Low-Cost Wireless Temperature Measurement: Design, Manufacture, and Testing of a PCB-Based Wireless Passive Temperature Sensor

Abstract

:1. Introduction

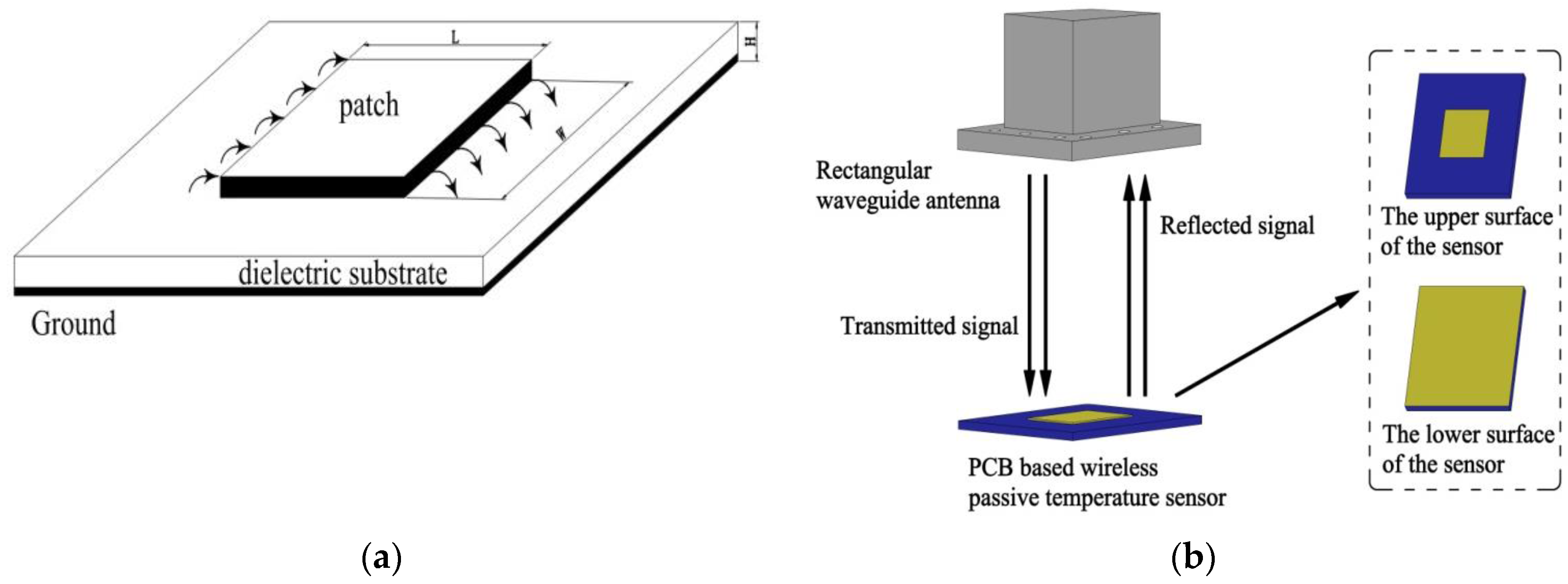

2. Measuring Principle

3. Design and Fabrication

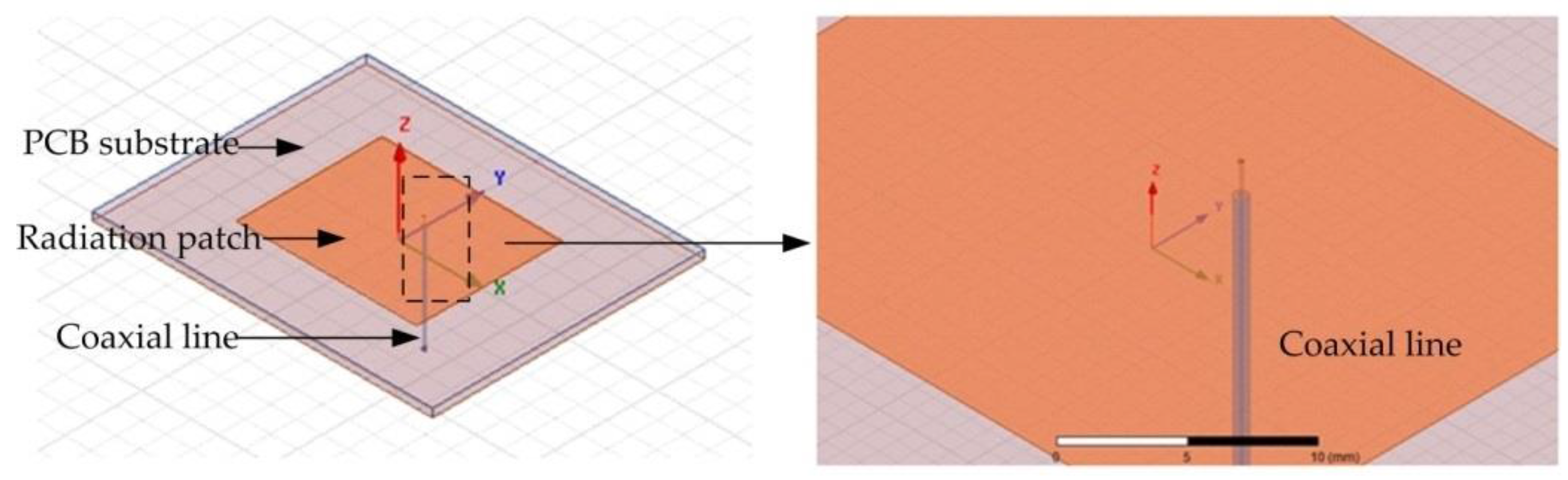

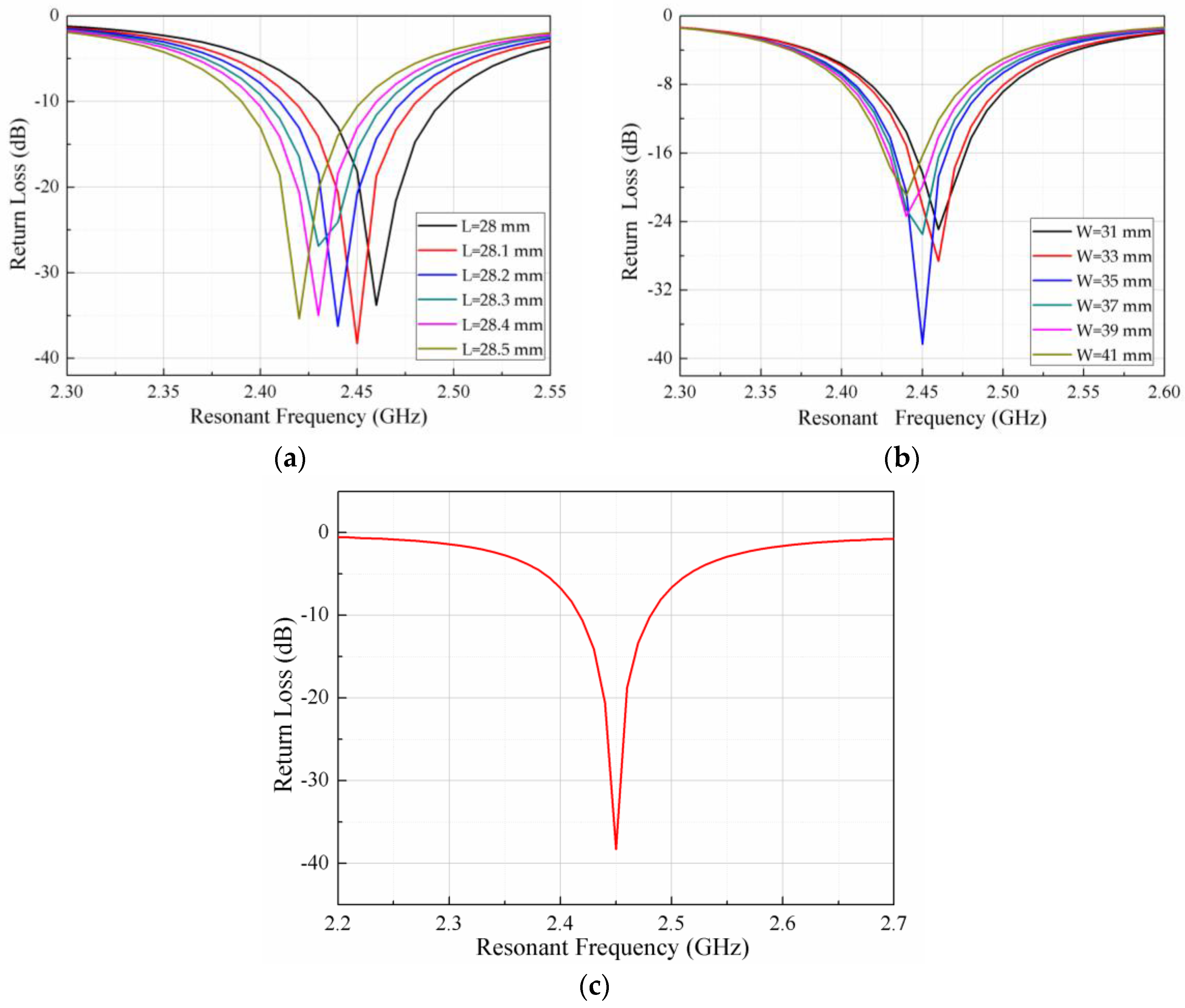

3.1. Sensor Design

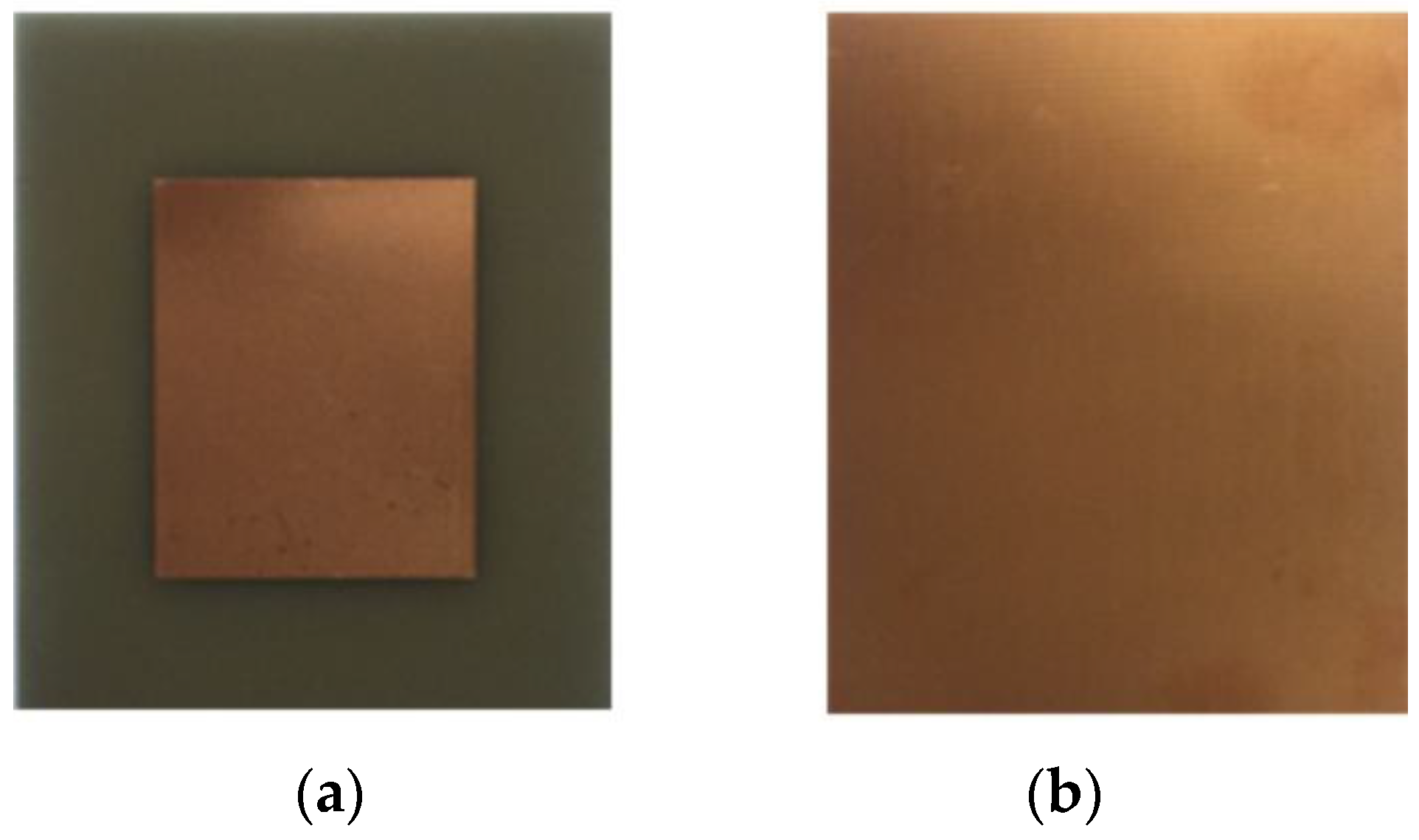

3.2. Sensor Fabrication

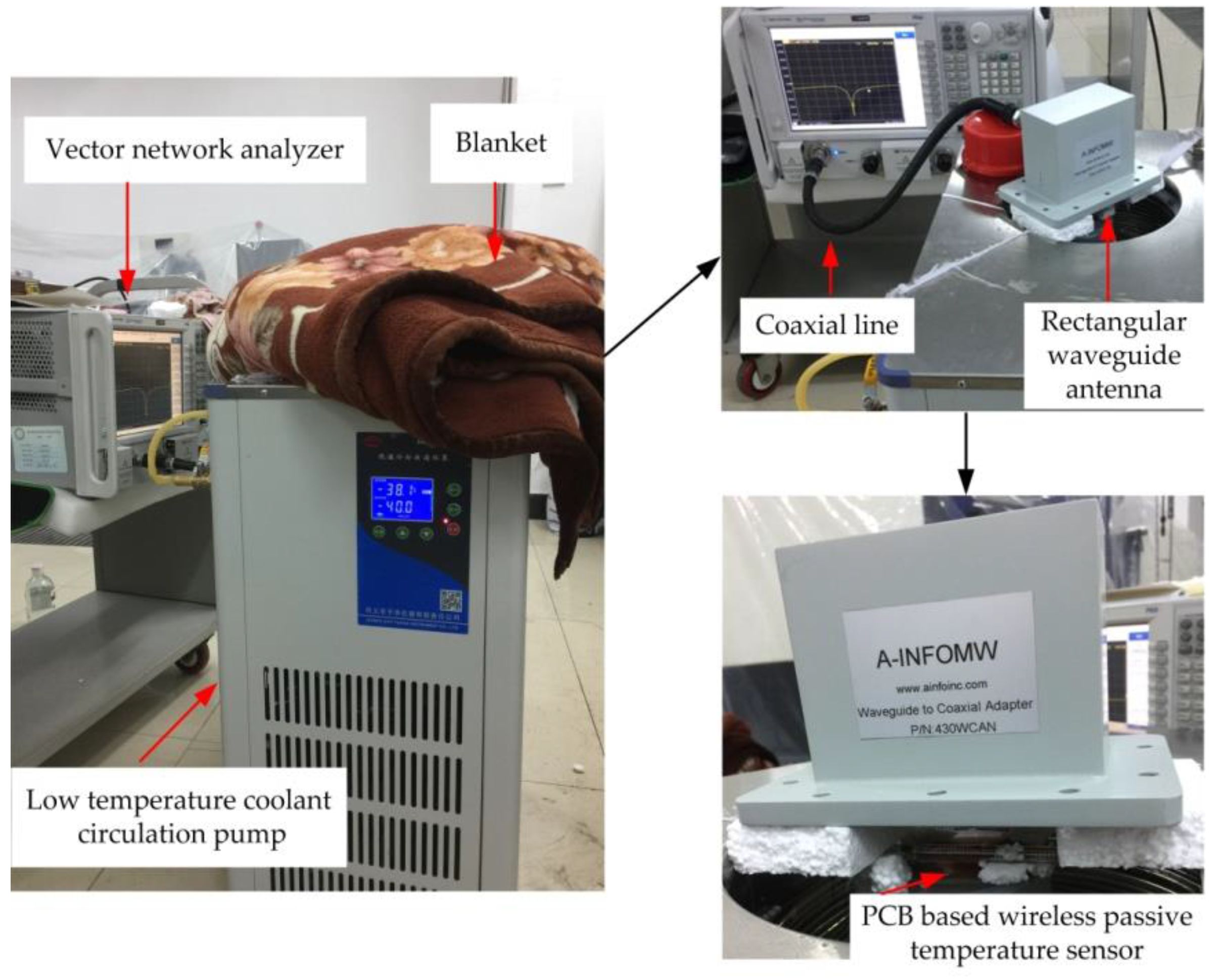

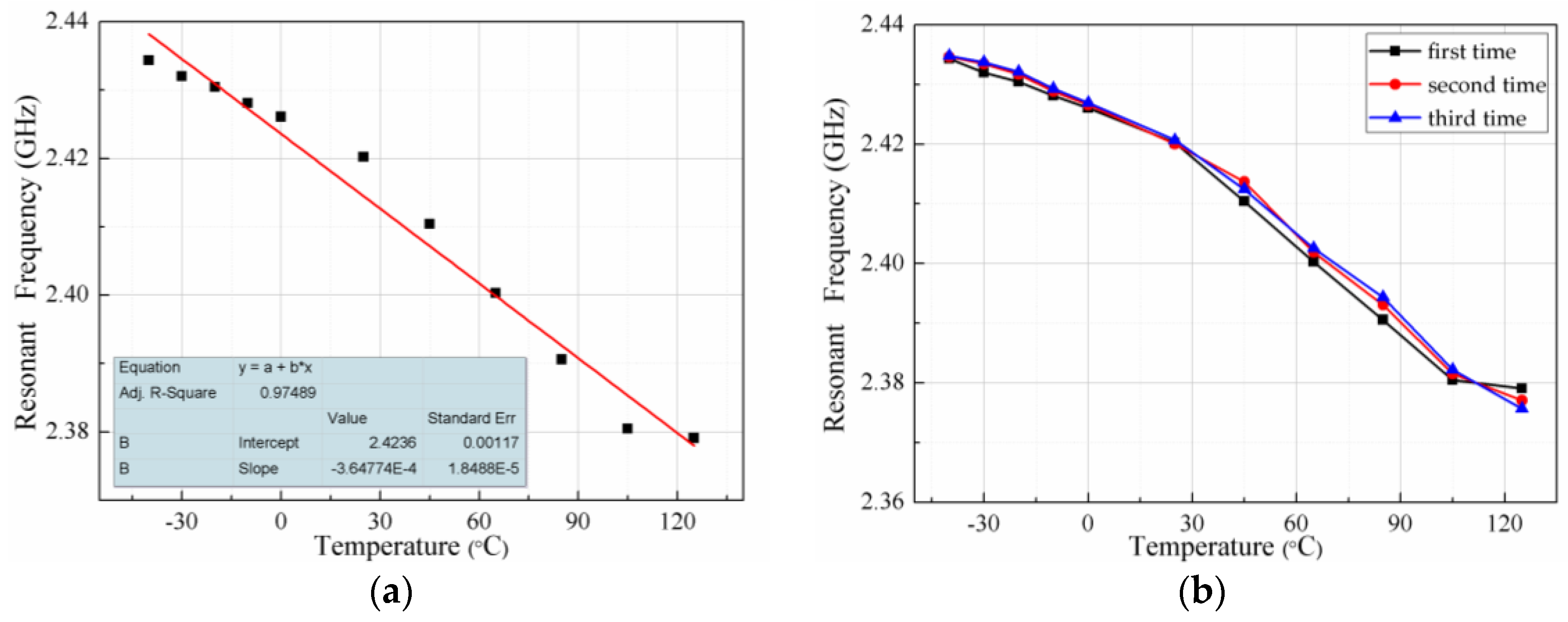

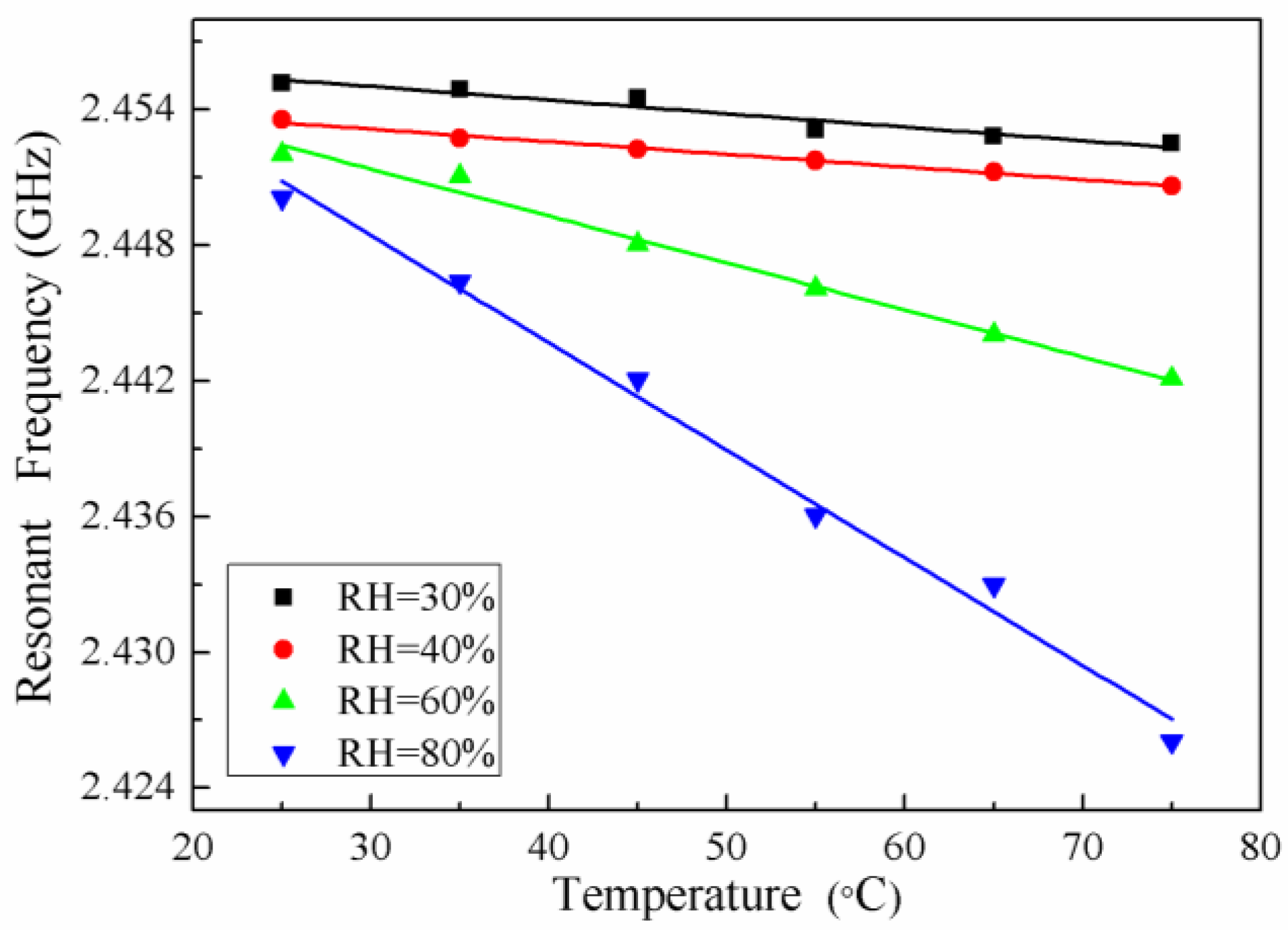

4. Testing and Discussion

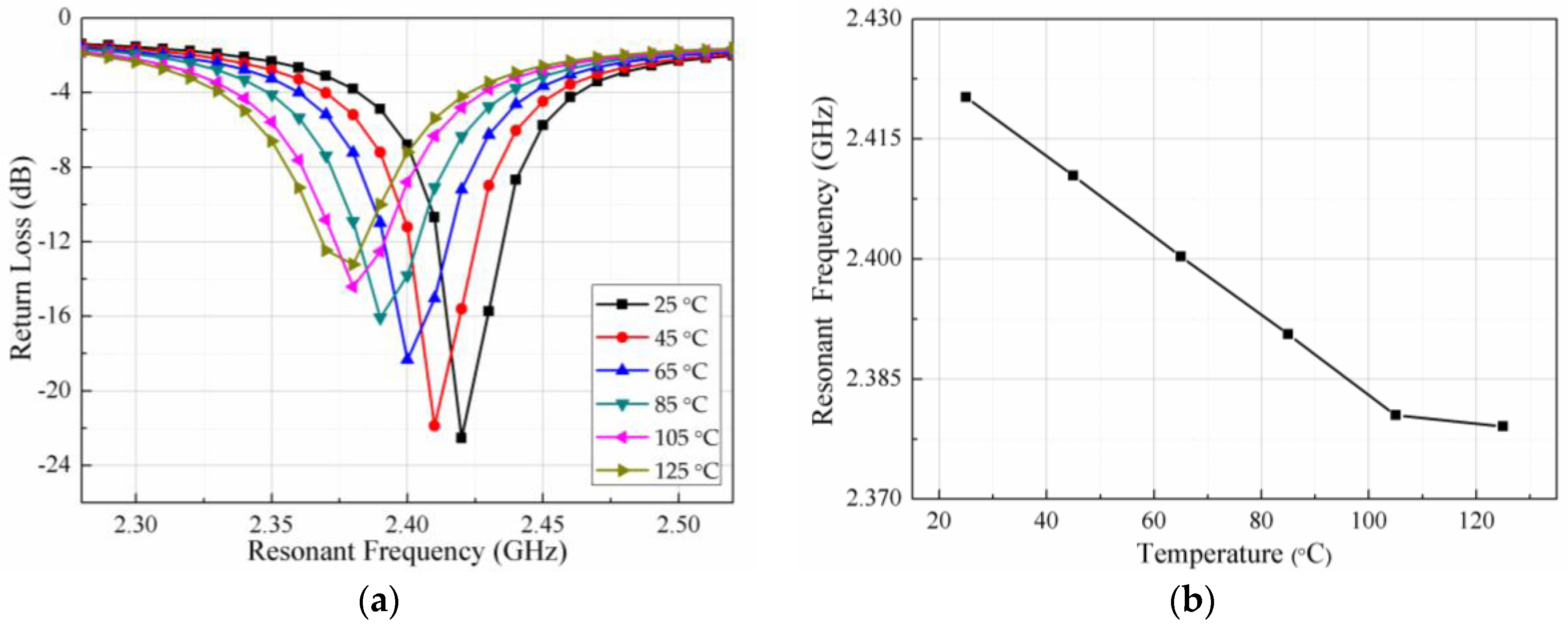

4.1. High-Temperature Test

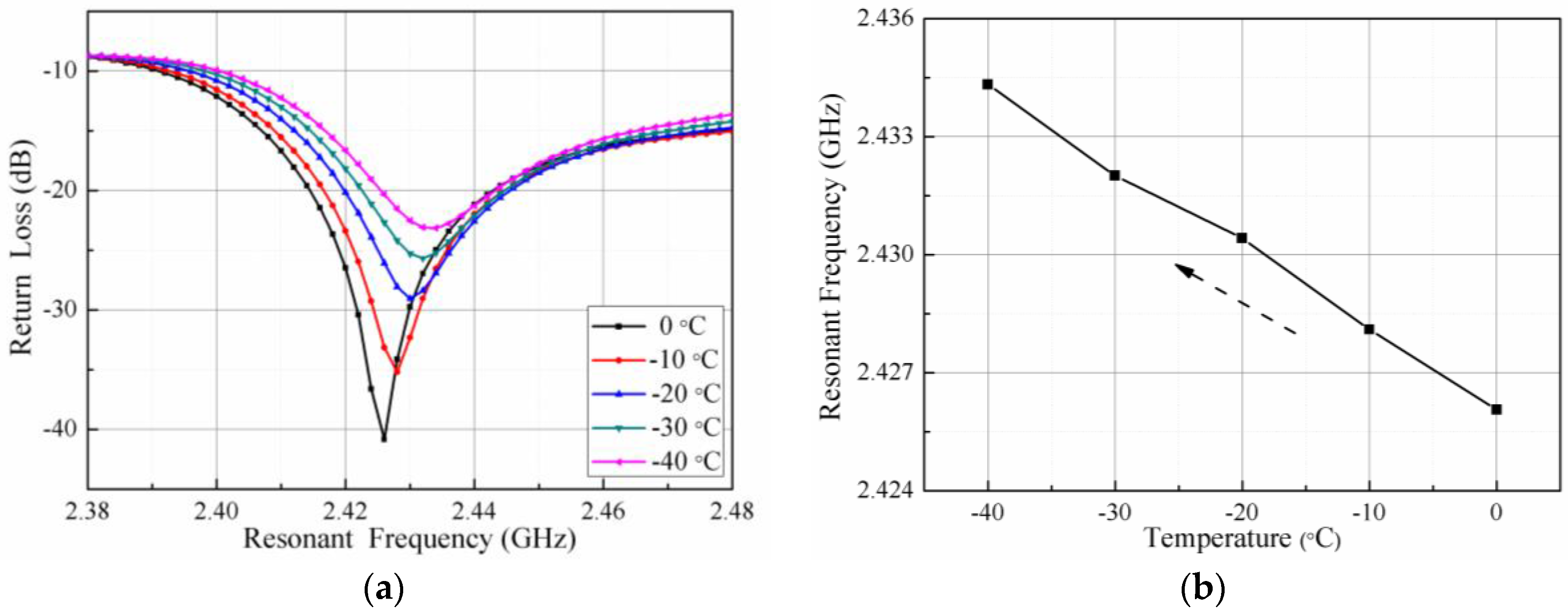

4.2. Low-Temperature Test

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kairm, H.; Delfin, D.; Shuvo, M.A.I.; Chavez, L.A.; Garcia, C.R.; Barton, J.H.; Gaytan, S.M.; Cadena, M.A.; Rumpf, R.C.; Wicker, R.B.; et al. Concept and model of a metamaterial-based passive wireless temperature sensor for harsh environment applications. IEEE Sens. J. 2015, 15, 1445–1452. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, I. A review of wireless sensor technologies and applications in agriculture and food industry: State of the art and current trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blay, V.; Bobadilla, L.F. Numerical study of the accuracy of temperature measurement by thermocouples in small-scale reactors. Chem. Eng. Res. Des. 2017. [Google Scholar] [CrossRef]

- Michalski, D.; Strak, K.; Piasecka, M. Comparison of two surface temperature measurement using thermocouples and infrared camera. EPJ Web of Conferences. EDP Sci. 2017, 143, 02075. [Google Scholar]

- Fu, J.; Liu, Z.; Han, S.; Zhao, J.; Huang, Y. Comparison of temperature difference measurement technologies used in vehicular heat exchangers. Exp. Ther. Fluid Sci. 2017, 82, 94–101. [Google Scholar] [CrossRef]

- Avenas, Y.; Dupont, L.; Khatir, Z. Temperature measurement of power semiconductor devices by thermo-sensitive electrical parameters—A review. IEEE Trans. Power Electron. 2012, 27, 3081–3092. [Google Scholar] [CrossRef]

- Ragay-Enot, M.; Lee, Y.H.; Kim, Y.G. Fabrication of a mini multi-fixed-point cell for the calibration of industrial platinum resistance thermometers. Meas. Sci. Technol. 2017, 28, 075007. [Google Scholar] [CrossRef]

- Blackburn, D.L. Temperature measurements of semiconductor devices-A review. In Proceedings of the Twentieth Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 11 March 2004; pp. 70–80. [Google Scholar]

- Niu, H.; Lorenz, R.D. Evaluating different implementations of online junction temperature sensing for switching power semiconductors. IEEE Trans. Ind. Appl. 2017, 53, 391–401. [Google Scholar] [CrossRef]

- Koch, G.H.; Brongers, M.P.H.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Cost and Preventive Strategies in the United States. J. Endocrinol. 2002, 122, 23–31. [Google Scholar]

- Reindl, L.M.; Shrena, I.M. Wireless measurement of temperature using surface acoustic wave sensors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2004, 51, 1457–1463. [Google Scholar] [CrossRef] [PubMed]

- François, B.; Sakharov, S.; Droit, C.; Davis, Z.; Richter, D.; Fritze, H.; Martin, G.; Friedt, J.M.; Plessky, V.P.; Brückner, G.; et al. Wireless Temperature Measurements above 500 °C using Surface Acoustic Wave Sensors. Procedia Eng. 2012, 47, 1227–1230. [Google Scholar] [CrossRef]

- Milan, R.; Bojana, M.L.; Cvejin, K.N.; Srdic, V.V.; Stojanovic, G.M. A Wireless LC Sensor Coated with Ba0.9Bi0.066TiO3 for Measuring Temperature. Sensors 2015, 15, 11454–11464. [Google Scholar]

- Ren, Q.-Y.; Wang, L.-F.; Huang, J.-Q.; Zhang, C.; Huang, Q.-A. Simultaneous Remote Sensing of Temperature and Humidity by LC-Type Passive Wireless Sensors. J. Microelectron. Mech. Syst. 2015, 24, 1117–1123. [Google Scholar] [CrossRef]

- Tan, Q.; Luo, T.; Xiong, J.; Kang, H.; Ji, X.; Zhang, Y.; Yang, M.; Wang, X.; Xue, C.; Liu, J.; et al. A harsh environment-oriented wireless passive temperature sensor realized by LTCC technology. Sensors 2014, 14, 4154–4166. [Google Scholar] [CrossRef] [PubMed]

- Ahn, C.-H.; Kim, H.-H.; Cha, J.-M.; Kwon, B.-H.; Ha, M.-Y.; Park, S.-H.; Jeong, J.-H.; Kim, K.-S.; Cho, J.-R.; Son, C.-M.; et al. Fabrication and Performance Evaluation of Temperature Sensor Matrix Using a Flexible Printed Circuit Board for the Visualization of Temperature Field. J. Korean Soc. Vis. 2010, 7, 17–21. [Google Scholar] [CrossRef]

- Sanders, J.W.; Yao, J.; Huang, H. Microstrip patch antenna temperature sensor. IEEE Sens. J. 2015, 15, 5312–5319. [Google Scholar] [CrossRef]

- Shi, X.W.; Yang, F.; Xu, S.; Li, M. A Passive Temperature-Sensing Antenna Based on a Bimetal Strip Coil. Sensors 2017, 17, 665. [Google Scholar] [CrossRef] [PubMed]

- Stephan, K.D.; Mead, J.B.; Pozar, D.M.; Wang, L.; Pearce, J.A. A near field focused microstrip array for a radiometric temperature sensor. IEEE Trans. Antennas Propag. 2007, 55, 1199–1203. [Google Scholar] [CrossRef]

- Yang, F.; Qiao, Q.; Virtanen, J.; Elsherbeni, A.Z.; Ukkonen, L.; Sydanheimo, L. Reconfigurable sensing antenna: A slotted patch design with temperature sensation. IEEE Antennas Wirel. Propag. Lett. 2012, 11, 632–635. [Google Scholar] [CrossRef]

- Daigle, B. Printed circuit board material and design considerations for wireless applications. In Proceedings of the 46th Electronic Components and Technology Conference, Orlando, FL, USA, 28–31 May 1996; pp. 354–357. [Google Scholar]

- Bois, K.J.; Kirk, B.; Tsuk, M.; Quint, D. Simple and accurate determination of complex permittivity and skin effect of FR4 material in gigahertz regime. In Proceedings of the 53rd Electronic Components and Technology Conference, New Orleans, LA, USA, 27–30 May 2003; pp. 1277–1282. [Google Scholar]

- Yamacli, S.; Ozdemir, C.; Akdagli, A. A method for determining the dielectric constant of microwave PCB substrates. Int. J. Infrared Millim. Waves 2008, 29, 207–216. [Google Scholar] [CrossRef]

- Yadav, R.K.; Kishor, J.; Lal Yadava, R. Effects of temperature variations on microstrip antenna. Int. J. Netw. Commun. 2013, 3, 21–24. [Google Scholar]

- Lai, J.; Lin, T. System operating environment effect on PCB material electrical property. In Proceedings of the 2016 Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; Volume 1, pp. 314–316. [Google Scholar]

- Hinaga, S.; Koledintseva, M.; Drewniak, J.L.; Koul, A.; Zhou, F. Thermal effects on PCB laminate material dielectric constant and dissipation factor. In Proceedings of the IPC APEX EXPO, Las Vegas, NV, USA, 6–8 April 2010. [Google Scholar]

- Constantine, A.B. Antenna Theory: Analysis and Design, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005; pp. 819–820. [Google Scholar]

- Bhardwaj, D.; Soni, B.; Bhatnagar, D.; Sancheti, S. Design of square patch antenna with a notch on FR4 substrate. IET Microw. Antennas Propag. 2008, 2, 880–885. [Google Scholar] [CrossRef]

- Brar, G.S.; Singh, J.; Sidhu, E. High Gain Rectangular Microstrip Patch Antenna Employing FR4 Substrate for Wi-MAX, LMDS and MMDS Applications. Int. J. Eng. Res. Appl. 2016, 6, 49–51. [Google Scholar]

- Yuan, Y.; Cui, Y.R.; Wu, K.T.; Huang, Q.Q.; Zhang, S.R. TiO2 and SiO2 filled PTFE composites for microwave substrate applications. J. Polym. Res. 2014, 21, 366. [Google Scholar] [CrossRef]

- Choudhary, P.; Kumar, R.; Gupta, N. Dielectric material selection of microstrip patch antenna for wireless communication applications using Ashby’s approach. Int. J. Microw. Wirel. Technol. 2015, 7, 579–587. [Google Scholar] [CrossRef]

- Ammann, M.J. A comparison of some low cost laminates for antennas operating in the 2.45 GHz ISM band. In Proceedings of the IEE Colloquium on Low Cost Antenna Technology, London, UK, 4 February 1998. [Google Scholar]

- Aguilar, J.R.; Beadle, M.; Thompson, P.T.; Shelley, M.W. The microwave and RF characteristics of FR4 substrates. In Proceedings of the IEE Colloquium on Low Cost Antenna Technology, London, UK, 4 February 1998. [Google Scholar]

- Chung, D.D.L. Materials for electromagnetic interference shielding. J. Mater. Eng. Perform. 2000, 9, 350–354. [Google Scholar] [CrossRef]

- Shunshi, Z. Microstrip Antenna Theory and Application; Xi’an University of Electronic Science and Technology Press: Xi’an, China, 1991; p. 228. [Google Scholar]

- Ritchey, L.W.; Speeding, E. A Survey and Tutorial of Dielectric Materials Used in the Manufacture of Printed Circuit Boards. Circuitree Magazine, November 1999. [Google Scholar]

- Hongyu, Z.; Eric, G.; Gnian, C.L. Investigation of laser via formation technology for the manufacturing of high density substrates. Opt. Lasers Eng. 2001, 36, 355–371. [Google Scholar]

- Takahashi, K.M. Conduction Paths and Mechanisms in FR-4 Epoxy/Glass Composite Printed Wiring Boards. J. Electrochem. Soc. 1991, 138, 1587–1593. [Google Scholar] [CrossRef]

- McCluskey, P.; Grybowski, R.R.; Condra, L.; Das, D.; Fink, J.; Jordan, J.; Torri, T. Reliability concerns in high temperature electronic systems. In Proceedings of the High-Temperature Electronic Materials, Devices and Sensors Conference, San Diego, CA, USA, 22–27 February 1998. [Google Scholar]

- Sreekantan, S.; Ling, Y.K.; Ahmad, Z.A.; Ain, M.F.; Othman, M.A.; Hassan, S.I.S. Simulation and experimental investigators on rectangular, circular and cylindrical dielectric resonator antenna. Prog. Electromagn. Res. C 2009, 7, 151–166. [Google Scholar] [CrossRef]

- Tata, U.; Huang, H.; Deb, S.; Wang, J.; Chiao, J.-C. A patch antenna-based strain sensor for structural health monitoring. In Proceedings of the Smart Structures, Devices, and Systems IV, Melbourne, Australia, 30 December 2008; Volume 7268. [Google Scholar]

- Qian, Z.; Tang, Q.; Li, J.; Zhao, H.; Zhang, W. Analysis and design of a strain sensor based on a microstrip patch antenna. In Proceedings of the 2012 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Shenzhen, China, 5–8 May 2012. [Google Scholar]

- Scott, S.; Dimitrios, P. A capacitively-loaded MEMS slot element for wireless temperature sensing of up to 300 °C. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009. [Google Scholar]

- Khan, A.; Rajesh, N. Analysis of five different dielectric substrates on microstrip patch antenna. Int. J. Comput. Appl. 2012, 55, 40–47. [Google Scholar] [CrossRef]

- Lili, M.; Bhanu, S.; Michael, P. Effects of moisture content on dielectric constant and dissipation factor of printed circuit board materials. ECS Trans. 2010, 27, 227–236. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, D.; Yang, Y.; Hong, Y.; Liang, T.; Yao, Z.; Chen, X.; Xiong, J. Low-Cost Wireless Temperature Measurement: Design, Manufacture, and Testing of a PCB-Based Wireless Passive Temperature Sensor. Sensors 2018, 18, 532. https://doi.org/10.3390/s18020532

Yan D, Yang Y, Hong Y, Liang T, Yao Z, Chen X, Xiong J. Low-Cost Wireless Temperature Measurement: Design, Manufacture, and Testing of a PCB-Based Wireless Passive Temperature Sensor. Sensors. 2018; 18(2):532. https://doi.org/10.3390/s18020532

Chicago/Turabian StyleYan, Dan, Yong Yang, Yingping Hong, Ting Liang, Zong Yao, Xiaoyong Chen, and Jijun Xiong. 2018. "Low-Cost Wireless Temperature Measurement: Design, Manufacture, and Testing of a PCB-Based Wireless Passive Temperature Sensor" Sensors 18, no. 2: 532. https://doi.org/10.3390/s18020532