1. Introduction

Railway track irregularity is one of the most important factors affecting the safe operation of the train. The irregularity can be assessed by track geometry parameters, the measurement of which plays a significant role in monitoring the track deformation and guiding the maintenance of railway lines [

1]. Trains with higher speed require higher track smoothness. With the development of high-speed railways, the demands for track irregularity measurement techniques with high-accuracy and high-efficiency are increasing rapidly [

2].

Traditionally, there are mainly two categories of track irregularity measurement methods namely dynamic measurement and static measurement. Methods based on Track Recording Coaches (TRCs) are a kind of dynamic one under wheel loading [

1,

2]. TRC can measure long wavelength track irregularities with high work efficiency, but their availability is restricted and the measuring accuracy does not fulfil the requirements for track renewals [

2]. Another method based on manual measuring devices is a kind of static one. These kinds of devices used for spot assessment are surpassed by railway track surveying trolleys in terms of data amounts and time efficiency. The lightweight and flexible track surveying trolleys can handle different measurement tasks such as measurements during the construction stage and measurements of shorter stretches of track [

1,

2].

The most well-known track surveying trolleys, widely deployed in China, are the GPR1000 series products provided by Amberg Technologies (Regensdorf, Switzerland) [

3]. These kinds of trolleys are all-in-one solutions for surveying railway tracks, enabling the assessment of parameters such as the cant, track gauge, chainage, alignment and level with high accuracy, and can provide sub-millimeter absolute accuracy measured by total station in stop-and-go mode. The Swiss Trolley is another representative track surveying trolley which is developed by the Institute of Geodesy and Photogrammetry at ETH Zurich [

1,

2]. Glaus [

2] has presented this kind of trolley thoroughly. The basic devices the Swiss Trolley is equipped with are an inclinator, track gauge measuring system and odometer can measure gradient, cant, gauge, and chainage. Absolute positioning is done by Global Positioning System (GPS) and total station. According to Glaus [

2], GPS measurements fulfill most accuracy requirements contrary to the general opinion that submillimeter absolute accuracy has to be obtained in railway surveying.

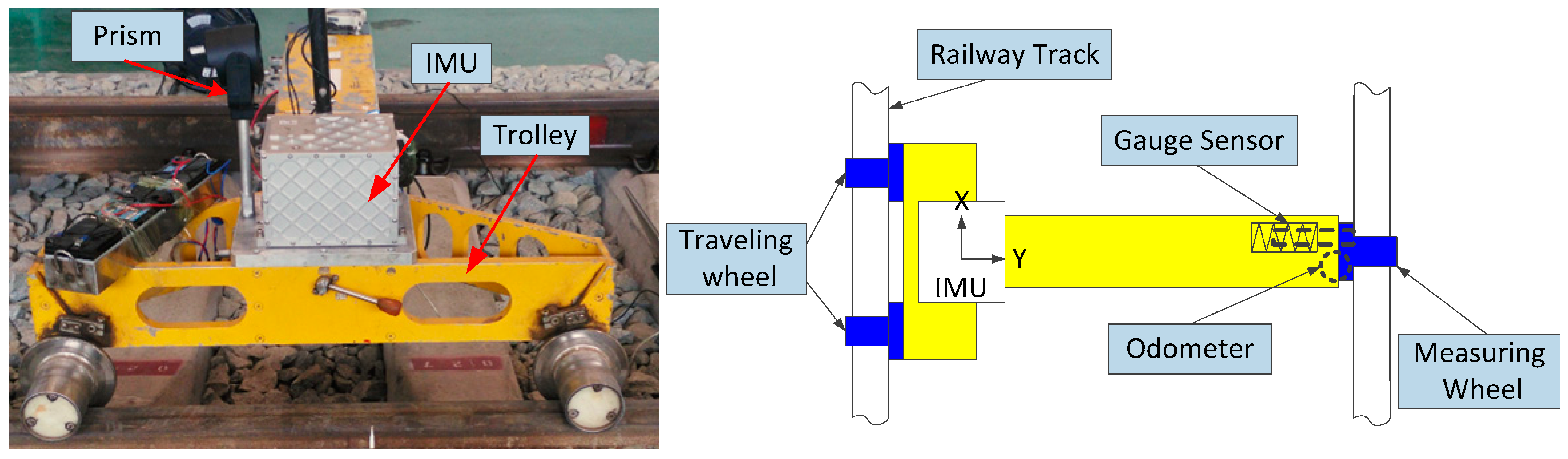

With the development of inertial sensors, INS is no longer expensive and bulky. Track surveying systems based on INS have been widely applied in railway track surveying. A limitation of a stand-alone INS is its unfavourable error propagation. Error drifts of INS should be depressed by other sensors providing relative or absolute measurement updates such as ZUPT, Control Points Coordinate Updates (CUPT) and so on. Luck [

4] discussed the design of track measurement systems based on INS/GPS integration for the dynamic inspection locomotive. Niu and Chen [

3] presented an INS/GPS integrated system to measure railway track irregularities with relative accuracy of 1 mm. Non-holonomic constraint and ZUPT are implemented in their integration algorithm to improve the surveying accuracy. In order to implement the measuring task with GPS outages, Li [

5] presented a track irregularity measurement trolley equipped with a laser-aided INS/odometer integration system for subway applications whose observations of control points for position updates are measured by the laser scanner. The standard deviations of alignment and vertical irregularities can reach approximately 1 mm. Jiang [

6] utilized the Inertial Measurement Unit (IMU)/odometer/landmark integration technique for railway track surveying and obtained absolute accuracy of 1 mm.

The key issue about INS-based track irregularity surveying systems is suppressing the position errors produced by drifts of inertial sensors using global position information [

5]. In previous works, a great job about the integrations of INS with position measurement sensors and the data fusion of INS measurement with position information has been done for track surveying, but there are few studies about the accuracy requirement of inertial sensors and observation updates that can meet the demands for railway irregularity measurement theoretically or experimentally. In addition, the traditional measurement approaches based on global position information have their own shortcomings. The GPS signal may be disturbed by obstructions which affect the GPS solutions negatively. The distribution and precision of control points are crucial to ensure measurement accuracy for approaches based on landmarks. The construction of control points is costly and their maintenance at millimeter scale is difficult. Even if high precision landmarks can be maintained well, high precise position observations cannot be provided frequently in order to insure the work efficiency of the measurement task, especially for environments without GPS signals, for instance tunnels. Therefore, it is significant to research approaches using less number of landmarks with low precision for railway track irregularity measurement.

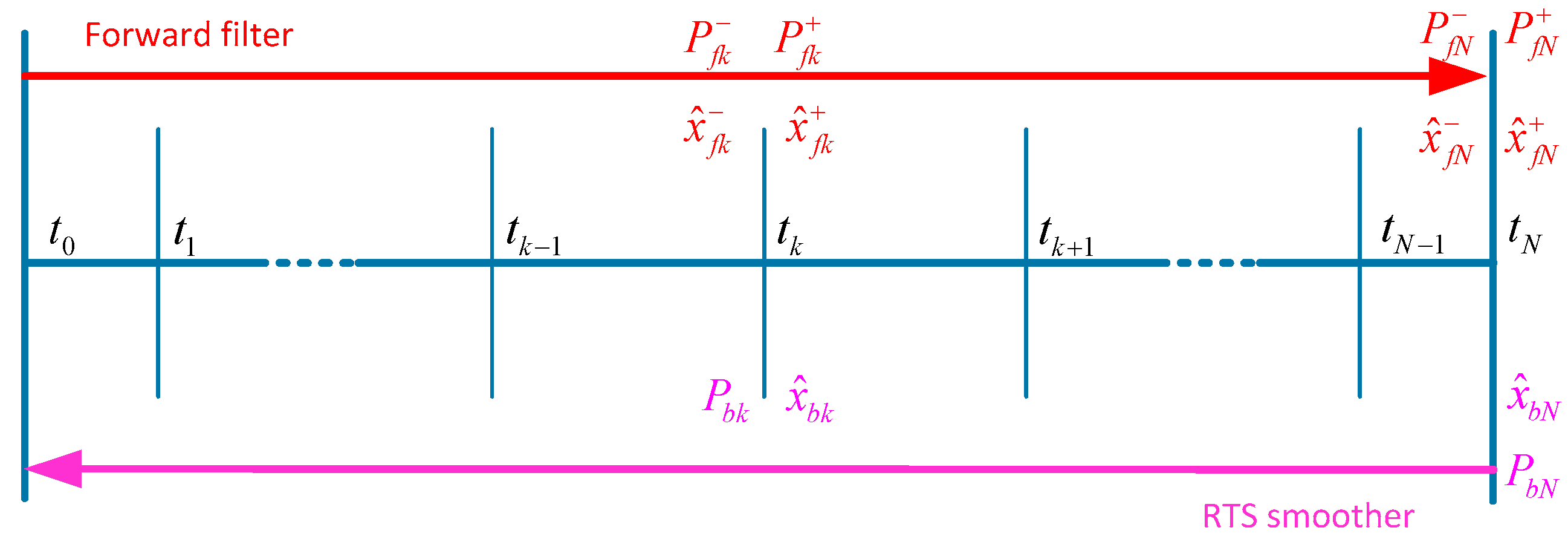

This paper focuses on the issue of the railway track irregularity measurement using a ZUPT-aided INS to achieve high accuracy measurement of relative track geometry parameters to reduce the requirement of high precision landmarks. A typical Kalman filter with 12 dimensional error states is designed in the paper and the Rauch-Tung-Striebel (RTS) smoother is employed to improve the position accuracy. Aiming at alignment and level irregularities of the track, we established the relationship between track irregularities and the absolute position deviations. Based on covariance analysis, the surveying accuracy of alignment and level irregularities is presented, the analytical relationship about irregularities with the precisions of inertial sensors, initial attitudes and observation updates are established. Simulation and experimental results are also presented.

The rest of the paper is organized as follows:

Section 2 describes the railway track irregularity and assessment.

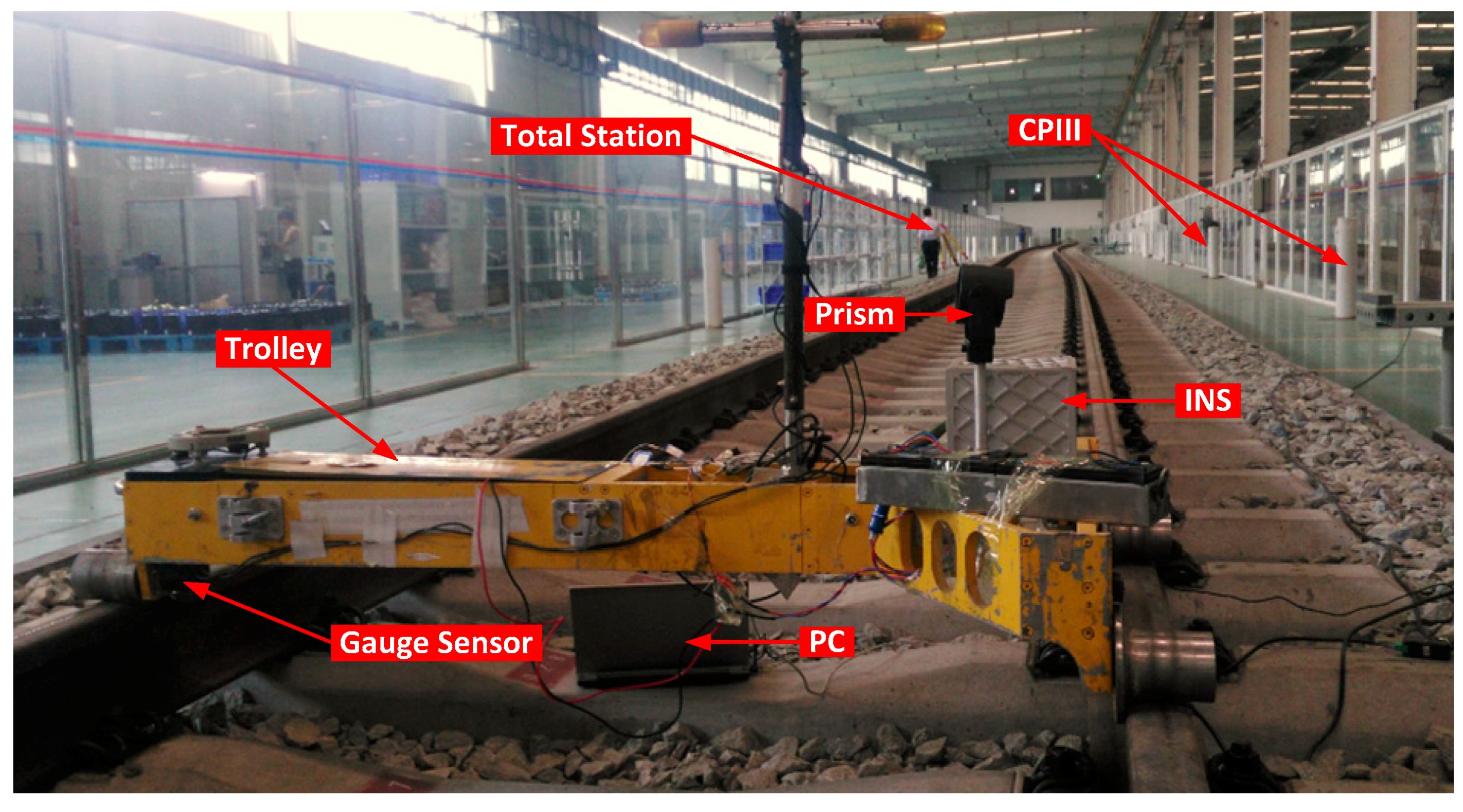

Section 3 describes the overview of the measurement system and the algorithm.

Section 4 describes the design of Kalman filter and smoother.

Section 5 presents the calculation method of alignment and level irregularities from absolute position as well as the covariance analysis of them.

Section 6 reports the simulation and experimental results of track irregularity.

Section 7 concludes this paper.

2. Railway Track Irregularity and Assessment

Railway tracks can be regarded as a 3-dimensional curve [

3,

5]. Track irregularity refers to the deviation of the track from its design geometry, which is usually determined by five geometry parameters, namely alignment (horizontal alignment), level (vertical alignment), cant (super-elevation or cross-level), twist and gauge [

7,

8,

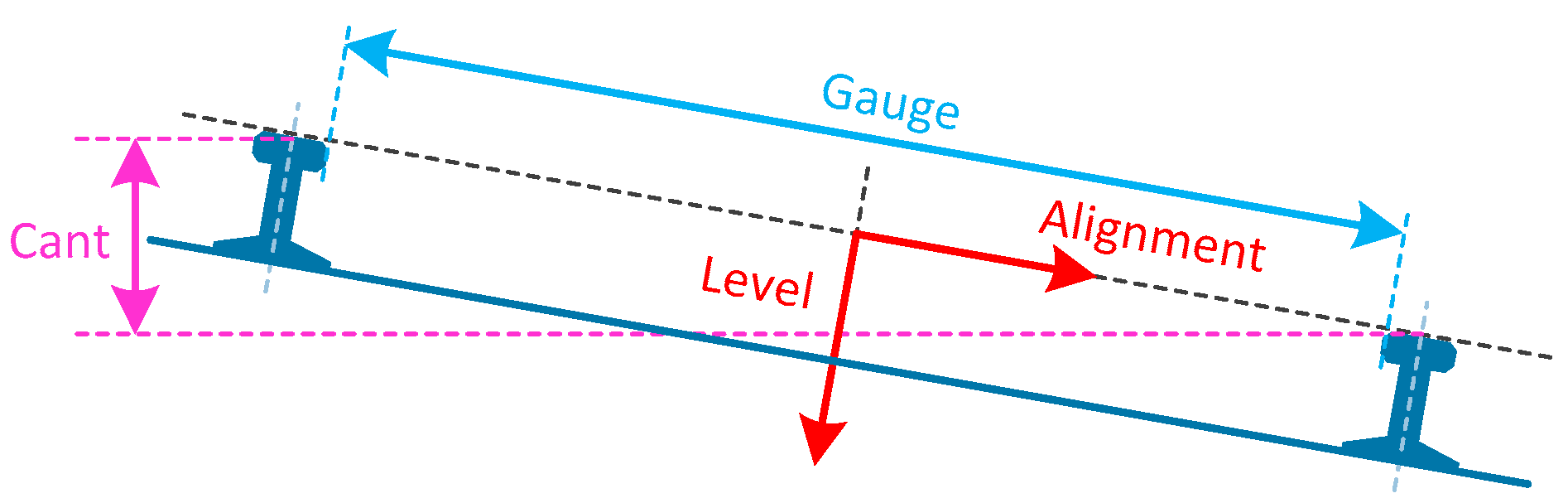

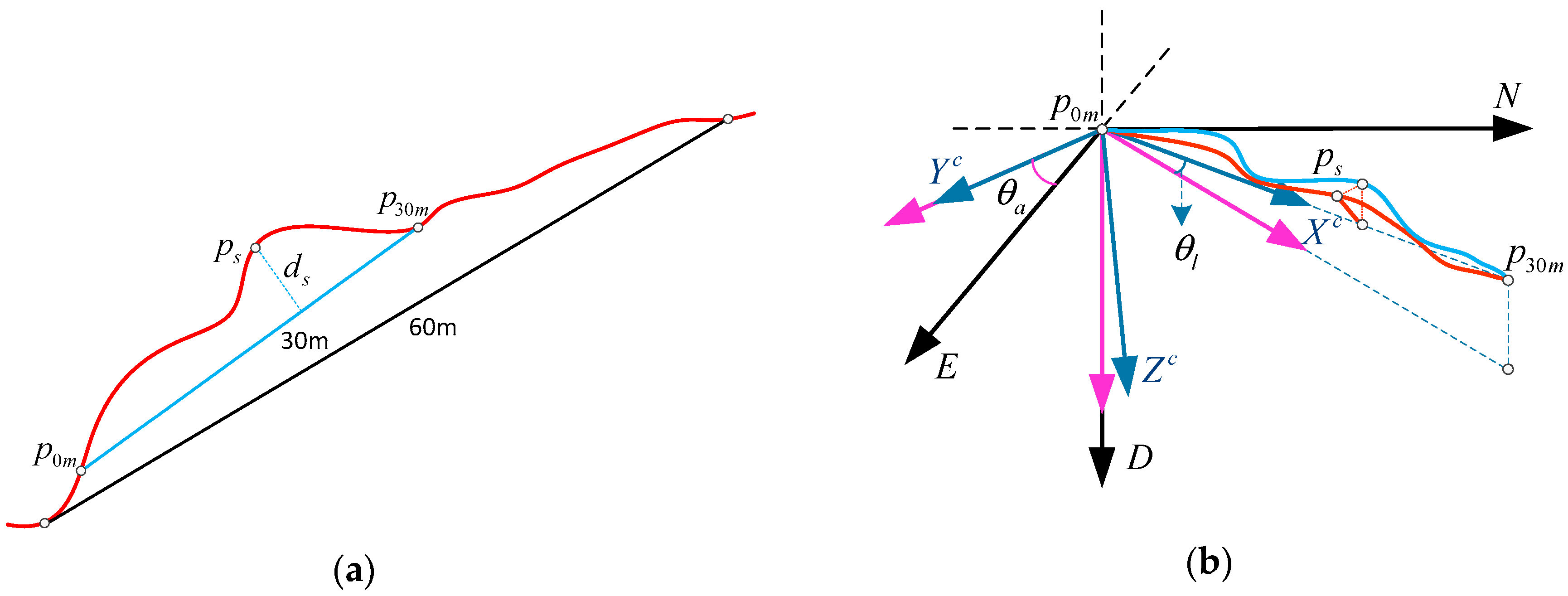

9]. As illustrated in

Figure 1, the axes of the rail coordinate system are defined as follows: the

x-axis is in the travelling direction,

y-axis parallel to the running surface, and

z-axis perpendicular to the running surface and pointing downwards. Alignment is the track’s displacement in the horizontal plane, which can be seen as the deviation of actual track from the design one in horizontal plane. Level is the displacement in the vertical plane [

1]. Gauge is the distance between the inner sides of the two railheads. Cant is the difference between the elevations of the running surface of two rails, representing the tilting of the track in curves in order to compensate the centripetal force. Twist is defined as the difference in cant over a given length.

In this paper, the gauges are estimated from track gauge measurement system. Cant and twist can be calculated in simple models, and will not be discussed in detail. The alignment and level irregularities will be evaluated as examples to demonstrate the measuring accuracy.

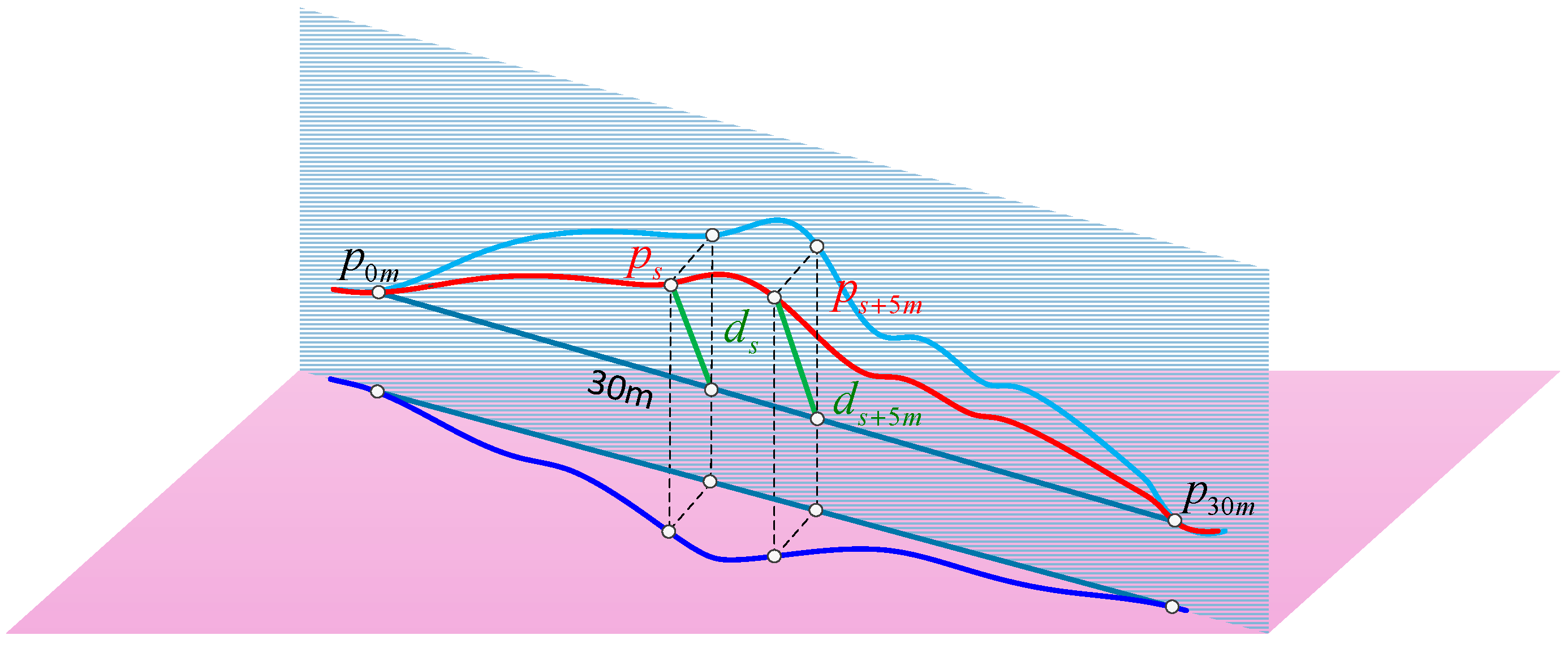

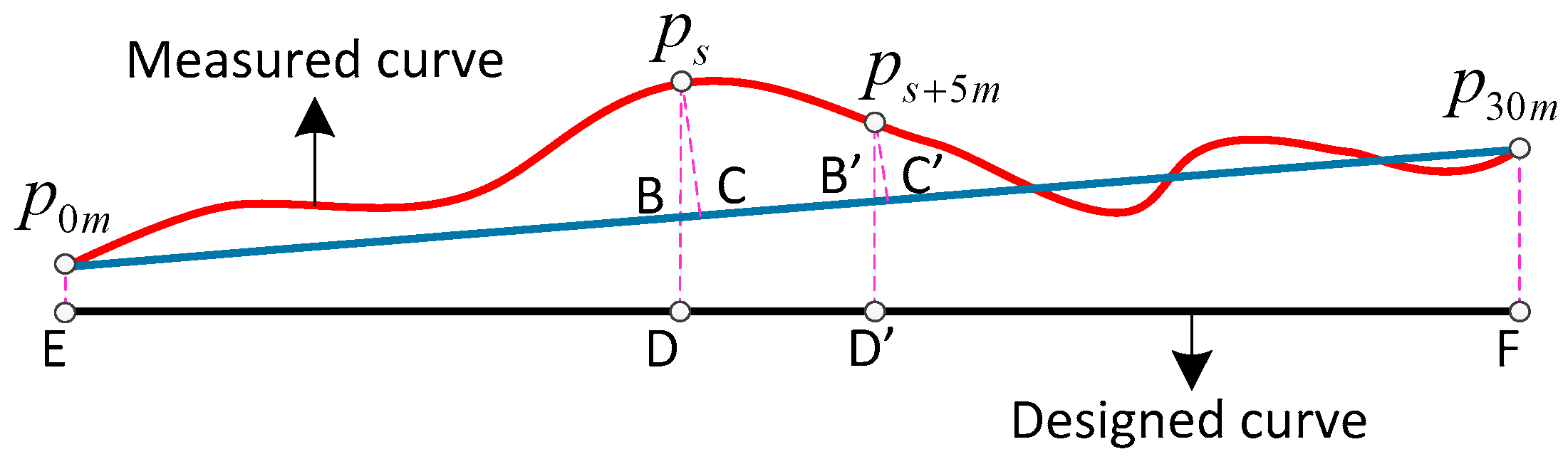

According to the railway standards [

8,

9], the alignment and level are measured by the vector distance value with a chord of fixed length (e.g., 30 m) on the rail surface in the horizontal and vertical directions respectively. The magnitude of alignment and level irregularities will be calculated by differential method of 30 m chord. As shown in

Figure 2, the red curve represents a segmentation of railway track in 3-dimensional space; the other two curves are the projections in horizontal plane and vertical plane respectively. The 30 m long chord is determined by points

and

on the curve. Take the point

on the curve as an example. The distance from

to the chord is the vector distance of this point represented by

. Vector distance of the next adjacent point

with 5 m interval is

. The track irregularity of point

can be calculated by Equation (1) [

8]:

where

and

represent measurement values of vector distances about points

and

.

and

represent the design values of them.

represents the track irregularity of point

, projection of which in the horizontal plane is the alignment irregularity and in the vertical plane is the level irregularity.

5. Covariance Analysis

The track irregularity measurement accuracy can be presented by its variance. According to Equations (18) and (19), in order to calculate the variance of track irregularity, the covariances among

and

(

) should be calculated. However, the analytical solutions of the Riccati equation and the state vector of the filtering and smoothing system are difficult to calculate, we will firstly carry out the covariance analysis theoretically for the simplified situation by ignoring the system noises, and numerically for the general situation with system noises. Since the projections of the Earth angular velocity through the attitude errors are small and remain constant in short time interval, they can be equivalent to the gyro drifts. The terms of Coriolis acceleration are so small that they can also be ignored in a short time interval. Therefore, the system matrix can be further simplified as expressed in Equation (20) for the simplified situation [

10]:

where

is the value of gravity. In addition, in order to simplify the solving process, we suppose that the railway track is a straight track in north direction without loss of generality. In these conditions, Equations (18) and (19) can be simplified as expressed by Equations (21) and (22):

For a ZUPT-aided INS with landmark integration, the distribution of trolley stop points and position observations is crucial to ensure the surveying accuracy [

5]. In general, higher-frequency observation updates will result in better accuracy. However higher-frequency observation means more stop points which will influence the work efficiency. Therefore, in this paper, the distance of two stop points is 60 m for measuring position and providing zero velocity, and the observation updates are only provided in the end of every 30 m chord interval as

Figure 6 shows.

For the measurement of every 30 m interval, the observation updates are measured at the end time epoch. For the forward filtering process, the optimal estimate of error state vector and its covariance matrix at other time epochs with no observations can be expressed as the functions of initial values in continuous form as Equation (23) shows according to Equation (11) [

13]:

where

is the system state transition matrix can be calculated as Equation (24) shows:

and the initial variance matrix can be expressed as Equation (25):

When the observations update at time epoch

, the updated estimate of state vector and its covariance can be obtained by disperse Kalman filter as shown in Equation (26):

For the backward smoothing process, the initial optimal smoothed estimate of state vector and its covariance are

and

. The optimal smoothed estimate and its covariance at arbitrarily time epoch t can be expressed in continuous form as Equation (27) shows:

The error of the optimal smoothed estimate of state vector can be obtained by subtracting true value from its optimal smoothed estimate as Equation (28) shows:

From Equation (28), we can get the position error

and

expressed by the initial errors of state vector by setting the corresponding time. Setting

,

,

,

,

,

,

, and

. The time of points

and

are represented by

and

, and their relationship is

. Substituting

and

into Equations (21) and (22) respectively and calculating the variances of

and

, we can obtain:

Calculating the partial derivatives about variables of Equations (29) and (30) respectively, we can get

and

. This means that the variances of alignment irregularity and level irregularity are monotone increasing functions. Only with variances about initial state errors and observations less than certain values can the measurements of track irregularity satisfy the surveying accuracy demands. According to Equation (30), the position error (

and

) has no effect on level irregularity. As a matter of fact, the influence of position error on the alignment irregularity is also so small than other error terms that can be ignored. When

which means that there is no position observation, the variance of alignment irregularity can be converted as Equation (31):

We can verify that the value of is very small by a numerical method. Consider that is a monotone increasing function of , it is feasible to implement track irregularity surveying tasks without position observations updating for the ZUPT-aided INS. As a result, the requirements of high precise landmarks are reduced at a large extent. The landmarks can be only used as a determination of the track segmentation that sub-decimeter scale can meet the demand. And they may be replaced by a sub-decimeter scale INS/odometer integration system in short time interval as well.

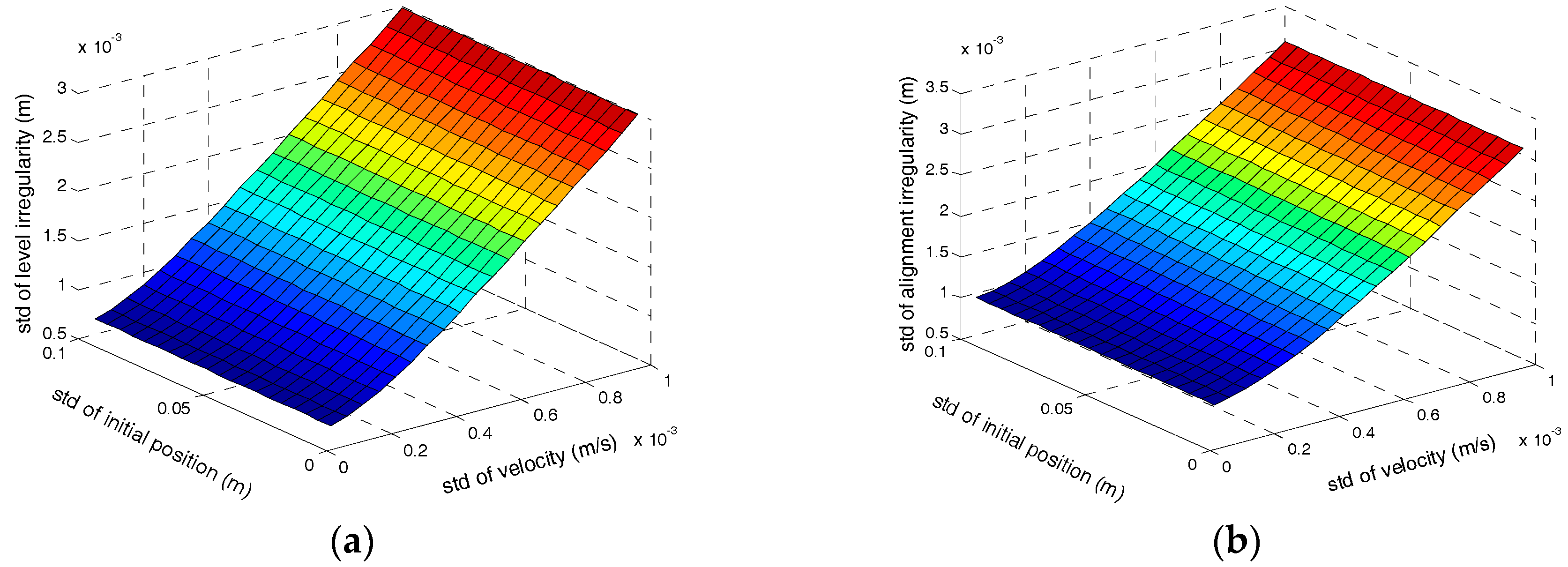

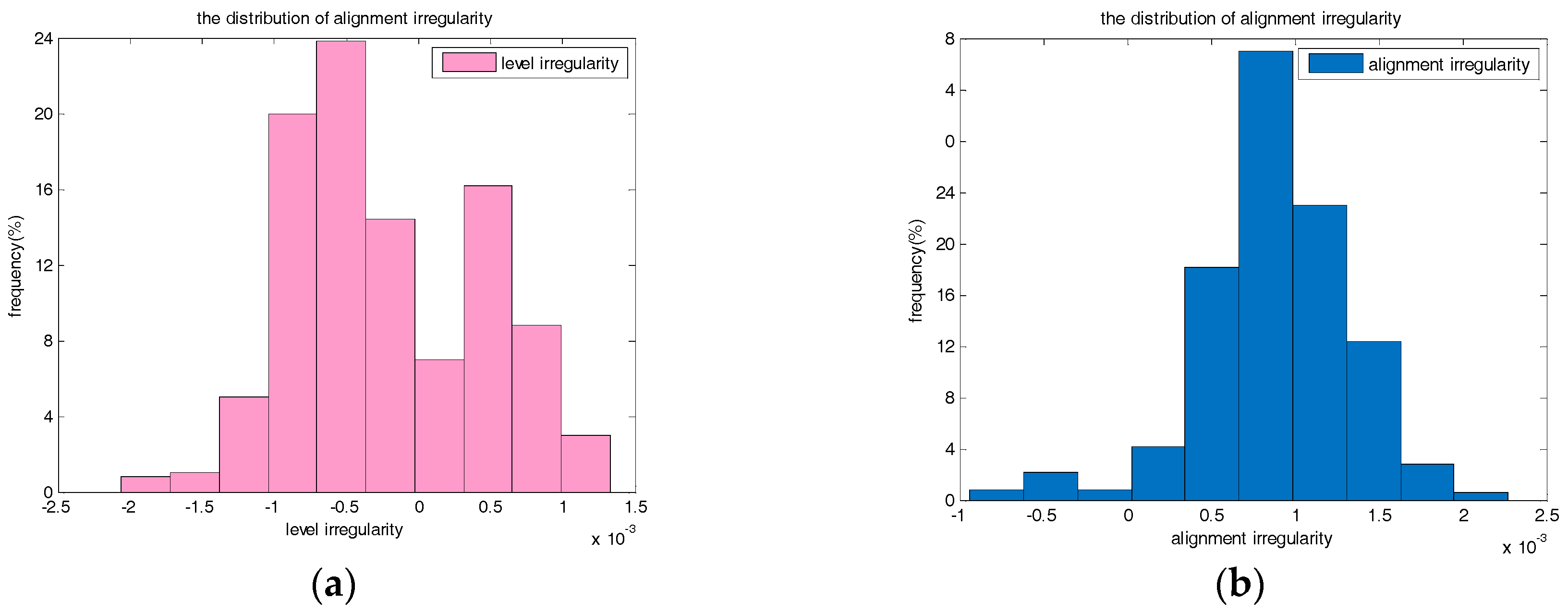

For the general situation, the system noises cannot be ignored and we carry out the covariance analysis in a numerical method. The measurement accuracy of alignment irregularity and level irregularity are related with the variances of initial error states, the accuracy of inertial sensors and the accuracy of observation update. Here, we suppose that the railway track is a straight track in the direction of north by east 45 degrees without loss of generality. The system matrix is the full form as Equation (7) shows without ignoring the projections of the Earth angular velocity through the attitude errors and the terms of Coriolis acceleration. Considering the previous analysis, we will only make use of the velocity observation to update the Kalman filter.

Firstly, we assess the influences of the observation accuracy on the irregularity measurement accuracy without position observation. Setting the tilt error to 0.006° and the orientation error is 0.06°. Setting the gyro bias instability to 0.01°/h and ARW is 0.005

, and setting the accelerometer bias instability to 50 μg and random noise is 10

. The measurement accuracy is also affected by the measurement time of every interval or the velocity of the trolley. Shorter measurement time means less integral time of the errors, and will result in higher measurement accuracy. Here we set the trolley velocity to 1 m/s (8 km/h at most for track surveying trolley), and 30 s will be consumed for every 30 m distance interval. The relationship between railway track irregularities measurement accuracy and the velocity observation accuracy as well as initial position accuracy are illustrated in

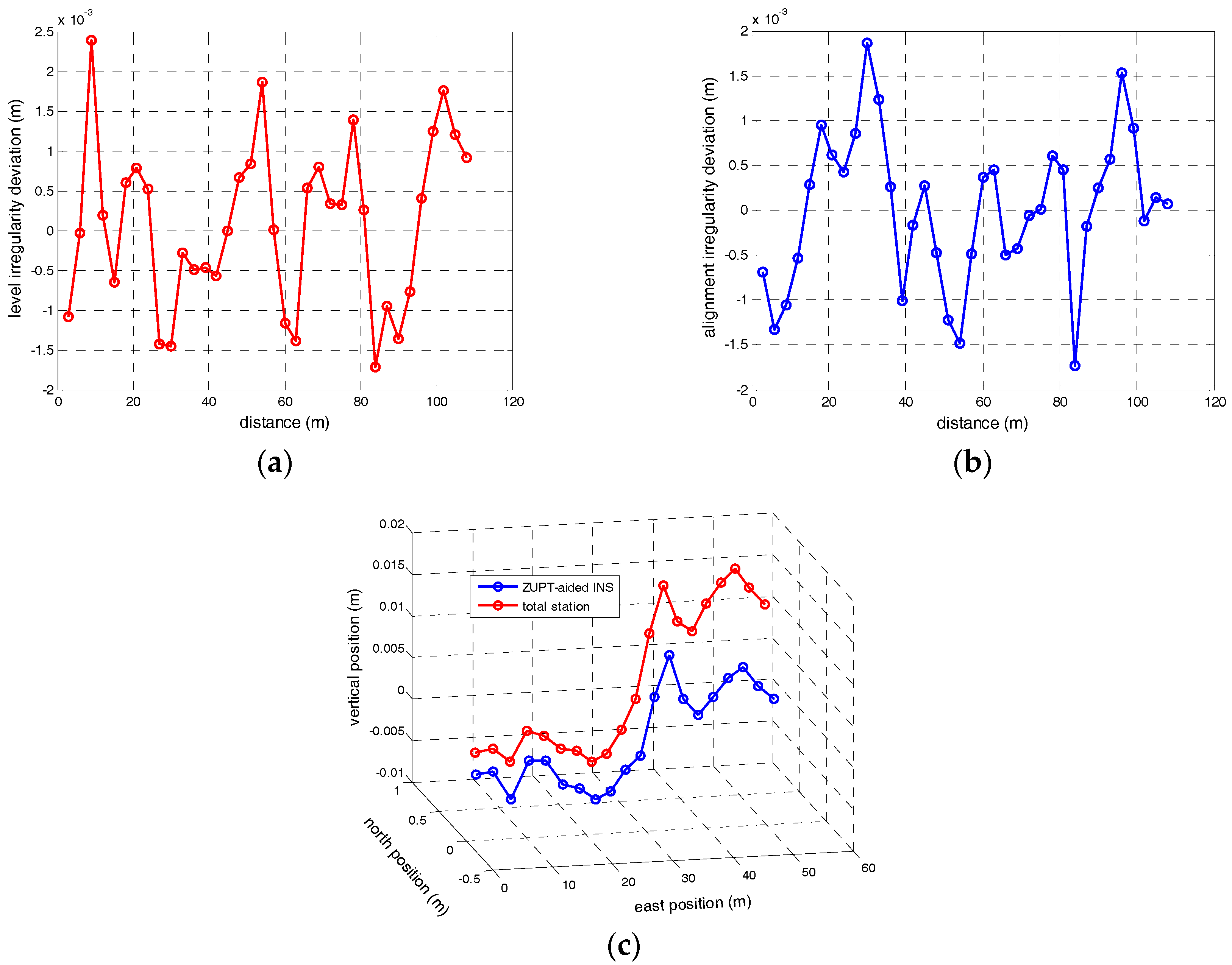

Figure 8.

According to

Figure 8, under the supposed conditions above, the observation accuracy of velocity causes larger influences than the initial position error for the track irregularities measurement accuracy. The initial position error has no effect on the track irregularity, which is coincident with the theoretical analysis previously. In order to satisfy the relative accuracy demand of 1mm, the accuracy of velocity observation should be less than 0.15 mm/s and ZUPT can satisfy the accuracy demand of velocity. A higher level of inertial sensors than the system above should be employed to satisfy the high-speed railway accuracy demand of 0.5 mm.

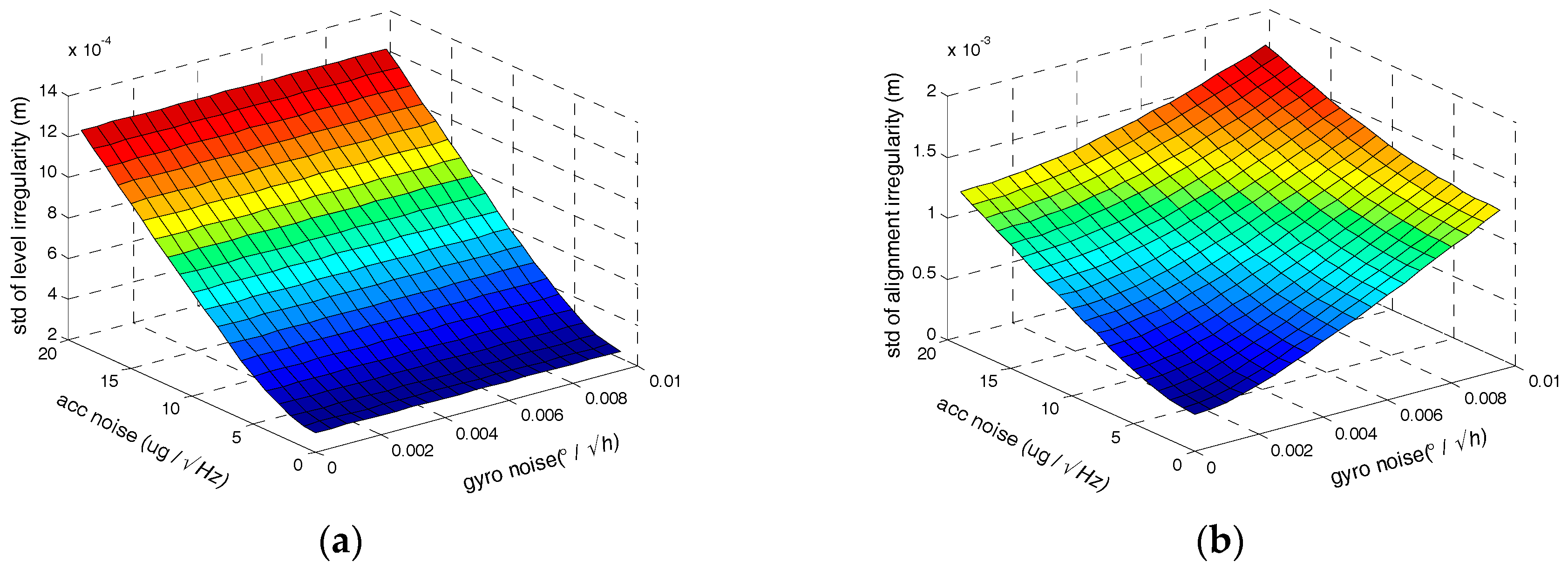

Secondly, we assess the influence of the random noises of inertial sensors on the irregularity measurement accuracy. Setting the tilt error to 0.006° and the orientation error is 0.06°. Setting the gyro bias instability to 0.01°/h, the accelerometer bias instability is 50

. and setting the accuracy of initial position to 10 cm the velocity observation is 0.1 mm/s. The relationship between track irregularities measurement accuracy and random noises of gyro and accelerometer are illustrated in

Figure 9, where under the supposed conditions above, the ARW of gyro should less than 0.0071

at most and random noise of accelerometer should less than 14.7

at most to satisfy the demand accuracy of 1 mm both with and without position observation.

Thirdly, the influences of the tilt errors and orientation error on the irregularity measurement accuracy have been assessed. Other parameters are fixed as described values previously. The relationship between track irregularities measurement accuracy and attitude errors are illustrated in

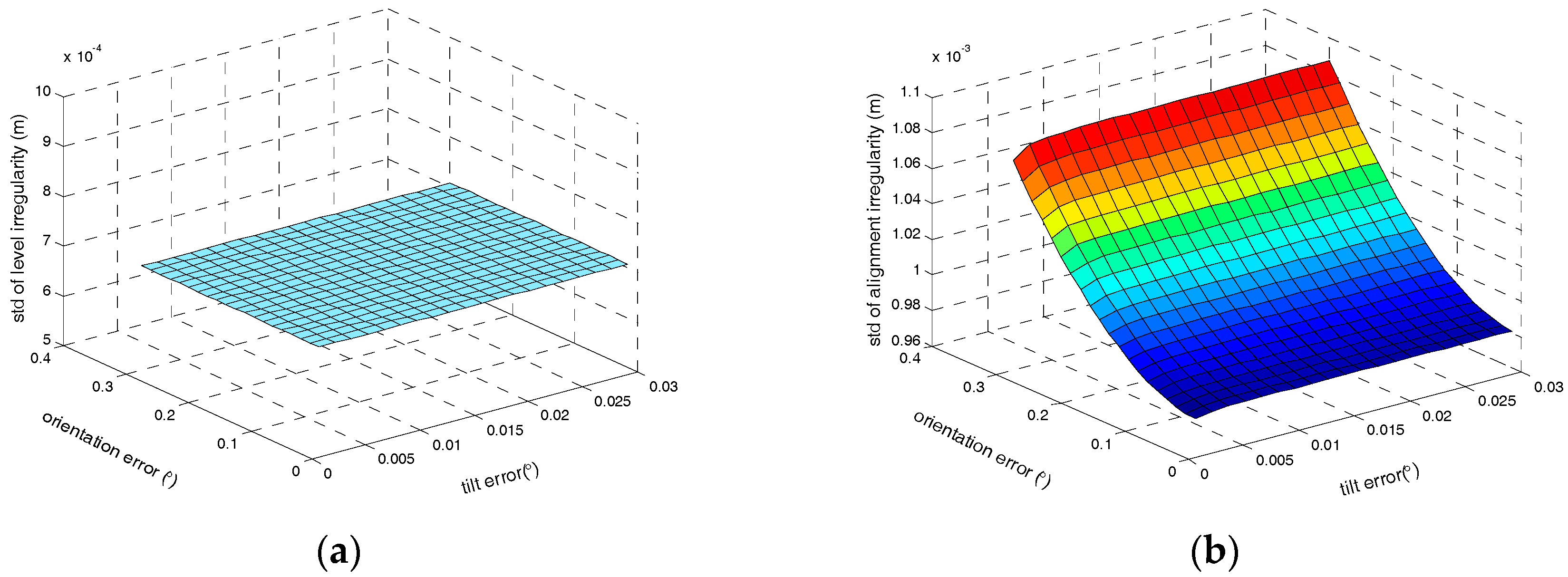

Figure 10.

As illustrated in

Figure 10, the attitude errors have no effect on the level irregularity, which is coincident with the theoretical analysis as Equation (30) shows. Since the orientation error is much bigger, it has a larger effect on alignment irregularity than the tilt errors.

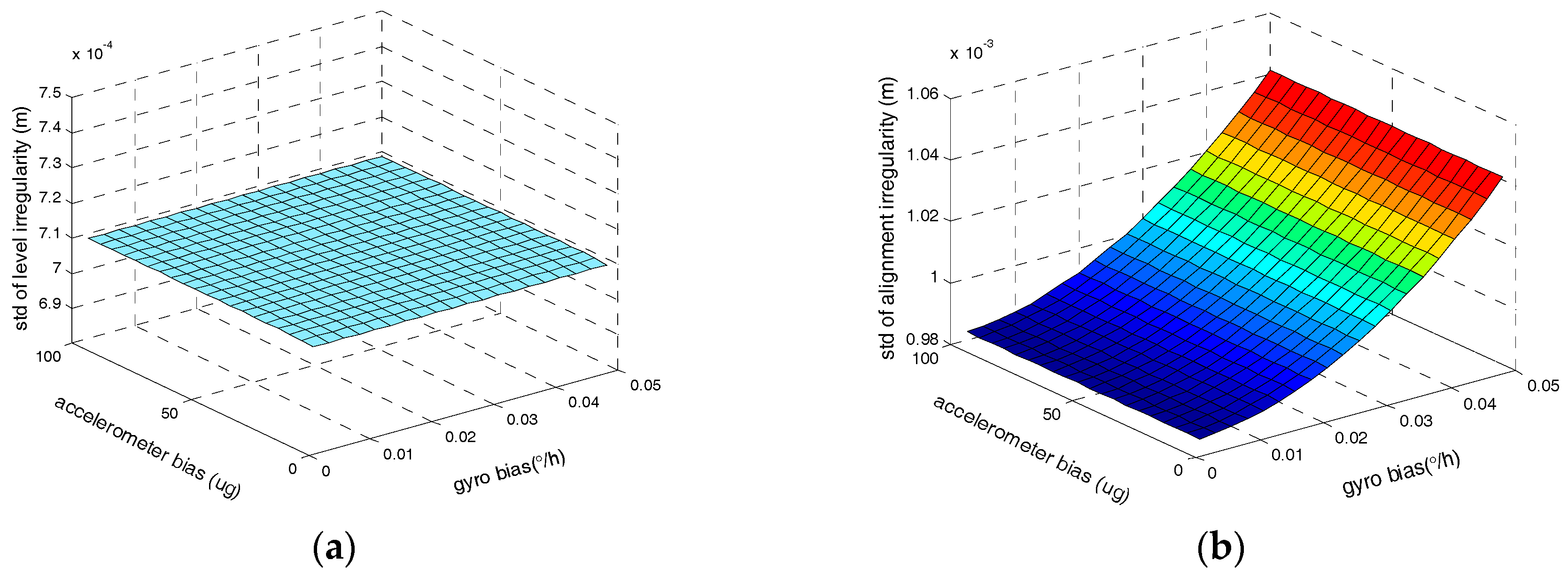

Finally, the influences of the equivalent biases of gyros and accelerometers on the irregularities measurement accuracy are assessed as illustrated in

Figure 11. Other parameters are also fixed at the previously described values.

As illustrated in

Figure 11, the gyro biases have no effect on the level irregularity, which is coincident with the theoretical analysis as shown in Equation (30) and the influence of the accelerometer bias on the level irregularity is small. In addition, the accelerometer bias has no effect on the alignment irregularity as well as Equation (29) shows.

7. Conclusions

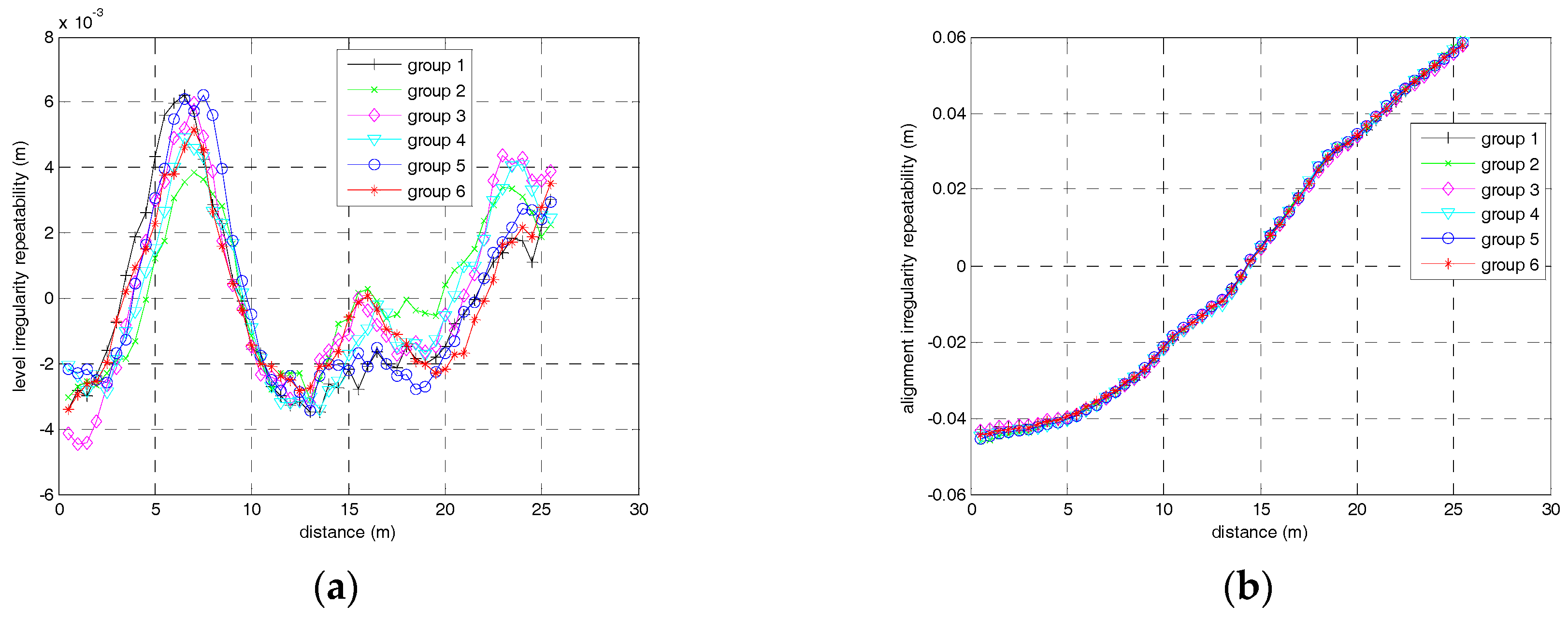

The measurement of railway track irregularity plays a significant role in monitoring the track deformation and guiding the maintenance of railway lines. This paper makes use of the ZUPT-aided INS for the track irregularity measuring applications. The RTS smoothing algorithm is employed to improve the performance of the surveying system.

The calculation equations of the track irregularity parameter from absolute positions have been deduced in the paper. Based on covariance analysis, the analytical relationships between the track irregularity with the drifts of inertial sensors, the accuracy of attitude and the accuracy of velocity observations as well as the accuracy of initial position are established. The theoretical analysis and numerical analysis show that the position observation of the Kalman filter has no effect on the measurement accuracy of the alignment irregularity and level irregularity, and we can implement track relative geometry surveying based on ZUPT-aided INS without position observation updates. The landmarks can be only used to determine track segmentation, sub-decimeter scale accuracy of which can satisfy the track surveying demand.

Simulations and experimental results show that the relative accuracy for 30 m chord of the proposed approach for track irregularity surveying can reach approximately 1 mm (1σ) with gyro bias instability of 0.01°/h, random walk noise of 0.005 and accelerometer bias instability of 50 , random noise of 10 , while only velocity observations are provided by the ZUPT technique in about every 60 m interval. This accuracy can meet the most stringent requirements of the track irregularity surveying for railway lines. For higher accuracy demand of irregularity surveying, the higher level of inertial sensors than that of this paper should be employed.

This paper proposes a relative geometry parameter measuring approach for the railway track. It reduces the requirement of high precision landmarks significantly and lightens the maintenance burden of control points to a large extent. In addition, it also can improve the work efficiency of railway track irregularity measurement task.