A Tailored Ontology Supporting Sensor Implementation for the Maintenance of Industrial Machines

Abstract

:1. Introduction

2. Need of Sensor Ontology

2.1. Role of Sensors in Industrial Services

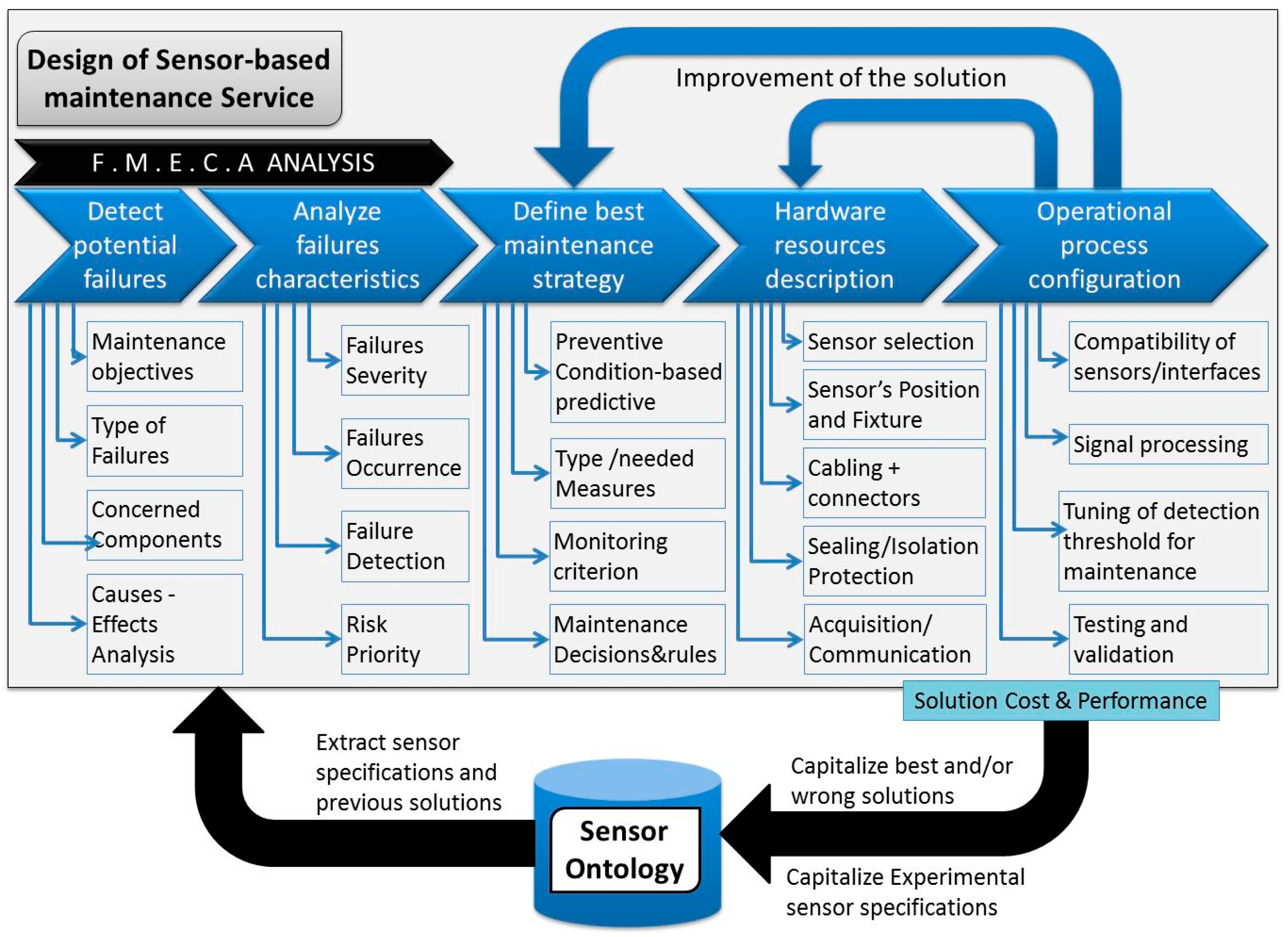

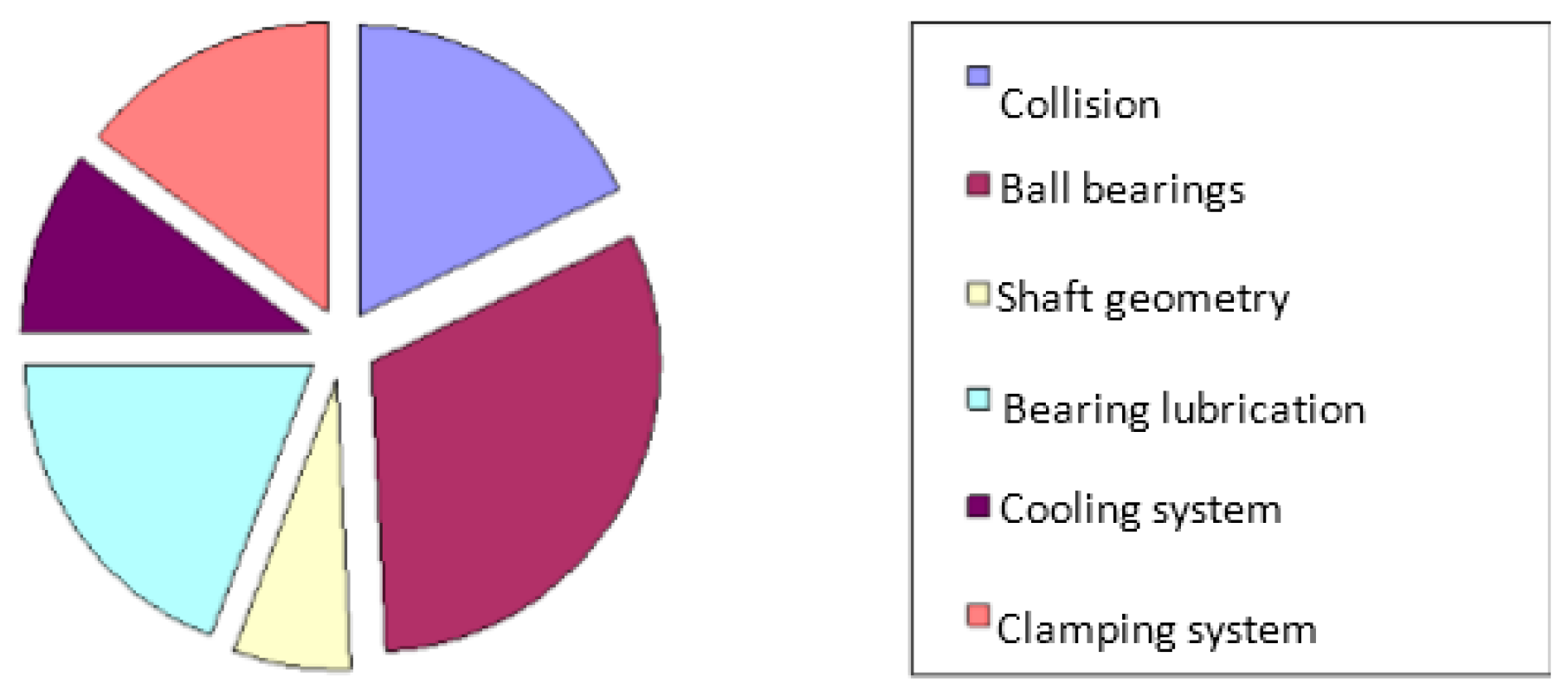

2.2. Sensor Implementation in the Maintenance Service Design Process

- What sensor specification is needed to support measuring performance, depending on the product’s working conditions?

- What additional equipment is needed to support the functioning of the selected sensors?

- What are the main potential positions of sensors regarding the product’s structure for maximum measuring performance?

- What is the ideal fixture system for connecting sensors to the product’s components?

- What is the expected performance of the selected sensor following a specific product–service configuration?

- What type of data processing and analysis method is needed?

3. Proposition of a Sensor Ontology Structuring the Knowledge Repository

3.1. Methodology of Sensor Ontology Design

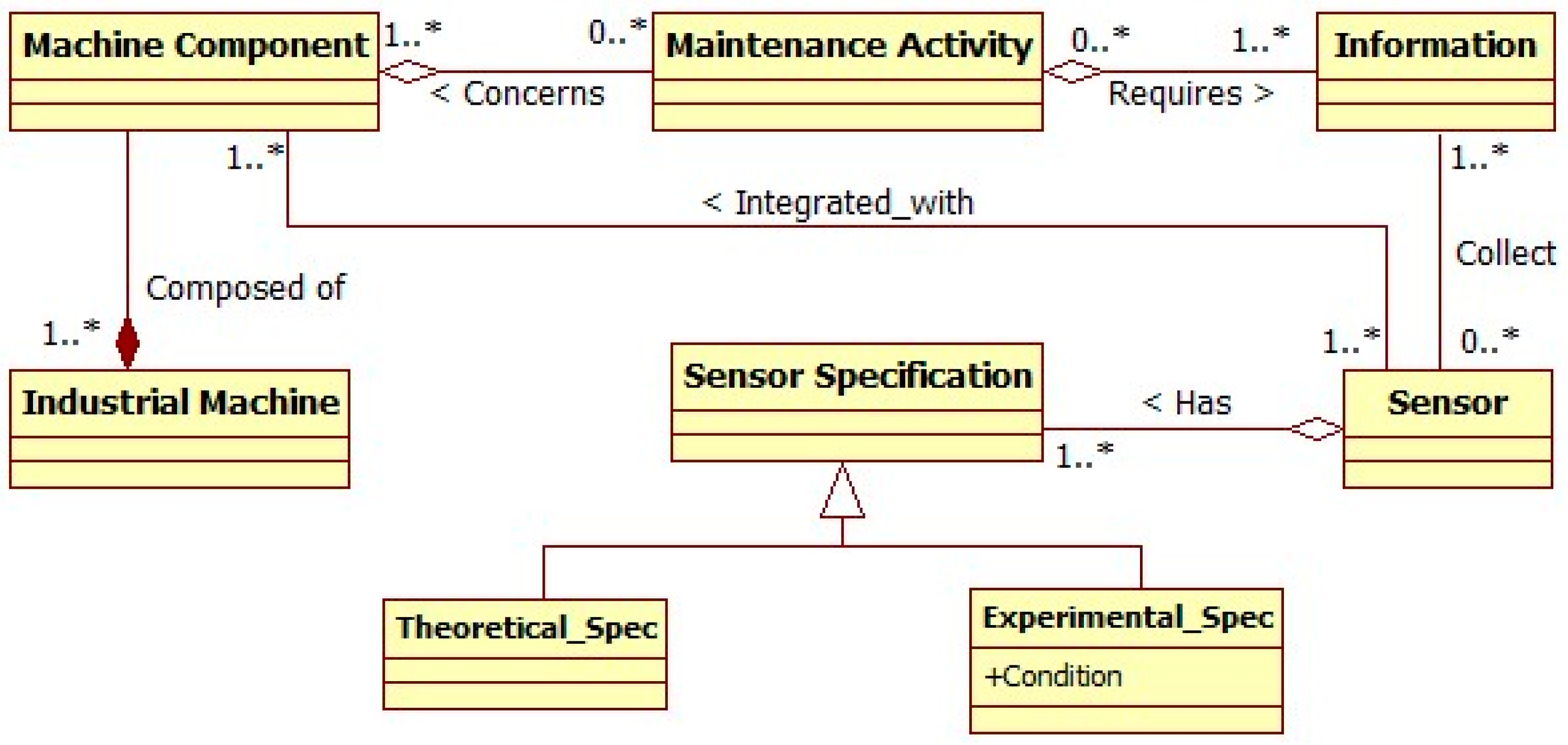

3.2. The Global Model of the Proposed Ontology

- (1)

- The maintenance engineer fixes the maintenance objectives and processes. He collaborates with the machine engineer during all analysis activities requested at the earlier stages of the sensor implementation process.

- (2)

- The sensor engineer creates and manages sensor data and the technological specifications of the existing sensors in the repository. He contributes to the identification of the best sensor kits.

- (3)

- The machine engineer uses legacy CAD (computer-aided design) tools to update and manage the necessary technical data of machine components in connection with the sensors. He provides his expertise on the nominal machine behavior as a contribution to the task of potential failures analysis.

- (4)

- The project leader has the main role of supervising the interactions between involved engineers through the collaborative platform. He validates the maintenance strategy and coordinates the integration of the final solution of the target maintenance service.

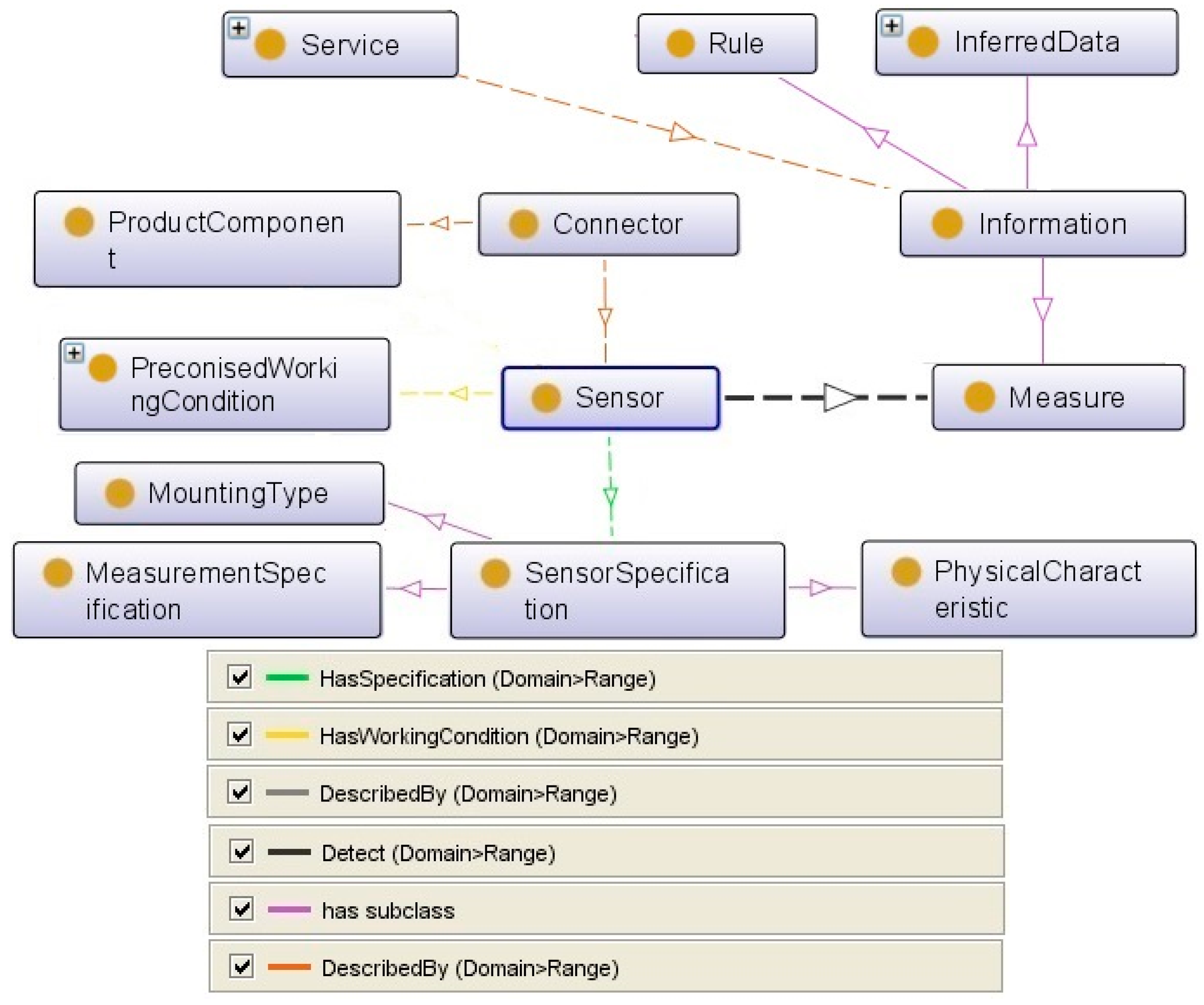

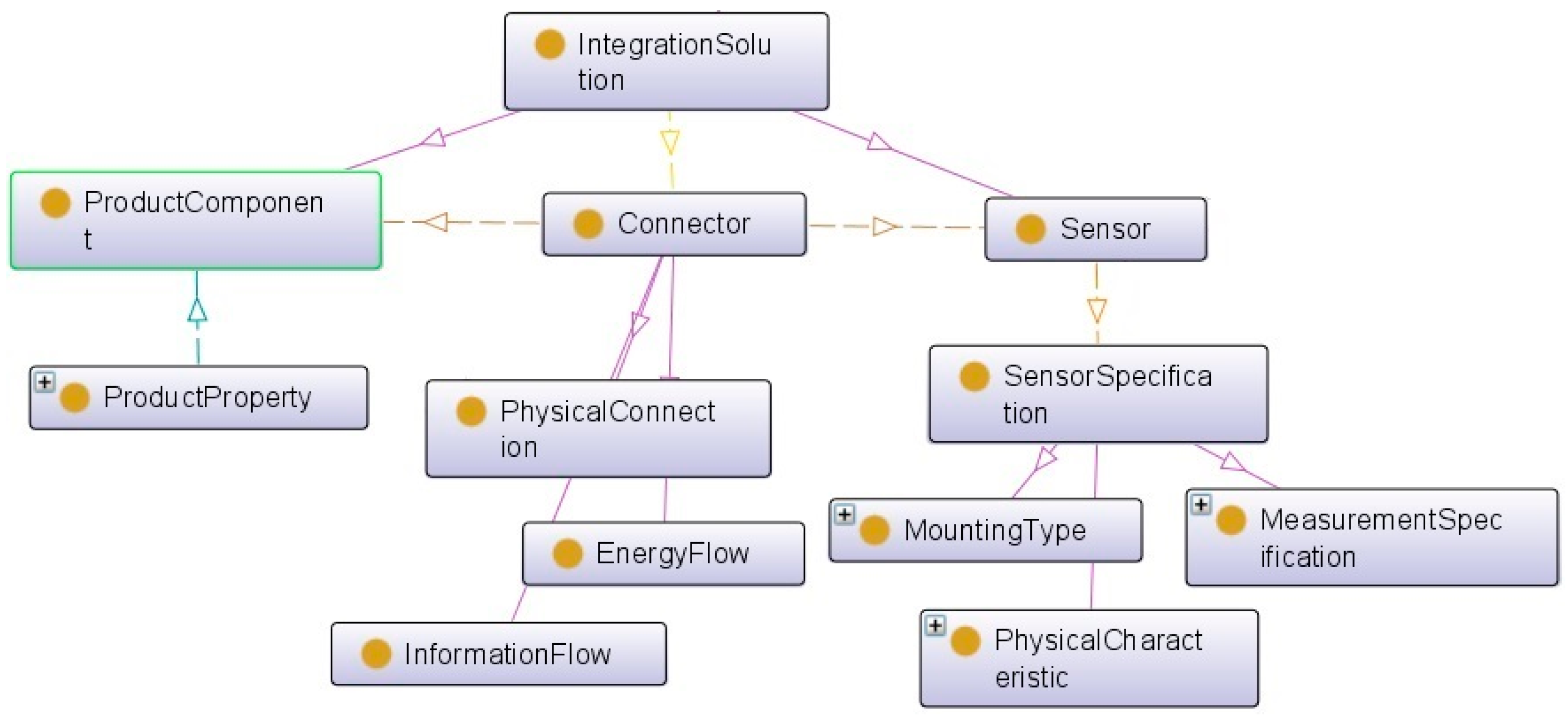

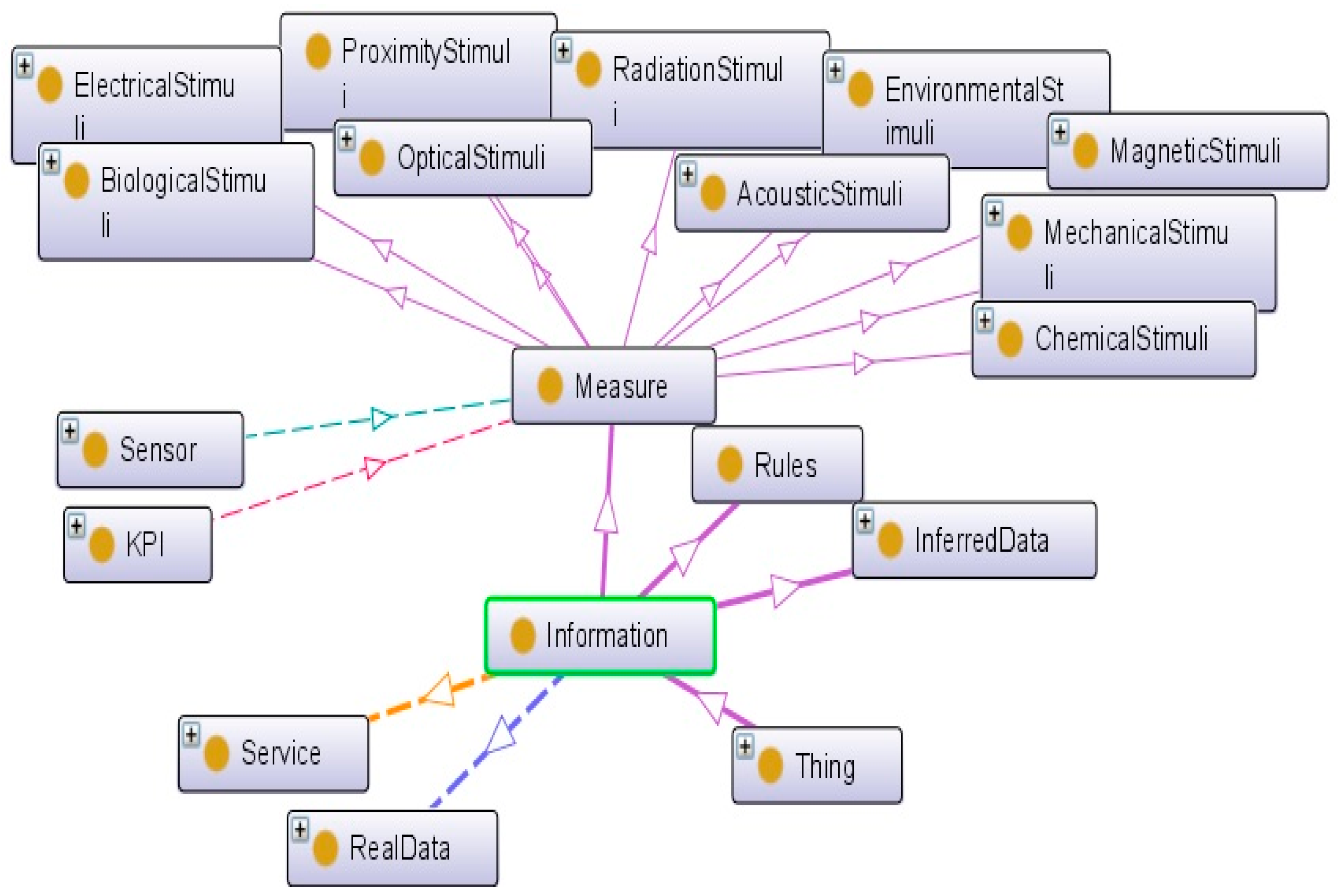

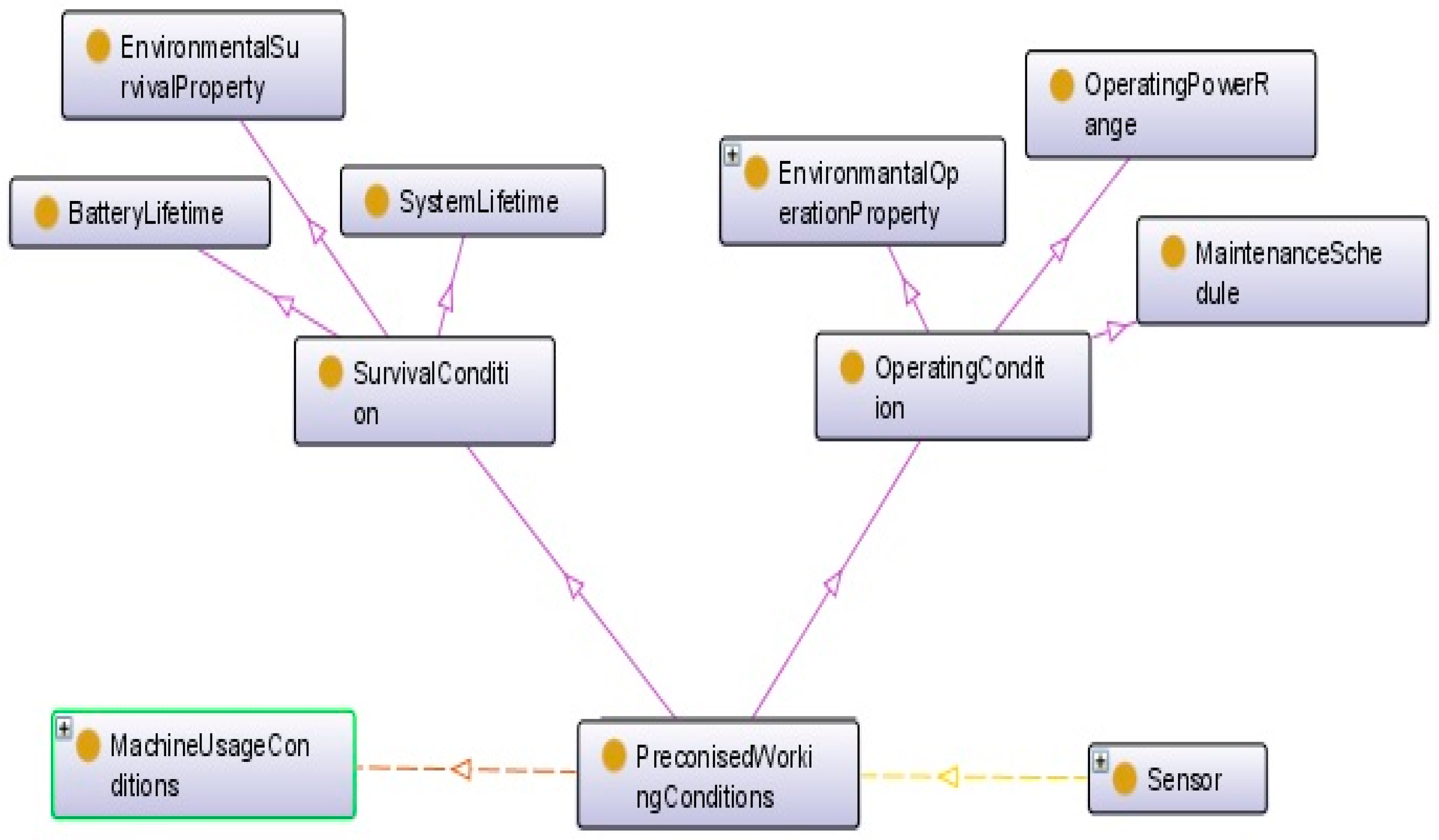

3.3. Sensor Ontology Structure

- Sensor (Technological Solution);

- Maintenance Activity as the Service;

- Information and Measure;

- Product/Machine Component;

- Sensor Specification;

- Mounting Type;

- Physical Characteristic;

- Measurement Specification;

- Working Condition; and

- Connection Constraint.

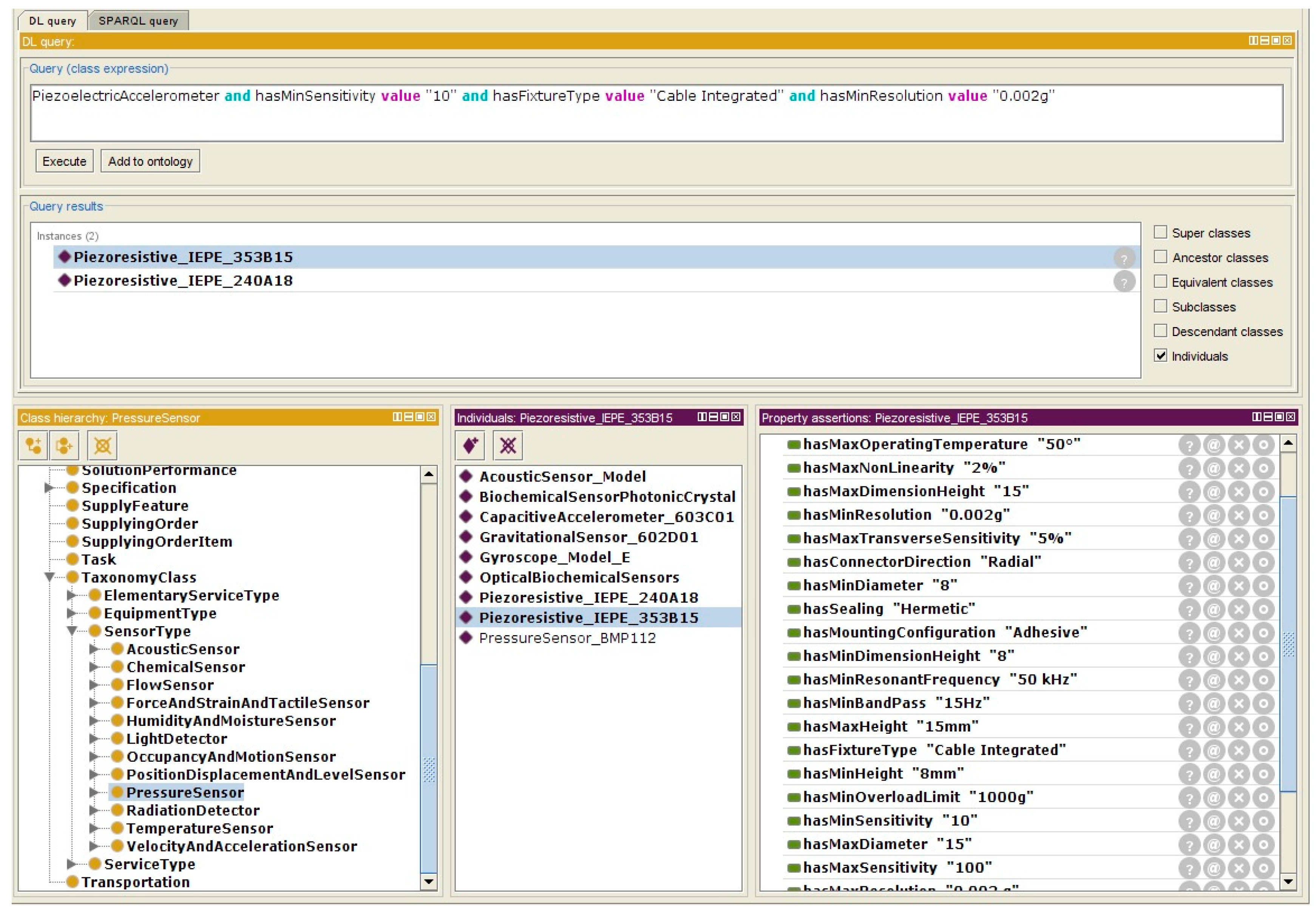

4. Application in Case Study

5. Conclusions and Discussion

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Krolczyk, J.B.; Gapinski, B.; Krolczyk, G.M.; Samardzic, I.; Maruda, R.W.; Soucek, K.; Legutko, S.; Nieslony, P.; Javadi, Y.; Stas, L. Topographic inspection as a method of weld joint diagnostic. Teh. Vjesn. 2016, 23, 301–306. [Google Scholar]

- Krolczyk, G.M.; Krolczyk, J.B.; Maruda, R.W.; Legutko, S.; Tomaszewski, M. Metrological changes in surface morphology of high-strength steels in manufacturing processes. Measurement 2016, 88, 176–185. [Google Scholar] [CrossRef]

- Roy, R.; Erkoyuncu, J.A.; Shaw, A. The future of maintenance for industrial product-service systems. In Product-Service Integration for Sustainable Solutions; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–15. [Google Scholar]

- Elghazel, W.; Bahi, J.M.; Guyeux, C.; Hakem, M.; Medjaher, K.; Zerhouni, N. Dependability of wireless sensor networks for industrial prognostics and health management. Comput. Ind. 2015, 68, 1–15. [Google Scholar] [CrossRef]

- Scholze, S.; Correia, A.T.; Stokic, D. Novel Tools for Product-Service System Engineering. Procedia CIRP 2016, 47, 120–125. [Google Scholar] [CrossRef]

- Roy, R.; Stark, R.; Tracht, K.; Takata, S.; Mori, M. Continuous maintenance and the future—Foundations and technological challenges. CIRP Ann. Manuf. Technol. 2016, 65, 667–688. [Google Scholar] [CrossRef] [Green Version]

- Lindström, J. Introducing Functional Products in production systems: Problems and issues encountered. Procedia CIRP 2016, 41, 45–50. [Google Scholar] [CrossRef]

- Müller, P.; Schmidt-Kretschmer, M.; Blessing, L. Function Allocation in Product-Service Systems—Are there Analogies between PSS and Mechatronics? In Proceedings of the AEDS 2007 Workshop, Pilsen, Czech Republic, 26–27 October 2007. [Google Scholar]

- Zheng, C.; Le Duigou, J.; Bricogne, M.; Eynard, B. Survey of Design Process Models for Mechatronic Systems Engineering. In Proceedings of the 1st World Congress on Controversies in Gastroenterology (CIGI 2013), Berlin, Germany, 13–15 June 2013. [Google Scholar]

- Davies, A.; Brady, T.; Hobday, M. Charting a path toward integrated solutions. MIT Sloan Manag. Rev. 2006, 47, 39–48. [Google Scholar]

- Belkadi, F.; Bernard, A.; Laroche, F. Knowledge based and PLM facilities for sustainability perspective in manufacturing: A global approach. Procedia CIRP 2015, 29, 203–208. [Google Scholar] [CrossRef]

- Roda, F.; Musulin, E. An ontology-based framework to support intelligent data analysis of sensor measurements. Expert Syst. Appl. 2014, 41, 7914–7926. [Google Scholar] [CrossRef]

- Schuh, G.; Pitsch, M.; Rudolf, S.; Karmann, W.; Sommer, M. Modular sensor platform for service-oriented cyber-physical systems in the European tool making industry. Procedia CIRP 2014, 17, 374–379. [Google Scholar] [CrossRef]

- Yue, X.; Cai, H.; Yan, H.; Zou, C.; Zhou, K. Cloud-assisted industrial cyber-physical systems: An insight. Microprocess. Microsyst. 2015, 39, 1262–1270. [Google Scholar] [CrossRef]

- Medina-Oliva, G.; Voisin, A.; Monnin, M.; Leger, J.B. Predictive diagnosis based on a fleet-wide ontology approach. Knowl. Based Syst. 2014, 68, 40–57. [Google Scholar] [CrossRef]

- Zhou, Q.; Yan, P.; Xin, Y. Research on a knowledge modelling methodology for fault diagnosis of machine tools based on formal semantics. Adv. Eng. Inform. 2017, 32, 92–112. [Google Scholar] [CrossRef]

- Nadoveza, D.; Kiritsis, D. Ontology-based approach for context modeling in enterprise applications. Comput. Ind. 2014, 65, 1218–1231. [Google Scholar] [CrossRef]

- Barbau, R.; Krima, S.; Rachuri, S.; Narayanan, A.; Fiorentini, X.; Foufou, S.; Sriram, R.D. OntoSTEP: Enriching product model data using ontologies. Comput. Aided Des. 2012, 44, 575–590. [Google Scholar] [CrossRef]

- Panetto, H.; Dassisti, M.; Tursi, A. ONTO-PDM: Product-driven ONTOlogy for Product Data Management interoperability within manufacturing process environment. Adv. Eng. Inform. 2012, 26, 334–348. [Google Scholar] [CrossRef]

- Fowler, J.W.; Rose, O. Grand challenges in modeling and simulation of complex manufacturing systems. Simulation 2004, 80, 469–476. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. CIRP Ann. Manuf. Technol. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Bialas, A. Computer-aided sensor development focused on security issues. Sensors 2016, 16, 759. [Google Scholar] [CrossRef] [PubMed]

- Afzal, M.; Hussain, M.; Ali, T.; Hussain, J.; Khan, W.A.; Lee, S.; Kang, B.H. Knowledge-based query construction using the CDSS knowledge base for efficient evidence retrieval. Sensors 2015, 15, 21294–21314. [Google Scholar] [CrossRef] [PubMed]

- Hayes, W.; Cohen, J.; Ferguson, R. Risk Priority Number: A Method for Defect Report Analysis; Software Engineering Institute, Carnegie-Mellon University: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Si, X.S.; Wang, W.; Hu, C.H.; Zhou, D.H. Remaining useful life estimation–a review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–4. [Google Scholar] [CrossRef]

- Monticolo, D.; Badin, J.; Gomes, S.; Bonjour, E.; Chamoret, D. A meta-model for knowledge configuration management to support collaborative engineering. Comput. Ind. 2015, 66, 11–20. [Google Scholar] [CrossRef]

- Belkadi, F.; Dremont, N.; Notin, A.; Troussier, N.; Messadia, M. A meta-modelling framework for knowledge consistency in collaborative design. Annu. Rev. Control 2012, 36, 346–358. [Google Scholar] [CrossRef]

- Shaw, A.; Roy, R. Think Tank Report, EPSRC Centre for Innovative Manufacturing in Through-Life Engineering Services; Cranfield University: Cranfield, UK, 2012. [Google Scholar]

- Serrano, M.A.; Gómez-Romero, J.; Patricio, M.A.; García, J.; Molina, J.M. Ontological Representation of Light Wave Camera Data to Support Vision-Based AmI. Sensors 2012, 12, 12126–12152. [Google Scholar] [CrossRef] [Green Version]

- Otero-Cerdeira, L.; Rodríguez-Martínez, F.J.; Gómez-Rodríguez, A. Definition of an ontology matching algorithm for context integration in smart cities. Sensors 2014, 14, 23581–23619. [Google Scholar] [CrossRef] [PubMed]

- Maleki, E.; Belkadi, F.; Zwaag, B.; Bernard, A. A sensor ontology enabling service implementation in Industrial Product-Service Systems. In Proceedings of the 20th World Congress of the International Federation of Automatic Control (IFAC 2017), Toulouse, France, 9–14 June 2017. [Google Scholar]

- Janowicz, K.; Compton, M. The stimulus-sensor-observation ontology design pattern and its integration into the semantic sensor network ontology. In Proceedings of the 3rd International Conference on Semantic Sensor Networks, Shanghai, China, 7–8 October 2010; Volume 668, pp. 64–78. [Google Scholar]

- Gašević, D.; Djurić, D.; Devedžić, V. Model Driven Engineering and Ontology Development, 2nd ed.; Springer Science & Business Media: Berlin, Germany, 2009; p. 194. [Google Scholar]

- Protégé Website. Available online: https://protege.stanford.edu/ (accessed on 30 August 2017).

- Compton, M.; Barnaghi, P.; Bermudez, L.; GarcíA-Castro, R.; Corcho, O.; Cox, S.; Graybeal, J.; Hauswirth, M.; Henson, C.; Herzog, A.; et al. The SSN ontology of the W3C semantic sensor network incubator group. Web Semant. Sci. Serv. Agents World Wide Web 2012, 17, 25–32. [Google Scholar] [CrossRef] [Green Version]

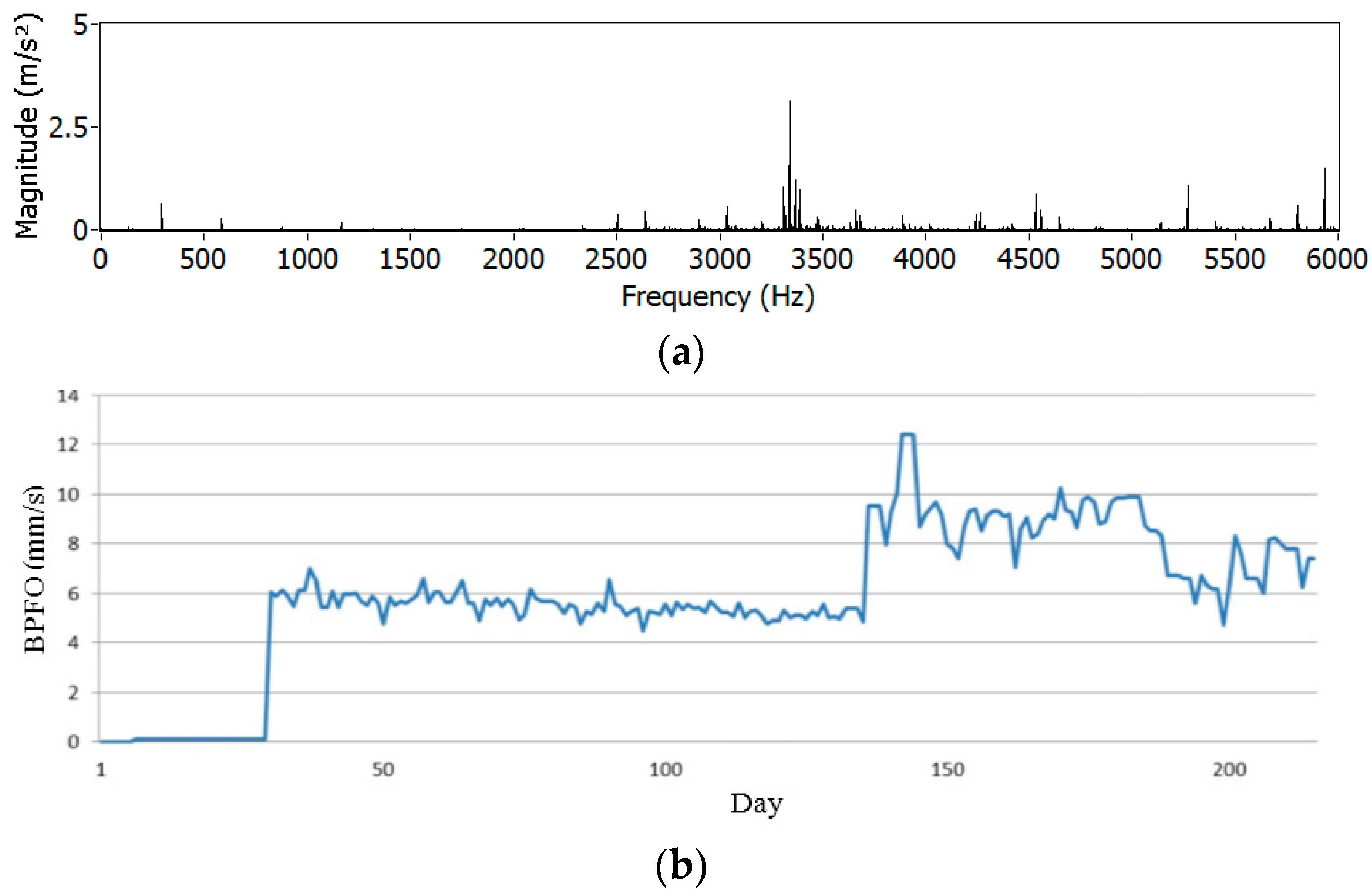

- De Castelbajac, C.; Ritou, M.; Laporte, S.; Furet, B. Monitoring of distributed defects on HSM spindle bearings. Appl. Acoust. 2014, 77, 159–168. [Google Scholar] [CrossRef]

| Specification | Attribute | |

|---|---|---|

| Predefined Specifications (Ontology Classes) | Technology | Piezoelectric |

| Class | IEPE | |

| Sensitivity | 10 or 100 mV/g | |

| Measurement range | 50 or 500 g | |

| Band-pass | 15 Hz to 10 kHz | |

| Resonant frequency | >50 kHz | |

| Resolution | ≤0.002 g | |

| Non-linearity | ≤2% | |

| Transverse sensitivity | ≤5% | |

| Overload limit | >1000 g | |

| Operating temperature | >50° | |

| Height | 8–15 mm | |

| Diameter | 8–15 mm | |

| Mounting configuration | Adhesive | |

| Type of electrical connector | Integrated cable | |

| Connector direction | Radial | |

| Sealing | Hermetic | |

| New Attribute | Saturation issue | None |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maleki, E.; Belkadi, F.; Ritou, M.; Bernard, A. A Tailored Ontology Supporting Sensor Implementation for the Maintenance of Industrial Machines. Sensors 2017, 17, 2063. https://doi.org/10.3390/s17092063

Maleki E, Belkadi F, Ritou M, Bernard A. A Tailored Ontology Supporting Sensor Implementation for the Maintenance of Industrial Machines. Sensors. 2017; 17(9):2063. https://doi.org/10.3390/s17092063

Chicago/Turabian StyleMaleki, Elaheh, Farouk Belkadi, Mathieu Ritou, and Alain Bernard. 2017. "A Tailored Ontology Supporting Sensor Implementation for the Maintenance of Industrial Machines" Sensors 17, no. 9: 2063. https://doi.org/10.3390/s17092063