Performance of Rayleigh-Based Distributed Optical Fiber Sensors Bonded to Reinforcing Bars in Bending

Abstract

:1. Introduction

1.1. Distributed Optical Fiber Sensors (DOFS) as a Tool for Structural Health Monitoring (SHM)

1.2. Strains Reading Anomalies (SRAs)

- their sheer size

- the large difference with the previous readings despite the load difference between the two being almost negligible

- the occurrence of large compressive peaks in a homogenously tense area of the structure

2. Experimental Investigation of the Strain-Reading Anomalies

2.1. Test Motivation and Setup

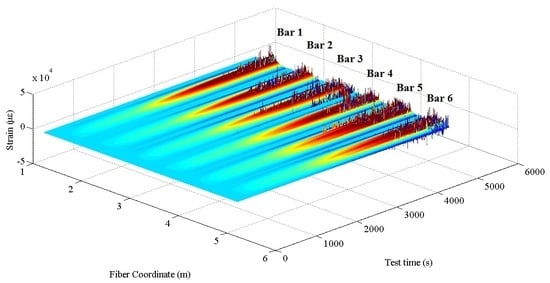

2.2. Test Procedure and Outputs

- the specimen’s rebars were not exactly on the same plane due to slight deformations occurring during the welding process. As a result, the applied load, herein defined as global load, is not evenly distributed among the rebars. Automatically some of them suffer more strains than others.

- As a consequence of the point above, the bars suffering larger strains are the ones reaching first the yielding stress. In that instance, only some bars have yielded while the others have not. Later in the test, with the increase of the global load, every bar eventually reaches its yielding point.

- Bar 1 behaves differently than the other six. Indeed, notwithstanding the other rebars do not precisely behave as end-fixed beams, as seen later, their behavior gets rather close. On the other hand, Bar 1 seems to have hardly any stiffness at its extremities and, because of such, does not seem to participate to the structure’s rigidity.

3. Discussion of the Results Regarding SRAs

3.1. Analytical Definition of an SRA

- Uj(v) the baseline spectrum for a given segment of data

- Uj(v − ∆vj) the measurement spectrum under a strain or temperature change

- * the symbol is used to represent the cross-correlation operator

3.2. SRAs Mechanics

- The strain profiles until point B and measured strains lower than 4000 με are clear and SRA-free.

- All segments of the DOFS have successfully recorded both impact loads demonstrating their ability to correctly withstand and record a sudden stress growth of 1.6 MPa and 16.0 MPa, as designed by (DM-SB2).

- The strain profiles do not report a change of linearity beyond the steel yielding strain, occurring in the mid-span, as it would be expected. εs,y for an S500 steel corresponds to 2500 με (reached at around 2800 s according to the above Figure 12, point A). This agrees with Figure 3 which also does not seem to report any curvature at around 2800 s.

- The strain profiles report correctly and precisely the variation of loading speed, both before and after the yielding of the steel rebars.

- The strain profiles correspond well with the applied load despite them being slightly offset compared to one another. The reason behind it is the difference among the heights of the bars when the specimen is unloaded and the consequent uneven distribution of the global load among them.

- Except for a few DOFS coordinates, the SRAs start beyond the specimen’s plasticity point reached around 3800 s.

- SRAs are often concentrated in specific areas where all neighboring sections give evidence of anomalistic behavior. Such areas can be defined as Anomalistic areas.

- Averagely SRAs seem to spring up from the mid-span of the rebars first which, not coincidentally, are the most stressed points of the seven rebars. The anomalies later spread outwards towards the neighboring section (clear in Bars 2, 3, 6) forming an anomalistic area.

- In Bars 4, 5, 6, the SRAs also rise in the incised sections concurrently or soon after having appeared in the mid-span (particularly evident in Bar 5). This further confirms the hypothesis of SRAs springing up from highly stressed rebar sections.

- HF-SRAs are usually proceeded by HL-SRAs.

- In some rebars HL-SRAs seem to start slightly before the specimen’s plasticity point while all HF-SRAs after that. In particular, Bar 3 starts having HL-SRAs as soon as 3000 s at DOFS coordinate 2.97 m.

- In some cases, a DOFS coordinate can be characterized strictly by HL-SRAs, always guaranteeing intervals of strain readability such as DOFS coordinate 4.16 m in bonded to Bar 4.

3.3. Adhesives Performance

- All three strain graphs are in very good agreement in their linear sections and in the mid-span.

- Bar 5 and Bar 6 are in excellent agreement on the strain distribution around Block 2, slightly less but still reasonably around Block 1 and differently in Block 3.

- Around Block 3 similar strain values are reported by Bar 4 and Bar 6 (despite their curve profile is not matching). Both include silicone while Bar 5, the only bar providing a different strain value, includes cyanoacrylate.

- Bar 5 and Bar 6, despite providing different strain values, have a similar curve profile especially around Block 3 where a “strain bump” is present. Differently, on the left side of the graph, Bar 4’s profile is almost linear.

4. Conclusions

- (DM-SB1) The surpassing of a Strain Anomaly Threshold (AST) beyond which the constitutive material of the fiber cannot bear any more stresses without showing anomalies in the readings. On the other hand, it also possible that, when the fibers are already under stress, they may display a high sensibility to variations in the mechanical behavior of its support that could lead up to SRAs.

- (DM-SB2) The present test was designed in such a way that only minor impact loads could be applied. Therefore, to correctly simulate the peaking of stresses that rebars experience whenever a crack opens in a RC member, further experimentation is required with higher impact loads or actual cracking concrete.

- (DM-AD1) The absence of concrete in the test prevented from checking the role that the friction of cracking concrete against the DOFS has in the rise of SRAs.

- The SRAs tend to rise in multiple neighboring DOFS coordinates forming Anomalistic areas.

- The anomalistic areas focus around sections of the rebar that are heavily stressed or that present a high strain gradient (such as the mid-span and the incised sections).

- The SRAs can be distinguished between Harmless SRAs (HL-SRAs) and Harmful SRAs (HM-SRAs) of which only the latter represents a serious threat for the investigators. Indeed, in the case of the first type of anomalies, following some anomalistic measurements are still multiple reliable ones making the HL-SRAs more of a nuisance than limit.

- Even though some HL-SRAs seem to appear earlier, most SRAs and all the HF-SRAs occur beyond a specific moment in the test which sees simultaneously the reaching of the strain value of roughly 4000 με (possible AST) in all the bars of the specimen and the yielding of the fixed ends of the bars causing a variation in the specimen’s load-deformation behavior. Only one or both these elements seem to have triggered the rise of SRAs.

- Different adhesives for the bonding of the fiber to the structural element were studied to evaluate their performance during the test. In particular, the adhesives used were cyanoacrylate, silicone and a combination of the two. The outcome of the test sees silicone to be the most resistant adhesive therefore ensuring a delayed appearance if SRAs and in smaller number to the expense of the precision of the strain measurements. Oppositely, the rigid but fragile nature of the cyanoacrylate provides the results with highest precision to the expense of resistance and endurance. In fact, the SRAs seem to spring up earlier and in bigger quantity in the latter. Meanwhile the combination of the two gives birth to a hybrid behavior. Regarding the adhesives, it was concluded that there was not a particularly better one, but it was rather a function of the objectives of the researcher.

Author Contributions

Funding

Conflicts of Interest

References

- Barrias, A.; Casas, J.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Glišić, B.; Hubbell, D.; Sigurdardottir, D.H.; Yao, Y. Damage detection and characterization using long-gauge and distributed fiber optic sensors. Opt. Eng. 2013, 52, 087101. [Google Scholar] [CrossRef]

- Ferdinand, P. The Evolution of Optical Fiber Sensors Technologies During the 35 Last Years and Their Applications in Structure Health Monitoring. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014. [Google Scholar]

- di Sante, R. Fibre Optic Sensors for Structural Health Monitoring of Aircraft Composite Structures: Recent Advances and Applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, J.; Yang, J.; Wang, Y.; Waisman, H.; Zhang, W. Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method. Sensors 2016, 16, 1956. [Google Scholar] [CrossRef] [PubMed]

- Deif, A.; Martín-Pérez, B.; Cousin, B.; Zhang, C.; Bao, X.; Li, W. Detection of cracks in a reinforced concrete beam using distributed Brillouin fibre sensors. Smart Mater. Struct. 2010, 19, 055014. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.; Villalba, S. Embedded Distributed Optical Fiber Sensors in Reinforced Concrete Structures—A Case Study. Sensors 2018, 18, 980. [Google Scholar] [CrossRef] [PubMed]

- Bao, X.; Chen, L. Recent Progress in Distributed Fiber Optic Sensors. Sensors 2012, 12, 8601–8639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cantarero, A. Raman Scattering Applied to Materials Science. Procedia Mater. Sci. 2015, 9, 113–122. [Google Scholar] [CrossRef]

- Gillibert, R.; Huang, J.Q.; Zhang, Y.; Fu, W.L.; de la Chapelle, M.L. Food quality control by Surface Enhanced Raman Scattering. TrAC Trends Anal. Chem. 2018, 105, 185–190. [Google Scholar] [CrossRef]

- Gillibert, R.; Huang, J.Q.; Zhang, Y.; Fu, W.L.; de la Chapelle, M.L. Explosive detection by Surface Enhanced Raman Scattering. TrAC Trends Anal. Chem. 2018, 105, 166–172. [Google Scholar] [CrossRef]

- Yoon, H.J.; Song, K.Y.; Kim, H.M.; Kim, J.S. Strain monitoring of composite steel girder bridge using distributed optical fibre sensor system. Procedia Eng. 2011, 10, 2544–2547. [Google Scholar] [CrossRef]

- Zeni, L.; Picarelli, L.; Avolio, B.; Coscetta, A.; Papa, P.; Zeni, G.; Di Maio, C.; Vassallo, R.; Minardo, A. Brillouin optical time-domain analysis for geotechnical monitoring. J. Rock Mech. Geotech. Eng. 2015, 7, 458–462. [Google Scholar] [CrossRef]

- Hong, C.Y.; Zhang, Y.F.; Li, G.W.; Zhang, M.X.; Liu, Z.X. Recent progress of using Brillouin distributed fiber optic sensors for geotechnical health monitoring. Sens. Actuators A Phys. 2017, 258, 131–145. [Google Scholar] [CrossRef]

- Villalba, S.; Casas, J.R. Application of optical fiber distributed sensing to health monitoring of concrete structures. Mech. Syst. Signal Process. 2013, 39, 441–451. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.R.; Villalba, S. Application study of embedded Rayleigh based Distributed Optical Fiber Sensors in concrete beams. Procedia Eng. 2017, 199, 2014–2019. [Google Scholar] [CrossRef]

- Davis, M.; Hoult, N.A.; Scott, A. Distributed strain sensing to determine the impact of corrosion on bond performance in reinforced concrete. Constr. Build. Mater. 2016, 114, 481–491. [Google Scholar] [CrossRef]

- Davis, M.; Hoult, N.A.; Scott, A. Distributed strain sensing to assess corroded RC beams. Eng. Struct. 2017, 140, 473–482. [Google Scholar] [CrossRef]

- Measures, R.M. Structural Monitoring with Fibre Optic Technology. Meas. Sci. Technol. 2001, 12, 1609–1610. [Google Scholar] [CrossRef]

- Andre, B.; Sara, N.; Hoult, N.A. Distributed Deflection Measurement of Reinforced Concrete Elements Using Fibre Optic Sensors. In Proceedings of the International Association for Bridge and Structural Engineering (IABSE) Symposium, Vancouver, BC, Canada, 19–23 September 2017; pp. 1469–1477. [Google Scholar]

- Ding, Z.; Wang, C.; Liu, K.; Jiang, J.; Yang, D.; Pan, G.; Pu, Z.; Liu, T. Distributed Optical Fiber Sensors Based on Optical Frequency Domain Reflectometry: A review. Sensors 2018, 18, 1072. [Google Scholar] [CrossRef] [PubMed]

- Kaklauskas, G. Crack Model for RC Members Based on Compatibility of Stress-Transfer and Mean-Strain Approaches. J. Struct. Eng. 2017, 143, 1–12. [Google Scholar] [CrossRef]

- ODiSI-A Optical Distributed Sensor Interrogator Users Guide. Available online: http://lunainc.com/wp-content/uploads/2014/05/ODiSI-A-Users-Guidev1.2.pdf (accessed on 30 July 2018).

- Barrias, A.; Casas, J.R.; Villalba, S. On the bonding performance of distributed optical fiber sensors (DOFS) in structural concrete. In Proceedings of the Sixth International Symposium on Life-Cycle Civil Engineering (IALCCE’18), Ghent, Belgium, 28–31 October 2018. accepted. [Google Scholar]

| Bars | First DOFS Coordinate Bonded to the Bar (m) | DOFS Coordinate of the Load Application Point of Each Bar (m) | Last DOFS Coordinate Bonded to the Bar (m) |

|---|---|---|---|

| 1 | 1.36 | 1.57 | 1.85 |

| 2 | 1.99 | 2.28 | 2.56 |

| 3 | 2.67 | 2.96 | 3.24 |

| 4 | 3.37 | 3.63 | 3.88 |

| 5 | 4.00 | 4.28 | 4.57 |

| 6 | 4.65 | 4.94 | 5.21 |

| Strain Level (με) | Total Number of Strain Readings | Total Number of SRA-Free Strain Readings | Percentage of Readings with SRAs |  |

| 500 | 169,070 | 151,913 | 10.15% | |

| 1000 | 131,553 | 114,411 | 13.03% | |

| 1500 | 108,452 | 91,361 | 15.76% | |

| 1750 | 98,605 | 81,560 | 17.29% | |

| 2000 | 89,367 | 72,389 | 20.22% | |

| 2250 | 81,819 | 64,878 | 21.95% | |

| 2500 | 74,560 | 57,675 | 23.90% | |

| 2750 | 67,725 | 50,906 | 26.08% | |

| 3000 | 60,820 | 44,047 | 28.78% | |

| 3250 | 55,015 | 38,262 | 31.52% | |

| 3500 | 49,346 | 32,631 | 34.75% | |

| 3750 | 43,330 | 26,748 | 38.82% | |

| 4000 | 38,731 | 22,259 | 42.71% | |

| 4250 | 33,891 | 17,609 | 47.68% | |

| 4500 | 29,560 | 13,496 | 53.23% | |

| 4750 | 27,523 | 11,698 | 55.93% | |

| 5000 | 26,156 | 10,557 | 57.73% | |

| 5250 | 25,210 | 9697 | 59.31% | |

| 5500 | 24,303 | 8899 | 60.85% | |

| 5750 | 23,965 | 8622 | 61.37% | |

| 6000 | 23,639 | 8375 | 61.87% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bado, M.F.; Casas, J.R.; Barrias, A. Performance of Rayleigh-Based Distributed Optical Fiber Sensors Bonded to Reinforcing Bars in Bending. Sensors 2018, 18, 3125. https://doi.org/10.3390/s18093125

Bado MF, Casas JR, Barrias A. Performance of Rayleigh-Based Distributed Optical Fiber Sensors Bonded to Reinforcing Bars in Bending. Sensors. 2018; 18(9):3125. https://doi.org/10.3390/s18093125

Chicago/Turabian StyleBado, Mattia Francesco, Joan Ramon Casas, and António Barrias. 2018. "Performance of Rayleigh-Based Distributed Optical Fiber Sensors Bonded to Reinforcing Bars in Bending" Sensors 18, no. 9: 3125. https://doi.org/10.3390/s18093125