A Comprehensive Study of a Micro-Channel Heat Sink Using Integrated Thin-Film Temperature Sensors

Abstract

:1. Introduction

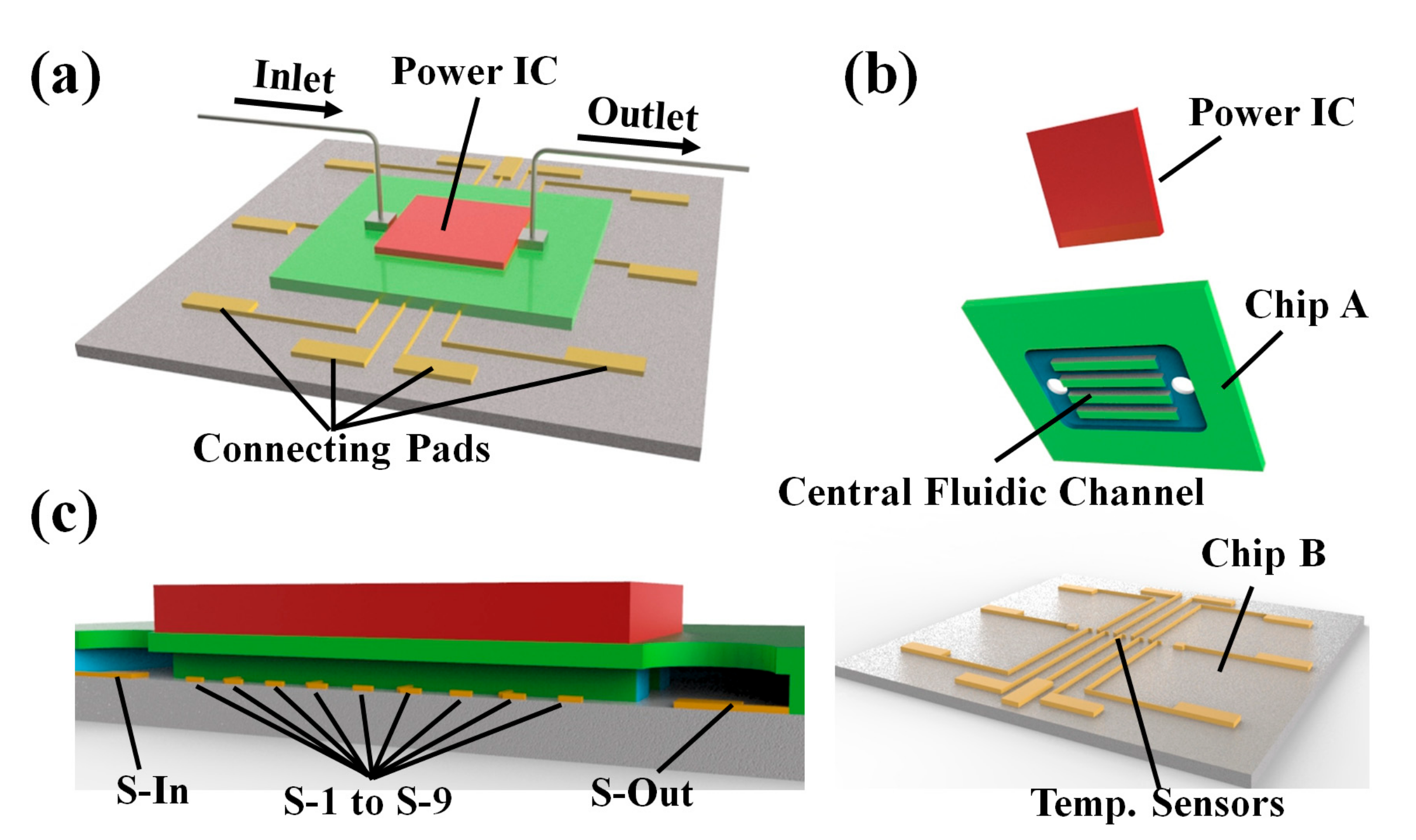

2. Design Considerations

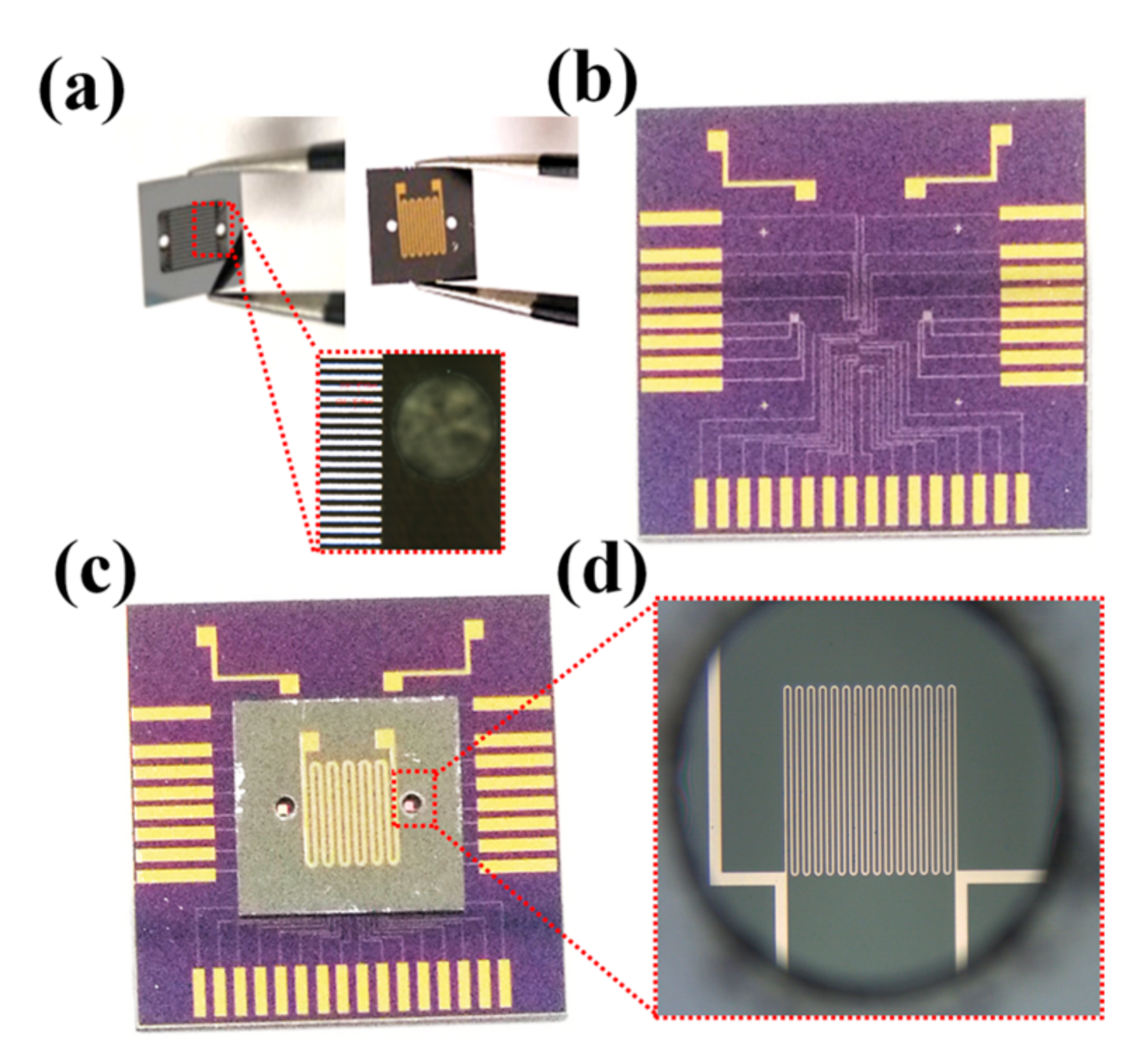

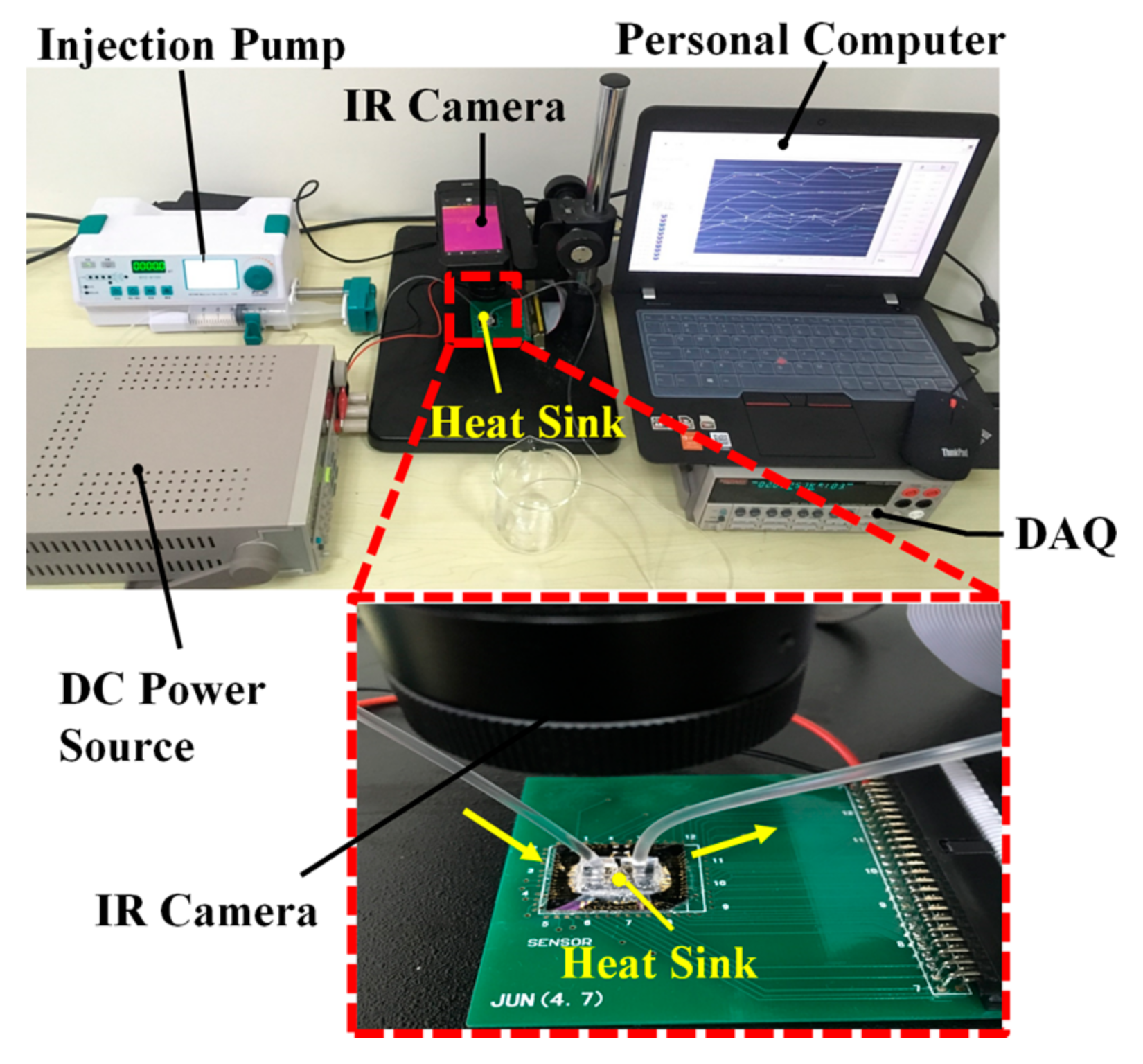

3. Fabrication and Measurement Setup

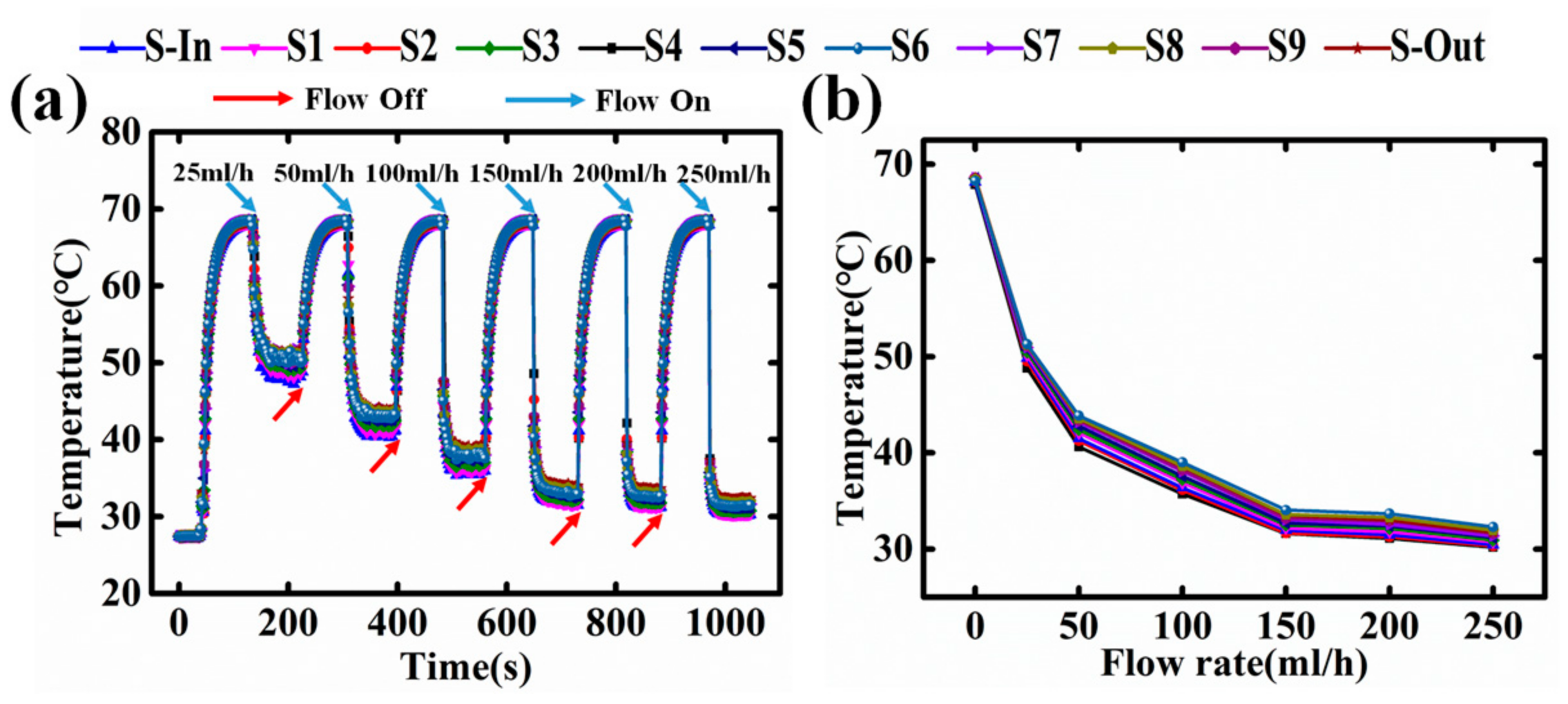

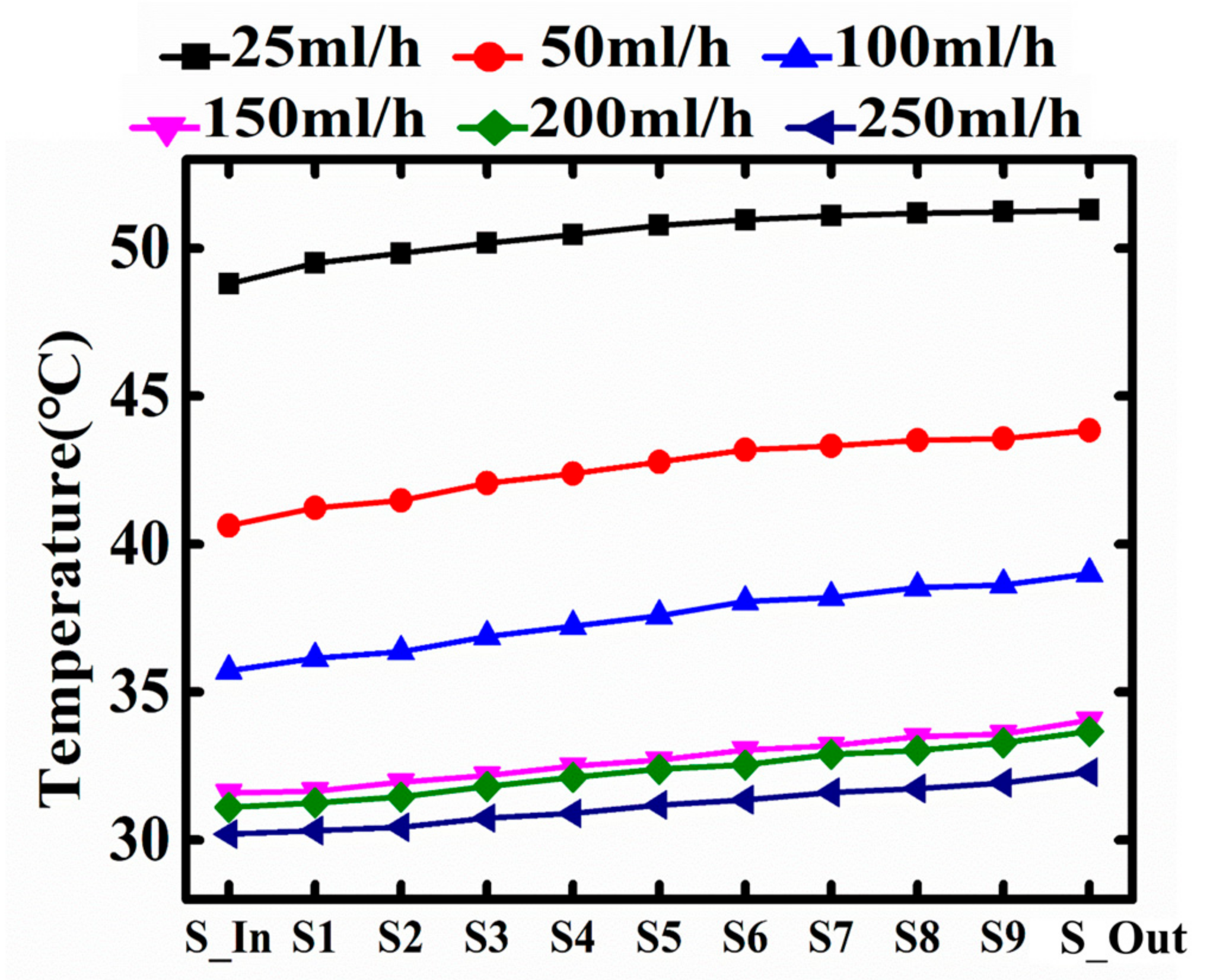

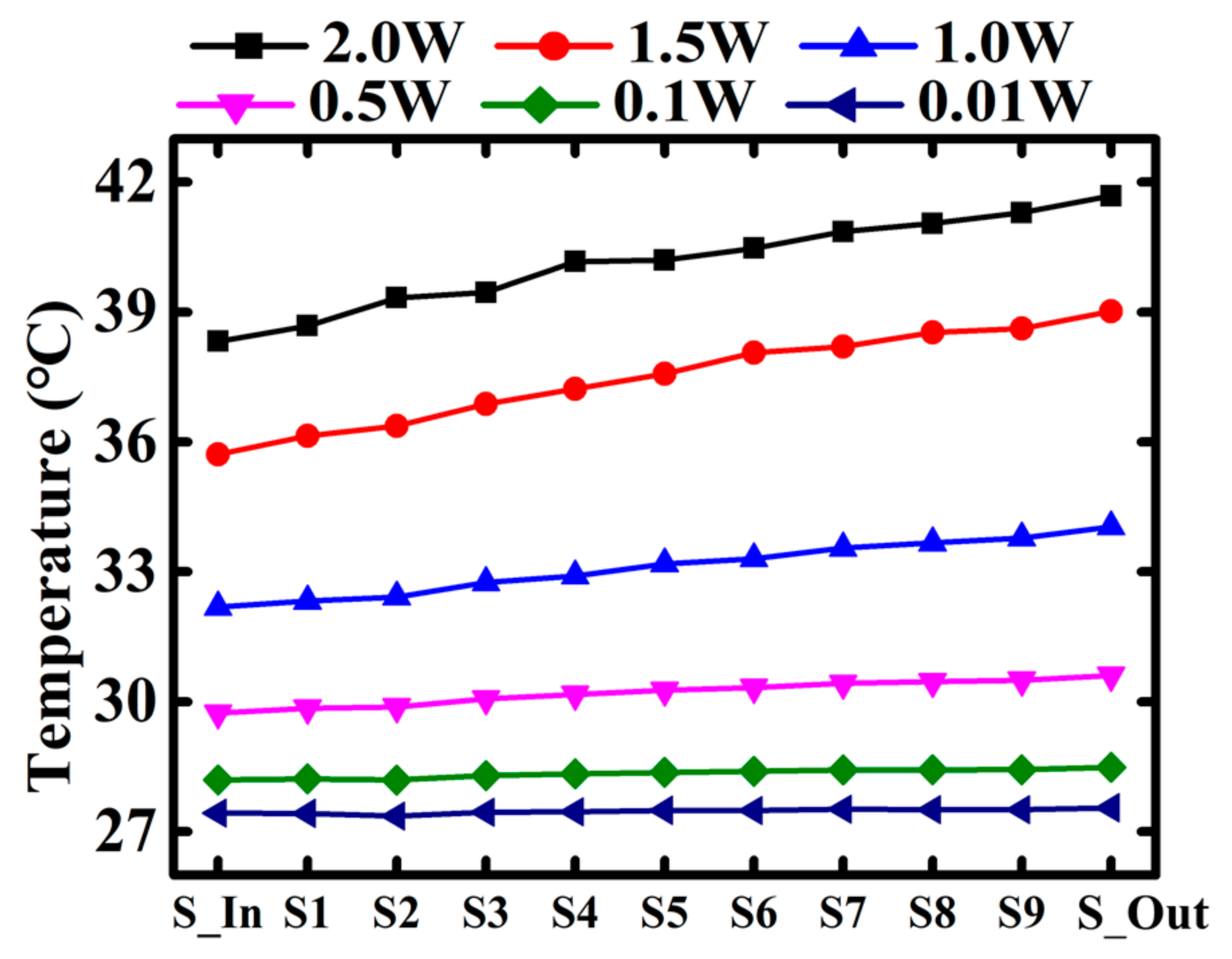

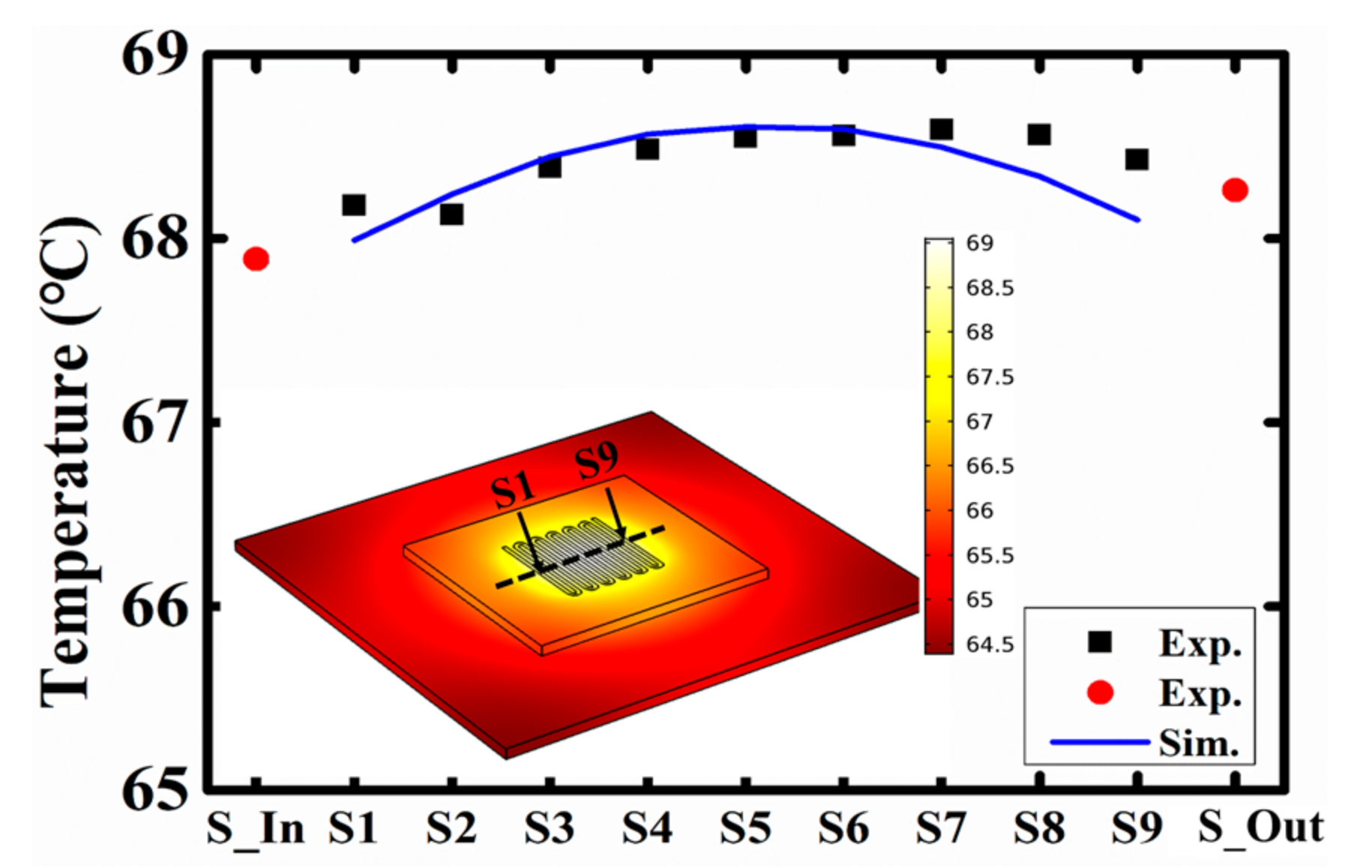

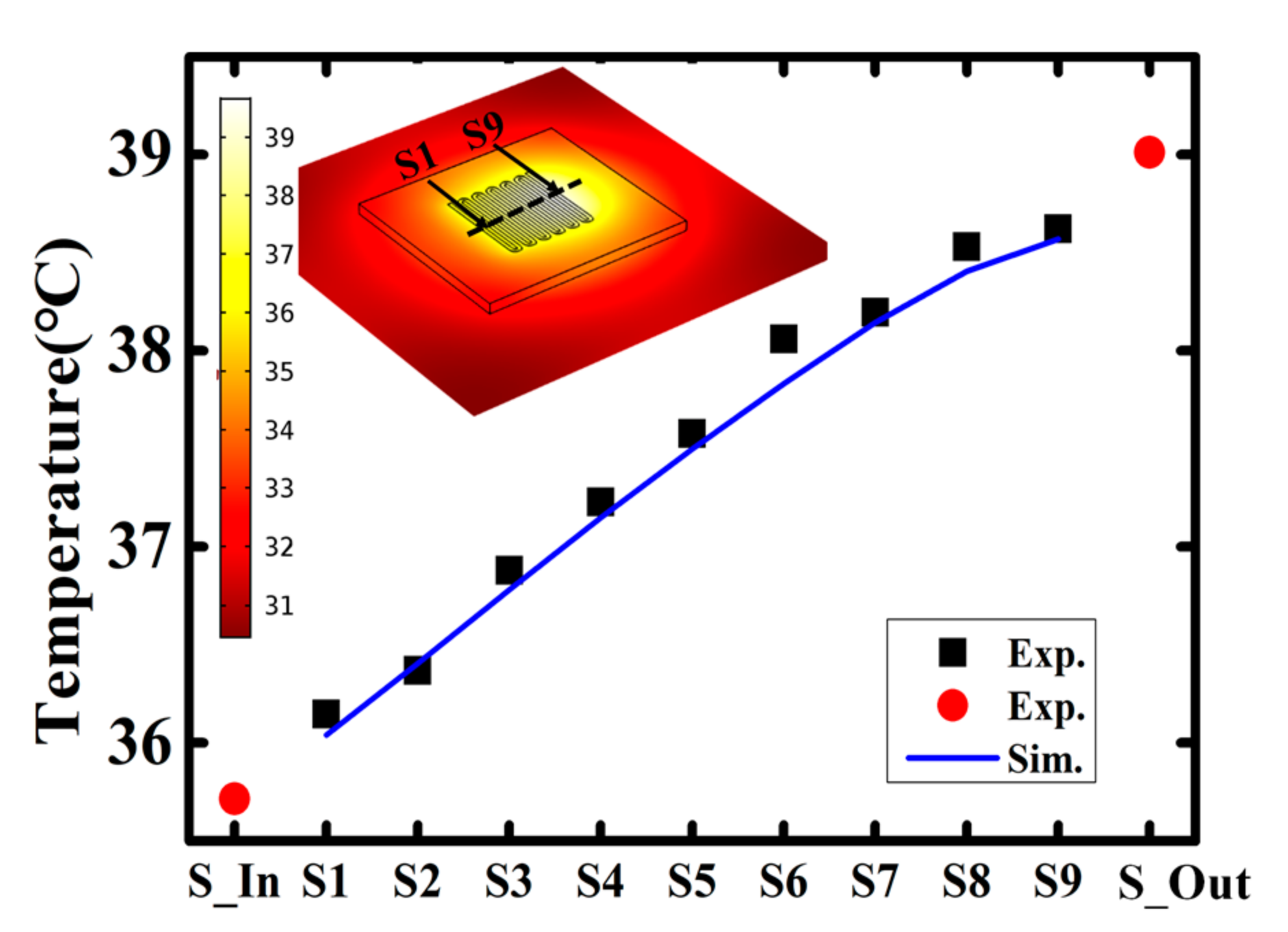

4. Results and Discussion

5. Conclusions

- (1)

- The integrated thin film temperature sensors can monitor the temperature in the channels accurately in real time, and the resolution is better than 0.1 °C. Due to their small size, the temperature profile within the micro-channel can be obtained with high resolution, high stability and high sensitivity.

- (2)

- The experimental results match well with simulation results and can be used to directly verify the modeling results, helping to build a convincing simulation model.

- (3)

- The slope of the temperature distribution trend in the micro-channel from inlet to outlet is related to the heating power and independent of the flow rate. Such temperature non-uniformity may bring problems for power IC and the micro-channel based heat sink should be designed and optimized for minimizing such temperature non-uniformity.

- (4)

- As the temperature increases, the temperature fluctuation is more obvious. The cause of the phenomenon is possibly the phase change or the decreasing of air solubility in water when the temperature rises. The integrated sensors could be a powerful tool for studying the micro-channel based heat sink.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arden, W.M. The international technology roadmap for semiconductors—Perspectives and challenges for the next 15 years. Curr. Opin. Solid State Mater. Sci. 2002, 6, 371–377. [Google Scholar] [CrossRef]

- Hsu, T.R. Reliability in mems packaging. In Proceedings of the IEEE International Reliability Physics Symposium Proceedings, San Jose, CA, USA, 26–30 March 2006; pp. 398–402. [Google Scholar]

- Brooks, D.; Martonosi, M. Dynamic thermal management for high-performance microprocessors. In Proceedings of the Seventh International Symposium on High-Performance Computing Architecture, Monterrey, Mexico, 19–24 January 2001; pp. 171–182. [Google Scholar]

- Maydanik, Y.F. Loop heat pipes. Appl. Therm. Eng. 2005, 25, 635–657. [Google Scholar] [CrossRef]

- Mahalingam, R.; Rumigny, N.; Glezer, A. Thermal management using synthetic jet ejectors. IEEE Trans. Compon. Packag. Technol. 2004, 27, 439–444. [Google Scholar] [CrossRef]

- Siu-Ho, A.; Qu, W.; Pfefferkorn, F. Experimental study of pressure drop and heat transfer in a single-phase micropin-fin heat sink. J. Electron. Packag. 2007, 129, 479. [Google Scholar] [CrossRef]

- Drummond, K.P.; Back, D.; Sinanis, M.D.; Janes, D.B.; Peroulis, D.; Weibel, J.A.; Garimella, S.V. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics. Int. J. Heat Mass Transf. 2018, 117, 319–330. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Grande, W.J. Evolution of microchannel flow passages—Thermohydraulic performance and fabrication technology. Heat Transf. Eng. 2003, 24, 3–17. [Google Scholar] [CrossRef]

- Sobhan, C.B.; Garimella, S.V. A comparative analysis of studies on heat transfer and fluid flow in microchannels. Microscale Thermophys. Eng. 2001, 5, 293–311. [Google Scholar] [CrossRef]

- Sakanova, A.; Yin, S.; Zhao, J.; Wu, J.M.; Leong, K.C. Optimization and comparison of double-layer and double-side micro-channel heat sinks with nanofluid for power electronics cooling. Appl. Therm. Eng. 2014, 65, 124–134. [Google Scholar] [CrossRef]

- Ghobadi, M.; Muzychka, Y.S. Heat transfer and pressure drop in mini channel heat sinks. Heat Transf. Eng. 2014, 36, 902–911. [Google Scholar] [CrossRef]

- Zhigang, L.; Ning, G.; Takei, M. An experimental investigation of single-phase heat transfer in 0.045 mm to 0.141 mm microtubes. Nanoscale Microscale Thermophys. Eng. 2007, 11, 333–349. [Google Scholar] [CrossRef]

- Kamal, H.; Dewan, A. Analysis of interrupted rectangular microchannel heat sink with high aspect ratio. J. Appl. Fluid Mech. 2017, 10, 117–126. [Google Scholar] [CrossRef]

- Wang, G.L.; Yang, D.W.; Wang, Y.; Niu, D.; Zhao, X.L.; Ding, G.F. Heat transfer and friction characteristics of the microfluidic heat sink with variously-shaped ribs for chip cooling. Sensors 2015, 15, 9547–9562. [Google Scholar] [CrossRef] [PubMed]

- Jiang, P.-X.; Xu, R.-N. Heat transfer and pressure drop characteristics of mini-fin structures. Int. J. Heat Fluid Flow 2007, 28, 1167–1177. [Google Scholar] [CrossRef]

- Hung, T.-C.; Yan, W.-M.; Wang, X.-D.; Chang, C.-Y. Heat transfer enhancement in microchannel heat sinks using nanofluids. Int. J. Heat Mass Transf. 2012, 55, 2559–2570. [Google Scholar] [CrossRef]

- Farsad, E.; Abbasi, S.P.; Zabihi, M.S. Fluid flow and heat transfer in a novel microchannel heat sink partially filled with metal foam medium. J. Therm. Sci. Eng. Appl. 2014, 6, 021011. [Google Scholar] [CrossRef]

- Bogojevic, D.; Sefiane, K.; Walton, A.J.; Lin, H.; Cummins, G. Two-phase flow instabilities in a silicon microchannels heat sink. Int. J.Heat Fluid Flow 2009, 30, 854–867. [Google Scholar] [CrossRef]

- Colgan, E.G.; Furman, B.; Gaynes, M.; Graham, W.S.; LaBianca, N.C.; Magerlein, J.H.; Polastre, R.J.; Rothwell, M.B.; Bezama, R.J.; Choudhary, R.; et al. A practical implementation of silicon microchannel coolers for high power chips. IEEE Trans. Compon. Packag. Technol. 2007, 30, 218–225. [Google Scholar] [CrossRef]

- García-Hernando, N.; Acosta-Iborra, A.; Ruiz-Rivas, U.; Izquierdo, M. Experimental investigation of fluid flow and heat transfer in a single-phase liquid flow micro-heat exchanger. Int. J. Heat Mass Transf. 2009, 52, 5433–5446. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Wang, Z.; Zhang, C.; Guan, N.; Jiang, G. Flow resistance and heat transfer characteristics in micro-cylinders-group. Heat Mass Transf. 2013, 49, 733–744. [Google Scholar] [CrossRef]

- Kozłowska, A.; Łapka, P.; Seredyński, M.; Teodorczyk, M.; Dąbrowska-Tumańska, E. Experimental study and numerical modeling of micro-channel cooler with micro-pipes for high-power diode laser arrays. Appl. Therm. Eng. 2015, 91, 279–287. [Google Scholar] [CrossRef]

- Li, J.; Peterson, G.P.; Cheng, P. Three-dimensional analysis of heat transfer in a micro-heat sink with single phase flow. Int. J. Heat Mass Transf. 2004, 47, 4215–4231. [Google Scholar] [CrossRef]

- Qu, W.L.; Mudawar, I. Analysis of three-dimensional heat transfer in micro-channel heat sinks. Int. J. Heat Mass Transf. 2002, 45, 3973–3985. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Wang, J.; He, J.; Wu, C.; Luo, W.; Shuai, Y.; Zhang, W.; Chen, X.; Zhang, J.; Lin, J. A Comprehensive Study of a Micro-Channel Heat Sink Using Integrated Thin-Film Temperature Sensors. Sensors 2018, 18, 299. https://doi.org/10.3390/s18010299

Wang T, Wang J, He J, Wu C, Luo W, Shuai Y, Zhang W, Chen X, Zhang J, Lin J. A Comprehensive Study of a Micro-Channel Heat Sink Using Integrated Thin-Film Temperature Sensors. Sensors. 2018; 18(1):299. https://doi.org/10.3390/s18010299

Chicago/Turabian StyleWang, Tao, Jiejun Wang, Jian He, Chuangui Wu, Wenbo Luo, Yao Shuai, Wanli Zhang, Xiancai Chen, Jian Zhang, and Jia Lin. 2018. "A Comprehensive Study of a Micro-Channel Heat Sink Using Integrated Thin-Film Temperature Sensors" Sensors 18, no. 1: 299. https://doi.org/10.3390/s18010299