DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction

Abstract

:1. Introduction

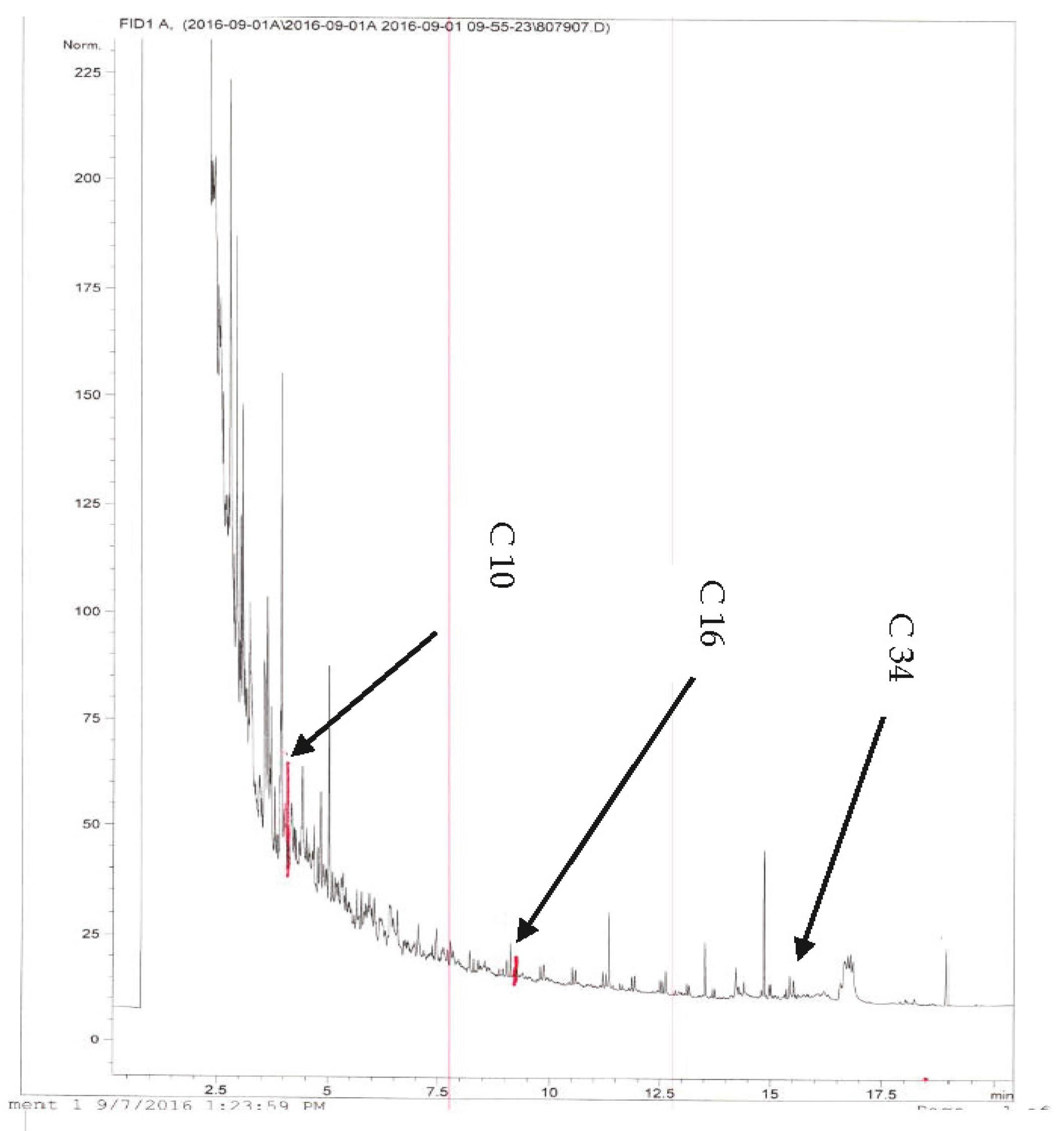

- Fraction 1: C6 to C10 hydrocarbon liquid

- Fraction 2: C10 to C16 hydrocarbon liquid

- Fraction 3: C16 to C34 hydrocarbon liquid

- Fraction 4: C34 to C50 hydrocarbon liquid

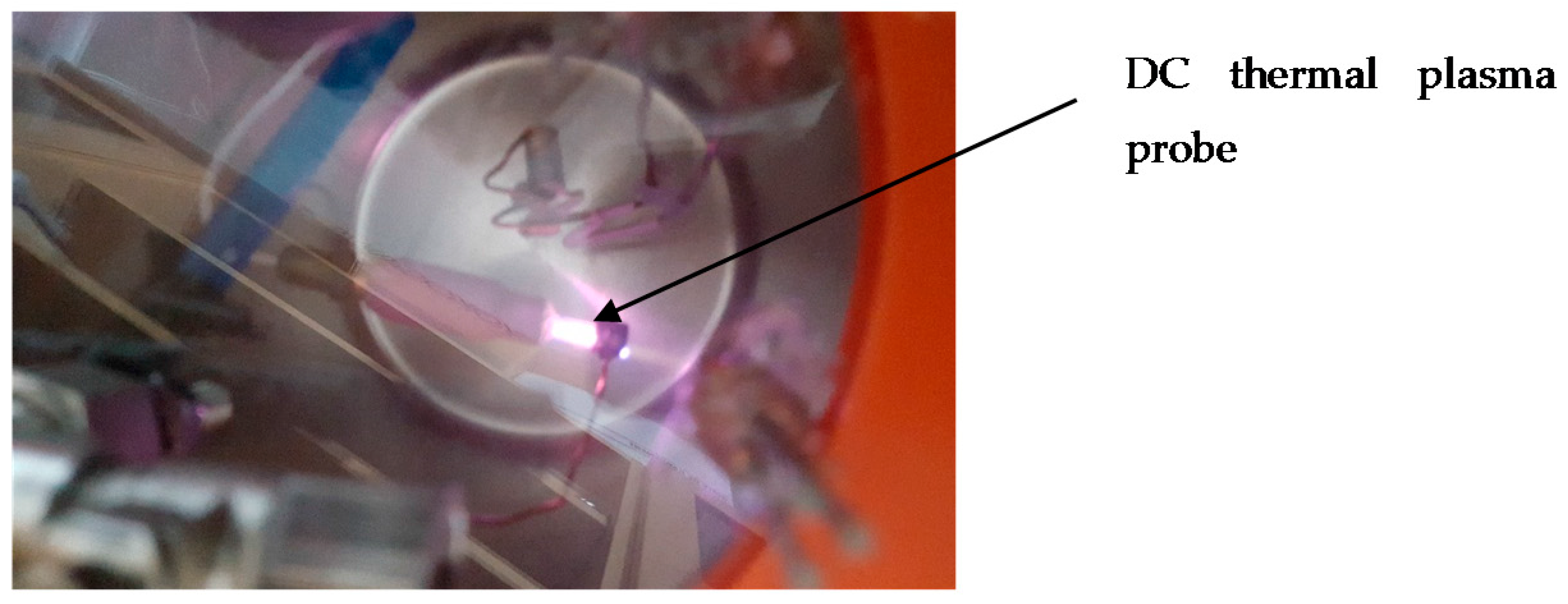

1.1. DC Thermal Plasma

1.2. Goal and Scope

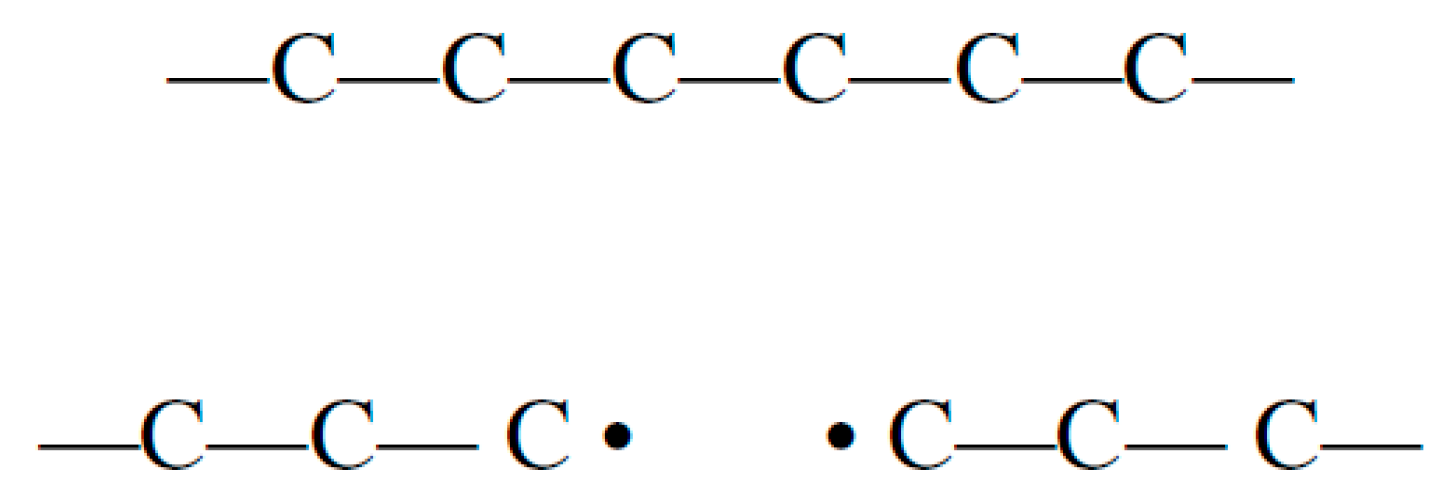

1.3. LDPE Degradation Mechanism

2. Methodology

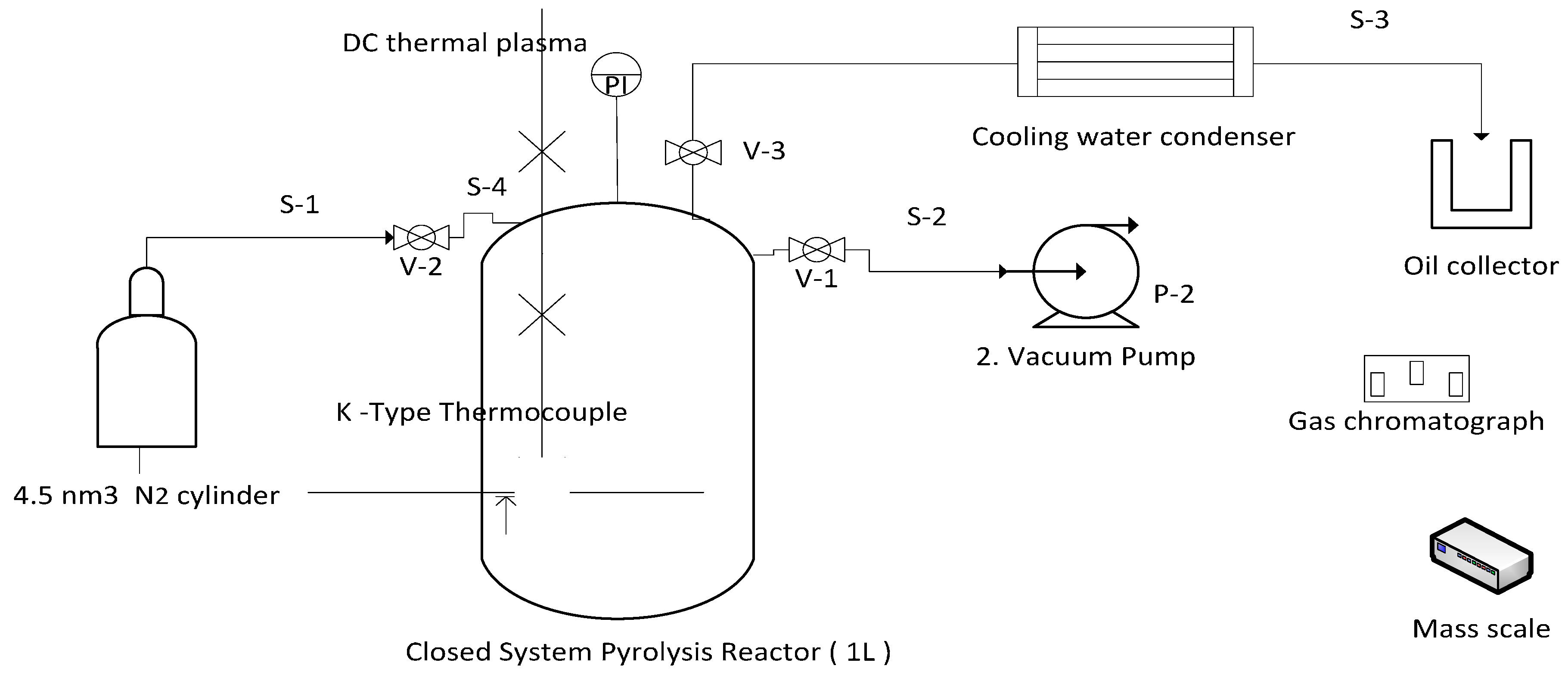

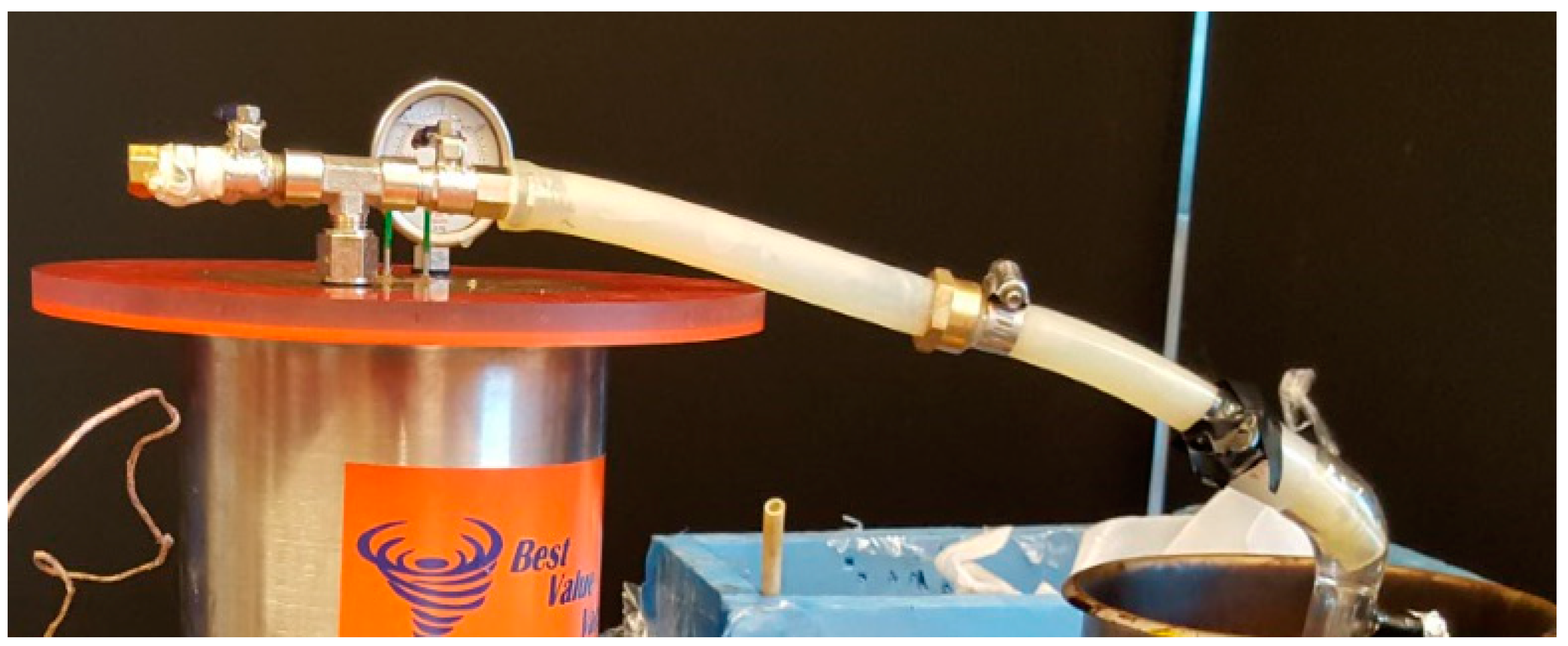

3. Experimental Setup

3.1. Operating Conditions

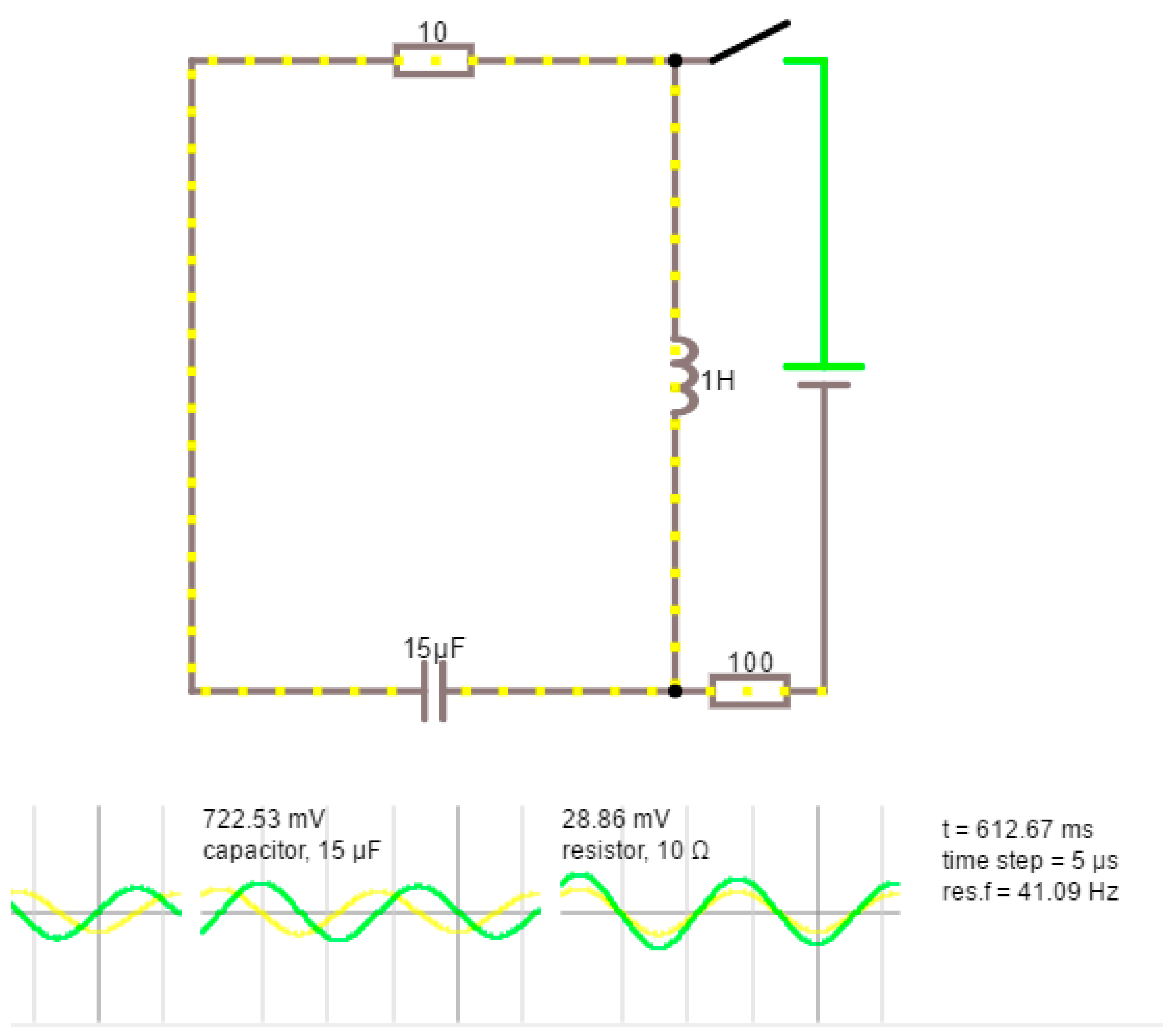

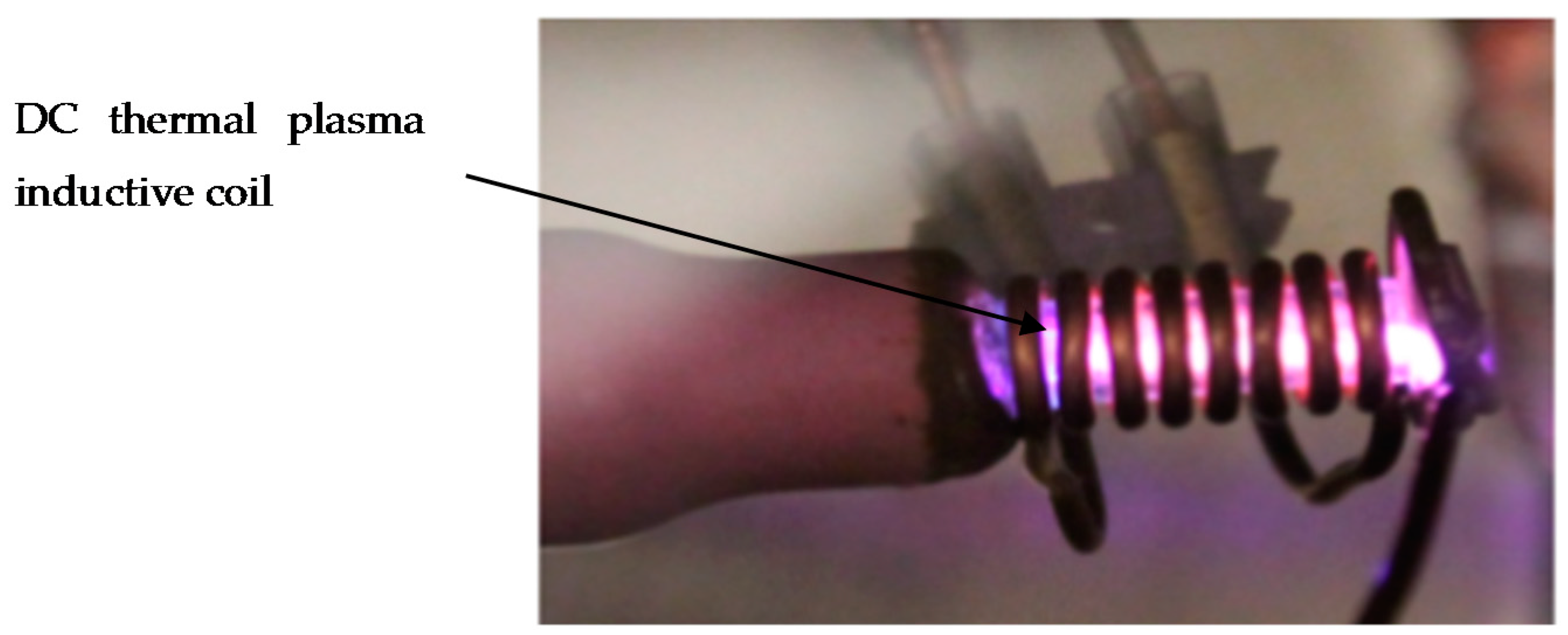

3.2. DC Thermal Plasma Circuit Design

- Switching off the main power supply.

- Pressure test before switching on the thermal plasma system to prevent leaks during operations.

- Ensure the pressure is below atmospheric for optimum plasma operation.

4. Experimental Results

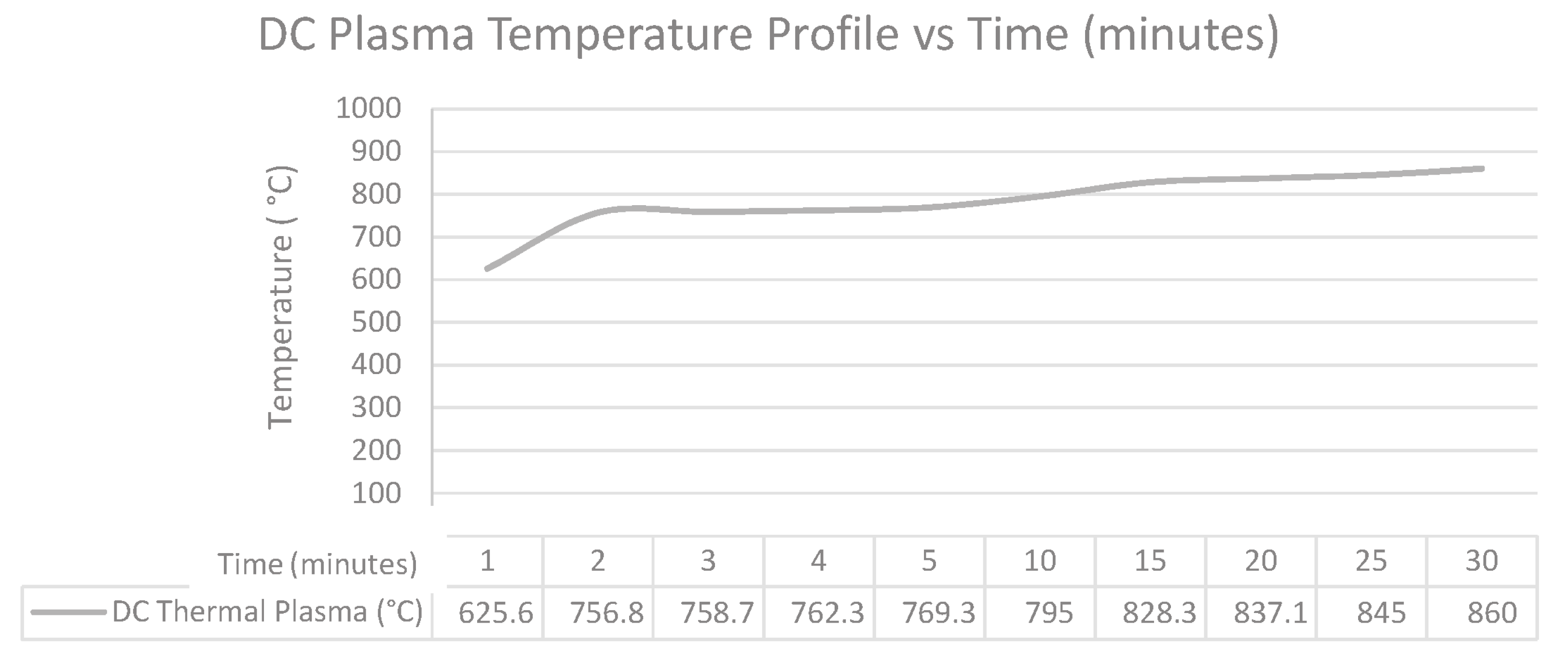

4.1. Temperature Profile

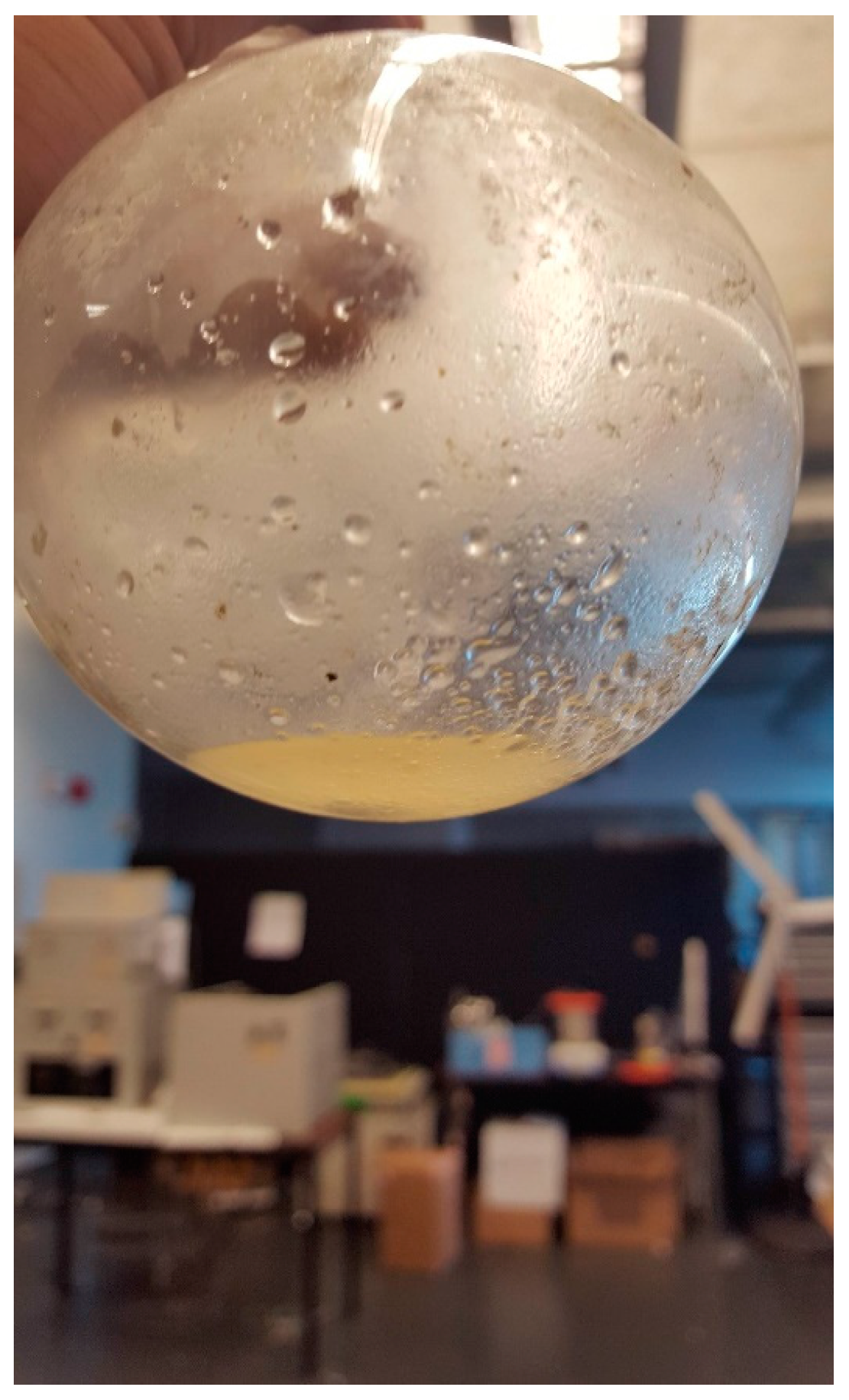

4.2. Collection of Oil Samples

4.3. Headspace GC-FID Analysis

- 1,4-dichlorobenzene, C6H4Cl2

- n-butyl benzene, C10H14

- Un-decane, C11H24

4.4. Product Yield Results

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| DRO | Diesel range oil |

| GC-FID | Gas chromatography-Flame ionization detector method |

| LDPE | Low density polyethylene |

Nomenclature

| CT | Total Capacitance (F) |

| Ea | Activation energy (KJ/mol) |

| k | Reaction constant (1/s) |

| ko | Reactant constant at standard pressure and temperature |

| L | Length of inductance (unit: Henry kg m2 s−2 A−2) |

| pF | Pico (10−12) Farad (s4 × A2 × m−2 × kg−1) |

| Tp | Plasma temperature (°C) |

| R | Ideal gas constant (atm/mol·K) |

| wo | Mass of initial LDPE sample (g) |

| wt | Mass of unreacted LDPE sample (g) |

| Mass of reactant residue(g) | |

| Reaction residence time(min) | |

| Conversion rate with respect to time (g/s) | |

| conversion of reactants to liquid oil products (g) |

References

- Lopez, A.; Marco, I.; Caballero, M.; Laresgioti, M.; Adrados, A. Pyrolysis of municpal plastic wastes: Influence of raw material composition. Waste Manag. 2010, 30, 620–627. [Google Scholar] [CrossRef] [PubMed]

- Syamsiro, M.; Saptoadi, H.; Norsujianto, T.; Noviasri, P.; Cheng, S.; Alimmudin, Z.; Yoshikawa, K. Fuel oil production from municipal plastic wastes in sequential pyrolysis and catalytic reforming reactors. Procedia Eng. 2014, 47, 180–188. [Google Scholar] [CrossRef]

- Shafferina, S.; Abnisa, F.; Daud, W.; Aroua, M. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar]

- Achilias, D.S.; Roupakias, C.; Megalokonomos, P.; Lappas, A.A.; Antonakou, E.V. Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J. Hazard. Mater. 2007, 149, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Balat, M.; Balat, M.; Kırtay, E.B. Main routes for the thermo-conversion of biomass into fuels and chemicals Part 1: Pyrolysis systems. Energy Convers. Manag. 2009, 50, 3147–3157. [Google Scholar] [CrossRef]

- Özge, Ç.; Pütün, A. Thermal and kinetic behaviors of biomass and plastic wastes in co-pyrolysis. Energy Convers. Manag. 2013, 75, 263–270. [Google Scholar]

- Almeida, D.; Marques, M. Thermal and catalytic pyrolysis of plastic waste. Polímeros 2016, 26, 44–51. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Yadavalli, G.; Zhu, L.; Wei, Y.; Liu, Y. Gasoline-range hydrocarbons produced from microwave-induced pyrolysis of low-density polyethylene over ZSM-5. Fuel 2015, 144, 33–42. [Google Scholar] [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process. Technol. 2014, 122, 79–90. [Google Scholar] [CrossRef]

- Park, J.; Park, K.; Park, J.; Kim, D. Characteristics of LDPE pyrolysis. Korean J. Chem. Eng. 2002, 19, 658–662. [Google Scholar] [CrossRef]

- Panda, A.; Singh, R.; Mishra, D. Thermolysis of waste plastics to liquid fuel—A suitable method for plastic waste management and manufacture of value added products—A world prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Derirbas, A. Pyrolysis of municipal plastic wastes for recovery of gasoline-range hydrocarbons. J. Anal. Appl. Pyrolysis 2004, 72, 1. [Google Scholar]

- Siddiqui, M.; Redwi, H. Pyrolysis of mixed plastics from the recovery of useful products. Fuel Process. Technol. 2009, 90, 4. [Google Scholar] [CrossRef]

- Aboulkas, A.; El Harfi, K.; El Bouadilli, A. Thermal degradation behaviors of polyethylene and polypropylene. Part I: Pyrolysis kinetics and mechanisms. Energy Convers. Manag. 2010, 51, 1363–1369. [Google Scholar] [CrossRef]

- Kayacan, I.; Dogan, O. Pyrolysis of low and high density polyethylene. Part I: Non-isothermal pyrolysis kinetics. Energy Source Part A Recovery Util. Environ. Eff. 2008, 30, 385–391. [Google Scholar] [CrossRef]

- Westerhout, R.W.J.; Waanders, J.; Kuipers, J.A.M.; van Swaaij, W.P.M. Kinetics of the low-temperature pyrolysis of polyethene, polypropene, and polystyrene modeling, experimental determination, and comparison with literature models and data. Ind. Eng. Chem. Res. 1997, 36, 1955–1964. [Google Scholar] [CrossRef]

- Wongkhorsub, C.; Chindaprasert, N. A comparison of the use of pyrolysis oils in diesel engine. Energy Power Eng. 2013, 5, 350–355. [Google Scholar] [CrossRef]

- Chiellini, E.; Solaro, R. Do biopolymers fulfill our expectations concerning environmental benefits. In Biodegradable Polymers and Plastics; Springer: Berlin, Germany, 2003; p. 89. [Google Scholar]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef]

- Feng, G. Pyrolysis of Waste Plastics into Fuels. Ph.D. Thesis, University of Catenbury, Chrstchurch, New Zealand, 2010. [Google Scholar]

- Preston, J.; Rodroguez, F.; Gent, A.; Stevens, M.; Bierwagen, G.; Kauffman, G. Major Industrial Polymers, LDPE. Available online: https://www.britannica.com/science/polyethylene (accessed on 6 June 2017).

- Onwudili, J.; Insura, N.; Williams, P. Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: Effects of temperature and residence time. J. Anal. Appl. Pyrolysis 2009, 86, 293–303. [Google Scholar] [CrossRef]

- Tamosiunas, A.; Valatkevicius, P.; Valincius, V.; Grigaitiene, V. Production of synthesis gas from propane using thermal water vapor plasma. Int. J. Hydrogen Energy 2014, 39, 2078–2086. [Google Scholar] [CrossRef]

- Huang, H.; Tang, L. Treatment of organic waste using themal plasma pyrolysis technology. Energy Convers. Manag. 2007, 48, 1331–1337. [Google Scholar] [CrossRef]

- Kim, Y.; Ferreri, V.; Rosocha, L.; Anderson, G.; Abbatte, S.; Kim, K. Effect of plasma chemistry on activated propane/air flames. IEEE Trans. Plasma Sci. 2006, 34, 2532–2536. [Google Scholar] [CrossRef]

- Pyrolysis of Waste Plastics: Effect of Heating Rate on Product Yields and Oil Properties. Available online: https://www.scientific.net/AMR.666.1 (accessed on 6 June 2017).

- Rao, L.; Rivard, F.; Carabin, P. Thermal Plasma Torches for Metallurigal Applications. Available online: http://www.pyrogenesis.com/wp-content/uploads/2014/01/1.-TMS-2013-publications_Pyro-extract.pdf (accessed on 6 June 2017).

- Yu, Q.; Kong, M.; Liu, T.; Fei, J.; Zheng, X. Non-thermal plasma assisted CO2 reforming of propane over Ni/γ-Al2O3 catalyst. Catal. Commun. 2011, 12, 1318–1322. [Google Scholar] [CrossRef]

- Fabry, F.; Rehmet, C.; Rohani, V.V.; Fulcheri, L. Waste gasification by thermal plasma: A review. Waste Biomass Valor 2013, 4, 421–439. [Google Scholar] [CrossRef]

- Tamosiunas, A.; Valatlevicius, P.; Grigaitiene, V.; Valincius, V. A cleaner production of synthesis gas from glycerol using thermal water steam plasma. J. Clean. Prod. 2016, 130, 187–194. [Google Scholar] [CrossRef]

- Tang, L.; Huang, H.; Hao, H.; Zhao, K. Development of plasma pyrolysis/gasification systems for energy efficient and environmentally sound waste disposal. J. Electrost. 2013, 71, 839–847. [Google Scholar] [CrossRef]

- Wampler, T. Analytical pyrolysis: An overview. In Applied Pyrolysis Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007; pp. 1–4. [Google Scholar]

- Williams, P.; Slaney, E. Analysis of products from the pyrolysis and liquefaction of single plastics and waste plastic mixtures. Resour. Conserv. Recycl. 2007, 51, 4. [Google Scholar] [CrossRef]

- Williams, P.; Williams, E. Fluidized bed pyrolysis of low density polyethylene to produce petrochemical feedstock. J. Anal. Appl. Pyrolysis 1999, 51, 107–126. [Google Scholar] [CrossRef]

- Jamradloedluka, J.; Lertsatitthanakorn, C. Characterization and utilization of char derived from fast pyrolysis of plastic wastes. Procedia Eng. 2014, 69, 1437–1442. [Google Scholar] [CrossRef]

- Wong, S.; Ngadi, N.; Abdullah, T.I.I. Current state and future prospects of plastic waste as source of fuel: A review. Renew. Sustain. Energy Rev. 2015, 50, 1167–1180. [Google Scholar] [CrossRef]

- Bird, J. Electrical circuit theory and technology. In Capacitors and Capacitance, 4th ed.; Oxford University Press: New York, NY, USA, 1997; p. 65. [Google Scholar]

- Banmongkol, C.; Mori, T.; Mizutani, T.; Ishioka, M.; Ishino, I. Effects of oxidation on electrical conduction and breakdown of low-density polyethylene films with different densities. Jpn. J. Appl. Phys. 1998, 37, 872–877. [Google Scholar] [CrossRef]

- Solonenko, O. Thermal Plasma Torches and Technologies, Plasma Torches: Basic Studies and Design, Chem; Science Publishing Group: New York, NY, USA, 2003. [Google Scholar]

- Horvat, N.; Ng, F. Tertiary polymer recycling: Study of polyethylene thermolysis as a first step to synthetic diesel fuel. Fuel 1999, 78, 459–470. [Google Scholar] [CrossRef]

| Reaction Temperature (°C) | Residence Time (min), |

|---|---|

| 440 | 132 |

| 450 | 90 |

| 460 | 95 |

| 470 | 61 |

| 500 | 40 |

| Classification of Plasma | Tp (K) | Applications |

|---|---|---|

| High temperature Plasma (Equilibrium Plasma) | 106–108 | Laser fusion plasma |

| Low temperature Plasma (Quasi-equilibrium Plasma) | 2 × 103–3 × 104 | Arc plasma, atmospheric RF discharge |

| Non-thermal Plasma (non-equilibrium Plasma) | 300–400 | Corona discharge |

| Compound | Result | Units |

|---|---|---|

| 1,4-Dichlorobenzene | 87.9 | wt.% |

| Benzene | 0.008 | µg/g |

| Ethylbenzene | 0.041 | µg/g |

| F1 (C6–C10)-Less BTEX | 61.8 | µg/g |

| F1 (C6–C10) Including BTEX | 62.4 | µg/g |

| p-Xylene | 0.098 | µg/g |

| o-Xylene | 0.183 | µg/g |

| Toluene | 0.271 | µg/g |

| Total Xylenes | 0.281 | µg/g |

| Undecane | 134 | µg/g |

| Fraction (C10–C16) | 2340 | µg/g |

| Fraction (C16–C34) | 685 | µg/g |

| Fraction (C34–C50) | <10 | µg/g |

| Experimental Results | LDPE Reactant (wo) | 15 g |

| Pyrolysis oil volume (density 1.22 g/cm3) | 7 mL (8.54 g) | |

| Hydrocarbon gases | 5.68 g | |

| Tar content | 0.78 g | |

| α = 0.569 (56.9 wt %) | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabbar, H.A.; Aboughaly, M.; Stoute, C.A.B. DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction. Energies 2017, 10, 784. https://doi.org/10.3390/en10060784

Gabbar HA, Aboughaly M, Stoute CAB. DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction. Energies. 2017; 10(6):784. https://doi.org/10.3390/en10060784

Chicago/Turabian StyleGabbar, Hossam A., Mohamed Aboughaly, and C.A. Barry Stoute. 2017. "DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction" Energies 10, no. 6: 784. https://doi.org/10.3390/en10060784

APA StyleGabbar, H. A., Aboughaly, M., & Stoute, C. A. B. (2017). DC Thermal Plasma Design and Utilization for the Low Density Polyethylene to Diesel Oil Pyrolysis Reaction. Energies, 10(6), 784. https://doi.org/10.3390/en10060784