MineLoC: A Rapid Production of Lab-on-a-Chip Biosensors Using 3D Printer and the Sandbox Game, Minecraft

Abstract

:1. Introduction

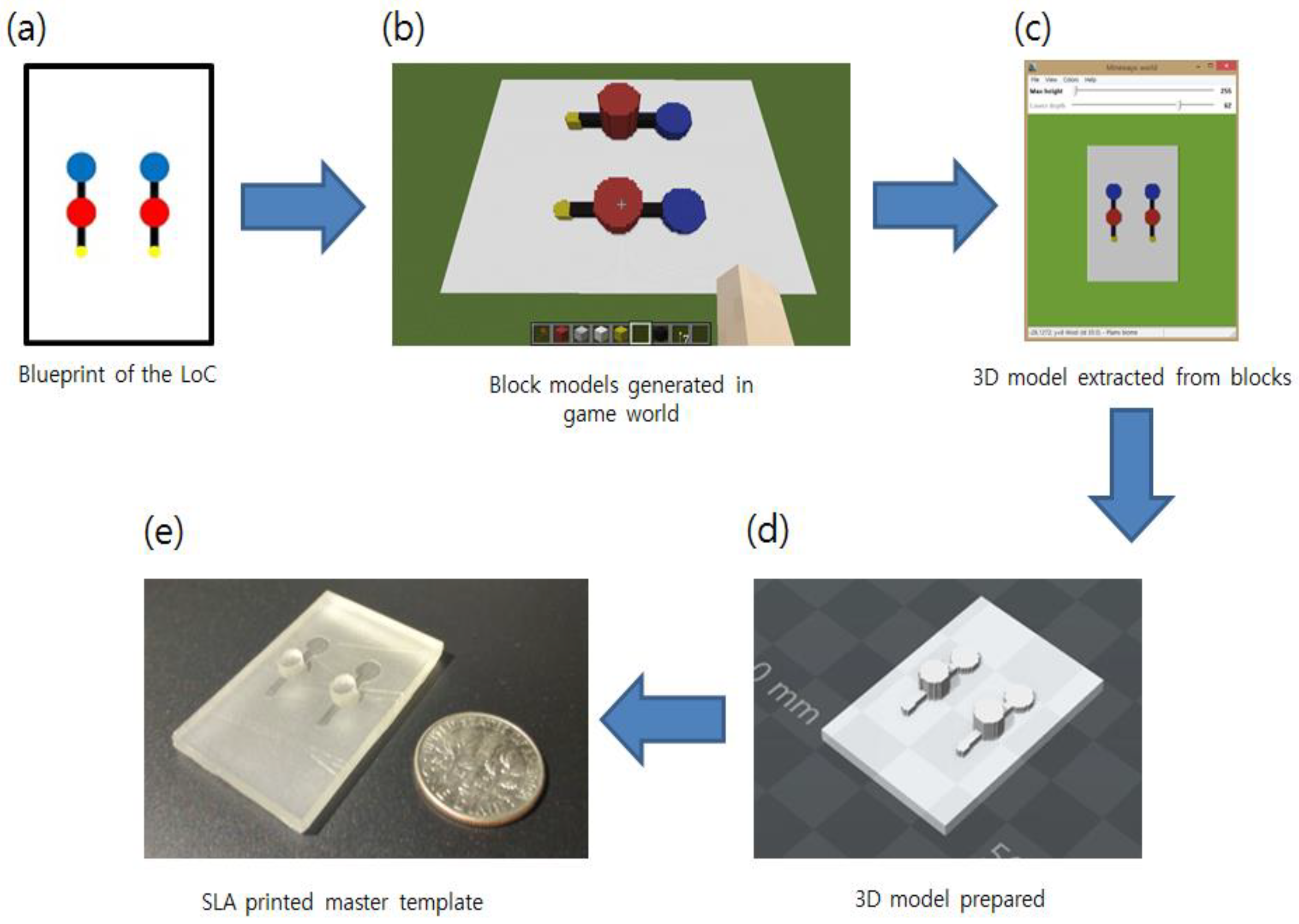

2. Materials and Methods

2.1. Chip Blueprint Preparation

2.2. Virtual Environment and Server Setup

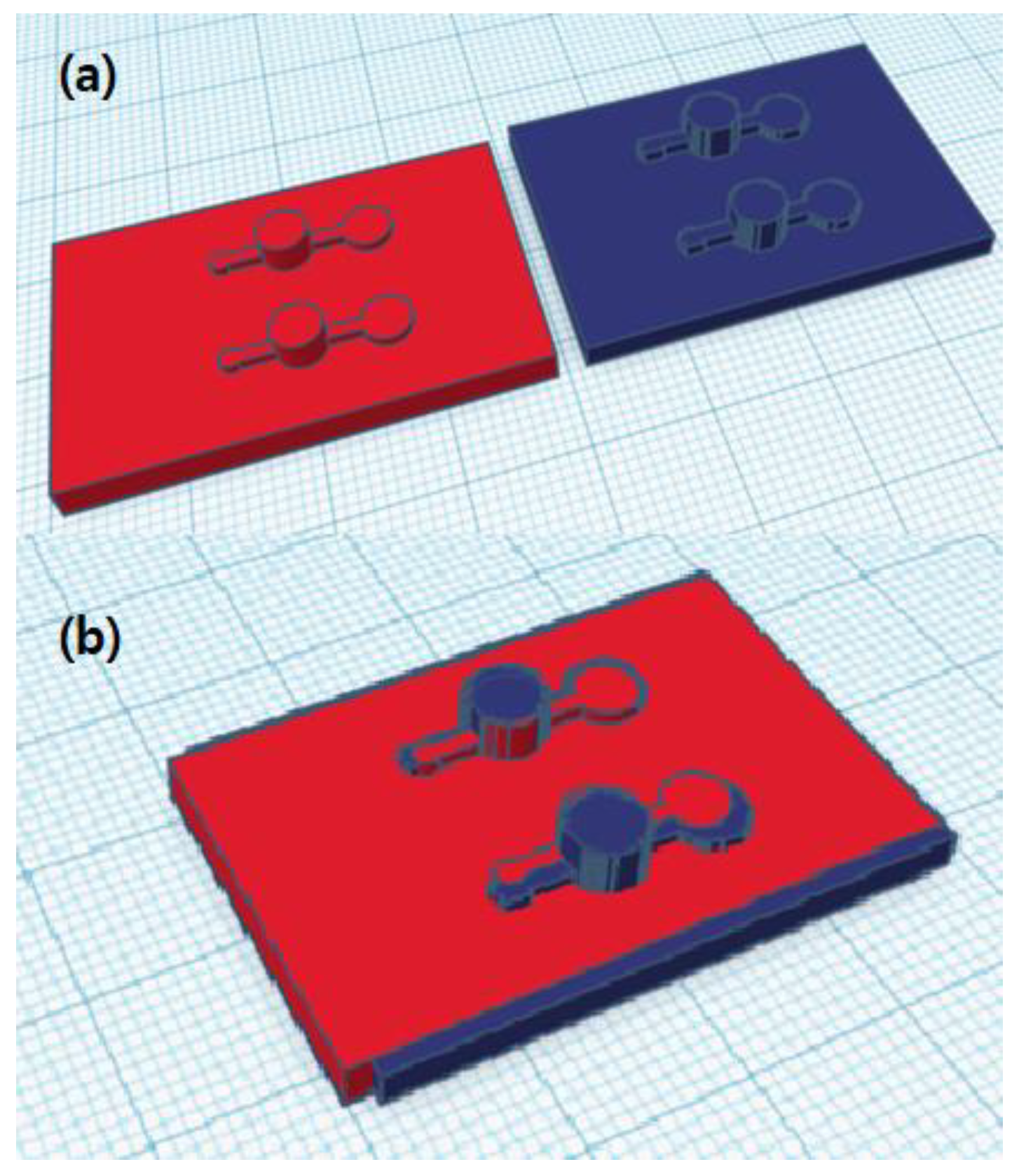

2.3. 3D-Printing and Chip Fabrication

2.4. Bacterial Cell Culture on PDMS Chips

3. Results and Discussion

3.1. Generated Model Comparison with the Conventional Method

3.2. Bacterial Cell Culture Experiment with the Fabricated Lab-on-a-Chip

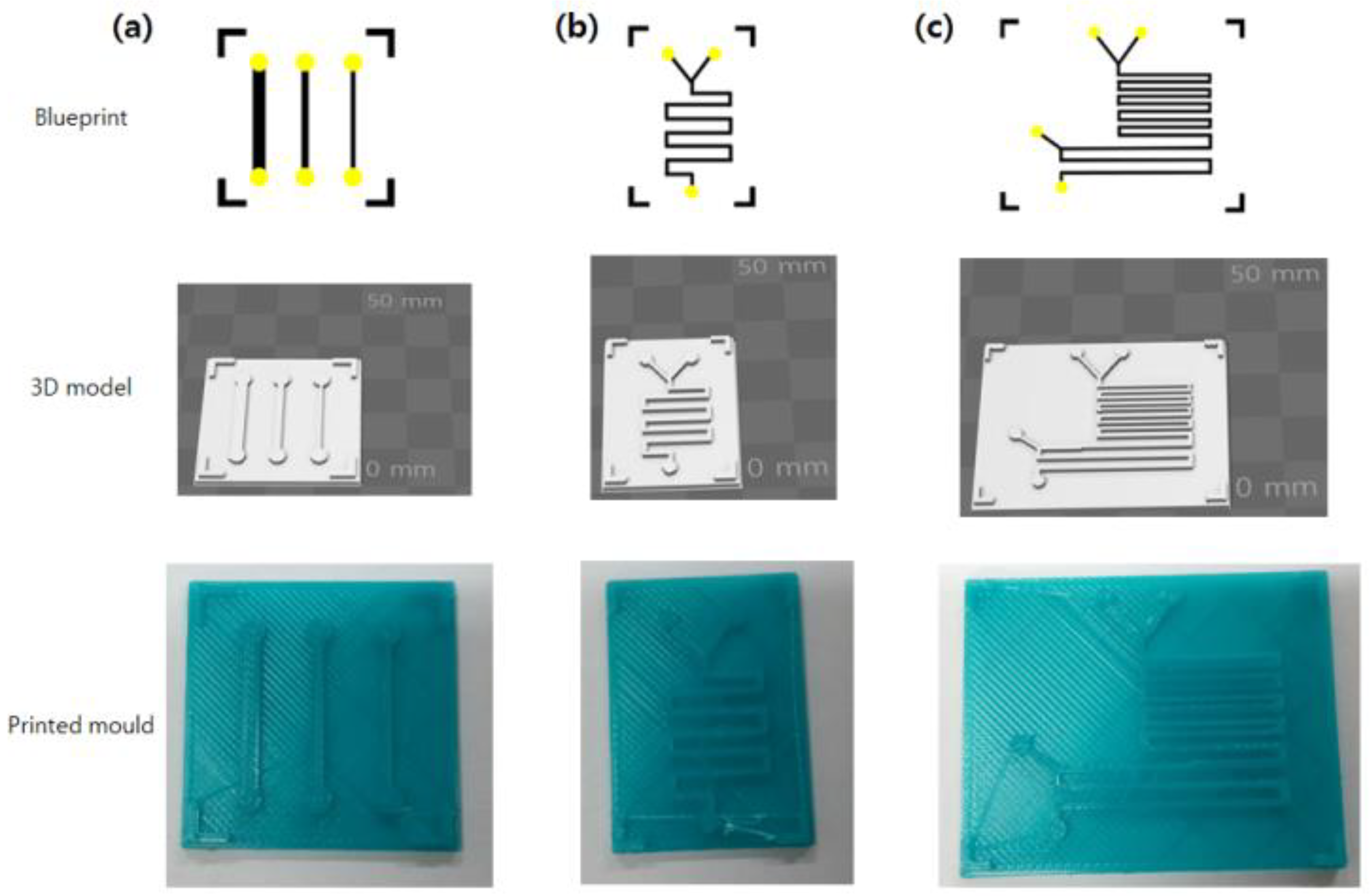

3.3. Generation of More Example Molds

3.4. Comparisons with Other Modeling Software

4. Conclusions and Future Work

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Detailed Steps of Deploying MineLoC Server

- Install Minecraft 1.9.4, MineWays (http://www.realtimerendering.com/erich/minecraft/public/mineways/), and MeshLab (http://meshlab.sourceforge.net)

- Download CraftBukkit server (https://www.getbukkit.org/craftbukkit.html). Version 1.9.4 was tested.

- Write “java -Xms1024M -Xmx1024M -jar craftbukkit.jar -o false PAUSE” in the notepad and save it as a run.cmd (for Windows)

- Open generated eula.txt file (generated when run.cmd is executed for the first time) and change eula option to true.

- Use terminal to execute run.cmd. Check access to the server.

- Open server.properties file. It is recommended to use the FLAT world setting (level-type) with no npcs, mobs, or animal spawn (spawn-monsters, spawn-animals, and spawn-npcs options). Change gamemode=1 (creative mode) for easier manipulation of the world. Change other options if necessary.

- Download WorldEdit form https://dev.bukkit.org/bukkit-plugins/worldedit/. WorldEdit-bukkit 6.1.2 was tested.

- Extract *.jar file and copy to the /plugin folder generated by the server. Restart the server and check generation of /plugin/WorldEdit folder.

- Generate /plugin/WorldEdit/craftscript folder and /plugin/WorldEdit/drawings folder for script execution.

- Save *.js script in craftscript folder and images in drawing folder.

- Download Rhino JavaScript engine Ver. 1.7.7.1 (https://developer.mozilla.org/en-US/docs/Mozilla/Projects/Rhino/Download_Rhino)

- Extract rhino-*.jar from the /lib folder and copy under /WorldEdit folder and change the name to js.jar.

- Restart the server and use the op <username> command to obtain permission.

- Test WorldEdit scripts. LoC generation script used in this research is available at (Github): https://github.com/W5-KAIST/MineLoc. “drawloc.js” is the currently tested version converting red, blue, yellow, and black colors to block structures.

Appendix B. Detailed Steps of Operating MineLoC in the Virtual World

- Execute Minecraft and enter the MineLoC server by entering multiplayer mode.

- The server command usage was “//cs drawloc.js locimage.png”.

- Check the generated structure and apply modifications if necessary (for stability of the output, it is recommended to stop the server first to save the changes).

- Run MineWays and clicked File → Open World → Find your world menu

- “World Data” is located at /world/level.dat file of the Minecraft server.

- Find the required build model and draw a square region with a right click.

- Save it as a Shapeways VRMW file (*.wrl) format.

- Adjust Height value, 3D printing options and erased superhollow and hollow out bottom option.

- Open the MeshLab and imported generate *.wrl file by clicking File → Import Mesh option.

- Check the model and export it by clicking File → Export Mesh As menu.

- Click *.stl option to get STL file for the 3D printing.

References

- ISO/ASTM52900–15. Available online: https://www.astm.org/Standards/ISOASTM52900.htm (accessed on 6 February 2018).

- Fab Foundation. Available online: http://www.fabfoundation.org/ (accessed on 23 December 2017).

- Comina, G.; Suska, A.; Filippini, D. PDMS lab-on-a-chip fabrication using 3D printed templates. Lab Chip 2014, 14, 424–430. [Google Scholar] [CrossRef] [PubMed]

- Kitson, P.; Rosnes, M.; Sans, V.; Dragone, V.; Cronin, L. Configurable 3D-Printed millifluidic and microfluidic ‘lab on a chip’ reactionware devices. Lab Chip 2012, 12, 3267–3271. [Google Scholar] [CrossRef] [PubMed]

- Symes, M.; Kitson, P.; Yan, J.; Richmond, C.; Cooper, G.; Bowman, R.; Vilbrandt, T.; Cronin, L. Integrated 3D-printed reactionware for chemical synthesis and analysis. Nat. Chem. 2012, 4, 349–354. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Costa, P.F.; Albers, H.J.; Linssen, J.E.A.; Middelkamp, H.H.T.; Van der Hout, L.; Passier, R.; van den Berg, A.; Malda, J.; van der Meer, A.D. Mimicking arterial thrombosis in a 3D-printed microfluidic in vitro vascular model based on computed tomography angiography data. Lab Chip 2017, 17, 2785–2792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lind, J.U.; Busbee, T.A.; Valentine, A.D.; Pasqualini, F.S.; Yuan, H.; Yadid, M.; Park, S.; Kotikian, A.; Nesmith, A.P.; Campbell, P.H.; et al. Instrumented cardiac microphysiological devices via multimaterial three-dimensional printing. Nat. Methods 2017, 16, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Hampson, S.M.; Rowe, W.; Christie, S.D.R.; Platt, M. 3D printed microfluidic device with integrated optical sensing for particle analysis. Sens. Actuator B Chem. 2018, 256, 1030–1037. [Google Scholar] [CrossRef]

- Kim, K.; Kim, S.; Jeon, J.S. Visual Estimation of Bacterial Growth Level in Microfluidic Culture Systems. Sensors 2018, 18, 447. [Google Scholar] [CrossRef] [PubMed]

- Ong, L.J.Y.; Islam, A.B.; DasGupta, R.; Iyer, N.G.; Leo, H.L.; Toh, Y. A 3D printed microfluidic perfusion device for multicellular spheroid cultures. Biofabrication 2017, 9, 045005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alessandri, K.; Andrique, L.; Feyeux, M.; Bikfalvi, A.; Nassoy, P.; Recher, G. All-in-one 3D printed microscopy chamber for multidimensional imaging, the UniverSlide. Sci. Rep. 2017, 7, 42378. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, M.; Tong, Y.; Webster, K.; Cesewski, E.; Haring, A.P.; Laheri, S.; Carswell, B.; O’Brien, T.J.; Aardema, C.H., Jr.; Senger, R.S.; et al. 3D printed conformal microfluidics for isolation and profiling of biomarkers from whole organs. Lab Chip 2017, 17, 2561–2572. [Google Scholar] [CrossRef] [PubMed]

- OOML. Available online: https://github.com/avalero/OOML (accessed on 23 December 2017).

- OpenSCAD. Available online: http://www.openscad.org/ (accessed on 23 December 2017).

- Short, D. Teaching Scientific Concepts using a Virtual World–Minecraft. J. Aust. Sci. Teach. Assoc. 2012, 58, 55–58. [Google Scholar]

- Bayliss, J. Teaching game AI through Minecraft mods. In Proceedings of the 2012 IEEE International Games Innovation Conference (IGIC 2012), Rochester, NY, USA, 7–9 September 2012; pp. 1–4. [Google Scholar]

- Cooper, S.; Khatib, F.; Treuille, A.; Barbero, J.; Lee, J.; Beenen, M.; Leaver-Fay, A.; Baker, D.; Popović, Z.; Players, F. Predicting protein structures with a multiplayer online game. Nature 2010, 466, 756–760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sea Hero Quest. Available online: http://www.seaheroquest.com (accessed on 6 February 2018).

- Owens, C.E.; Hart, A.J. High-precision modular microfluidics by micromilling of interlocking injection-molded blocks. Lab Chip 2018, 18, 890–901. [Google Scholar] [CrossRef] [PubMed]

- Shin, Y.; Han, S.; Jeon, J.; Yamamoto, K.; Zervantonakis, I.; Sudo, R.; Kamm, R.; Chung, S. Microfluidic assay for simultaneous culture of multiple cell types on surfaces or within hydrogels. Nat. Protoc. 2012, 7, 1247–1259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, K.; Choi, D.; Lim, H.; Kim, H.; Jeon, J. Vision Marker-Based In Situ Examination of Bacterial Growth in Liquid Culture Media. Sensors 2016, 16, 2179. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Hyun, J.; Jeon, J. Light Emitting Marker for Robust Vision-Based On-The-Spot Bacterial Growth Detection. Sensors 2017, 17, 1459. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, H.; Han, S.; Lee, J.; Oh, J.; Chung, S.; Park, H. Hydrodynamic effects on bacterial biofilm development in a microfluidic environment. Lab Chip 2013, 13, 1846–1849. [Google Scholar] [CrossRef] [PubMed]

- Salmi, M.; Ituarte, I.F.; Chekurov, S.; Huotilainen, E. Effect of build orientation in 3D printing productionfor material extrusion, material jetting, binder jetting, sheet object lamination, vat photopolymerisation, and powder bed fusion. Int. J. Collab. Enterp. 2016, 5, 218–231. [Google Scholar] [CrossRef]

- Fuh, J.Y.H.; Li, W.D. Advances in collaborative CAD: The-state-of-the-art. Comput. Aided Des. 2005, 37, 571–581. [Google Scholar] [CrossRef]

- BlockSCAD. Available online: https://www.blockscad3d.com/ (accessed on 30 March 2018).

- TinkerCAD. Available online: https://www.tinkercad.com/ (accessed on 30 March 2018).

- 3D Slash. Available online: https://www.3dslash.net/index.php (accessed on 30 March 2018).

- MagicaVoxel. Available online: https://ephtracy.github.io/ (accessed on 30 March 2018).

- Onshape. Available online: https://www.onshape.com/ (accessed on 30 March 2018).

- Truecraft–A Free and Open-Source Implementation of Minecraft Beta 1.7.3. Available online: https://truecraft.io (accessed on 22 May 2018).

- Bae, H.; Hwang, Y.; Dokmeci, M.; Khademhosseini, A. Research highlights—A complete, zero-shear celluar analysis assay. Lab Chip 2013, 13, 4693–4696. [Google Scholar] [CrossRef]

- Zhao, L.; Wu, T.; Lefèvre, J.; Leray, I.; Delaire, J. Fluorimetric lead detection in a microfluidic device. Lab Chip 2009, 9, 2818–2823. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Chen, D.; Bau, H. An automated, pre-programmed, multiplexed, hydraulic microvalve. Lab Chip 2009, 9, 3594–3598. [Google Scholar] [CrossRef] [PubMed]

| BlocksCAD | TinkerCAD | 3D Slash | MagicaVoxel | Onshape | Proposed | |

|---|---|---|---|---|---|---|

| Price policy | Free | Free | Free 2 | Free | Not free 3 | Free (server) |

| Rendering | Slow | Slow | Fast | Fast | Fast | Fast |

| Difficulty | Medium | Medium | Low | Low | Very High | Low |

| Co-modeling | N/A 1 | N/A | N/A | N/A | Available | Available |

| MagicaVoxel | 3D Slash (Free) | 3D Slash (Paid) | Proposed | |

|---|---|---|---|---|

| Voxel Limit | 126 × 126 × 126 | 128 × 128 × 128 | 512 × 512 × 512 | 1000 × 1000 × 120 1 |

| Configurable Bounding Box | N/A | N/A | N/A | Available with 256 voxels height limit |

| Resolution 2 | 0.302 mm | 0.297 mm | 0.0742 mm | 0.0500 mm 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.; Kim, H.; Kim, S.; Jeon, J.S. MineLoC: A Rapid Production of Lab-on-a-Chip Biosensors Using 3D Printer and the Sandbox Game, Minecraft. Sensors 2018, 18, 1896. https://doi.org/10.3390/s18061896

Kim K, Kim H, Kim S, Jeon JS. MineLoC: A Rapid Production of Lab-on-a-Chip Biosensors Using 3D Printer and the Sandbox Game, Minecraft. Sensors. 2018; 18(6):1896. https://doi.org/10.3390/s18061896

Chicago/Turabian StyleKim, Kyukwang, Hyeongkeun Kim, Seunggyu Kim, and Jessie S. Jeon. 2018. "MineLoC: A Rapid Production of Lab-on-a-Chip Biosensors Using 3D Printer and the Sandbox Game, Minecraft" Sensors 18, no. 6: 1896. https://doi.org/10.3390/s18061896