Thermomechanical Noise Characterization in Fully Monolithic CMOS-MEMS Resonators

Abstract

:1. Introduction

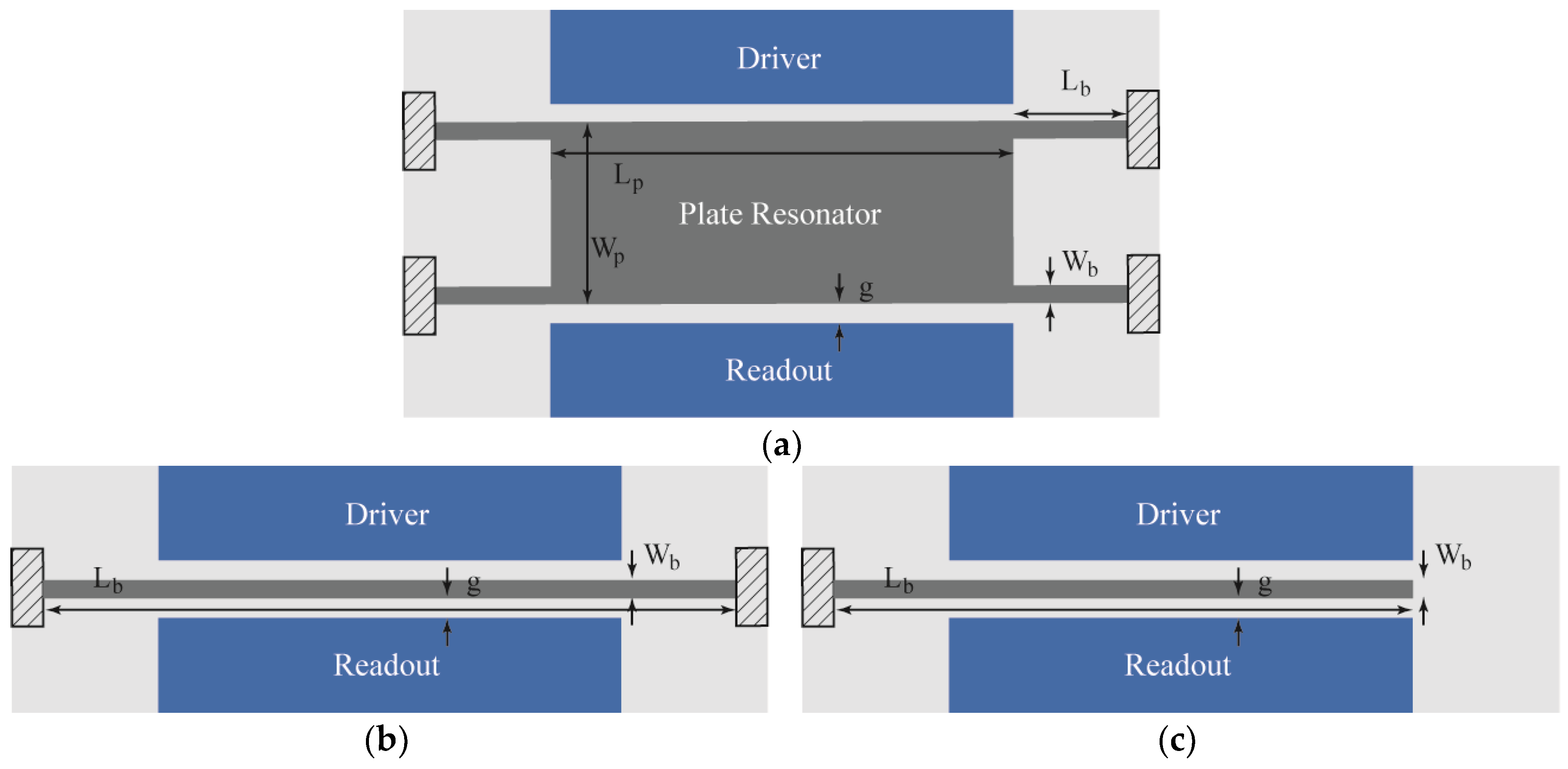

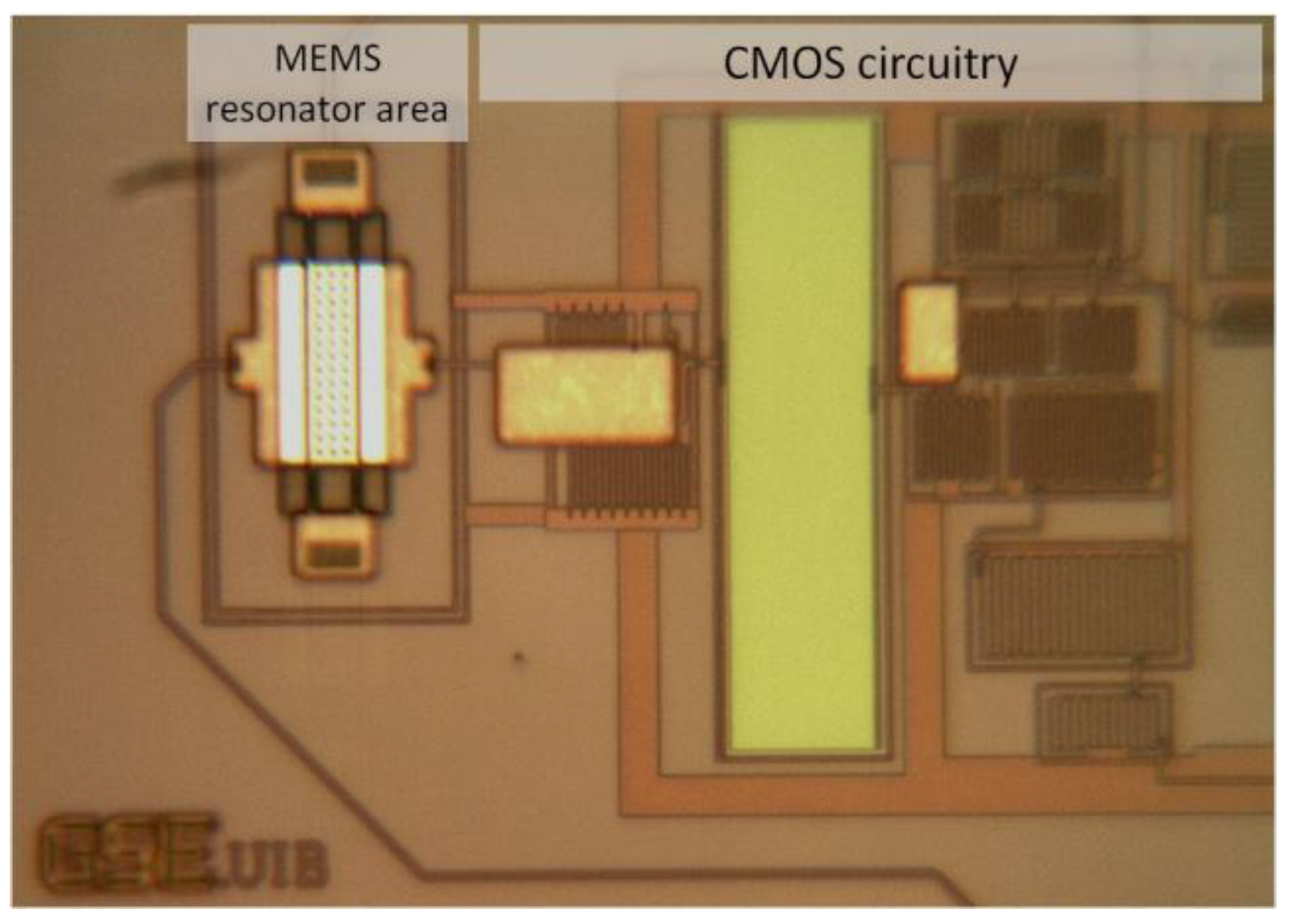

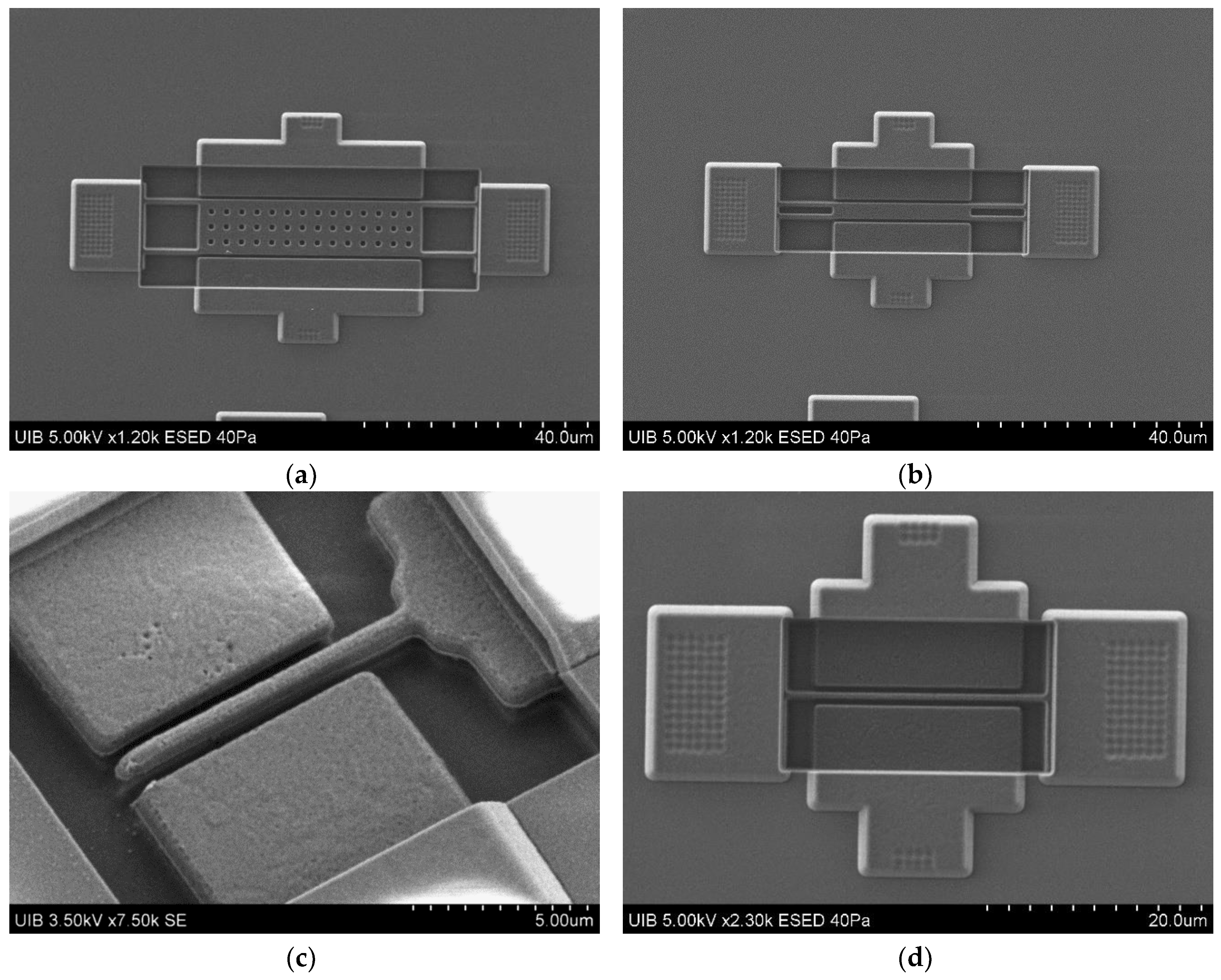

2. Fabrication and Experimental Setup

2.1. Fabrication

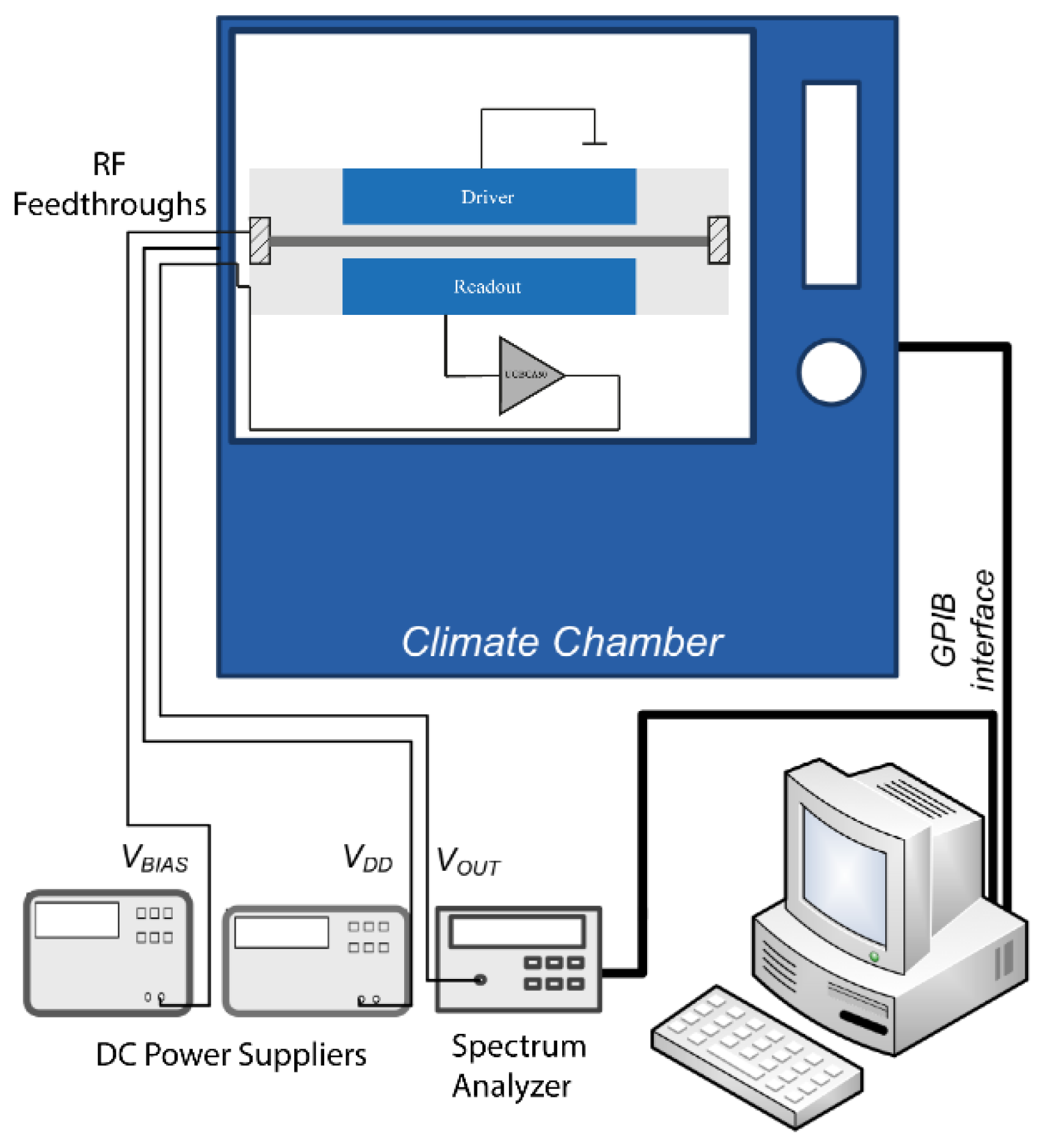

2.2. Experimental Setup

3. Noise Sources Model

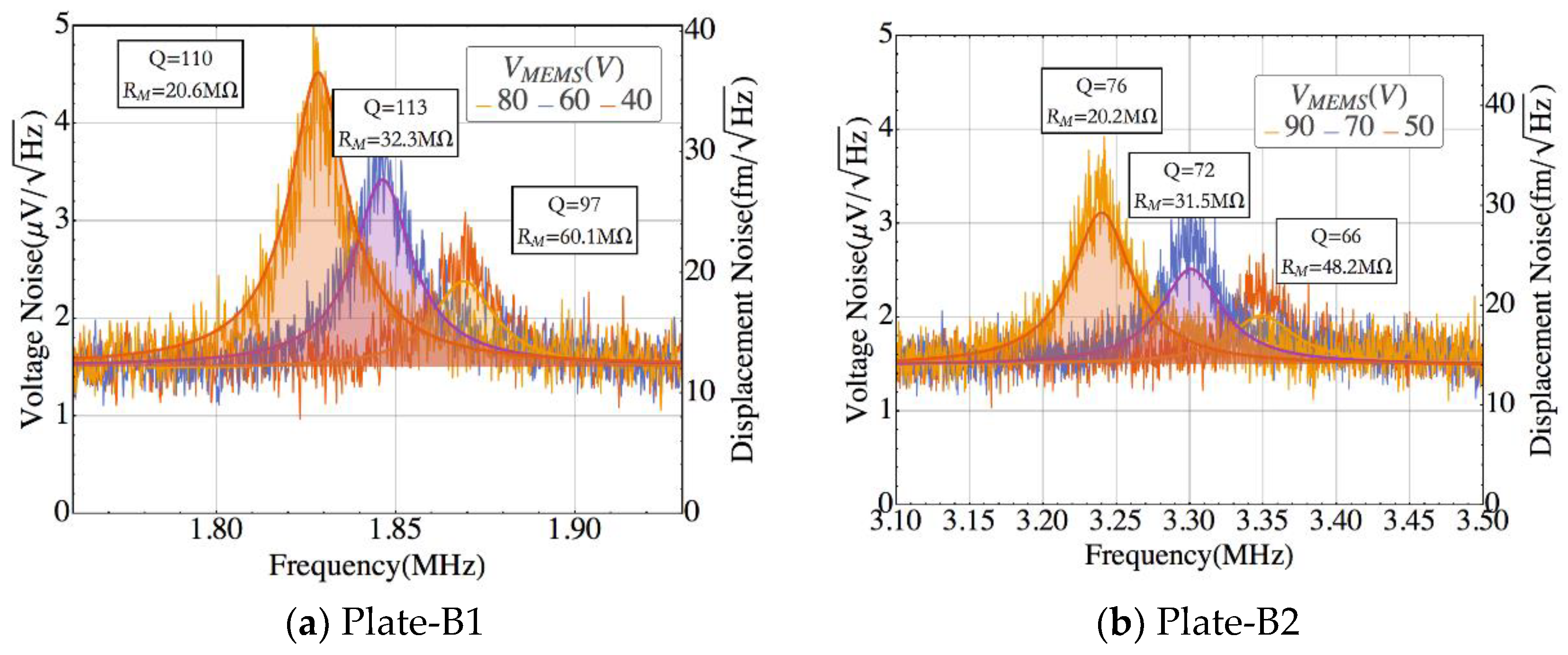

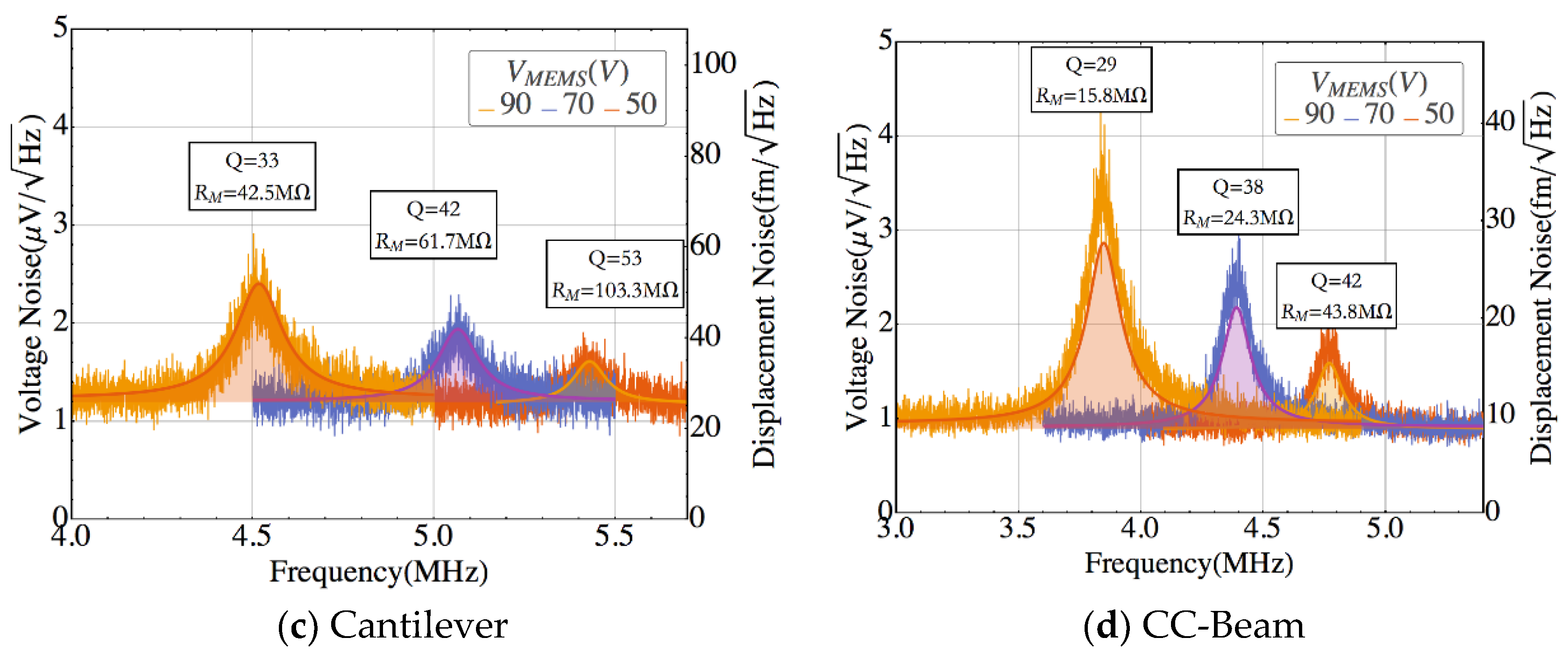

4. Results

Ultimate Resolution Limit

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Urasinska-Wojcik, B.; Vincent, T.A.; Chowdhury, M.F.; Gardner, J.W. Ultrasensitive WO3 gas sensors for NO2 detection in air and low oxygen environment. Sens. Actuators B Chem. 2017, 239, 1051–1059. [Google Scholar] [CrossRef]

- Kilinc, N.; Cakmak, O.; Kosemen, A.; Ermek, E.; Ozturk, S.; Yerli, Y.; Ozturk, Z.Z.; Urey, H. Fabrication of 1D ZnO nanostructures on MEMS cantilever for VOC sensor application. Sens. Actuators B Chem. 2014, 202, 357–364. [Google Scholar] [CrossRef]

- Verd, J.; Uranga, A.; Abadal, G.; Teva, J.L.; Torres, F.; López, J.; PÉrez-Murano, F.; Esteve, J.; Barinol, N. Monolithic CMOS MEMS oscillator circuit for sensing in the attogram range. IEEE Electron Device Lett. 2008, 29, 146–148. [Google Scholar] [CrossRef]

- Chaste, J.; Eichler, A.; Moser, J.; Ceballos, G.; Rurali, R.; Bachtold, A. A nanomechanical mass sensor with yoctogram resolution. Nat. Nanotechnol. 2012, 7, 301–304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cleland, A.N.; Roukes, M.L. Noise processes in nanomechanical resonators. J. Appl. Phys. 2002, 92, 2758–2769. [Google Scholar] [CrossRef] [Green Version]

- Ekinci, K.L.; Yang, Y.T.; Roukes, M.L. Ultimate limits to inertial mass sensing based upon nanoelectromechanical systems. J. Appl. Phys. 2004, 95, 2682–2689. [Google Scholar] [CrossRef]

- Kouh, T.; Hanay, M.S.; Ekinci, K.L. Nanomechanical motion transducers for miniaturized mechanical systems. Micromachines 2017, 8, 1–27. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, J.; Wang, X.; Xia, G.M.; Qiu, A.P.; Su, Y.; Xu, Y.P. A sub-ug bias-instability MEMS oscillating accelerometer with an ultra-low-noise read-out circuit in CMOS. IEEE J. Solid State Circuits 2015, 50, 2113–2126. [Google Scholar] [CrossRef]

- Arcamone, J.; Misischi, B.; Brugger, J.; Torres, F.; Abadal, G.; Barniol, N. A compact and low-power CMOS circuit for fully integrated NEMS resonators. IEEE Trans. Circuits Syst. II Express Briefs 2007, 54, 377–381. [Google Scholar] [CrossRef]

- Colinet, E.; Durand, C.; Duraffourg, L.; Audebert, P.; Dumas, G.; Casset, F.; Ollier, E.; Ancey, P.; Carpentier, J.F.; Buchaillot, L.; et al. Ultra-sensitive capacitive detection based on SGMOSFET compatible with front-end CMOS process. IEEE J. Solid State Circuits 2009, 44, 247–257. [Google Scholar] [CrossRef]

- Tan, S.S.; Liu, C.Y.; Yeh, L.K.; Chiu, Y.H.; Lu, M.S.C.; Hsu, K.Y.J. An integrated low-noise sensing circuit with efficient bias stabilization for CMOS MEMS capacitive accelerometers. IEEE Trans. Circuits Syst. I Regul. Pap. 2011, 58, 2661–2672. [Google Scholar] [CrossRef]

- Li, M.; Tang, H.X.; Roukes, M.L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2007, 2, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Mile, E.; Jourdan, G.; Bargatin, I.; Labarthe, S.; Marcoux, C.; Andreucci, P.; Hentz, S.; Kharrat, C.; Colinet, E.; Duraffourg, L. In-plane nanoelectromechanical resonators based on silicon nanowire piezoresistive detection. Nanotechnology 2010, 21, 165504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ding, L.; Baker, C.; Senellart, P.; Lemaitre, A.; Ducci, S.; Leo, G.; Favero, I. High frequency GaAs nano-optomechanical disk resonator. Phys. Rev. Lett. 2010, 105, 263903. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhao, X.; Wang, Y.; Huang, Q.; Xia, J. Femtogram scale high frequency nano-optomechanical resonators in water. Opt. Express 2017, 25, 821–830. [Google Scholar] [CrossRef] [PubMed]

- Houmadi, S.; Legrand, B.; Salvetat, J.P.; Walter, B.; Mairiaux, E.; Aime, J.P.; Ducatteau, D.; Merzeau, P.; Buisson, L.; Elezgaray, J.; et al. When capacitive transduction meets the thermomechanical limit: Towards femto-newton force sensors at very high frequency. In Proceedings of the 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 150–153. [Google Scholar]

- Weber, P.; Güttinger, J.; Noury, A.; Vergara-Cruz, J.; Bachtold, A. Force sensitivity of multilayer graphene optomechanical devices. Nat. Commun. 2016, 7, 12496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verd, J.; Uranga, A.; Teva, J.; López, J.; Torres, F.; Esteve, J.; Abadal, G.; Perez-Murano, F.; Barinol, N. Integrated CMOS MEMS with on-chip readout electronics for high-frequency applications. IEEE Electron Device Lett. 2006, 27, 495–597. [Google Scholar] [CrossRef]

- Verd, J.; Uranga, A.; Abadal, G.; Teva, J.; Torres, F.; Pérez-Murano, F.; Fraxedas, J.; Esteve, J.; Barinol, N. Monolithic mass sensor fabricated using a conventional technology with attogram resolution in air conditions. Appl. Phys. Lett. 2007, 91, 013501. [Google Scholar] [CrossRef] [Green Version]

- Verd, J.; Sansa, M.; Uranga, A.; Perez-Murano, F.; Segura, J.; Barniol, N. Metal microelectromechanical oscillator exhibiting ultra-high water vapor resolution. Lab Chip 2011, 11, 2670–2672. [Google Scholar] [CrossRef] [PubMed]

- Verd, J.; Perello-Roig, R.; Bota, S.; Barceló, J.; Segura, J. Monolithic CMOS-MEMS capacitive plate resonator as a low-cost platform for high-resolution distributed mass detection. In Proceedings of the XXXI Design Circuits and Integrated Systems Conference, Granada, Spain, 23–25 November 2016. [Google Scholar]

- Do, C.; Erbes, A.; Yan, J.; Seshia, A.A. Design and implementation of a low-power hybrid capacitive MEMS oscillator. Microelectron. J. 2016, 56, 1–9. [Google Scholar] [CrossRef]

- Lübbe, J.; Temmen, M.; Rode, S.; Rahe, P.; Kühnle, A.; Reichling, M. Thermal noise limit for ultra-high vacuum noncontact atomic force microscopy. Beilstein J. Nanotechnol. 2013, 4, 32–44. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Imboden, M.; Mohanty, P. Dissipation in nanoelectromechanical systems. Phys. Rep. 2014, 534, 89–146. [Google Scholar] [CrossRef]

- Olcum, S.; Cermak, N.; Wasserman, S.C.; Payer, C.; Shen, W.; Lee, J.; Manalis, S.R. Suspended nanochannel resonators at attogram precission. In Proceedings of the IEEE 27th International Conference on Micro Electro. Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014. [Google Scholar]

| Structure | Lb(μm) | Wb(μm) | Lp(μm) | Wp(μm) |

|---|---|---|---|---|

| Plate-B1 | 10 | 0.8 | 41 | 10 |

| Plate-B2 | 10 | 0.8 | 25 | 3.0 |

| Cantilever | 10 | 0.6 | - | - |

| CC-Beam | 25 | 0.6 | - | - |

| Structure | Meff (pg) | K (Nm−1) | RM (MΩ) | F (MHz) | Q | |

|---|---|---|---|---|---|---|

| Plate-B1 | 967 | 57.0 | 4.28·10−8 | 65.3 | 1.86 | 97 |

| 10.4 * | 1.87 * | 610 * | ||||

| Plate-B2 | 199 | 57.0 | 2.61·10−8 | 68.7 | 3.35 | 66 |

| 11.1 * | 3.36 * | 446 * | ||||

| Cantilever | 9.90 | 16.0 | 0.836·10−8 | 107.4 | 5.43 | 53 |

| 23.9 * | 5.21 * | 238 * | ||||

| CC-Beam | 29.3 | 49.3 | 2.01·10−8 | 71.5 | 4.78 | 42 |

| 5.53 * | 5.12 * | 543 * |

| Structure | ||||

|---|---|---|---|---|

| Plate-B1 | 0.053 | 154 | 65.3 | 60.1 |

| Plate-B2 | 0.045 | 92.5 | 68.7 | 48.2 |

| Cantilever | 0.070 | 90.4 | 107.4 | 103.3 |

| CC-Beam | 0.054 | 61.3 | 71.5 | 43.8 |

| Reference | Detection/SoC | (V·HZ−1/2) | (m·HZ−1/2) | (Vm−1) | (m·Hz−1/2) | (FHZ−1/2) | |

|---|---|---|---|---|---|---|---|

| B1 * | Capacitive/Monolithic | 1.85 MHz | 1.6 × 10−6 | 3.4 × 10−14 | 1.2 × 108 | 1.3 × 10−14 | 1.1 × 10−23 |

| 8.0 × 10−14 | 1.9 × 108 | 8.5 × 10−15 | 7.3 × 10−24 | ||||

| B2 * | Capacitive/Monolithic | 3.30 MHz | 1.5 × 10−6 | 2.4 × 10−14 | 1.1 × 108 | 1.4 × 10−14 | 7.4 × 10−24 |

| 6.1 × 10−14 | 1.8 × 108 | 8.3 × 10−15 | 4.3 × 10−24 | ||||

| Cantilever * | Capacitive/Monolithic | 5.00 MHz | 1.2 × 10−6 | 4.7 × 10−14 | 4.6 × 107 | 2.6 × 10−14 | 4.3 × 10−24 |

| 11 × 10−14 | 4.6 × 107 | 2.6 × 10−14 | 4.4 × 10−24 | ||||

| CC-Beam * | Capacitive/Monolithic | 4.50 MHz | 1.0 × 10−6 | 2.9 × 10−14 | 1.0 × 108 | 9.7 × 10−15 | 4.0 × 10−24 |

| 9.5 × 10−14 | 2.1 × 108 | 4.8 × 10−15 | 2.0 × 10−24 | ||||

| [8] | Capacitive/NOT | 21 kHz | 3.0 × 10−7 | - | - | - | 2.7 × 10−21 |

| [9] | Capacitive/Monolithic | 1.5 MHz | 3.5 × 10−8 | - | - | 1.5 × 10−11 | 2.6 × 10−21 |

| [10] | Capacitive/Hybrid | 13 MHz | 5.0 × 10−7 | - | - | - | 1.3 × 10−19 |

| [11] | Capacitive/Monolithic | 5.3 kHz | 2.5 × 10−5 | - | - | - | 1.6 × 10−20 |

| [12] | Piezo/Monolithic | 126 MHz | 1.5 × 10−9 | - | 3.8 × 104 | 3.9 × 10−14 | - |

| [13] | Piezo/Hybrid | 19 MHz | 1.3 × 10−8 | - | 4.2 × 104 | 3.1 × 10−13 | - |

| [14] | Optical/NOT | 860 MHz | 1.1 × 10−6 | - | 5.6 × 1010 | 2.0 × 10−17 | - |

| [15] | Optical/NOT | 5.4 GHz | - | - | - | 1.1 × 10−17 | - |

| [16] | Optical/NOT | 13 MHz | 2.0 × 10−8 | - | 2.0 × 107 | 1.0 × 10−15 | - |

| [17] | MW Cavity/NOT | 54 MHz | - | - | - | 1.3 × 10−15 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perelló-Roig, R.; Verd, J.; Bota, S.; Segura, J. Thermomechanical Noise Characterization in Fully Monolithic CMOS-MEMS Resonators. Sensors 2018, 18, 3124. https://doi.org/10.3390/s18093124

Perelló-Roig R, Verd J, Bota S, Segura J. Thermomechanical Noise Characterization in Fully Monolithic CMOS-MEMS Resonators. Sensors. 2018; 18(9):3124. https://doi.org/10.3390/s18093124

Chicago/Turabian StylePerelló-Roig, Rafel, Jaume Verd, Sebastià Bota, and Jaume Segura. 2018. "Thermomechanical Noise Characterization in Fully Monolithic CMOS-MEMS Resonators" Sensors 18, no. 9: 3124. https://doi.org/10.3390/s18093124