accessed on 8 July 2017).

- Energy for All: Financing Access for the Poor. Available online: http://www.worldenergyoutlook.org/media/weowebsite/energydevelopment/weo2011_{}energy_{}for_{}all.pdf (accessed on 15 September 2015).

- United Nations Development Programme (UNDP). Energizing the Millenium Development Goals. New York, 2005. Available online: http://www.unmillenniumproject.org/goals/ (accessed on 13 June 2017).

- United Nations Development Programme (UNDP). Sustainable Development Goals. Rio De Janerio, 2012. Available online: http://www.undp.org/content/undp/en/home/sustainable-development-goals.html (accessed on 13 June 2017).

- Ramakumar, R.; Hughes, W. Renewable Energy Sources and Rural Development in Developing Countries. IEEE Trans. Educ. 1981, 24. [Google Scholar] [CrossRef]

- Decisions by Topic: Rural Development. United Nations Sustainable Development Knowledge Platform. Available online: https://sustainabledevelopment.un.org/topics/ruraldevelopment/decisions (accessed on 9 July 2017).

- Best Practices of the Alliance for Rural Electrification: What Renewable Energy Can Achieve in Developing Countries. Alliance for Rural Electrification. Available online: http://www.ruralelec.org/fileadmin/DATA/Documents/06_Publications/Position_papers/ARE_Publication_-_Case_studies_for_renewables_in_Developing_countries.pdf (accessed on 25 September 2015).

- Schnitzer, D.; Lounsbury, D.; Carvallo, J.P.; Deshmukh, R.; Apt, J.; Kammen, D.M. Microgrids for Rural Electrification: A Critical Review of Best Practices Based on Seven Case Studies; United Nations Foundation (UNF): Washington, DC, USA, 2014. [Google Scholar]

- Ramakumar, R. Technical and Socio-Economic aspects of solar energy and rural development in developing countries. Sol. Energy 1977, 19, 643–649. [Google Scholar] [CrossRef]

- Ramakumar, R. Renewable Energy Sources and Developing Countries. IEEE Trans. Power Appar. Syst. 1983, PAS-102. [Google Scholar] [CrossRef]

- Larsen, R.S.; Welbourn, D.; Wessner, D.; Podmore, R.; Lacourciere, M.; Larsen, A.; Lee, P.; Moulton, R.; Myers, S.; Niboh, M.; et al. “Learning beyond the Light Bulb” among Least Developed Countries based on a sustainable PV solar utility model. In Proceedings of the 2014 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 10–13 October 2014; pp. 106–114. [Google Scholar]

- IEEE Smart Village, Frequently Asked Questions. Available online: http://ieee-smart-village.org/resources/faq/ (accessed on 1 October 2015).

- Koutroulis, E.; Kolokotsa, D.; Potirakis, A.; Kalaitzakis, K. Methodology for optimal sizing of stand-alone photovoltaic/wind-generator systems using genetic algorithms. Sol. Energy 2006, 80, 1072–1088. [Google Scholar] [CrossRef]

- Ashok, S. Optimised model for community-based hybrid energy system. Renew. Energy 2007, 32, 1155–1164. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, W.; Lu, L.; Fang, Z. Optimal sizing method for stand-alone hybrid solar-wind system with LPSP technology by using genetic algorithm. Sol. Energy 2008, 82, 354–367. [Google Scholar] [CrossRef]

- Kanase-Patil, A.B.; Saini, R.P.; Sharma, M.P. Integrated renewable energy systems for off grid rural electrification of remote area. Renew. Energy 2010, 35, 1342–1349. [Google Scholar] [CrossRef]

- Ahlborg, H. Electricity for Better Lives in Rural Tanzania and Mozambique. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2012. [Google Scholar]

- Agarwal, N.; Kumar, A. Optimization of grid independent hybrid PV-diesel-battery system for power generation in remote villages of Uttar Pradesh, India. Energy Sustain. Dev. 2013, 17, 210–219. [Google Scholar] [CrossRef]

- Ramoji, S.K.; Kumar, B.J. Optimal economical sizing of a PV-wind hybrid energy system using genetic algorithm and teaching learning based optimization. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2014, 3, 7352–7367. [Google Scholar]

- Ko, M.J.; Yong, S.K.; Min, H.C.; Hung, C.J. Multi-objective optimization design for a hybrid energy system using the genetic algorithm. Energies 2015, 8, 2924–2949. [Google Scholar] [CrossRef]

- Barman, M.; Mahapatra, S.; Palit, D.; Chaudhury, M.K. Performance and impact evaluation of solar home lighting systems on the rural livelihood in Assam, India. Energy Sustain. Dev. 2017, 38, 10–20. [Google Scholar] [CrossRef]

- Maheshwari, Z.; Ramakumar, R. Smart Integrated Renewable Energy System (SIRES) for Rural Communities. In Proceedings of the 2016 Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016. [Google Scholar]

- Brown, N.L.; Tata, P.B.S. Biomethanation. In Bioenergy; International Development Research Centre: Ottawa, ON, Canada, 1990; pp. 111–117. [Google Scholar]

- Fan, L.; Li, G.; Wang, F.; Geissen, V.; Ritsema, C.J. Factors Affecting Domestic Water Consumption in Rural Households upon Access to Improved Water Supply: Insights from the Wei River Basin, China. PLoS ONE 2013, 8, e71977. [Google Scholar] [CrossRef] [PubMed]

- Bassam, E.; Maegaard, P. Integrated Renewable Energy for Rural Communities; Elseveir Publication: Amsterdam, The Netherlands, 2004; pp. 10–11. [Google Scholar]

- Longe, O.M.; Ouahada, K.; Ferreira, H.C.; Chinnappen, S. Renewable Energy Sources microgrid design for rural area in South Africa. In Proceedings of the 2014 IEEE PES Innovative Smart Grid Technologies Conference (ISGT), Washington, DC, USA, 19–22 February 2014; pp. 1–5. [Google Scholar]

- Fraenkel, P.L. Water Lifting Devices; Food and Agriculture Organization of the United Nations: Rome, Italy, 1986; pp. 31–32. [Google Scholar]

- U.S. Climate Data. Available online: http://usclimatedata.com/climate/stillwater/oklahoma/united-states/usok0507 (accessed on 20 September 2015).

- Caslin, B. Potential of Farm Scale AD in Ireland; Agriculture and Food Development Authority: Carlow, Ireland, 2009. [Google Scholar]

- Zhang, Y.; Kang, L.; Cao, B.; Huang, C.; Wu, G. Simulation of biogas generation. In Proceedings of the 2009 Transmission & Distribution Conference & Exposition: Asia and Pacific, Seoul, Korea, 26–30 October 2009; pp. 1–5. [Google Scholar]

- Lotfi, S.; Tarazouei, F.L.; Ghiamy, M. Optimal Design of a hybrid Solar-Wind-Diesel Power System for Rural Electrification using Imperialist Competitive Algorithm. Int. J. Renew. Energy Res. 2013, 3, 403–411. [Google Scholar]

- Mathew, S.; Pandey, K.P. Modelling the integrated output of wind-driven roto-dynamic pumps. Renew. Energy 2003, 28, 1143–1155. [Google Scholar] [CrossRef]

- Helmy, E.G.; Safya, M.E. Using Photovoltaic Array for Solar Water Pumping in Toshka Region, Egypt. In Proceedings of the 15th International Water Technology Conference, Alexandria, Egypt, 31 March– 2 April 2011. [Google Scholar]

- Abdullah, K.; Coit, D.W.; Smith, A.E. Multi-Objective Optimization Using Genetic Algorithms: A Tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar]

- Taylor, M.; Daniel, K.; Ilas, A.; Young, E. Renewable Power Generation Costs in 2014; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2015. [Google Scholar]

- Purohit, P. Financial evaluation of renewable energy technologies for irrigation water pumping in India. Energy Policy 2006, 35, 3134–3144. [Google Scholar] [CrossRef]

- Paulsen, J.; Reynolds, T. Alternative Energy Pumps to Irrigate Smallholder Farmers’ Land: What Is the State of the Art? Evans School Policy Analysis and Research: Seattle, WA, USA, 2010. [Google Scholar]

- Kossmann, W.; Ponitz, U.; Habermehl, S.; Hörz, T.; Krämer, P.; Klingler, B.; Kellner, C.; Wittur, T.; von Klopotek, F.; Krieg, A.; et al. Biogas Digest: Biogas-Costs and Benefits. Inf. Advis. Serv. Appropr. Technol. 1999, 3, 10–11. [Google Scholar]

- ALTE Polycrystalline Photovoltaic Module. Available online: https://www.altestore.com/static/datafiles/Others/ALT100-24P_alte-solar-modules-spec-sheet.pdf (accessed on 5 January 2016).

- Bergey Excel 1 kW Wind Turbine. Available online: http://bergey.com/products/wind-turbines/bergey-excel-1 (accessed on 5 January 2016).

- Solar Powered Water Surface Pumps. Available online: https://www.altestore.com/store/solar-water-pumps/surface-solar-pumps/suncentric-centrifugal-pump/dankoff-suncentric-7521-dc-surface-pump-p392/ (accessed on 5 January 2016).

- Wind Mechanical Water Pumps. Available online: http://www.ironmanwindmill.com/pumping-capacity.htm (accessed on 6 January 2016).

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower System Modeling with HOMER; National Renewable Energy Laboratory: Golden, CO, USA, 2006; pp. 415–416.

- HOMER Energy Support. Total Net Present Cost in HOMER. Available online: http://usersupport.homerenergy.com/customer/en/portal/articles/2187252-total-net-present-cost-in-homer (accessed on 22 July 2017).

- Basu, A.K.; Chowdhury, S.; Chowdhury, S.P. Value-Based Operational Strategy of CHP-Based Microgrid: A Comparative Analysis. In Proceedings of the 2010 45th International Universities Power Engineering Conference (UPEC), Cardiff, UK, 31 August–3 September 2010; pp. 1–5. [Google Scholar]

- Dutt, G.S.; Ravindranath, N.H. Bioenergy: Direct Applications in Cooking. In Renewable Energy: Sources of Fuels and Electricity; Owino, F., Desai, A., Eds.; Wiley Eastern Limited: Maharashtra, India, 1993; pp. 676–677. [Google Scholar]

| Basic Needs | Population Without Access (in World) | Percentage Living in Rural Areas |

|---|---|---|

| Safe Water | 750 million | 90% |

| Proper stove for cooking | 2.5 billion | 85% |

| Electricity | 1.3 billion | 85% |

| Appliance | Rating (W) | Quantity | Hours of Daily Usage | Total Energy Consumption (Wh)/day |

|---|---|---|---|---|

| Bulbs | 15 | 4 | 5 | 300 |

| TV | 70–150 | 1 | 5 | 350–750 |

| Radio | 15 | 1 | 2 | 30 |

| Refrigerator | 100 | 1 | 24 | 1200 * |

| Cellphone | 5–10 | 2 | 2 | 20–40 |

| Fan | 100 | 2 | 3 | 600 |

| Miscellaneous | 100–300 | |||

| Total | 2500–2940 | |||

| Sl No. | Purpose/Need | Quantity Per Day |

|---|---|---|

| 1 | Biogas for cooking | 238–294 m |

| 2 | Domestic water | 50 m |

| 3 | Electricity load | 345–415 kWh |

| 4 | Irrigation water | 2000–4800 m |

| Component | Capital Cost (Per Unit) | Maintenance Cost (/Year) | Replacement Cost | Lifetime (Years) |

|---|---|---|---|---|

| Solar PV | $3000/kW | $65 | $0 | 25 |

| Wind Turbine | $1800/kW | $95 | $0 | 25 |

| Biogas Digester | $65/m | $100 | $0 | 25 |

| Biogas Generator | $1200/kW | $100 | $1000 | 8 |

| Reservoir | $2000/acre-ft | $50 | $0 | 25 |

| Pico Hydropower | $2300/kW | $15 | $0 | 25 |

| Battery | $1500/kAh | $50 | $1500 | 8 |

| Wind powered water pump | $1000/pump | $100 | $0 | 25 |

| Solar powered water pump | $6000/kW | $50 | $0 | 25 |

| Biogas powered water pump | $2500/kW | $100 | $2500 | 25 |

| Diesel Generator | $500/kW | $135 | $500 | 8 |

| Other components | $10,000 | $80 | $0 | 25 |

| Specifications | Values |

|---|---|

| Solar PV module specifications | |

| Open-Circuit Voltage (Voc) | 44.6 V |

| Optimum Operating Voltage(Vmp) | 36.0 V |

| Short-Circuit Current (Isc) | 3.03 A |

| Optimum Operating Current(Imp) | 2.78 A |

| Maximum Power at STC (Pmax) | 100 Wp |

| Module Efficiency | 13.8% |

| Nominal Operating Cell Temperature (NOCT) | 48 ± |

| Temperature Coefficient of Voc | 0.36%/ |

| Temperature Coefficient of Isc | +0.06%/ |

| Module Dimensions | 1090 × 665 × 35 mm |

| Wind turbine specifications | |

| Cut-in Wind Speed | 2.5 m/s |

| Rated Speed | 11 m/s |

| Furling Speed | 13 m/s |

| Rated power | 1 kW |

| Rotor Diameter | 2.5 m |

| Pico-Hydro power specifications | |

| Height of reservoir | 20 m |

| Flow rate | 10 L/s |

| Efficiency | 70% |

| Biogas Digester specifications | |

| Size (m) | 140 |

| Biogas Generator specifications | |

| Efficiency of generator | 70% |

| Wind powered water pump | |

| Rotor diameter | 5 m |

| Tower height | 20 m |

| Pump diameter | 200 mm |

| Solar powered water pump | |

| Maximum suction lift | 3 m |

| Minimum PV array power | 1.1 kW |

| Maximum Amp | 22.3 A |

| Pump rate | 30 gpm |

| Biogas powered water pump | |

| Power rating | 3.8 kW |

| Efficiency | 50% |

| Overhead Reservoir | |

| Size (acre-foot) | 5 acre-feet |

| Battery Specifications | |

| Rated Capacity, Voltage | 1000 Ah, 24 V |

| Charging Efficiency | 90% |

| Needs | SIRES | Microgrid |

|---|---|---|

| Cooking | 250 m of Biogas | 850 kWh |

| Pumping Water | 3600 m of Water | 400 kWh |

| Electricity | 300 kWh | 300 kWh |

| Approach to Rural Development | Grid Extension | Microgrid with Diesel Generator (MDG) | Microgrid without Diesel Generator (MWDG) | SIRES |

|---|---|---|---|---|

| Annualized Cost of System | – | $26,296.4 | $22,197.9 | $13,950.2 |

| Initial Installation Cost | $300,000 | $217,000 | $225,300 | $122,900 |

| Net Present Cost (NPC) | – | $501,839.7 | $423,624.04 | $266,225.2 |

| Internal Rate of Return (IRR) | – | 11% | 9% | 10% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maheshwari, Z.; Ramakumar, R. Smart Integrated Renewable Energy Systems (SIRES): A Novel Approach for Sustainable Development. Energies 2017, 10, 1145. https://doi.org/10.3390/en10081145

Maheshwari Z, Ramakumar R. Smart Integrated Renewable Energy Systems (SIRES): A Novel Approach for Sustainable Development. Energies. 2017; 10(8):1145. https://doi.org/10.3390/en10081145

Chicago/Turabian StyleMaheshwari, Zeel, and Rama Ramakumar. 2017. "Smart Integrated Renewable Energy Systems (SIRES): A Novel Approach for Sustainable Development" Energies 10, no. 8: 1145. https://doi.org/10.3390/en10081145