1. Introduction

Construction processes produce not only gas emission pollution [

1], but also acoustic pollution, i.e., noise, which harmfully annoys people [

2]. Various categories of noise-related problems have been classified, including noise-induced hearing impairment [

3], interference with speech communication, disturbance of rest and sleep, psycho-physiological or mental impacts, and interference with intended activities [

4]. Some countries have stipulated noise standards for noise control. While the noise ≤70 dBA is generally believed to not cause hearing impairment in the large majority of people [

5], construction processes often produce noises over 85–90 dBA [

6]. Because construction of buildings or infrastructures often takes place in congested urban areas, construction noise can be a great annoyance to the nearby people in addition to the workers involved. For example, nearly 18% of all noise complaints in Singapore were pertinent to the noise from construction sites [

7]. Some governments have also stipulated related regulations or standards, especially for construction noise [

8,

9,

10].

In consideration of the noise fluctuation over time due to uncertain and dynamic construction environments, instantaneous value of noise cannot comprehensively reflect the actual noise level and its influences on people including nearby residents and construction workers [

9]. Hence, equivalent continuous noise over a period of time [

5,

11], called

Leq-T in this paper, is often used to indicate the actual noise level over time. In fact, some construction noise standards [

8,

9,

10] consider the noise in terms of

Leq-T. For example, the China GB12523 noise standard [

10] stipulates that the maximum

Leq-T over 20 min (namely

max-

Leq-20m) should not exceed 75 dBA and 55 dBA, respectively, for daytime and nighttime, while the U.S. noise standard [

8] stipulates that the maximum

Leq-T over 8 h (namely

max-

Leq-8h) at a residential area should not exceed 80 dBA and 70 dBA, respectively, for daytime and nighttime. The instantaneous noise level may be affected by equipment properties and geometric parameters, while the

Leq-T depends on the proportion of time during which multiple equipment items operate concurrently and the number of concurrently operated pieces of equipment. Meanwhile, the proportion of time and the number of concurrently operated equipment are affected by the start time, duration and preceding-logical conditions and resource requirements of each activity. Obviously, there exist complexities such as uncertainties, dynamics and interactions in determining the

Leq-T.

To evaluate construction plans to address noise standards or decide suitable noise reduction measures, it is necessary to predict the construction noise, particularly the equivalent continuous noise. Due to uncertainties, dynamics and interactions in construction, field measurement of the noise and particularly the

Leq-T may be impractical for every case and the results are inapplicable to every case [

12,

13]. Manatakis and Skarlatos [

14] proposed a statistical model for predicting the noise from construction equipment. Hamoda [

5] used the Back-Propagation Neural Network (BPNN) to predict the construction noise by modeling the nonlinear and imprecise relationship between inputs and outputs. Monte Carlo technique had been adopted to predict the construction noise by reflecting the uncertainties [

15,

16,

17]. However, these studies did not consider the equivalent continuous noise (

Leq-T) over a period of time, let alone the uncertainties, dynamics and interactions that are particularly sensitive to the

Leq-T. Moreover, these studies could not model interactions among multiple noise-affected factors, leading to difficulty in analyzing major factors.

Due to the capabilities in modeling uncertainties, dynamics and interactions of an operational system, discrete-event simulation (DES) that has been successfully used to predict durations, costs and productivities of construction process [

18,

19,

20,

21]. DES has also been applied to predict construction noises [

22]. However, no more relevant references about DES application in predicting construction noises have been noticed so far. In addition, the existing DES application for predicting construction noises still did not address equivalent continuous noise (

Leq-T). Moreover, the simulation framework regarding how to implement the noise-calculation algorithm through DES was not clearly presented.

With regards to the abovementioned backgrounds, this study focuses on applying the DES method to predict the equivalent continuous noise (Leq-T) of construction. First, the noise-calculating models in consideration of noise synchronization and propagation as well as Leq-T are presented. Meanwhile, uncertainties, dynamics and interactions related to the Leq-T are discussed. Then, the simulation framework for implementing the noise-calculating models, including the modeling features for the noise-affected factors and the simulation strategy guiding simulation advancement, is proposed. Finally, an application study is presented to demonstrate and justify the proposed simulation method.

3. Noise-Calculating Model for Equivalent Continuous Level

The construction process is a representative case where the noise levels fluctuate from time to time because different types or items of equipment may be operated simultaneously and stopped or restarted according to schedules or logical dependencies. Therefore, ISO [

11] recommended converting the instantaneous noise level to a single number called “equivalent continuous noise”, i.e.,

Leq-T, to describe the noise level over a period of time

T. The

Leq-T is defined as the average-weighted sound pressure level of a noise fluctuating over a period of time

T, and is calculated as:

For the discrete cases where noise levels may change at discrete points of time but remain constant between two adjacent discrete points of time, the

Leq-T can be calculated as:

where

T (=

T1 +

T2 +, …, +

Tn) is the period of time corresponding to the

Leq-T,

Ti (

i = 1, ...,

n) is a shorter period of time divided from

T, and

Li is the assumed constant noise level over the period of time

Ti. The construction process can be considered as the case in which the noise level changes at the discrete points of time when an item of equipment is started or stopped from time to time and the noise level remains constant during the operation period once it is randomly determined for each cycle. Consequently the

Leq-T for the construction noise can be calculated using Equation (10).

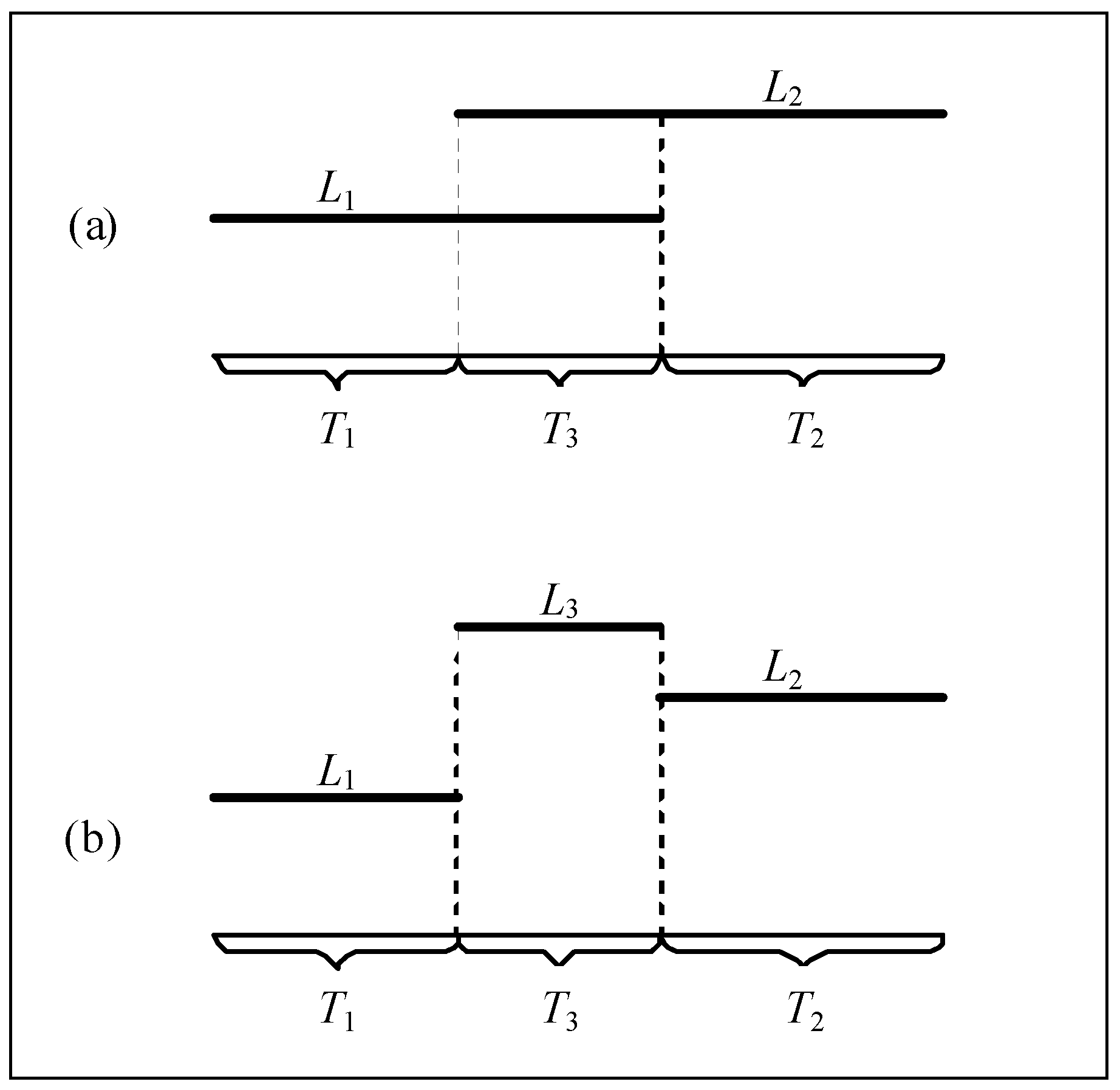

Multiple items of equipment serving different construction activities may be operated simultaneously during some periods of time. For example, two items of equipment that respectively serve different activities and produce the noise levels

L1 and

L2 are operated simultaneously during the period of

T3 as shown in

Figure 1a, though they are started and stopped at different times. To calculate the

Leq-T over the period of

T (=

T1 +

T2 +

T3) at the receptor, the overlapped noises during the period of

T3 should be synchronized using Equation (2) or Equation (3) to get the noise level

L3 at first, then Equations from (4) to (8) are used to calculate the noise levels

L1,

L2 and

L3 (see

Figure 1b) at the receptor by accounting for the attenuation during propagation. Finally the noise levels

L1,

L2 and

L3 at the receptor, which correspond respectively to the periods of

T1,

T2 and

T3, are average-weighted to obtain the

Leq-T using Equation (10).

4. Uncertainties, Dynamics and Interactions Related to Equivalent Continuous Noise

The noise level depends on the properties and maintenance conditions of equipment as well as the on-site conditions, which are uncertain for different cases, so the noise level at the source may be uncertain or random. The type and age of an item of equipment should influence the equipment’s properties. The geometric locations or layouts of the equipment and the receptor, such as heights and distance of/between the noise source and the receptor, also affect the noise propagation and the noise level at the receptor [

27]. The geometric locations may be uncertain majorly due to the temporary and dynamic natures in the construction process, thus dynamically influencing the noise level at the receptor according to Equations from (2) to (8). The uncertain factors can be modeled in terms of probability distributions with respect to different cases.

In addition to equipment properties and geometric parameters which greatly affect source noise levels, the Leq-T also relies on the proportion of time during which multiple items of equipment operate concurrently and the number of concurrently operated equipment. Meanwhile, the proportion of time and the number of concurrently operated equipment are affected by the start time, duration and preceding-logical conditions and resource requirements of each activity. Moreover, these factors affecting the Leq-T may be stochastic and interact with each other. It is also indicated that the Leq-T varies dynamically over time because of the proportion of time and the number of concurrently operated equipment change during the construction process.

Though the general methods including the Monte Carlo methods [

15,

16] could address uncertainties or randomness, but they could not model the dynamics and complex interactions over time. The discrete-event simulation (DES) method has the capabilities for modeling uncertainties, dynamics and interactions [

28], so the DES method is selected to estimate the construction noise in terms of

Leq-T by implementing the noise-calculating models from Equations (2)–(10) as well as accounting for the uncertainties, dynamics and complex interactions.

5. Simulation Framework for Implementing the Noise-Calculating Models

A DES platform, i.e., the activity object-oriented simulation (AOOS) [

20], is modified to implement the noise-calculating models described above for predicting the construction noise in terms of

Leq-T. The simulation framework regarding the modeling features and simulation strategy needs to be modified.

5.1. Modeling Features for the Noise-Affected Factors

The activity object-oriented simulation (AOOS) [

20] was developed based on activity cycle diagram (ACD) [

28] and object-oriented approach. The AOOS adopts the simulation model similar to the activity-on-node (AON) network to describe a construction process over a computer-based platform, on which simulation experimentation is performed. Unlike CYCLONE [

18] and STROBOSCOPE [

21] that use two kinds of modeling elements for activities (i.e., conditional and unconditional activities) and queue elements for entities flow, the AOOS model does not classify the conditional and unconditional activities and does not consider the queue elements.

In view of the requirements to model the noise-affected factors for implementing

Leq-T calculation through simulation as well as the particularities of the AOOS model, the AOOS model should be developed according to the following modeling procedure:

Decompose a construction process into a series of activities, with random activity durations in terms of probability distributions and the logical dependencies among the activities;

Identify the number of each resource including items of equipment required by each activity, including whether the noise from the equipment at the current activity is considered according to the distance of the current activity to the receptor;

Determine overall properties and total numbers of all types of equipment required during the construction process, including the uncertain source noise level of each item of equipment in terms of probability distribution;

Determine the distance between the noise source (on-site equipment) and the receptors (neighboring points) as well as the noise source height and the receptor height;

Determine the fixed period of time T and the interval between two adjacent periods of time to calculate the Leq-T during the simulation experiments.

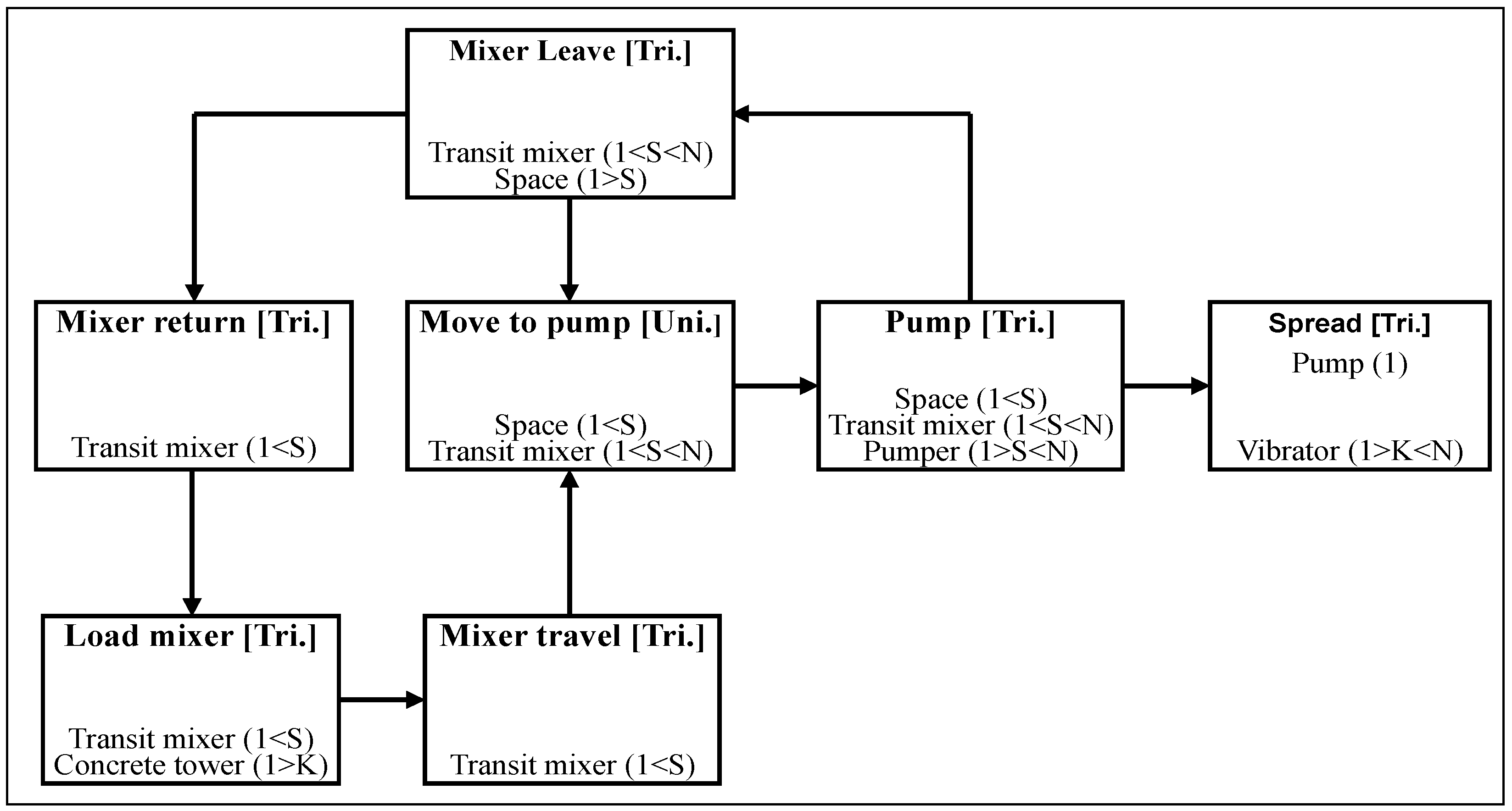

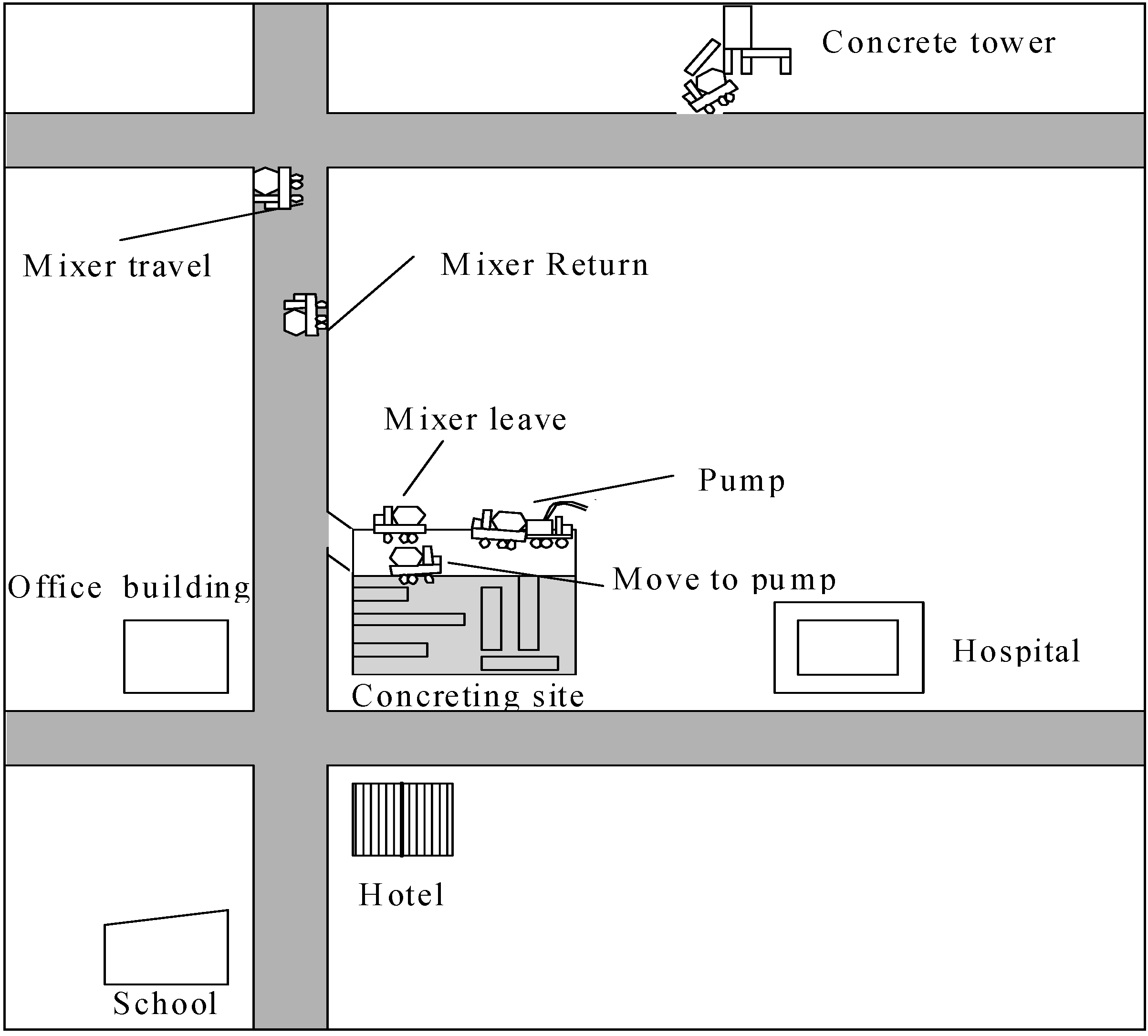

Figure 2 is an AOOS model for predicting the noise from a foundation concreting project, where seven activities are decomposed according to the characteristics of the concreting process. The name of each activity is displayed at the top line of the activity element. Three types of information, such as activity name followed by the probability distribution type for the random activity duration, e.g., triangular, uniform, normal, beta and exponential distributions which are respectively represented by “Tri.”, “Uni.”, “Nor.”, “Bet.” and “Exp.”, logical dependency on the preceding activity and resource-related information, are listed in the activity element from top to bottom.

If there are the same resources between the current activity and another one, the logical dependency is indicated by an arrow line rather than the logical information indicated in the activity element. Various types of resources (including equipment generating emissions and noise) are displayed line by line, and each line of the resource-related information includes the resource name, resource’s flowing direction indication (“K” for remain, “S” for flowing to one succeeding activity and “F” for flowing to the activity meeting the conditions earliest), and the number of this type of resource. If the resource is an item of equipment producing noise and the current activity (or location) is close to the receptors and should be controlled for noise, each line of the resource-related information also includes the noise-producing indication “N” after the flowing direction indication in turn. In

Figure 2, for example, the noises from the transit mixer, concrete pump and vibrator that are operated at the activities “Move to pump”, “Pump”, “Spread” and “Mixer leave” are considered because they are close to the receptors sensitive to the noise. Other three activities “Mixer travel”, “Mixer return”, and “Load mixer” do not happen completely at construction site and are somewhat far away from the receptors, hence the noises from these activities are not considered. It is noted that the noises from the operations that do not happen completely at construction site are not considered in the simulation method. The modeling steps 1 and 2 are achieved through the activity-associated dialog. The modeling steps 3–5 that concern the equipment-configuration, noise-affecting factors such as the source noise level of each item of equipment in terms of probability distribution and relevant parameters for calculating

Leq-T are achieved through an overall dialog. The probability distribution types considered for the random source noise levels contain the triangular, uniform and normal distributions. The requirements on the resource-attributes (e.g., empty or full of a truck) for each activity, which reflects the starting sequence of the activities, are inputted and displayed through the activity-associated dialog. Detailed descriptions of the AOOS model are not presented herein due to length limitation of the paper and readers can refer to Zhang et al. [

20].

5.2. Simulation Strategy Incorporated with the Noise-Calculating Models

In order to achieve simulation experimentation based on the built model, a simulation strategy is required to advance simulation clock and timely control various operations such as timely tracing noise variation and calculating noise level at discrete points of time such as start and end events [

28]. Like the three-phase strategy for the CYCLONE [

18] modified based on the activity scanning (AS) strategy, the AOOS strategy [

20] is also modified based on the AS strategy in accordance with the AOOS model. Because the simulation under study is developed by utilizing the AOOS, the AOOS strategy is used herein. Before advancing the simulation time, the start conditions are checked so that the start events meeting the conditions are initiated, which is performed continuously until no activities meet the conditions. The start time of an activity should be the latest available time of the required resources and the logical dependencies.

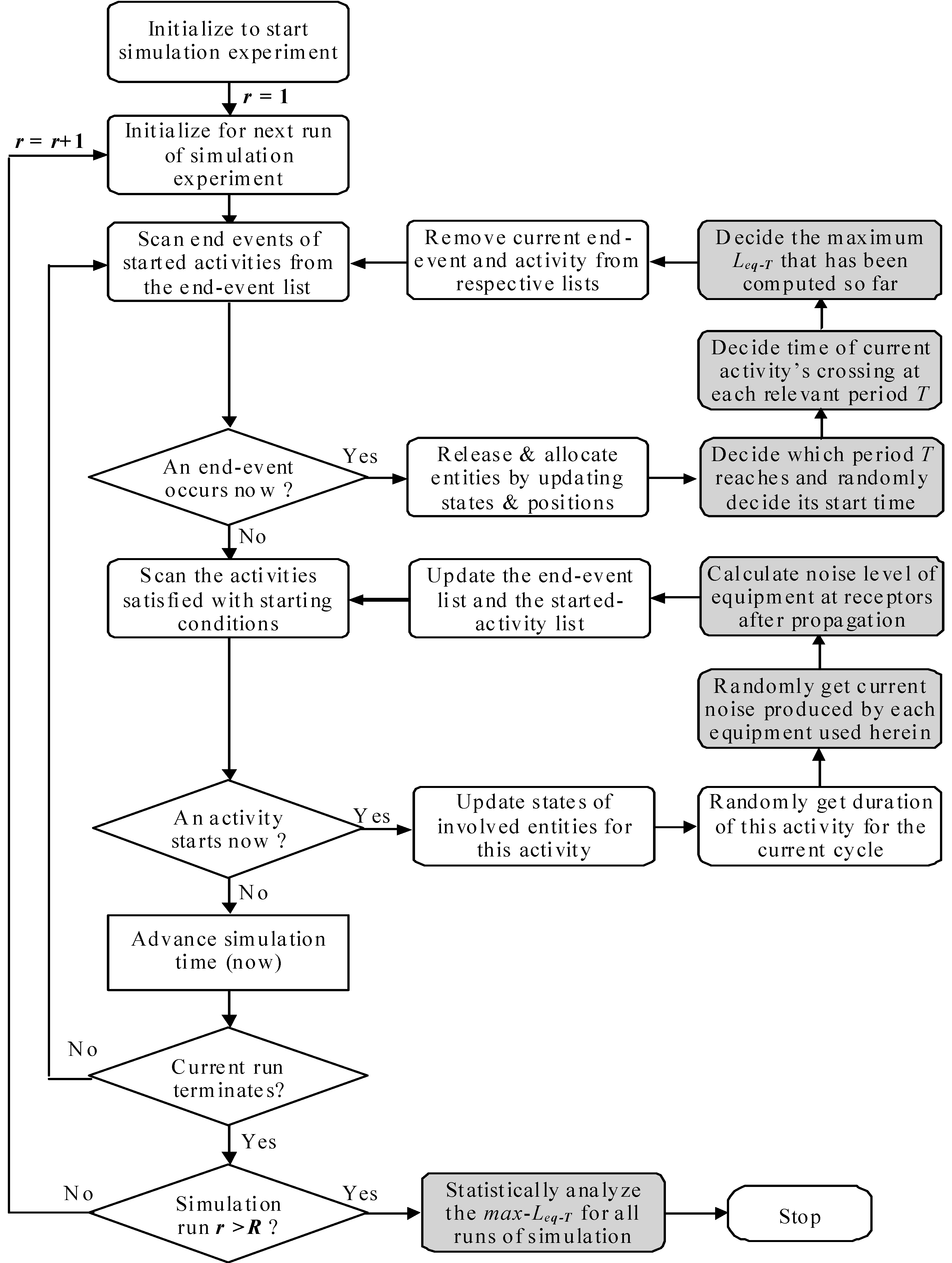

Figure 3 shows the flow chart of the improved AOOS strategy, where the parts marked in dark rectangules are added based on the noise-calculating models including Equations from (2) to (10). The noise level for each piece of equipment at each activity may be random and may change upon the instantaneous occurrence of a start or end event. Once a start event is activated to start an activity, the real-time noise level of a piece of equipment at an activity for current cycle must be determined randomly according to the probability distributions given in modeling. For detailed descriptions of the AOOS strategy, we refer to Zhang et al. [

20].

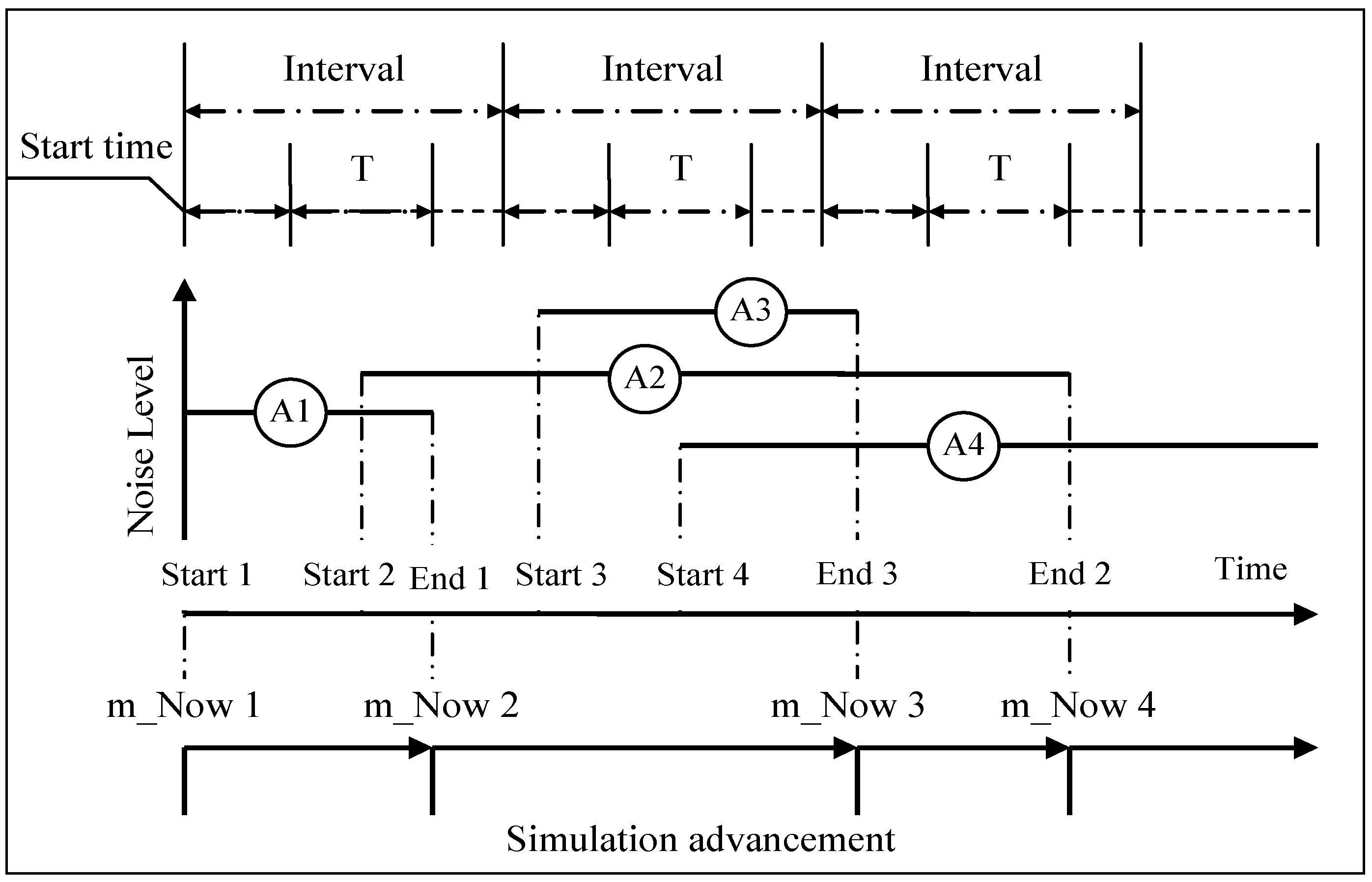

The procedure of calculating the

Leq-T during the simulation experiment is illustrated in

Figure 4, where four activities (i.e., A1, A2, A3 and A4) are involved and the

Leq-T over the period of time

T is timely calculated during the simulation experiment. In accordance with the measurement procedure, the

Leq-T is repetitively calculated for each equal interval of the construction duration. The period of time

T and the interval between two adjacent periods of time which are assumed constant across the simulation experiment need to be specified before simulation. The start time to calculate the

Leq-T at each interval is determined randomly from 0 to interval subtracting the time

T.

Each period of T should be automatically advanced with the simulation progress, and the start time for each period of T should be randomly determined. The start and end events associated with each activity should be checked to see which periods of T the current activity crosses when initiating the end event. Then the noise level associated with the activity and the time of the activity crossing in this period of T can be timely determined, thus computing the time-weighted noise level. The time-weighted noise level related to each activity should be added to calculate the Leq-T for the certain period of T according to Equation (10).

The value of Leq-T for each period may be obviously different due to dynamic natures and long construction duration, so the maximum value of the Leq-T from a lot of periods, that is, max-Leq-T, should be determined. One max-Leq-T can be obtained for each simulation run, so a series of the max-Leq-T samples can be collected after simulation and the statistic results (e.g., confidence interval) of the max-Leq-T can be calculated.

According to the enhanced AOOS modeling features and the modified AOOS strategy, visual C++ that was used to develop the prototype of the AOOS system is also used to implement the proposed DES method.