Candle Soot Coating for Latent Fingermark Enhancement on Various Surfaces

Abstract

:1. Introduction

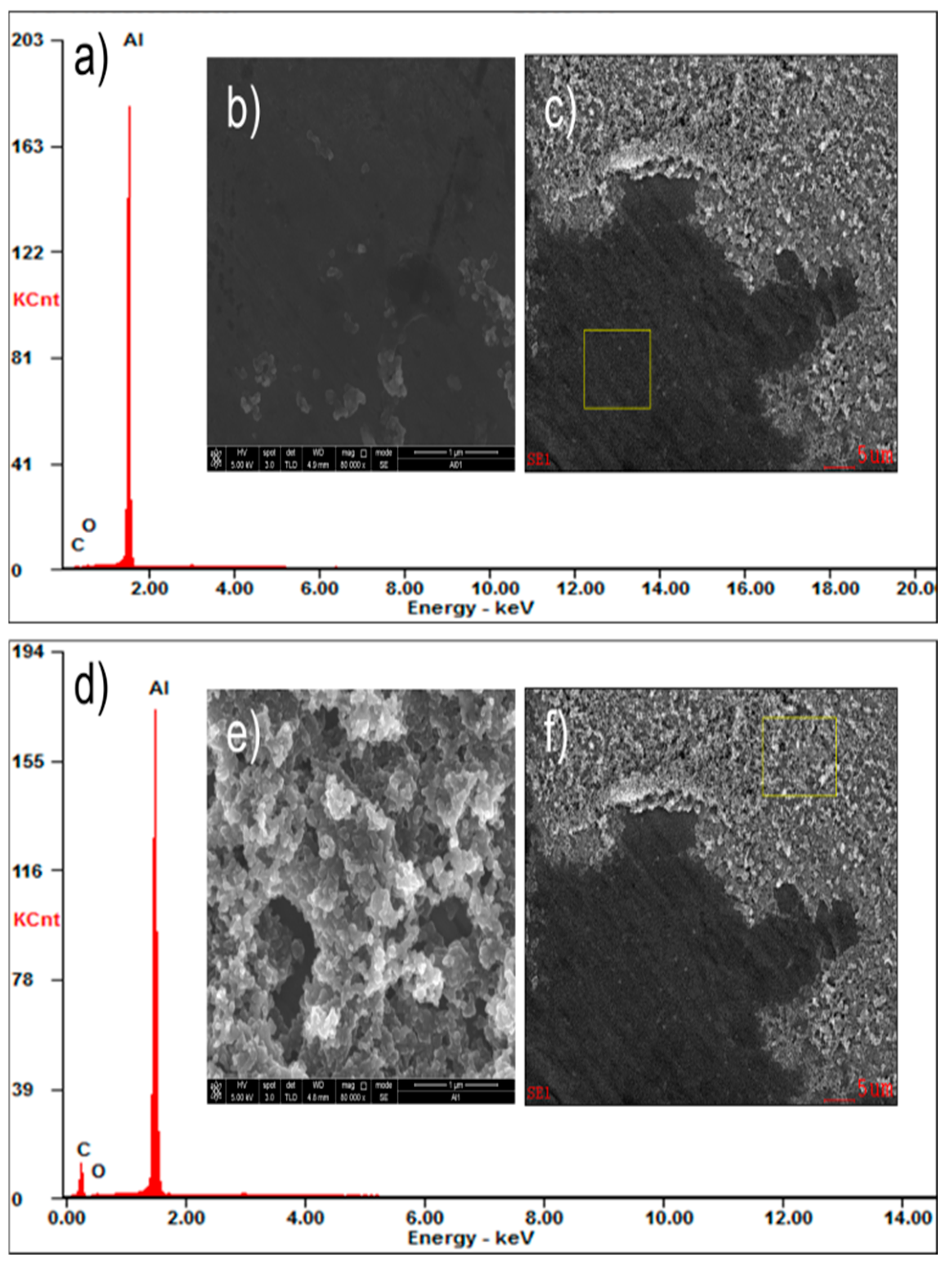

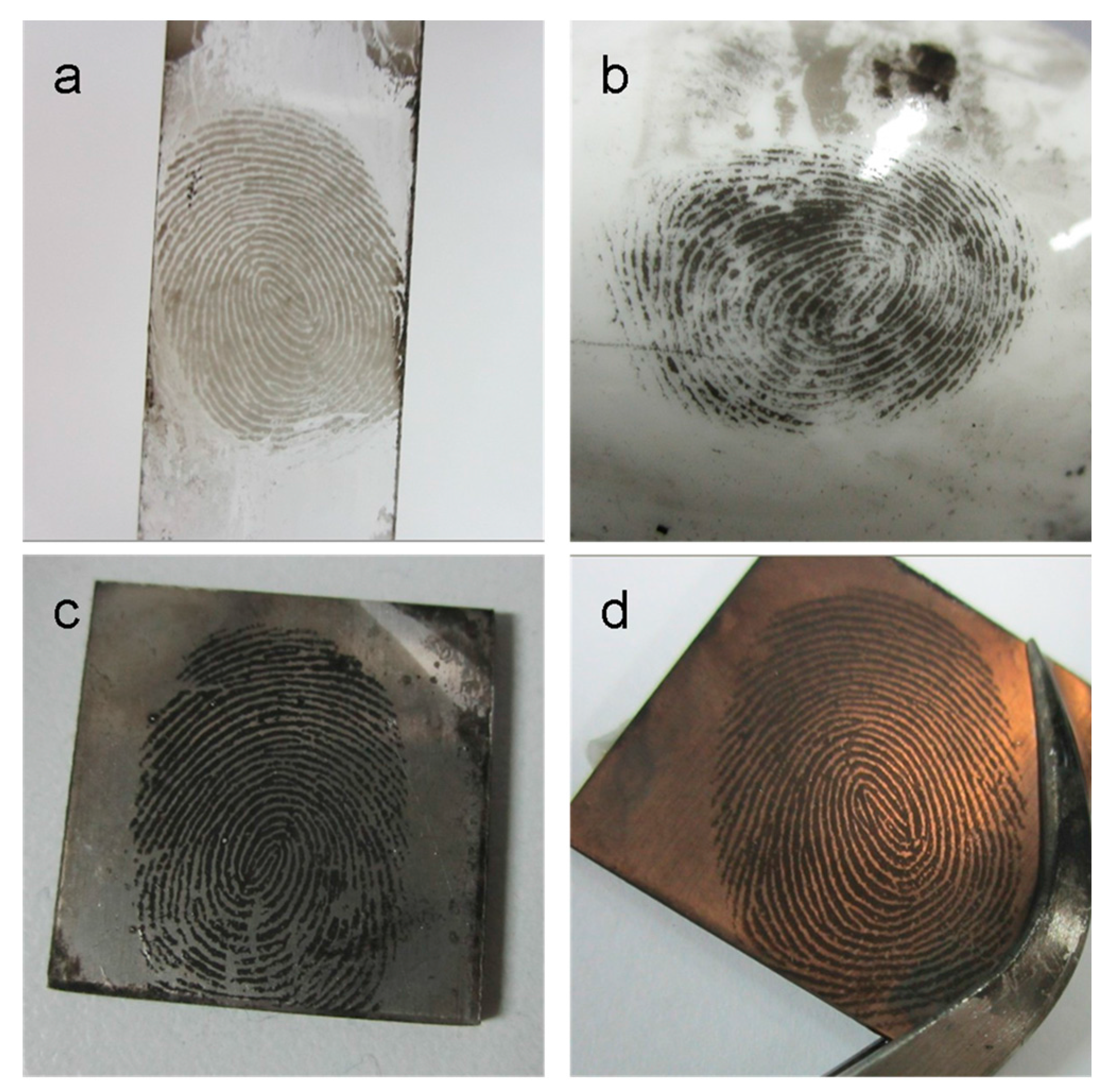

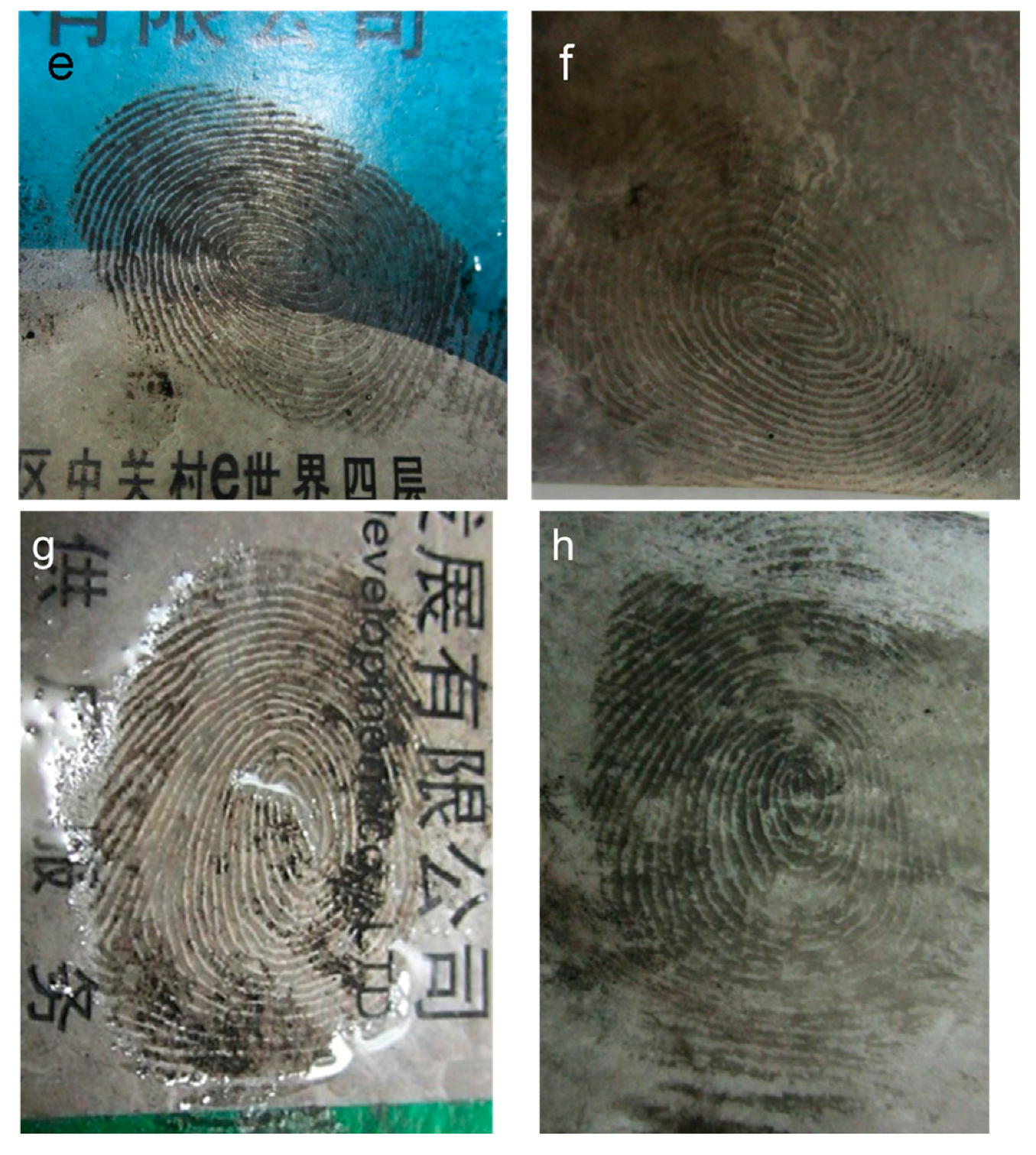

2. Experimental and Discussion

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Champod, C.; Lennard, C.J.; Margot, P.; Stoilovic, M. Fingermarks and Other Ridge Skin Impressions; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Faulds, H. On the skin-furrows of the hand. Nature 1880, 22, 605. [Google Scholar] [CrossRef]

- Wilshire, B.; Pounds, C.A.; James, J.D. Flake metal powders for revealing latent fingerprints. J. Forensic Sci. 1991, 36, 1368–1375. [Google Scholar]

- Bolinger, B.; Devault, G.L.; Lewis, L.A.; Smithwick, R.W.; Lewis, S.A. Processes involved in the development of latent fingerprints using the cyanoacrylate fuming method. J. Forensic Sci. 2001, 46, 241–246. [Google Scholar]

- Oden, S.; Hofsten, B.V. Detection of fingerprints by the ninhydrin reaction. Nature 1954, 173, 449–450. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Qin, G.; Zuo, Y.; Zhang, T.; Zhang, Y.; Su, L.; Qiu, H.; Zhang, X. SECM imaging of latent fingerprints developed by deposition of Al-doped ZnO thin film. Electrochim. Acta 2012, 78, 412–416. [Google Scholar] [CrossRef]

- Jones, N.; Stoilovic, M.; Lennard, C.; Roux, C. Vacuum metal deposition: Factors affecting normal and reverse development of latent fingerprints on polyethylene substrates. J. Forensic Sci. Int. 2001, 115, 73–88. [Google Scholar] [CrossRef]

- Schnetz, B.; Margot, P. Technical note: Latent fingermarks, colloidal gold and multimetal deposition (MMD): Optimisation of the method. J. Forensic Sci. Int. 2001, 118, 21–28. [Google Scholar] [CrossRef]

- Zhang, M.; Becue, A.; Prudent, M.; Champod, C.; Girault, H.H. SECM imaging of MMD-enhanced latent fingermarks. Chem. Commun. 2007, 38, 3948–3950. [Google Scholar] [CrossRef] [PubMed]

- Qin, G.; Zhang, M.; Zhang, Y.; Zhu, Y.; Liu, S.; Wu, W.; Zhang, X. Visualizing latent fingerprints by electrodeposition of metal nanoparticles. J. Electroanal. Chem. 2013, 693, 122–126. [Google Scholar] [CrossRef]

- Qin, G.; Zhang, M.; Zhang, Y.; Zhu, Y.; Liu, S.; Wu, W.; Zhang, X. Visualization of latent fingerprints using Prussian blue thin films. Chin. Chem. Lett. 2013, 24, 173–176. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, Y.; Yu, X.; Liu, S.; Wang, M.; Wei, Q.; Hu, X.; Tang, Q.; Zhao, Y.; Zhang, X. Application of electrodepositing graphene nanosheets for latent fingerprint enhancement. Electroanalysis 2014, 26, 209–215. [Google Scholar] [CrossRef]

- Zhang, M.; Yu, X.; Qin, G.; Zhu, Y.; Wang, M.; Wei, Q.; Zhang, Y.; Zhang, X. Latent fingerprint enhancement on conductive substrates using electrodeposition of copper. Sci. China Chem. 2015, 58, 1200–1205. [Google Scholar] [CrossRef]

- Wolfbeis, O.S. Nanoparticle-enhanced fluorescence imaging of latent fingerprints reveals drug abuse. Angew. Chem. Int. Ed. 2009, 48, 2268–2269. [Google Scholar] [CrossRef] [PubMed]

- Leggett, R.; Lee-Smith, E.E.; Jickells, S.M.; Russell, D.A. “Intelligent” fingerprinting: Simultaneous identification of drug metabolites and individuals by using antibody-functionalized nanoparticles. Angew. Chem. 2007, 119, 4178–4181. [Google Scholar] [CrossRef]

- Shan, X.; Patel, U.; Wang, S.; Iglesias, R.; Tao, N. Imaging local electrochemical current via surface plasmon resonance. Science 2010, 327, 1363–1366. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Qin, W.; Li, F.; Zhao, X.; Jiang, B.; Wang, K.; Deng, S.; Fan, C.; Li, D. Nanoplasmonic imaging of latent fingerprints and identification of cocaine. Angew. Chem. 2013, 125, 11756–11759. [Google Scholar] [CrossRef]

- Ifa, D.R.; Manicke, N.E.; Dill, A.L.; Cooks, R.G. Latent fingerprint chemical imaging by mass spectrometry. Science 2008, 321, 805. [Google Scholar] [CrossRef] [PubMed]

- Ng, P.H.R.; Walker, S.; Tahtouh, M.; Reedy, B. Latent fingerprint chemical imaging by mass spectrometry. Anal. Bioanal. Chem. 2009, 394, 2039–2048. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Mao, Z.; Liu, X.; Lu, Y.; Li, Z.; Zhao, B.; Lu, L. Detection of protein deposition within latent fingerprints by surface-enhanced Raman spectroscopy imaging. Nanoscale 2012, 4, 2333–2338. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Li, Y.; Wu, S.; Liu, X.; Su, B. Imaging latent fingerprints by electrochemiluminescence. Angew. Chem. 2012, 124, 8192–8196. [Google Scholar] [CrossRef]

- Zhang, M.; Girault, H.H. SECM for imaging and detection of latent fingerprints. Analyst 2009, 134, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Surovikin, V.F.; Rogov, A.V.; Vershinin, L.V. Carbon black formation in the in complete combustion of benzene. Combust. Explos. Shock Waves 1975, 11, 202–209. [Google Scholar] [CrossRef]

- Howard, J.B.; Lafleur, A.L.; Makarovsky, Y.; Mitra, S.; Pope, C.J.; Yadav, T.K. Fullerenes synthesis in combustion. Carbon 1992, 30, 1183–1201. [Google Scholar] [CrossRef]

- Baker, S.N.; Baker, G.A. Luminescent carbon nanodots: Emergent nanolights. Angew. Chem. Int. Ed. 2010, 49, 6726–6744. [Google Scholar] [CrossRef] [PubMed]

- Pereira, J.S.F.; Antes, F.G.; Diehl, L.O.; Knorr, C.L.; Mortari, S.R.; Dressler, V.L.; Flores, E.M.M. Microwave-induced combustion of carbon nanotubes for further halogen determination. J. Anal. Atom. Spectrom. 2010, 25, 1268–1274. [Google Scholar] [CrossRef]

- Deng, X.; Mammen, L.; Butt, H.J.; Vollmer, D. Candle soot as a template for a transparent robust super amphiphobic coating. Science 2012, 335, 67–70. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Ye, T.; Mao, C. Fluorescent carbon nanoparticles derived from candle soot. Angew Chem. Int. Ed. 2007, 46, 6473–6475. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Bohidar, H.B.J. Physical and fluorescent characteristics of non-functionalized carbon nanoparticles from candle soot. J. Nanopart. Res. 2012, 14, 1–10. [Google Scholar] [CrossRef]

- Bottini, M.; Mustelin, T. Carbon materials: Nanosynthesis by candlelight. Nat. Nanotechnol. 2007, 2, 599–600. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Liao, J.; Li, A.; Chen, C.; Lin, H.; Wang, X.; Xu, Y. Relationship between wettabilities and chemical compositions of candle soots. Fuel 2014, 128, 422–427. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, M.; Ogorevc, B.; Zhang, X. Recent advances in the chemical imaging of human fingermarks (a review). Analyst 2016, 141, 6172–6189. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Q.; Zhu, Y.; Liu, S.; Gao, Y.; Li, X.; Shi, M.; Zhang, X.; Zhang, M. Candle Soot Coating for Latent Fingermark Enhancement on Various Surfaces. Sensors 2017, 17, 1612. https://doi.org/10.3390/s17071612

Wei Q, Zhu Y, Liu S, Gao Y, Li X, Shi M, Zhang X, Zhang M. Candle Soot Coating for Latent Fingermark Enhancement on Various Surfaces. Sensors. 2017; 17(7):1612. https://doi.org/10.3390/s17071612

Chicago/Turabian StyleWei, Qianhui, Yu Zhu, Shouliang Liu, Yongjie Gao, Xiaolong Li, Mi Shi, Xueji Zhang, and Meiqin Zhang. 2017. "Candle Soot Coating for Latent Fingermark Enhancement on Various Surfaces" Sensors 17, no. 7: 1612. https://doi.org/10.3390/s17071612