Used Cooking Oils in the Biogas Chain: A Technical and Economic Assessment

Abstract

:1. Introduction

2. Materials and Methods

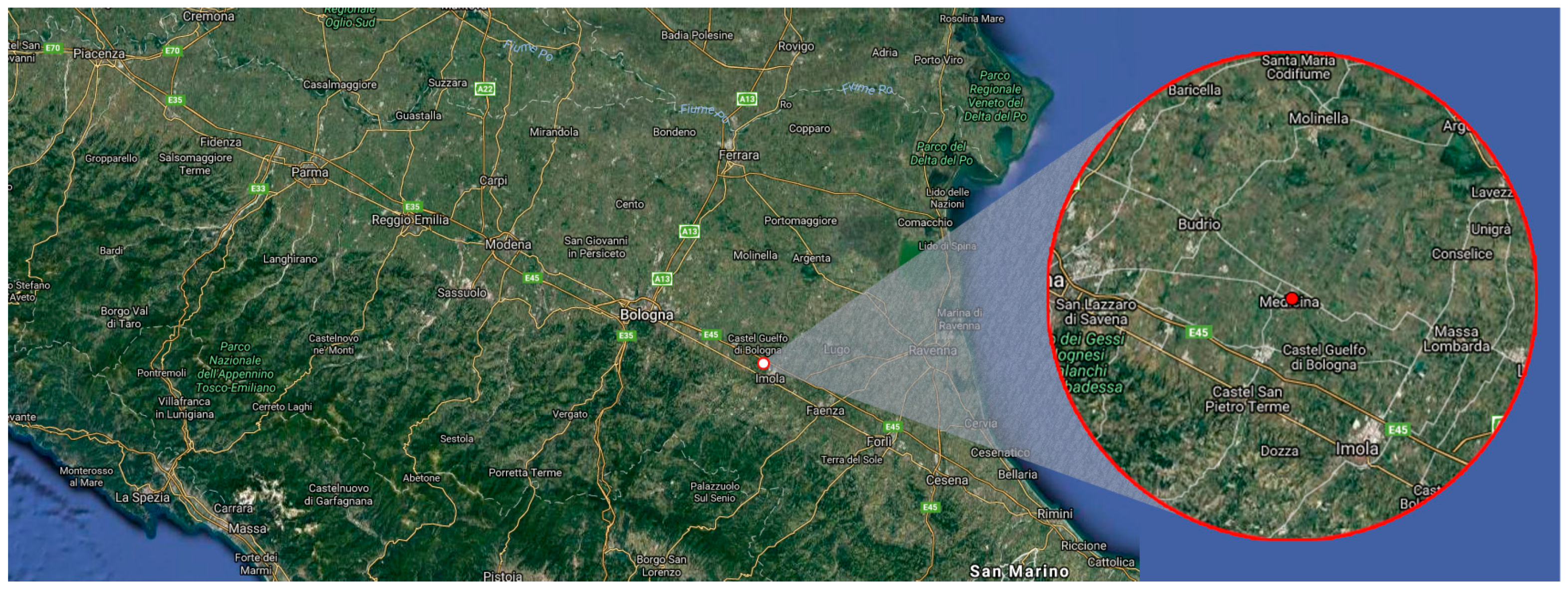

2.1. Case Study Area

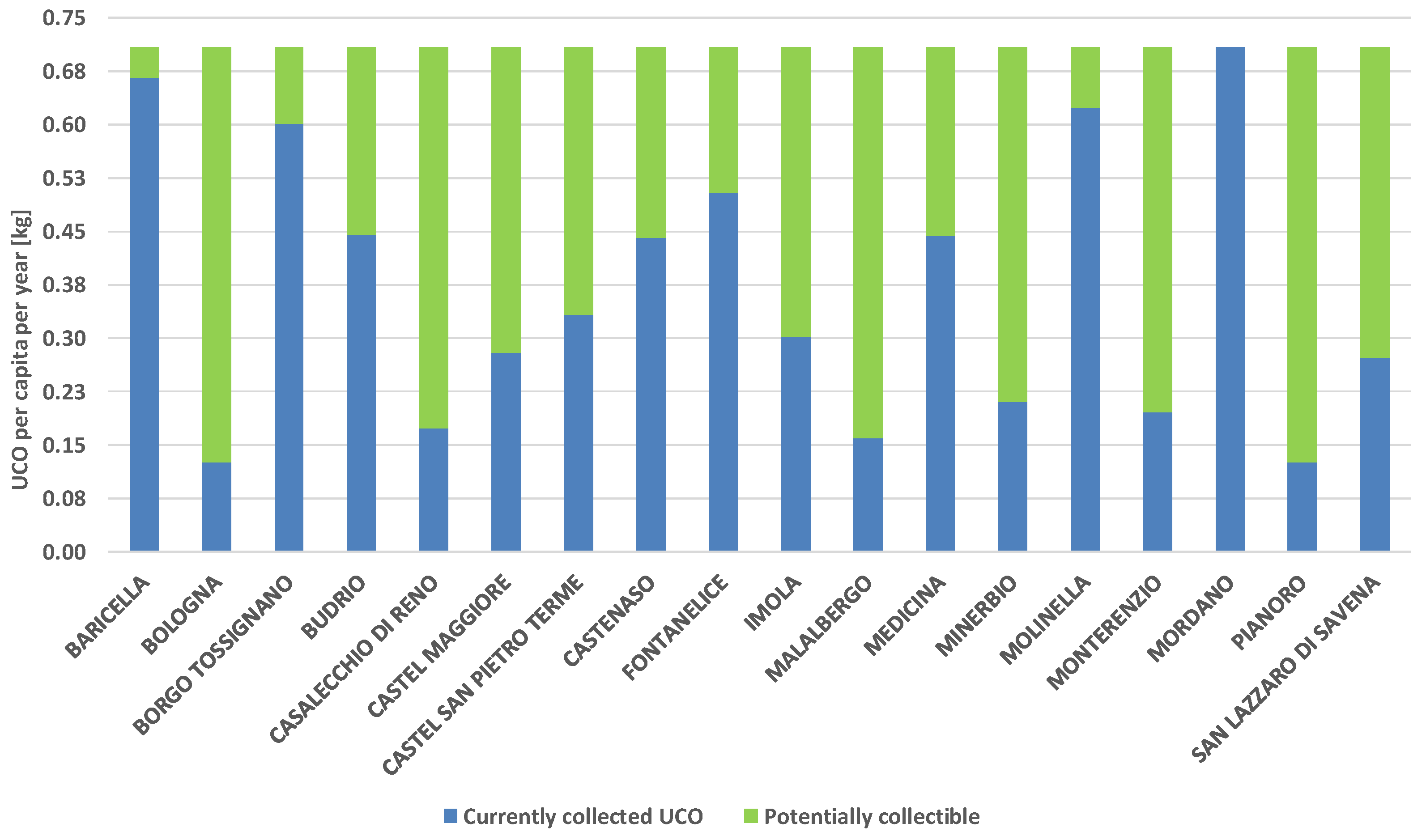

2.2. Data Gathering and Used Cooking Oil Collection

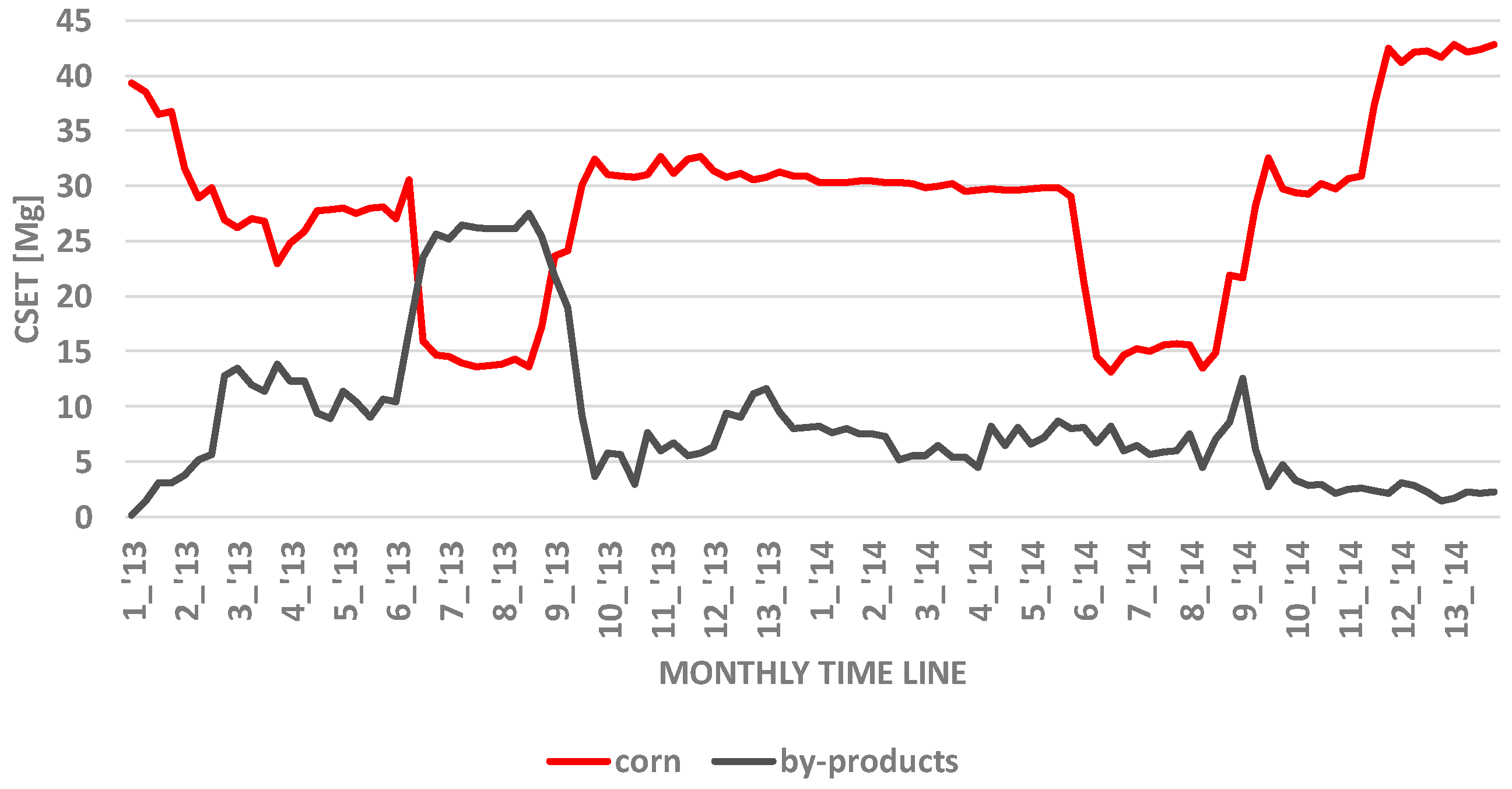

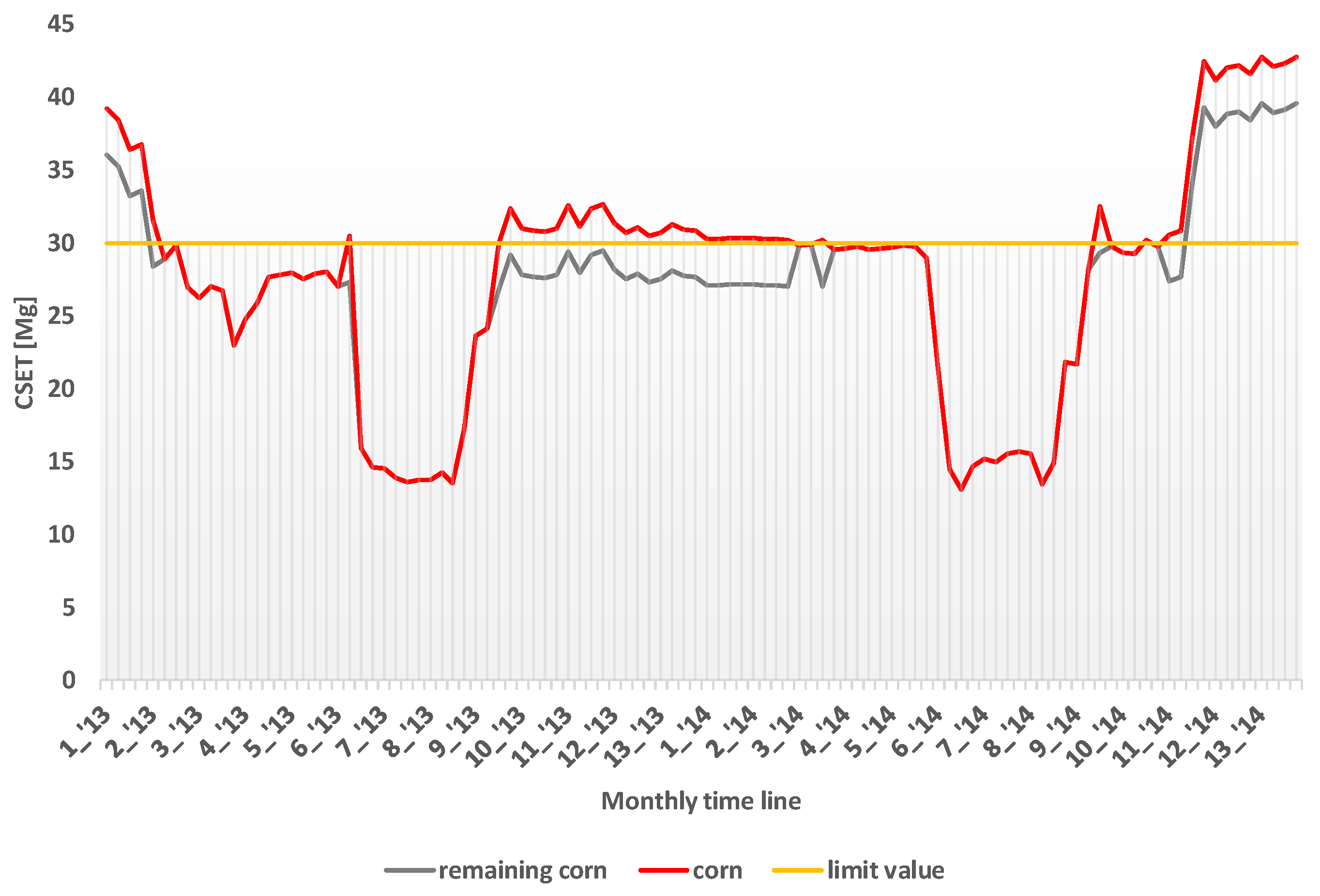

2.3. Biogas Plant Description

2.4. Scenario Analysis

2.4.1. Scenario S1: Baseline

2.4.2. Scenario S2: Intermediate

2.4.3. Scenario S3: Best Case

2.5. Revenue Account

3. Results and Discussion

3.1. Scenario S1: Baseline

3.2. Scenario S2: Intermediate

3.3. Scenario S3: Best Case

3.4. Economic Assessment

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations. Global Agriculture towards 2050, How to Feed the Word, High-Level Expert Forum; Food and Agriculture Organization of the United Nations: Rome, Italy, 2009. [Google Scholar]

- Tscharntke, T.; Clough, Y.; Wanger, T.C.; Jackson, L.; Motzke, I.; Perfecto, I.; Vandermeer, J.; Whitbread, A. Global food security, biodiversity conservation and the future of agricultural intensification. Biol. Conserv. 2012, 151, 53–59. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2014. Synthesis Report. Available online: https://www.ipcc.ch/report/ar5/wg2/ (accessed on 10 October 2016).

- Lutz, C.; Lehr, U.; Wiebe, K.S. Economic effects of peak oil. Energy Policy 2012, 48, 829–834. [Google Scholar] [CrossRef]

- Organisation for Economic Co-Operation and Development (OECD); International Energy Agency (IEA). World Energy Outlook; Organisation for Economic Co-Operation and Development (OECD) Publishing: Paris, France, 2012. [Google Scholar]

- Mech, A.Z.; Rouse, S. Macro and micro economic principles of the Kyoto Protocol result—Making money. In Proceedings of the 2006 IEEE Electrical Insulation Conference (EIC) Climate Change Technology, Ottawa, ON, Canada, 10–12 May 2006; pp. 1–2.

- Unite Nation Framework Convention on Climate Change. Kyoto Protocol Reference Manual on Accounting of Emissions and Assigned Amount; Unite Nation Framework Convention on Climate Change: New York, NY, USA, 2003; pp. 10–122. [Google Scholar]

- Sousa, A.; Faria, J.; Fernandes, H.; Gonçalves, R.; Paredes, H.; Martins, P.; Barroso, J. GREENBOX: A management system for used cooking oils collection. In Proceedings of the World Automation Congress (WAC), Piscataway, NJ, USA, 24–28 June 2012; pp. 1–6.

- European Commission, Commission Stuff Working Document, Impact Assessment, Comunication from the Commission to the European Parliament, the Council, the European Economic and Social Commiteeand the Committee of the Regions. A Policy Framework for Climate and Energy in the Period from 2020 to 2030. Available online: http://ec.europa.eu/smart-regulation/impact/ia_carried_out/docs/ia_2014/swd_2014_0015 (accessed on 8 August 2016).

- Pagani, M.; Vittuari, M.; Johnson, T.G.; de Menna, F. An assessment of the energy footprint of dairy farms in Missouri and Emilia-Romagna. Agric. Syst. 2016, 145, 116–126. [Google Scholar] [CrossRef]

- Molari, G.; Milani, M.; Toscano, A.; Borin, M.; Taglioli, G.; Villani, G.; Demetrio, A.Z. Energy characterization of herbaceous biomass irrigated with marginal water. Biomass Bioenergy 2014, 70, 392–399. [Google Scholar] [CrossRef]

- McKandry, P. Energy production from biomass (part 2): Conversion technologies. Bioresour. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- EurObserv’ER, 2010. The State of Renewable Energies in Europe. 10th EurObserv’ER Report. Available online: http://www.eurobserv.er.org/pdf/barobilan10.pdf (accessed on 16 November 2016).

- Jean Vasile, A.; Raluca Andreea, I.; Popescu, G.H.; Elvira, N.; Marian, Z. Implications of agricultural bioenergy crop production and prices in changing the land use paradigm—The case of Romania. Land Use Policy 2016, 50, 399–407. [Google Scholar] [CrossRef]

- Palmer, J.R. Biofuels and the politics of land-use change: Tracing the interactions of discourse and place in European policy making. Environ. Plan. A 2014, 46, 337–352. [Google Scholar] [CrossRef]

- Bowyer, C.; Kretschmer, B. Anticipated Indirect Land Use Change Associated with Expanded Use of Biofuels and Bioliquids in the EU—An Analysis of the National Renewable Energy Action Plans; International Institute for Education Planning: Paris, France, 2010; pp. 8–9. [Google Scholar]

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Biogas generation through anaerobic digestion process—An overview. Res. J. Chem. Environ. 2014, 18, 80–93. [Google Scholar]

- Riva, C.; Schievano, A.; D’Imporzano, G.; Adani, F. Production costs and operative margins in electric energy generation from biogas. Full-scale case studies in Italy. Waste Manag. 2014, 34, 1429–1435. [Google Scholar] [CrossRef] [PubMed]

- Bacenetti, J.; Duca, D.; Negri, M.; Fusi, A.; Fiala, M. Mitigation strategies in the agro-food sector: The anaerobic digestion of tomato purée by-product. An Italian case study. Sci. Total Environ. 2015, 527, 88–97. [Google Scholar] [CrossRef] [PubMed]

- Dinuccio, E.; Balsari, P.; Gioelli, F.; Menardo, S. Evaluation of the biogas productivity potential of some Italian agro-industrial biomasses. Bioresour. Technol. 2010, 101, 3780–3783. [Google Scholar] [CrossRef] [PubMed]

- De Menna, F.; Malagnino, R.; Vittuari, M.; Molari, G.; Seddaiu, G.; Deligios, P.; Solinas, S.; Ledda, L. Potential biogas production from artichoke byproducts in Sardinia, Italy. Energies 2016, 9, 92. [Google Scholar] [CrossRef]

- Namsree, P.; Suvajittanont, W.; Puttanle, C.; Uttapap, D.; Rungsardthon, V. Anaerobic digestion of pineapple pulp and peel in a plug-flow reactor. J. Environ. Manag. 2012, 110, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Gianico, A.; Braguglia, C.M.; Mescia, D.; Mininni, G. Ultrasonic and thermal pretreatments to enhance the anaerobic bioconversion of olive husks. Bioresour. Technol. 2013, 147, 623–626. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, J.; Treitz, M.; Rentz, O.; Geldermann, J. Production planning by pinch analysis for biomass use in dynamic and seasonal markets. Int. J. Prod. Res. 2009, 47, 2079–2090. [Google Scholar] [CrossRef]

- Peiró, L.T.; Méndez, G.V.; Durany, X.G.I. Exergy analysis of integrated waste management in the recovery and recycling of used cooking oils. Environ. Sci. Technol. 2008, 42, 4977–4981. [Google Scholar] [CrossRef]

- Regulation (EC) No. 1774/2002 of the European Parliament and of the Council of 3 October 2002 Laying down Health Rules Concerning Animal by-Products Not Intended for Human Consumption. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32002R1774 (accessed on 8 August 2016).

- Legislative Decree 3 April 2006, n. 152. Environmental Regulations, Official Gazette no. 88, 2006, Ordinary Supplement n. 96. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A62013CJ0551 (accessed on 8 August 2016).

- Knothe, G.; Steidley, K.R. A comparison of used cooking oils: A very heterogeneous feedstock for biodiesel. Bioresour. Technol. 2009, 100, 5796–5801. [Google Scholar] [CrossRef] [PubMed]

- GREENEA Team, Used Cooking Oil Collection: A Market Worth 470 Million Euros, with France Representing Only 5%. GREENEA 2014. Available online: http://www.greenea.com/it/articoli/category/12-used-cooking-oil.html (accessed on 8 August 2016).

- Sheinbaum, C.; Balam, M.V.; Robles, G.; de Larrea, S.L.; Mendoza, R. Biodiesel from waste cooking oil in Mexico City. Waste Manag. Res. 2015, 33, 730–739. [Google Scholar] [CrossRef] [PubMed]

- Prussi, M.; Chiaramonti, D.; Recchia, L.; Martelli, F.; Guidotti, F.; Pari, L. Alternative feedstock for the biodiesel and energy production: The OVEST project. Energy 2013, 58, 2–8. [Google Scholar] [CrossRef]

- Kolyaei, M.; Zahedi, G.; Nasef, M.M. Optimization of biodiesel production from waste cooking oil using ion exchange resins. In Proceedings of the 2011 4th International Conference on Modeling, Simulation and Applied Optimization (ICMSAO), Kuala Lumpur, Malaysia, 19–21 April 2011; pp. 1–5.

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste cooking oil as an alternate feedstock for biodiesel production. Energies 2008, 1, 3–18. [Google Scholar] [CrossRef]

- Anastopoulos, G.; Zannikou, Y.; Stournas, S.; Kalligeros, S. Transesterification of vegetable oils with ethanol and characterization of the key fuel properties of ethyl esters. Energies 2009, 2, 362–376. [Google Scholar] [CrossRef]

- Ding, J.; Xia, Z.; Lu, J. Esterification and deacidification of a waste cooking oil (TAN 68.81 mg KOH/g) for biodiesel production. Energies 2012, 5, 2683–2691. [Google Scholar] [CrossRef]

- Fierro, J.; Martínez, E.J.; Morán, A.; Gómez, X. Valorisation of used cooking oil sludge by codigestion with swine manure. Waste Manag. 2014, 34, 1537–1545. [Google Scholar] [CrossRef]

- Nuchdang, S.; Phalakornkule, C. Anaerobic digestion of glycerol and co-digestion of glycerol and pig manure. J. Environ. Manag. 2012, 101, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Italian National Consortium for Mandatory Collection and Processing of Waste Vegetable and Animal Oils and Fat (CONOE). Il Contributo del CONOE Alla Green Economy; Technical Report; CONOE: Roma, Italy, 2016. [Google Scholar]

- INEA. Italian Agriculture in Figure 2013. Available online: http://dspace.inea.it/bitstream/inea/843/1/Italian_agriculture_figures_2013.pdf (accessed on 11 October 2016).

- Cavicchi, B. Sustainability that bikefires: The case of biogas in Emilia Romagna. Environ. Innov. Soc. Trans. 2016, 21, 13–27. [Google Scholar] [CrossRef]

- Italian Ministry of Economic Development. Incentives for Biomass and Biogas from Short Chain Biomass. Decreto Ministeriale del 6 Luglio 2010. Available online: http://www.sviluppoeconomico.gov.it/images/stories/documenti/bozza_decreto_interministeriale_mise_ambiente_23_settembre_2015 (accessed on 8 August 2016).

- Danieli, L.; Aldrovandi, A. Replace energy crops with the ad hoc biomass. Inf. Agrar. Suppl. 2011, 38, 25–28. [Google Scholar]

- Schievano, A.; D’Imporzano, G.; Adani, F. Substituting energy crops with organic wastes and agro-industrial residues for biogas production. J. Environ. Manag. 2009, 90, 2537–2541. [Google Scholar] [CrossRef] [PubMed]

- Bordoni, A.; Romagnoli, E.; Foppa Pedretti, E.; Toscano, G.; Rossini, E.; Cozzolino, E.; Riva, G. La Filiera del Biogas. Aspetti Salienti Dello Stato Dell’arte e Prospettive; Laboratorio Biomasse, Università Politecnica delle Marche: Ancona, Italy, 2013; pp. 5–45. [Google Scholar]

- Soldano, M.; Fabbri, C.; Labartino, N.; Piccinini, S. Valutazione del Potenziale Metanigeno di Biomasse di Scarto Dell’industria Agroalimentare, Atti Convengo ECOMONDO 2011. Available online: http://www.crpa.it/media/documents/crpa_www/Settori/Ambiente/Download/Archivio-2011/Ecomondo2011_01.pdf (accessed on 8 August 2016).

- Karellas, S.; Boukis, I.; Kontopoulos, G. Development of an investment decision tool for biogas production from agricultural waste. Renew. Sustain. Energy Rev. 2010, 14, 1273–1282. [Google Scholar] [CrossRef]

| 2013–2014 Average | S1 | S2 | S3 |

|---|---|---|---|

| CTOT,C [Mg per year] | 10,020.70 | 8450.20 | 5097.70 |

| LU [ha per year] | 182.20 | 155.30 | 92.70 |

| LUd [ha per day] | 0.50 | 0.43 | 0.25 |

| UCO collected [Mg per year] | 0.00 | 146.30 | 486.50 |

| UCO fed plant [Mg per year] | 0.00 | 146.30 | 486.50 |

| Land save [ha per year] | 0.00 | 26.90 | 89.50 |

| Value | S1 | S2 | S3 |

|---|---|---|---|

| CA [M€] | 0.61 | 0.56 | 0.43 |

| CI [M€] | 0.21 | 0.21 | 0.21 |

| Cg [M€·(kWh)−1] | 0.23 | 0.23 | 0.23 |

| CT [M€] | 1.1 | 1.0 | 0.89 |

| RT [M€] | 2.1 | 2.1 | 2.1 |

| NPV [M€] | 1.1 | 1.2 | 1.3 |

| MS [M€] | 0.0 | 0.05 | 0.17 |

| PO [€·Mg−1] | 0.0 | 350 | 350 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carnevale, E.; Molari, G.; Vittuari, M. Used Cooking Oils in the Biogas Chain: A Technical and Economic Assessment. Energies 2017, 10, 192. https://doi.org/10.3390/en10020192

Carnevale E, Molari G, Vittuari M. Used Cooking Oils in the Biogas Chain: A Technical and Economic Assessment. Energies. 2017; 10(2):192. https://doi.org/10.3390/en10020192

Chicago/Turabian StyleCarnevale, Erika, Giovanni Molari, and Matteo Vittuari. 2017. "Used Cooking Oils in the Biogas Chain: A Technical and Economic Assessment" Energies 10, no. 2: 192. https://doi.org/10.3390/en10020192