Integrated Environmental Risk Assessment and Whole-Process Management System in Chemical Industry Parks

Abstract

:1. Introduction

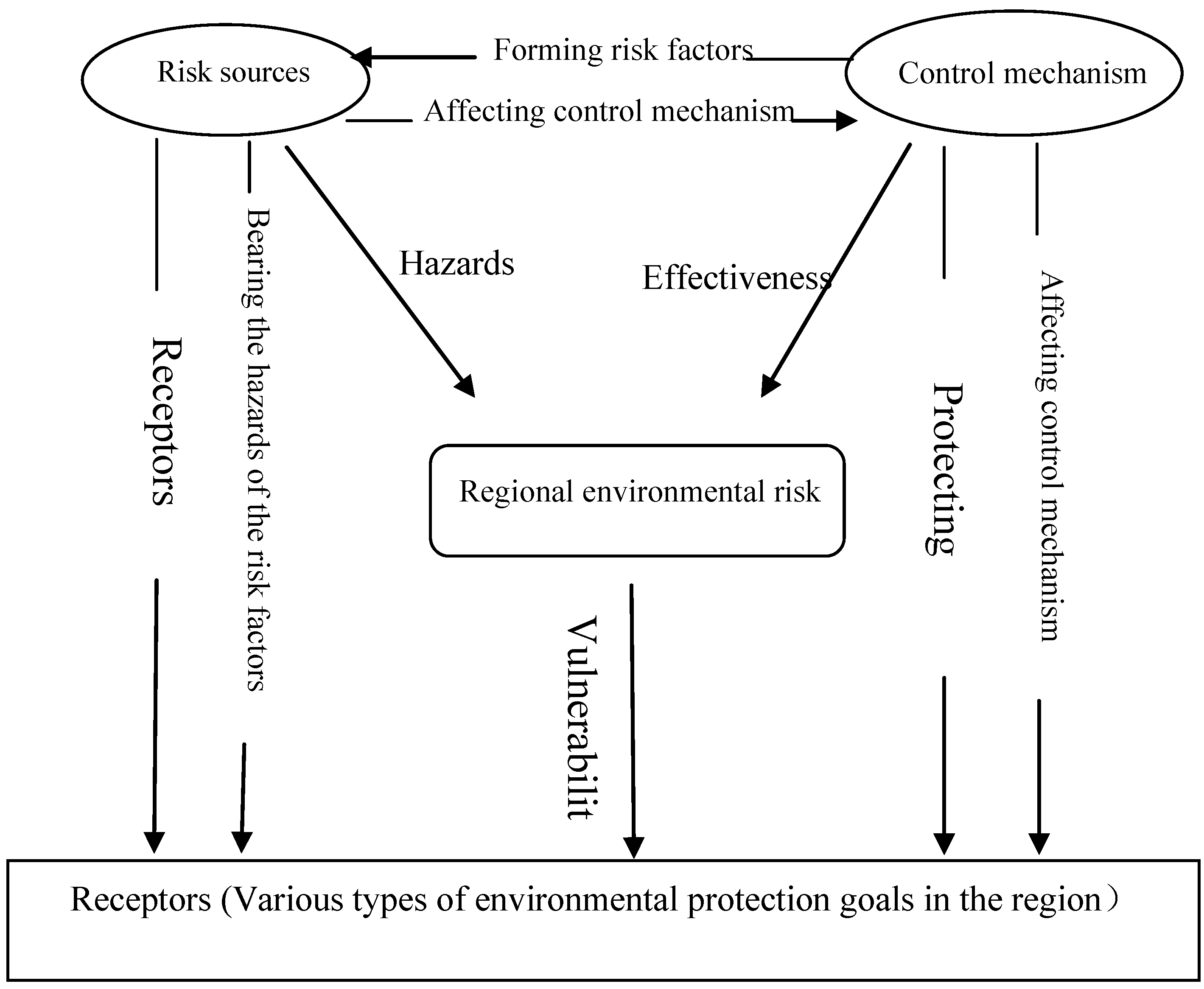

2. Development of Analytical Framework

2.1. Environmental Risk Formulation Mechanism

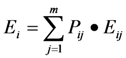

2.2. Research Design

3. Methodology on ERA and Environmental Risk Zoning

3.1. Regional ERF Model

3.1.1. Accident Probability

3.1.2. The Physical Hazard Index

3.2. Regional ERA Method

| Targets for environmental protection | Scale (0–10) | |

|---|---|---|

| Natural Reserve | ||

| National Natural Reserve | [8,10] | |

| Natural reserves of province or city | [6,8] | |

| Basic Farmland | [4,6] | |

| Natural Wetland | [4,6] | |

| Areas of Dense Population | ||

| Density of Population > 3,500/km2 | [8,10] | |

| 500/km2 < Density of Population ≤ 3,500/km2 | [6,8] | |

| 200/km2 < Density of Population ≤ 500/km2 | [4,6] | |

| Density of Population ≤200/km2 | [2,4] | |

| Unwrought Land Resources | [0,2] | |

| Other Types | [0,2] | |

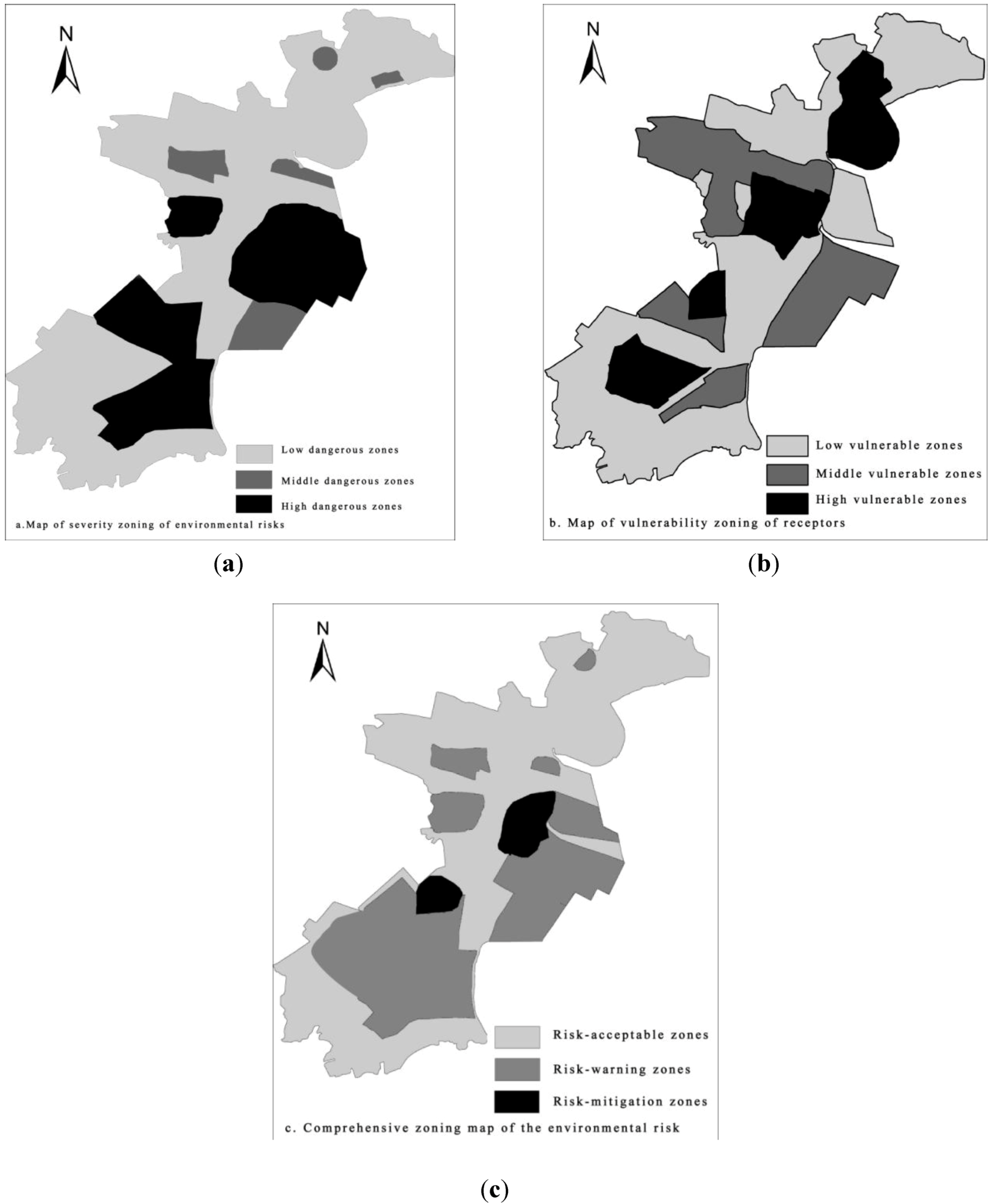

3.3. Regional Environmental Risk Zoning

| Vulnerability of receptors | Degree of hazards of the accidents | ||

|---|---|---|---|

| Low danger areas | Medium danger areas | High danger areas | |

| Low vulnerability areas | Risk-acceptable zones | Risk-acceptable zones | Risk-acceptable zones |

| Middle vulnerability areas | Risk-acceptable zones | Risk-warning zones | Risk-warning zones |

| High vulnerability areas | Risk-acceptable zones | Risk-warning zones | Risk-mitigation zones |

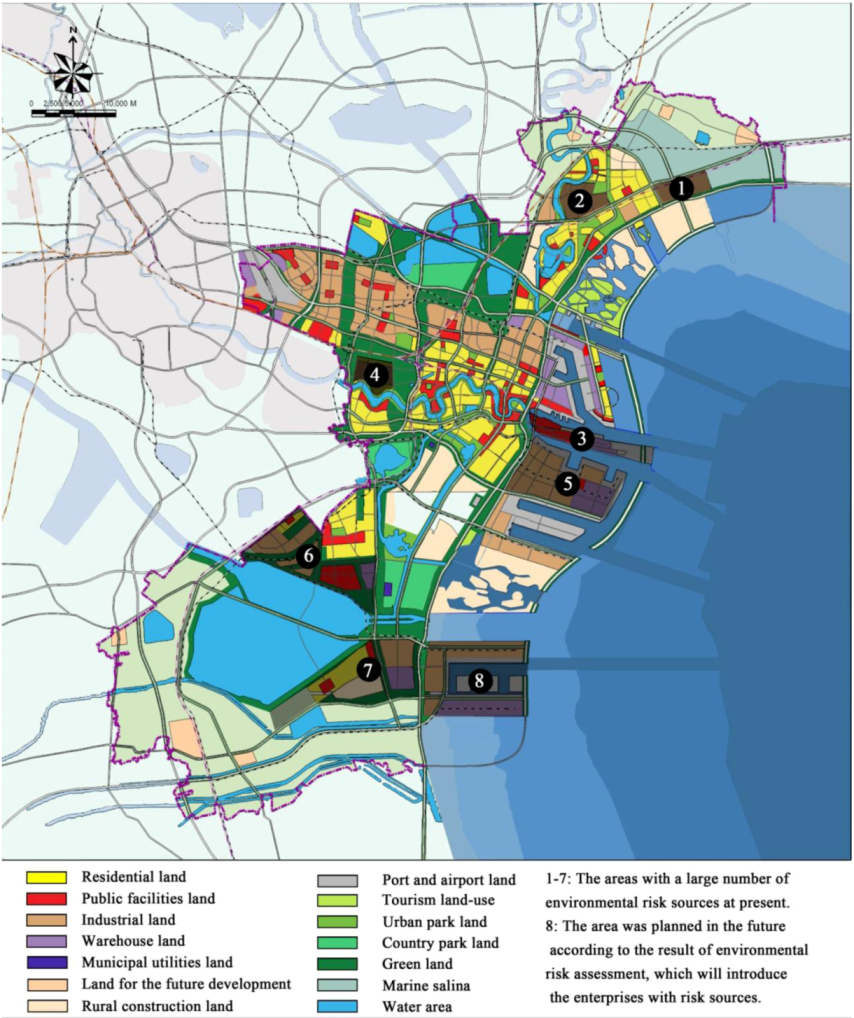

3.4. Case Study

- The leakage of toxic and deleterious materials during the production and transportation: focusing on petrochemical industry, marine chemical industry, C1 chemical industry and comprehensive utilization of resources, Tianjin Binhai New Area has carried out several large-scale projects, such as two million-ton oil refining projects, three million tons of ethane production project, and other petrochemical projects concerning million tons of polyvinyl chloride, polyethylene, polystyrene, cacodyl and so on. During the production and transportation, considerable amounts of toxic, deleterious, flammable and explosive materials may leak into the atmosphere, and the spread of benzene, hydrogen sulfide, ammonia, ethane and other materials will harm the ecological environment and people’s health.

- The storage and transportation accidents of dangerous materials: located in the eastern part of Tianjin Binhai New Area, South Port’s coverage for bulk cargo logistics has reached 12 km2. Storage deposits for gasoline and related chemicals have been established and the total storage volume has reached 12.5 million squares. The storage volume of the petrochemicals in the large-scale petrochemical companies is also very high and the demand for transported materials is increasing. Thus, the risk coming from the storage and transportation of the chemical materials is increasing.

- The oil leakage in the port: according to the incomplete statistics, about 65 leakage accidents took place from 1998 to 2011 in Tianjin Port. Fortunately, oil spill accidents over 10 thousand tons have not happened so far, but with the increasing port handling capacity and increasing numbers of ships passing Tianjin Port, the risk of great oil spill accident is also increasing.

- The operation of the environmental protection facilities: in Tianjin Binhai New Area, a large-scale petrochemical project group has formed and a large-scale steel smelting base has been established. Due to the large scale of production and operation of the companies, any misoperation of the infrastructure for water treatment, atmosphere pollution treatment and so on will cause considerable pollutants released in short time, which will harm the ecology and human health.

| The main regions with risk sources | Amount of the major risk sources 1 | Risk transmission paths | Range of influence 2 | Value of environmental risk |

|---|---|---|---|---|

| Land area of harbors, which is ③ in Figure 5. | 21, which are the oil and chemical storage tanks. | Atmospheric diffusion for the storage and transportation accidents of dangerous materials. | 2,000–3,500 me for a single major accident, and 10,500 m for all major accidents. | 3 × 10−4–5 × 10−2 |

| Water area of harbors, which are coastal zones in Tianjin Binhai New Area. | 2, which are the two big wharfs. | Water Diffusion for the oil leakages of large ships. | 200–1,500 m for an oil leakage, and 8,000 m for all oil leakages. | 2 × 10−5–6 × 10−4 |

| Petrochemical industry areas, which are ②, ⑤, ⑥ and ⑦ in Figure 5. | 60, which are the 60 petrochemical enterprises with dangerous chemicals. | Atmospheric diffusion for air pollution accidents, and water Diffusion for water pollution accidents. | 500–3,500 m for air pollution accidents, and 200-800 m for water pollution accidents. | 5 × 10−4–3 × 10−1 |

| High emission zones of atmospheric pollutants, which are ① and ④ in Figure 5. | 5, which are 5 large-scale enterprises with high use of coal for energy | Atmospheric diffusion for the abnormal discharges of sulfur dioxide and oxynitride. | 350–1,200 m for a single enterprise, and the maximum is 2,500 m for all enterprises. | 7 × 10−5–2 × 10−2 |

| Category of environmental protection goals | The main regions with environmental protection goals | Value of vulnerability |

|---|---|---|

| Natural Reserve | Bei-Da-Gang reservoir, which is the important water area in Figure 5, and belongs to the natural reserves of Tianjin. | 8 |

| Natural Wetland | The remaining water areas in Figure 5. | 5 |

| Basic Farmland | The rural construction lands in Figure 5. | 5 |

| Areas of Dense Population | Dagang residential zone, Tanggu residential zone and Hangu residential zone with the population density of 2,100–5,000 per square km, which are the residential lands in Figure 5. | 7–9 |

| The industrial concentration district the population density of 300–1,500 per square km, which the industrial lands in Figure 5. | 5–6 | |

| Other Types | The remaining land utilization in Figure 5. | 0–2 |

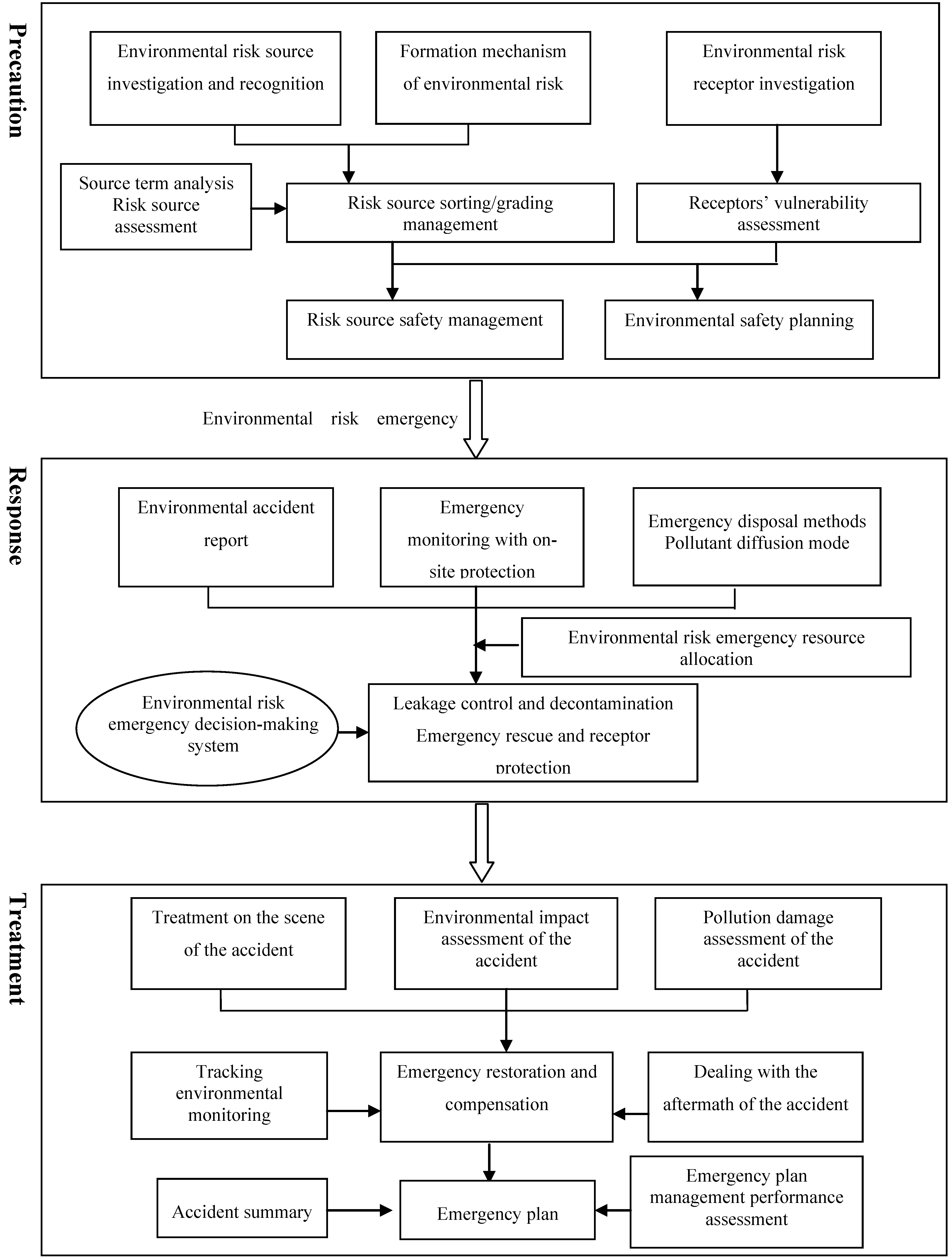

4. Theoretical Framework of Whole-Process Management Mechanism of Environmental Risk

4.1. Environmental Risk Source Management

- Investigation and recognition of environmental risk sources. Investigation of environmental risk sources should be promoted and basic supervision of the environmental risk and chemicals should be enhanced with focus on important industries such as the chemical and petrochemical industries to establish an effective management mechanism for environmental risk prevention and chemical supervision policies. In addition, the investigation of environmental risk sources should take into consideration the formulation mechanism of the main pollutants during urbanization and the use of quantitative evaluation system; the regional pollutants can be sorted and classified according to risk. The investigation should also consider the basic parameters that establish toxicity, exposure level, and environmental chemical properties as evaluation indices. The purpose is to obtain quantitative evaluation results of regional hormone pollutants sorted and classified according to risk, as well as to identify the pollutants that should be controlled in surface water, air, and soil environments in a typical industrial concentration area.

- Environmental risk source assessment. Based on the analysis of safety system project and causation theory of pollution incidents, the corresponding relationship between the hazard level of environmental risk sources and environmental pollution incidents can be established by using current identification methods of major environmental risk sources. These methods consider the possible consequences of environmental risk sources and the distribution of environmentally sensitive targets in the surrounding environment. To achieve a dynamic management of environmental risk sources, standards for grading and classifying environmental risk sources should be established. Different types of sudden environmental pollution incidents can then be categorized according to fixed sources (storage tank, storage and production of fuels, raw materials, medicines, and intermediates), mobile sources (vehicles, ships, and aircrafts for transporting dangerous goods), pipelines (oil and gas), and other indices such as the degree of harm, frequency of occurrence, and characteristics of pollutants.

- Environmental risk source management system. An environmental risk source management system is the solid foundation of environmental risk source management. This system is essential to whole-process management of environmental risk for compliance with related laws, regulations, and standards. The Emergency Response Law of the PRC failed to direct clearly the environmental risk precaution and management because of deficiencies in implementing rules and supporting regulations. Thus, effective environmental risk precaution and management mechanism as well as chemical supervision policies and measures should be established by standardizing emergency plans for sudden environmental pollution incidents in key areas (industrial zones) and enterprises. Environmental risk sources at different levels should be distinguished to improve management efficiency. For the risk sources with high hazard which can cause environmental pollution and ecological damage, the strict management system needs to be carried out.

4.2. Regional Environmental Safety Planning

- Environmental risk source layout. Environmental risk source dispersal is a method for reducing the overall regional environmental risk by decomposing a specific risk source into smaller risk sources. Risk adjustment and control are applied to major environmental risk sources that cannot meet the safety planning objectives in the region to increase regional safety. However, new enterprises with risk sources are selected according to the distribution of environmentally sensitive targets, environmental background, and other factors at the regional level.

- Protection of receptors. To protect the population and environmentally sensitive targets, safety distances are investigated and verified for different industrial activities or facilities, sites and residential buildings, public regions, and other important regions by considering the regional development orientation, properties, scale, and state of spatial development. The safety distance depends on the type of industrial activity as well as the type and level of hazard. With risk management, the vulnerability of the receptors can be decreased with increased resilience.

- Allocation of emergency resources. The rational use of resources is essential to the implementation of an environmental pollution emergency plan. However, shortage and irrational allocation of emergency resources are key constraints in the current emergency management of sudden environmental pollution incidents in China. The establishment of an effective emergency resource allocation system is an important measure of receptor safety. This system is based on the type of environmental risk incidents in industrial areas and the distribution of environmental risk sources and receptors. Moreover, the emergency material reserve protection system as well as the regulatory, production, reservation, allocation, and emergency distribution systems of important emergency supplies should be gradually perfected.

4.3. Environmental Risk Emergency Management

- Emergency planning system. An effective emergency plan directs an efficient and systematic emergency operation, and ensures prompt action on risk sources at different levels, and different distributions, of the receptors. There are five aspects to consider in emergency planning as follows: emergency organization; management and command system; emergency engineering and rescue system; support system with synthesized coordination, prompt response, and fully prepared safety and supply systems; and integrated rescue abilities of the emergency team.

- Emergency decisions. An emergency management system with classified management and graded responsibility should be established and perfected. A computer-based emergency decision support system that can assist decision makers in semi-structured or unstructured interactive decision making can be established. Information technology, management science theory, computer science, and other disciplines related to pollutant leakage control and pollution cleanup, emergency rescue and receptor protection, and communication on risk information can be used to develop this system. An emergency management system includes the following key steps: development of a technology to control and manage environmental risk sources; risk prevention through knowledge of emergency treatment technologies that counter the effects of hazardous substances; preventions; establishment of an emergency monitoring network of risk sources; and use of emergency treatment technologies such as rapid-closure for pollutants and rapid reduction of upper-air diffusion of pollutants. In addition, access to official channels should be provided for awareness on the progress, cause, and results of emergency management measures.

4.4. Assessment and Environmental Restoration after the Occurrence of Environmental Pollution Incidents

- Assessment after environmental pollution incidents. This process includes the following: (a) evaluation of the effects exerted by major pollution incidents on the environment and introduction of compensation schemes; (b) prediction of the medium- and long-term effects of pollution incidents as well as proposal of corresponding pollution-mitigation measures and environmental protection programs; (c) identification of appropriate measures, namely, early warning, response, rescue operations, and pollution control; (d) improvement of environmental emergency plans according to the emergency response situation; and (e) investigation of the causes for pollution incidents to provide evidence for responsibility confirmation of other pollution incidents, treatments, and reference for the prevention of environmental risks.

- Environmental restoration. Environmental restoration and ecological compensation schemes should be developed in response to the possible medium- and long-term effects of pollution incidents on the ecosystems (e.g., proposing ecological compensation programs for affected farmland to protect the safety of agricultural products and introducing restoration programs for the affected environment to ensure that environmental quality standards are attained).

5. Conclusions

- A pollutant hazard index analysis and assessment methods were proposed based on the intensity and hazard of pollutant leakage. A basic physical model and the characterization techniques of regional ERF were established by using related predictive modeling. Based on these, we proposed that the consequences of environmental risks caused by accidents consist of two parts: the intensity of atmospheric ERF (the product of the probability of accident occurrence and the risk index of pollutants) and the vulnerability of the receptors.

- A risk load theory-based path was designed to optimize the regional environmental risk source layout as well as to protect the population and major sensitive targets of the environment against the risk source layout in industrial parks.

- The mechanism for whole-process environmental risk management was established. This mechanism includes a set of risk management strategies such as major pollution accident prevention, sudden emergency capacity building, and environmental pollution accident compensation. The three stages of environmental risk accidents covered prevention, response during accidents, and disposal after accidents.

Acknowledgments

References

- Bi, J.; Yang, L.; Li, Q.L. Regional Environmental Risk Analysis and Management; China Environmental Science Press: Beijing, China, 2006; pp. 25–38. [Google Scholar]

- Roselló, M.J.; Martinez, J.M.; Navarro, B.A. Vulnerability of human environment to risk: Case of groundwater contamination risk. Environ. Inter. 2009, 35, 325–335. [Google Scholar]

- Huttunen, H.; Wyness, L.E.; Kalliokoski, P. Identification of environmental hazards of gasoline oxygenate tert-amyl methyl ether (TAME). Chemosphere 1997, 35, 1199–1214. [Google Scholar]

- Manassaram, D.M.; Orr, M.F.; Kaye, W.E. Hazardous substances events associated with the manufacturing of chemicals and allied products. J. Hazard. Mater. 2003, 104, 123–135. [Google Scholar]

- Colbournea, D.; Suenb, K.O. Appraising the flammability hazards of hydrocarbon refrigerants using quantitative risk assessment model. Int. J. Refrig. 2004, 774–783. [Google Scholar]

- Reniers, G.L.L.; de Jongh, K.; Gorrens, B. Transportation Risk Analysis tool for hazardous Substances (TRANS—A user-friendly, semi-quantitative multi-mode hazmat transport route safety risk estimation methodology for Flanders. Transport Res. Transport Environ. 2010, 15, 489–496. [Google Scholar]

- Bernechea, E.J.; Viger, J.A. Design optimization of hazardous substance storage facilities to minimize project risk. Safety Sci. 2013, 51, 49–62. [Google Scholar]

- Landucci, G.; Antonioni, G.; Tugnoli, A.; Cozzani, V. Release of hazardous substances in flood events: Damage model for atmospheric storage tanks. Reliab. Eng. Syst. Safe. 2012, 106, 200–216. [Google Scholar]

- Li, Q.; Bi, J.; Yang, J. Fuzzy evaluation model for industry park’s environmental risk management performance and its apply. Environ. Protect. 2005, 12, 20–23, in Chinese. [Google Scholar]

- Environmental Protection Apartment of China. Technical Guidelines for Environmental Risk Assessment on Projects (HJ/T 169-2004). Available online: http://kjs.mep.gov.cn/hjbhbz/bzwb/other/pjjsdz/200412/t20041211_63369.htm (assessed on 8 February 2013).

- Pollard, S.; Purchase, D.; Herbert, S. A Practical Guide to Environmental Risk Assessment for Waste Management Facilities (Guidance Note 25 Version 2). Available online: http://infohouse.p2ric.org/ref/16/15252.pdf (assessed on 8 February 2013).

- Venter, H.S.; Eloff, J.H.P.; Li, Y.L. Standardizing vulnerability categories. Comput. Secur. 2008, 27, 71–83. [Google Scholar]

- Suter, G.W., II; Vermeire, T.; Munns, W.R., Jr.; Sekizawa, J. An integrated framework for health and ecological risk assessment. Toxicol. Appl. Pharm. 2005, 207, 611–616. [Google Scholar]

- Guiding Principles for Chemical Accident Prevention, Preparedness and Response; OECD: Paris, France, 2003.

- UNEP. APELL-Information and Tools for Emergency Response Planning, 2003. Available online: www.unep.fr/scp/sp/programme/ (assessed on 8 February 2013).

- COUNCIL DIRECTIVE 82/501/EEC on the Major Accident Hazards of Certain Industrial Activities; Commission of the European Communities: Brussels, Luxembourg, 1990; pp. 1–18.

- European Communities. Directive 2012/18/EU of the European Parliament and of the Council. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32012L0018:EN:NOT (assessed on 8 February 2013).

- AEA Technology plc, Major Hazard Incident Data Service; Health and Safety Executive: London, UK, 2010.

- Netherlands Organization for Applied Scientific Research. Failure and Accidents Technical Information System. Available online: www.factsonlin.nl/ (assessed on 8 February 8 2013).

- Federal Envimnmentel Agency. Central Major Accident Notification System. Available online: www.infosis.uba.de/index.php/en/site/13947/zema/index.html/ (accessed on 8 February 2013).

- French Ministry of Ecology, Energy, Sustainable Development. Analysis, Research and Information on Accidents. Available online: www.aria.development-durable.gouv.fr/ (accessed on 8 February 2013).

- Mago, V.K.; Bhatia, N. Cross-Disciplinary Applications of Artificial Intelligence and Pattern Recognition: Advancing Technologies; IGI Global: Hershey, PA, USA, 2012; pp. 1–16. [Google Scholar]

- National Bureau of Statistics of ChinaEnvironmental Protection Apartment of ChinaChina Environment Statistical Yearbook; China Statistics Press: Beijing, China, 2011.

- The editorial department of environmental protection. Preventing environmental risks and ensuring environmental safety. Environ. Protect. 2011, 29, 15–16, in Chinese.

- Meel, A.; O’Neill, L.M.; Levin, J.H.; Oktem, U.; Keren, N. Operational risk assessment of chemical industries by exploiting accident databases. J. Loss Prevent. Proc. 2007, 20, 113–127. [Google Scholar]

- Shi, C.; Duo, Y.Q. Safety Capacity for hazardous chemicals transportation of chemical industry park. Transport Standard. 2010, 5, 64–67, in Chinese. [Google Scholar]

- Kappes, M.S.; Keiler, M.; Elverfeldt, K.V.; Glade, T. Challenges of analyzing multi-hazard risk: A review. Nat. Hazards. 2012, 64, 1925–1958. [Google Scholar]

- Perles Roselló, M.J.; Prados, F.C. Problems and challenges in analyzing multiple territorial risks: Methodological proposals for the development of multi-hazard mapping. De la AGE y Otros. 2010, 52, 245–271. [Google Scholar]

- Crossthwaite, P.J.; Fitzpatrick, R.D.; Hurst, N.W. Risk assessment for the siting of developments near liquefied petroleum gas installations. IChemE Symp. Ser. 1988, 110, 373–400. [Google Scholar]

- COVO Commission, Risk Analysis of Six Potentially Hazardous Industrial Objects in the Rijnmond Area, a Pilot Study: A Report to the Rijnmond Public Authority; Central Environmental Control Agency Rijnmond: Dordtrecht, The Netherlands, 1981.

- Logtenberg, M.T. Derivation of Failure Frequencies for LOC Cases; TNO: Apeldoorn, The Netherlands, 1998. [Google Scholar]

- Spouge, J. New generic leak frequencies for process equipment. Proc. Safety Prog. 2005, 24, 249–257. [Google Scholar]

- The Major Accident Hazards Bureau, European Commission. Accidental Risk Assessment Methodology for Industries in the Framework of SEVESO II Directive. Available online: http://mahb.jrc.it/index.php?id=440 (accessed on 17 March 2013).

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Shao, C.; Yang, J.; Tian, X.; Ju, M.; Huang, L. Integrated Environmental Risk Assessment and Whole-Process Management System in Chemical Industry Parks. Int. J. Environ. Res. Public Health 2013, 10, 1609-1630. https://doi.org/10.3390/ijerph10041609

Shao C, Yang J, Tian X, Ju M, Huang L. Integrated Environmental Risk Assessment and Whole-Process Management System in Chemical Industry Parks. International Journal of Environmental Research and Public Health. 2013; 10(4):1609-1630. https://doi.org/10.3390/ijerph10041609

Chicago/Turabian StyleShao, Chaofeng, Juan Yang, Xiaogang Tian, Meiting Ju, and Lei Huang. 2013. "Integrated Environmental Risk Assessment and Whole-Process Management System in Chemical Industry Parks" International Journal of Environmental Research and Public Health 10, no. 4: 1609-1630. https://doi.org/10.3390/ijerph10041609

APA StyleShao, C., Yang, J., Tian, X., Ju, M., & Huang, L. (2013). Integrated Environmental Risk Assessment and Whole-Process Management System in Chemical Industry Parks. International Journal of Environmental Research and Public Health, 10(4), 1609-1630. https://doi.org/10.3390/ijerph10041609