A 3D Laser Profiling System for Rail Surface Defect Detection

Abstract

:1. Introduction

2. Related Work

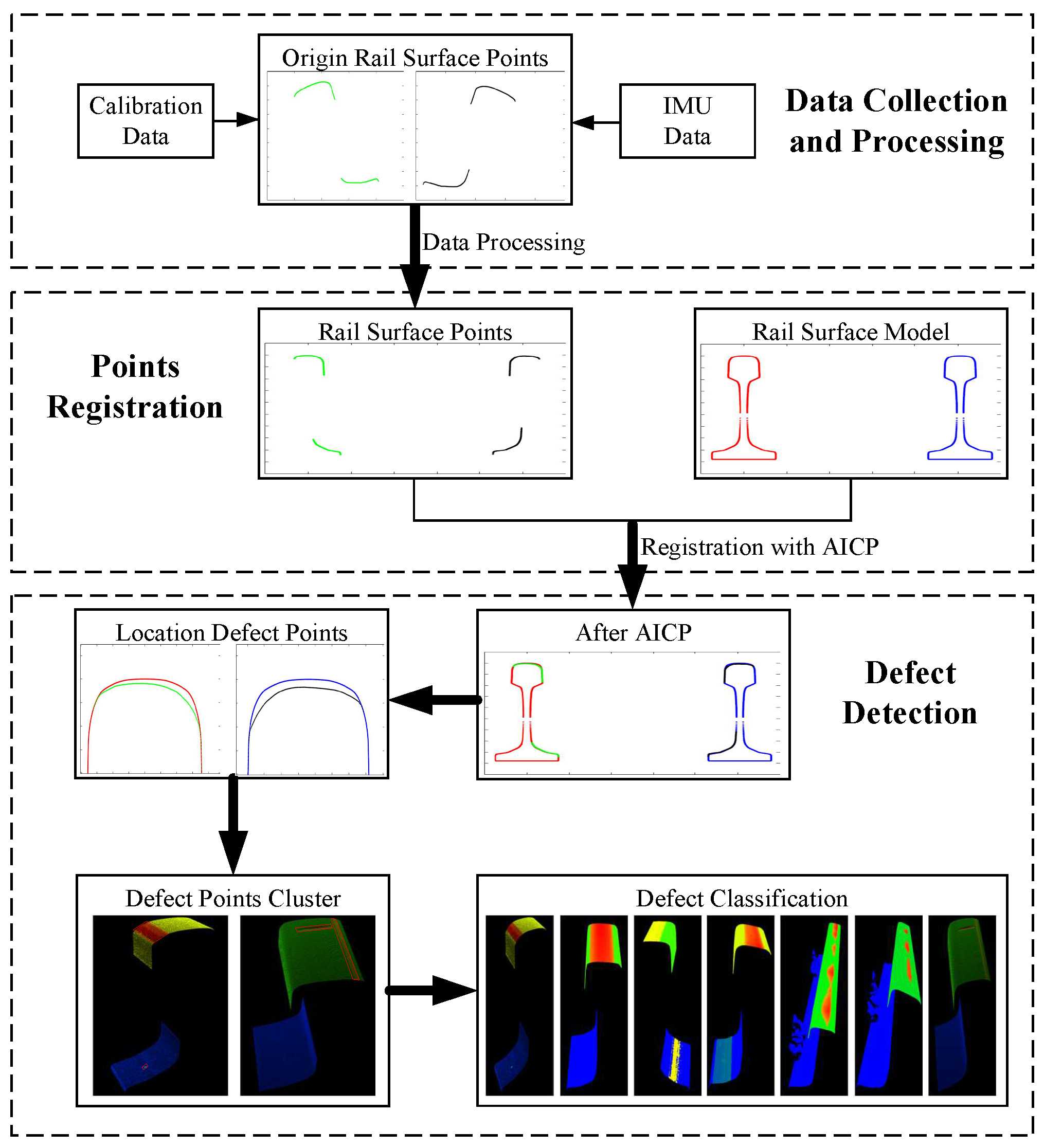

2.1. Rail Surface Defect Detection

2.2. Defect Point Registration

3. Design of the 3D-LPS

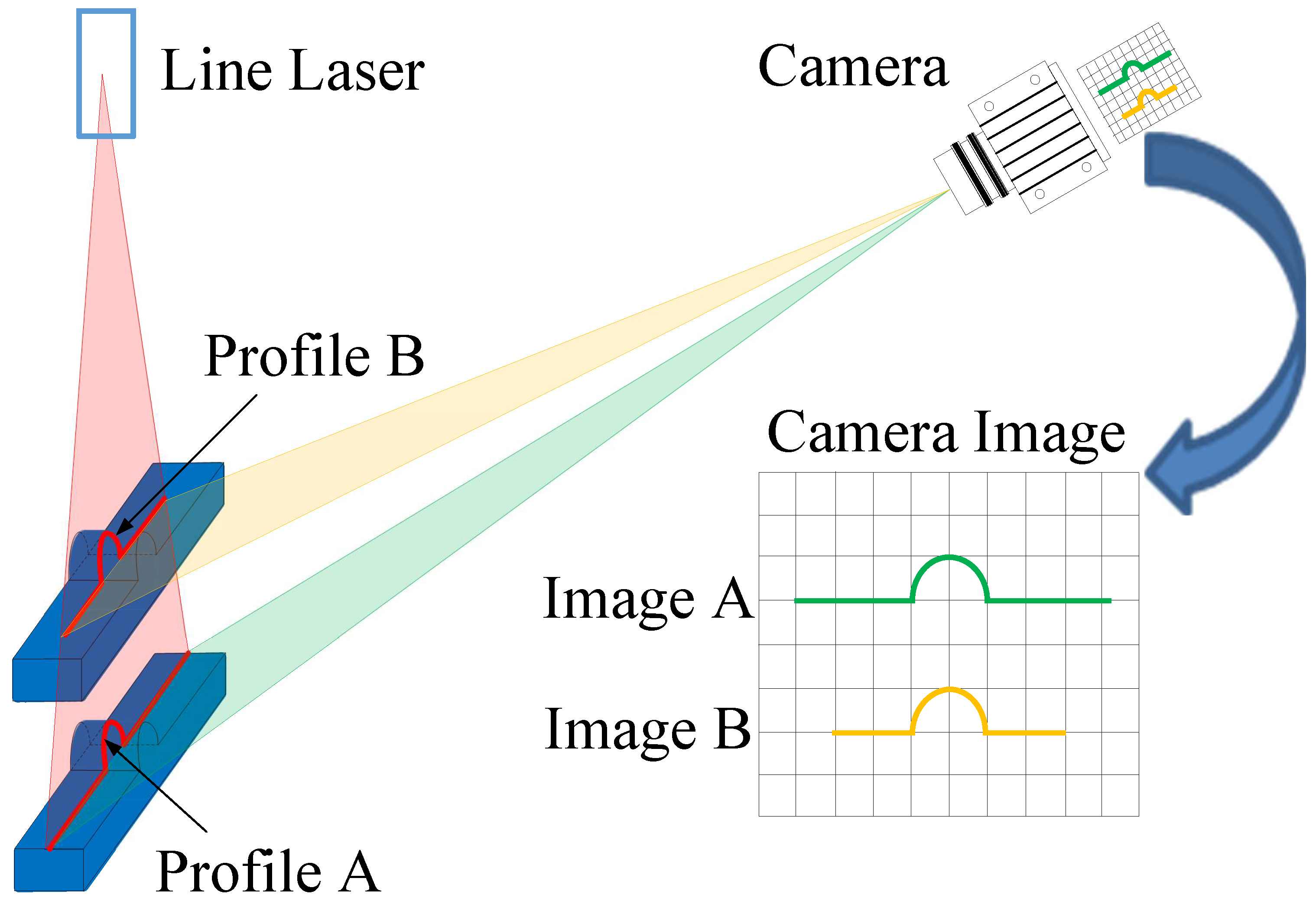

3.1. System Principle

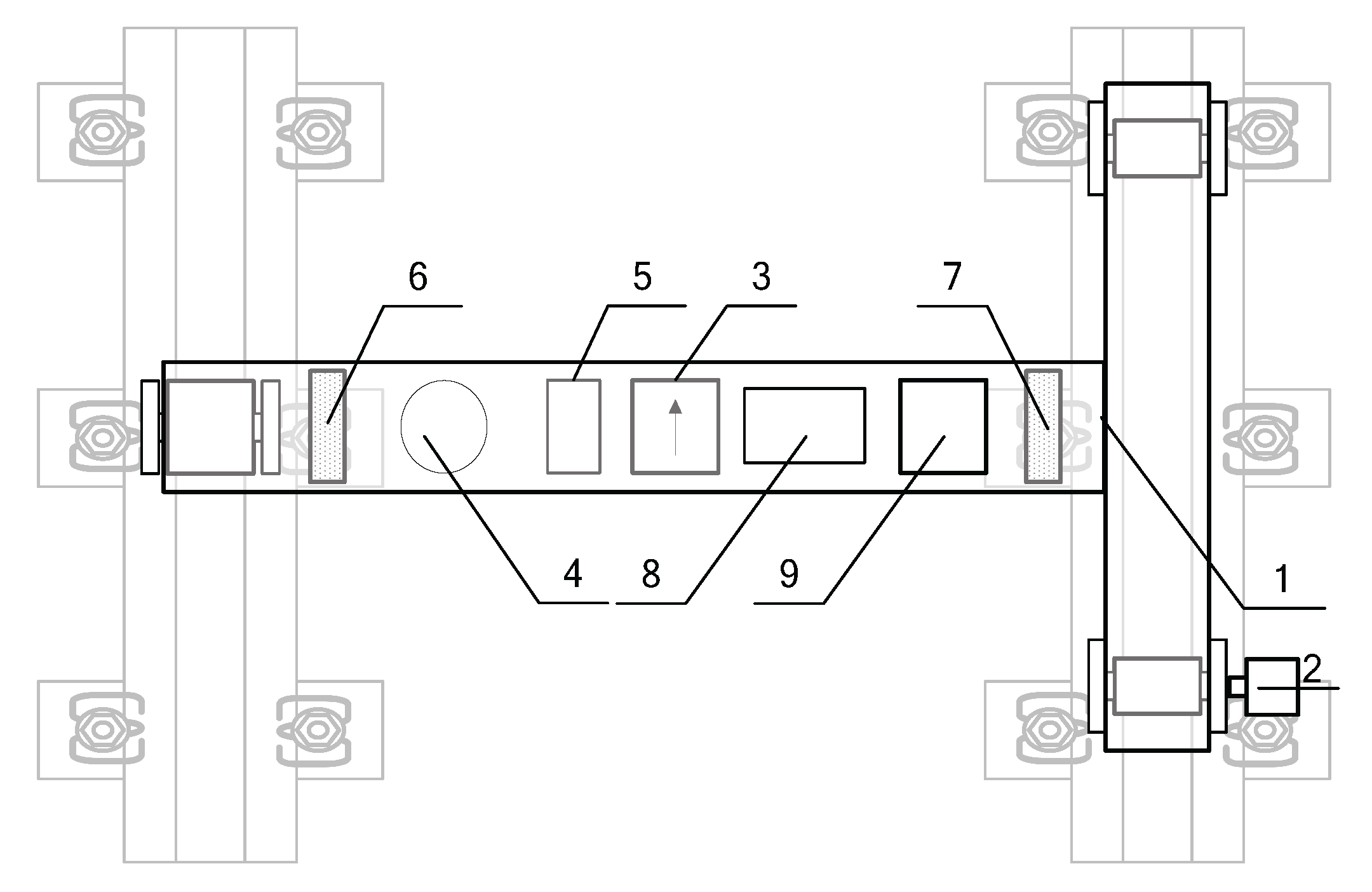

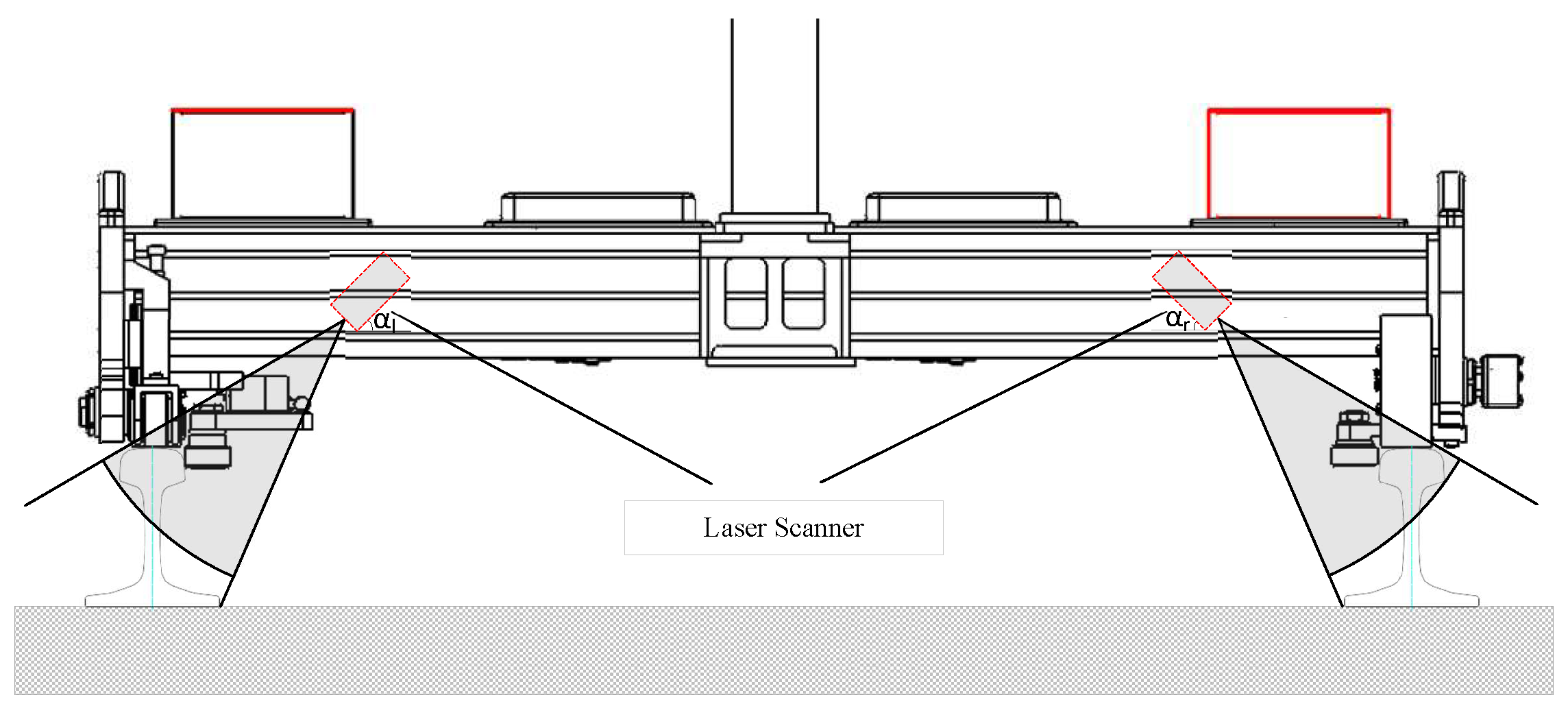

3.2. System Architecture

3.3. Pre-Processing

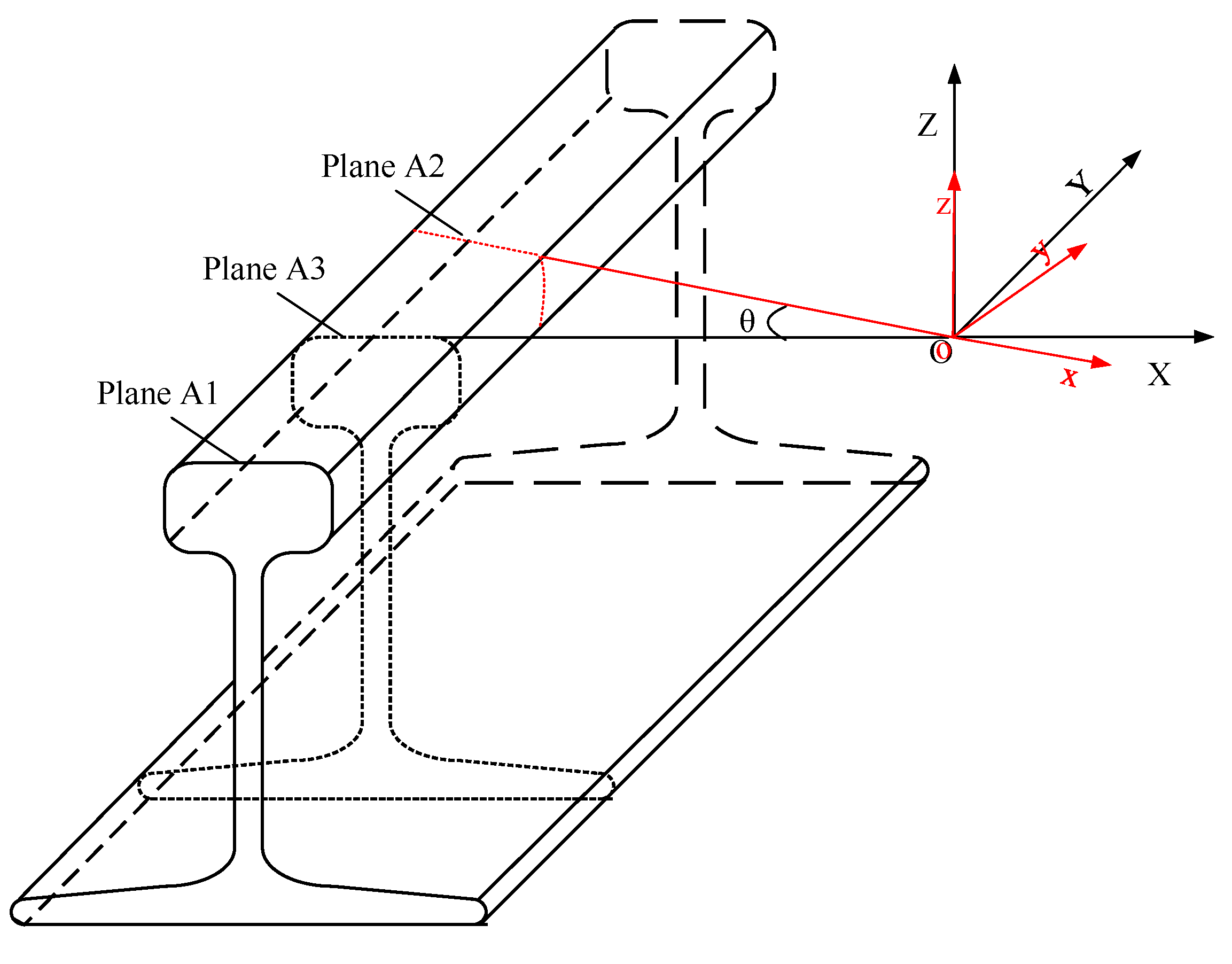

3.4. Calibration of 3D-LPS

- (i)

- Choose the center of the left rail top as the coordinate origin; use the gauging rule measuring the gauge G between the left and right rail; measure the distance from the center of the right rail top to the center of the left rail top; record as D;

- (ii)

- According to D and the standard rail model, let the center of the left standard rail model top be the coordinate origin, then the center of the right standard rail model top will be located on (D, 0);

- (iii)

- Let the structured light vertically project onto the rail top and capture the rail surface profile;

- (iv)

- Adjust the left rail surface profile manually until it completely matches with the left standard rail model; calculate the transformation parameters as ; the same for .

4. Rail Surface Defect Detection Method

4.1. Rail Profile Registration

- (i)

- Take point set from target point set P;

- (ii)

- Calculate the point set from reference point set Q as the corresponding point set of , and make ;

- (iii)

- Calculate the transformation from to , and make , then record the rotation vector as and translation vector as ;

- (iv)

- Update the point set, and compute ;

- (v)

- Calculate the average distance between and , and record as ;

- (vi)

- If , then return to Step 2 until or the iteration times are greater than the preset maximum iteration times.

- (i)

- Suppose the N-th profile point set is , and take the transformation (translation and rotation ) between the -th profile point set and the standard model as the predicted transformation from to ;

- (ii)

- Divide the rail surface profile into two parts: the rail head part and rail bottom part. Pay attention that the rail head is different from the rail head clarified by Lin; the rail head here is just part of the whole rail head and is the upper part of the profile points, which is used to distinguish from the bottom part of the profile points, the rail head point set and the rail bottom point set , with the as the initial value. Calculate the transformation from , to separately, and record as , , then output each part’s average distance , ;

- (iii)

- Calculate the minimum value of , and take the transformation corresponding with the minimum value as the calculated transformation from to ;

- (iv)

- Calculate the average distance from to under the transformation parameter ;

- (v)

- Evaluate the and ; the greater the distance, the smaller the weight and the smaller the probability. Update the probability and ;

- (vi)

- According to the Kalman filter model, update the transformation between and as .

4.2. Rail Defect Detection

- (i)

- Suppose the current profile is after registration. Let n stand for the point number in current profile, and let the standard model be . For every point , take its x coordinate as the reference, and choose the point in that has the closest x coordinate value with as ’s corresponding point, then pick out P’s corresponding point set in ;

- (ii)

- Make the deviation of Q and P, and calculate the deviation set ;

- (iii)

- Let be the depth threshold of the rail surface defect, and pick out the point in P that has a deviation value in D greater than as the defect point, then gather these defect points as the current profile’s defect point set ; k means the defect point number in the current profile;

- (iv)

- Take continuous defective profiles as a defect point set , and let be the defect point number of the s-th profile

- (v)

- Use k-means method to cluster all of the defect point sets, and divide into M bounding boxes ; each box would contain several defect point set. Record its number , and calculate its center , radius and distance between different defect point sets ;

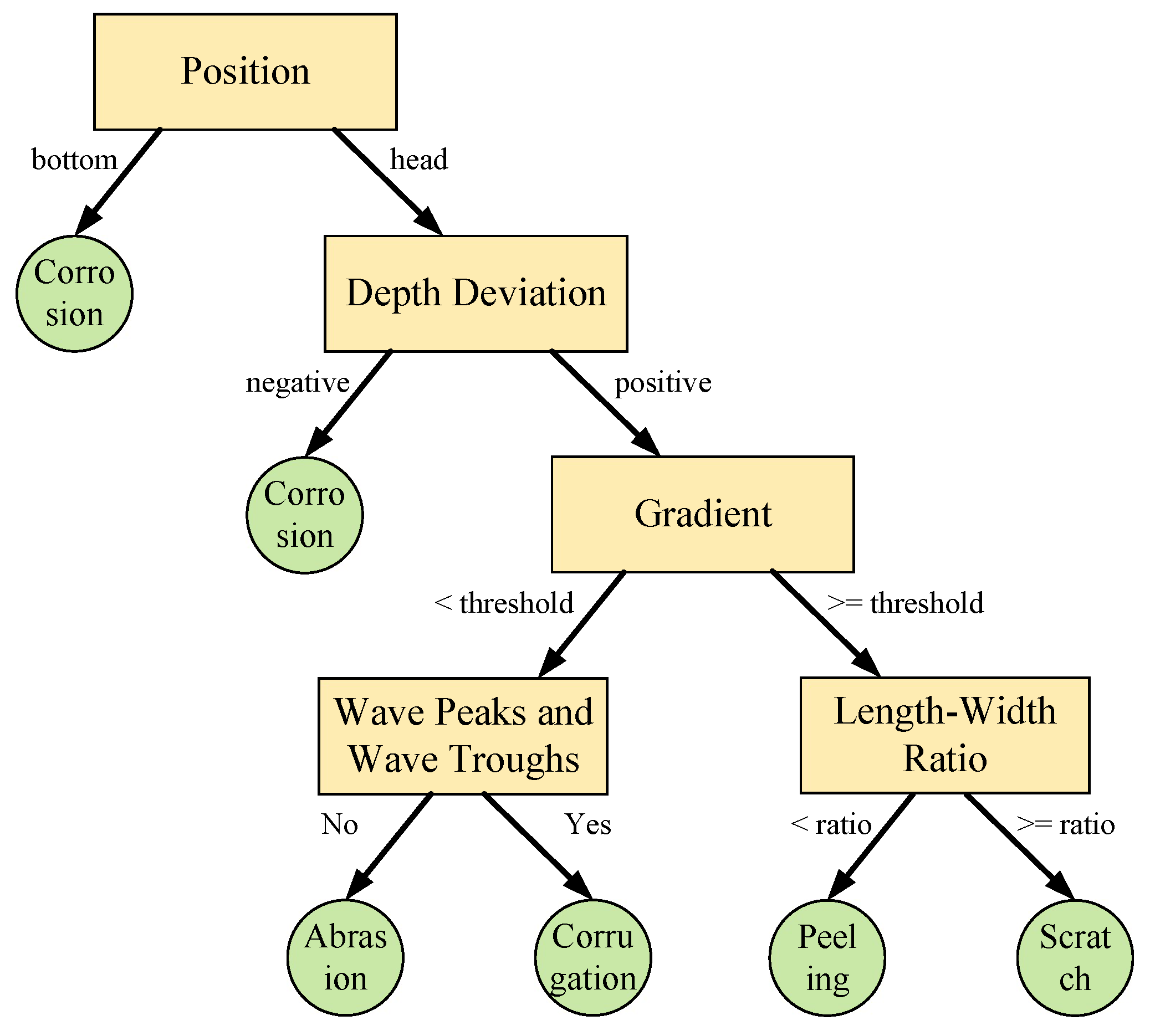

4.3. Rail Defect Classification

5. Experiments and Results

5.1. System Calibration Accuracy Verification

5.2. Comparison of AICP with ICP

5.3. Rail Surface Defect Extraction

5.4. Result of Defect Classification

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kumar, A.; Pang, G.K. Defect detection in textured materials using Gabor filters. IEEE Trans. Ind. Appl. 2002, 38, 425–440. [Google Scholar] [CrossRef]

- Toliyat, H.A.; Abbaszadeh, K.; Rahimian, M.M.; Olson, L.E. Rail defect diagnosis using wavelet packet decomposition. IEEE Trans. Ind. Appl. 2003, 39, 1454–1461. [Google Scholar] [CrossRef]

- Mandriota, C.; Nitti, M.; Ancona, N.; Stella, E.; Distante, A. Filter-based feature selection for rail defect detection. Mach. Vis. Appl. 2004, 15, 179–185. [Google Scholar] [CrossRef]

- Marino, F.; Stella, E. ViSyR: A Vision System for Real-Time Infrastructure Inspection; INTECH Open Access: Rijeka, Croatia, 2007. [Google Scholar]

- Jie, L.; Siwei, L.; Qingyong, L.; Hanqing, Z.; Shengwei, R. Real-time rail head surface defect detection: A geometrical approach. In Proceedings of the IEEE International Symposium on Industrial Electronics, Lausanne, Switzerland, 8–10 July 2009; pp. 769–774. [Google Scholar]

- Yuan, X.C.; Wu, L.S.; Peng, Q. An improved Otsu method using the weighted object variance for defect detection. Appl. Surf. Sci. 2015, 349, 472–484. [Google Scholar] [CrossRef]

- Li, Q.; Ren, S. A real-time visual inspection system for discrete surface defects of rail heads. IEEE Trans. Instrum. Meas. 2012, 61, 2189–2199. [Google Scholar] [CrossRef]

- Feng, H.; Jiang, Z.; Xie, F.; Yang, P.; Shi, J.; Chen, L. Automatic fastener classification and defect detection in vision-based railway inspection systems. IEEE Trans. Instrum. Meas. 2014, 63, 877–888. [Google Scholar] [CrossRef]

- Papaelias, M.P.; Lugg, M.; Roberts, C.; Davis, C. High-speed inspection of rails using ACFM techniques. NDT E Int. 2009, 42, 328–335. [Google Scholar] [CrossRef]

- Clark, R. Rail flaw detection: Overview and needs for future developments. NDT E Int. 2004, 37, 111–118. [Google Scholar] [CrossRef]

- Bartoli, I.; di Scalea, F.L.; Fateh, M.; Viola, E. Modeling guided wave propagation with application to the long-range defect detection in railroad tracks. NDT E Int. 2005, 38, 325–334. [Google Scholar] [CrossRef]

- Coccia, S.; Bartoli, I.; Salamone, S.; Phillips, R.; di Scalea, F.; Fateh, M.; Carr, G. Noncontact ultrasonic guided wave detection of rail defects. Transp. Res. Rec. J. Transp. Res. Board 2009, 77–84. [Google Scholar] [CrossRef]

- Lanza di Scalea, F.; Rizzo, P.; Coccia, S.; Bartoli, I.; Fateh, M. Laser-air-coupled hybrid noncontact system for defect detection in rail tracks: Status of FRA prototype development at University of California-San Diego. Transp. Res. Rec. 2006, 1943, 57–64. [Google Scholar] [CrossRef]

- Alippi, C.; Casagrande, E.; Scotti, F.; Piuri, V. Composite real-time image processing for railways track profile measurement. IEEE Trans. Instrum. Meas. 2000, 49, 559–564. [Google Scholar] [CrossRef]

- Babenko, P. Visual Inspection of Railroad Tracks. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, 2009. [Google Scholar]

- Deutschl, E.; Gasser, C.; Niel, A.; Werschonig, J. Defect detection on rail surfaces by a vision based system. In Proceedings of the Intelligent Vehicles Symposium, Parma, Italy, 14–17 June 2004; pp. 507–511. [Google Scholar]

- Rose, J.L.; Avioli, M.J.; Mudge, P.; Sanderson, R. Guided wave inspection potential of defects in rail. NDT E Int. 2004, 37, 153–161. [Google Scholar] [CrossRef]

- Zumpano, G.; Meo, M. A new damage detection technique based on wave propagation for rails. Int. J. Solids Struct. 2006, 43, 1023–1046. [Google Scholar] [CrossRef]

- Xie, X. A review of recent advances in surface defect detection using texture analysis techniques. Electron. Lett. Comput. Vis. Image Anal. 2008, 7, 1–22. [Google Scholar]

- Forest, J.; Salvi, J. A review of laser scanning three-dimensional digitisers. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; Volume 1, pp. 73–78. [Google Scholar]

- Graebling, P.; Lallement, A.; Zhou, D.Y.; Hirsch, E. Optical high-precision three-dimensional vision-based quality control of manufactured parts by use of synthetic images and knowledge for image-data evaluation and interpretation. Appl. Opt. 2002, 41, 2627–2643. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; He, J.; Li, X. 3D vision inspection for internal surface based on circle structured light. Sens. Actuators A Phys. 2005, 122, 68–75. [Google Scholar] [CrossRef]

- Van Gestel, N.; Cuypers, S.; Bleys, P.; Kruth, J.P. A performance evaluation test for laser line scanners on CMMs. Opt. Lasers Eng. 2009, 47, 336–342. [Google Scholar] [CrossRef] [Green Version]

- Wu, B.; Xue, T.; Zhang, T.; Ye, S. A novel method for round steel measurement with a multi-line structured light vision sensor. Meas. Sci. Technol. 2010, 21, 025204. [Google Scholar] [CrossRef]

- Salvi, J.; Matabosch, C.; Fofi, D.; Forest, J. A review of recent range image registration methods with accuracy evaluation. Image Vis. Comput. 2007, 25, 578–596. [Google Scholar] [CrossRef]

- Yamany, S.M.; Farag, A.A. Free-form surface registration using surface signatures. In Proceedings of the Seventh IEEE International Conference on Computer Vision, Kerkyra, Greece, 20–27 September 1999; Volume 2, pp. 1098–1104. [Google Scholar]

- Yamany, S.M.; Farag, A.A. Surface signatures: An orientation independent free-form surface representation scheme for the purpose of objects registration and matching. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 1105–1120. [Google Scholar] [CrossRef]

- Johnson, A.E. Spin-Images: A Representation for 3-D Surface Matching. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 1997. [Google Scholar]

- Ashbrook, A.; Fisher, R.; Werghi, N.; Robertson, C. Aligning Arbitrary Surfaces Using Pairwise Geometric Histograms. In Noblesse Workshop on Non-Linear Model Based Image Analysis; Springer: Berlin, Germany, 1998; pp. 103–108. [Google Scholar]

- Zhang, D. Harmonic Shape Images: A 3D Free-Form Surface Representation and Its Applications in Surface Matching. Ph.D. Thesis, Carnegie Mellon University Pittsburgh, Pittsburgh, PA, USA, 1999. [Google Scholar]

- Stein, F.; Medioni, G. Structural indexing: Efficient 3-D object recognition. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 125–145. [Google Scholar] [CrossRef]

- Hummel, R.A.; Zucker, S.W. On the foundations of relaxation labeling processes. IEEE Trans. Pattern Anal. Mach. Intell. 1983, 3, 267–287. [Google Scholar] [CrossRef]

- Li, N.; Cheng, P.; Sutton, M.; McNeill, S. Three-dimensional point cloud registration by matching surface features with relaxation labeling method. Exp. Mech. 2005, 45, 71–82. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. Method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 586–606. [Google Scholar] [CrossRef]

- Keerthi, S.S.; Shevade, S.K.; Bhattacharyya, C.; Murthy, K.R. A fast iterative nearest point algorithm for support vector machine classifier design. IEEE Trans. Neural Netw. 2000, 11, 124–136. [Google Scholar] [CrossRef] [PubMed]

- Rusinkiewicz, S.; Levoy, M. Efficient variants of the ICP algorithm. In Proceedings of the Third International Conference on 3-D Digital Imaging and Modeling, Quebec City, QC, Canada, 28 May–1 June 2001; pp. 145–152. [Google Scholar]

- Chetverikov, D.; Svirko, D.; Stepanov, D.; Krsek, P. The trimmed iterative closest point algorithm. In Proceedings of the 16th International Conference on Pattern Recognition, Quebec City, QC, Canada, 11–15 August 2002; Volume 3, pp. 545–548. [Google Scholar]

- Stewart, C.V.; Tsai, C.L.; Roysam, B. The dual-bootstrap iterative closest point algorithm with application to retinal image registration. IEEE Trans. Med. Imaging 2003, 22, 1379–1394. [Google Scholar] [CrossRef] [PubMed]

- Bishop, G.; Welch, G. An introduction to the kalman filter. In Proceedings of the Special Interest Group on Computer Graphics and Interactive Techniques, Los Angeles, CA, USA, 12–17 August 2001. [Google Scholar]

- Julier, S.J.; Uhlmann, J.K. New extension of the Kalman filter to nonlinear systems. Int. Soc. Opt. Photonics 1997, 3, 182–193. [Google Scholar]

- Chen, Z.; Zou, H.; Jiang, H.; Zhu, Q.; Soh, Y.C.; Xie, L. Fusion of WiFi, smartphone sensors and landmarks using the Kalman filter for indoor localization. Sensors 2015, 15, 715–732. [Google Scholar] [CrossRef] [PubMed]

- Kanungo, T.; Mount, D.M.; Netanyahu, N.S.; Piatko, C.D.; Silverman, R.; Wu, A.Y. An efficient k-means clustering algorithm: Analysis and implementation. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 881–892. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, X.; Li, X.; Chen, Y.J.; Zhen, W.; Chang, J.; Zheng, C.; Liu, Z. White Blood Cell Segmentation by Color-Space-Based K-Means Clustering. Sensors 2014, 14, 16128–16147. [Google Scholar] [CrossRef] [PubMed]

- Zou, Q.; Ni, L.; Wang, Q.; Hu, Z.; Li, Q.; Wang, S. Local Pattern Collocations Using Regional Co-Occurrence Factorization. IEEE Trans. Multimed. 2017, 19, 492–505. [Google Scholar] [CrossRef]

- Friedl, M.A.; Brodley, C.E. Decision tree classification of land cover from remotely sensed data. Remote Sens. Environ. 1997, 61, 399–409. [Google Scholar] [CrossRef]

- Pal, M.; Mather, P.M. An assessment of the effectiveness of decision tree methods for land cover classification. Remote Sens. Environ. 2003, 86, 554–565. [Google Scholar] [CrossRef]

- Madzarov, G.; Gjorgjevikj, D.; Chorbev, I. A multi-class SVM classifier utilizing binary decision tree. Informatica 2009, 33, 233–241. [Google Scholar]

- Li, Q.; Zou, Q.; Mao, Q.; Chen, X.; Li, B. Efficient calibration of a laser dynamic deflectometer. IEEE Trans. Instrum. Meas. 2013, 62, 806–813. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A library for support vector machines. ACM Trans. Intell. Syst. Technol. 2011, 2, 27. [Google Scholar] [CrossRef]

- Zou, Q.; Ni, L.; Wang, Q.; Li, Q.; Wang, S. Robust Gait Recognition by Integrating Inertial and RGBD Sensors. IEEE Trans. Cybern. 2017, 1–15. [Google Scholar] [CrossRef] [PubMed]

| ID | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

|---|---|---|---|---|---|---|

| 1 | 0.95 | 0.53 | 1.95 | 1.41 | 1435.34 | 1435.42 |

| 2 | 0.86 | 0.51 | 1.89 | 1.53 | 1435.46 | 1435.57 |

| 3 | 0.63 | 0.54 | 1.81 | 1.24 | 1435.81 | 1436.02 |

| 4 | 0.72 | 0.41 | 1.74 | 1.28 | 1436.35 | 1436.29 |

| 5 | 0.78 | 0.38 | 1.75 | 1.32 | 1436.19 | 1436.24 |

| 6 | 0.91 | 0.61 | 1.79 | 1.43 | 1436.25 | 1436.37 |

| 7 | 0.87 | 0.42 | 1.71 | 1.35 | 1435.78 | 1436.12 |

| 8 | 0.76 | 0.58 | 1.85 | 1.38 | 1435.49 | 1435.42 |

| 9 | 0.92 | 0.49 | 1.91 | 1.41 | 1435.81 | 1435.64 |

| 10 | 1.12 | 0.64 | 1.95 | 1.49 | 1436.06 | 1436.31 |

| ID | Type | Statistical value | AR | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ICP | Average value | 26.8 | 0.267 | 0.273 | 55.6 | 0.173 | 0.196 | 48.3 | 0.163 | 0.067 | 0.603 | 99.9% |

| Standard deviation | 2.21 | 0.048 | 0.011 | 3.22 | 0.018 | 0.012 | 3.64 | 0.024 | 0.006 | - | - | ||

| Maximum value | 30 | 0.346 | 0.291 | 60 | 0.198 | 0.213 | 54 | 0.203 | 0.075 | - | - | ||

| AICP | Average value | 22.4 | 0.238 | 0.273 | 35.1 | 0.117 | 0.196 | 48.2 | 0.161 | 0.067 | 0.516 | 99.9% | |

| Standard deviation | 1.02 | 0.006 | 0.012 | 1.45 | 0. 003 | 0.014 | 2.74 | 0.022 | 0.006 | - | - | ||

| Maximum value | 24 | 0.246 | 0.293 | 37 | 0.121 | 0.217 | 52 | 0.198 | 0.075 | - | - | ||

| 2 | ICP | Average value | 25.8 | 0.264 | 0.423 | 51.3 | 0.148 | 0.361 | 46.2 | 0.162 | 0.069 | 0.574 | 33.3% |

| Standard deviation | 2.24 | 0.045 | 0.012 | 5.62 | 0.024 | 0.025 | 3.12 | 0.022 | 0.007 | - | - | ||

| Maximum value | 29 | 0.338 | 0.441 | 61 | 0.186 | 0.395 | 50 | 0.192 | 0.081 | - | - | ||

| AICP | Average value | 24.6 | 0.241 | 0.424 | 33.5 | 0.119 | 0.364 | 49.6 | 0.164 | 0.068 | 0.525 | 99.9% | |

| Standard deviation | 1.84 | 0.018 | 0.012 | 3.23 | 0.005 | 0. 026 | 2.81 | 0.018 | 0.006 | - | - | ||

| Maximum value | 27 | 0.268 | 0.443 | 38 | 0.127 | 0.396 | 53 | 0.191 | 0.077 | - | - | ||

| 3 | ICP | Average value | 27.8 | 0.322 | 0.418 | 30.6 | 0.109 | 0.201 | 74.8 | 0.297 | 0.157 | 0.728 | 33.4% |

| Standard deviation | 2.31 | 0.052 | 0.013 | 3.21 | 0.008 | 0.015 | 5.47 | 0.017 | 0.011 | - | - | ||

| Maximum value | 31 | 0.407 | 0.442 | 35 | 0.121 | 0.223 | 82 | 0.323 | 0.173 | - | - | ||

| AICP | Average value | 14.5 | 0.188 | 0.418 | 45.2 | 0.139 | 0.201 | 24.3 | 0.109 | 0.155 | 0.436 | 99.9% | |

| Standard deviation | 4.67 | 0.038 | 0.014 | 3.18 | 0.016 | 0.013 | 6.74 | 0.011 | 0.011 | - | - | ||

| Maximum value | 22 | 0.237 | 0.445 | 50 | 0.168 | 0.219 | 35 | 0.127 | 0.175 | - | - | ||

| 4 | ICP | Average value | 21.6 | 0.237 | 0.566 | 53.4 | 0.167 | 0.471 | 53.6 | 0.306 | 0.408 | 0.721 | 0.01% |

| Standard deviation | 6.43 | 0.074 | 0.035 | 4.36 | 0.025 | 0.023 | 7.01 | 0.049 | 0.015 | - | - | ||

| Maximum value | 30 | 0.357 | 0.621 | 60 | 0.205 | 0.503 | 63 | 0.382 | 0.445 | - | - | ||

| AICP | Average value | 26.7 | 0.257 | 0.568 | 30.2 | 0.109 | 0.472 | 16.8 | 0.129 | 0.098 | 0.495 | 99.9% | |

| Standard deviation | 3.21 | 0.021 | 0.029 | 3.43 | 0.008 | 0.016 | 4.92 | 0.018 | 0.013 | - | - | ||

| Maximum value | 32. | 0.288 | 0.618 | 35 | 0.122 | 0.496 | 24 | 0.158 | 0.117 | - | - |

| ID | Len (mm) | Length (mm) | Wid (mm) | Width (mm) | (mm) | Depth (mm) |

|---|---|---|---|---|---|---|

| 1 | 22 | 22.76 | 1.5 | 1.56 | 1.7745 | 1.80 |

| 2 | 15 | 15.54 | 1.2 | 1.24 | 0.8174 | 0.84 |

| 3 | 18 | 18.18 | 1.8 | 1.78 | 1.3548 | 1.36 |

| 4 | 4 | 4.08 | 32.7 | 32.64 | 0.6854 | 0.66 |

| 5 | 4 | 4.12 | 26.4 | 26.22 | 0.8123 | 0.80 |

| 6 | 5 | 4.96 | 15.3 | 15.12 | 1.0254 | 1.08 |

| 7 | 5 | 4.92 | 7.8 | 7.76 | 1.1214 | 1.12 |

| 8 | 5 | 4.94 | 10.2 | 10.24 | 1.0146 | 0.98 |

| 9 | 6 | 6.08 | 9.3 | 9.38 | 0.8564 | 0.86 |

| 10 | 6 | 6.12 | 10.5 | 10.68 | 0.9631 | 0.96 |

| Defect Type | Predicted | ||||||

|---|---|---|---|---|---|---|---|

| Abrasion | Corrugation | Scratch | Corrosion | Peeling | Total | ||

| Actual | Abrasion | 141 | 6 | 2 | 0 | 1 | 150 |

| Corrugation | 6 | 74 | 0 | 0 | 0 | 80 | |

| Scratch | 3 | 2 | 43 | 0 | 2 | 50 | |

| Corrosion | 0 | 0 | 0 | 120 | 0 | 120 | |

| Peeling | 2 | 1 | 3 | 0 | 44 | 50 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Z.; Li, Q.; Mao, Q.; Zou, Q. A 3D Laser Profiling System for Rail Surface Defect Detection. Sensors 2017, 17, 1791. https://doi.org/10.3390/s17081791

Xiong Z, Li Q, Mao Q, Zou Q. A 3D Laser Profiling System for Rail Surface Defect Detection. Sensors. 2017; 17(8):1791. https://doi.org/10.3390/s17081791

Chicago/Turabian StyleXiong, Zhimin, Qingquan Li, Qingzhou Mao, and Qin Zou. 2017. "A 3D Laser Profiling System for Rail Surface Defect Detection" Sensors 17, no. 8: 1791. https://doi.org/10.3390/s17081791