A Novel Low-Power-Consumption All-Fiber-Optic Anemometer with Simple System Design

Abstract

:1. Introduction

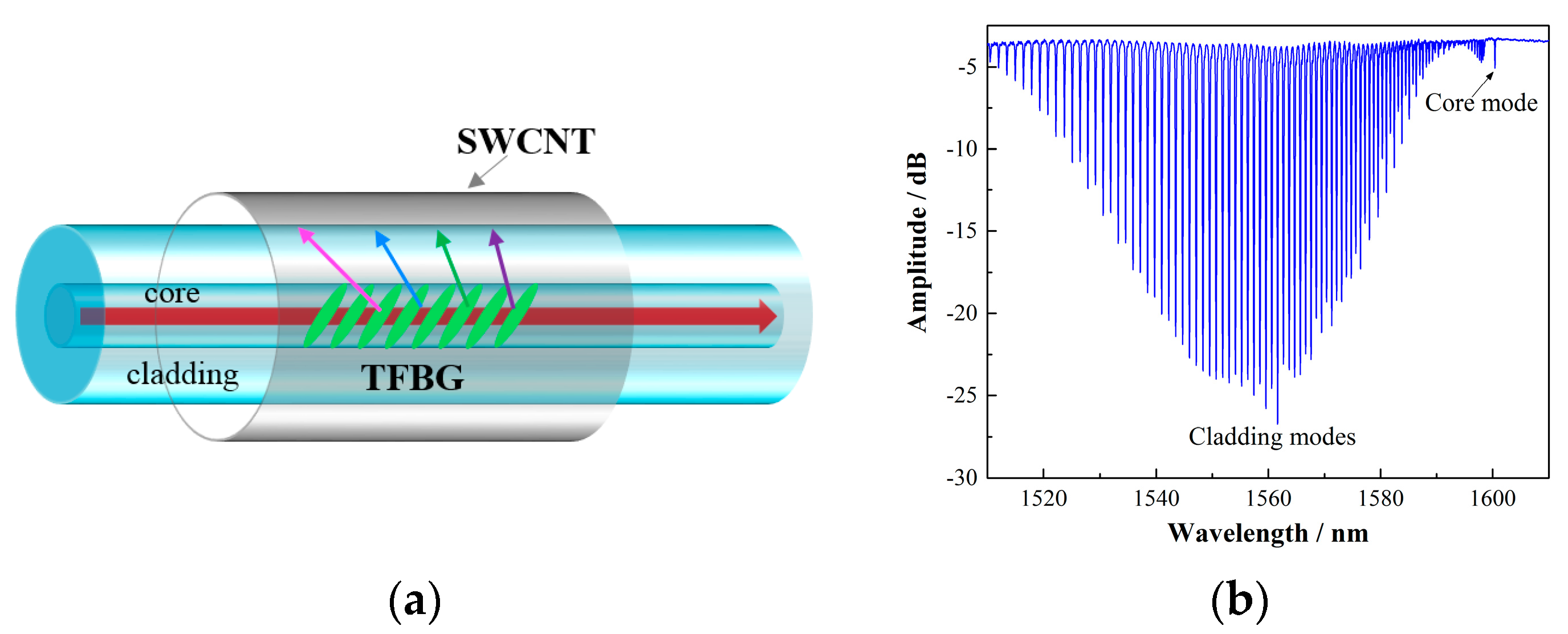

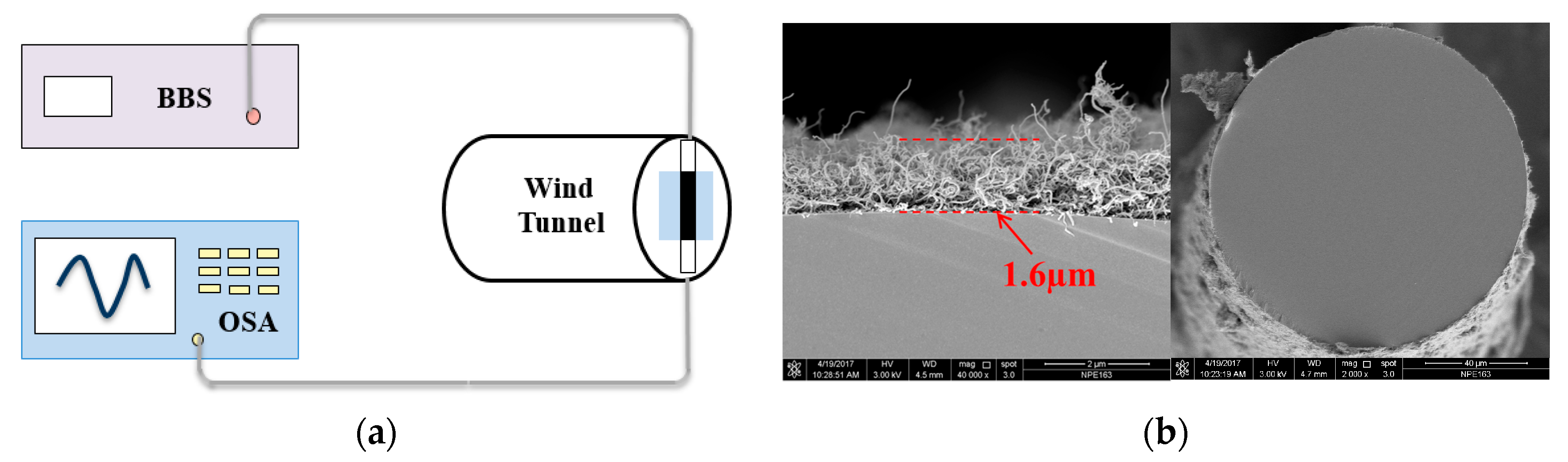

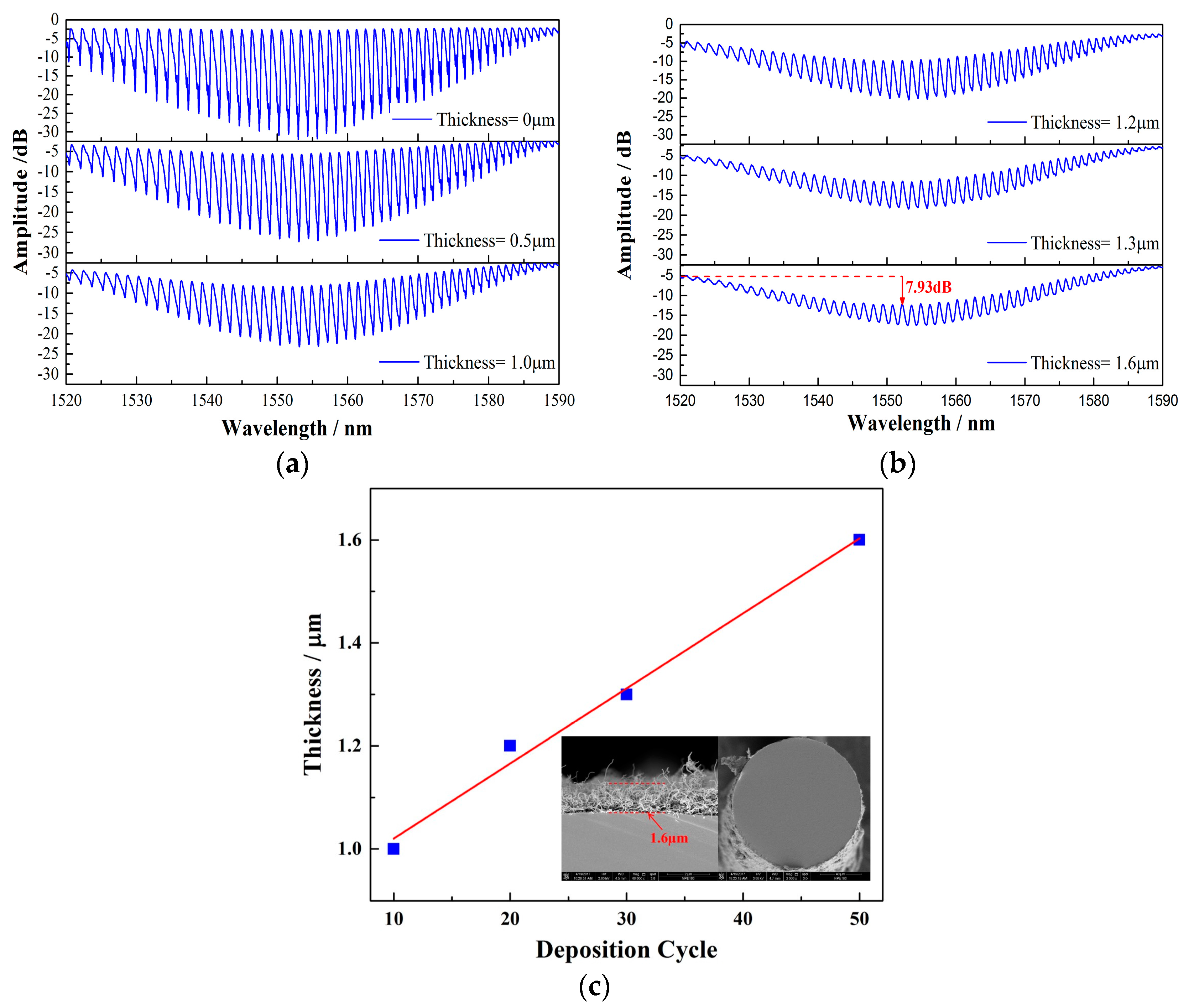

2. Principle and Experimental System

3. Results and Discussion

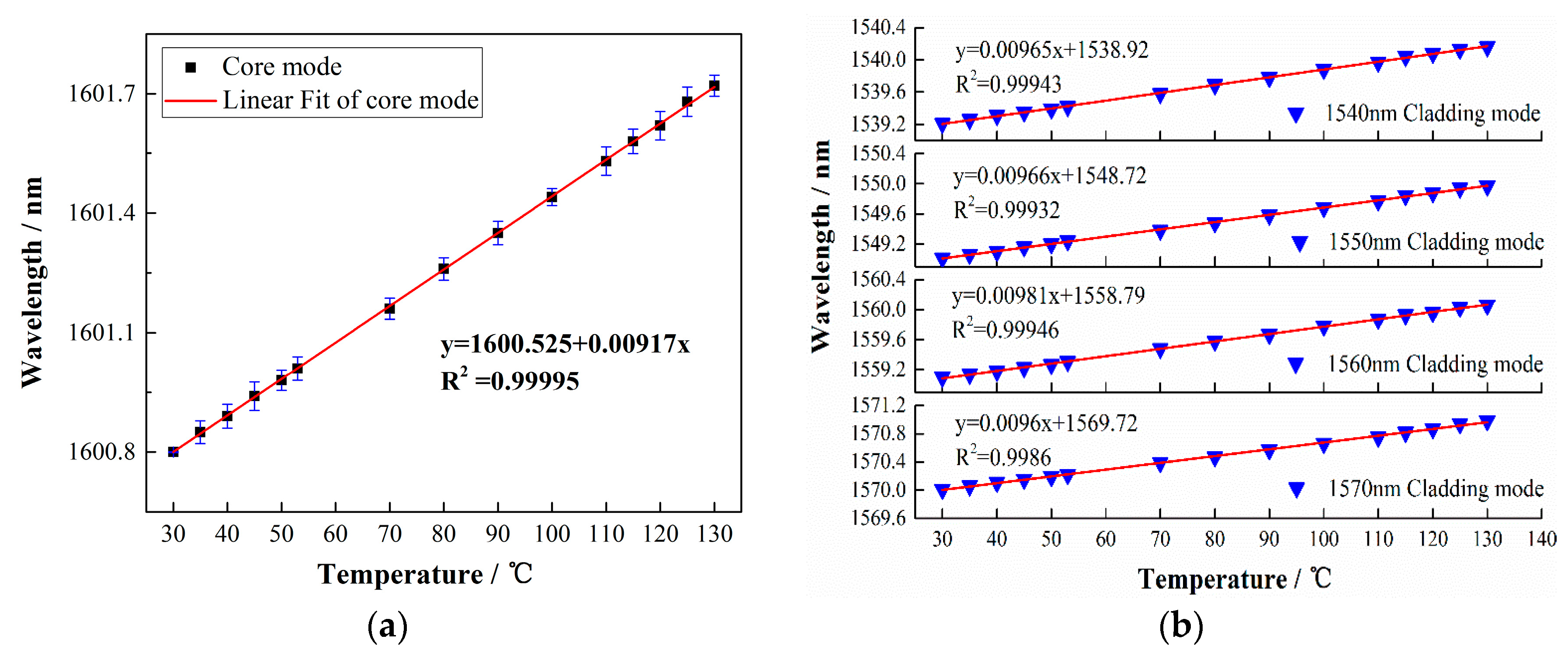

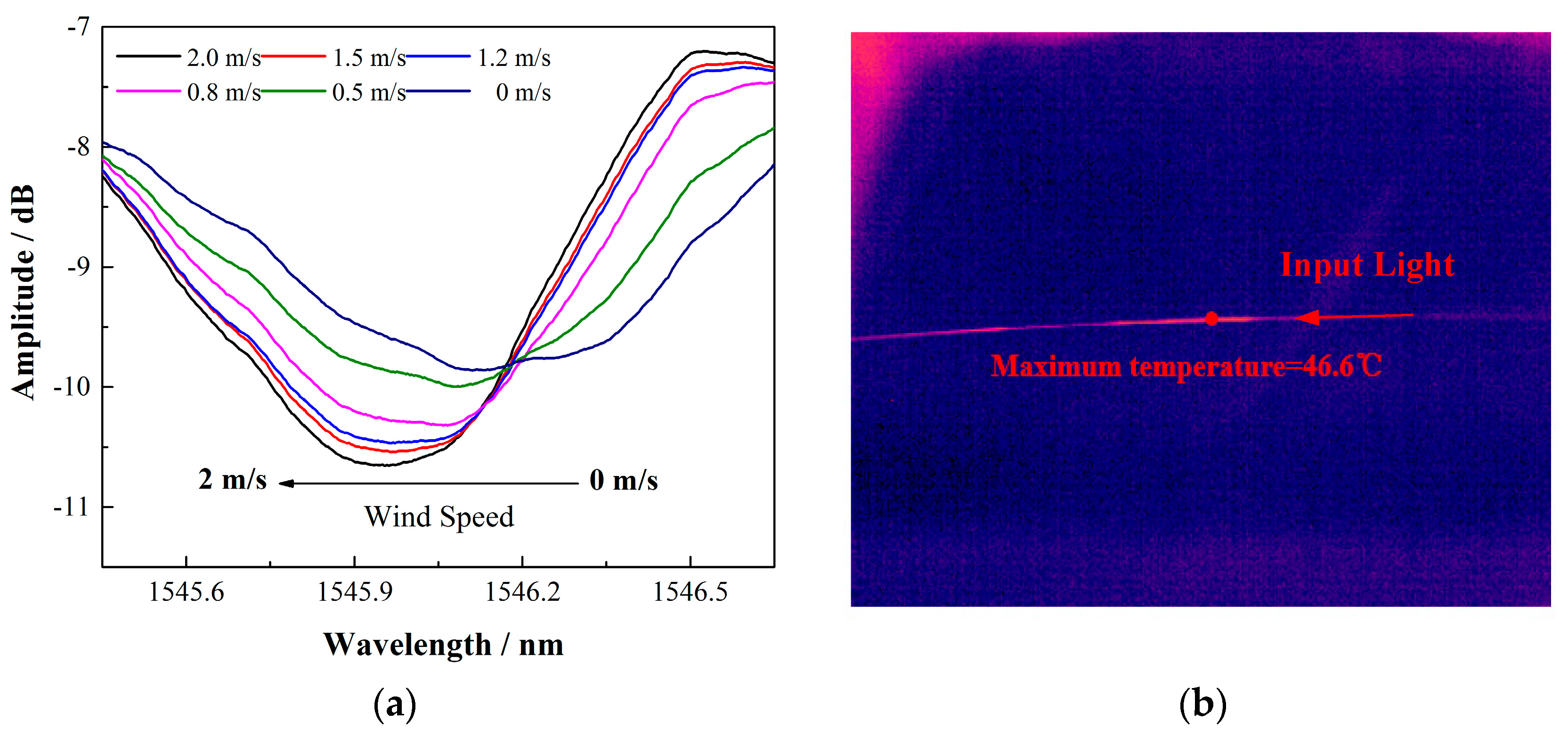

3.1. Temperature Responses

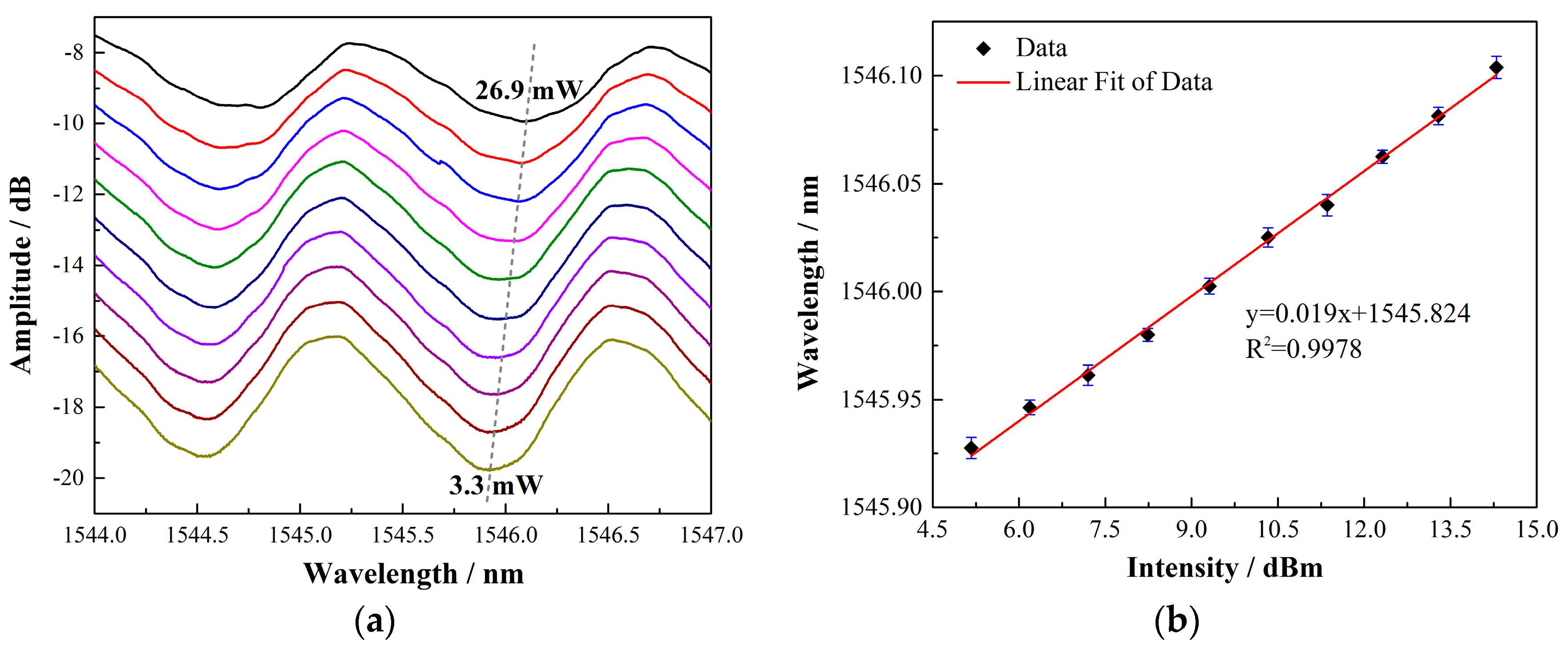

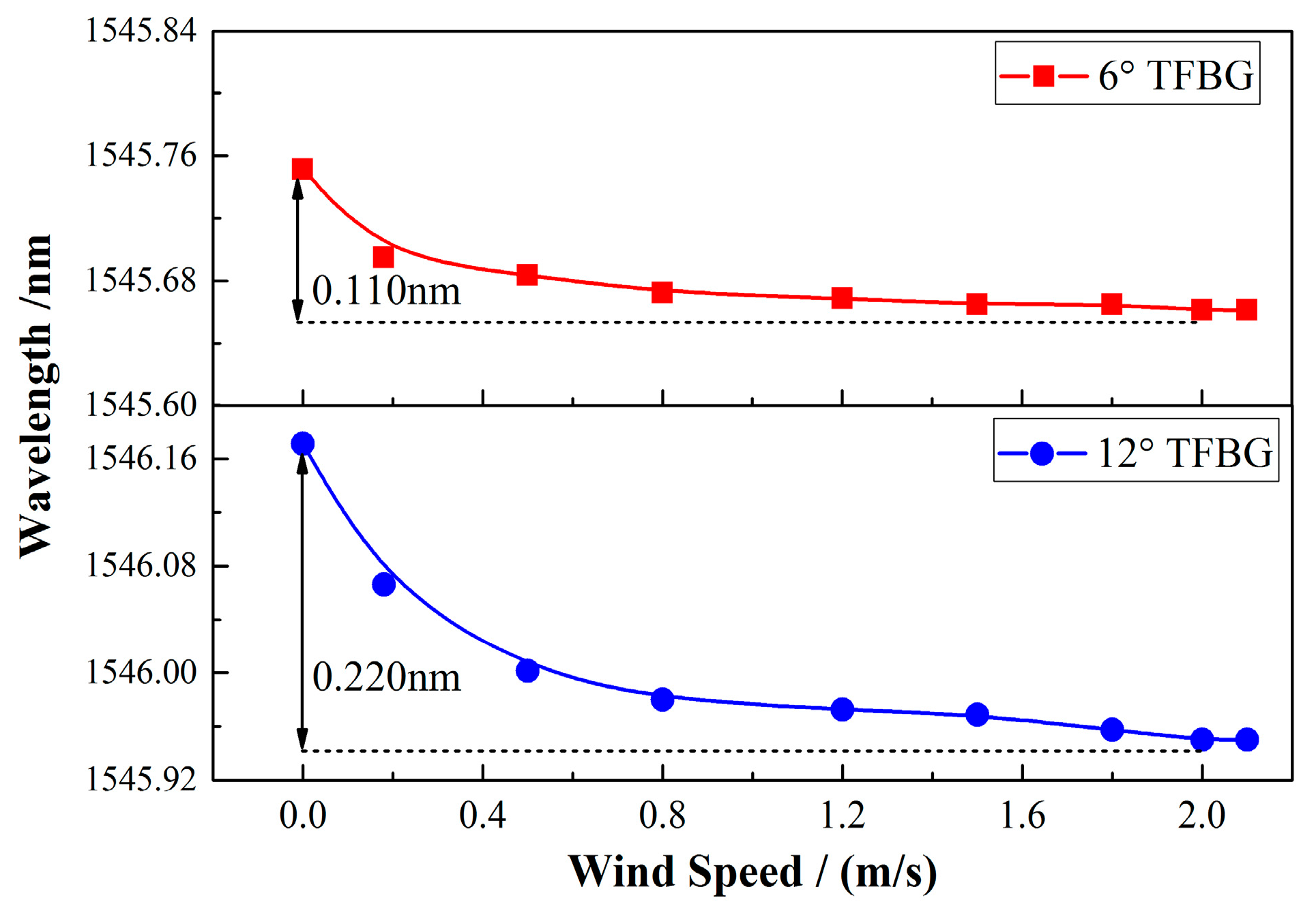

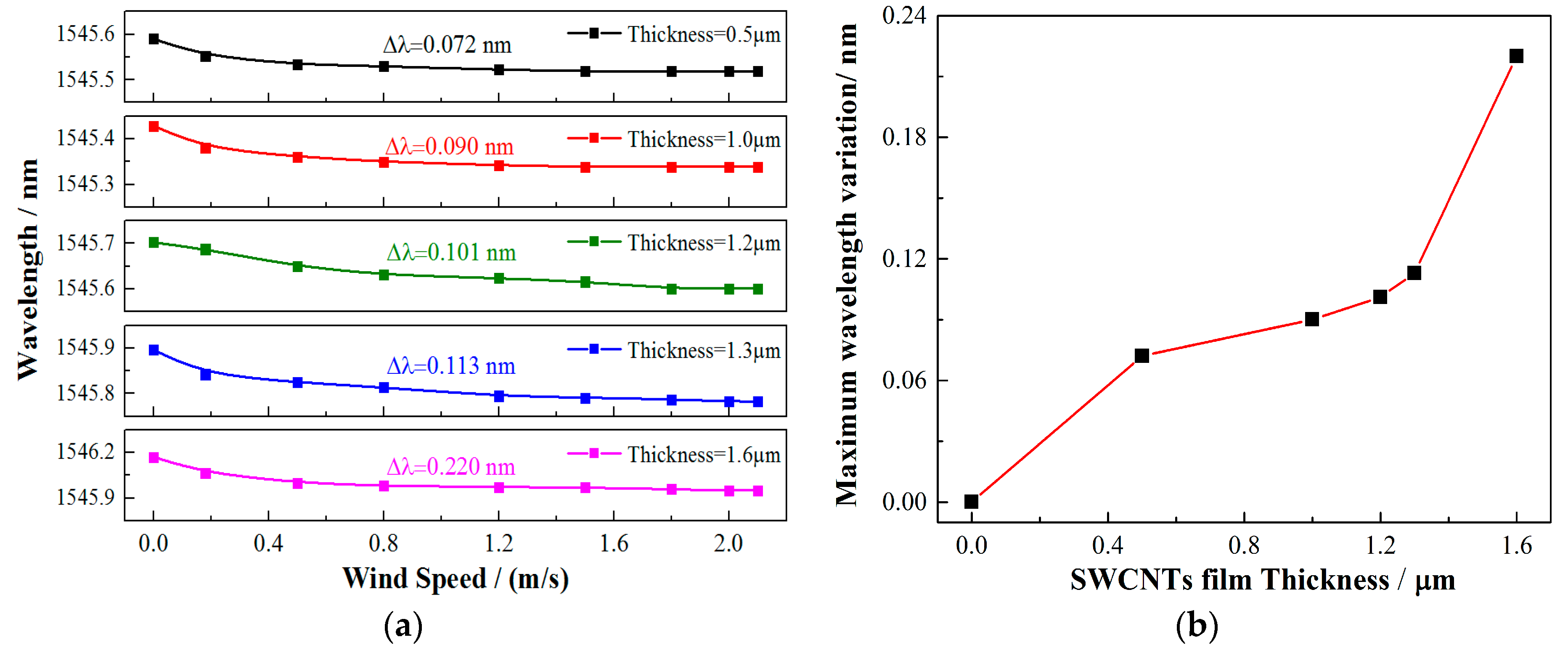

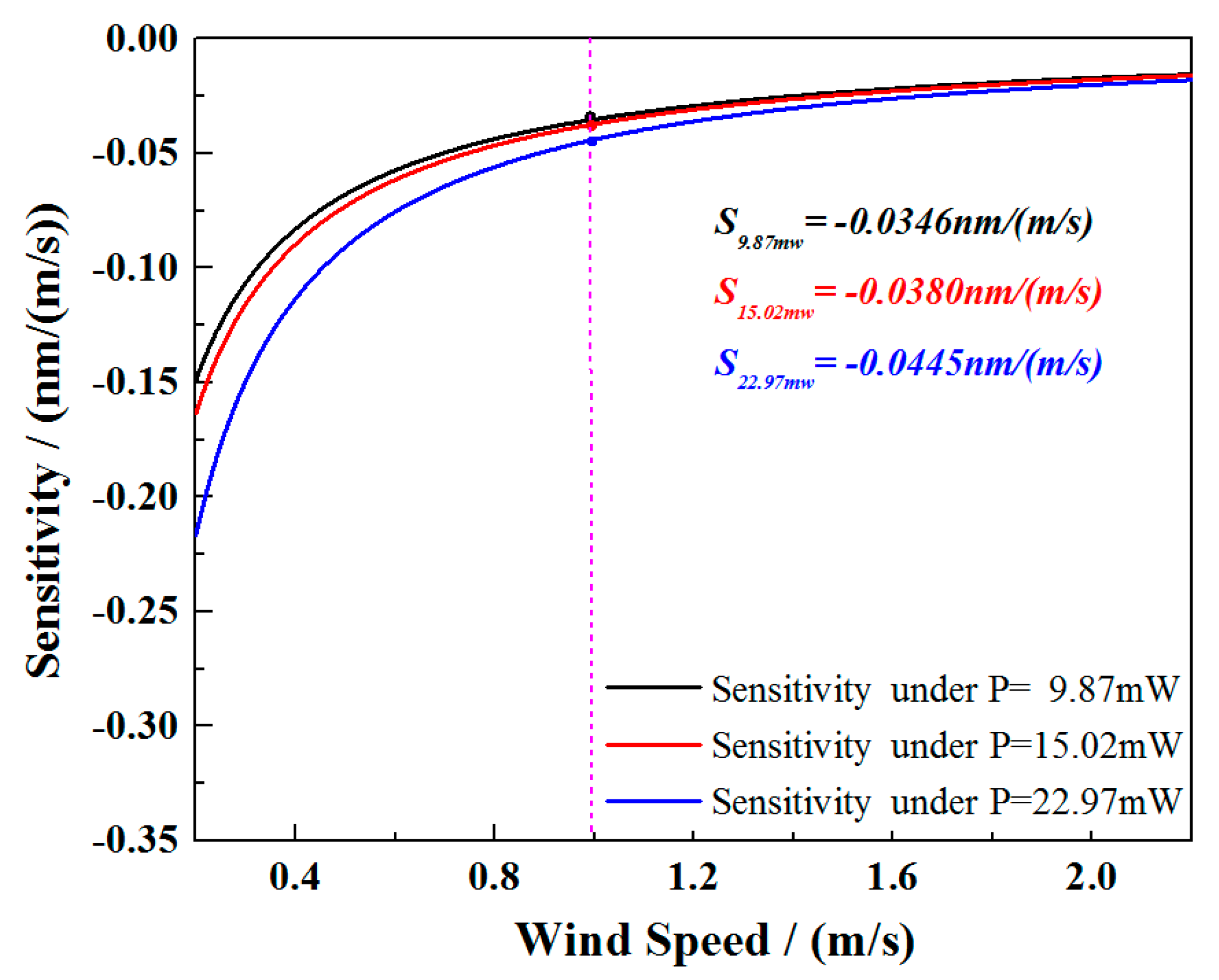

3.2. Measurement Results of the Anemometer

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Song, H.; Chen, Y.P.; Zhang, G.; Liu, Y.; Huang, P.C.; Zhao, H.W.; Yang, M.H.; Dai, J.X.; Li, Z. Optical fiber hydrogen sensor based on an annealing-stimulated Pd-Y thin film. Sens. Actuators B Chem. 2015, 216, 11–16. [Google Scholar] [CrossRef]

- Newkirk, A.V.; Antonio-Lopez, J.E.; Salceda-Delgado, G.; Piracha, M.U.; Amezcua-Correa, R.; Schülzgen, A. Multicore fiber sensors for simultaneous measurement of force and temperature. IEEE Photonic Technol. Lett. 2015, 27, 1523–1526. [Google Scholar] [CrossRef]

- Liu, Z.G.; Zhang, X.P.; Gong, Z.F.; Zhang, Y.; Peng, W. Fiber Ring Laser Based Displacement Sensor. IEEE Photonic Technol. Lett. 2016, 28, 1723–1726. [Google Scholar] [CrossRef]

- Xu, F.; Horak, P.; Brambilla, G. Optical microfiber coil resonator refractometric sensor. Opt. Express 2007, 15, 7888–7893. [Google Scholar] [CrossRef] [PubMed]

- Puiu, M.; Bala, C. SPR and SPR Imaging: Recent Trends in Developing Nanodevices for Detection and Real-Time Monitoring of Biomolecular Events. Sensors 2016, 16, 870. [Google Scholar] [CrossRef] [PubMed]

- Laghrouche, M.; Adane, A.; Boussey, J.; Ameur, S.; Meunier, D.; Tardu, S. A miniature silicon hot wire sensor for automatic wind speed measurements. Renew. Energy 2005, 30, 1881–1896. [Google Scholar] [CrossRef]

- Wu, J.; Sansen, W. Electrochemical time of flight flow sensor. Sens. Actuator A Phys. 2002, 97, 68–74. [Google Scholar] [CrossRef]

- Piao, L.H.; Zhang, T.; Ma, Y.F.; Wang, J.P. Structural optimization of mental cone rotameter based on CFD. Transducer Microsyst. Technol. 2011, 30, 89–90. [Google Scholar]

- Firth, J.; Ladouceur, F.; Brodzeli, Z.; Wyres, M.; Silvestri, L. A novel optical telemetry system applied to flowmeter networks. Flow Meas. Instrum. 2016, 48, 15–19. [Google Scholar] [CrossRef]

- Liu, G.G.; Hou, W.L.; Qiao, W.; Han, M. Fast-response fiber-optic anemometer with temperature self-compensation. Opt. Express 2015, 23, 13562–13570. [Google Scholar] [CrossRef] [PubMed]

- Takagi, S. A hot-wire anemometer compensated for ambient temperature variations. J. Phys. E Sci. Instrum. 1986, 19, 739–743. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Q.; Zhang, B.; Chen, R.; Chen, K.P. Distributed flow sensing using optical hot-wire grid. Opt. Express 2012, 20, 8240–8249. [Google Scholar] [CrossRef] [PubMed]

- Brunn, H.H. Hot-Wire Anemometry: Principles and Signal Analysis; Oxford University: London, UK, 1995. [Google Scholar]

- Lee, C.L.; Lee, C.F.; Li, C.M.; Chiang, T.C.; Hsiao, Y.L. Directional anemometer based on an anisotropic flat-clad tapered fiber Michelson interferometer. Appl. Phys. Lett. 2012, 101, 023502. [Google Scholar] [CrossRef]

- Frazão, O.; Caldas, P.; Araújo, F.M.; Ferreira, L.A.; Santos, J.L. Optical flowmeter using a modal interferometer based on a single nonadiabatic fiber taper. Opt. Lett. 2007, 32, 1974–1976. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Zhou, Y.; Zhou, W.; Cheng, J.; Su, Z. Compact anemometer using silver-coated fiber Bragg grating. IEEE Photonics J. 2012, 4, 1381–1386. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Htein, L.; Cheng, L.K.; Martina, Q.; Jansen, R.; Tam, H.Y. Highly sensitive miniature fluidic flowmeter based on an FBG heated by Co2+-doped fiber. Opt. Express 2017, 25, 4393–4420. [Google Scholar] [CrossRef] [PubMed]

- Caldas, P.; Jorge, P.A.; Rego, G.; Frazão, O.; Santos, J.L.; Ferreira, L.A.; Araújo, F. Fiber optic hot-wire flowmeter based on a metallic coated hybrid long period grating fiber Bragg grating structure. Appl. Opt. 2011, 50, 2738–2743. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.R.; Zhang, A.P.; Tam, H.Y.; Cho, L.H.; Lu, C. All-optical fiber anemometer based on laser heated fiber Bragg gratings. Opt. Express 2011, 19, 10124–10130. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, Z.Y.; Gao, S.R.; Zhang, A.P.; Shen, Y.H.; Tam, H.Y. Fiber-Optic Anemometer Based on Bragg Grating Inscribed in Metal-Filled Microstructured Optical Fiber. J. Lightwave Technol. 2016, 34, 4884–4888. [Google Scholar] [CrossRef]

- Erdogan, T.; Sipe, J.E. Tilted fiber phase gratings. J. Opt. Soc. Am. A 1996, 13, 296–313. [Google Scholar] [CrossRef]

- Albert, J.; Shao, L.Y.; Caucheteur, C. Tilted fiber Bragg grating sensors. Laser Photonics Rev. 2013, 7, 83–108. [Google Scholar] [CrossRef]

- Zhou, W.; Mandia, D.J.; Griffiths, M.B.E.; Barry, S.T.; Albert, J. Effective Permittivity of Ultrathin Chemical Vapor Deposited Gold Films on Optical Fibers at Infrared Wavelengths. J. Phys. Chem. C 2014, 118, 670–678. [Google Scholar] [CrossRef]

- Zhou, W.; Mandia, D.J.; Barry, S.T.; Albert, J. Absolute near-infrared refractometry with a calibrated tilted fiber Bragg grating. Opt. Lett. 2015, 40, 1713–1716. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.J.; Coleman, K.S.; Azamia, B.R.; Bagshaw, C.B.; Green, M.L.H. Chemical and biochemical sensing with modified single-walled carbon nanotubes. Chem. Eur. J. 2003, 9, 3732–3739. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.D.; Zhang, W.H. Carbon Nanotubes as Active Components for Gas Sensors. J. Sens. 2009, 2009, 160698. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single shell carbon nanotubes of one nanometer diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, F.; Duan, Z.; Liu, Z.; Liu, Z.; Wu, Z.; Gu, Y.; Sun, C.; Peng, W. A Novel Low-Power-Consumption All-Fiber-Optic Anemometer with Simple System Design. Sensors 2017, 17, 2107. https://doi.org/10.3390/s17092107

Zhang Y, Wang F, Duan Z, Liu Z, Liu Z, Wu Z, Gu Y, Sun C, Peng W. A Novel Low-Power-Consumption All-Fiber-Optic Anemometer with Simple System Design. Sensors. 2017; 17(9):2107. https://doi.org/10.3390/s17092107

Chicago/Turabian StyleZhang, Yang, Fang Wang, Zhihui Duan, Zexu Liu, Zigeng Liu, Zhenlin Wu, Yiying Gu, Changsen Sun, and Wei Peng. 2017. "A Novel Low-Power-Consumption All-Fiber-Optic Anemometer with Simple System Design" Sensors 17, no. 9: 2107. https://doi.org/10.3390/s17092107