1. Introduction

High-temperature sensing is in great demand in the aerospace and manufacturing industries. Real-time sensing and in situ temperature monitoring are critical in improving the working efficiency of devices and ensuring the safe operation of equipment. For example, the excessively high temperature of a furnace wall or pipe wall can lead to its deformation or bursting, which will reduce work efficiency and cause safety risks [

1,

2]. In a combustion chamber, the combustion temperature directly affects the engine’s working efficiency and output power [

3,

4]. When the blade of a turbine engine runs at a high speed, an increase in the surface temperature causes the blade to deform [

5,

6]. Therefore, the applications of high-temperature sensors that are stable and function in temperatures up to 1000 °C are extensive. Such sensors are required to be small, easy to manufacture, inexpensive, and highly reliable.

Microwave scattering sensing technology has become increasingly popular owing to its higher quality, lower environmental interference, and anti-low frequency interference compared to near-field coupled capacitive-inductive (LC) sensing technology and surface acoustic wave (SAW) sensing technology. For instance, Cheng et al. [

7] designed a microwave temperature sensor and tested it in temperatures from 50 to 1050 °C it showed a high sensitivity of 0.58 MHz/°C at 1050 °C. This sensor can be used as temperature sensor and antenna simultaneously and its characteristic of stability at high frequencies enables its survival in harsh environments. Xiong et al. [

6] reported a sensor with a center frequency of 2.4 GHz which can work in temperatures from 27 to 800 °C with a sensitivity of 0.19 MHz/°C. This sensor is based on a microwave dielectric resonator and experiments have proved that it can perform effective monitoring at high temperatures. The recently developed chipless radio frequency identification (RFID) technology is based on the microwave backscatter principle. The tags can transmit information about its current temperature back to the reader via wireless transmission. It is widely used in environment parameter sensing, as it can simultaneously identify targets and detect information about the target object. The tags do not need to be powered by a battery [

8], can be fabricated at a low cost, and have a long lifetime [

9]. For example, Herrojo et al. [

10] proposed a novel near-field chipless RFID system used for angular velocity measurements by operating in time domain and based on sequential bit reading. Vena et al. [

11] fabricated a low-cost wireless fully inkjet-printed chipless sensor on a flexible laminate for CO

2 detection. Temperature is a vital factor that must be monitored in harsh environments. Currently, there has been little research on high-temperature sensing using this method, hence the research of high-temperature sensors combined with chipless RFID technology is necessary and promising.

The potential applications of metamaterials have emerged because of their unique electromagnetic properties under the irradiation of electromagnetic waves at certain frequencies [

12]. These metamaterials are periodically arranged from subwavelength, high-conductivity metal structures and are fabricated on a dielectric substrate. One of the most fundamental periodical unit cells is a split-ring resonator (SRR) [

13]. Several studies have been reported that any geometric deviation caused by external strain applied to SRR devices and any sensitive materials attached to the devices’ surface result in a resonant frequency change of the resonator [

13,

14,

15]. SRR-based sensors have been applied to various situations, such as medical monitoring (i.e., glaucoma monitoring) [

13], strain measurement [

14], biological detection [

15], and early detection of breaches in pipeline coatings [

16]. The substrate dielectric constant also has an effect on the resonant frequency of SRR-based sensors. Our previous research has shown that it is reliable and feasible to directly measure the temperature dependence of the dielectric constant of the substrate material [

17,

18,

19]. Therefore, dielectric constant sensitive SRR-based sensors in combination with chipless RFID technology is predicted to be very suitable for microwave temperature sensing with advanced properties.

In this paper, we propose a novel approach for pushing the temperature limits of the devices by combining a metamaterial unit cell with high-temperature co-fired ceramic (HTCC) technology and chipless RFID technology. A thin-film sensor for high-temperature sensing based on the microwave backscattering principle has been fabricated. This sensor embeds two interleaved metallic rings with two opposite gaps on alumina ceramic, and is easily fabricated, has a flexible design, and has a high sensitivity. Experimental results show that the sensor can work up to 1100 °C with an average sensitivity of 95.63 kHz/°C around 2.42 GHz. The size of the SRR structure can be reduced to micro- and nanoscales, thus the miniaturization of these sensors can be achieved. In addition to measuring ultra-high temperatures in harsh environments, some temperature-sensitive nanomaterials can also be used to measure temperatures that are not so high. For example, graphene can be coated on the SRR structures for long-term passive temperature measurements around 150 °C. In this case, sensors can be printed on a flexible substrate with conductive ink, such as a paper and plastic film with a commercial desktop inkjet printer. This will allow SRR-based sensors further applicability to a variety of devices.

2. Materials and Methods

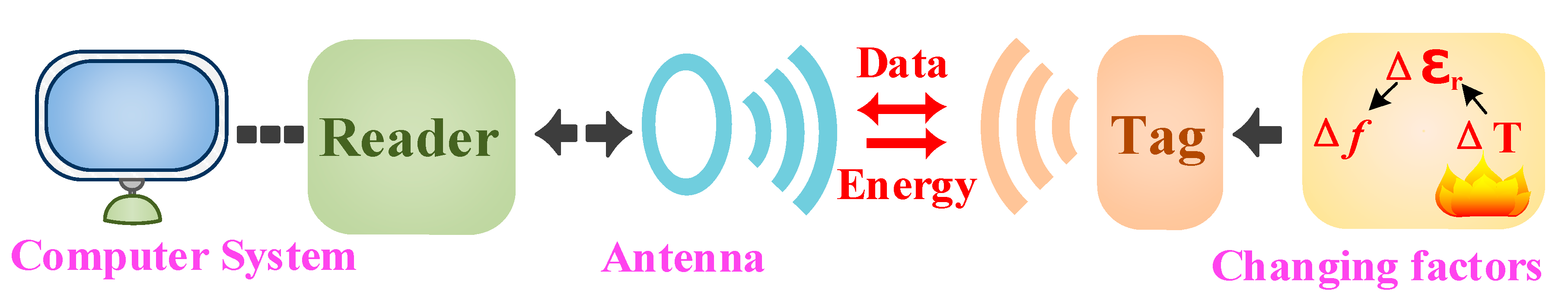

The principles of the chipless RFID system are shown in

Figure 1. The system consists of three parts: tag, reader, and a computer data processing system. The chipless RFID tag relies entirely on the conductor printed on the tag to store information and uses a type of frequency-domain coding. A reader antenna is used to receive or transmit electromagnetic waves. When the tag is irradiated by an electromagnetic wave, the tag can be coupled with the electromagnetic wave through its own structure characteristics, and then the structure characteristic information is returned to the reader. Each tag will reflect signals of different characteristics in a backscattering manner and the reader can recognize the target by interpreting the structural information of the tag. The computer data processing system then processes the return signals. In this study, we printed a SRR structure on an alumina ceramic substrate to form the sensing tag by using screen printing technology. When the temperature of the environment changes, the dielectric constant of the alumina ceramic changes accordingly, which causes a sensitive and strong change in the capacitance of the narrow gap in the SRR structures and between the rings, resulting in a change of the resonant frequency of the tag. By using computer data software to process the return signal, the temperature change can be analyzed, and hence temperature sensing is achieved.

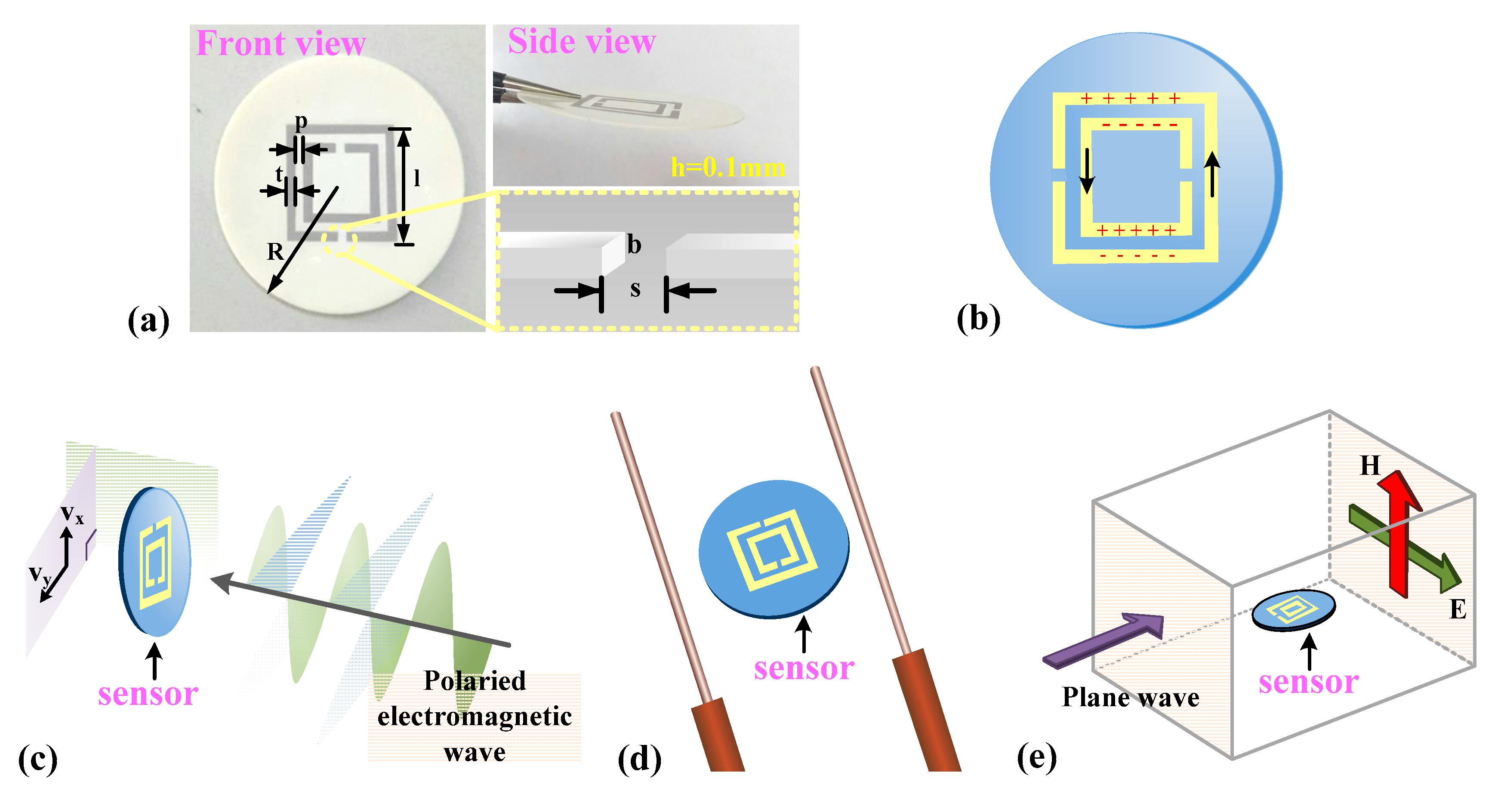

The sensor embeds two interleaved metallic rings with two opposite gaps on alumina ceramic. The whole structure acts as an LC oscillator [

20] in an external electromagnetic field causing sharp absorption of power corresponding to the resonance frequency.

Figure 2a shows the schematic diagram and equivalent circuit diagram of the sensor. The resonant frequency (

fs) is given as follows:

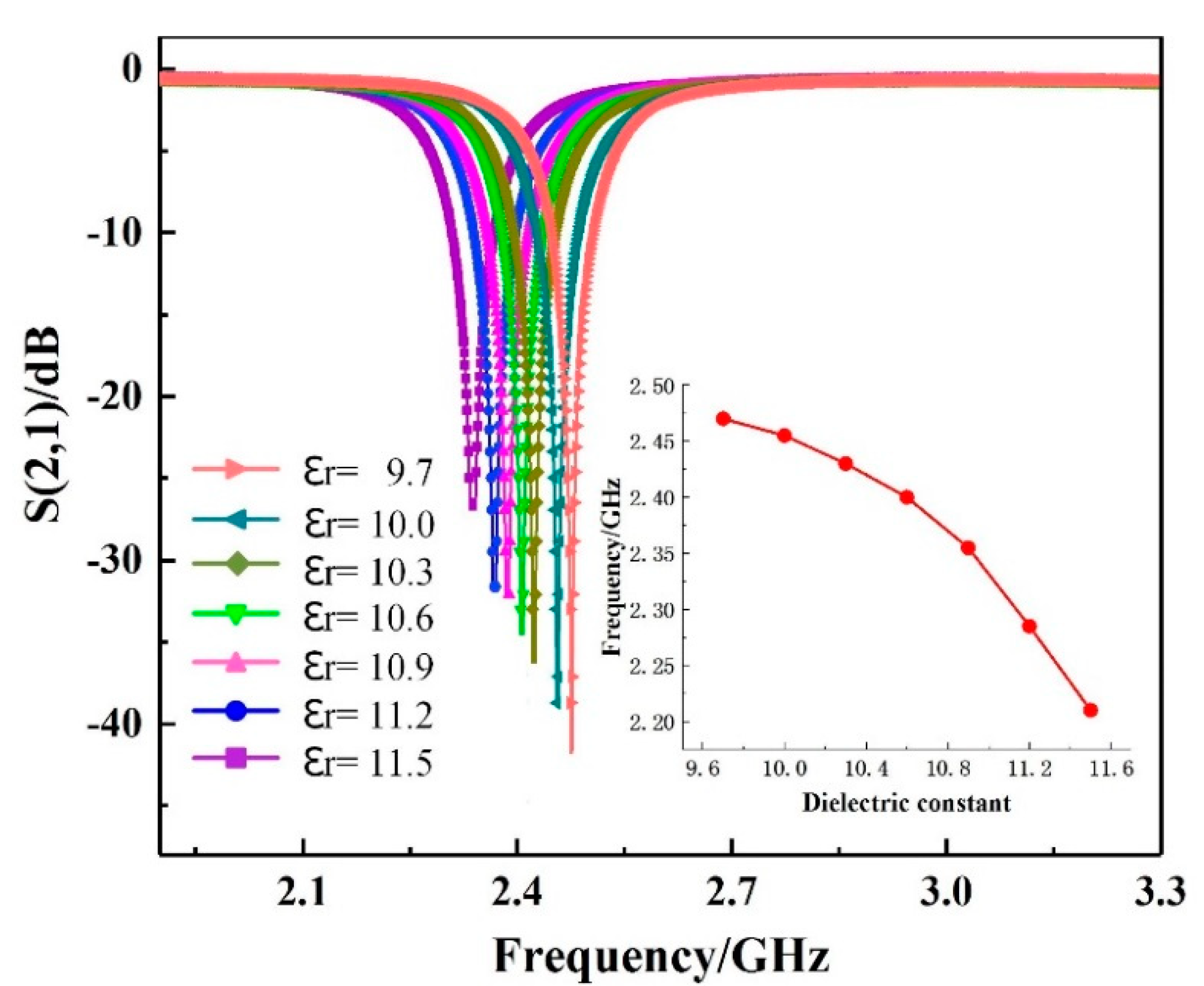

Therefore, we mainly consider the influence of the changes in capacitance (

Cs) and inductance (

Ls) on the resonant frequency (

fs). Ls related to the metal width t, the length of the outer ring sides

l, the space between the inner and outer rings p, and the relative permeability of the dielectric matrix

μr according to Reference [

21]. The capacitance (

Cs) consists of two parts, the capacitance between the two rings (inter-ring capacitance

Ci) and the gap capacitance (

Cg), thus the whole capacitance can be expressed as follows [

22]:

where

ε0 and

εr are the dielectric constant of vacuum and dielectric matrix, respectively, r

out and r

in represent the radius of the outer circumference and the inner circumference of the SRR, respectively, A is the cross-sectional area of the split of the metal ring. The relative dielectric constant (

εr) is usually defined as the ratio of the electric field in the absence of the dielectric (

ε0) to the actual field intensity in the dielectric (

Ee) and can be expressed in Equation (4). The sensor can be irradiated by time varying electromagnetic wave which was generated by poled horn antenna or polarized patch antenna. Another way is to use a pair of monopole antennae or place the sensor in a vacuum waveguide to realize sensing function. When using the second method, it is necessary to ensure that the direction of the electric field should be perpendicular to the symmetrical plane of the rings. This is because there is an electric dipole in the direction perpendicular to the symmetry plane (electric wall) of the particle at the first resonant frequency when the sensor is irradiated in an electromagnetic wave, the charge distribution in the metal rings is depicted in

Figure 2b. This simultaneously proves that the sensor can be irradiated by means of a time varying electric field applied in the plane of the particle codirectional to the direction of the electric dipole. The possible relative positions of the antenna and sensor are shown in

Figure 2c–e.

When putting a sensor into an alternating electromagnetic field, alumina ceramic dielectrics can generate polarized charges. The thermal motion of ions goes intense when temperatures increase, the orderliness caused by the effect of the electric field becomes lower, resulting in a weaker polarization of charges. This will make the actual electric field (

Ee) intensity become smaller and the higher the temperature, the faster the frequency change (as can be seen in Figure 8). The relationship between

Ee,

εr,

Cs,

T, and f can be clearly described as follows:

It can be seen from the above descriptions that the temperature is inversely proportional to the resonant frequency (fs), which makes the sensor suitable for microwave wireless passive temperature sensing applications.

4. Experiments and Discussion

We set up a distance testing platform (

Figure 6a) to study the influence of the sensing distance on the return signal. The antenna used in the experiment was a patch antenna with bandwidth that contained the resonant frequency of the sensor. The reader antenna and sensor were mounted on a 2D stage machine and slider 1 remained stationary. By changing the distance (moving slider 2 to vary the interrogation distance) between the reader antenna and sensor, the resonant frequency of the sensor and impedance of the system can be changed. We used a network analyzer (Agilent E5061B) as the signal acquisition instrument and changed the distance from 3 to 15 mm in 3 mm intervals. It can be seen from the curves that the resonant frequency remains nearly unchanged while S (1, 1) decreases with an increase in distance. When the interrogation distance becomes small, most of the electromagnetic waves emitted from the antenna can cause the resonance of the sensor, and there is little electromagnetic wave attenuated in the free space, so a large return loss | S (1, 1) | can be obtained. The inset of

Figure 6b shows the relationship between | S (1, 1) | and the interrogation distance (d).

k is physically defined as attenuation rate of the impedance.

k1 and

k2 represent the slopes of the fitted curve at the interrogation distances of 6 mm and 12 mm. It can be seen that the return loss | S (1, 1) | increases with the distance and the attenuation is getting faster and faster.

The attenuation rate of the impedance (k) increases with an increase in distance (k1 < k2). When the sensing distance is larger than 20 mm, the return signal becomes indistinct. The value of | S (1, 1) | is about 60 dB and 20 dB when the query distance was 3 mm and 15 mm, respectively. The thickness of the furnace wall was approximately 10 to 20 mm. When measuring the temperature of the furnace wall, the sensor can be placed inside the wall with the antenna outside the furnace wall. In order to obtain strong signals, we set the distance between the reader antenna and the sensor to be 5 mm in later experiments. Due to the influence of the aluminum alloy components on the 2D working stage, the center frequency has a degree of deviation from the actual testing frequency, where there is no metal environment.

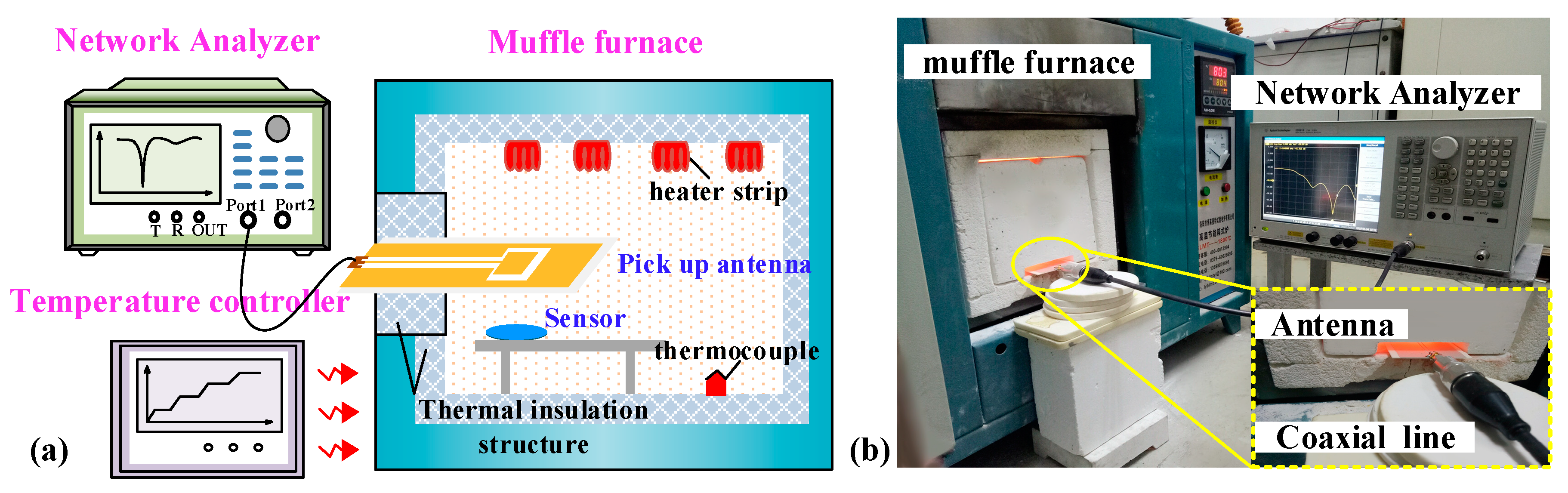

To measure high temperatures, the fabricated sensor was placed in a muffle furnace. The schematic of the high-temperature test platform is shown in

Figure 7. A mullite insulation layer was used to maintain the temperature inside the furnace. A coplanar waveguide (CPW) antenna with a center frequency of 2.02 GHz was used for wireless inquiry, with a relative bandwidth of 49.5% and maximum vertical gain of 1.7 dB. The reader antenna excites the sensor through the coaxial cable connected to the network analyzer (Agilent E5061B) and receives a return signal from the sensor. The temperature curve set by the temperature controller is sent to the high-temperature muffle furnace (Nabertherm LHT 02/1). The heating rate was set to 10 °C/min and dataset was recorded every 50 °C until | S (1, 1) | was less than 10 dB, which occurred when the temperature reached 1100 °C. The test curve is shown in

Figure 8a. It can be seen from the test curve that the frequency of the sensor is 2.42 GHz and the value of | S (1, 1) | is −57.65 dB at 28 °C. The measured resonant frequency at 28 °C has slight deviation with the simulated resonant frequency, which may be caused by the inaccuracy of the fabrication process and relative constant of alumina ceramic. As the temperature increases from 28 to 1100 °C, the resonance frequency of the sensor is reduced from 2.417 to 2.320 GHz accordingly.

Repeated experiments have been conducted to verify the feasibility of the sensor. Tests were repeated four times, and by extracting the frequency peak, the good repeatability of the sensor was verified in

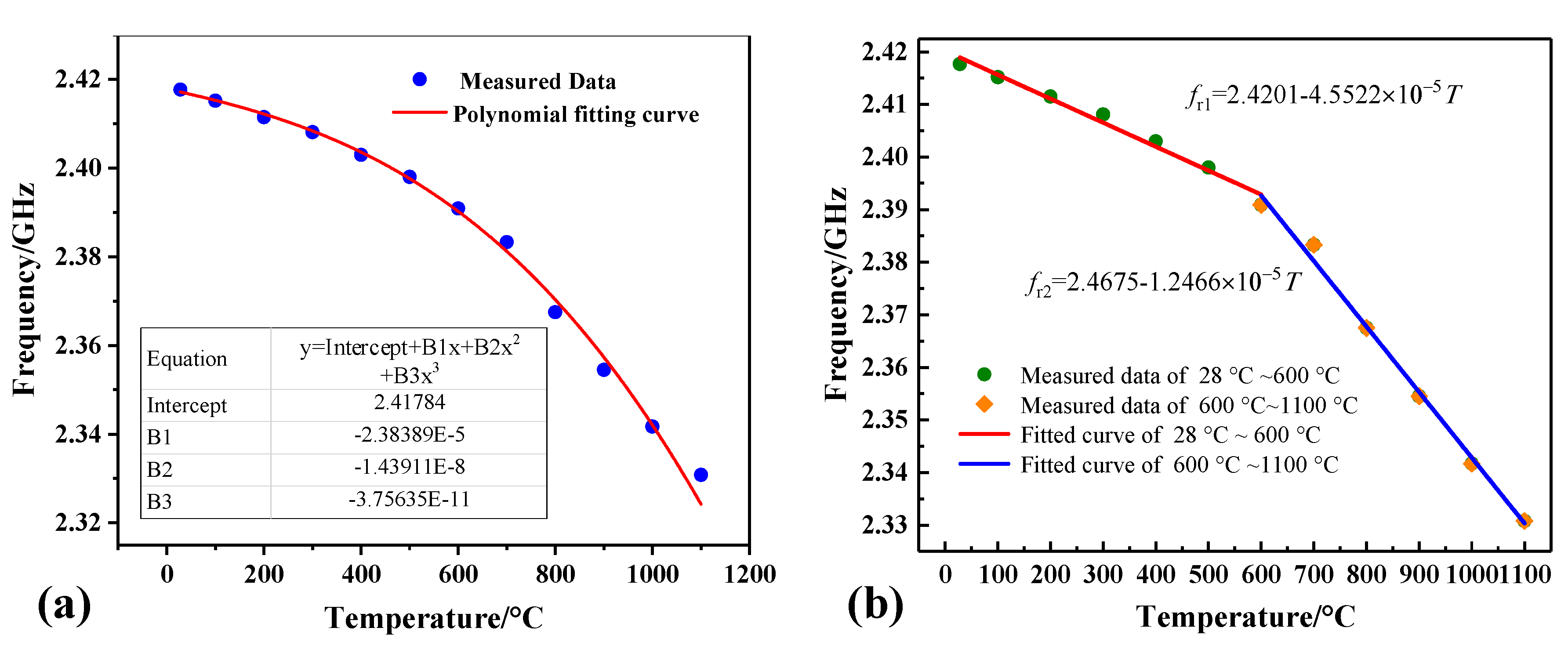

Figure 8b. We used the average value of four test experiments to make a frequency temperature curve. The relationship between temperature and frequency can be better obtained by a cubic polynomial,

fr means the frequency at a certain temperature (

T) on the fitting curve and the fitting curve is expressed as follows (

Figure 9a):

We define S = ∆

fr/∆

T (kHz/°C) as the average absolute sensitivity of the proposed sensor,

k’ = d

fr/d

t (kHz/°C) as the rate of change of frequency with temperature. The experimental results show that the average sensitivity of the sensor is 95.63 kHz/°C in the temperature range of 28–1100 °C and the value of |

k’ | increases with the increase of temperature according to the principle mentioned in

Section 2.

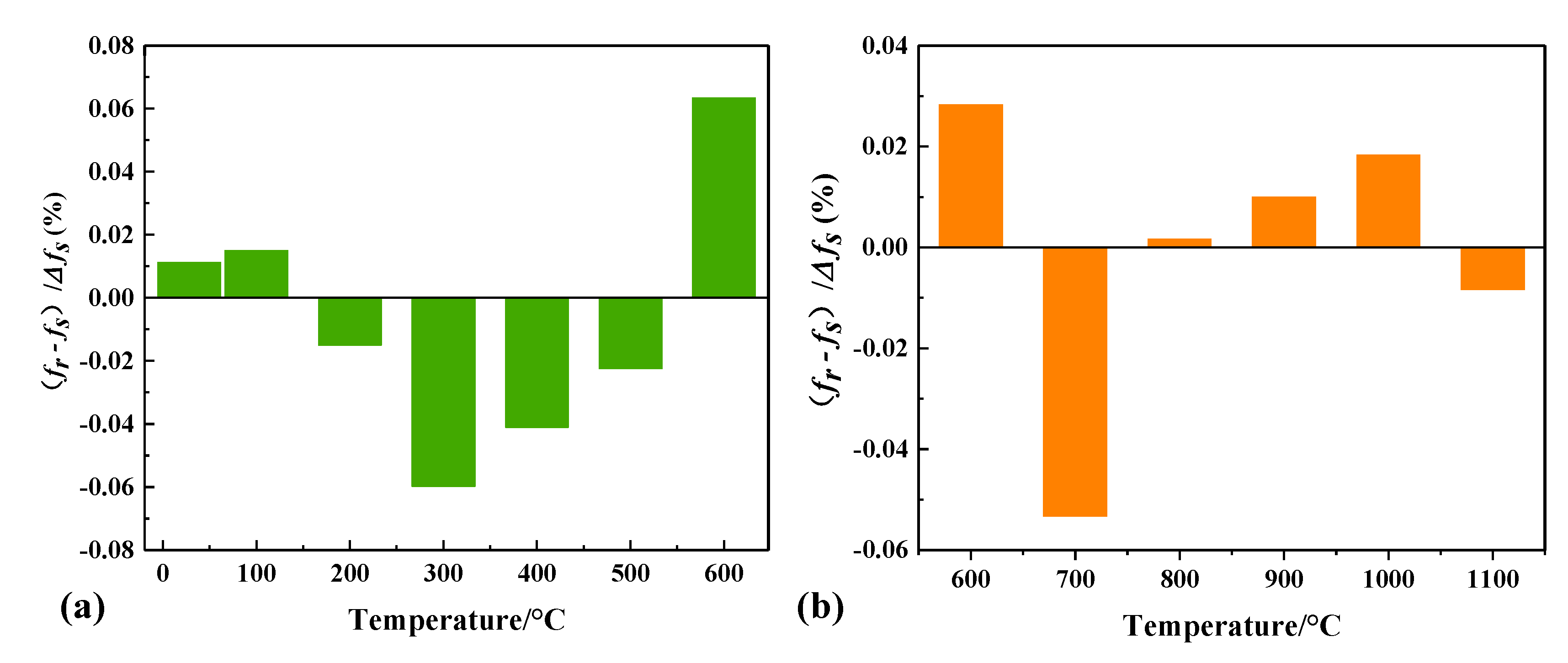

To simplify the expression of the sensor and make the sensor have excellent linearity in a certain temperature range, we divided the test results into two temperature ranges and performed a piecewise fitting of the test data (

Figure 9b). The sensitivity of the sensor is found to be 45.5 kHz/°C in the range of 28–600 °C, 124.6 kHz/°C in the range of 600–1100 °C, respectively. In

Figure 10, the SRR-based sensor had a maximum of 0.0017 GHz nonlinearity errors in the range of 28–600 °C, corresponding to 6.34% nonlinearity error; a maximum of 0.0032 GHz nonlinearity errors in the range of 600–1100 °C, corresponding to 5.32% nonlinearity error. Therefore, better linearity can be obtained by using different formulas in different temperature ranges:

Table 2 shows visualized parameters of the SRR-based RFID temperature sensor we fabricated and other kinds of wireless temperature microwave sensors. As we can see in

Table 3, the sensor proposed in this paper has a lower profile and wider temperature sensing range. For the sensitivity and sensing distance of sensors, the resonator-based microwave sensor in Reference [

18] has a high sensitivity of 0.24 MHz/°C with a sensing distance of 30 mm, while the dielectric resonance temperature sensor in Reference [

6] has a sensitivity of 194 kHz/°C with a sensing distance of about 10 mm. Although the sensor in this paper has a sensitivity of 95.63 kHz/°C which was not so high as the above two sensors, the sensing distance can reach to about 200 mm when using horn antenna.