A Capacitively-Fed Inverted-F Antenna for Displacement Detection in Structural Health Monitoring

Abstract

:1. Introduction

2. Design and Theory

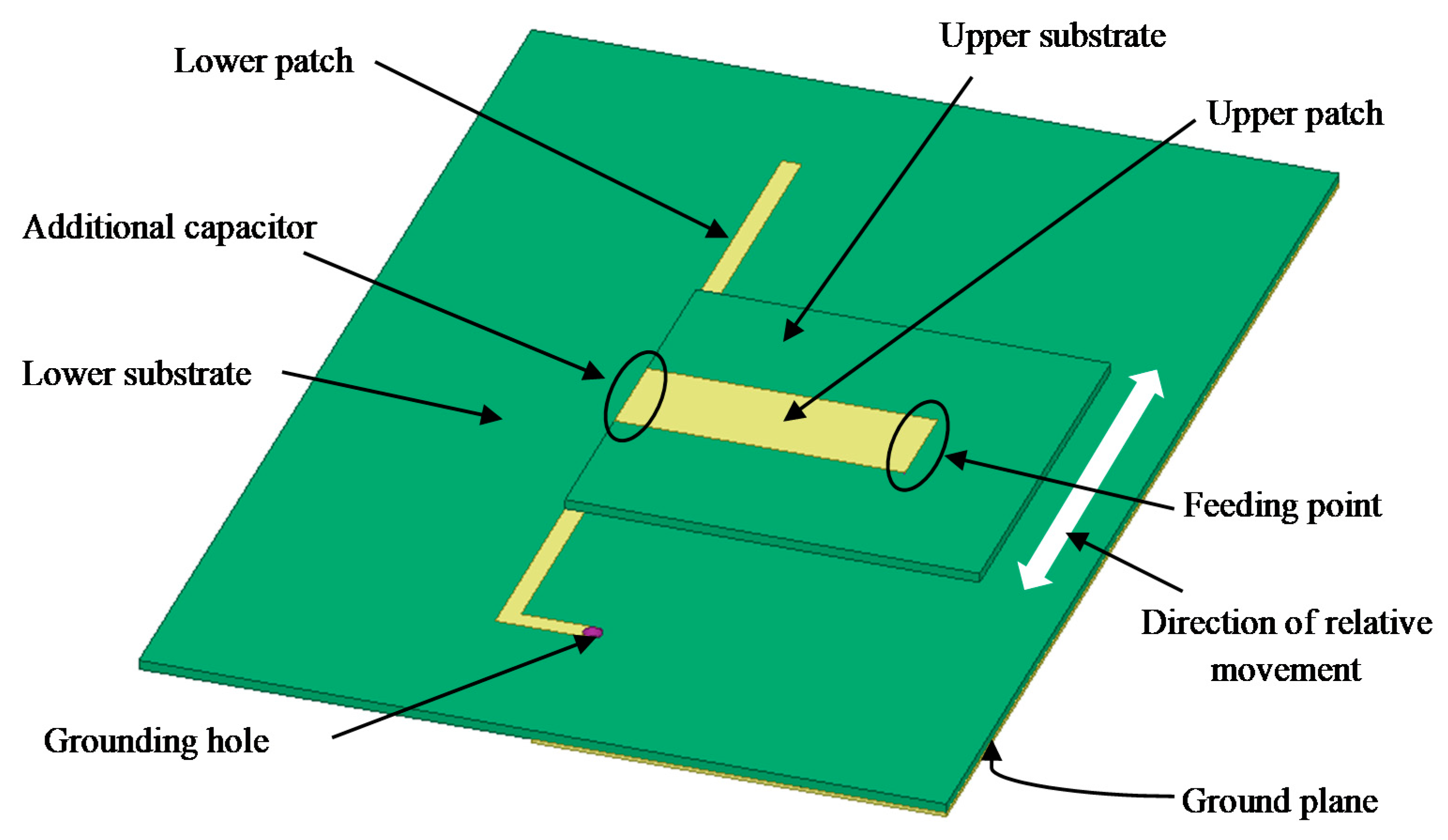

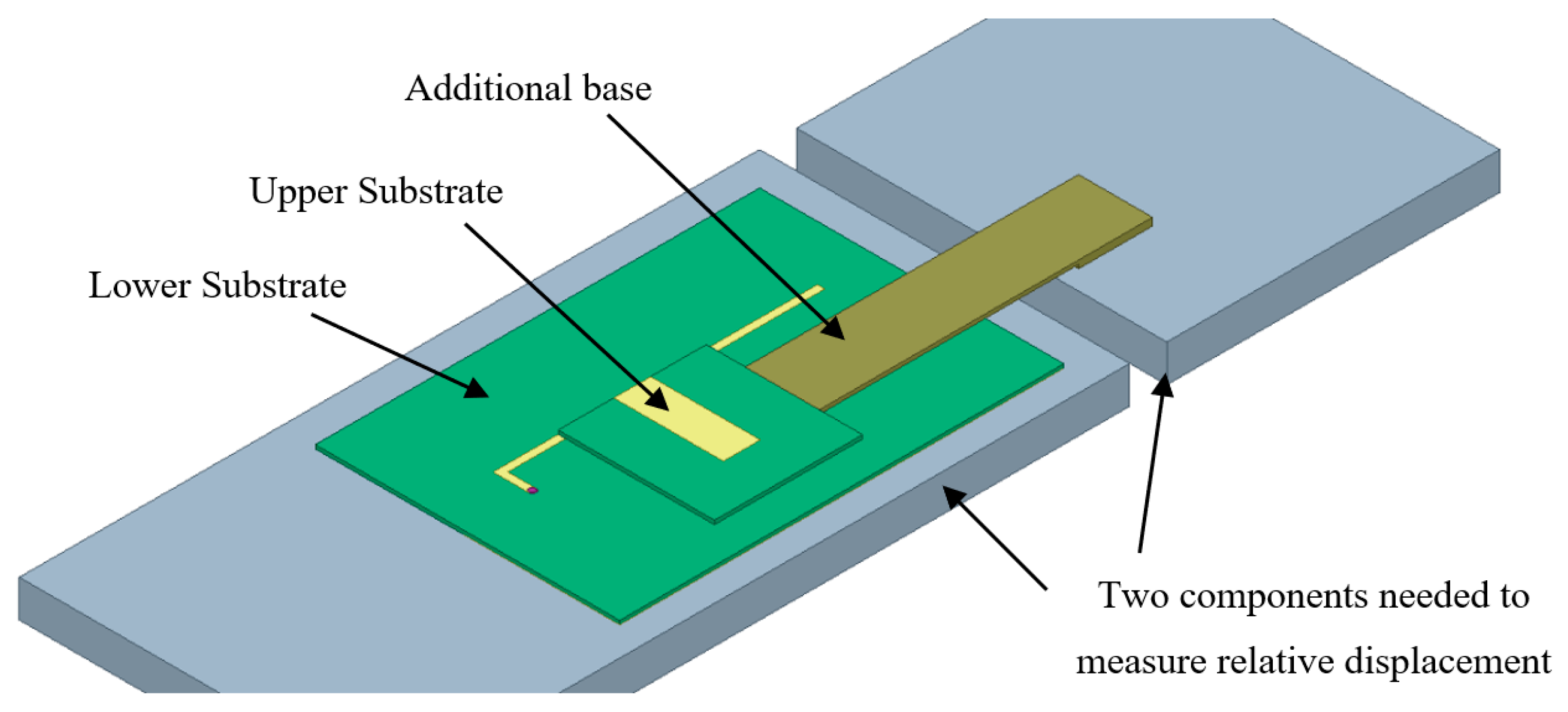

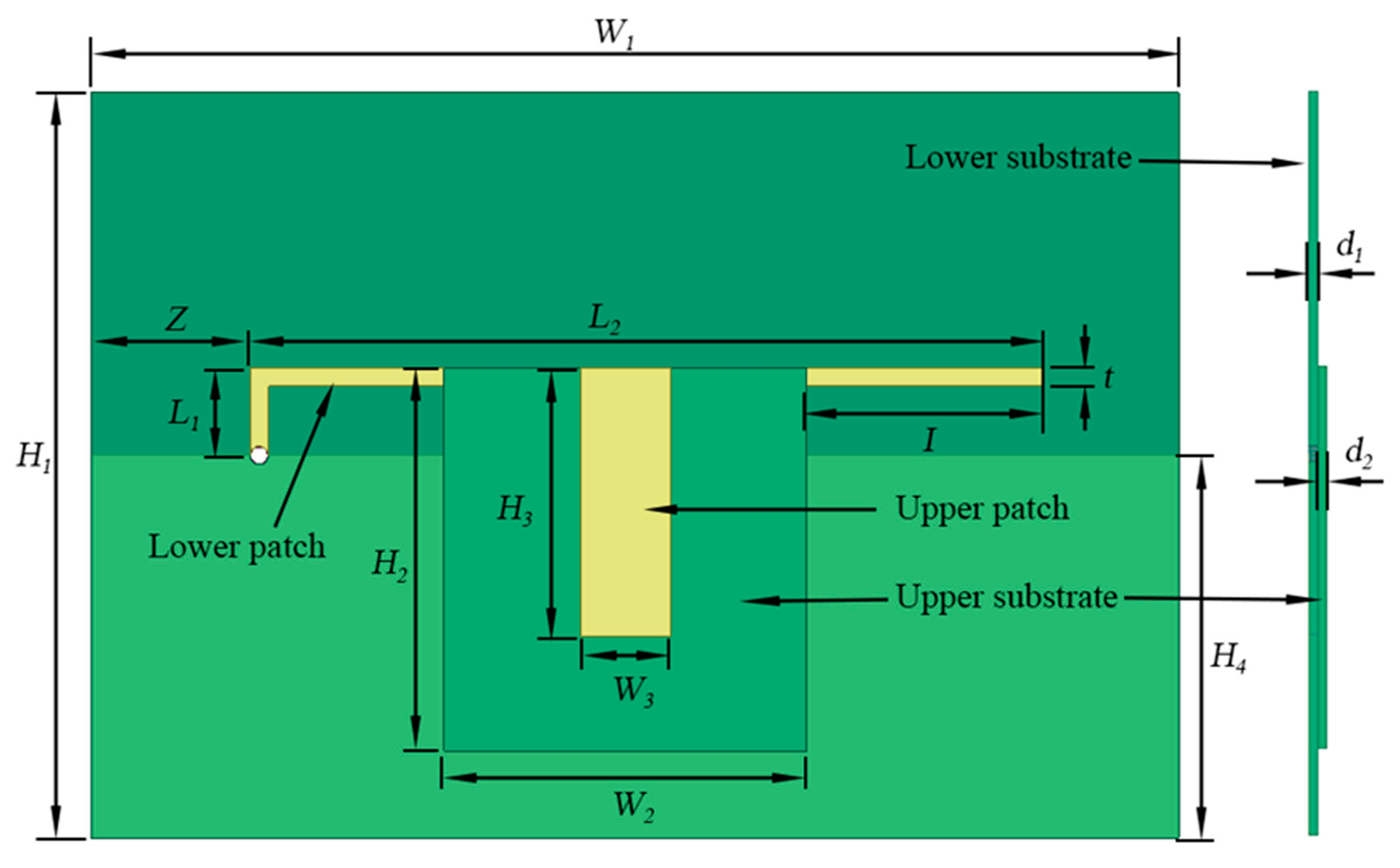

2.1. Design of the Capacitively Fed Inverted-F Antenna

2.2. Theory of the Capacitively-Fed Inverted-F Antenna

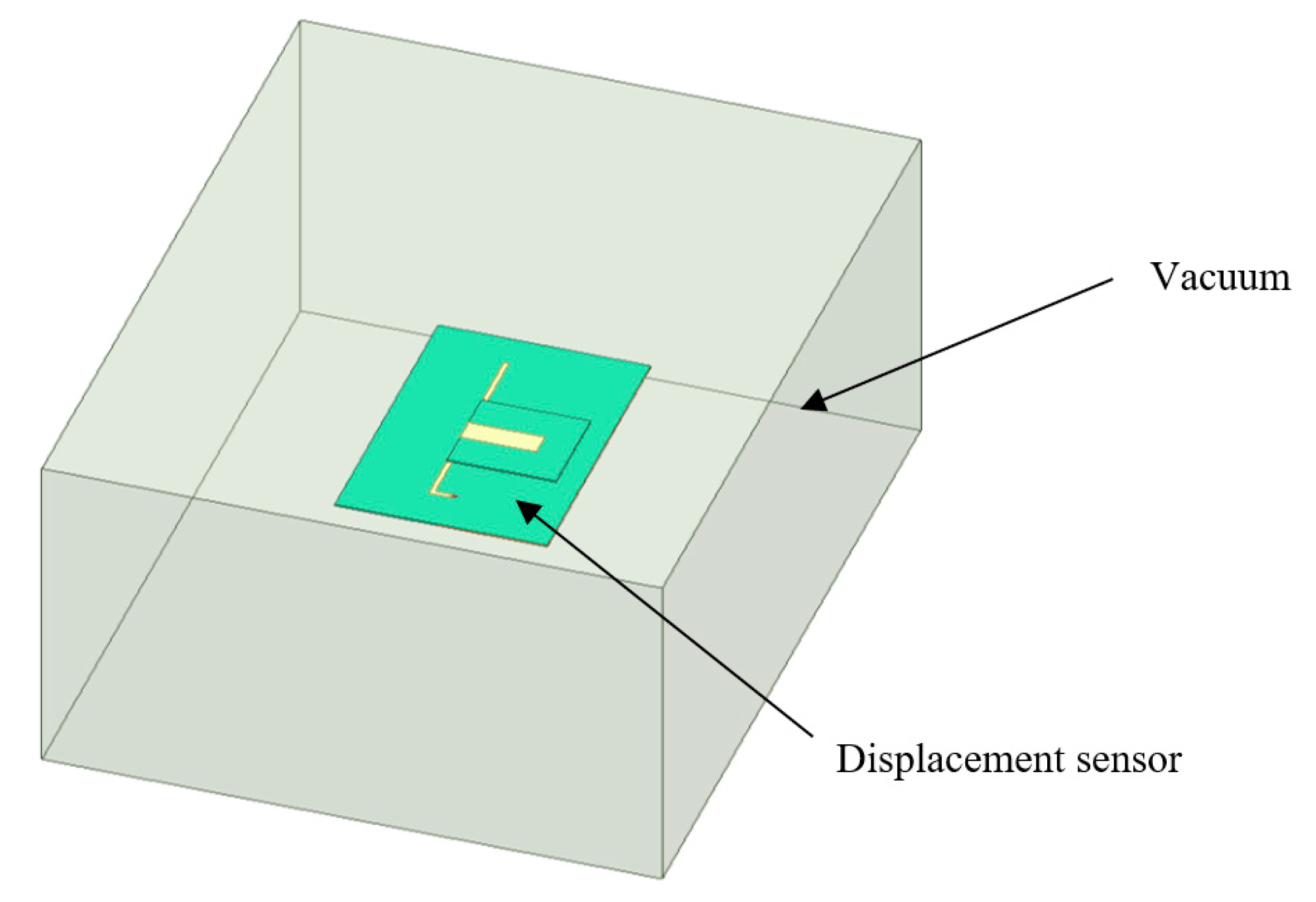

3. Simulation

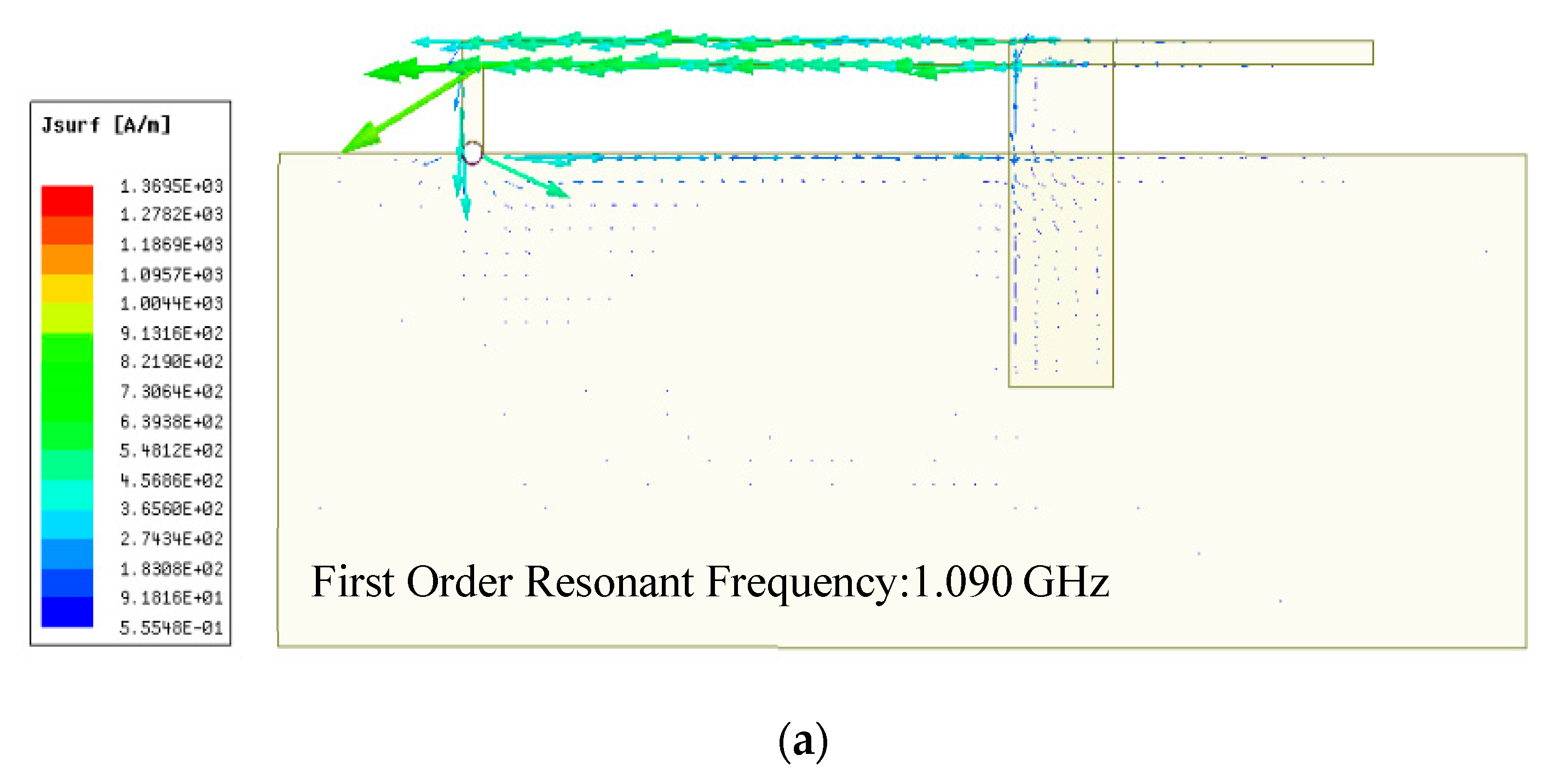

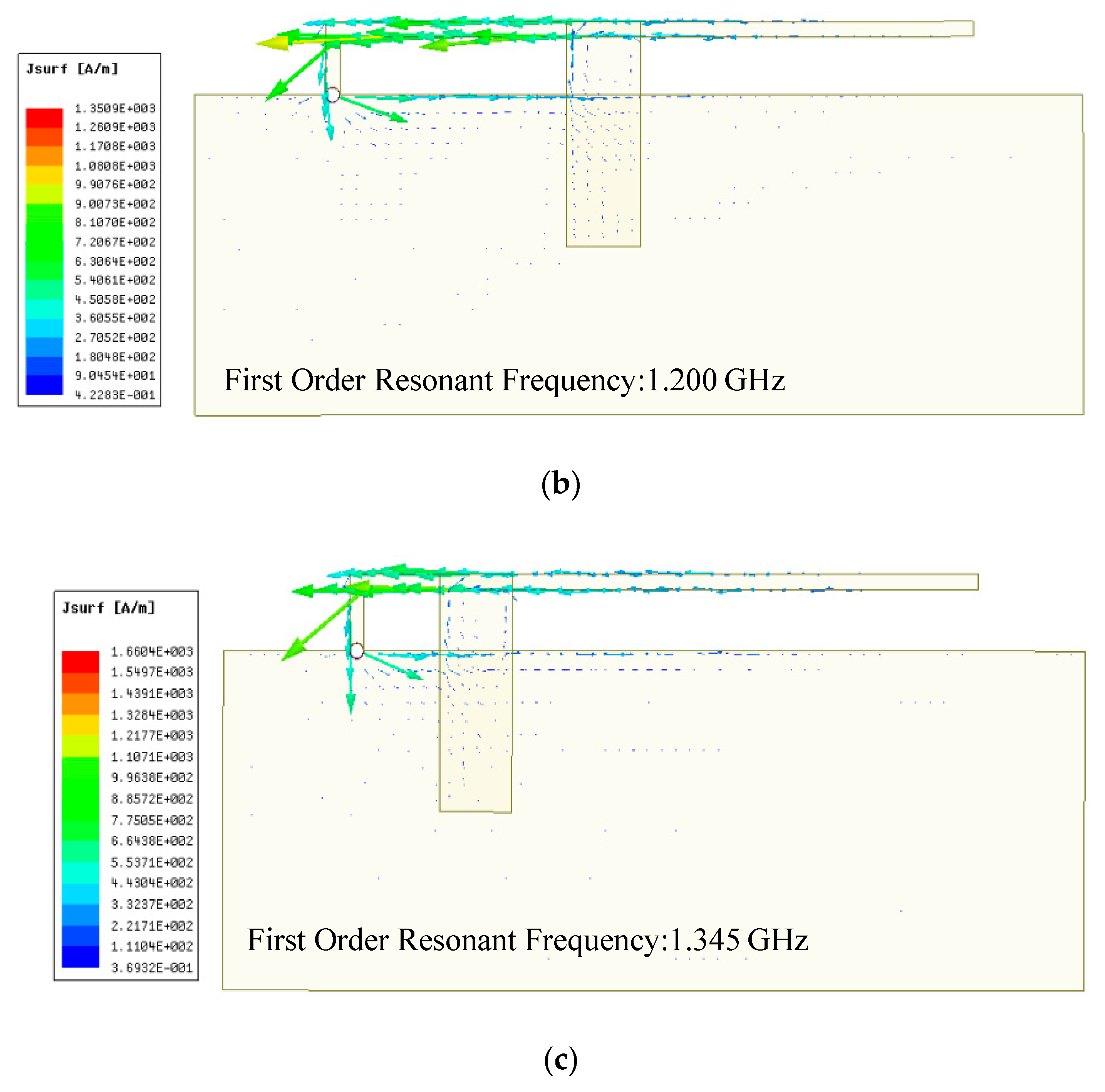

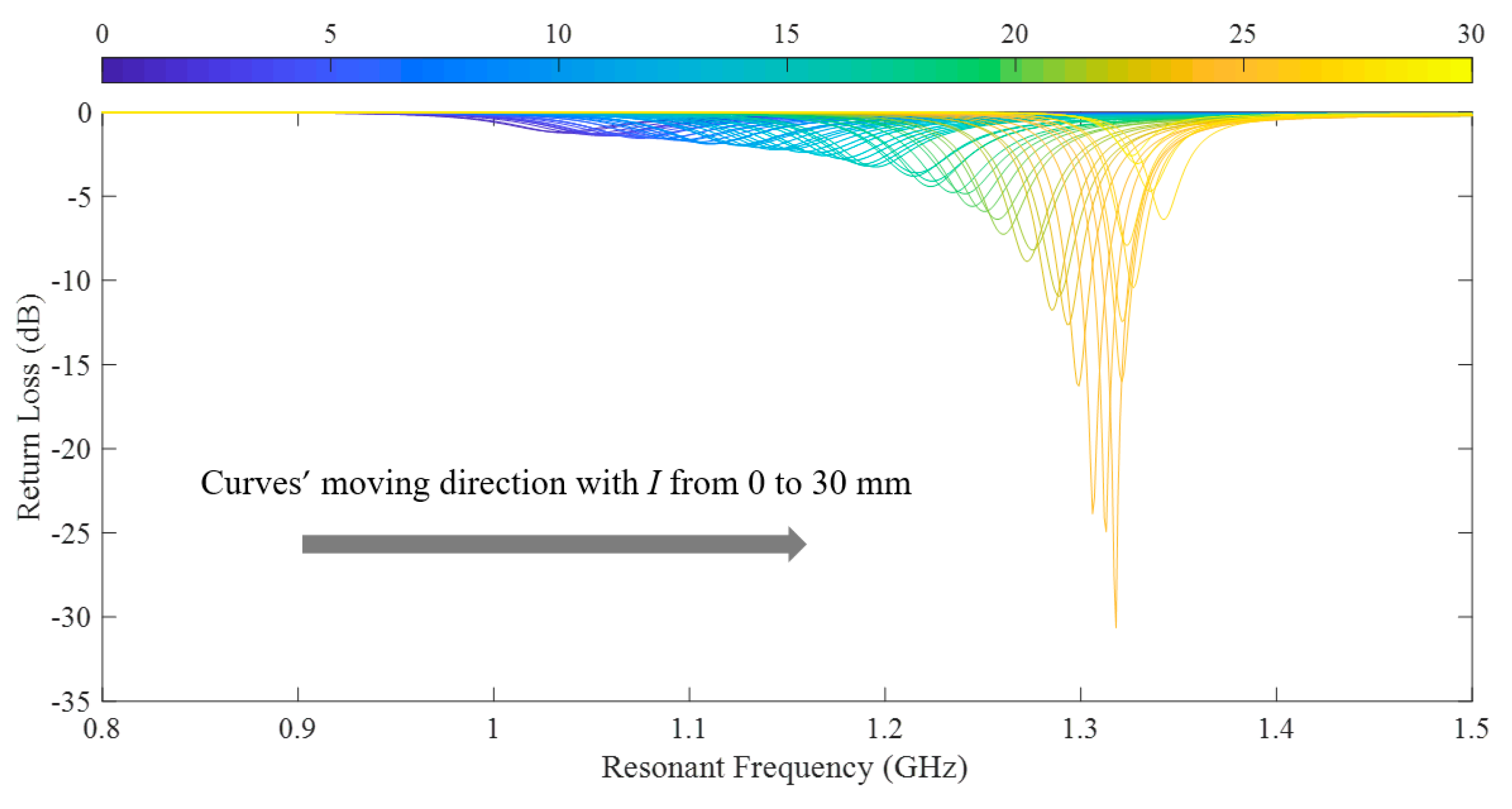

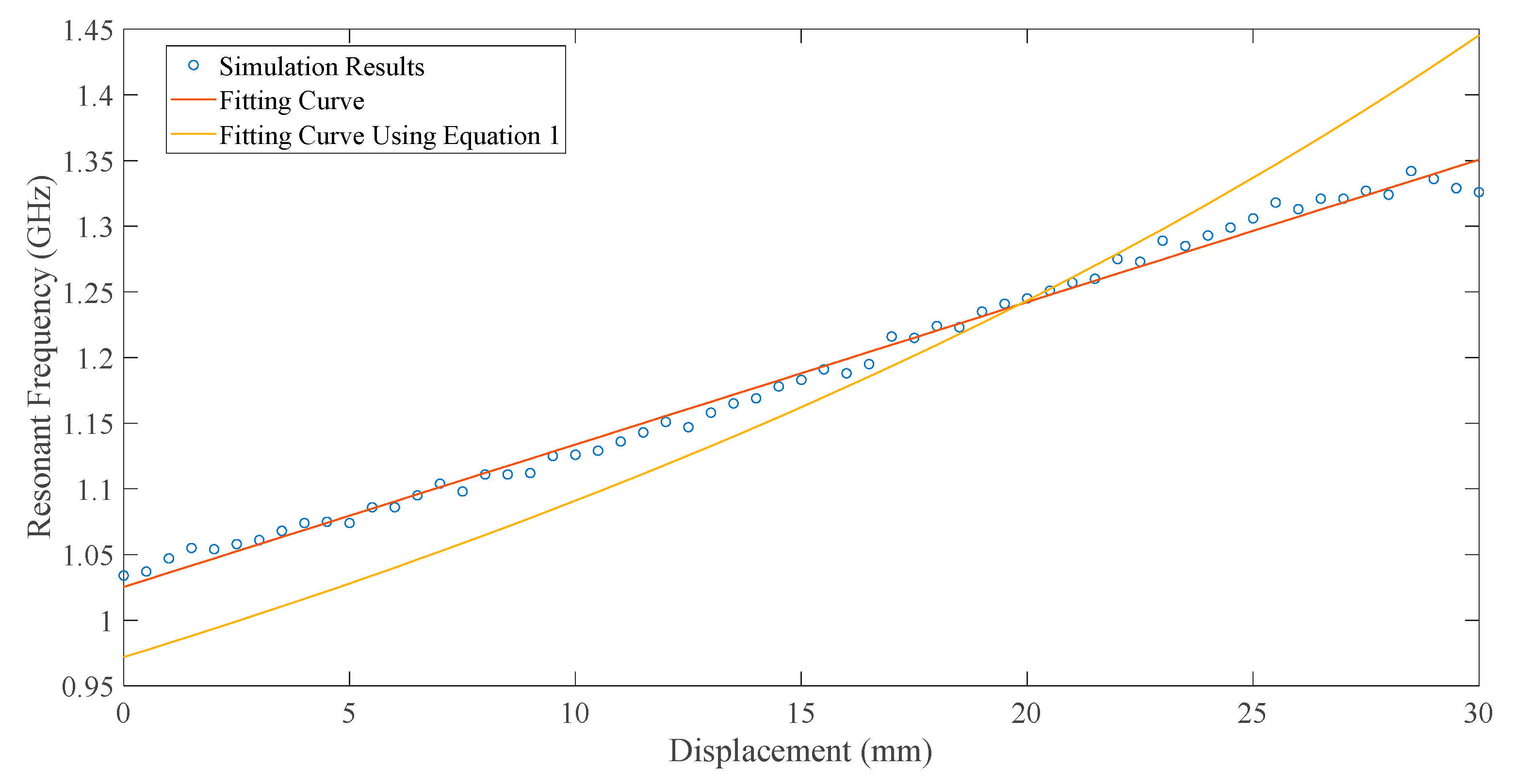

3.1. Verification of the Assumption in Section 2

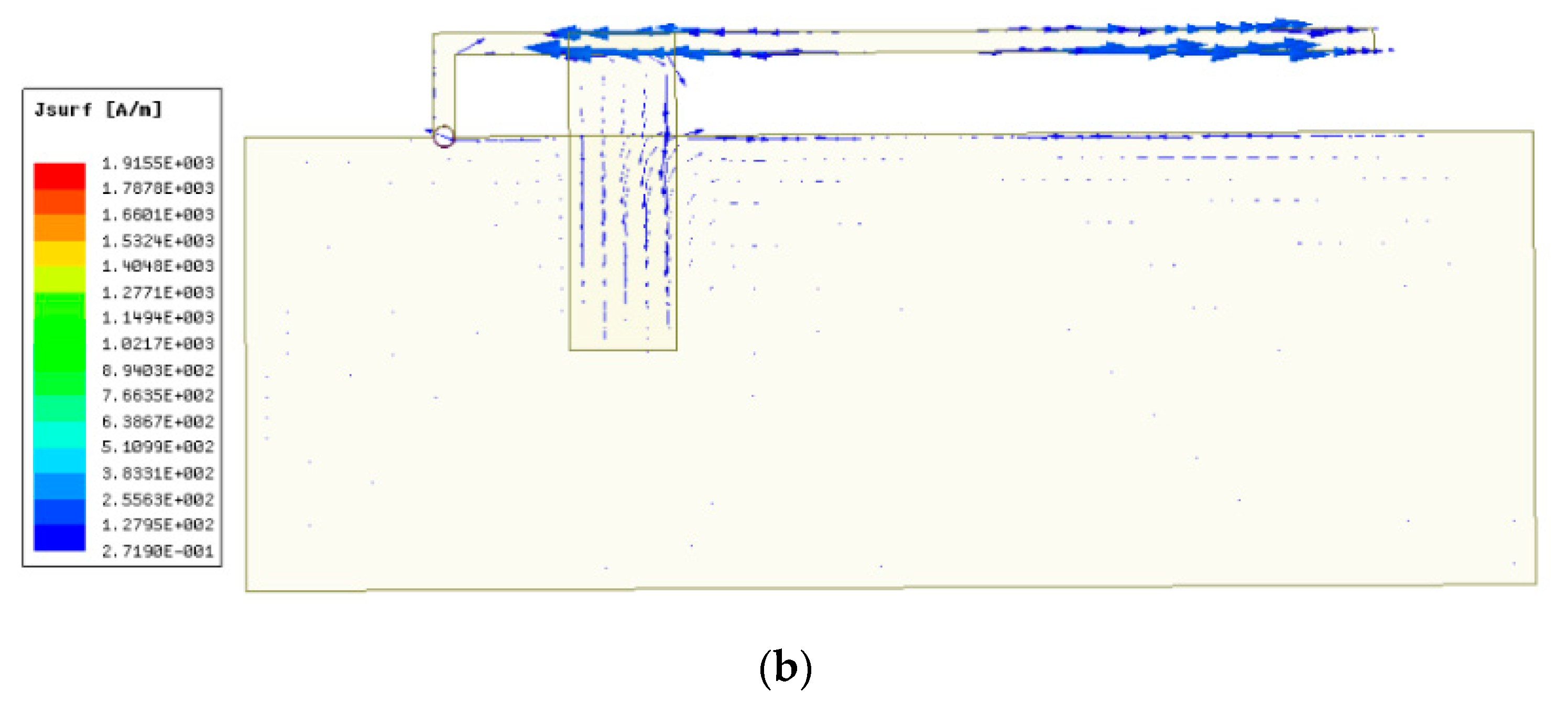

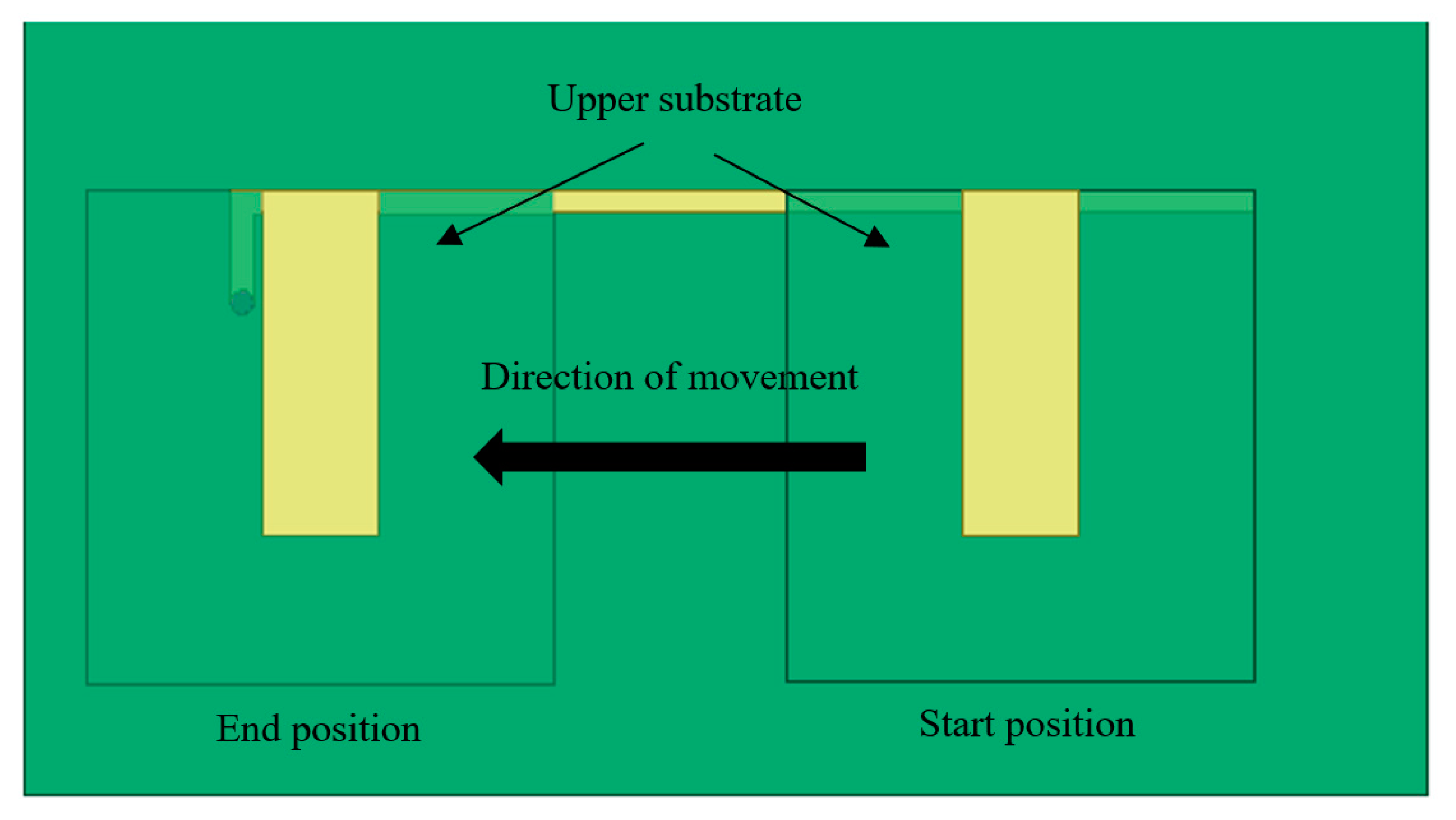

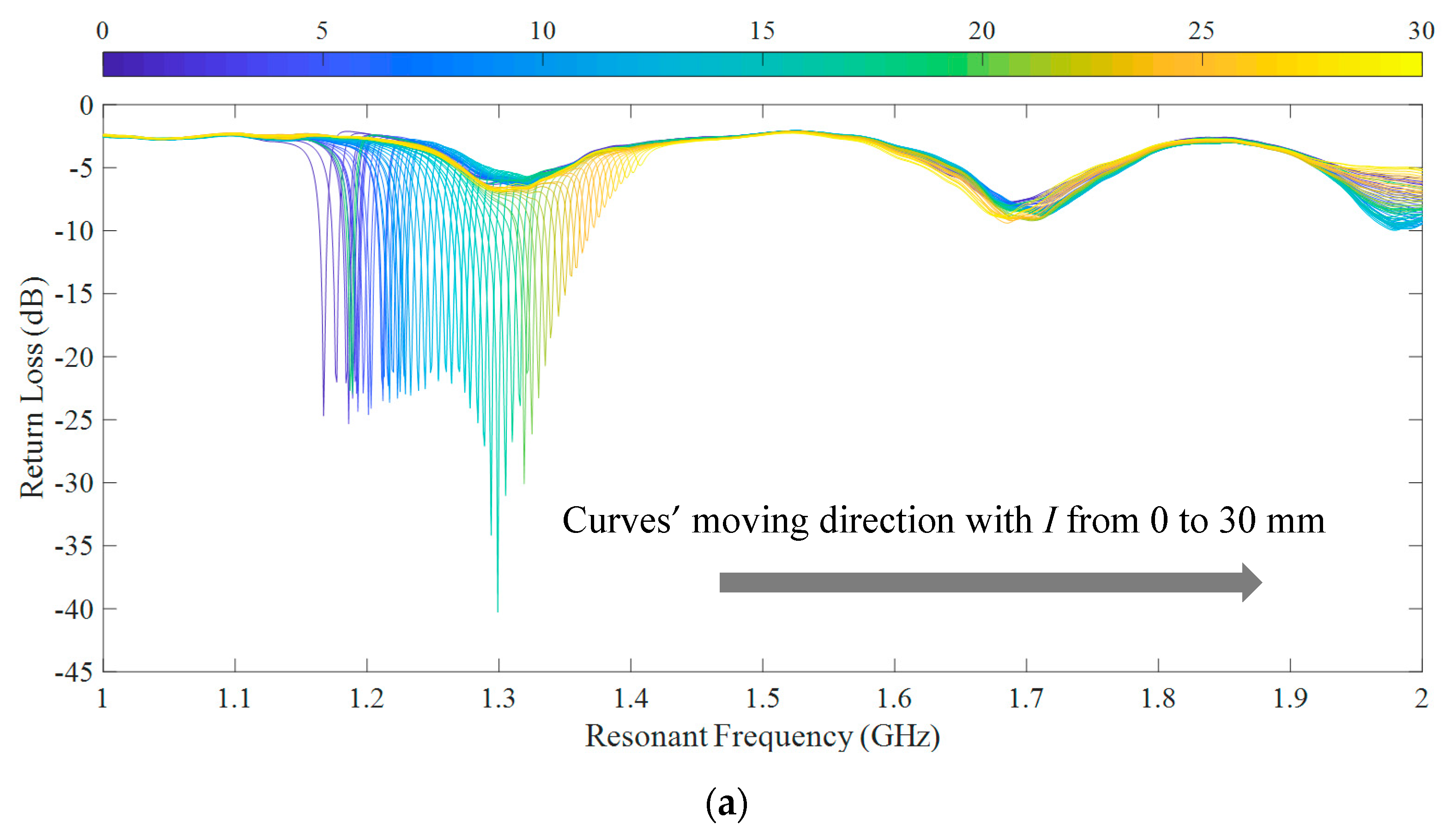

3.2. Performance Simulation

4. Experiment

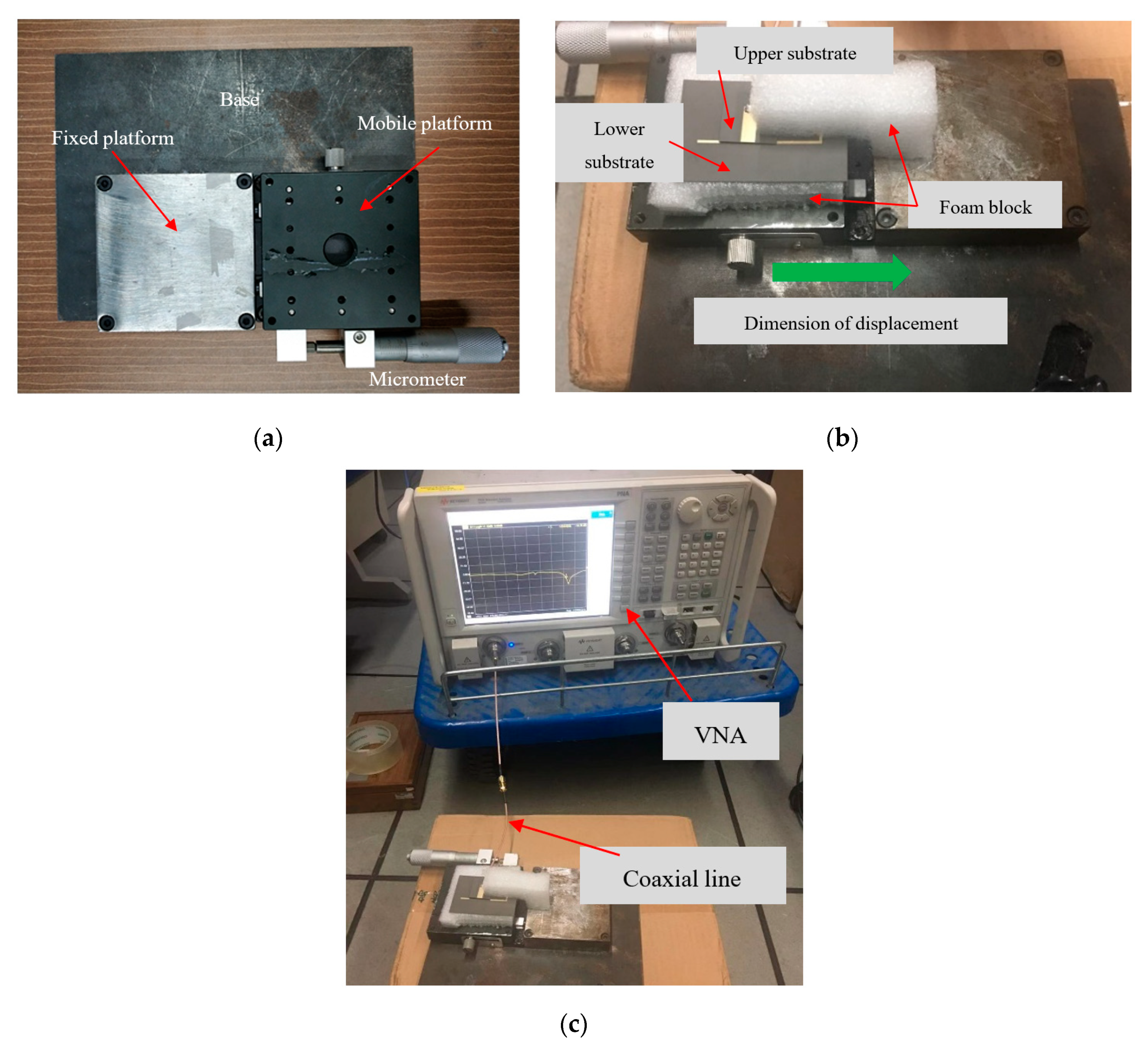

4.1. Instrumentation Setup

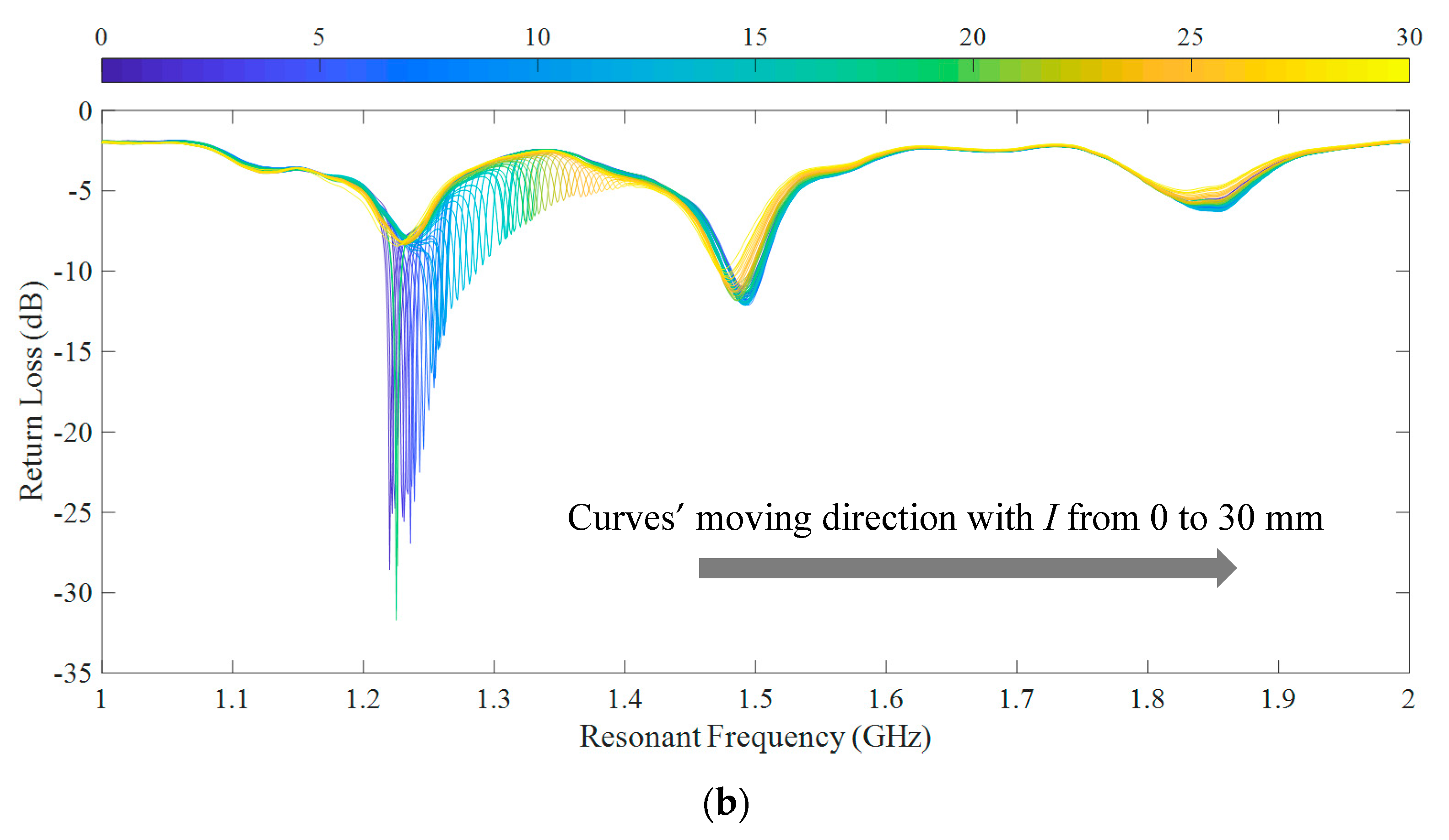

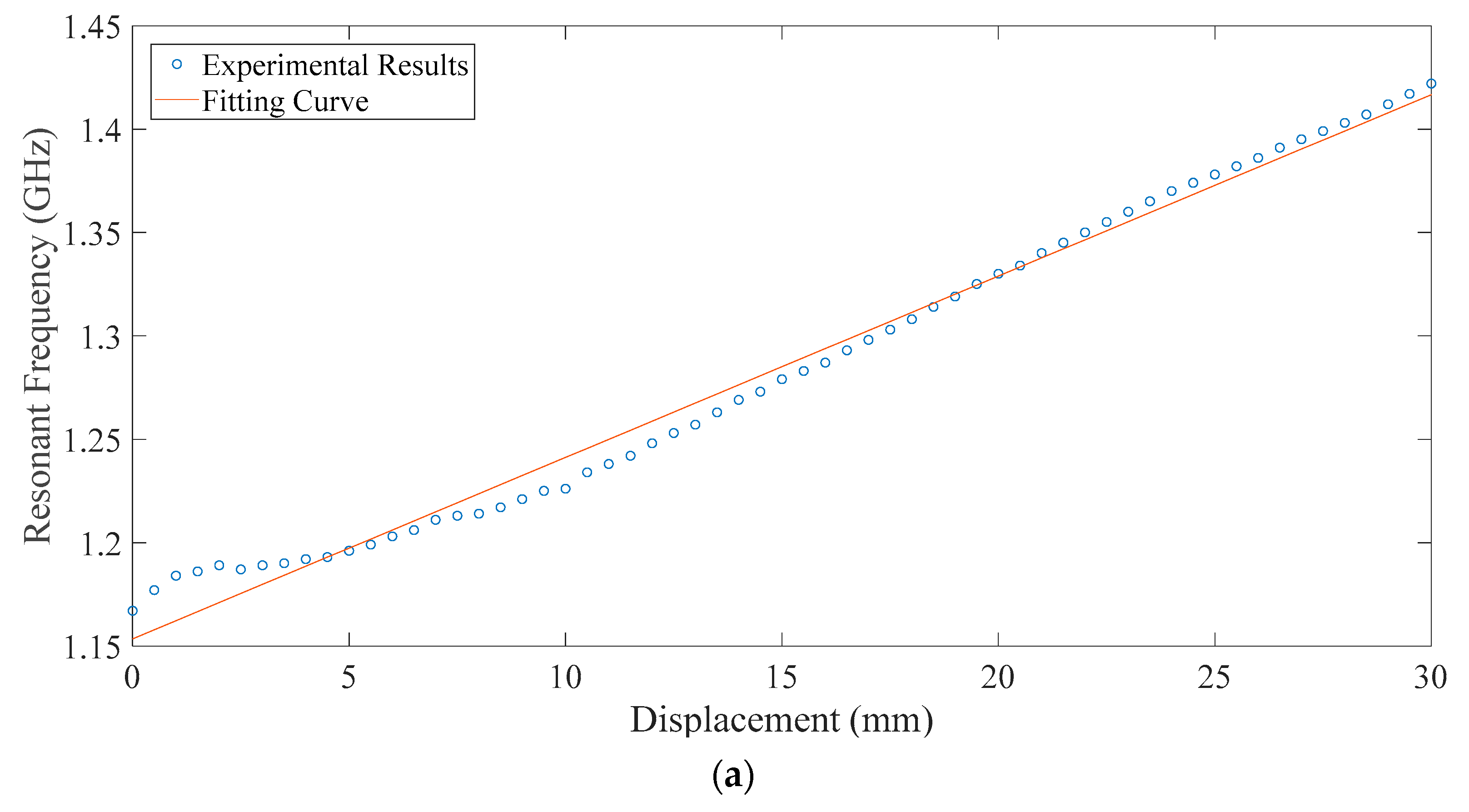

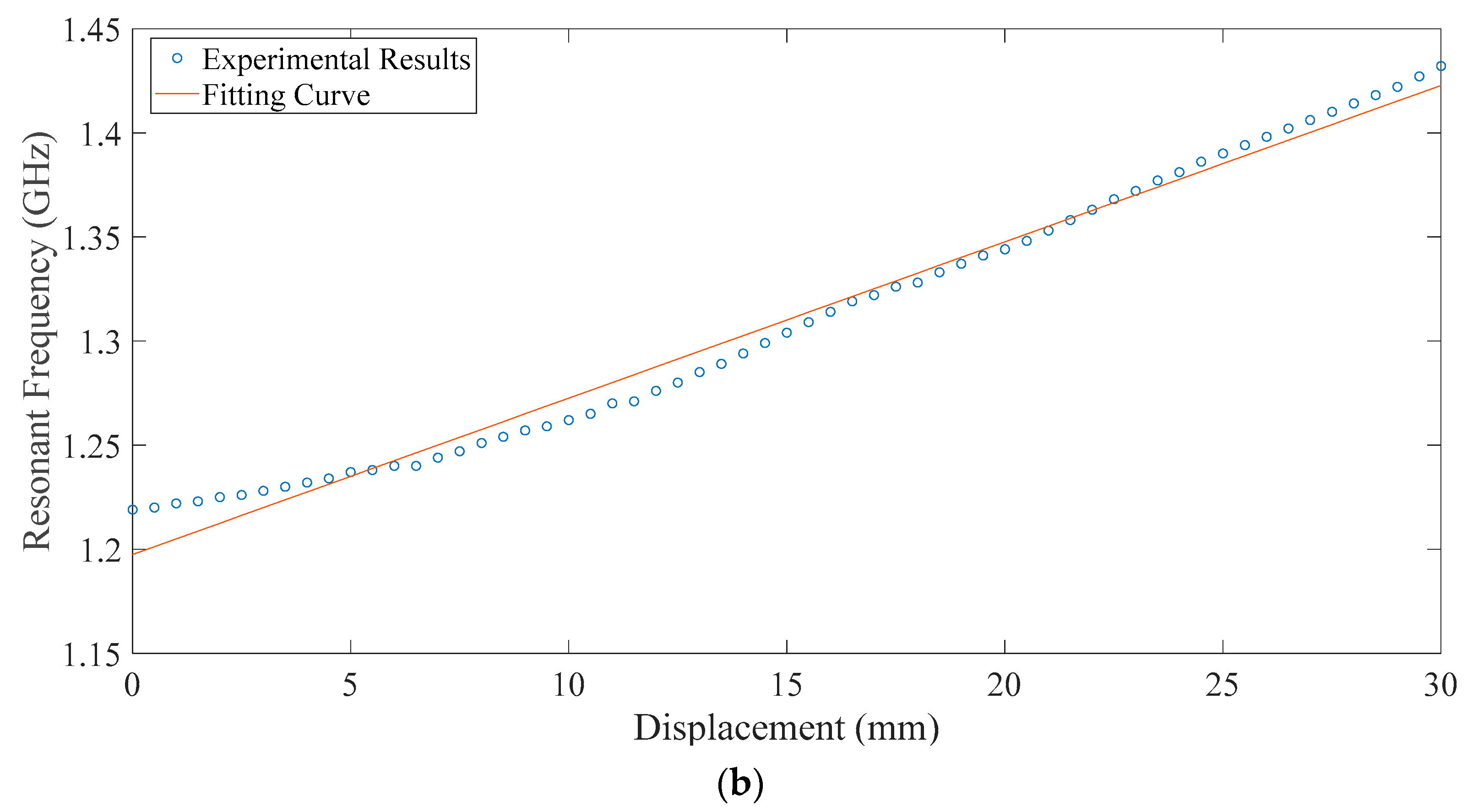

4.2. Experimental Results

5. Results and Discussion

- (1)

- The welding of the feeding point and environmental interference may cause some errors, which are not considered in the simulation.

- (2)

- In the practical experiment, it is impossible for the upper and lower substrates of the inverted-F antenna to sit close enough to each other to achieve an air-tight connection. This results in an air film between the two substrates, and this is not considered in the simulation.

- (3)

- Antenna machining errors. While the antenna fabrication is batch processing, the substrate or patch is not completely flat, and the dimensions of each part of the antenna are also subject to some errors.

- (4)

- The upper substrate of the antenna produces translation and rotation away from the direction of the relative displacement. In the simulation of the antenna sensor, the upper substrate moves along the lower patch. However, in the experiment, due to manual operation, it is inevitable to produce a tiny translation or rotation out of the relative displacement direction, which can affect the electromagnetic characteristics of the antenna.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Glisic, B.; Inaudi, D.; Casanova, N. SHM process as perceived through 350 projects. Smart Sens. Phenom. Technol. Netw. Syst. 2010, 7648, 76480P. [Google Scholar]

- Liu, Y.; Nayak, S. Structural health monitoring: State of the art and perspectives. JOM 2012, 64, 789–792. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Fu, T.; Paek, J.; Kothari, N.; Rangwala, S.; Caffrey, J.; Govindan, R.; Johnson, E.; Masri, S. Monitoring civil structures with a wireless sensor network. IEEE Int. Comput. 2006, 10, 26–34. [Google Scholar] [CrossRef]

- Cho, S.; Yun, C.-B.; Lynch, J.P.; Zimmerman, A.T.; Spencer, B.F., Jr.; Nagayama, T. Smart wireless sensor technology for structural health monitoring of civil structures. Steel Struct. 2008, 8, 267–275. [Google Scholar]

- Caizzone, S.; Di Giampaolo, E. Wireless Passive RFID Crack Width Sensor for Structural Health Monitoring. IEEE Sens. J. 2015, 15, 6767–6774. [Google Scholar] [CrossRef] [Green Version]

- Chakaravarthi, G.; Logakannan, K.P.; Philip, J.; Rengaswamy, J.; Ramachandran, V.; Arunachalam, K. Reusable Passive Wireless RFID Sensor for Strain Measurement on Metals. IEEE Sens. J. 2018, 18, 5143–5150. [Google Scholar] [CrossRef]

- Dong, C.-Z.; Celik, O.; Catbas, F.N.; OBrien, E.; Taylor, S. A Robust Vision-Based Method for Displacement Measurement under Adverse Environmental Factors Using Spatio-Temporal Context Learning and Taylor Approximation. Sensors 2019, 19, 3197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, C.Z.; Catbas, F.N. A review of computer vision–based structural health monitoring at local and global levels. Struct. Health Monit. 2020. [Google Scholar] [CrossRef]

- Alshamaa, D.; Mourad-Chehade, F.; Honeiné, P. Localization of Sensors in Indoor Wireless Networks: An Observation Model Using WiFi RSS. In Proceedings of the 9th IFIP International Conference on New Technologies, Mobility and Security (NTMS), Paris, France, 26–28 February 2018; pp. 1–5. [Google Scholar]

- Jawad, H.M.; Nordin, R.; Gharghan, S.K.; Jawad, A.M.; Ismail, M. Energy-Efficient Wireless Sensor Networks for Precision Agriculture: A Review. Sensors 2017, 17, 1781. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated irrigation system using a wireless sensor network and GPRS module. IEEE Trans. Instrum. Meas. 2013, 63, 166–176. [Google Scholar] [CrossRef]

- Kovacic, M.; Vražic, M.; Gašparac, I. Bluetooth wireless communication and 1-wire digital temperature sensors in synchronous machine rotor temperature measurement. In Proceedings of the 14th International Power Electronics and Motion Control Conference, Ohrid, Makedonija, 6–8 September 2010; pp. T7-25–T7-28. [Google Scholar]

- Kobo, H.I.; Abu-Mahfouz, A.M.; Hancke, G.P. Fragmentation-Based Distributed Control System for Software-Defined Wireless Sensor Networks. IEEE Trans. Ind. Inform. 2019, 15, 901–910. [Google Scholar] [CrossRef]

- Tentzeris, M.M.; Georgiadis, A.; Roselli, L. Energy harvesting and scavenging. Proc. IEEE 2014, 102, 1644–1648. [Google Scholar] [CrossRef]

- Zhang, J.; Tian, G.Y.; Marindra, A.M.J.; Sunny, A.I.; Zhao, A.B. A review of passive RFID tag antenna-based sensors and systems for structural health monitoring applications. Sensors (Switzerland) 2017, 17, 265. [Google Scholar] [CrossRef]

- Wang, W.; Xue, X.; Fan, S.; Liu, M.; Liang, Y.; Lu, M. Development of a wireless and passive temperature-compensated SAW strain sensor. Sens. Actuators A Phys. 2020, 308, 112015. [Google Scholar] [CrossRef]

- Huang, Y.S.; Chen, Y.Y.; Wu, T.T. A passive wireless hydrogen surface acoustic wave sensor based on Pt-coated ZnO nanorods. Nanotechnology 2010, 21, 095503. [Google Scholar] [CrossRef]

- Choudhary, A.; Gopal, K.; Sood, D.; Tripathi, C.C. Development of compact inductive coupled meander line RFID tag for near-field applications. Int. J. Microw. Wirel. Technol. 2016, 9, 757–764. [Google Scholar] [CrossRef]

- Phan, H.P.; Nguyen, T.K.; Dinh, T.; Qamar, A.; Iacopi, A.; Lu, J.; Dao, D.V.; Rais-Zadeh, M.; Nguyen, N.T. Wireless battery-free SiC sensors operating in harsh environments using resonant inductive coupling. IEEE Electron Device Lett. 2019, 40, 609–612. [Google Scholar] [CrossRef] [Green Version]

- Manoj, A.J.Y.D. Wireless Sensor System for Infrastructure Health Monitoring. Ph.D. Thesis, Western Sydney University, Sydney, Australia, 2017. [Google Scholar]

- Zaid, J.; Abdulhadi, A.E.; Denidni, T.A. Miniaturized multi-port microstrip patch antenna using metamaterial for passive UHF RFID-tag sensor applications. Sensors 2019, 19, 1982. [Google Scholar] [CrossRef] [Green Version]

- Jayawardana, D.; Kharkovsky, S.; Liyanapathirana, R.; Zhu, X. Measurement System with Accelerometer Integrated RFID Tag for Infrastructure Health Monitoring. IEEE Trans. Instrum. Meas. 2015, 65, 1163–1171. [Google Scholar] [CrossRef]

- Xue, S.; Jiang, K.; Guan, S.; Xie, L.; Wan, G.; Wan, C. Long-Range Displacement Meters Based on Chipped Circular Patch Antenna. Sensors 2020, 20, 4884. [Google Scholar] [CrossRef]

- Borgese, M.; Dicandia, F.A.; Costa, F.; Genovesi, S.; Manara, G. An Inkjet Printed Chipless RFID Sensor for Wireless Humidity Monitoring. IEEE Sens. J. 2017, 17, 4699–4707. [Google Scholar] [CrossRef] [Green Version]

- Girbau, D.; Ramos, Á.; Lazaro, A.; Rima, S.; Villarino, R. Passive wireless temperature sensor based on time-coded UWB chipless RFID tags. IEEE Trans. Microw. Theory Tech. 2012, 60, 3623–3632. [Google Scholar] [CrossRef]

- Huang, H. Antenna sensors in passive wireless sensing systems. In Handbook of Antenna Technologies, 1st ed.; Chen, Z.N., Ed.; Springer: Singapore, 2016; pp. 2795–2838. [Google Scholar]

- Xue, S.; Yi, Z.; Xie, L.; Wan, G.; Ding, T. A displacement sensor based on a normal mode helical antenna. Sensors 2019, 19, 3767. [Google Scholar] [CrossRef] [Green Version]

- Donelli, M. An RFID-based sensor for masonry crack monitoring. Sensors 2018, 18, 4485. [Google Scholar] [CrossRef] [Green Version]

- Daliri, A.; Galehdar, A.; Rowe, W.S.T.; Ghorbani, K.; John, S. Utilising microstrip patch antenna strain sensors for structural health monitoring. J. Intell. Mater. Syst. Struct. 2012, 23, 169–182. [Google Scholar] [CrossRef]

- Yi, X.; Cho, C.; Cooper, J.; Wang, Y.; Tentzeris, M.M.; Leon, R.T. Passive wireless antenna sensor for strain and crack sensing—Electromagnetic modeling, simulation, and testing. Smart Mater. Struct. 2013, 22, 085009. [Google Scholar] [CrossRef]

- Yi, X.; Wu, T.; Wang, Y.; Tentzeris, M.M. Sensitivity modeling of an RFID-based strain-sensing antenna with dielectric constant change. IEEE Sens. J. 2015, 15, 6147–6155. [Google Scholar] [CrossRef]

- Kuhn, M.F.; Breier, G.P.; Dias, A.R.P.; Clarke, T.G.R. A Novel RFID-Based Strain Sensor for Wireless Structural Health Monitoring. J. Nondestruct. Eval. 2018, 37, 22. [Google Scholar] [CrossRef]

- Xue, S.; Xu, K.; Xie, L.; Wan, G. Crack sensor based on patch antenna fed by capacitive microstrip lines. Smart Mater. Struct. 2019, 28, 085012. [Google Scholar] [CrossRef]

- Xue, S.; Yi, Z.; Xie, L.; Wan, G.; Ding, T. A passive wireless crack sensor based on patch antenna with overlapping sub-patch. Sensors 2019, 19, 4327. [Google Scholar] [CrossRef] [Green Version]

- Guan, S.; Xie, L.; Xue, S.; Wan, G. Displacement Sensor Based on Separated Inverted-F Antenna. In Proceedings of the 2019 IEEE International Conference on Computational Electromagnetics, Shanghai, China, 20–22 March 2019. [Google Scholar]

- Soras, C.; Karaboikis, M.; Tsachtsiris, G.; Makios, V. Analysis and Design of an Inverted-F Antenna Printed on a PCMCIA Card for the 2.4 GHz ISM Band. IEEE Antennas Propag. Mag. 2002, 44, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Vandenbosch, G.A.E.; van de Capelle, A.R. Study of the Capacitively Fed Microstrip Antenna Element. IEEE Trans. Antennas Propag. 1994, 42, 1648–1652. [Google Scholar] [CrossRef]

- Rowell, C.R.; Murch, R.D. A capacitively loaded PIFA for compact mobile telephone handsets. IEEE Trans. Antennas Propag. 2002, 45, 837–842. [Google Scholar] [CrossRef]

- Su, C.-M.; Wong, K.-L.; Chen, W.-S.; Cheng, Y.-T. A microstrip-coupled printed inverted-f monopole antenna. Microw. Opt. Technol. Lett. 2004, 43, 470–472. [Google Scholar] [CrossRef]

- Hui, P. Design of integrated inverted F antennas made of asymmetrical coplanar striplines. Appl. Microw. Wirel. 2002, 14, 28–37. [Google Scholar]

- Esselle, K.; Ge, Y. Small multiband printed monopole antennas. In Printed Antennas for Wireless Communications, 1st ed.; Waterhouse, R., Ed.; John Wiley & Sons, Ltd.: West Sussex, UK, 2007; pp. 257–279. [Google Scholar]

- Zhuoran, Y.; Songtao, X.; Liyu, X.; Wan, G.C. Design and Numerical Simulation of Displacement Sensor Based on Liquid Antenna. In Proceedings of the 2019 IEEE International Conference on Computational Electromagnetics, Shanghai, China, 20–22 March 2019. [Google Scholar]

- Ozbey, B.; Unal, E.; Ertugrul, H.; Kurc, O.; Puttlitz, C.M.; Erturk, V.B.; Altintas, A.; Demir, H.V. Wireless displacement sensing enabled by metamaterial probes for remote structural health monitoring. Sensors 2014, 14, 1691–1704. [Google Scholar] [CrossRef] [Green Version]

- Mandel, C.; Kubina, B.; Schusler, M.; Jakoby, R. Passive chipless wireless sensor for two-dimensional displacement measurement. In Proceedings of the European Microwave Week 2011: “Wave to the Future”, EuMW 2011, Manchester, UK, 9–14 September 2011; pp. 79–82. [Google Scholar]

- Kuhn, M.F.; Breier, G.P.; Clarke, T.G.R. Passive Wireless Sensor for Displacement Monitoring in Metal Structures. IEEE Lat. Am. Trans. 2018, 16, 1353–1357. [Google Scholar] [CrossRef]

| H1 | W1 | H2 | W2 | H3 | W3 | H4 | L1 | L2 | Z | t | d1 | d2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 41.1 | 60 | 21.1 | 20 | 14.8 | 5 | 21.1 | 4.8 | 43.8 | 8.8 | 1 | 0.508 | 0.508 |

| Case | Group | Sensitivity (MHz/mm) | Measuring Range (mm) | Correlation Coefficient |

|---|---|---|---|---|

| Simulation | / | 10.8 | 30 | 0.9966 |

| Experiment | Group1 | 8.8 | 30 | 0.9938 |

| Group2 | 7.5 | 30 | 0.9931 |

| Sensor type | Sensitivity (MHz/mm) | Measuring Range (mm) | Application Scenarios | Reference |

|---|---|---|---|---|

| Displacement meters based on chipped circular patch antenna | 0.28 | 270 | Long-range displacement | [23] |

| Helical antenna | 0.616 | 7 | Built-in | [27] |

| Patch antenna fed by capacitive microstrip lines | 146.8 | 1 | Crack propagation | [33] |

| Patch antenna with overlapping sub-patch | 120.24 | 1.5 | Crack propagation | [34] |

| Liquid antenna | 31.25 | 4 | Liquid surface displacement | [42] |

| Metamaterial-based sensor | 4.48~12.7 | 20 | Displacement | [43] |

| Sensor with complementary split-ring resonators | 50~110 | 4 | Two-dimensional displacement | [44] |

| Deformation sensor based on an inverted-F antenna | 0.7 | 0.2 | Metal surface displacement | [45] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, S.; Zheng, Z.; Guan, S.; Xie, L.; Wan, G.; Wan, C. A Capacitively-Fed Inverted-F Antenna for Displacement Detection in Structural Health Monitoring. Sensors 2020, 20, 5310. https://doi.org/10.3390/s20185310

Xue S, Zheng Z, Guan S, Xie L, Wan G, Wan C. A Capacitively-Fed Inverted-F Antenna for Displacement Detection in Structural Health Monitoring. Sensors. 2020; 20(18):5310. https://doi.org/10.3390/s20185310

Chicago/Turabian StyleXue, Songtao, Zhiquan Zheng, Shuai Guan, Liyu Xie, Guochun Wan, and Chunfeng Wan. 2020. "A Capacitively-Fed Inverted-F Antenna for Displacement Detection in Structural Health Monitoring" Sensors 20, no. 18: 5310. https://doi.org/10.3390/s20185310