Atomic Force Microscopy Sidewall Imaging with a Quartz Tuning Fork Force Sensor

Abstract

:1. Introduction

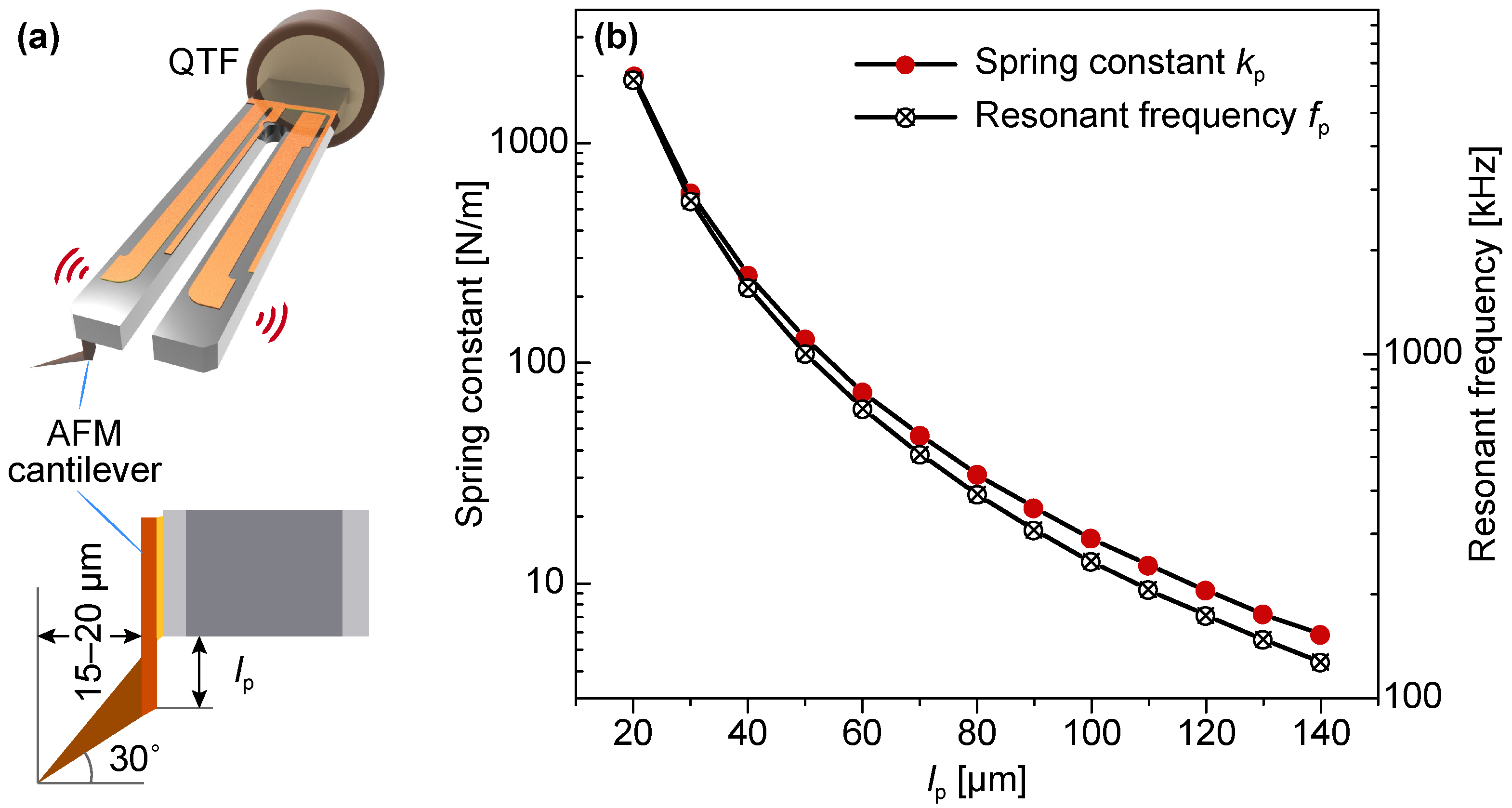

2. Preparation of the QTF Force Sensor

2.1. Determination of the Suspended Cantilever Length of the QTF

- (1)

- The suspended cantilever should be stiff enough to be able to accurately detect tip-sample interaction with negligible bending deformations.

- (2)

- Its fundamental resonance frequency should be much higher than that of the QTF to avoid coupling vibration noise.

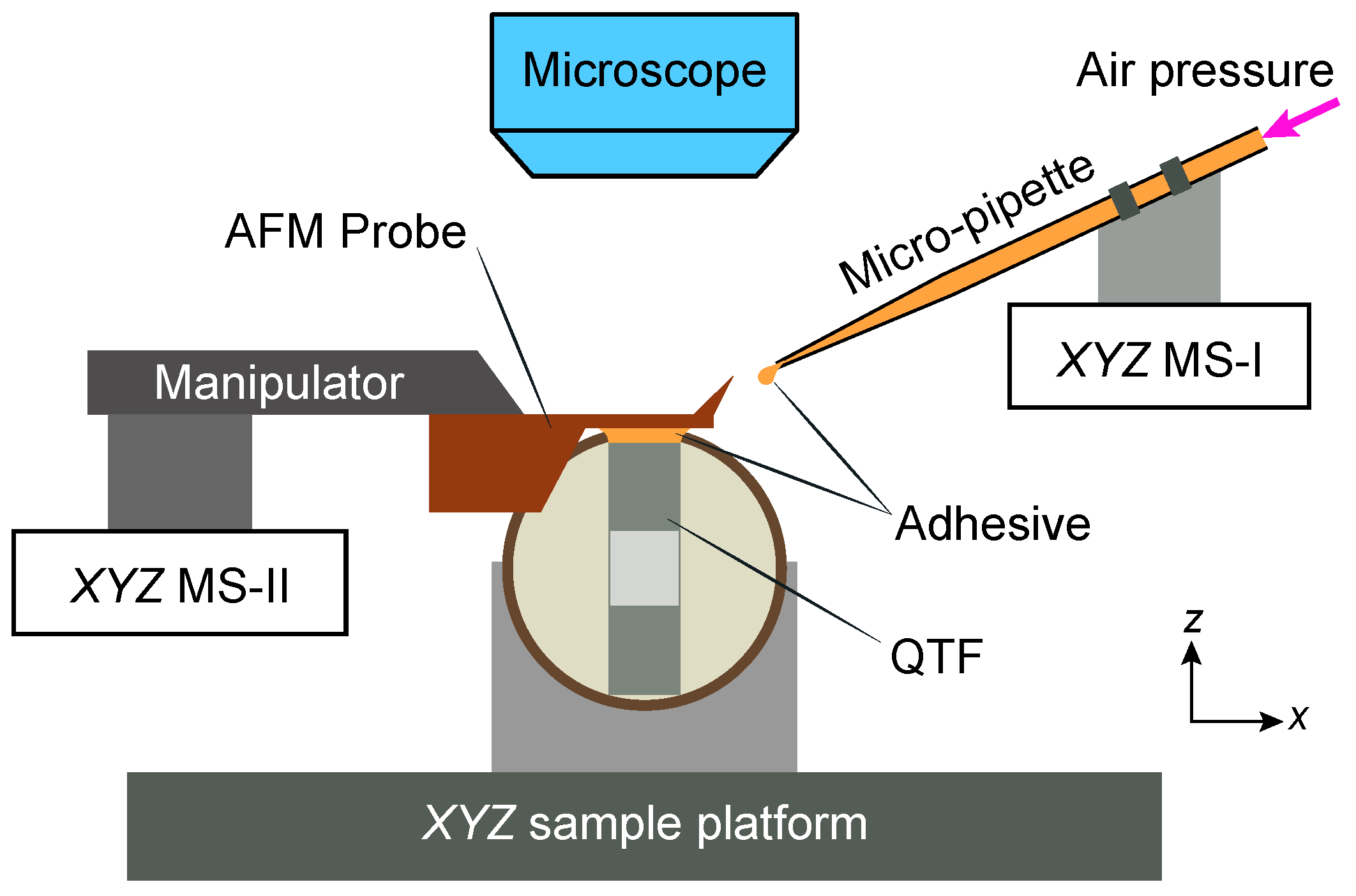

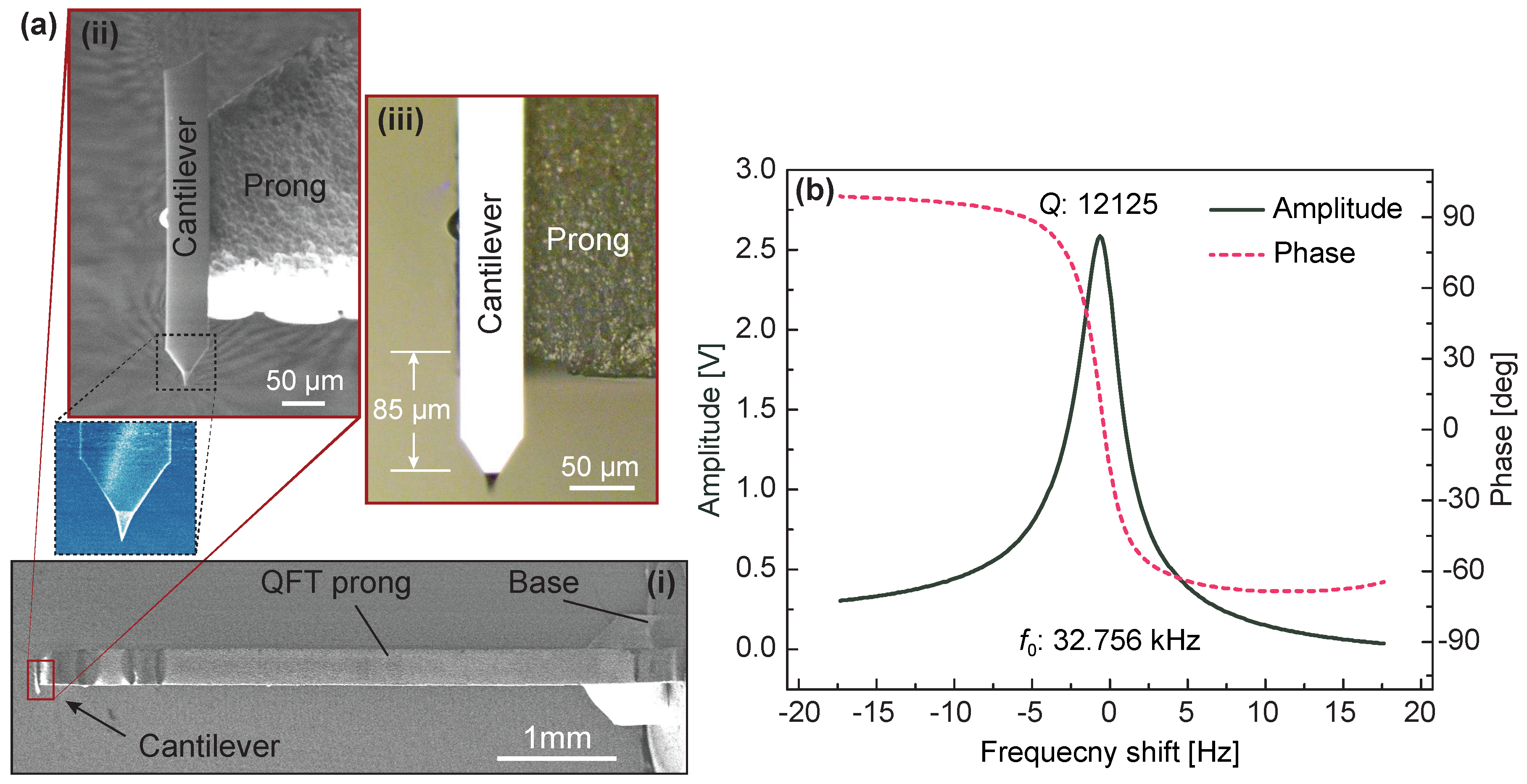

2.2. Microassembly of the QTF

- (1)

- The prong of the QTF is located under the optical microscope by moving the XYZ sample platform. At this point, the end of the prong is within the field-of-view of the microscope.

- (2)

- By moving the micropositioning stage XYZ MS-I, the micropipette (filled with sufficient adhesive) is translated to slightly touch the desired bonding position at the end of the prong. Then, a small amount of adhesive is carefully deposited on the outer side of the prong by applying insufflation pneumatic pressure (5 kPa). In order to obtain an uniform distribution of adhesive at the bonding position, the micropipette is translated slightly from left to right during deposition.

- (3)

- By moving the micropositioning stage XYZ MS-II, the AFM probe is positioned just above the bonding position with a desired length of the suspended cantilever. Then, the AFM probe is brought into contact with the deposited adhesive, and slight pressure is applied to compress the probe on the adhesive by moving the z-axis (MS-II).

- (4)

- After the glue is fully cured (6–8 h), the cantilever is isolated from the chip of AFM probe by gently moving the left manipulator along the z-axis.

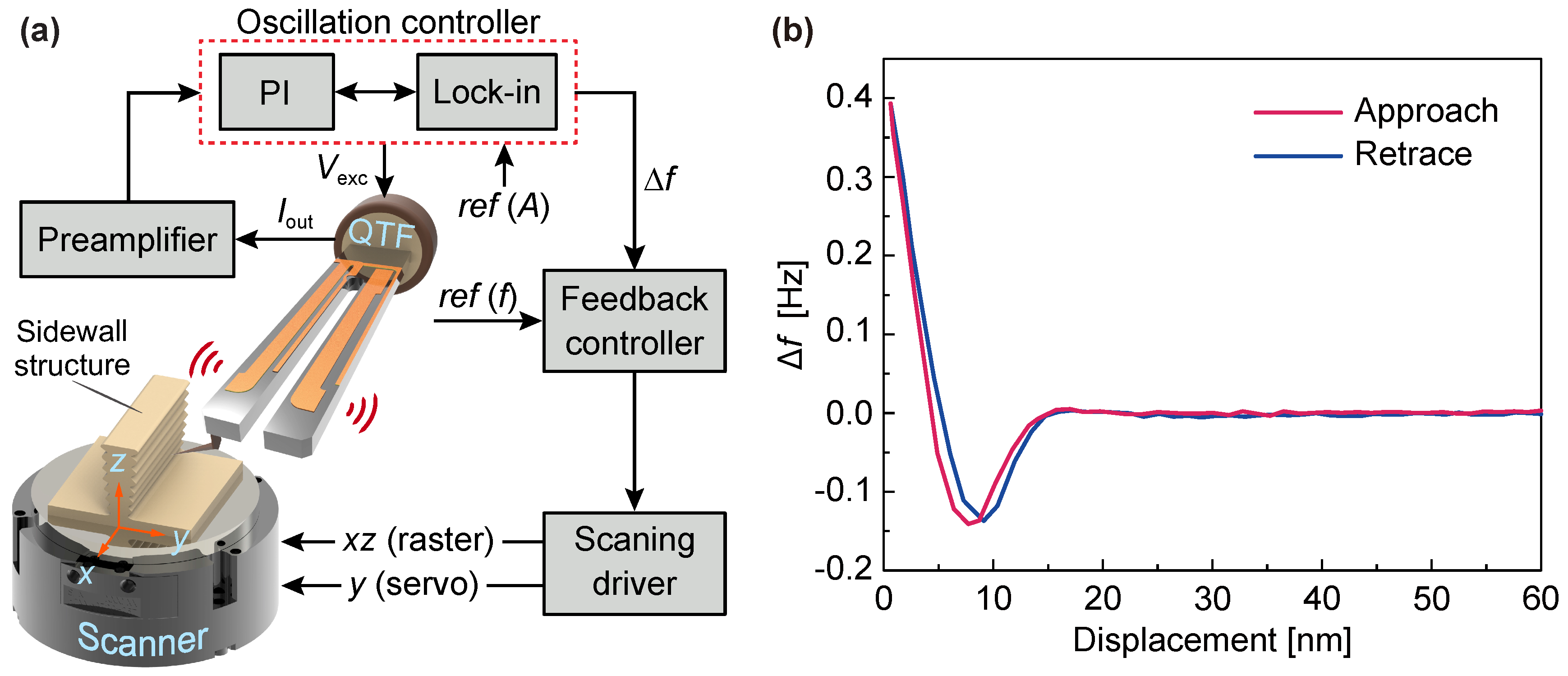

3. Sidewall Imaging AFM System

3.1. Sidewall Imaging System

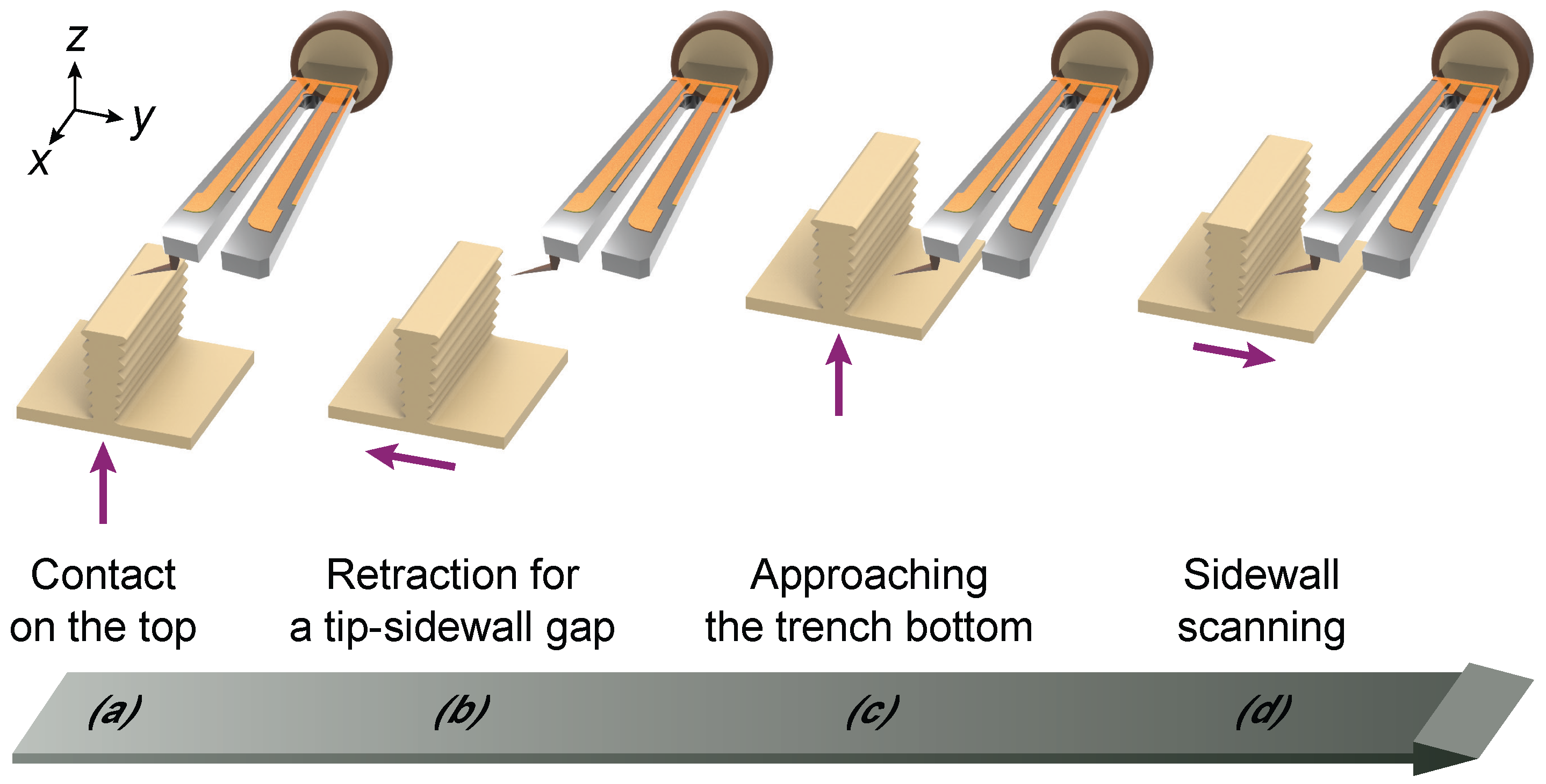

3.2. Sidewall Imaging Protocol

- (1)

- When the tip is near the surface, z-servo is started with small vibration amplitude. The tip contacts the top surface and servo becomes stable as shown in Figure 5a.

- (2)

- The z-servo is stopped and the sample is moved hundreds of nanometers downwards by the scanner to prevent damage to the sample or tip. Then, the sample is moved on the y-axis of the scanner to form an appropriate tip-sidewall gap, so that the tip is over the deep trench, as shown in Figure 5b.

- (3)

- z-servo started to raise the sample upwards and the cantilever with the tip penetrates the trench (Figure 5c). In this case, the tip can touch the trench bottom if the trench is shallower than the z-travel distance of the scanner (while considering the initial z-position) or it can not touch the bottom if the trench is deeper than the z-travel distance.

- (4)

- Finally, servo is switched from the z-axis to y-axis and the tip is approached on the sidewall (Figure 5d). The target sidewall is then scanned with the fast and slow scans on x- and z-axes, respectively.

3.3. Algorithms of Sidewall Roughness and Line Edge Roughness

4. Experiments and Discussion

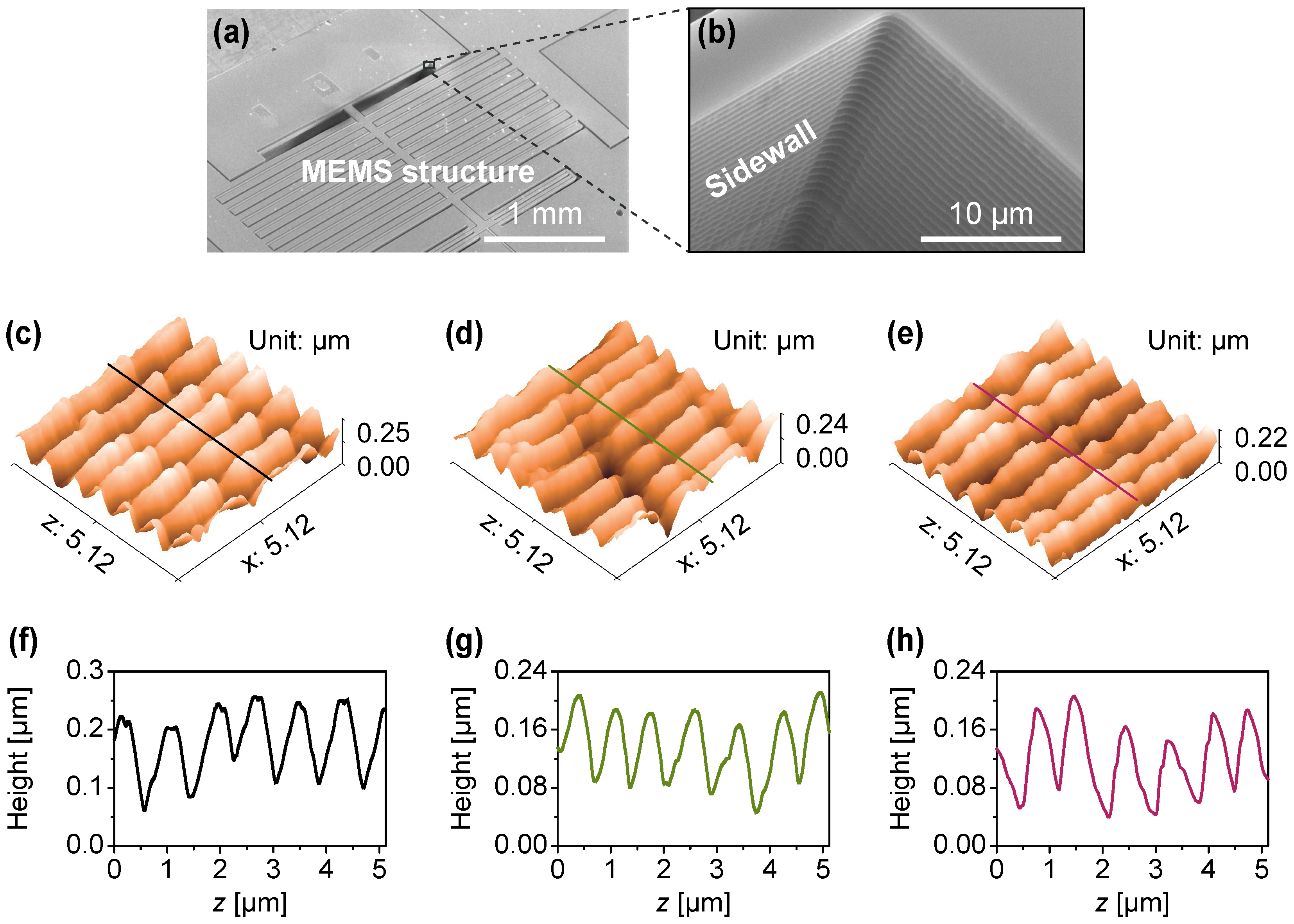

4.1. Sidewall Scanning of a MEMS Structure

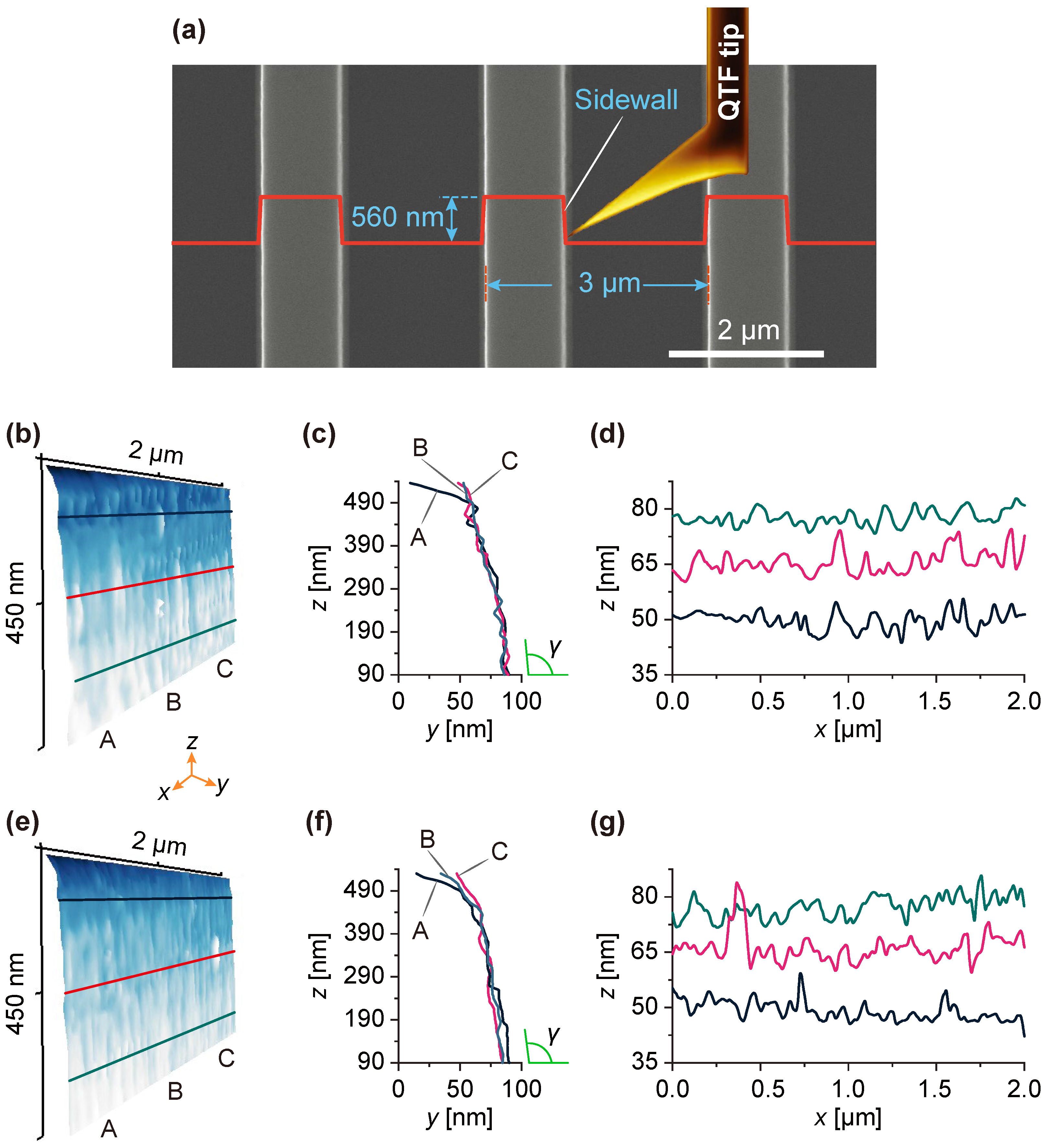

4.2. Sidewall Scanning of a Step Grating

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pike, W.; Karl, W.; Kumar, S.; Vijendran, S.; Semple, T. Analysis of sidewall quality in through-wafer deep reactive-ion etching. Microelectron. Eng. 2004, 73, 340–345. [Google Scholar] [CrossRef]

- Cheemalapati, S.; Ladanov, M.; Winskas, J.; Pyayt, A. Optimization of dry etching parameters for fabrication of polysilicon waveguides with smooth sidewall using a capacitively coupled plasma reactor. Appl. Opt. 2014, 53, 5745–5749. [Google Scholar] [CrossRef] [PubMed]

- Thathachary, A.V.; Lavallee, G.; Cantoro, M.; Bhuwalka, K.K.; Heo, Y.C.; Maeda, S.; Datta, S. Impact of sidewall passivation and channel composition on InxGa1-x As FinFET performance. IEEE Electron Device Lett. 2015, 36, 117–119. [Google Scholar] [CrossRef]

- Lee, J.S.; Choi, Y.K.; Ha, D.; Balasubramanian, S.; King, T.J.; Bokor, J. Hydrogen annealing effect on DC and low-frequency noise characteristics in CMOS FinFETs. IEEE Electron Device Lett. 2003, 24, 186–188. [Google Scholar]

- Barwicz, T.; Haus, H.A. Three-dimensional analysis of scattering losses due to sidewall roughness in microphotonic waveguides. J. Lightwave Technol. 2005, 23, 2719. [Google Scholar] [CrossRef]

- Grillot, F.; Vivien, L.; Laval, S.; Pascal, D.; Cassan, E. Size influence on the propagation loss induced by sidewall roughness in ultrasmall SOI waveguides. IEEE Photonics Technol. Lett. 2004, 16, 1661–1663. [Google Scholar] [CrossRef]

- Lacey, J.; Payne, F. Radiation loss from planar waveguides with random wall imperfections. Proc. Inst. Electron. Eng. J. 1990, 137, 282–288. [Google Scholar] [CrossRef]

- Yap, K.P.; Delâge, A.; Lapointe, J.; Lamontagne, B.; Schmid, J.H.; Waldron, P.; Syrett, B.A.; Janz, S. Correlation of scattering loss, sidewall roughness and waveguide width in silicon-on-insulator (SOI) ridge waveguides. J. Lightwave Technol. 2009, 27, 3999–4008. [Google Scholar]

- Reynolds, G.W.; Taylor, J.W. Factors contributing to sidewall roughness in a positive-tone, chemically amplified resist exposed by X-ray lithography. J. Vac. Sci. Technol. 1999, 17, 334–344. [Google Scholar] [CrossRef]

- Nyyssonen, D.; Landstein, L.; Coombs, E. Two-dimensional atomic force microprobe trench metrology system. J. Vac. Sci. Technol. 1991, 9, 3612–3616. [Google Scholar] [CrossRef]

- Martin, Y.; Wickramasinghe, H.K. Method for imaging sidewalls by atomic force microscopy. Appl. Phys. Lett. 1994, 64, 2498–2500. [Google Scholar] [CrossRef]

- Orji, N.G.; Vorburger, T.V.; Fu, J.; Dixson, R.G.; Nguyen, C.V.; Raja, J. Line edge roughness metrology using atomic force microscopes. Meas. Sci. Technol. 2005, 16, 2147. [Google Scholar] [CrossRef]

- Nelson-Thomas, C.M.; Palmateer, S.C.; Lyszczarz, T.M. Metrology methods for the quantification of edge roughness. Proc. SPIE 1998, 3332, 19–29. [Google Scholar]

- Xie, H.; Hussain, D.; Yang, F.; Sun, L. Atomic force microscopy deep trench and sidewall imaging with an optical fiber probe. Rev. Sci. Instrum. 2014, 85, 123704. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Hahm, K.; Scholze, F.; Henn, M.A.; Gross, H.; Fluegge, J.; Bosse, H. Measurements of CD and sidewall profile of EUV photomask structures using CD-AFM and tilting-AFM. Meas. Sci. Technol. 2014, 25, 044002. [Google Scholar] [CrossRef]

- Cho, S.J.; Ahn, B.W.; Kim, J.; Lee, J.M.; Hua, Y.; Yoo, Y.K.; Park, S.I. Three-dimensional imaging of undercut and sidewall structures by atomic force microscopy. Rev. Sci. Instrum. 2011, 82, 023707. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Hussain, D.; Yang, F.; Sun, L. Atomic force microscope caliper for critical dimension measurements of micro and nanostructures through sidewall scanning. Ultramicroscopy 2015, 158, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Murayama, K.; Gonda, S.; Koyanagi, H.; Terasawa, T.; Hosaka, S. Side-wall measurement using tilt-scanning method in atomic force microscope. Jpn. J. Appl. Phys. 2006, 45, 5423. [Google Scholar] [CrossRef]

- Dai, G.; Wolff, H.; Weimann, T.; Xu, M.; Pohlenz, F.; Danzebrink, H.U. Nanoscale surface measurements at sidewalls of nano-and micro-structures. Meas. Sci. Technol. 2007, 18, 334. [Google Scholar] [CrossRef]

- Polesel-Maris, J.; Lubin, C.; Thoyer, F.; Cousty, J. Combined dynamic scanning tunneling microscopy and frequency modulation atomic force microscopy investigations on polythiophene chains on graphite with a tuning fork sensor. J. Appl. Phys. 2011, 109, 074320. [Google Scholar] [CrossRef]

- Gonzalez, L.; Martínez-Martín, D.; Otero, J.; de Pablo, P.J.; Puig-Vidal, M.; Gómez-Herrero, J. Improving the lateral resolution of quartz tuning fork-based sensors in liquid by integrating commercial AFM tips into the fiber end. Sensors 2015, 15, 1601–1610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rensen, W.; Van Hulst, N.; Ruiter, A.; West, P. Atomic steps with tuning-fork-based noncontact atomic force microscopy. Appl. Phys. Lett. 1999, 75, 1640–1642. [Google Scholar] [CrossRef]

- Giessibl, F.J.; Hembacher, S.; Bielefeldt, H.; Mannhart, J. Subatomic features on the silicon (111)−(7 × 7) surface observed by atomic force microscopy. Science 2000, 289, 422–425. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B. Springer Handbook of Nanotechnology; Springer Science & Business Media: Heidelberg, Germany, 2010. [Google Scholar]

- Ng, B.P.; Zhang, Y.; Kok, S.W.; Soh, Y.C. Improve performance of scanning probe microscopy by balancing tuning fork prongs. Ultramicroscopy 2009, 109, 291–295. [Google Scholar] [CrossRef] [PubMed]

- Jahng, J.; Lee, M.; Noh, H.; Seo, Y.; Jhe, W. Active Q control in tuning-fork-based atomic force microscopy. Appl. Phys. Lett. 2007, 91, 023103. [Google Scholar] [CrossRef]

- Xie, H.; Hussain, D.; Yang, F.; Sun, L. Development of three-dimensional atomic force microscope for sidewall structures imaging with controllable scanning density. IEEE/ASME Trans. Mechatron. 2016, 21, 316–328. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, G.C.; Lu, T.M. Characterization of Amorphous and Crystalline Rough Surface—Principles and Applications; Academic Press: Cambridge, MA, United States, 2001; Volume 37. [Google Scholar]

- Baylav, B.; Maloney, C.; Levinson, Z.; Bekaert, J.; Vaglio Pret, A.; Smith, B.W. Impact of pupil plane filtering on mask roughness transfer. J. Vac. Sci. Technol. 2013, 31, 06F801. [Google Scholar] [CrossRef]

- Fouchier, M.; Pargon, E.; Bardet, B. An atomic force microscopy-based method for line edge roughness measurement. J. Appl. Phys. 2013, 113, 104903. [Google Scholar] [CrossRef]

- Sun, L.; Wang, J.; Rong, W.; Li, X.; Bao, H. A silicon integrated micro nano-positioning XY-stage for nano-manipulation. J. Micromech. Microeng. 2008, 18, 125004. [Google Scholar] [CrossRef]

- Jang, J.; Zhao, W.; Bae, J.; Selvanathan, D.; Rommel, S.; Adesida, I.; Lepore, A.; Kwakernaak, M.; Abeles, J. Direct measurement of nanoscale sidewall roughness of optical waveguides using an atomic force microscope. Appl. Phys. Lett. 2003, 83, 4116–4118. [Google Scholar] [CrossRef]

| Region | (nm) | (nm) |

|---|---|---|

| 1 | 42.64 | 362.11 |

| 2 | 49.53 | 266.25 |

| 3 | 31.91 | 219.07 |

| Mean | 41.36 | 282.48 |

| Segments | 1/4–1/2 | 1/2–3/4 | 0–1/4 | 0–1/2 | 0–3/4 |

|---|---|---|---|---|---|

| Lines | Sidewall I | Sidewall II | ||||

|---|---|---|---|---|---|---|

| Green | Pink | Black | Green | Pink | Black | |

| LER (3) | 7.57 | 10.29 | 8.91 | 7.75 | 10.98 | 7.57 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, D.; Wen, Y.; Zhang, H.; Song, J.; Xie, H. Atomic Force Microscopy Sidewall Imaging with a Quartz Tuning Fork Force Sensor. Sensors 2018, 18, 100. https://doi.org/10.3390/s18010100

Hussain D, Wen Y, Zhang H, Song J, Xie H. Atomic Force Microscopy Sidewall Imaging with a Quartz Tuning Fork Force Sensor. Sensors. 2018; 18(1):100. https://doi.org/10.3390/s18010100

Chicago/Turabian StyleHussain, Danish, Yongbing Wen, Hao Zhang, Jianmin Song, and Hui Xie. 2018. "Atomic Force Microscopy Sidewall Imaging with a Quartz Tuning Fork Force Sensor" Sensors 18, no. 1: 100. https://doi.org/10.3390/s18010100