4.2. Static MBR Model Validation with Hydrodynamic and Non-Shear Effects

The flow regimes during filtration processes were all laminar which were well within expectations since calculated ReNN values were much less than 2 × 105.

As mentioned in

Section 4.1.2, in this static fouling model, parameter α solely contributed to pore blocking; parameter β wholly contributed to pore constriction and finally a combination of parameters

f’.R’,

Rbo,

go and

kAb, all served to define the cake filtration.

The aeration rates for all the data sets for the static MBR system were similar in scale to that of the rotating MBR system operated under lab scale conditions. Hence, similar constant values for air scouring coefficient, αv, (i.e., 0.0292), and resistance distribution factor, δ, (i.e., 4.6 × 10−4 m−1) were used during all simulations. Additionally, since the static square-shaped MBR system was not operated under rotation, the shear effects parameters m, n and kω were removed and not used during all simulations. As discussed in section 4.1.2 and also as applied to the static fouling model, the key parameters necessary for analysis, curve fitting, and fouling mechanisms determination were f’.R’, α, β, Rbo/Rm, go and kAb. These output values were determined in Matlab using the “Genetic Algorithm” function in concurrence with the minimised sum of squared residuals between the fouling model and experimental data. Simulations were swiftly performed for each TMP at correspondingly 15 kPa, 30 kPa, 45 kPa and 58 kPa for MLSS concentrations of 6.32 g/L and 7.24 g/L.

Best fit parameters

f’.R’, α, β,

Rbo/Rm,

go and

kAb as presented in

Table 3, all appear to be in sensible agreement with prior conducted work [

15,

17]. A justification for this is that despite variations depending on the TMP used, these values remained constant within simulated MLSS concentrations range of 6.32 g/L and 7.24 g/L.

In

Table 3, when comparing pore blocking parameter, α, at different data sets, its lowest value of 0.094 is found for the Avanti static square-shaped MBR system for TMP step of 15 kPa. This suggests that the pore blocking’s effect on fouling was minimal during filtration. Moreover, this is justified since its corresponding pore constriction parameter, β, is much bigger. Thus, a possible conclusion is that at lower TMPs, pore blocking is less likely to dominate fouling, which is also in-line with Paul and Jones [

17] findings. In contrast, the highest value of the pore blocking parameter, α, is 0.907 and is found for the Avanti static square-shaped MBR system for TMP step of 45 kPa. It implies that pore blocking was one of the dominant fouling mechanisms during filtration, which is reasonable since its corresponding pore constriction parameter, β, is much smaller. Therefore an inference is that at very high TMPs, pore blocking is more likely to be one of the dominant fouling mechanisms, which again happens to be in-line with prior work [

17].

Table 3.

Simulations best fit model parameters including hydrodynamic effects.

Table 3.

Simulations best fit model parameters including hydrodynamic effects.

| Optimised Parameters | f’R’ (m/kg) | α (m2/kg) | β (kg) | σa (kg·m3) | Rbo/Rm (−) | go (−) | kAb (−) |

|---|

| Duclos-Orsello et al. [15] data | 1.81 × 1011 | 0.576 | 2.538 | 19.4 × 10−17 | 0.168 | 24.58 | 1.46 |

| Pilot MBR unit at Coors (UK) data | 1.76 × 1011 | 0.122 | 0.289 | 2.21 × 10−17 | 0.159 | 27.24 | 0.108 |

| Static MBR unit (15 kpa) | 0.834 × 1011 | 0.094 | 0.492 | 3.79 × 10−17 | 0.126 | 63.75 | 9.36 |

| Static MBR unit (30 kpa) | 0.947 × 1011 | 0.184 | 0.305 | 2.33 × 10−17 | 0.692 | 10.99 | 2.032 |

| Static MBR unit (45 kpa) | 108.8 × 1011 | 0.907 | 0.486 | 3.78 × 10−17 | 0.526 | 15.36 | 14.23 |

| Static MBR unit (58 kpa) | 32.01 × 1011 | 0.221 | 0.212 | 1.62 × 10−17 | 0.457 | 29.66 | 1.26 |

When comparing pore constriction parameter, β, at various data sets, its lowest value of 0.212 is found for the Avanti static square-shaped MBR system for TMP step of 58 kPa (see

Table 3). As such, it can be inferred that pore constriction had a lesser impact on fouling or was equally as influential as other fouling mechanisms. Since its equivalent pore blocking parameter, α, is almost equal in value (though still a bit less), it can be argued that both pore blocking and pore constriction had almost equal importance in the occurrence of fouling. Consequently, a conclusion that can be drawn is that at higher TMPs, pore constriction is less likely to be dominant [

17]. On the other hand, the highest value of pore constriction, β, is 2.538 and is found for the Duclos-Orsello

et al. [

15] data set for constant TMP of 14 kPa. It therefore implies that pore constriction was one of the dominant fouling mechanisms during filtration. Additionally, this is justified since its corresponding pore blocking parameter, α, is almost five times smaller. Accordingly, it can be concluded that at lower TMPs, pore constriction is more likely to dominate fouling [

17].

As shown in

Table 3, when comparing the combination of parameters

f’.R’ (fractional amount of total foulants multiplied by specific cake layer resistance),

Rbo (initial resistance of solids deposit),

go (cake removal factor) and

kAb (blocked pores area constant), which all pertains to cake filtration, its lowest combination is found for the Avanti static square-shaped MBR system for TMP step of 15 kPa. This suggests that cake formation (and by extension cake filtration) was fairly weak and less influential during fouling. Thus, at lower TMPs, cake filtration is expected to be less dominant and prevalent during fouling [

17]. Conversely, the highest combination of parameters

f’.R’,

Rbo,

go and

kAb, is found for the Avanti static square-shaped MBR system for TMP step of 45 kPa. It implies that cake filtration was fairly strong and more significant during fouling. As such, it can be deduced that at high TMPs, cake filtration is expected to be one of the dominant fouling mechanisms [

17].

Overall, the calculated model parameter values gave very respectable fits when compared to the original data collected for the static square-shaped MBR system, although extreme MLSS concentration values of 8 g/L and 12 g/L respectively for the Duclos-Orsello

et al. [

15] data, and the Coors (UK) data [

16], gave rather poor fits. This is largely as expected since the sludge rhealogical effects which themselves are volatile will dominate all membrane fouling mechanisms in unpredictable ways especially at high MLSS concentrations with associated high viscosities. Additionally for the static square-shaped MBR system it can be seen that at higher TMPs, the simulation fit progressively deteriorated as the flux declined rapidly. Thus, at a TMP step with constant TMP of 45 kPa, the simulation’s fit was extremely poor and, by extension, was poor for the 58 kPa case as well. This situation is less prevalent for the rotating MBR system, as both air scouring and rotational shear contribute to the reductions in fouling.

In order to validate the static model, two distinct sets of data were used. The first set was collected from the study carried out by Duclos-Orsello

et al. [

15], and the other was data provided by a pilot MBR plant operated at Coors (UK) [

16]. It should be noted that, for the Coors (UK) data, the viscosity (Pa·s) was calculated from the MLSS data provided and by using Equation (19) [

20].

Additionally, four sets of data all obtained via a TMP stepping procedure using the static square-shaped MBR system were used to validate this static fouling model. The data was collected at TMP steps with constant TMPs of 15 kPa, 30 kPa, 45 kPa and 58 kPa respectively. There were obviously no induced shear effects to take into account, which simplified the entire simulation procedure since only the hydrodynamics effects were included with appropriate parameters and coefficients used during simulation runs.

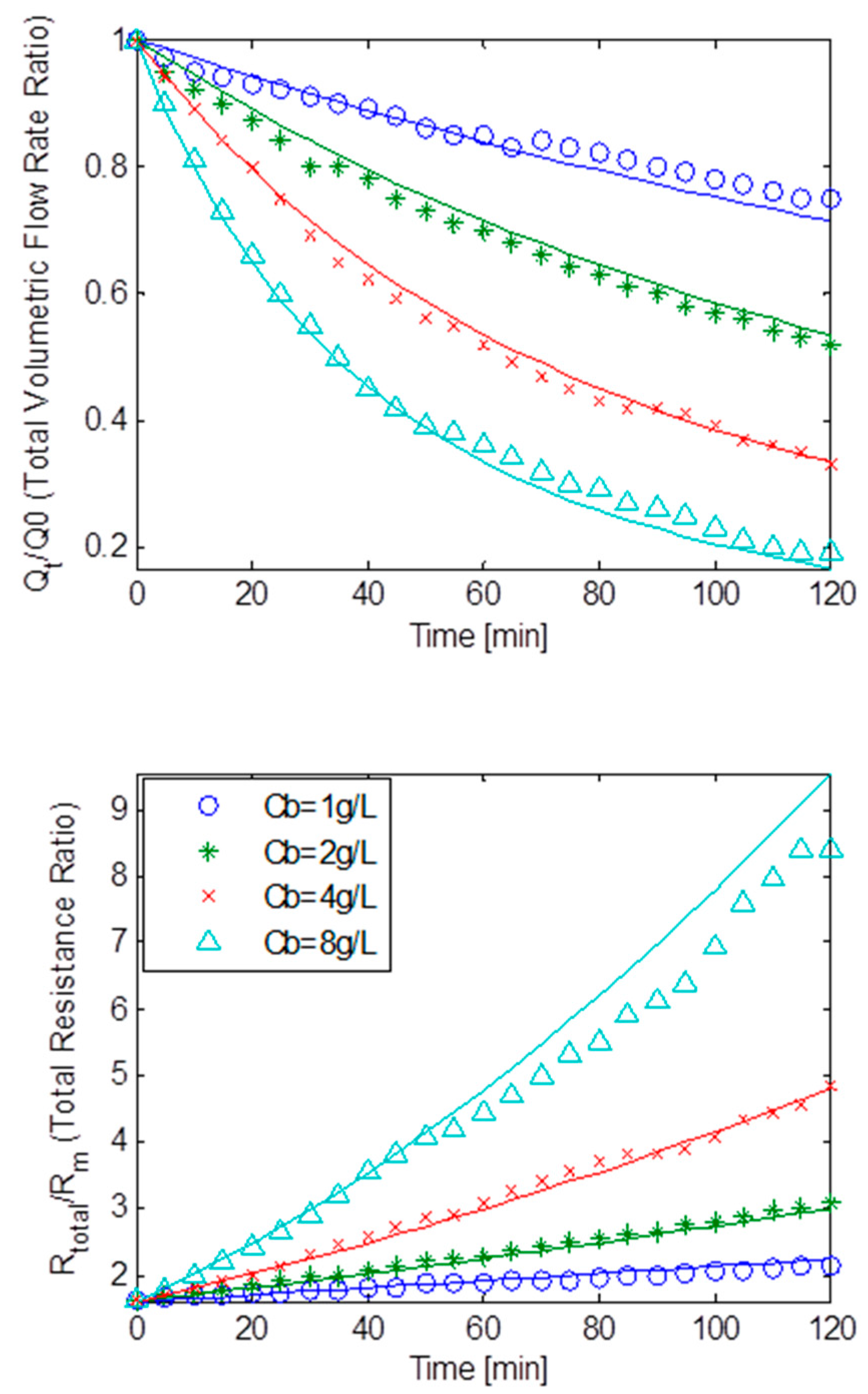

Figure 7 depicts the TMP step data as normalised volumetric flow rates and the total membrane resistance ratios plotted against the filtration time at a constant TMP of 14 kPa for MLSS concentrations varying from 1 g/L to 8 g/L based upon the Duclos-Orsello data; with the solid lines representing the best fit simulation solutions. Again, the total resistance was acquired via Darcy’s law. It was immediately noticeable that at the highest MLSS concentration of 8 g/L, the flux decline was much greater than for all lesser concentrations. In fact it was an actual decrease of about 84% making the total membrane resistance climb steeply for this entire filtration event. This indicated that fouling was dominated by pore constriction even though all three types of fouling mechanisms were in operation to a greater or lesser degree. This conclusion appears justifiable since the calculated pore constriction parameter, β, was found to be roughly four times the size of the pore blockage parameter, α (when referring to

Table 3). Additionally, a weak deposit layer as depicted by

Rbo, and a big cake removal factor,

go, indicated a fairly weak cake layer formation which is reinforced by a smaller

f’.R’ factor and a small blocked pores area constant,

kAb. Thus, the combination of parameters

f’.R’,

Rbo,

go and

kAb, implied that cake filtration was relatively less significant during fouling which was expected for such low TMP operations. These finding seem to concur with the results found in the original study by Duclos-Orsello

et al. [

15]. As with the original study, at bulk concentrations of 1 g/L and 2 g/L the resistances and the volumetric flow rates seemed essentially linear.

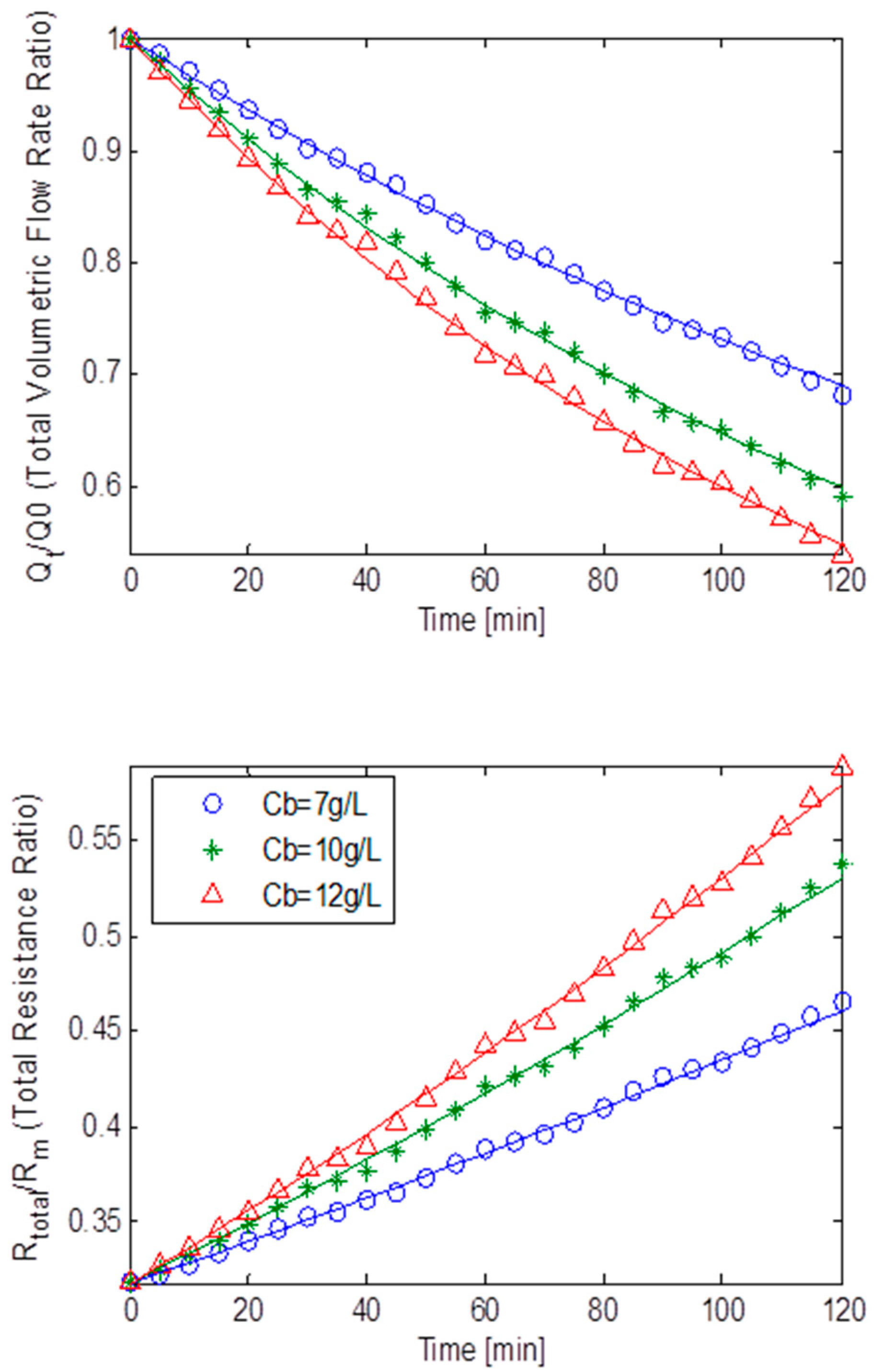

Figure 8 shows the normalised volumetric flow rates and the total resistances ratios versus the filtration time at a constant TMP of 18 kPa with initial flow rate of 1.24 × 10

−5 m

3/s, for normalised MLSS bulk concentrations of 7 g/L, 10 g/L and 12 g/L respectively for the data supplied by the pilot MBR unit operated at Coors (UK) [

16]. This MBR system’s data set had typically high MLSS values that are usually associated with high overall fluid viscosities. This suggested that the flux was expected to decline rapidly at the highest MLSS concentrations. Indeed it is found that at a MLSS concentration of 12 g/L, the flux had declined almost linearly by 63%. High MLSS concentrations at respectively 7 g/L and 10 g/L exhibited this similar declining behaviour albeit at slightly reduced rates of 59% and 61% respectively. Although slightly below theoretical expectations due to arguably a low TMP regime, the linear increase in resistances was probably caused by the combined effect of all three fouling mechanisms occurring simultaneously with pore constriction being slightly more dominant. As shown in

Table 3, and as expected for a low TMP operational regime, an analysis of the combination of parameters

f’.R’,

Rbo,

go and

kAb, indicated that cake formation was moderately weak. Moreover, a much bigger β than α suggested that pore constriction was somewhat more prevalent in fouling.

Figure 7.

Flux decline and total resistance data obtained from Duclos-Orsello

et al. [

15] with best model fits.

Figure 7.

Flux decline and total resistance data obtained from Duclos-Orsello

et al. [

15] with best model fits.

Figure 8.

Flux decline and total resistance data obtained from pilot MBR plant located at Coors (UK) with best model fits.

Figure 8.

Flux decline and total resistance data obtained from pilot MBR plant located at Coors (UK) with best model fits.

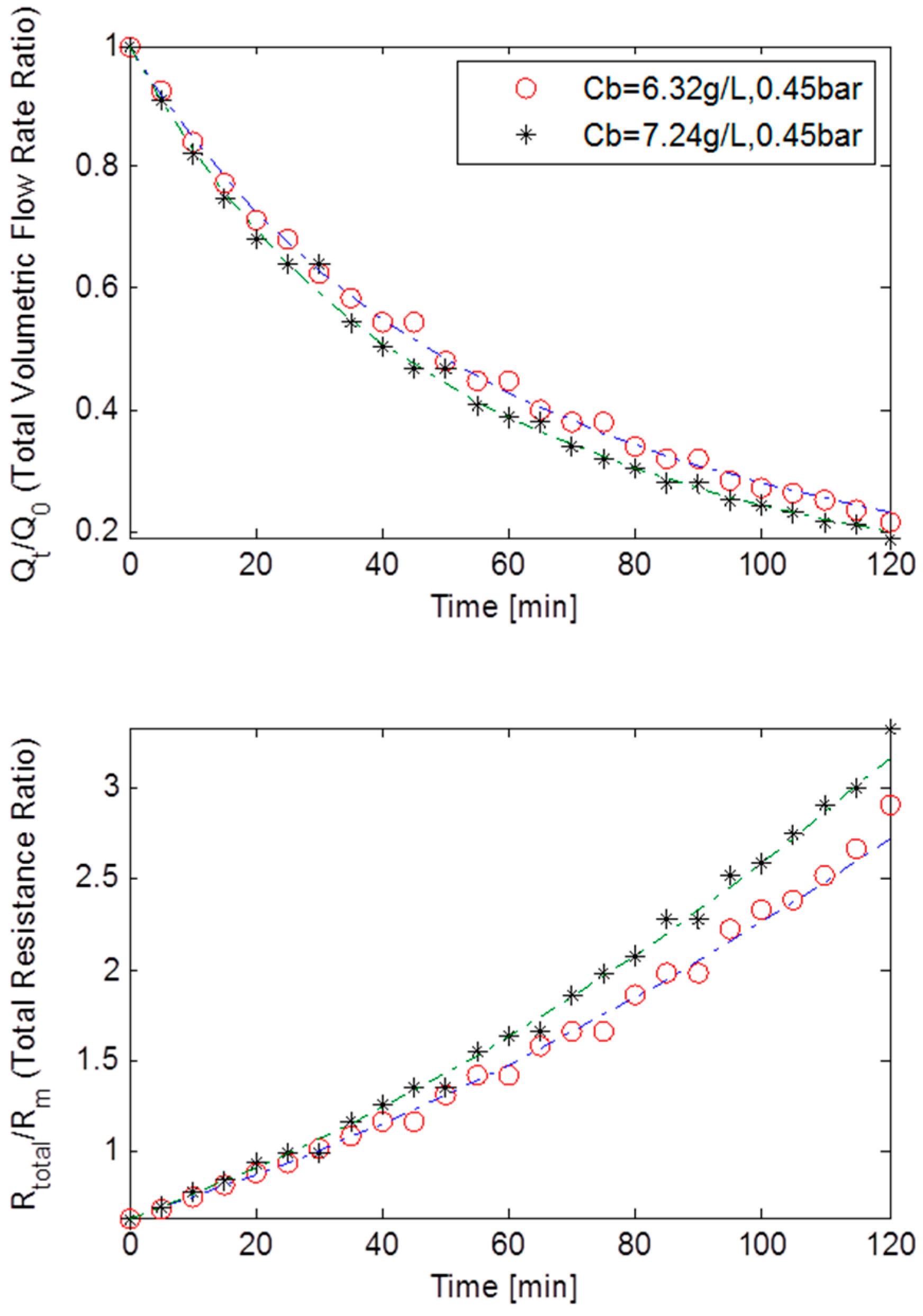

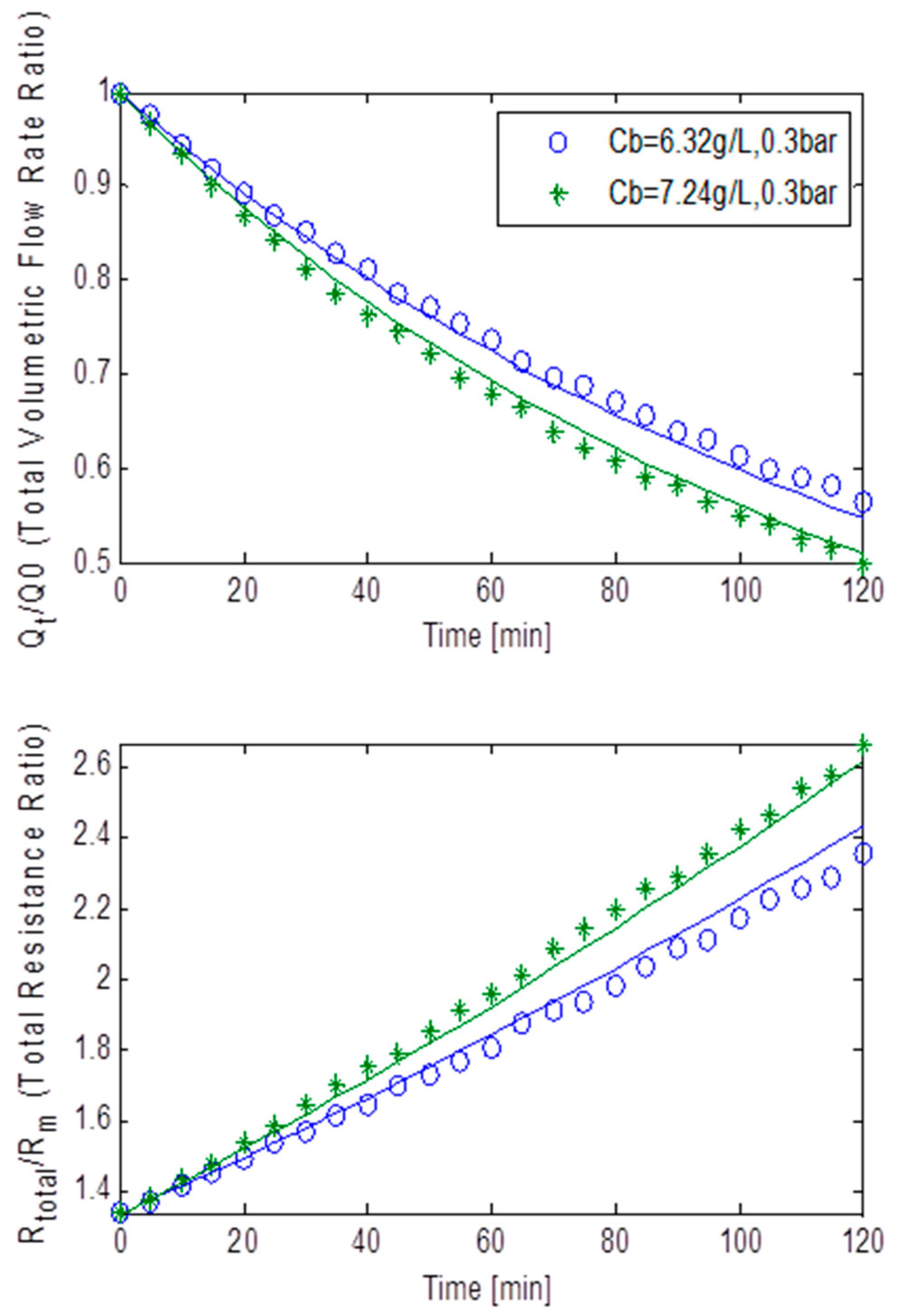

Figure 9 displays the normalised volumetric flow rates and the total resistances ratios plotted against the filtration time at a constant TMP of 15 kPa, for MLSS concentrations of 6.32 g/L and 7.24 g/L for the static square-shaped MBR system. These MLSS concentrations of 6.32 g/L and 7.24 g/L had their fluxes decline at a steady rate and go down approximately by 64%. The resistances displayed an almost linear trend, suggesting fouling was caused by the combination of all three fouling mechanisms. As observed in

Table 3, a fairly small

Rbo factor and a big

go, indicated the formation of a weak cake layer which was further reinforced by a small

f’.R’ and

kAb. As a result, the combined parameters

f’.R’,

Rbo,

go and

kAb, suggested that cake filtration was less dominant during fouling which was anticipated since at a low TMP of 15 kPa, cake formation is expected to be less prevalent [

17]. Furthermore, β being roughly five times bigger than α, ultimately suggested that fouling was mostly caused by pore constriction.

As can be seen, after two hours of ultra-filtration at MLSS concentrations of 6.32 g/L and 7.24 g/L, and at a constant TMP of 30 kPa, a similar flux decline comparable in size to the 15 kPa TMP case was observed. The rate of decline was steady and this gradual drop was expected since it was in-line with critical flux theory [

9].

Figure 9.

Flux decline and total resistance for TMP step of 15 kPa for the static square-shaped MBR system with best model fits.

Figure 9.

Flux decline and total resistance for TMP step of 15 kPa for the static square-shaped MBR system with best model fits.

Figure 10 portrays the normalised volumetric flow rates and the total resistances ratios plotted against the filtration time at a constant TMP of 30 kPa, for MLSS concentrations of 6.32 g/L and 7.24 g/L for the static square-shaped MBR system. The resistance-time plot, once again, seems to indicate that fouling could be attributed to the combined effect of all three mechanisms. Again as shown in

Table 3, a fairly big

Rbo and a small

go, indicated a reasonably adequate cake layer formation which was supported by a bigger

f’.R’ factor and a small

kAb when compared to the data from the constant TMP step of 15 kPa,. Consequently, the combination of parameters

f’.R’,

Rbo,

go and

kAb, suggested that cake filtration was adequately prevalent during fouling. In addition α being much smaller than β, all seemingly implied that most of the fouling was dominated by both pore constriction and cake filtration.

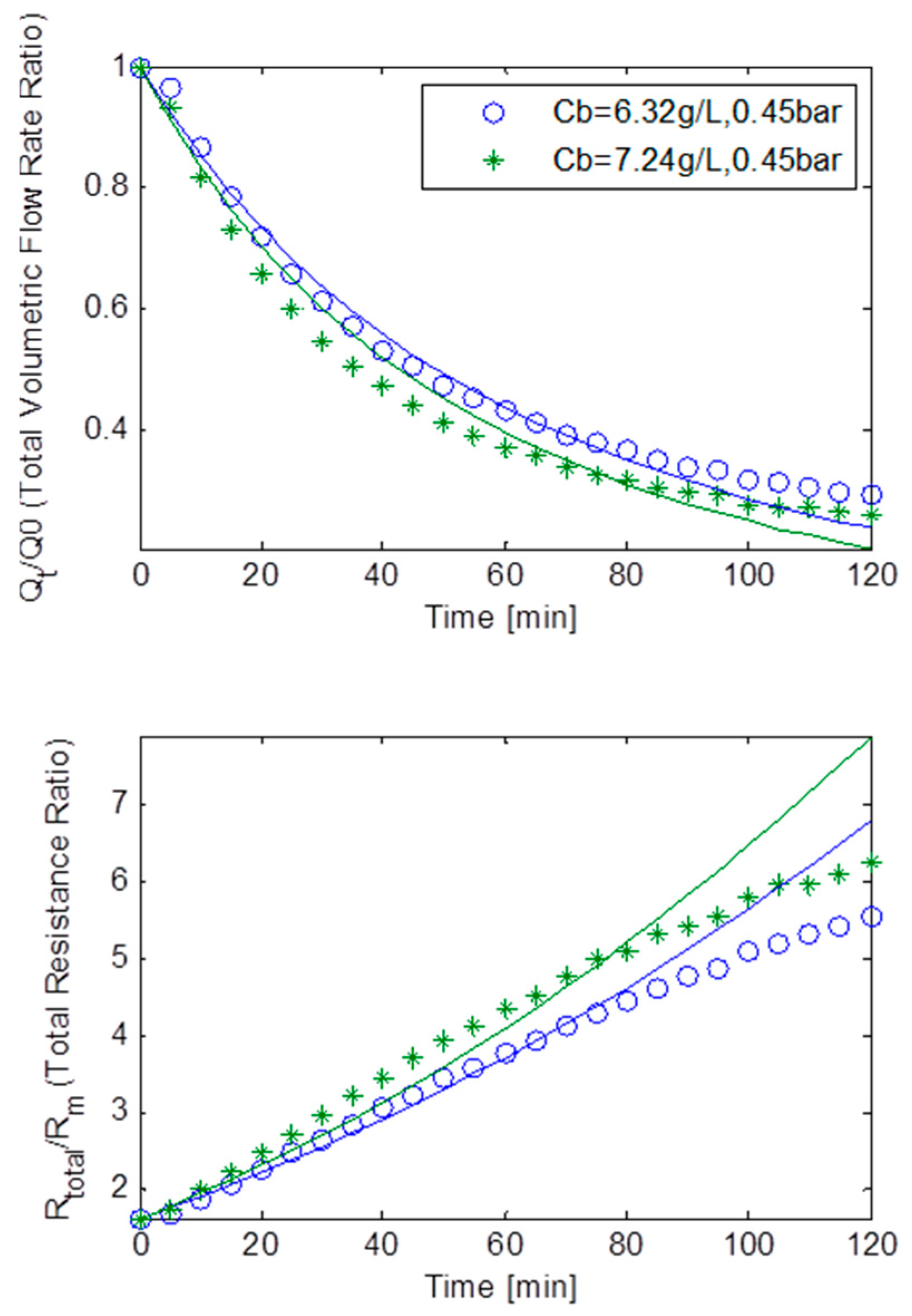

Figure 11 represents the effects of the fouling behaviour of the static square-shaped MBR system, using both the normalised volumetric flow rates and total resistance ratios for MLSS concentrations of 6.32 g/L and 7.24 g/L at a constant TMP of 45 kPa. Due to a colossal drop in flux at this high TMP, the total resistance increases at an exponential rate. It is noticeable that the best fit curve at this high TMP is extremely poor (especially after 80 min), but however the curve’s trend is of the right scale and in the right direction to allow analysis of the fouling behaviour that is occurring. At first glance, analysis would suggest that fouling may be due to all three fouling mechanisms, but it can be argued that fouling was mainly dominated by cake filtration and pore blocking. A reasonably big

Rbo and

f’.R’ coupled with similar sized

go and

kAb, all strongly indicated that a fairly large cake layer was formed (as seen

Table 3). However, with α being roughly twice as big as β, it can be concluded that the pore blocking fouling mechanism was also prevalent during fouling. Hence, the bulk of the fouling was dominated by both cake filtration and pore blocking.

Figure 10.

Flux decline and total resistance for TMP step of 30 kPa for the static square-shaped MBR system with best model fits.

Figure 10.

Flux decline and total resistance for TMP step of 30 kPa for the static square-shaped MBR system with best model fits.

Figure 12 shows the fouling behaviour of the static square-shaped MBR system, using both the normalised volumetric flow rates and total resistance ratios for MLSS concentrations of 6.32 g/L and 7.24 g/L at a constant TMP of 58 kPa. The total resistance seemingly increases in a linear fashion with filtration time albeit at a high rate. This is probably because fouling was caused by all three mechanisms happening simultaneously. Parameters α and β being of almost equal size suggests that neither of the two fouling mechanisms was dominant (

Table 3). Furthermore, a moderately big

Rbo and

f’.R’ when compared to the data from the constant TMP step of 15 kPa, together with an adequate

go value and a small

kAb value, all indicated that a fairly decent size cake layer was formed. Accordingly, all three fouling mechanisms were of equally great importance during fouling.

Figure 11.

Flux decline and total resistance for TMP step of 45 kPa for the static square-shaped MBR system with best model fits.

Figure 11.

Flux decline and total resistance for TMP step of 45 kPa for the static square-shaped MBR system with best model fits.

Figure 12.

Flux decline and total resistance for TMP step of 58 kPa for the static square-shaped MBR system with best model fits.

Figure 12.

Flux decline and total resistance for TMP step of 58 kPa for the static square-shaped MBR system with best model fits.

4.3. Comparison of Simulation Results Generated from Rotating and Static MBR Models

After every simulation done in Matlab, a mean of minimised residuals (i.e., mean fitness) and the best minimised residuals (i.e., best fitness), are automatically calculated. These can in turn be used to accurately determine how well a simulation fit was conducted. Needless to say, the smaller these values, the better analysis can be conducted. Using these facts, a comparison between both models (static and rotating) and their fitness values will be conducted and some conclusions drawn.

When comparing and fitting the data obtained from the rotating MBR system to that obtained from the static square-shaped MBR system, the most prominent difference found for the latter case is the poor fit between the experimental data and the simulation runs.

Table 4 summarises the best fitness values after simulations for both systems for the same two TMP steps at constant TMPs of 15 kPa and 45 kPa respectively. As can be seen, the best fitness values for the rotating MBR system are all much smaller than those for the static square-shaped MBR system. In fact the best fitness values for the latter are roughly ten times greater than that for the rotating MBR system. The difference here can be probably attributed to the fact that the shear effects are instrumental in reducing the overall fouling for the rotating MBR system while the static square-shaped MBR system is only aided by standard air scour alone. This concurs with critical flux theory and the area-loss model that explains any rapid TMP jump phenomenon [

9], since greater fouling will lead to greater uneven cake build up, leading to loss of clean membrane surface, meaning that locally critical flux could be exceeded, thus promoting the likelihood of rapid declines in fluxes at higher TMPs at unpredictable rates.

Table 4.

Statistics with fitness values from simulations as computed in Matlab.

Table 4.

Statistics with fitness values from simulations as computed in Matlab.

| Fitness Statistics | Avanti Rotating MBR | Avanti Static Square-Shape MBR |

|---|

| Fit Parameters | 15 kPa TMP | 45 kPa TMP | 15 kPa TMP | 45 kPa TMP |

|---|

| Best fitness (−) | 0.0361 | 0.0294 | 0.346 | 1.293 |

| Mean fitness (−) | 0.0849 | 0.0672 | 0.968 | 4.541 |

In simple terms, this means that for the same constant TMP regime for both systems, the fouling build up expected on the rotational MBR system would be less with a reduced likelihood of local critical flux being exceeded. Thus, data sets obtained under this system would be expected to have flux declines occurring in more predictable and consistent ways, and at reduced levels even at higher TMPs when compared to the static MBR system. Consequently, it would be expected that more consistent and less variable data would give rise to better simulation fits for the rotating MBR system, and conversely produce a much less reasonable and agreeable fit for the static MBR system even though both were manufactured by the same company, using the same pipe manifolds, same membrane materials, same membrane pore sizes, and same spacing between individual membrane sheets.

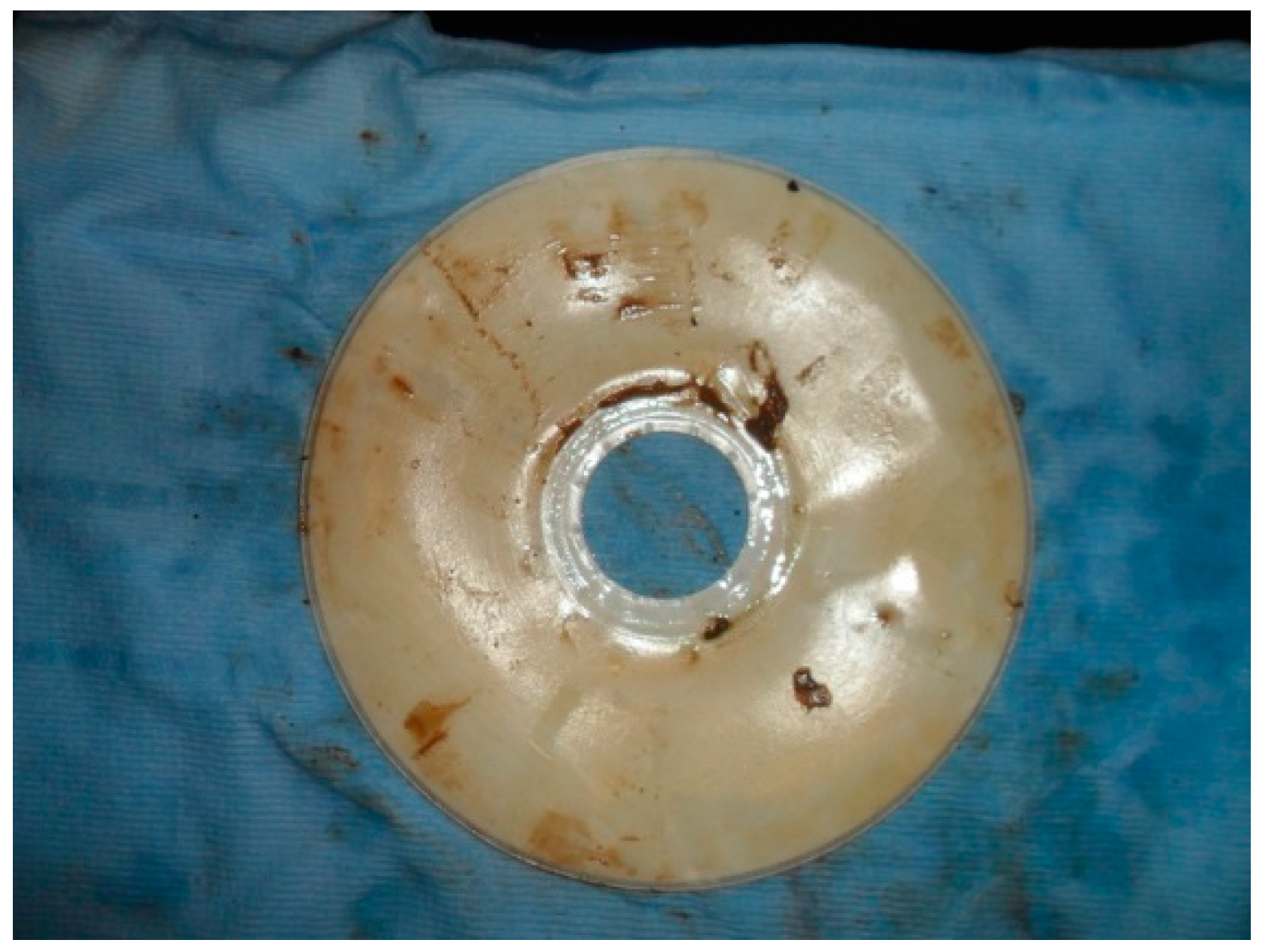

A logical conclusion from these all these results is that for the rotating MBR system, its additional rotation shear evens out the cake formation on the membrane surface while for the square-shaped MBR system, the cake distribution is highly uneven and less predictable. In physical terms this hypothesis can be confirmed, since it is very evident when carrying out membrane autopsies for both system types, it is clear that huge cake build up occurs on the membrane surface for the static MBR system.

Figure 13 and

Figure 14 show the actual typical caking patterns observed on both types of membrane sheets when they were individually removed from the bioreactor. It must be particularly noted in

Figure 14, the heavy fouling that is occurring on the bottom half of the square membrane sheet where the air scour effect is least prevalent due to the small distance travelled by the coarse air bubbles used. All of these simulation results and actual physical observations, indicate that the rotating MBR system may be a more preferable option if reduced fouling was a key need in the system design.