Coupling p+n Field-Effect Transistor Circuits for Low Concentration Methane Gas Detection

Abstract

:1. Introduction

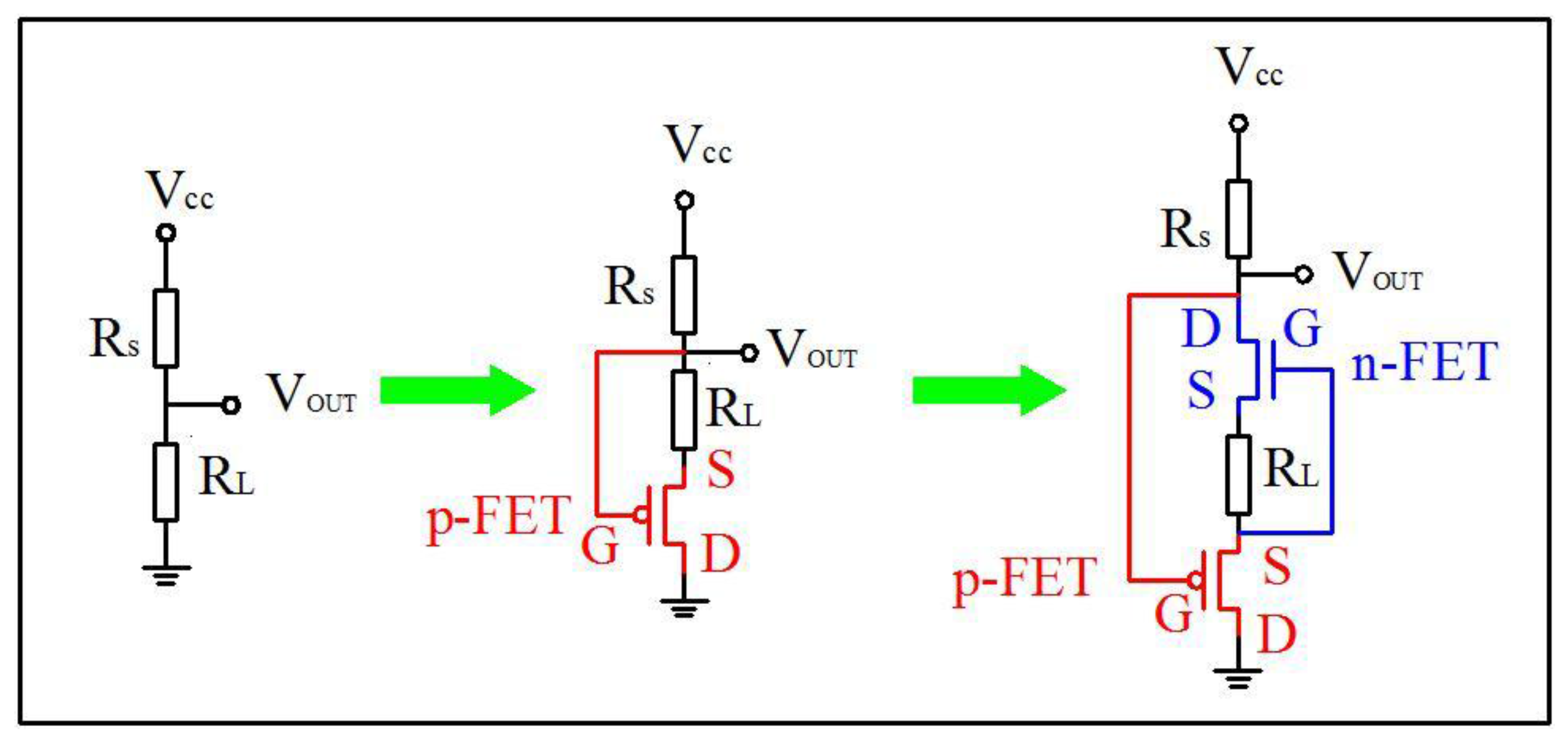

2. Design Scheme of the Amplification Circuit

3. Experimental

4. Results and Discussion

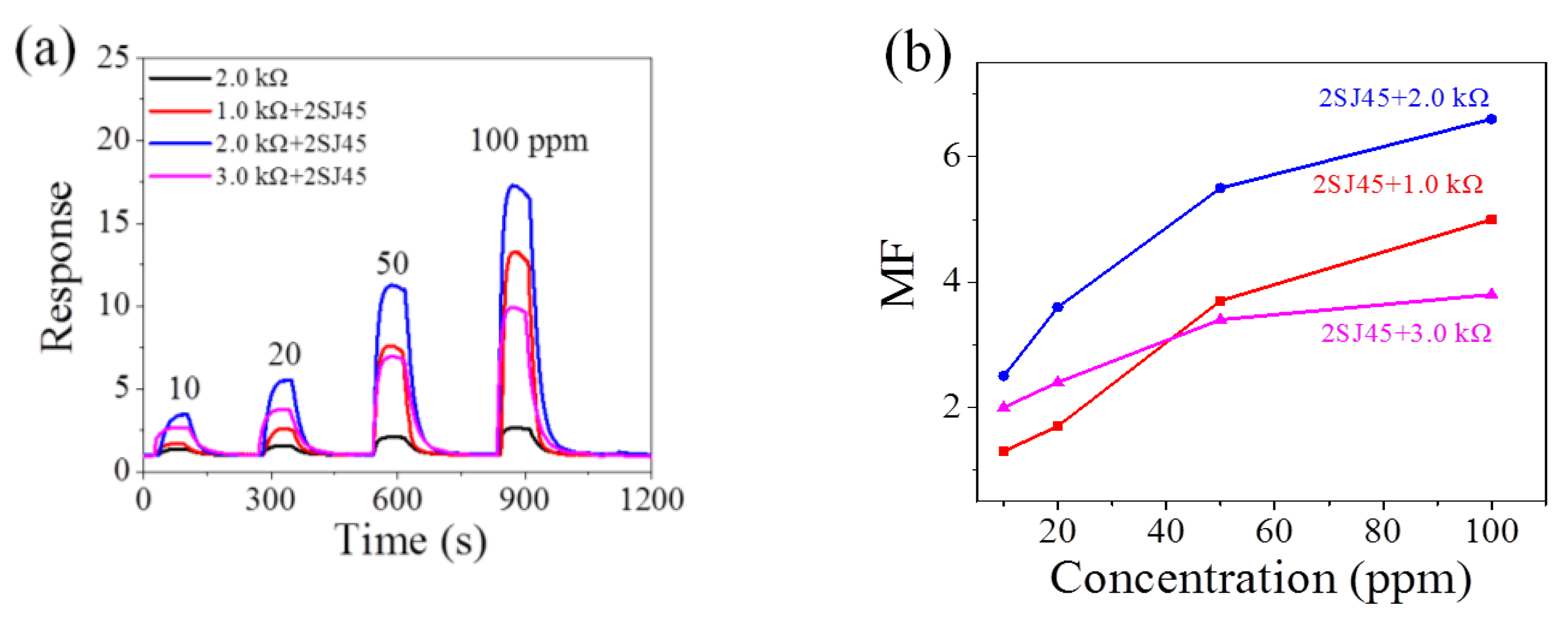

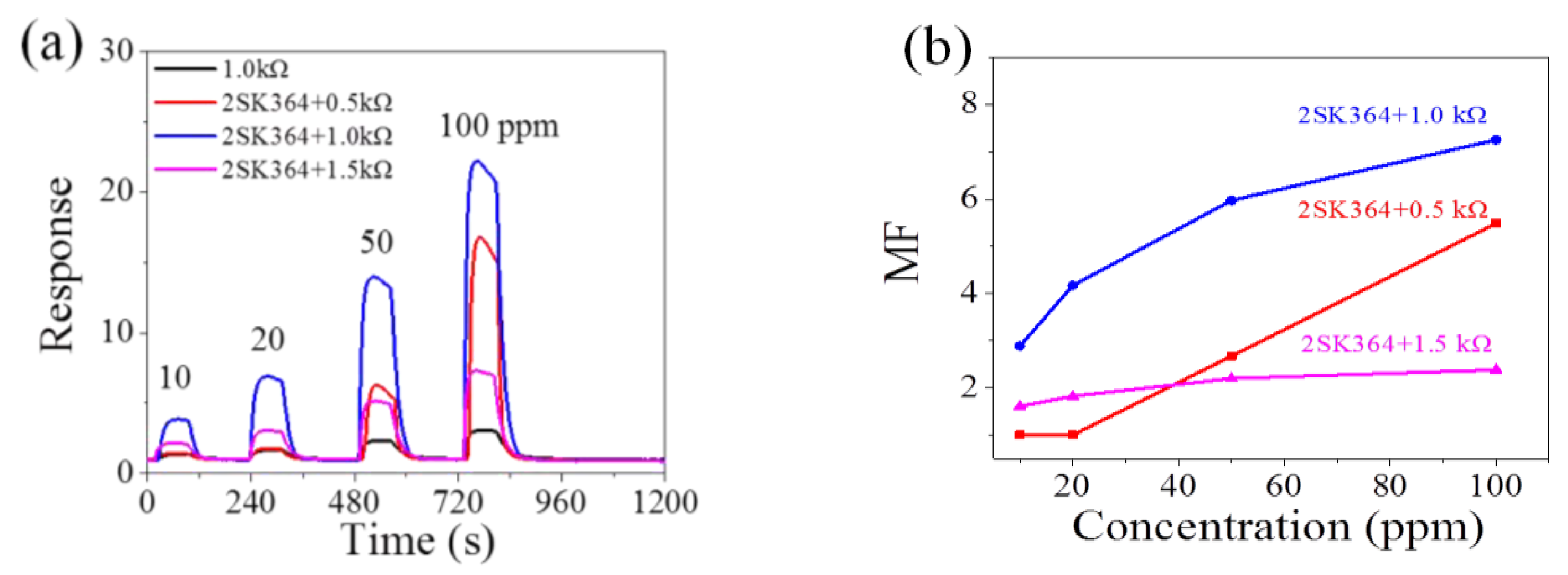

4.1. Single FET Amplification Circuit

r2 = 0.999

r2 = 0.989

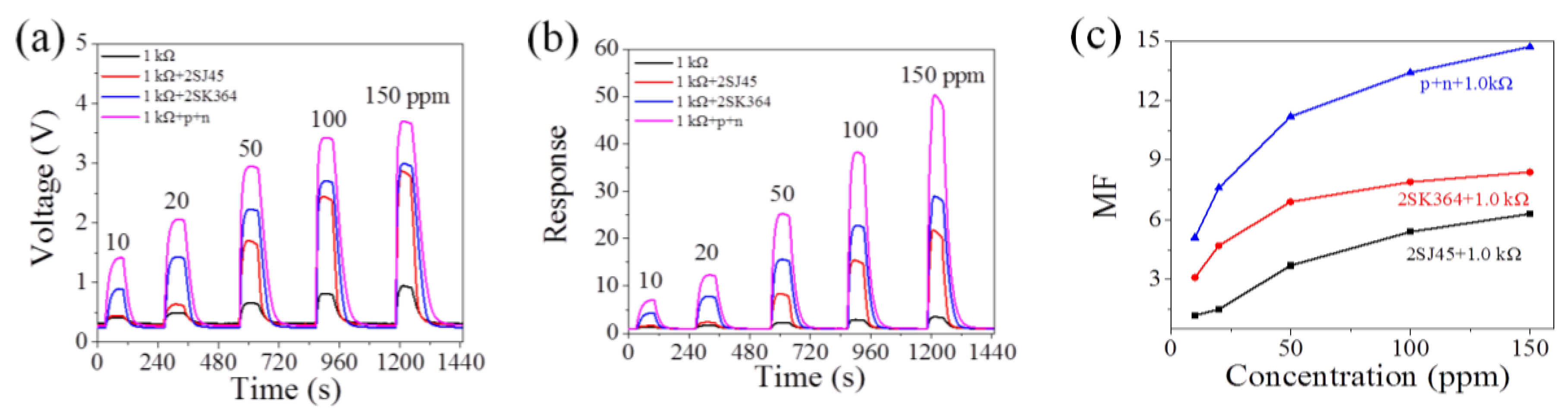

4.2. Coupling the p+n FET Amplification Circuit

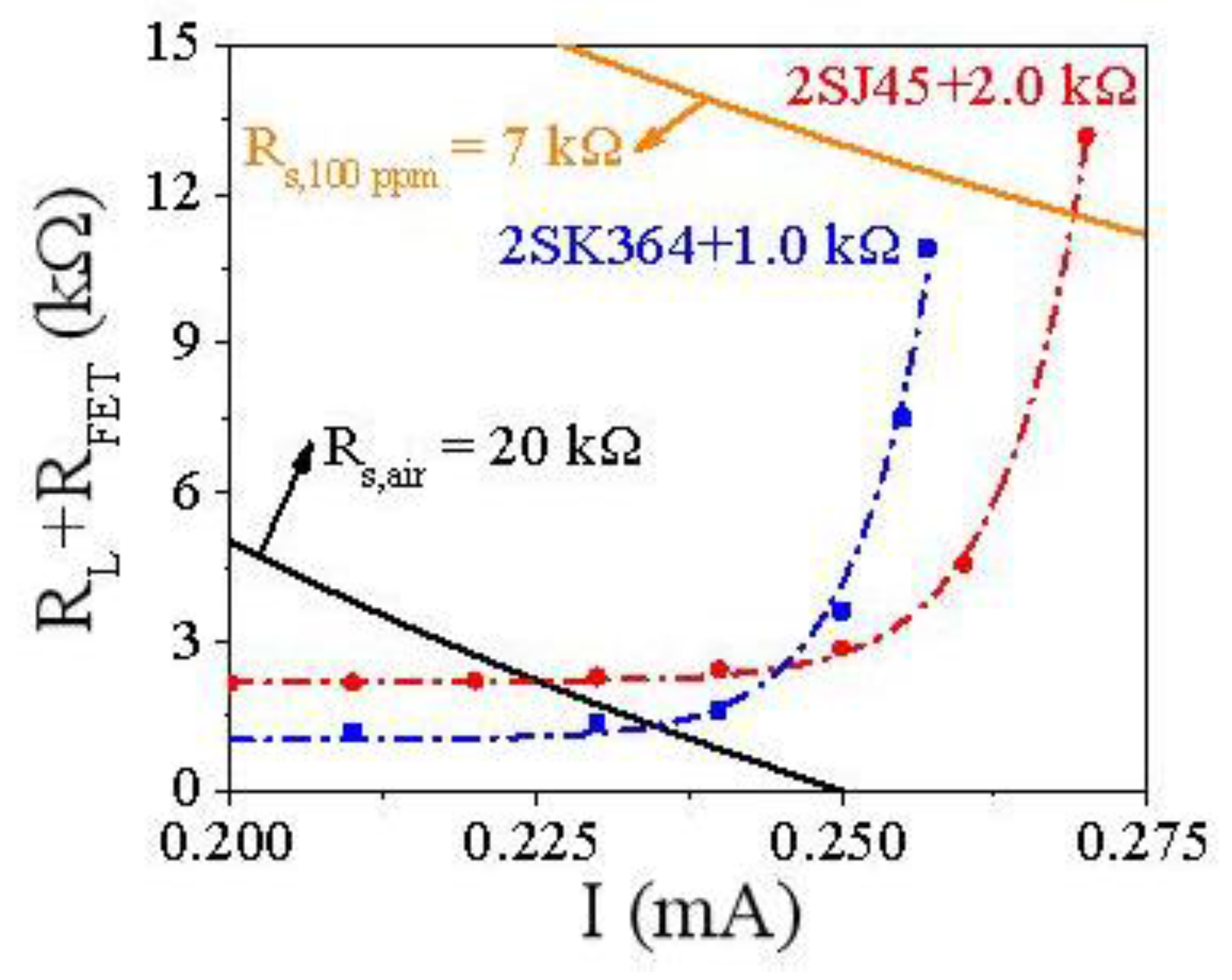

4.3. Mechanism of the Coupling p+n FET Amplification Circuit

- The first stage is in clean air, i.e., the baseline of the sensor. The RL of the coupling p+n FET circuit is 1.0 kΩ. Both of the FETs are in the ON state, so their resistances can be neglected. Therefore, the coupling circuit in clean air is equivalent to the single n-type or p-type FET circuit. Hence, the curves of both the coupling circuit (magenta solid line) and the single n- and p-type FET circuits (blue and gray dash lines) overlap each other, where RL + RFET ≈ VGS(n)/I = 1.0 kΩ, as seen in Figure 7.

- When trace concentrations (≤6.9 ppm) of methane gas are injected, which is the second stage, 2SK364 starts to enter the OFF state and amplifies VOUT, while 2SJ45 is still in the ON state. Therefore, the coupling p+n FET circuit is equivalent to the single n-type FET circuit, namely RL + RFET = (VGS(n) + VDS(n))/I, whose curve overlaps the fitting curve of the single n-type FET circuit with RL of 1.0 kΩ (blue dash curve), as shown in Figure 7. It should be noted that all circuits, with or without FETs, cannot effectively detect methane lower than 6.9 ppm if the effective voltage signal is set to 1.0 V.

- Injecting more than 6.9 ppm of methane gas is the third stage. Both 2SK364 and 2SJ45 play an excellent amplifying role. In this stage, the coupling p+n FET circuit is roughly thought of as the single p-type FET circuit, where RL is subject to the n-FET. Consequently, this coupling circuit can be regarded as the p-type FET circuit with variable RL, which is distinguished from constant RL in the former single FET circuit and gives far higher MF than single FET circuits.

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- De Smedt, G.; de Corte, F.; Notele, R.; Berghmans, J. Comparison of two standard test methods for determining explosion limits of gases at atmospheric conditions. J. Hazard. Mater. 1999, A70, 105–113. [Google Scholar] [CrossRef]

- Vuong, N.M.; Hieu, N.M.; Hieu, H.N.; Yi, H.; Kim, D.; Han, Y.; Kim, M. Ni2O3-decorated SnO2 particulate films for methane gas sensors. Sens. Actuators B Chem. 2014, 192, 327–333. [Google Scholar] [CrossRef]

- Patsha, A.; Sahoo, P.; Amirthapandian, S.; Prasad, A.K.; Das, A.; Tyagi, A.K.; Cotta, M.A.; Dhara, S. Localized Charge Transfer Process and Surface Band Bending in Methane Sensing by GaN Nanowires. J. Phys. Chem. C 2015, 119, 21251–21260. [Google Scholar] [CrossRef]

- Yvon-Durocher, G.; Allen, A.P.; Bastviken, D.; Conrad, R.; Gudasz, C.; St-Pierre, A.; Thanh-Duc, N.; del Giorgio, P.A. Methane fluxes show consistent temperature dependence across microbial to ecosystem scales. Nature 2014, 507, 488–491. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Cao, L.; Li, L.; Wei, J.; Li, G.; Yuan, Y. Highly sensitive methane catalytic combustion micro-sensor based on mesoporous structure and nano-catalyst. Nanoscale 2013, 5, 9720–9725. [Google Scholar] [CrossRef] [PubMed]

- Nagai, D.; Nishibori, M.; Itoh, T.; Kawabe, T.; Sato, K.; Shin, W. Ppm level methane detection using micro-thermoelectric gas sensors with Pd/Al2O3 combustion catalyst films. Sens. Actuators B Chem. 2015, 206, 488–494. [Google Scholar] [CrossRef]

- Ercolino, G.; Karimi, S.; Stelmachowski, P.; Specchia, S. Catalytic combustion of residual methane on alumina monoliths and open cell foams coated with Pd/Co3O4. Chem. Eng. J. 2017, 326, 339–349. [Google Scholar] [CrossRef]

- Shaalan, N.M.; Rashad, M.; Moharram, A.H.; Abdel-Rahim, M.A. Promising methane gas sensor synthesized by microwave-assisted Co3O4 nanoparticles. Mater. Sci. Semicond. Process. 2016, 46, 1–5. [Google Scholar] [CrossRef]

- Hussain, T.; Kaewmaraya, T.; Khan, M.; Chakraborty, S.; Islam, M.S.; Amornkitbamrung, V.; Ahuja, R. Improved sensing characteristics of methane over ZnO nano sheets upon implanting defects and foreign atoms substitution. Nanotechnology 2017, 28, 415502. [Google Scholar] [CrossRef] [PubMed]

- Gustafsson, U.; Sandsten, J.; Svanberg, S. Simultaneous detection of methane, oxygen and water vapour utilising near-infrared diode lasers in conjunction with difference-frequency generation. Appl. Phys. B 2000, 71, 853–857. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, Y.; Yu, J.; Wu, S.; Zhang, Z.; Zheng, F.; Lou, X.; Guo, W. Tunable multi-mode diode laser absorption spectroscopy for methane detection. Sens. Actuators A Phys. 2013, 199, 106–110. [Google Scholar] [CrossRef]

- Loftfield, N.; Flessa, H.; Augustin, J.; Beese, F. Automated Gas Chromatographic System for Rapid Analysis of the Atmospheric Trace Gases Methane, Carbon Dioxide, and Nitrous Oxide. J. Environ. Qual. 1997, 26, 560–564. [Google Scholar] [CrossRef]

- Kamiński, M.; Kartanowicz, R.; Jastrzębski, D.; Kamiński, M.M. Determination of carbon monoxide, methane and carbon dioxide in refinery hydrogen gases and air by gas chromatography. J. Chromatogr. A 2003, 989, 277–283. [Google Scholar] [CrossRef]

- Benounis, M.; Jaffrezic-Renault, N.; Dutasta, J.P.; Cherif, K.; Abdelghani, A. Study of a new evanescent wave optical fibre sensor for methane detection based on cryptophane molecules. Sens. Actuators B Chem. 2005, 107, 32–39. [Google Scholar] [CrossRef]

- Tao, C.; Li, X.; Yang, J.; Shi, Y. Optical fiber sensing element based on luminescence quenching of silica nanowires modified with cryptophane-A for the detection of methane. Sens. Actuators B Chem. 2011, 156, 553–558. [Google Scholar] [CrossRef]

- Basu, S.; Basu, P.K. Nanocrystalline Metal Oxides for Methane Sensors: Role of Noble Metals. J. Sens. 2009, 2009, 1–20. [Google Scholar] [CrossRef]

- Haridas, D.; Gupta, V. Enhanced response characteristics of SnO2 thin film based sensors loaded with Pd clusters for methane detection. Sens. Actuators B Chem. 2012, 166–167, 156–164. [Google Scholar] [CrossRef]

- Kim, H.R.; Haensch, A.; Kim, I.D.; Barsan, N.; Weimar, U.; Lee, J.H. The Role of NiO Doping in Reducing the Impact of Humidity on the Performance of SnO2-Based Gas Sensors: Synthesis Strategies, and Phenomenological and Spectroscopic Studies. Adv. Funct. Mater. 2011, 21, 4456–4463. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Zhou, Z. Novel high sensitivity and selectivity semiconductor gas sensor based on the p+n combined structure. Solid-State Electron. 2000, 44, 1603–1607. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Wang, J.; Xie, Z.; Wu, X.; Han, N.; Chen, Y. Amplifying the Signal of Metal Oxide Gas Sensors for Low Concentration Gas Detection. IEEE Sens. J. 2017, 17, 2841–2847. [Google Scholar] [CrossRef]

- Xing, R.Q.; Xu, L.; Song, J.; Zhou, C.Y.; Li, Q.L.; Liu, D.L.; Song, H.W. Preparation and Gas Sensing Properties of In2O3/Au Nanorods for Detection of Volatile Organic Compounds in Exhaled Breath. Sci. Rep. 2015, 5, 10717. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Wang, D.W.; Zhou, X.; Sun, P.; Wang, H.Y.; Ma, J.; Lu, G.Y. Hydrothermal preparation and gas sensing properties of Zn-doped SnO2 hierarchical architectures. Sens. Actuators B Chem. 2014, 191, 45–52. [Google Scholar] [CrossRef]

- Bai, S.L.; Du, L.; Sun, J.H.; Luo, R.X.; Li, D.Q.; Chen, A.F.; Liu, C.C. Preparation of reduced graphene oxide/Co3O4 composites and sensing performance to toluene at low temperature. RSC Adv. 2016, 6, 60109–60116. [Google Scholar] [CrossRef]

- Qin, N.; Wang, X.H.; Xiang, Q.; Xu, J.Q. A biomimetic nest-like ZnO: Controllable synthesis and enhanced ethanol response. Sens. Actuators B Chem. 2014, 191, 770–778. [Google Scholar] [CrossRef]

- Chen, A.; Bai, S.; Shi, B.; Liu, Z.; Li, D.; Liu, C.C. Methane gas-sensing and catalytic oxidation activity of SnO2–In2O3 nanocomposites incorporating TiO2. Sens. Actuators B Chem. 2008, 135, 7–12. [Google Scholar] [CrossRef]

- Malyshev, V.V.; Pislyakov, A.V. Metal oxide semiconductors based on tin dioxide: Gas-sensitivity to methane in a wide range of temperatures, concentrations and humidities of the gas phase. J. Anal. Chem. 2009, 64, 90–100. [Google Scholar] [CrossRef]

- Zhang, H.; Cen, Y.; Du, Y.; Ruan, S. Enhanced Acetone Sensing Characteristics of ZnO/Graphene Composites. Sensors 2016, 16, 1876. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Wang, Y.; Wang, Z.; Yang, L.; Wu, X.; Han, N.; Chen, Y. Synergetic p+n field-effect transistor circuits for ppb-level xylene detection. IEEE Sens. J. 2018. under review. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Yang, L.; Bian, Y.; Ma, X.; Han, N.; Chen, Y. Coupling p+n Field-Effect Transistor Circuits for Low Concentration Methane Gas Detection. Sensors 2018, 18, 787. https://doi.org/10.3390/s18030787

Zhou X, Yang L, Bian Y, Ma X, Han N, Chen Y. Coupling p+n Field-Effect Transistor Circuits for Low Concentration Methane Gas Detection. Sensors. 2018; 18(3):787. https://doi.org/10.3390/s18030787

Chicago/Turabian StyleZhou, Xinyuan, Liping Yang, Yuzhi Bian, Xiang Ma, Ning Han, and Yunfa Chen. 2018. "Coupling p+n Field-Effect Transistor Circuits for Low Concentration Methane Gas Detection" Sensors 18, no. 3: 787. https://doi.org/10.3390/s18030787