Armored Geomembrane Cover Engineering

Abstract

:1. Introduction

2. Case History Background

2.1. Project History

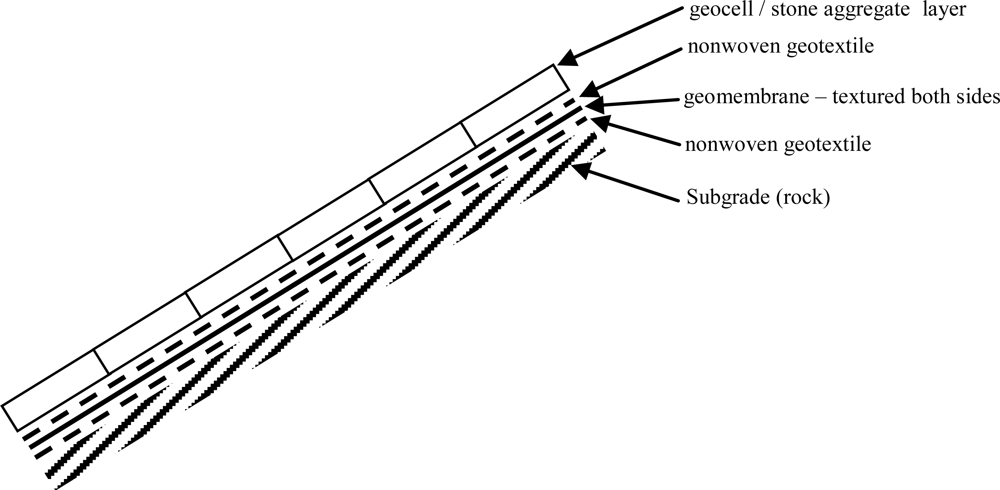

2.2. Cover Design

3. Armor Support

3.1. Geogrid

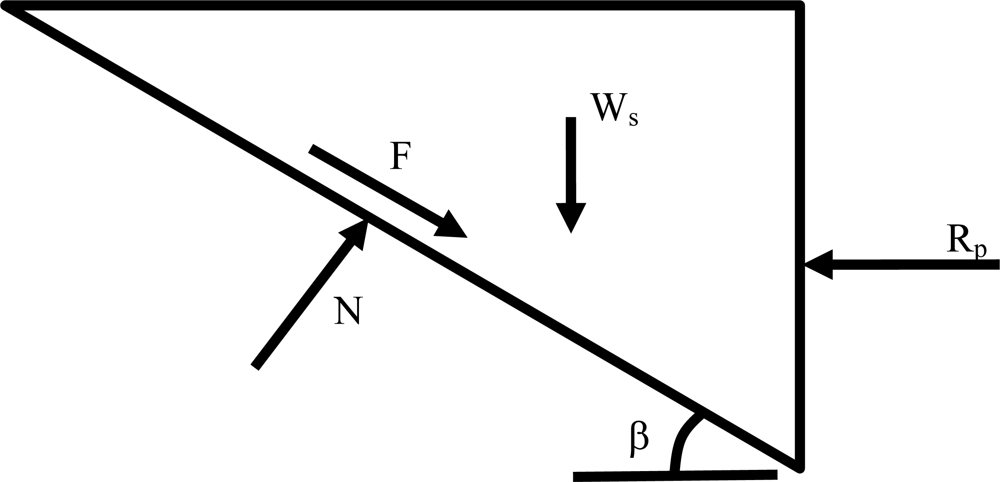

3.1.1. Interface Friction

3.1.2. Geogrid Reinforcement

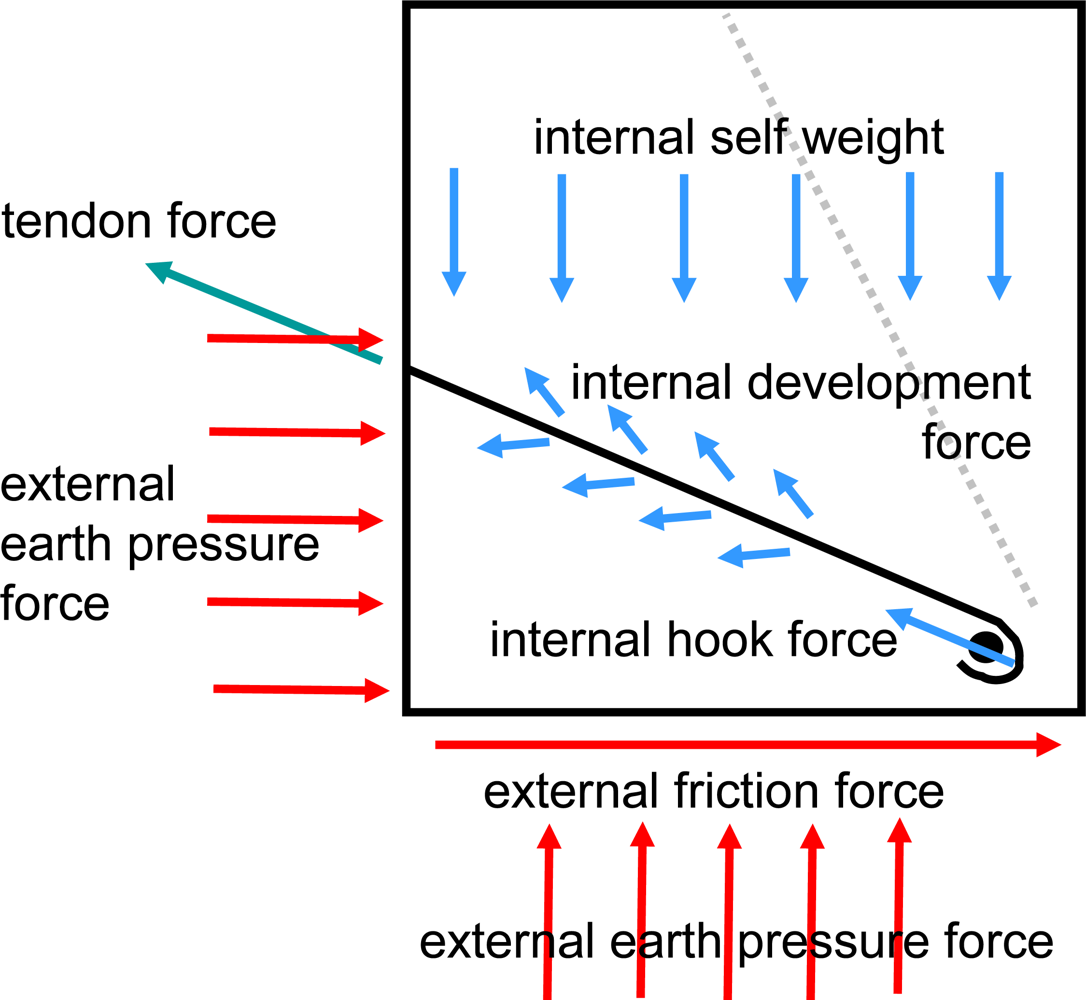

3.2. Steel Tendons

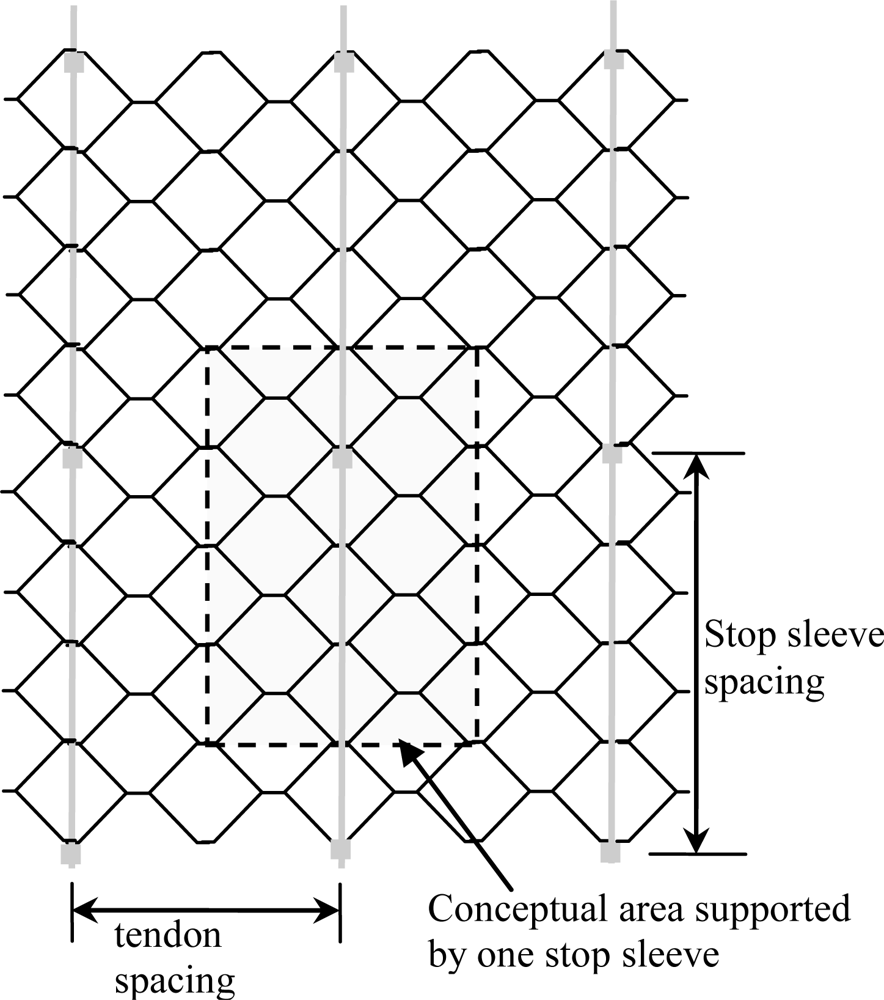

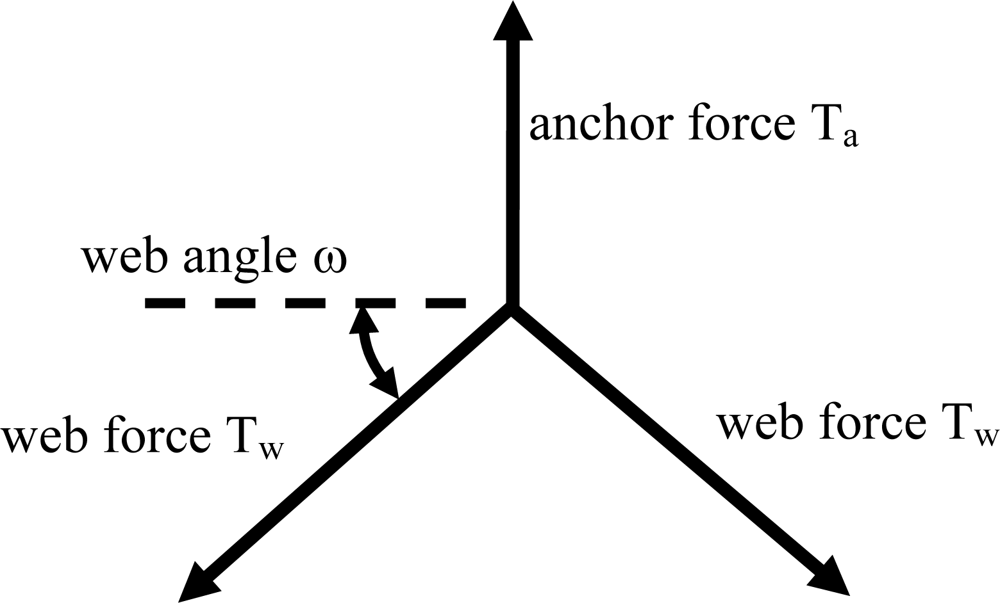

3.2.1. Stop Sleeve Spacing

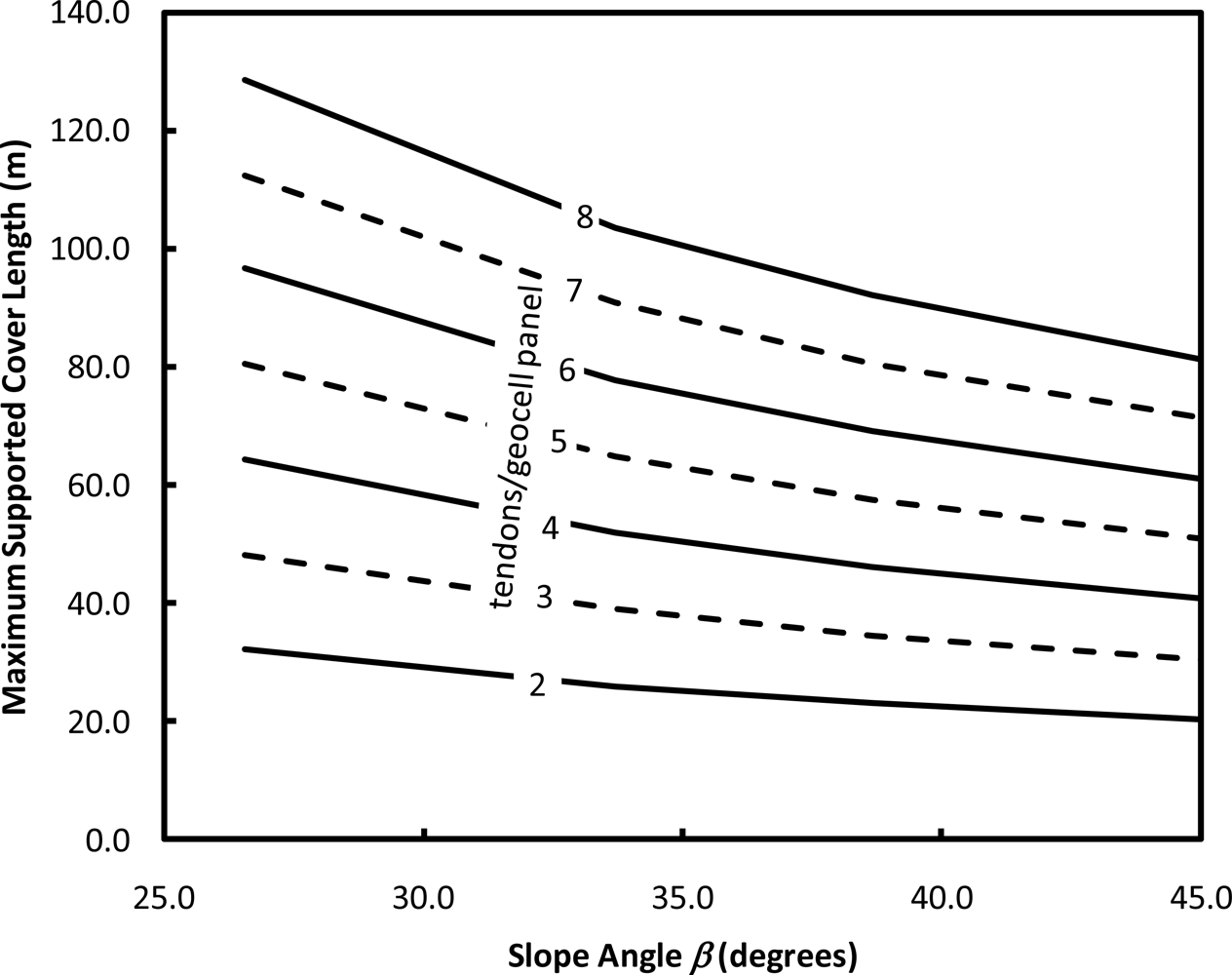

3.2.2. Tendon Spacing

3.2.3. Elongation

4. Armor System Anchorage

4.1. Geogrid Anchor

4.2. Deadman Anchor

4.2.1. Soil Anchorage Calculation

4.2.2. Load Transfer to Concrete Deadman Anchor

4.3. Anchor Beam

4.3.1. Beam Sizing

4.3.2. Tendon Slip Restraint Design

4.3.3. Ground Anchor Bearing Assembly Design

4.3.4. Ground Anchor Design

5. Conclusions

Acknowledgments

References

- Koerner, RM; Soong, T-Y. Analysis and Design of Veneer Cover Soils. In Proceedings of the 6th International Conference on Geosynthetics; Atlanta, GA, USA, 1998; pp. 1–23. [Google Scholar]

- Richardson, GN. Exposed geomembrane covers: Part 1—Geomembrane stresses. GFR Magazine 2000, 18, 1–5. [Google Scholar]

- Giroud, JP; Pelte, T; Bathurst, RJ. Uplift of geomembranes by wind. Geosynth. Int 1995, 2, 897–952. [Google Scholar]

- Wilson-Fahmy, RF; Narejo, D; Koerner, RM. Puncture protection of geomembranes part I: Theory. Geosynth. Int 1996, 3, 605–628. [Google Scholar]

- Koerner, RM. Designing with Geosynthetics, 4th ed; Prentice Hall: Upper Saddle River, NJ, USA, 1998. [Google Scholar]

- Koerner, GR; Narejo, D. Direct Shear Database of Geosynthetic-to-Geosynthetic and Geosynthetic-to-Soil Interfaces; GRI Report #30; Geosynthetic Research Institute: Folsom, PA, USA, 2005. [Google Scholar]

- ASTM International. Standard Test Method for Determining Performance Strength of Geomembranes by the Wide Strip Tensile Method; ASTM D4885; ASTM: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM International. Standard Test Method for Determining the Integrity of Nonreinforced Geomembrane Seams Produced Using Thermo-Fusion Methods; ASTM D6392; ASTM: West Conshohocken, PA, USA, 2008. [Google Scholar]

- American Concrete Institute (ACI). Building Code Requirements for Structural Concrete (ACI 318-98) and Commentary; ACI: Farmington Hills, MI, USA, 1998. [Google Scholar]

- American Institute of Steel Construction (AISC). Load and Resistance Factor Design Manual of Steel Construction, 2nd ed.; AISC: Chicago, IL, USA, 1998. [Google Scholar]

- Federal Highway Administration (FHWA). Ground Anchors and Anchored Systems, Geotechnical Engineering Circular No. 4; FHWA-IF-99-015; FHWA: Washington, DC, USA, 1999. [Google Scholar]

| Interface | δ |

|---|---|

| crushed stone-to-nonwoven geotextile | 33° |

| nonwoven geotextile-to-textured HDPE geomembrane | 26° |

| textured HDPE geomembrane-to-nonwoven geotextile | 26° |

| nonwoven geotextile-to-weathered rock | 30° |

| Design Parameter | Snow Design Scenario | Ice Design Scenario |

|---|---|---|

| Interface Friction Angle | 22° | 0 |

| Geocell Infill Unit Weight(1) | 18.1 kN/m3 | 20.4 kN/m3 |

| Geocell Thickness | 100 mm | 100 mm |

| Overburden Snow Unit Load(2) | 1.50 kN/m2 | 0 |

| Test | Reference Standard | Average Result |

|---|---|---|

| wide-width tension, break strength (Tw) | ASTM D4885 [7]* | 1,030 N |

| seam peel, seam strength | ASTM D6392 [8]* | 1,810 N |

| washer bearing (2-ply), break strength | n/a—see Figure 8 | 2,890 N |

| Slope | β | Number of Tendons per 2.55-m Wide Geocell Panel | ||||||

|---|---|---|---|---|---|---|---|---|

| 8 | 7 | 6 | 5 | 4 | 3 | 2 | ||

| 2H:1V | 26.6° | 128.7 m | 112.5 m | 96.6 m | 80.5 m | 64.3 m | 48.2 m | 32.3 m |

| 1.5H:1V | 33.7° | 103.7 m | 90.9 m | 77.7 m | 64.9 m | 51.8 m | 39.0 m | 25.9 m |

| 1.25H:1V | 38.7° | 92.1 m | 80.5 m | 69.2 m | 57.6 m | 46.0 m | 34.5 m | 23.2 m |

| 1H:1V | 45.0° | 81.4 m | 71.3 m | 61.0 m | 50.9 m | 40.9 m | 30.5 m | 20.4 m |

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Foye, K. Armored Geomembrane Cover Engineering. Int. J. Environ. Res. Public Health 2011, 8, 2240-2264. https://doi.org/10.3390/ijerph8062240

Foye K. Armored Geomembrane Cover Engineering. International Journal of Environmental Research and Public Health. 2011; 8(6):2240-2264. https://doi.org/10.3390/ijerph8062240

Chicago/Turabian StyleFoye, Kevin. 2011. "Armored Geomembrane Cover Engineering" International Journal of Environmental Research and Public Health 8, no. 6: 2240-2264. https://doi.org/10.3390/ijerph8062240