A Non-Destructive and Direction-Insensitive Method Using a Strain Sensor and Two Single Axis Angle Sensors for Evaluating Corn Stalk Lodging Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials

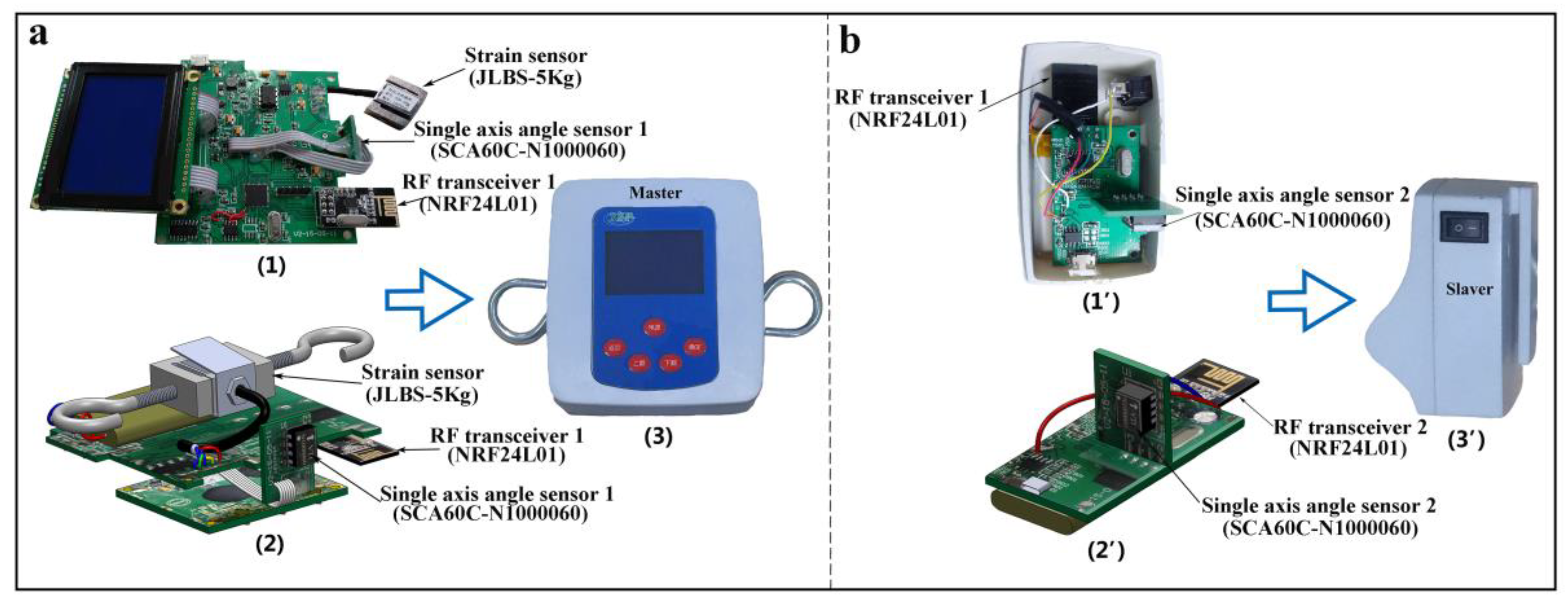

2.2. Measurement System Design

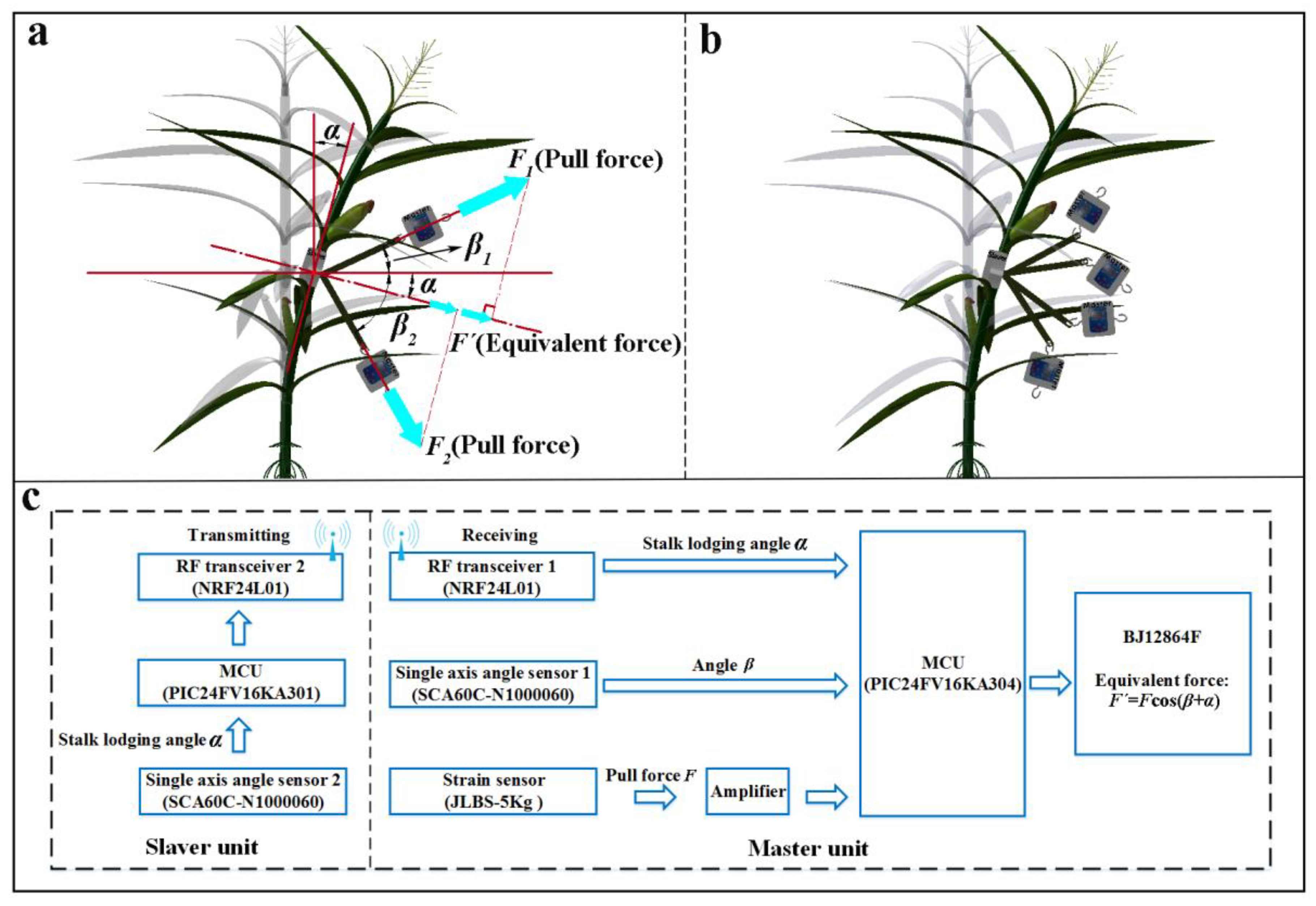

2.3. Measurement Principle of Equivalent Forces

3. Results and Discussion

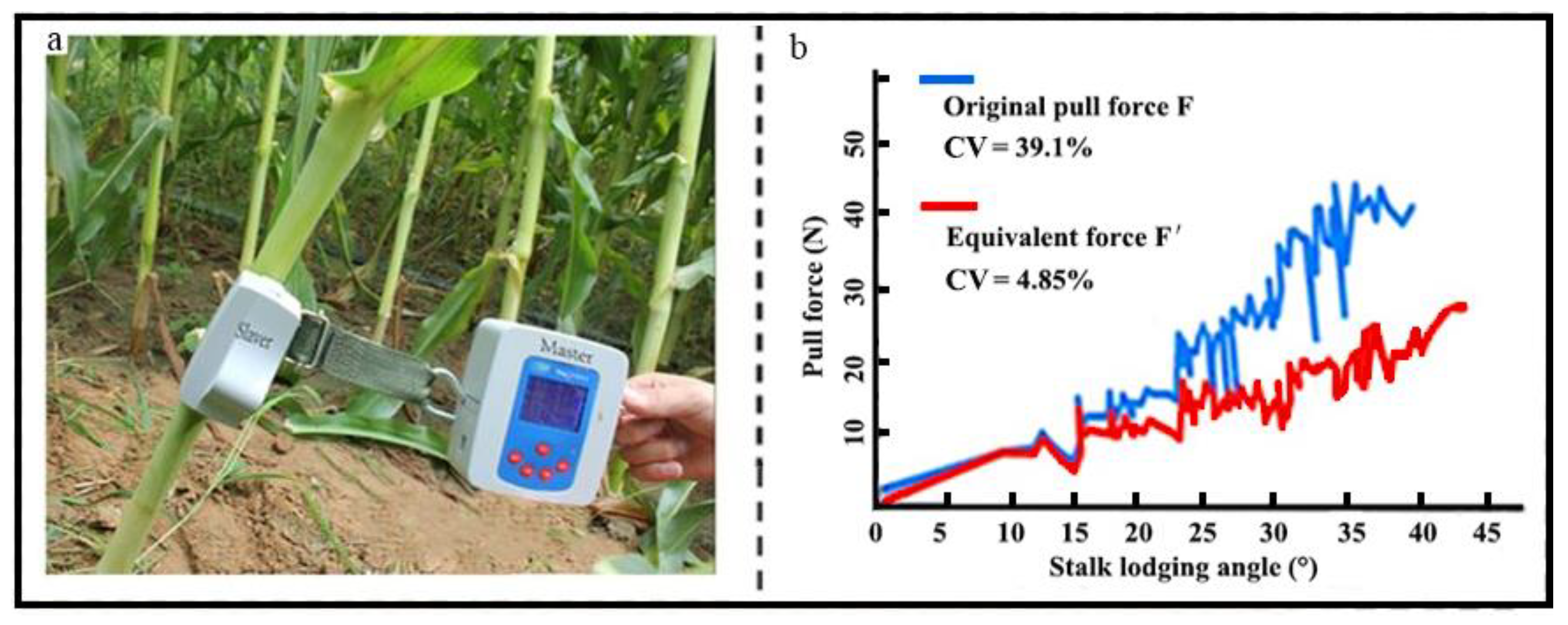

3.1. Stability Results

3.2. Equivalent Forces Changed with Stalk Lodging Angles

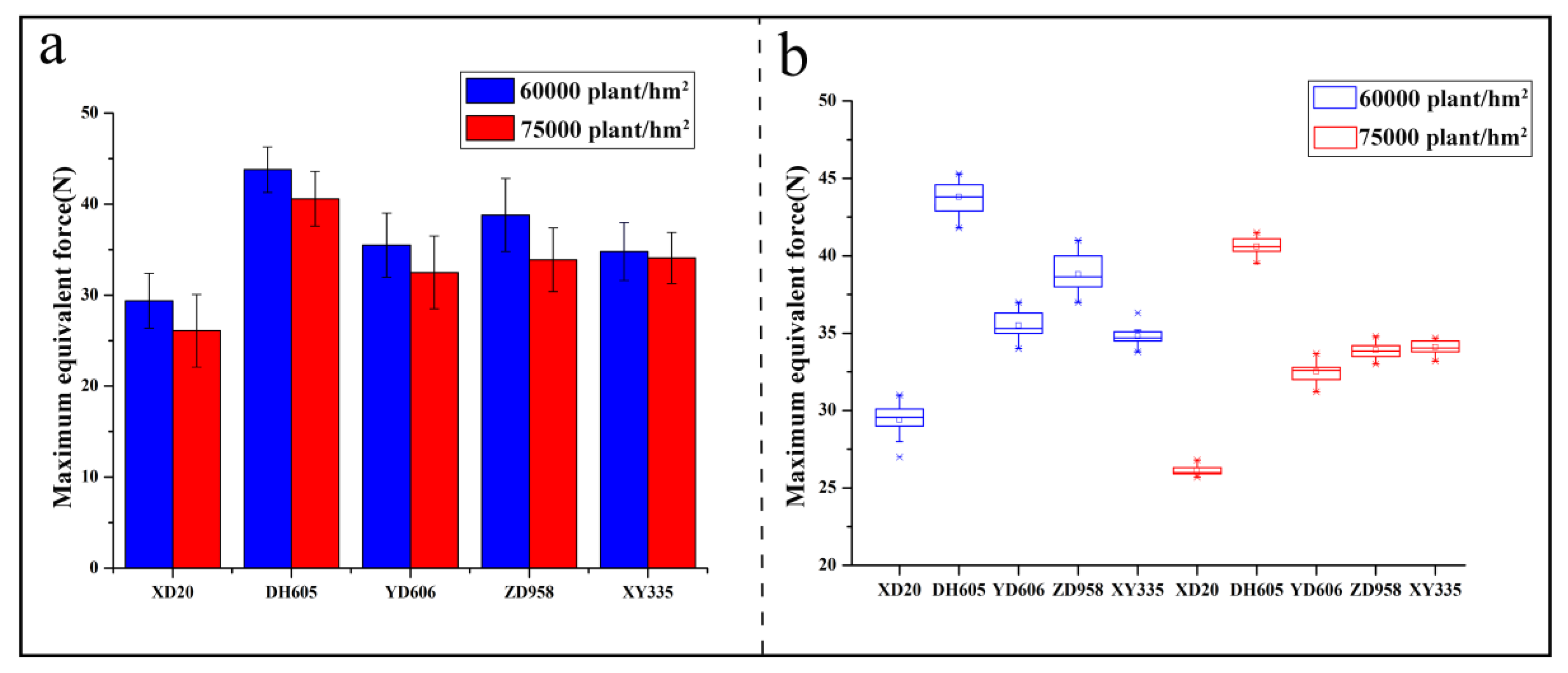

3.3. Maximum Equivalent Forces

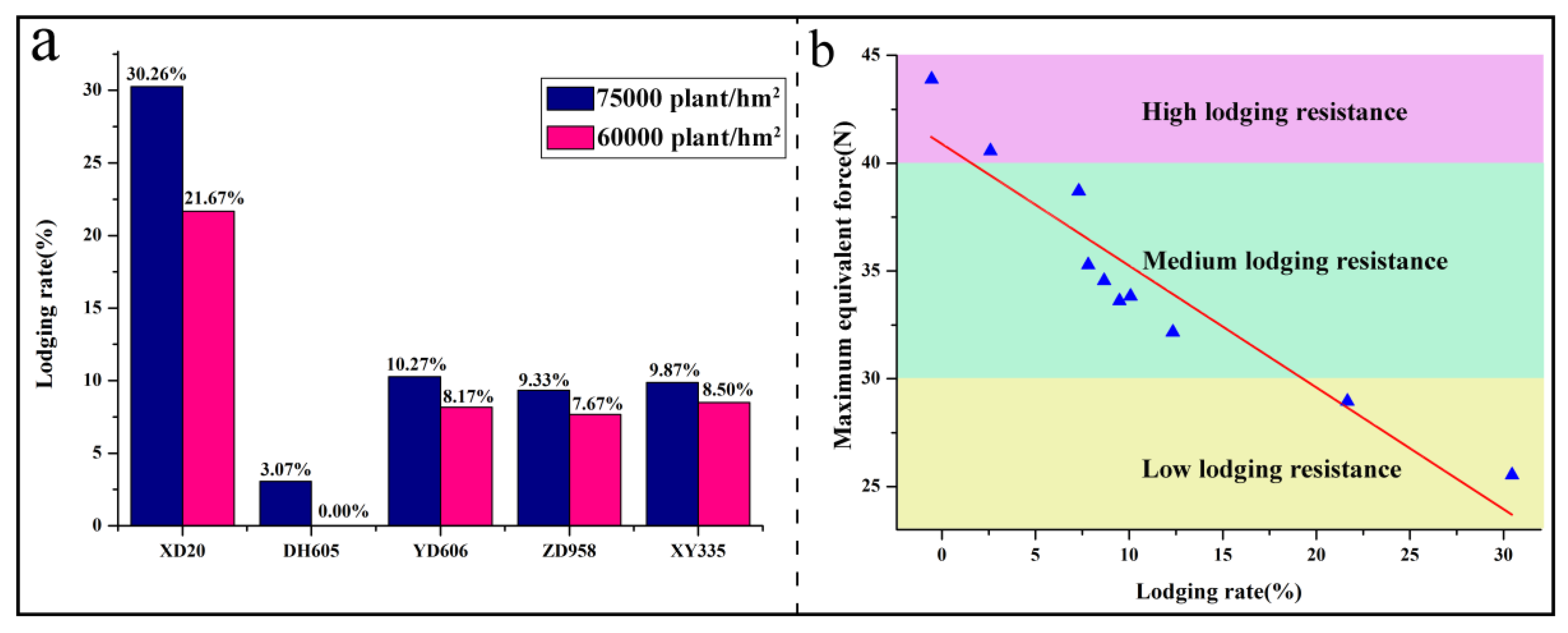

3.4. Field Stalk Lodging Rates

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beck, D.L.; Darrah, L.L.; Zuber, M.S. An improved technique for measuring resistance to root pulling in maize. Crop Sci. 1987, 27, 356–358. [Google Scholar] [CrossRef]

- Berry, P.M.; Spink, J.H.; Gay, A.P.; Craigon, J. A comparison of root and stem lodging risks among winter wheat cultivars. J. Agric. Sci. 2003, 141, 191–202. [Google Scholar] [CrossRef]

- Zhang, H.L.; Ma, Q.; Fan, L.F.; Zhao, P.F.; Wang, J.X.; Zhang, X.D.; Zhu, D.-H.; Huang, L.; Zhao, D.-J.; Wang, Z.-Y. Nondestructive in situ measurement method for kernel moisture content in corn ear. Sensors 2016, 16, 2196. [Google Scholar] [CrossRef] [PubMed]

- Easson, D.L.; White, E.M.; Pickles, S.J. The effect of weather, seed rate and cultivar on lodging and yield in winter wheat. J. Agric. Sci. 1993, 121, 145–156. [Google Scholar] [CrossRef]

- Pinthus, M.J. Lodging in wheat, barley, and oats: The phenomenon, its causes, and preventive measures. Adv. Agron. 1974, 25, 209–263. [Google Scholar]

- Wu, W.; Ma, B. A new method for assessing plant lodging and the impact of management options on lodging in canola crop production. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Ennos, A.R. The mechanics of anchorage in wheat Triticumaestivum L.: II. Anchorage of mature wheat against lodging. J. Exp. Bot. 1991, 42, 1607–1613. [Google Scholar] [CrossRef]

- Donovan, L.S.; Jui, P.; Klock, M.; Nicholls, C.F. An improved method of measuring root strength in corn (Zea mays l.). Can. J. Plant Sci. 1982, 62, 223–227. [Google Scholar] [CrossRef]

- Crook, M.J.; Ennos, A.R. Stem and root characteristics associated with lodging resistance in four winter wheat cultivars. J. Agric. Sci. 1994, 123, 167–174. [Google Scholar] [CrossRef]

- Ramsey, S.L.; Kernodle, S.P. A method for accelerated trait conversion in plant breeding. Theor. Appl. Genet. 2009, 118, 1499–1508. [Google Scholar]

- Ennis, W.B., Jr.; Dowler, W.M.; Klassen, W. Crop protection to increase food supplies. Science 1975, 188, 593–598. [Google Scholar] [CrossRef] [PubMed]

- Cheng, F.L. Lodging of summer maize and the effects on grain yield. J. Mai. Sci. 2011, 19, 105–108. [Google Scholar]

- Goodman, A.M.; Crook, M.J.; Ennos, A.R. Anchorage mechanics of the tap root system of winter–sown oilseed rape (Brassica napus L.). Ann. Bot. 2001, 87, 397–404. [Google Scholar] [CrossRef]

- Foulkes, M.J.; Slafer, G.A.; Davies, W.J.; Berry, P.M.; Sylvester-Bradley, R.; Martre, P.; Calderini, D.F.; Griffiths, S.; Reynolds, M.P. Raising yield potential of wheat. III. Optimizing partitioning to grain while maintaining lodging resistance. J. Exp. Bot. 2011, 62, 469–486. [Google Scholar] [CrossRef] [PubMed]

- Berry, P.M.; Sterling, M.; Spink, J.; Baker, C.J.; Sylvester-Bradley, R.; Mooney, S.J.; Tams, A.R.; Ennos, R. Understanding and reducing lodging in cereals. Adv. Agron. 2004, 84, 217–271. [Google Scholar]

- Martin, M.J.; Russell, W.A. Response of a maize synthetic to recurrent selection for stalk quality. Crop Sci. 1984, 24, 331–337. [Google Scholar] [CrossRef]

- Albrecht, K.A.; Martin, M.J.; Russel, W.A.; Wedin, W.F.; Buxton, D.R. Chemical and in vitro digestible dry matter composition of maize stalks after selection for stalk strength and stalk-rot resistance. Crop Sci. 1986, 26, 1051–1055. [Google Scholar] [CrossRef]

- Berk, P.; Hocevar, M.; Stajnko, D. Development of alternative plant protection product application techniques in orchards, based on measurement sensing systems: A review. Comput. Electron. Agric. 2016, 124, 273–288. [Google Scholar] [CrossRef]

- Sharma, L.; Bu, H.; Franzen, D. Use of corn height measured with an acoustic sensor improves yield estimation with ground based active optical sensors. Comput. Electron. Agric. 2016, 124, 254–262. [Google Scholar] [CrossRef]

- Niu, L.; Feng, S.; Ru, Z.; Li, G.; Zhang, Z. Rapid determination of single-stalk and population lodging resistance strengths and an assessment of the stem lodging wind speeds for winter wheat. Field Crops Res. 2012, 139, 1–8. [Google Scholar] [CrossRef]

- Flint-garcia, S.A.; Jampatong, C.; Darrah, L.L.; Mcmullen, M.D. Quantitative trait locus analysis of stalk strength in four maize populations. Crop Sci. 2003, 43, 13–22. [Google Scholar] [CrossRef]

- Sanchez, A.C.; Subudhi, P.K.; Rosenow, D.T.; Nguyen, H.T. Mapping QTLs associated with drought resistance in sorghum (Sorghum bicolor L. Moench). Plant Mol. Biol. 2002, 48, 713–726. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.X.; Liu, W.X.; Fu, Z.Y.; Song, C.L.; Chen, S.J. QTL mapping of stalk bending strength in a recombinant inbred. Theor. Appl. Genet. 2013, 126, 2257–2266. [Google Scholar] [CrossRef] [PubMed]

- Ishimaru, K.; Shirota, K.; Higa, M.; Kawamitsu, Y. Identification of quantitative trait loci for adaxial and abaxial stomatal frequencies in Oryza sativa. Plant Physiol. Biochem. 2001, 39, 173–177. [Google Scholar] [CrossRef]

- Fouéré, A.; Pellerin, S.; Duparque, A. A portable electronic device for evaluating root lodging resistance in maize. Agro J. 1995, 87, 1020–1024. [Google Scholar] [CrossRef]

- Hu, H.; Meng, Y.; Wang, H.; Liu, H.; Chen, S. Identifying quantitative trait loci and determining closely related stalk traits for rind penetrometer resistance in a high-oil corn population. Theor. Appl. Genet. 2012, 124, 1439–1447. [Google Scholar] [CrossRef] [PubMed]

| Sample | Density (Plants/hm2) | Variety | Plant Height (Hp)/mm | Ear Height (He)/mm | Stalk Diameter (DS)/mm | Internode Length (Li)/mm | Ear Height Coefficient (Ce) |

|---|---|---|---|---|---|---|---|

| 1 | 60,000 | ZD958 | 2606.00 b | 1080.00 b | 23.10 a | 71.00 c | 0.40 bc |

| 2 | 60,000 | YD606 | 2603.00 b | 1060.20 c | 23.20 a | 98.10 a | 0.41 b |

| 3 | 60,000 | XD20 | 2464.20 d | 1183.10 a | 23.40 a | 94.00 ab | 0.48 a |

| 4 | 60,000 | XY335 | 2702.20 a | 1093.10 b | 23.10 a | 93.00 b | 0.41 b |

| 5 | 60,000 | DH605 | 2538.00 c | 1000.00 c | 23.40 a | 74.20 c | 0.39 c |

| 6 | 75,000 | ZD958 | 2620.10 b | 1106.00 c | 22.50 a | 80.00 c | 0.42 b |

| 7 | 75,000 | YD606 | 2652.00 b | 1076.20 c | 22.11 a | 109.30 ab | 0.42 b |

| 8 | 75,000 | XD20 | 2547.40 c | 1272.00 a | 21.60 a | 111.00 a | 0.50 a |

| 9 | 75,000 | XY335 | 2736.30 a | 1140.60 b | 22.50 a | 95.10 b | 0.42 b |

| 10 | 75,000 | DH605 | 2562.00 c | 1030.60 c | 22.60 a | 78.20 c | 0.40 c |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Q.; Chen, R.; Sun, X.; Jiang, M.; Sun, H.; Wang, S.; Ma, L.; Yang, Y.; Hu, J. A Non-Destructive and Direction-Insensitive Method Using a Strain Sensor and Two Single Axis Angle Sensors for Evaluating Corn Stalk Lodging Resistance. Sensors 2018, 18, 1852. https://doi.org/10.3390/s18061852

Guo Q, Chen R, Sun X, Jiang M, Sun H, Wang S, Ma L, Yang Y, Hu J. A Non-Destructive and Direction-Insensitive Method Using a Strain Sensor and Two Single Axis Angle Sensors for Evaluating Corn Stalk Lodging Resistance. Sensors. 2018; 18(6):1852. https://doi.org/10.3390/s18061852

Chicago/Turabian StyleGuo, Qingqian, Ruipeng Chen, Xiaoquan Sun, Min Jiang, Haifeng Sun, Shun Wang, Liuzheng Ma, Yatao Yang, and Jiandong Hu. 2018. "A Non-Destructive and Direction-Insensitive Method Using a Strain Sensor and Two Single Axis Angle Sensors for Evaluating Corn Stalk Lodging Resistance" Sensors 18, no. 6: 1852. https://doi.org/10.3390/s18061852