A Novel Real-Time Path Servo Control of a Hardware-in-the-Loop for a Large-Stroke Asymmetric Rod-Less Pneumatic System under Variable Loads

Abstract

:1. Introduction

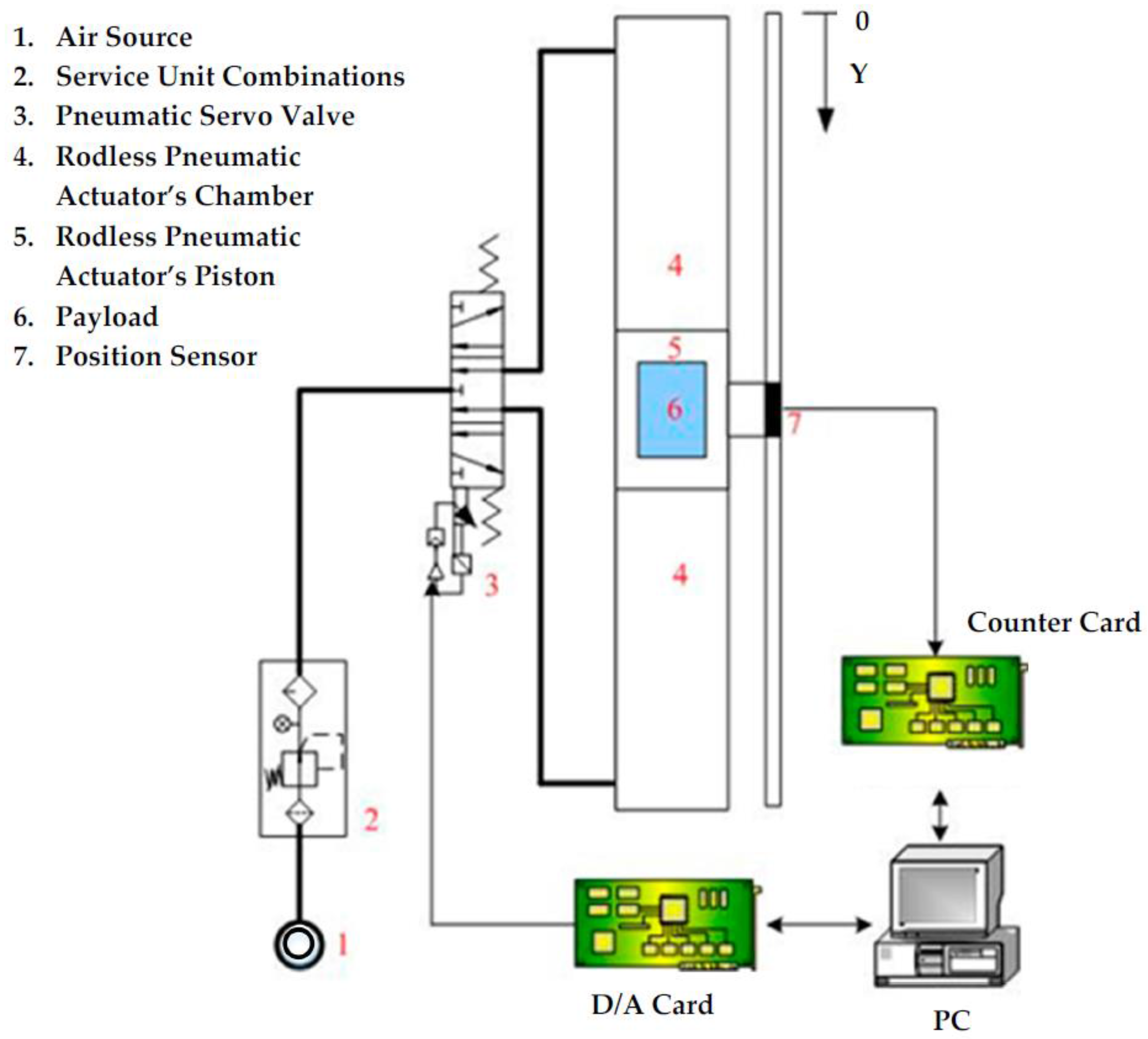

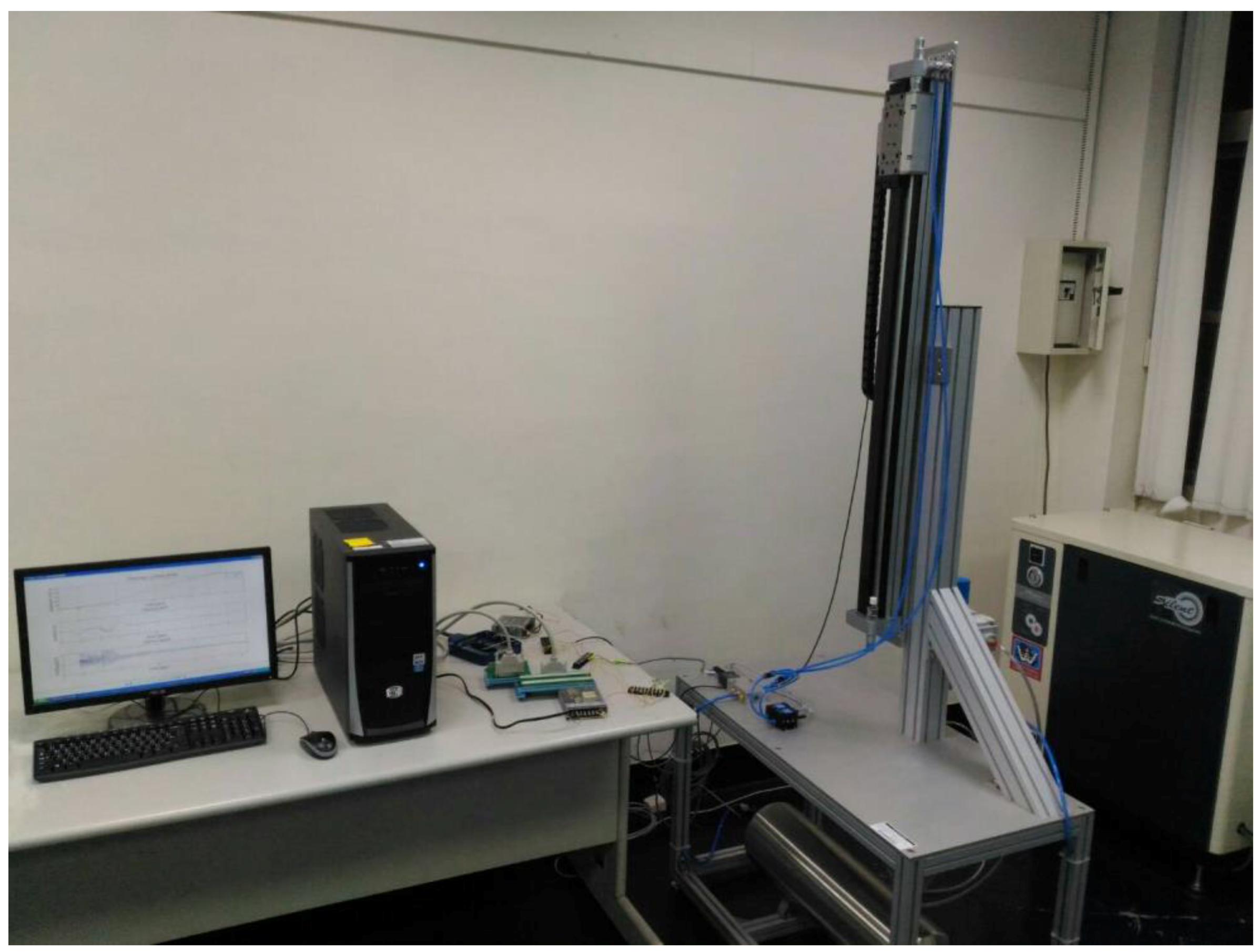

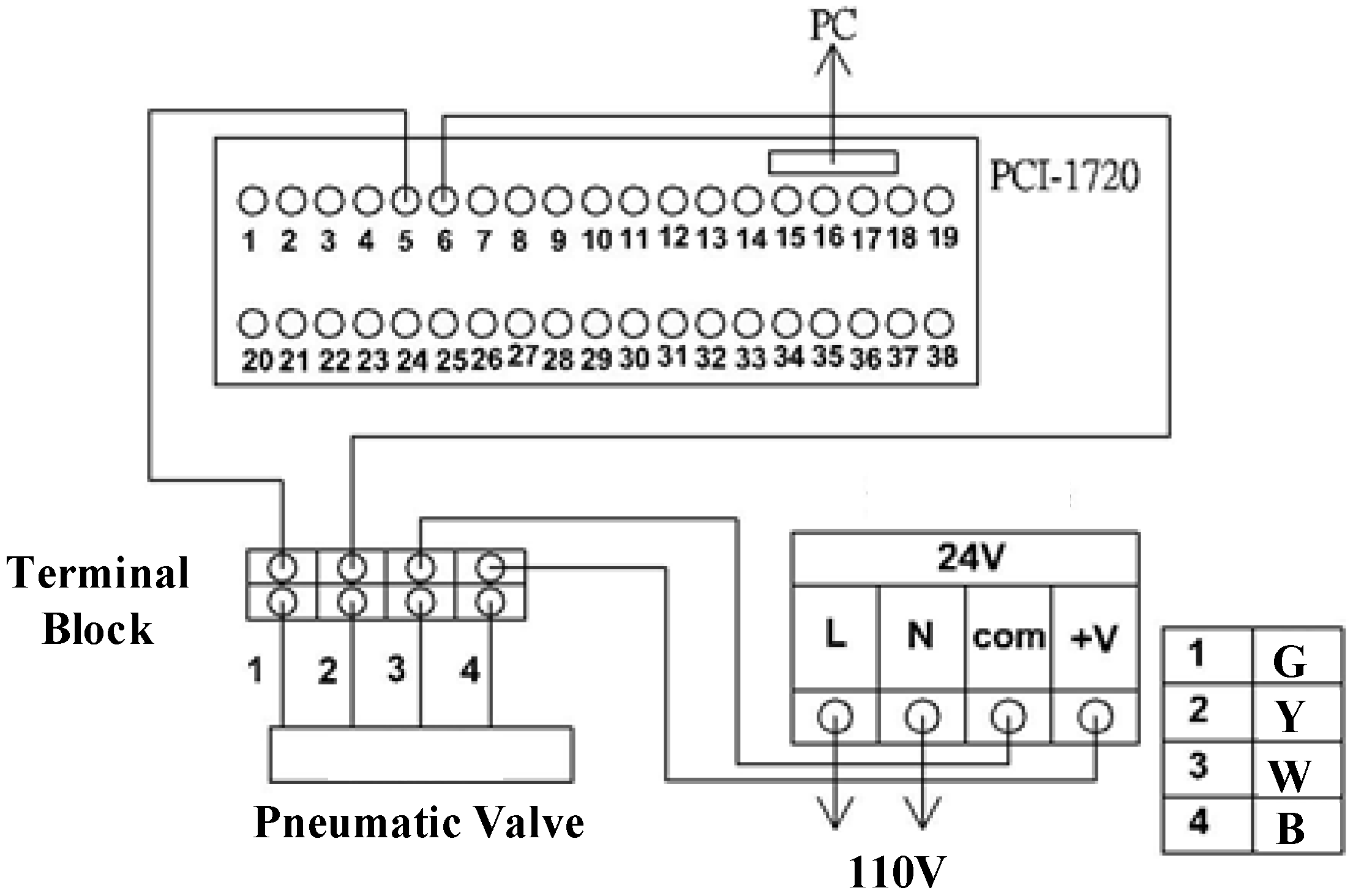

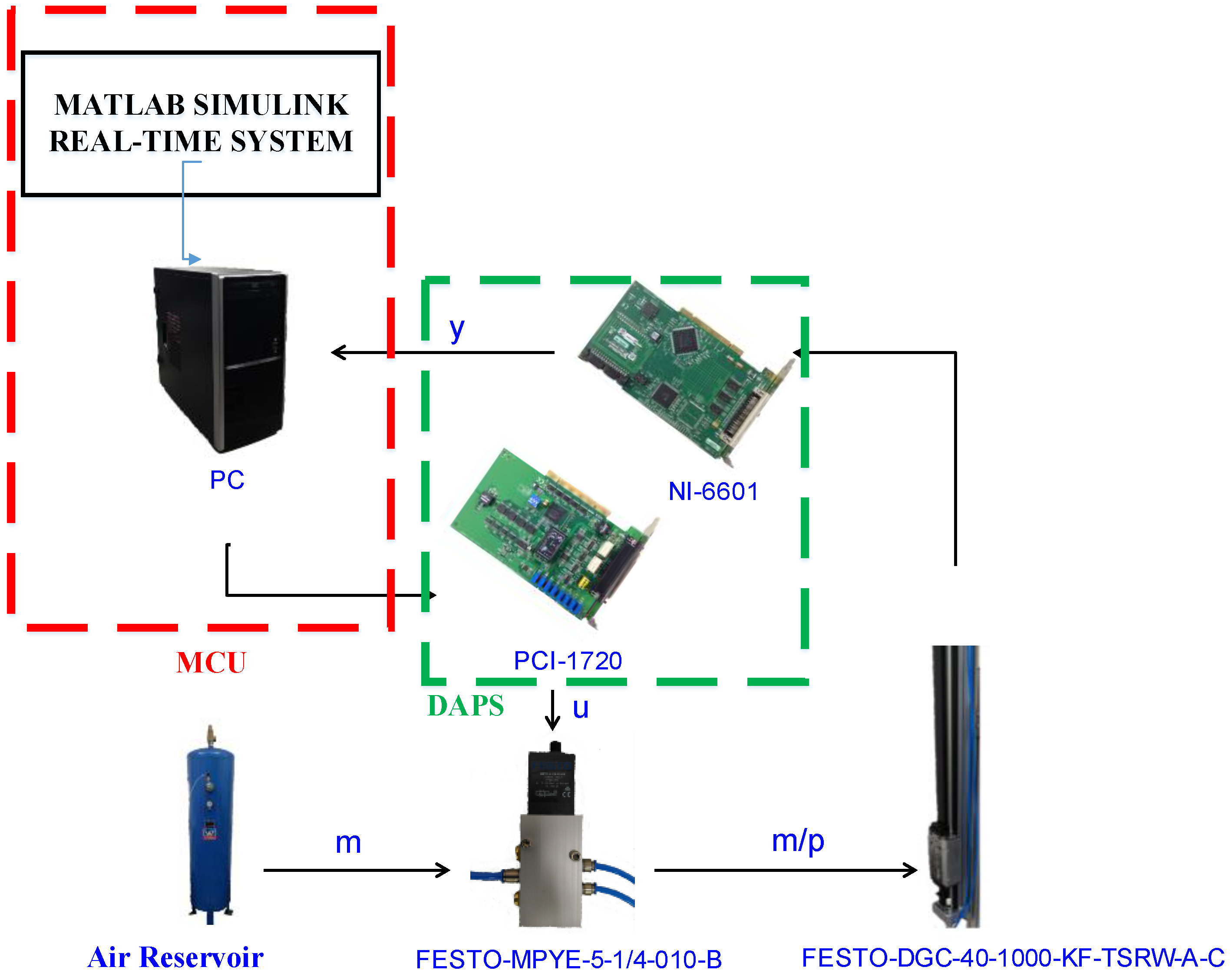

2. The Sensor-Integrated Hardware-in-the-Loop of a Large-Stroke Asymmetric Pneumatic Servo System

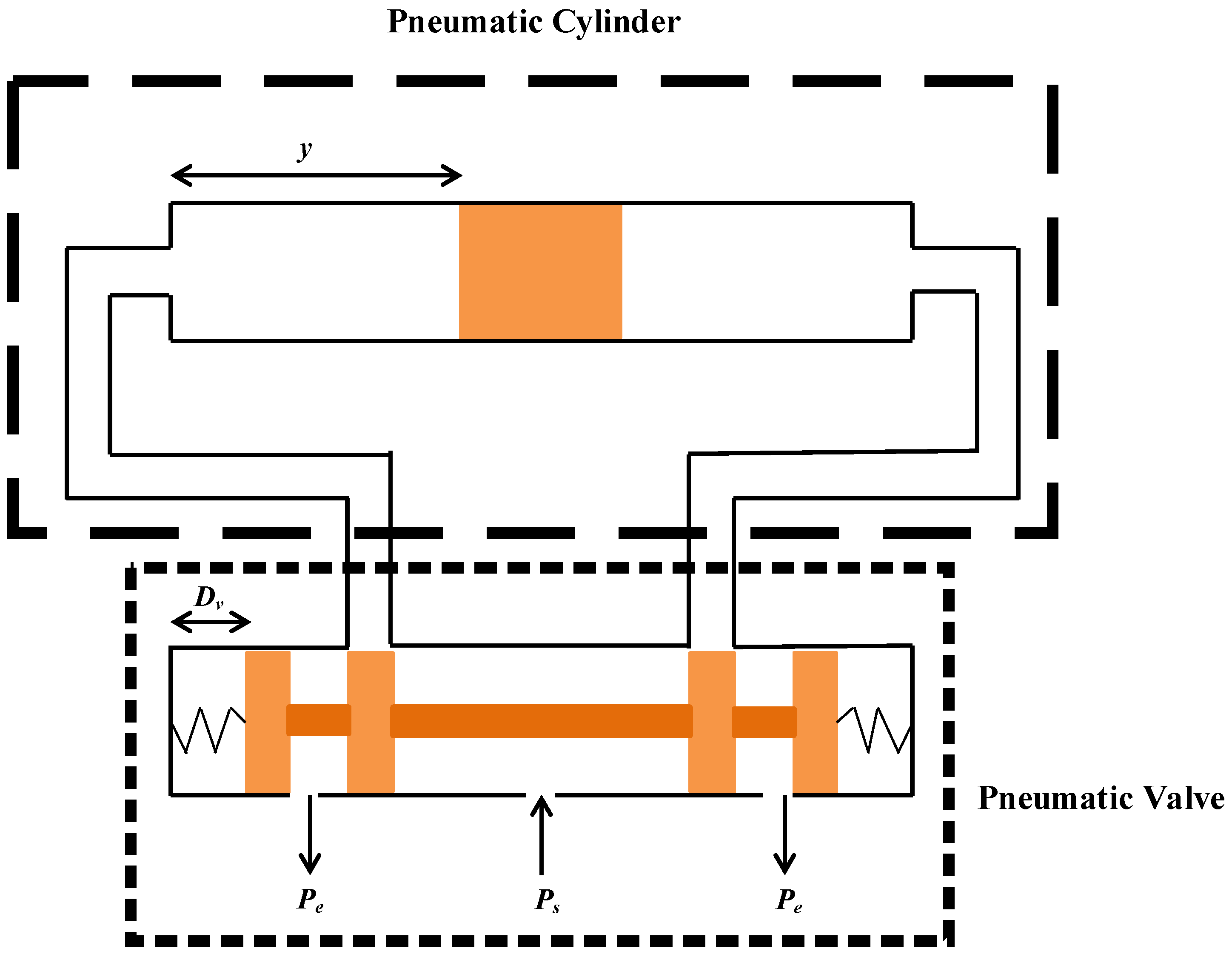

3. Establishment of Dynamic Models for the Pneumatic System

3.1. Models for the Pneumatic Valve

3.2. Mass Flow Rates of a Pneumatic Cylinder

3.3. Continuous Equations

3.4. The Load Motion Equation

4. Controller Design

5. Experiments

5.1. The Hardware-in-the Loop of a Large-Stroke Asymmetric Pneumatic Servo System

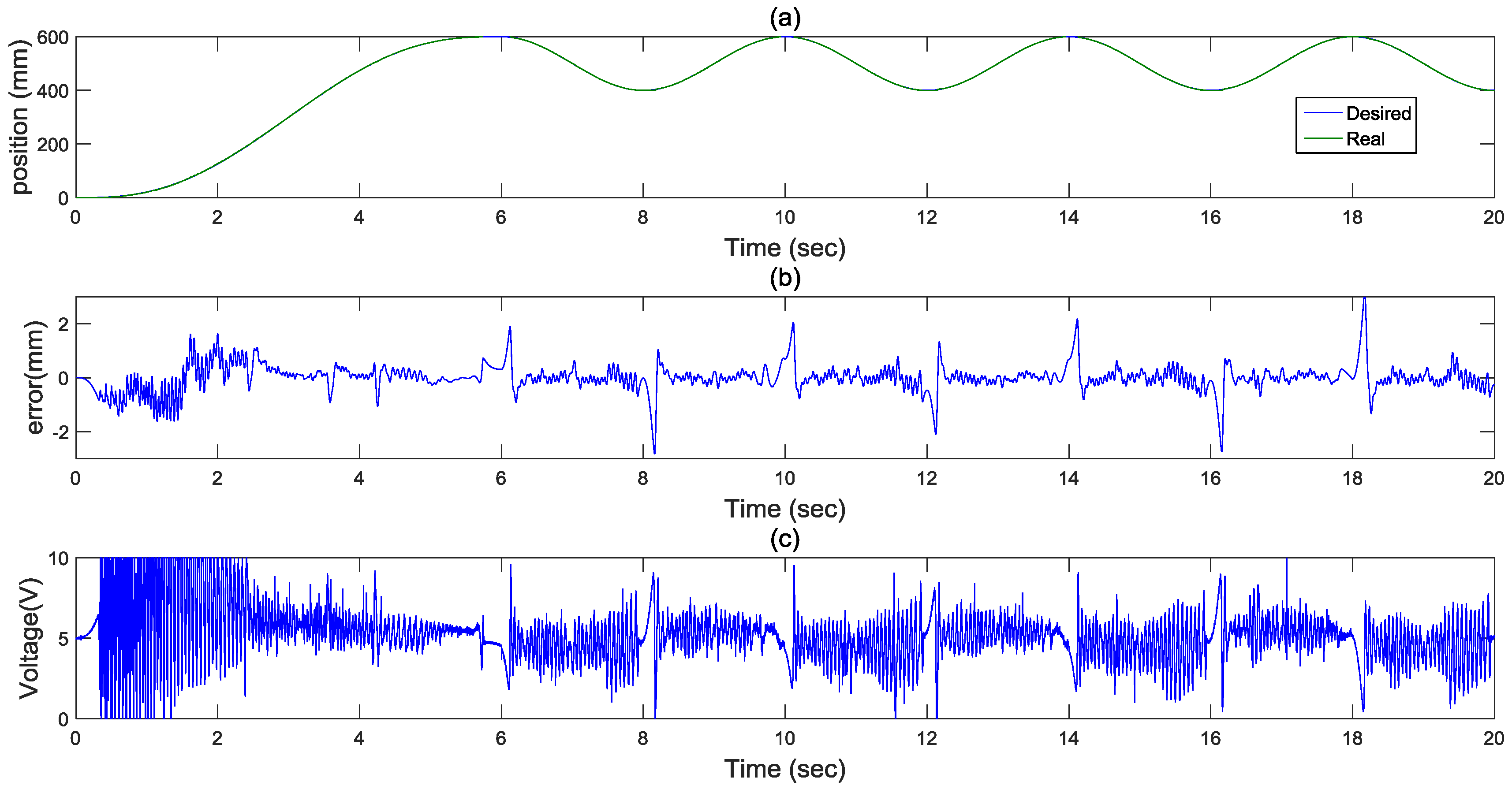

5.2. A Single Direction of 5th Path Real-Time Tracking Experiments

5.3. A Bi-Direction of 5th Path Real-Time Tracking Experiments

5.4. A Different Loading of 5th Path Real-Time Tracking Experiments

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Weston, R.H.; Moore, P.R.; Thatcher, T.W.; Morgon, G. Computer Controlled Pneumatic Servo Drives. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1984, 198, 275–281. [Google Scholar] [CrossRef]

- Noritsugu, T. Electro-Pneumatic Feedback Speed Control of a Pneumatic Motor. Part I: With an Electro-Pneumatic Proportional Valve. J. Fluid Control 1987, 17, 17–37. [Google Scholar]

- Noritsugu, T. Development of PWM Mode Electro-Pneumatic Servomechanism. Part II: Position Control of a Pneumatic Cylinder. Fluid Control 1987, 66, 65–80. [Google Scholar]

- Song, J.; Ishida, Y. A Robust Sliding Mode Control for Pneumatic Servo System. Int. J. Eng. Sci. 1997, 35, 711–723. [Google Scholar] [CrossRef]

- Shih, M.C.; Ma, M.A. Position control of a pneumatic cylinder using fuzzy PWM control method. Mechatronics 1998, 8, 241–253. [Google Scholar] [CrossRef]

- Su, T.C.; Kuo, C.Y. Variable structure control of a rodless pneumatic servo actuator with discontinuous sliding surfaces. In Proceedings of the 2000 American Control Conference, Chicago, IL, USA, 28–30 June 2000; pp. 1617–1621. [Google Scholar]

- Shu, N.; Bone, G.M. High steady-state accuracy pneumatic servo positioning system with PVA/PV control and friction compensation. Robot. Autom. 2002, 3, 2824–2829. [Google Scholar]

- Kaitwanidvilai, S.; Parnichkun, M. Position control of a pneumatic servo system by genetic algorithm based fixed-structure robust H infinity loop shaping control. In Proceedings of the Industrial Electronics Society, IECON 2004 30th Annual Conference of IEEE, Busan, Korea, 2–6 November 2004. [Google Scholar]

- Chen, C.K.; Hwang, J. PD-type iterative learning control for trajectory tracking of a pneumatic X-Y table with disturbances. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; pp. 3500–3505. [Google Scholar]

- Ning, S.; Bone, M. Development of a nonlinear dynamic model for a servo pneumatic positioning system. In Proceedings of the IEEE International Conference on Mechatronics and Automation, Niagara Falls, ON, Canada, 29 July–1 August 2005; pp. 43–48. [Google Scholar]

- Kato, T.; Kawashima, K.; Funaki, T.; Tadano, K.; Kagawa, T. A new, high precision, quick response pressure regulator for active control of pneumatic vibration isolation tables. Precis. Eng. 2010, 34, 43–48. [Google Scholar] [CrossRef]

- Chiang, M.H. Development of X-Y servo pneumatic-piezoelectric hybrid actuators for position control with high response, large stroke and nanometer accuracy. Sensors 2010, 10, 2675–2693. [Google Scholar] [CrossRef] [PubMed]

- Antonio, L.M.; Hugo, V.B.; Josep, B.M. Sliding-mode-control-based boost converter for high-voltage-low-power applications. IEEE Trans. Ind. Electron. 2015, 62, 229–237. [Google Scholar]

- Robinson, R.M.; Kothera, C.S.; Sanner, R.M.; Wereley, N.M. Nonlinear control of robotic manipulators driven by pneumatic artificial muscles. IEEE/ASME Trans. Mech. 2016, 2, 55–68. [Google Scholar] [CrossRef]

- Sheng, S.; Sun, C. Nonlinear adaptive rotational speed control design and experiment of the propeller of an electric micro air vehicle. Appl. Sci. 2016, 6, 17. [Google Scholar] [CrossRef]

- Samet, B.; Hasan, K. Optimized sliding mode control to maximize existence region for single-phase dynamic voltage restorers. IEEE Trans. Ind. Inform. 2016, 12, 1486–1497. [Google Scholar]

- Alessandro, P.; Mara, T.; Antonella, F. Switched/time-based adaptation for second-order sliding mode control. Automatica 2016, 64, 126–132. [Google Scholar]

- Precup, R.E.; Radac, M.B.; Roman, R.C.; Petriu, E.M. Model-free sliding mode control of nonlinear systems: Algorithms and experiments. Inf. Sci. 2017, 381, 176–192. [Google Scholar] [CrossRef]

- Wang, X.; Sun, J.; Li, G. Finite-time composite position control for a disturbed pneumatic servo system. Math. Probl. Eng. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Antonio, C.V.; Carla, S.R.; Claudio, F.R.; Marat, R. Nonlinear mathematical modeling in pneumatic servo position applications. Math. Prob. Eng. 2011, 2011, 1–16. [Google Scholar]

- Ren, H.P.; Fan, J.T. Adaptive backstepping slide mode control of pneumatic position servo system. Chin. J. Mech. Eng. 2016, 29, 1–7. [Google Scholar] [CrossRef]

- Sean, H.; Mahdi, T.; Minh, T.P.; Arnaud, L. Nonlinear discontinuous dynamics averaging and pwm-based sliding control of solenoid-valve pneumatic actuators. IEEE/ASME Trans. Mechatron. 2015, 20, 876–888. [Google Scholar]

- Rao, Z.; Bone, G.M. Nonlinear modeling and control of servo pneumatic actuators. IEEE Trans. Control Syst. Technol. 2008, 16, 562–569. [Google Scholar]

| Component | Specification |

|---|---|

| Pneumatic rod-less cylinder | Piston diameter: 40 mm |

| Stroke: 1000 mm | |

| Pneumatic proportional directional control valve | Valve function: 5/3 way |

| Input voltage: 0–10 V | |

| A/D D/A card | 4-ch analog output with 12-bit D/A converter |

| Counter card | 4-ch 32-bit counter with 20 MHz maximum source frequency |

| Optical encoder | Range: 1000 mm |

| Resolution: 0.1 μm |

| Vertical Direction | 45 Degrees Direction | ||

|---|---|---|---|

| 5th Path | Sine Wave | 5th Path | |

| Tracking Errors | 2 mm | 2 mm | 1.8 mm |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.-T. A Novel Real-Time Path Servo Control of a Hardware-in-the-Loop for a Large-Stroke Asymmetric Rod-Less Pneumatic System under Variable Loads. Sensors 2017, 17, 1283. https://doi.org/10.3390/s17061283

Lin H-T. A Novel Real-Time Path Servo Control of a Hardware-in-the-Loop for a Large-Stroke Asymmetric Rod-Less Pneumatic System under Variable Loads. Sensors. 2017; 17(6):1283. https://doi.org/10.3390/s17061283

Chicago/Turabian StyleLin, Hao-Ting. 2017. "A Novel Real-Time Path Servo Control of a Hardware-in-the-Loop for a Large-Stroke Asymmetric Rod-Less Pneumatic System under Variable Loads" Sensors 17, no. 6: 1283. https://doi.org/10.3390/s17061283