Review on the Traction System Sensor Technology of a Rail Transit Train

Abstract

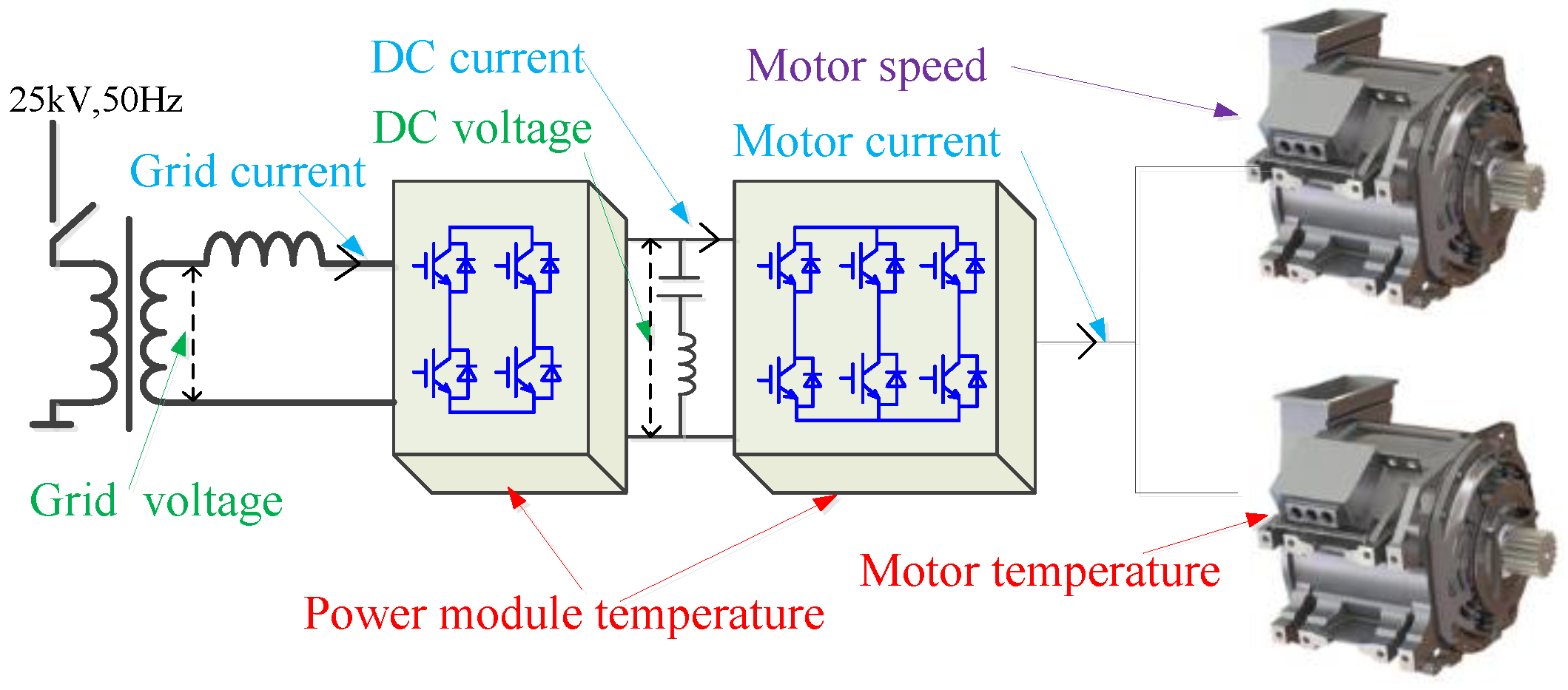

:1. Introduction

2. Signal Sensing Technologies of Traction System Sensors

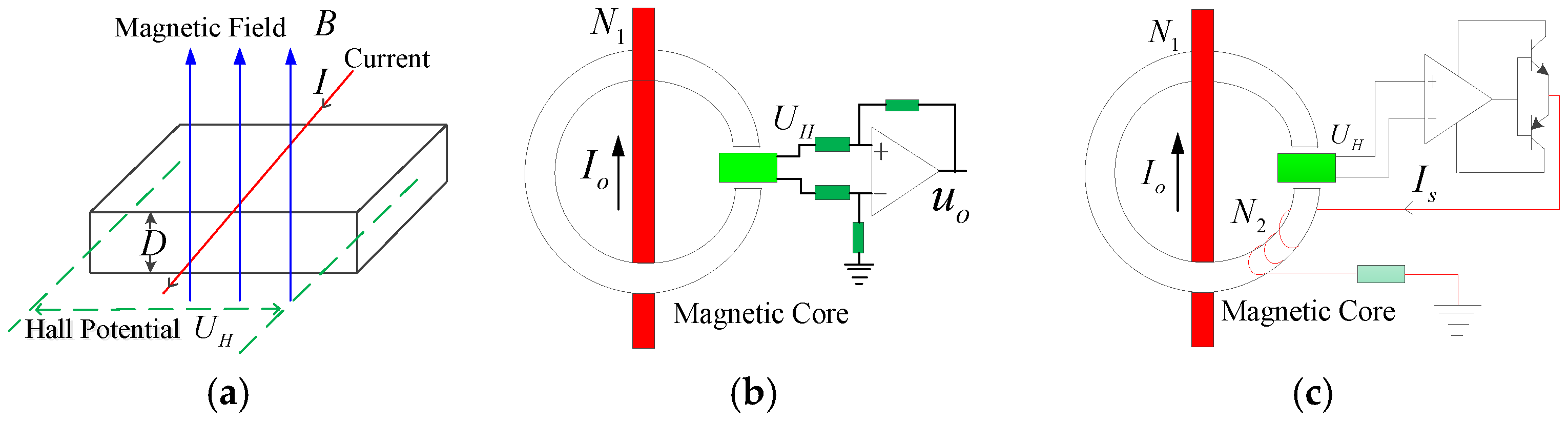

2.1. Signal Sensing Principle of Current and Voltage Sensors

2.2. Signal Sensing Principle for Speed Sensors

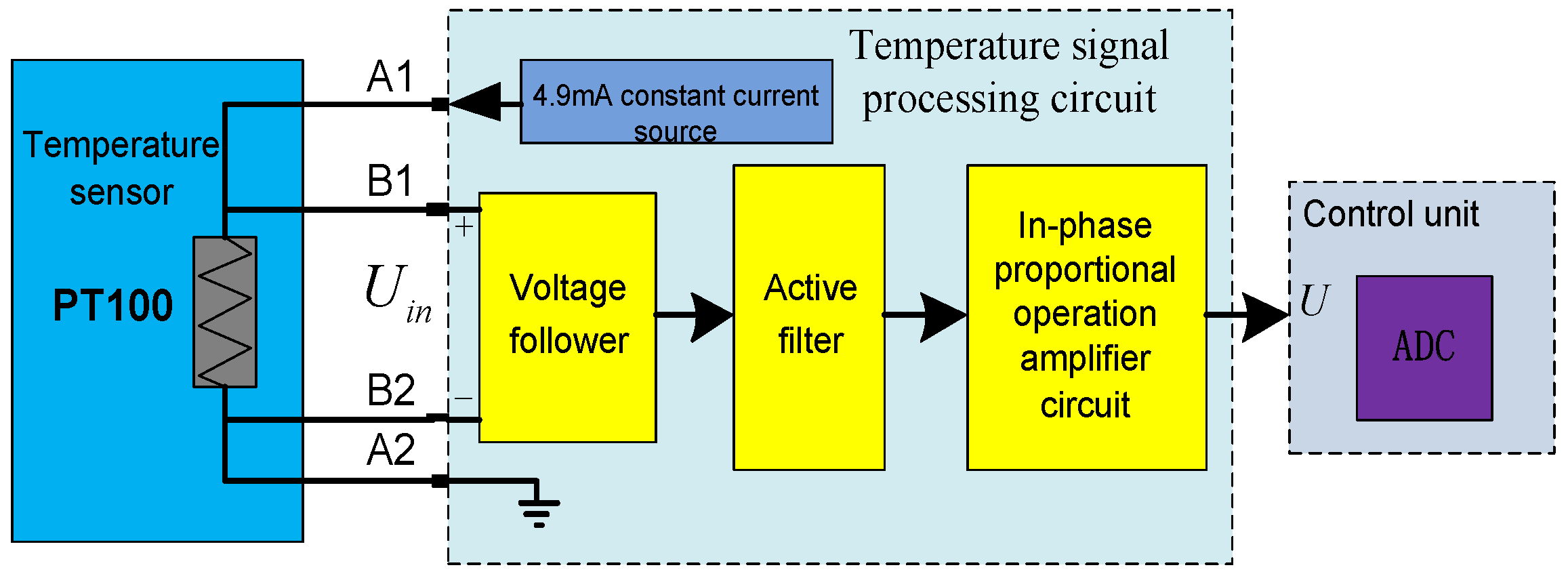

2.3. Signal Sensing Principle of Temperature Sensors

2.4. Application Prospect of the New Signal Sensing Technology

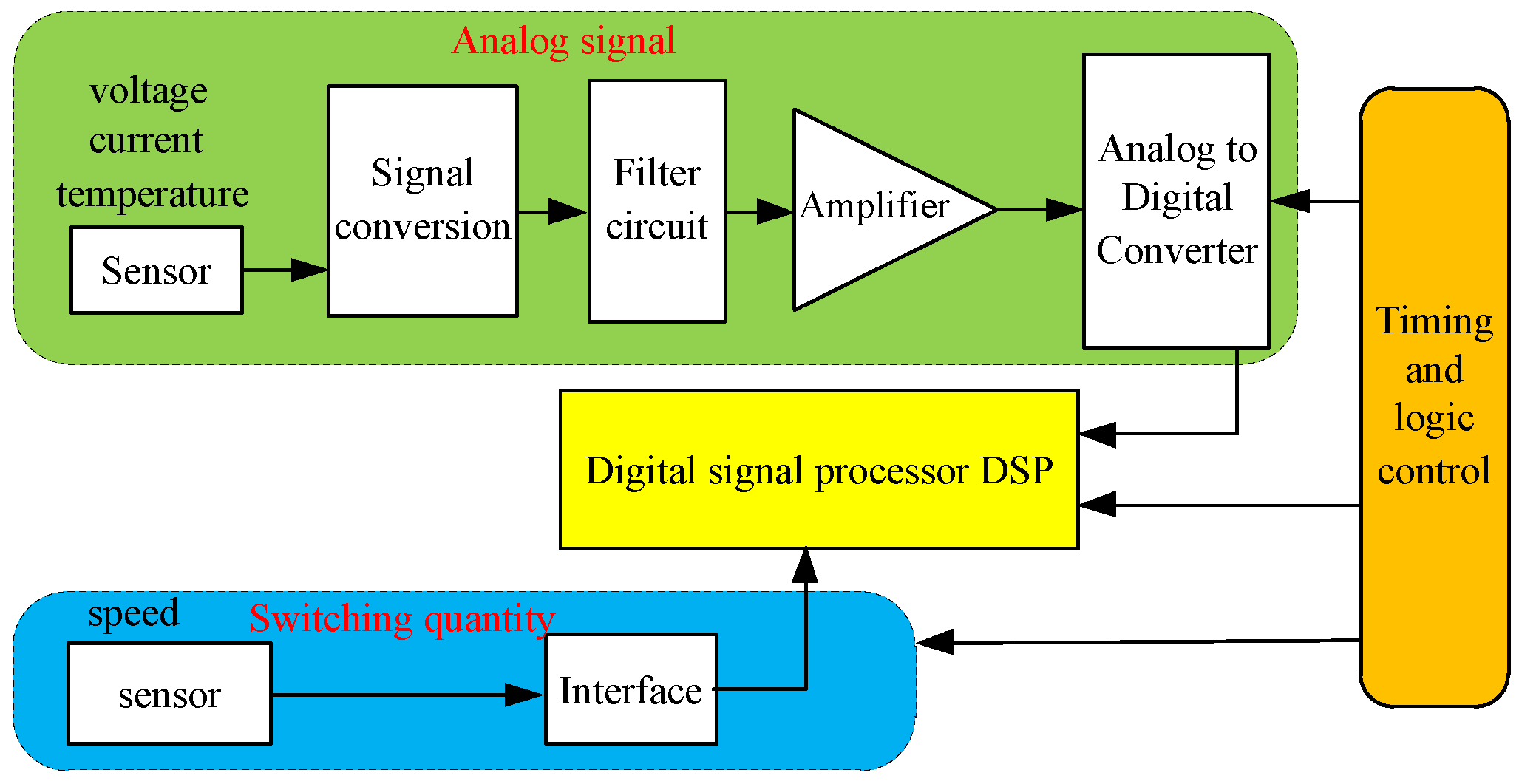

3. Sensor Data Acquisition and Processing

3.1. Analog Signal Processing

3.2. Sensor Data Sampling Technology

3.3. Digital Filtering Technology

- Digital filtering can be used as an effective supplement to hardware filtering, and can overcome the disadvantage of fixed hardware filtering frequency characteristics.

- Digital filtering can be employed to filter indirect measure signals. For example, motor torque signals are observed by flux linkage and current signals. The observed torque has significant high-frequency fluctuations, and cannot be utilized to the control loop before filtering.

- The digital filter is also used to extract particular signals. For example, the DC link voltage of the traction drive system has twice the power frequency pulsation. A notch filter is required to extract the ripple voltage. When the high-frequency voltage is injected to observe the location of the permanent magnet synchronous motor rotor, a band-pass or band-stop filter is also required to extract certain signals [36,37].

4. Sensor Fault Diagnosis

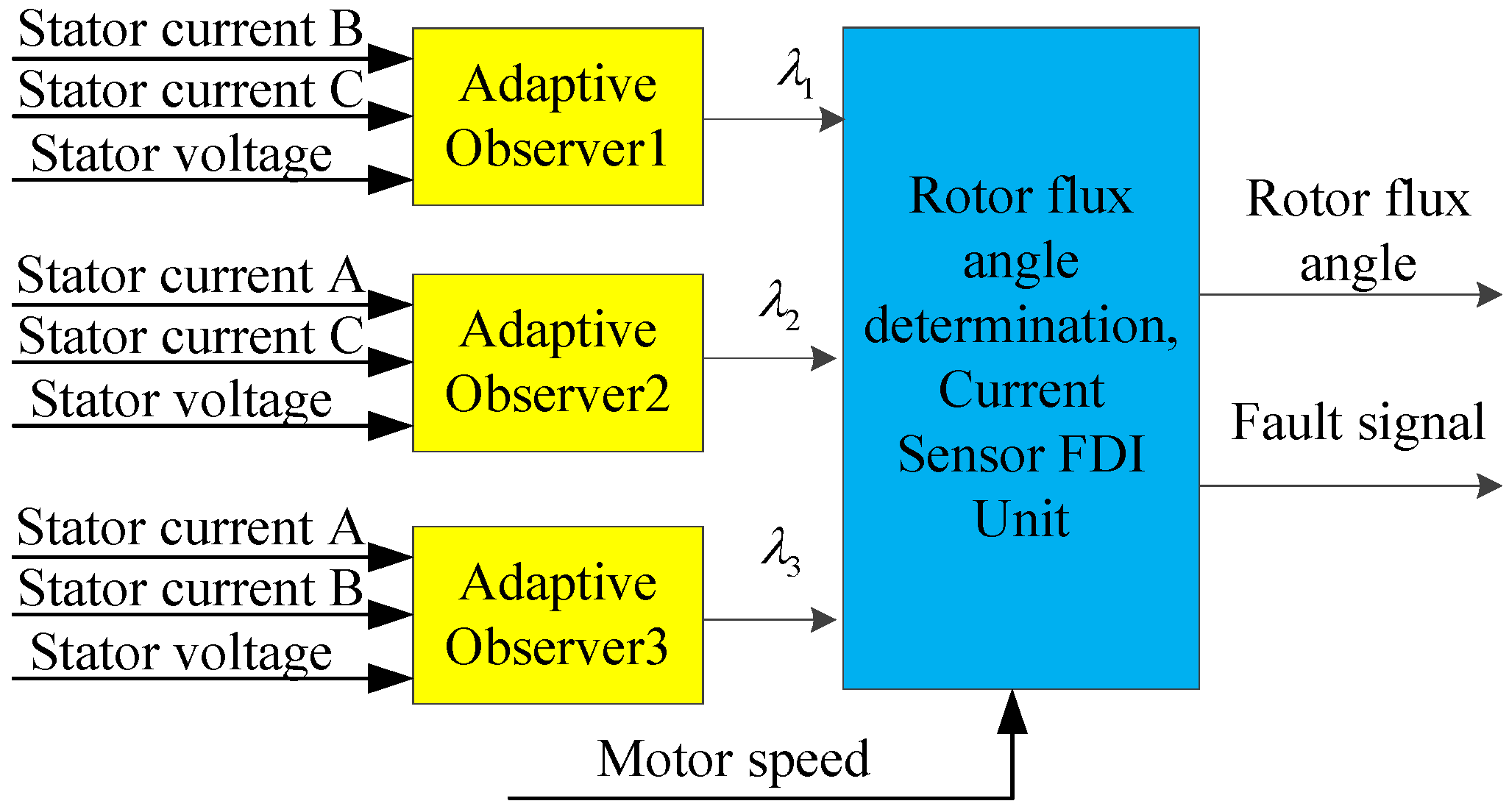

4.1. Current Sensor Fault Diagnosis

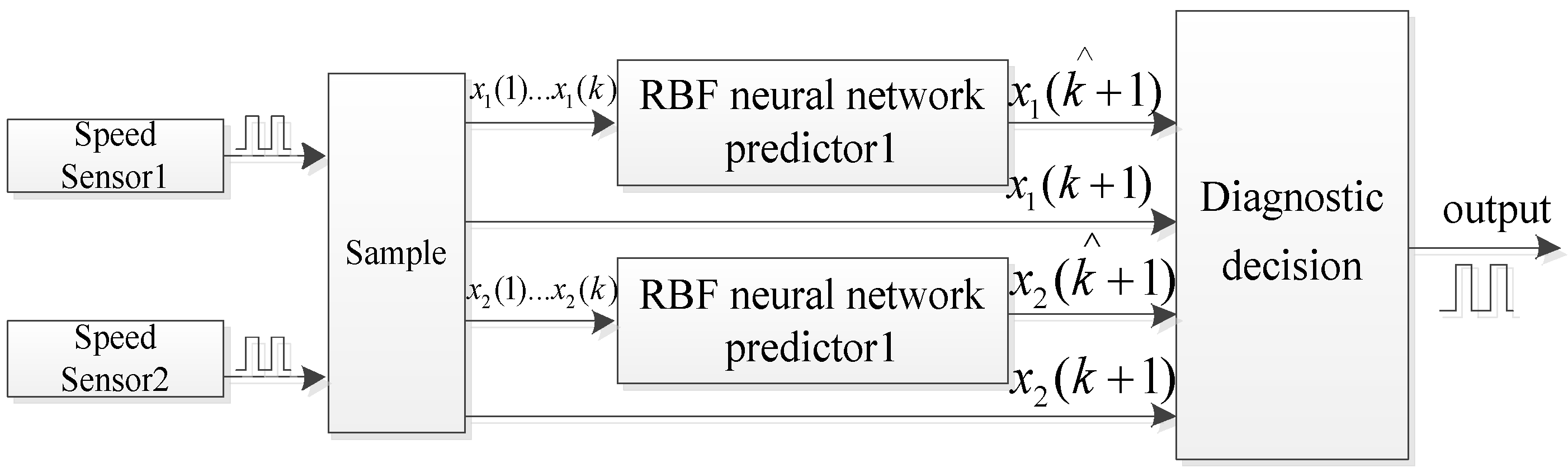

4.2. Speed Sensor Fault Diagnosis

4.3. Temperature Sensor Fault Diagnosis

5. Intelligent Sensor Technology

5.1. Technical Features of Intelligent Sensors

5.2. Key Technology of Intelligent Sensors

5.2.1. Signal Sensing and Integration Technology

5.2.2. Signal Processing Technology

5.2.3. Signal Transmission Technology

6. Future Research Hotspots and Challenges on Railway Transit Sensor

7. Conclusions

Author Contributions

Conflicts of Interest

References

- Zhao, N.; Roberts, C.; Hillmansen, S.; Nicholson, G. A Multiple Train Trajectory Optimization to Minimize Energy Consumption and Delay. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2363–2372. [Google Scholar] [CrossRef]

- Zhang, H.; Quan, W.; Song, J.; Jiang, Z.; Yu, S. Link State Prediction-Based Reliable Transmission for High-Speed Railway Networks. IEEE Trans. Veh. Technol. 2016, 65, 9617–9629. [Google Scholar] [CrossRef]

- Dong, H.; Ning, B.; Chen, Y.; Sun, X.; Wen, D.; Hu, Y.; Ouyang, R. Emergency Management of Urban Rail Transportation Based on Parallel Systems. IEEE Trans. Intell. Transp. Syst. 2013, 14, 627–636. [Google Scholar] [CrossRef]

- Glickenstein, H. China Becomes a Major Player in the Rail Market. IEEE Trans. Veh. Technol. 2011, 6, 18–23. [Google Scholar] [CrossRef]

- Quraan, M.; Siam, J. Modeling and Simulation of Railway Electric Traction with Vector Control Drive. In Proceedings of the 2016 IEEE International Conference on Intelligent Rail Transportation (ICIRT), Birmingham, UK, 23–25 August 2016; pp. 105–110. [Google Scholar]

- Aguirre, M.; Calleja, C.; Lopez-de-Heredia, A.; Poza, J.; Aranburu, A.; Nieva, T. FOC and DTC comparison in PMSM for railway traction application. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications, Birmingham, UK, 1–10 September 2011. [Google Scholar]

- Hu, H.; Li, Y.D.; Zeng, Y. Direct Torque Control of Induction Motor for Railway Traction in Whole Speed Range. In Proceedings of the IEEE 2002 28th Annual Conference of the Industrial Electronics Society, IECON 02, Sevilla, Spain, 5–8 November 2002; pp. 2161–2166. [Google Scholar]

- Yin, J.; Chen, D.; Li, L. Intelligent Train Operation Algorithms for Subway by Expert System and Reinforcement Learning. IEEE Trans. Intell. Transp. Syst. 2014, 15, 2561–2571. [Google Scholar] [CrossRef]

- Hengyu, L.; Hongze, X. An integrated intelligent control algorithm for High-Speed Train ATO systems based on running conditions. In Proceedings of the Third International Conference on Digital Manufacturing and Automation (ICDMA), GuiLin, China, 31 July–2 August 2012; pp. 202–205. [Google Scholar]

- Zhongguancun’s Internet of Things (IOT) Industry Alliance. Beijing-Shanghai high-speed railway security guard—1000 intelligent safety sensors. Int. Things Technol. 2011, 5, 36–37. (In Chinese) [Google Scholar]

- Liran, W.; Mingli, W.; Kejian, S. Analysis of Electrical Load Characteristics of HXD1B locomotive based on measured data. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–6. [Google Scholar]

- Gou, B.; Ge, X.; Wang, S.; Feng, X.; Kuo, J.B.; Habetler, T.G. An Open-Switch Fault Diagnosis Method for Single-Phase PWM Rectifier Using a Model-Based Approach in High-Speed Railway Electrical Traction Drive System. IEEE Trans. Power Electron. 2016, 31, 3816–3826. [Google Scholar] [CrossRef]

- Youssef, M.Z.; Woronowicz, K.; Aditya, K.; Azeez, N.A.; Williamson, S.S. Design and Development of an Efficient Multilevel DC/AC Traction Inverter for Railway Transportation Electrification. IEEE Trans. Power Electron. 2016, 31, 3036–3042. [Google Scholar] [CrossRef]

- Kumar, A.; John, V. Power Electronic Converter for Characterization of Hall-effect Current Sensors. In Proceedings of the 2014 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Mumbai, India, 16–19 December 2014; pp. 1–6. [Google Scholar]

- Jobling, D. New Open-Loop Current Transducers with near Closed-Loop Performance. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 20–22 May 2014; pp. 1–5. [Google Scholar]

- Lorenzen, D.M.; Falls, B. Rotary Speed Sensor with Base line Compensation of Hall Cell Output Signal. U.S. Patent US4992731 A, 12 February 1991. [Google Scholar]

- Xu, Z.; Wang, W.; Sun, Y. Performance Degradation Monitoring for Onboard Speed Sensors of Trains. IEEE Trans. Intell. Transp. Syst. 2012, 13, 1287–1297. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Zhao, H. A Temperature Measurement System Based on PT100. In Proceedings of the International Conference on Electrical and Control Engineering (ICECE), Wuhan, China, 25–27 June 2010; pp. 296–298. [Google Scholar]

- Narayana, K.V.L.; Kumar, V.N. Development of an Intelligent Temperature Transducer. IEEE Sens. J. 2016, 16, 4696–4703. [Google Scholar] [CrossRef]

- Chen, X.; He, S.; Li, D.; Wang, K.; Fan, Y.; Wu, S. Optical Fiber Voltage Sensor Based on Michelson Interferometer Using Phase Generated Carrier Demodulation Algorithm. IEEE Sens. J. 2016, 16, 349–354. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, L.; Pan, W.; Luo, B.; Wang, P.; Guo, L.; Zhou, W. Sensitivity Enhancement of Strain Sensing Utilizing a Differential Pair of Fiber Bragg Gratings. Sensor 2012, 12, 3891–3900. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Wang, X.; Meng, H. Study on the characteristics of all fibre optical current sensor linear fitting algorithm. In Proceedings of the IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Qingdao, China, 16–18 July 2015; pp. 1530–1535. [Google Scholar]

- Allil, R.C.d.B.; Werneck, M.M. Optical High-Voltage Sensor Based on Fiber Bragg Grating and PZT Piezoelectric Ceramics. IEEE Trans. Instrum. Meas. 2011, 60, 2118–2125. [Google Scholar] [CrossRef]

- The Ministry of Railways Transport. Evaluation Opinions about the Solutions of CRH LKJ Speed Signal Problems; The Ministry of Railways Transport: Naypyidaw, Myanmar, 2010. (In Chinese)

- Hu, C.; Wang, Y. Digital signal processing for fluorescence-based fiber-optic temperature sensor. In Proceedings of the Advanced Sensor Systems and Applications, Shanghai, China, 15–18 October 2002. [Google Scholar]

- Maya-Hernandez, P.M.; Alvarez-Simon, L.C.; Sanz-Pascual, M.T.; Calvo-Lopez, B. An Integrated Low-Power Lock-In Amplifier and Its Application to Gas Detection. Sensors 2014, 14, 15880–15899. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Kempf, A. On a Non-Fourier Generalization of Shannon Sampling Theory. In Proceedings of the 10th Canadian Workshop on Information Theory (CWIT), Edmonton, AB, Canada, 6–8 June 2007; pp. 193–196. [Google Scholar]

- Kaboli, S.H.; Zolghadri, M.R.; Homaifar, A. Effects of Sampling Time on the Performance of Direct Torque Controlled Induction Motor Drive. IEEE Int. Symp. Ind. Electron. 2003, 2, 1049–1052. [Google Scholar]

- Aphiratsakun, N.; Techakittiroj, K.; Threevithayanon, W. Vector-control of induction motor: Study of sampling time, switching frequency and output quantization step. In Proceedings of the 2004 IEEE Region 10 Conference TENCON 2004, Chiang Mai, Thailand, 21–24 November 2004; pp. 13–16. [Google Scholar]

- Lin, B.; Recke, B.; Knudsen, J.K.H.; Jørgensen, S.B. Data-driven soft sensor design with multiple-rate sampled data: A comparative study. Ind. Eng. Chem. Res. 2009, 48, 5379–5387. [Google Scholar] [CrossRef]

- Yamaguchi, N.; Hasegawa, M.; Doki, S.; Okuma, S. New approach for stability improvement of speed sensorless induction-motor controls at zero frequency using multirate adaptive observer. IEE Proc. Electr. Power Appl. 2006, 153, 544–550. [Google Scholar] [CrossRef]

- Wang, S.; Dinavahi, V.; Xiao, J. Multi-rate real-time model-based parameter estimation and state identification for induction motors. IET Electr. Power Appl. 2013, 7, 77–86. [Google Scholar] [CrossRef]

- Xu, P.; Xiao, J.; Wang, S.; Lu, K. Application of multirate Extended Kalman Filter to speed estimation of PMSM. Comput. Eng. Appl. 2014, 50, 236–241. (In Chinese) [Google Scholar]

- Pandya, S.N.; Chatterjee, J.K. Torque Ripple Minimization in Direct Torque Control Based Induction Motor Drive Using Optimal Multirate Sampling Technique. In Proceedings of the 2010 Joint International Conference on Power Electronics, Drives and Energy Systems & 2010 Power India, New Delhi, India, 20–23 December 2010. [Google Scholar]

- Pandya, S.N.; Chatterjee, J.K. Torque Ripple Minimization in Direct Torque Control based IM Drive Part-II: Multirate Control Strategy. In Proceedings of the 2008 Joint International Conference on Power System Technology and IEEE Power India Conference, New Delhi, India, 12–15 October 2008. [Google Scholar]

- Ramezani, M.; Ojo, O. The Modeling and Position-Sensorless Estimation Technique for A Nine-Phase Interior Permanent-Magnet Machine Using High-Frequency Injections. IEEE Trans. Ind. Appl. 2016, 52, 1555–1565. [Google Scholar]

- Mohammed, O.A.; Khan, A.A.; El-Tallawy, A.M.; Nejadpak, A.; Roberts, M.J. A Wavelet Filtering Scheme for Noise and Vibration Reduction in High-frequency Signal Injection-Based Sensorless Control of PMSM at Low Speed. IEEE Trans. Energy Convers. 2012, 27, 250–260. [Google Scholar] [CrossRef]

- Beylkin, G.; Lewis, R.D.; Monzón, L. On the Design of Highly Accurate and Efficient IIR and FIR Filters. IEEE Trans. Signal Process. 2012, 60, 4045–4054. [Google Scholar] [CrossRef]

- Halikias, G.D.; Jaimoukha, I.M. Design of Infinite Impulse Response (IIR) filters with almost linear phase characteristics. In Proceedings of the European Control Conference (ECC), Cambridge, UK, 1–4 September 2003; pp. 3034–3039. [Google Scholar]

- Gou, B.; Ge, X.; Pu, J.; Feng, X. A Fault Diagnosis and Fault tolerant Control Method for DC-link Circuit Using Notch Filter in Power Traction Converter. In Proceedings of the 2016 IEEE 8th International Power Electronics and Motion Control Conference (IPEMC-ECCE Asia), Hefei, China, 22–26 May 2016; pp. 1–6. [Google Scholar]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault-tolerant techniques-partⅠ: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Lee, K.S.; Ryu, J.S. Instrument fault detection and compensation scheme for direct torque controlled induction motor drives. IEE Proc. Control Theory Appl. 2003, 150, 376–382. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Z.; Xu, D. Speed and current sensor fault detection and isolation based on adaptive observers for induction motor drivers. J. Power Electron. 2014, 14, 967–979. [Google Scholar] [CrossRef]

- Najafabadi, T.A.; Salmasi, F.R.; Maralani, P.J. Detection and Isolation of Speed-, Dc-link Voltage-, and Current-Sensor Faults Based on an Adaptive Observer in Induction-Motor Drives. IEEE Trans. Ind. Electron. 2011, 58, 1662–1672. [Google Scholar] [CrossRef]

- Zhang, C.F.; Liao, H.J.; Li, X.F.; Sun, J.; He, J. Fault Reconstruction Based on Sliding Mode Observer for Current Sensors of PMSM. J. Sens. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Huang, G.; Luo, Y.P.; Zhang, C.F.; He, J.; Huang, Y.S. Current sensor fault reconstruction for PMSM drives. Sensors 2016, 16, 178. [Google Scholar] [CrossRef] [PubMed]

- Gou, B.; Ge, X.; Liu, Y.; Feng, X. Load-current-based current sensor fault diagnosis and tolerant control scheme for traction inverters. Electron. Lett. 2016, 52, 17171719. [Google Scholar] [CrossRef]

- El Khil, S.K.; Jlassi, I.; Estima, J.O.; Mrabet-Bellaaj, N.; Cardoso, A.J.M. Current sensor fault detection and isolation method for PMSM drives, using average normalised currents. Electron. Lett. 2016, 52, 1434–1436. [Google Scholar] [CrossRef]

- Klimkowski, K.; Dybkowski, M. Neural Network Approach for Stator Current Sensor Fault Detection and Isolation for Vector Controlled Induction Motor Drive. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016; pp. 1072–1078. [Google Scholar]

- Li, H.; Monti, A.; Ponci, F. A Fuzzy-Based Sensor Validation Strategy for AC Motor Drives. IEEE Trans. Ind. Inform. 2012, 8, 839–848. [Google Scholar] [CrossRef]

- Zhang, X.; Foo, G.; Vilathgamuwa, M.D.; Tseng, K.J.; Bhangu, B.S.; Gajanayake, C. Sensor fault detection, isolation and system reconfiguration based on extended Kalman filter for induction motor drives. IET Electr. Power Appl. 2013, 7, 607–617. [Google Scholar] [CrossRef]

- Bourogaoui, M.; Jlassi, I.; Khil, S.K.E.L.; Sethom, H.B.A. An Effective Encoder Fault Detection in PMSM Drives at Different Speed Ranges. In Proceedings of the 2015 IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Guarda, Portugal, 1–4 September 2015; pp. 90–96. [Google Scholar]

- Chakraborty, C.; Verma, V. Speed and Current Sensor Fault Detection and Isolation Technique for Induction Motor Drive Using Axes Transformation. IEEE Trans. Ind. Electron. 2015, 62, 1943–1954. [Google Scholar] [CrossRef]

- Klimkowski, K.; Dybkowski, M. A Comparative Analysis of the Chosen Speed Sensor Faults Detectors for Induction Motor Drives. In Proceedings of the 2015 International Conference on Electrical Drives and Power Electronics (EDPE), Tatranska Lomnica, Slovakia, 21–23 September 2015. [Google Scholar]

- Sergeyev, I.Y. Signal processing system of intelligent sensor with nonlinear characteristic. In Proceedings of the 2013 IEEE 2nd International Conference Actual Problems of Unmanned Air Vehicles Developments (APUAVD), Kiev, Ukraine, 15–17 October 2013; pp. 193–195. [Google Scholar]

- Zhang, Y.; Gu, Y.; Vlatkovic, V.; Wang, X. Progress of Smart Sensor and Smart Sensor Networks. In Proceedings of the Fifth World Congress on Intelligent Control and Automation, WCICA 2004, Hangzhou, China, 15–19 June 2004; pp. 3600–3606. [Google Scholar]

- Al-Ali, A.R.; Aji, Y.R.; Othman, H.F.; Fakhreddin, F.T. Wireless smart sensors networks overview. In Proceedings of the Second IFIP International Conference on Wireless and Optical Communications Networks, WOCN 2005, Dubai, United Arab Emirates, 6–8 March 2005; pp. 536–540. [Google Scholar]

- Gervais-Ducouret, S. Next smart sensors generation. In Proceedings of the 2011 IEEE Sensors Applications Symposium (SAS), San Antonio, TX, USA, 22–24 February 2011. [Google Scholar]

- Saponara, S.; Petri, E.; Fanucci, L.; Terreni, P. Sensor Modeling, Low-Complexity Fusion Algorithms, and Mixed-Signal IC Prototyping for Gas Measures in Low-Emission Vehicles. IEEE Trans. Instrum. Meas. 2011, 60, 372–384. [Google Scholar] [CrossRef]

- Sisto, A.; Pilato, L.; Serventi, R.; Saponara, S.; Fanucci, L. Application specific instruction set processor for sensor conditioning in automotive applications. Microprocess. Microsyst. 2016, 47, 375–384. [Google Scholar] [CrossRef]

- Costantino, N.; Serventi, R.; Tinfena, F.; D’Abramo, P.; Chassard, P.; Tisserand, P.; Saponara, S.; Fanucci, L. Design and Test of an HV-CMOS Intelligent Power Switch With Integrated Protections and Self-Diagnostic for Harsh Automotive Applications. IEEE Trans. Ind. Electron. 2011, 58, 2715–2727. [Google Scholar] [CrossRef]

- Miseje, M.; Sturcel, J. Signal Processing in Smart Sensor Systems. J. Electr. Eng. 2003, 54, 154–159. [Google Scholar]

- Garcia, G.J.; Jara, C.A.; Pomares, J.; Alabdo, A.; Poggi, L.M.; Torres, F. A Survey on FPGA-Based Sensor systems: Towards Intelligent and Reconfigurable Low-Power Sensors for Computer Vision, Control and Signal Processing. Sensors 2014, 14, 6247–6278. [Google Scholar] [CrossRef] [PubMed]

- Saponara, S.; Fanucci, L.; Bernardo, F.; Falciani, A. Predictive Diagnosis of High-Power Transformer Faults by Networking Vibration Measuring Nodes with Integrated Signal Processing. IEEE Trans. Instrum Meas. 2016, 65, 1749–1760. [Google Scholar] [CrossRef]

- Saponara, S. Distributed Measuring System for Predictive Diagnosis of Uninterruptible Power Supplies in Safety-Critical Applications. Energies 2016, 9, 327. [Google Scholar] [CrossRef]

- Stanley, M.; Gervais-Ducouret, S.; Adams, J.T. Intelligent Sensor Hub Benefits for Wireless Sensor Networks. In Proceedings of the 2012 IEEE Sensors Applications Symposium (SAS), Brescia, Italy, 7–9 February 2012. [Google Scholar]

- Wang, H.; Ping, Z.; Shen, J.; Zhang, L. Key Technology of Network Integration for Urban Rail Transit System. In Proceedings of the 2014 International Conference on Wireless Communication and Sensor Network, Wuhan, China, 13–14 December 2014; pp. 474–479. [Google Scholar]

- Yan-min, D.U. Wireless Sensor Network (WSN) safety review. Comput. Eng. Softw. 2015, 36, 127–131. (In Chinese) [Google Scholar]

- Saponara, S.; Bacchillone, T. Network Architecture, Security Issues, and Hardware Implementation of a Home Area Network for Smart Grid. J. Comput. Netw. Commun. 2012, 2012, 1–19. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Xu, J.; Liao, W.; Liu, Y. Review on the Traction System Sensor Technology of a Rail Transit Train. Sensors 2017, 17, 1356. https://doi.org/10.3390/s17061356

Feng J, Xu J, Liao W, Liu Y. Review on the Traction System Sensor Technology of a Rail Transit Train. Sensors. 2017; 17(6):1356. https://doi.org/10.3390/s17061356

Chicago/Turabian StyleFeng, Jianghua, Junfeng Xu, Wu Liao, and Yong Liu. 2017. "Review on the Traction System Sensor Technology of a Rail Transit Train" Sensors 17, no. 6: 1356. https://doi.org/10.3390/s17061356