The Lateral Tracking Control for the Intelligent Vehicle Based on Adaptive PID Neural Network

Abstract

:1. Introduction

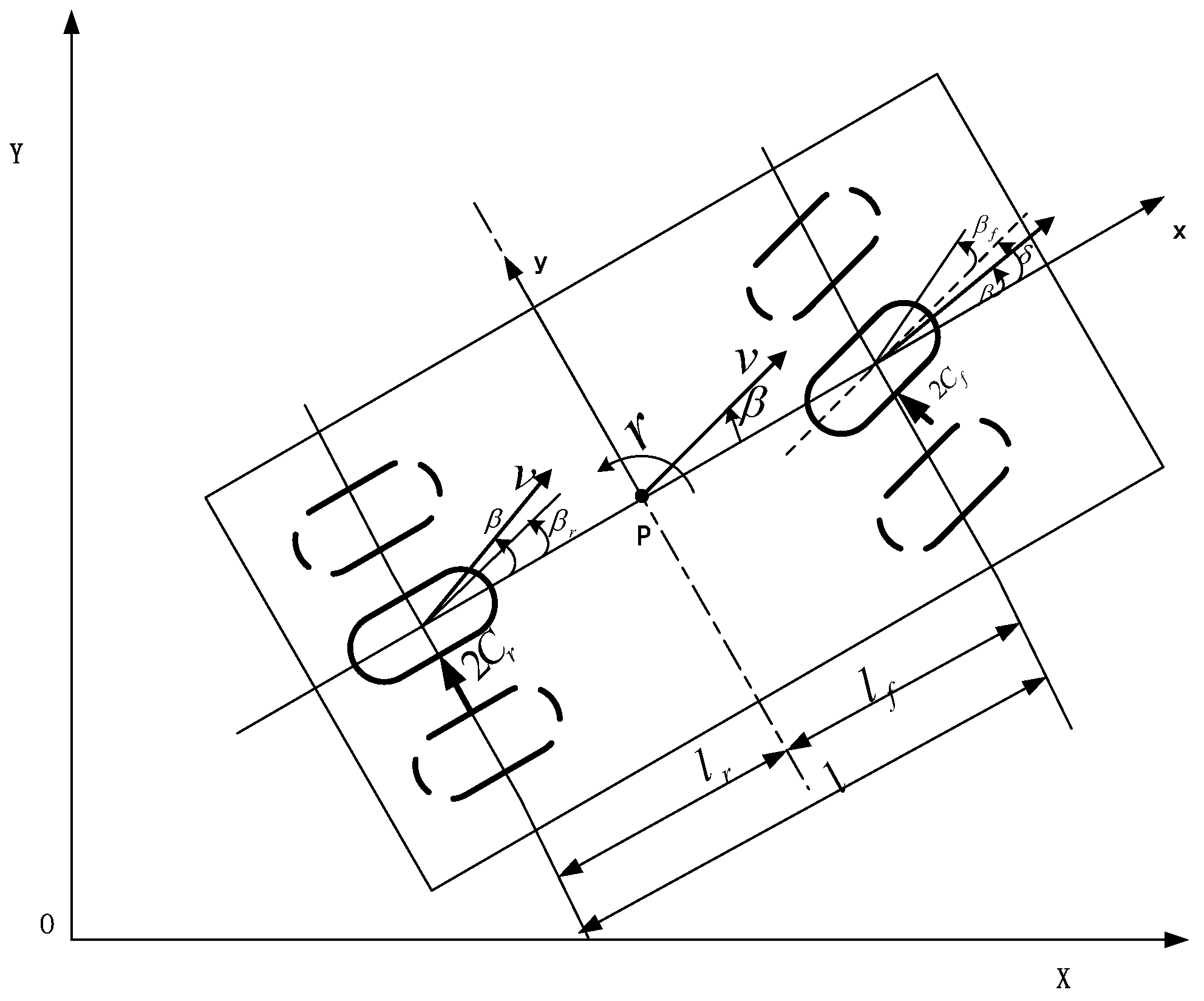

2. Vehicle Dynamics Analysis and Modeling

2.1. Vehicle Model

2.2. Vehicle Dynamics Analysis

3. Vehicle Steering System Control Modeling

3.1. Identification Signal

3.2. Identification and Analysis of Vehicle Steering System

3.3. Identification of Simulation Calculation

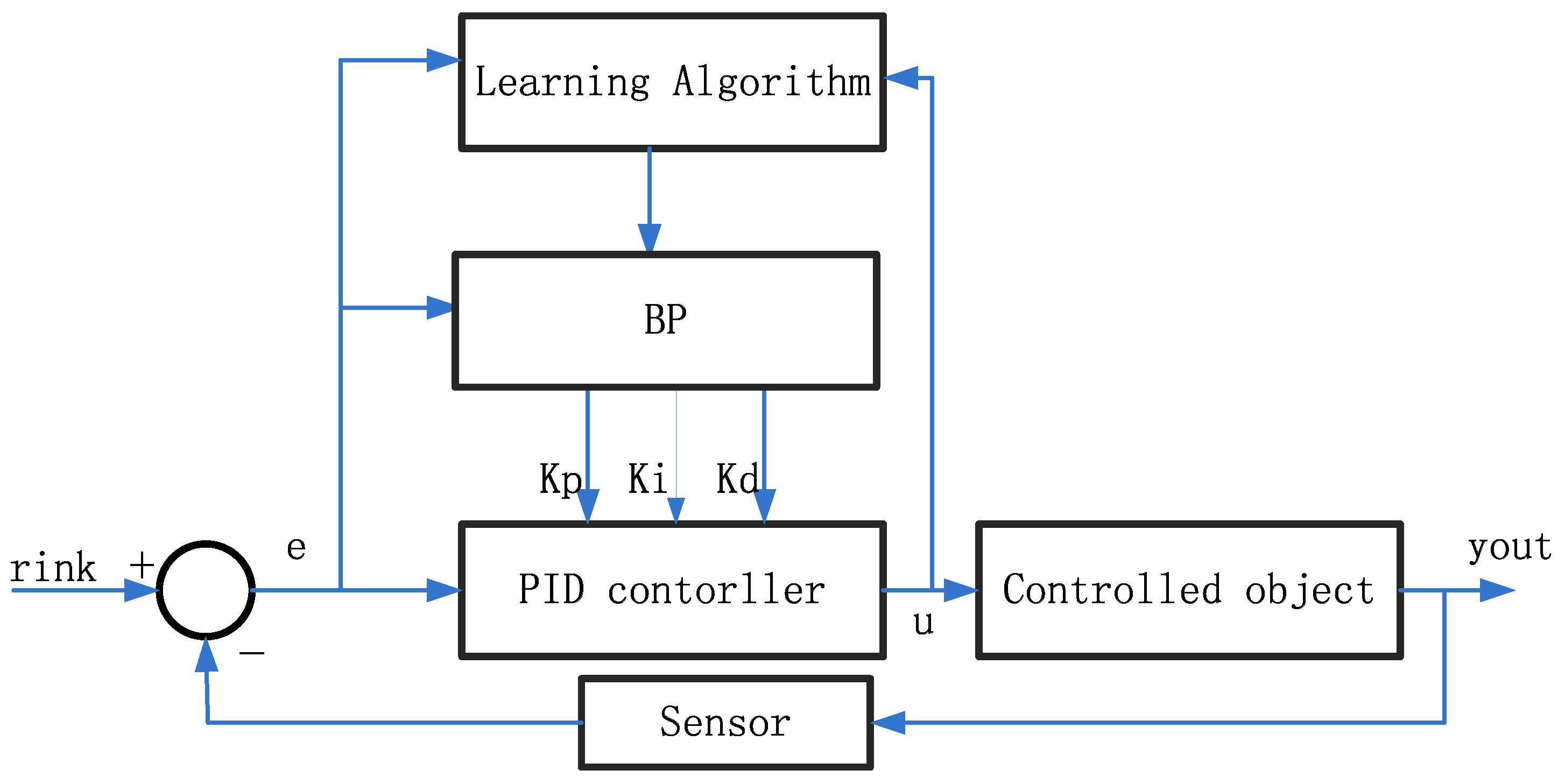

4. The Heading Angle Neural Network PID Control System

4.1. The Neural Network PID Control Structure

- Step1: The determined system structure of the BP network is 1-3-1, the given system weight coefficients initial value, learning rate and inertia coefficient, the iteration times k = 1.

- Step2: Sampling get rink(k) and yout(k), calculating error at time: e(k) = rink(k) − yout(k).

- Step3: According to calculate input and output of NN neurons in each layer by, the output of the NN is PID controller parameters Kp, Ki, Kd.

- Step4: According to the Equation (15) to calculate the output of the PID controller u(k) .

- Step5: Neural network learning, online adjust the weighting coefficient to realize the adaptive adjustment of PID control parameters.

- Step6: The iteration times k = k + 1, to return Step 2.

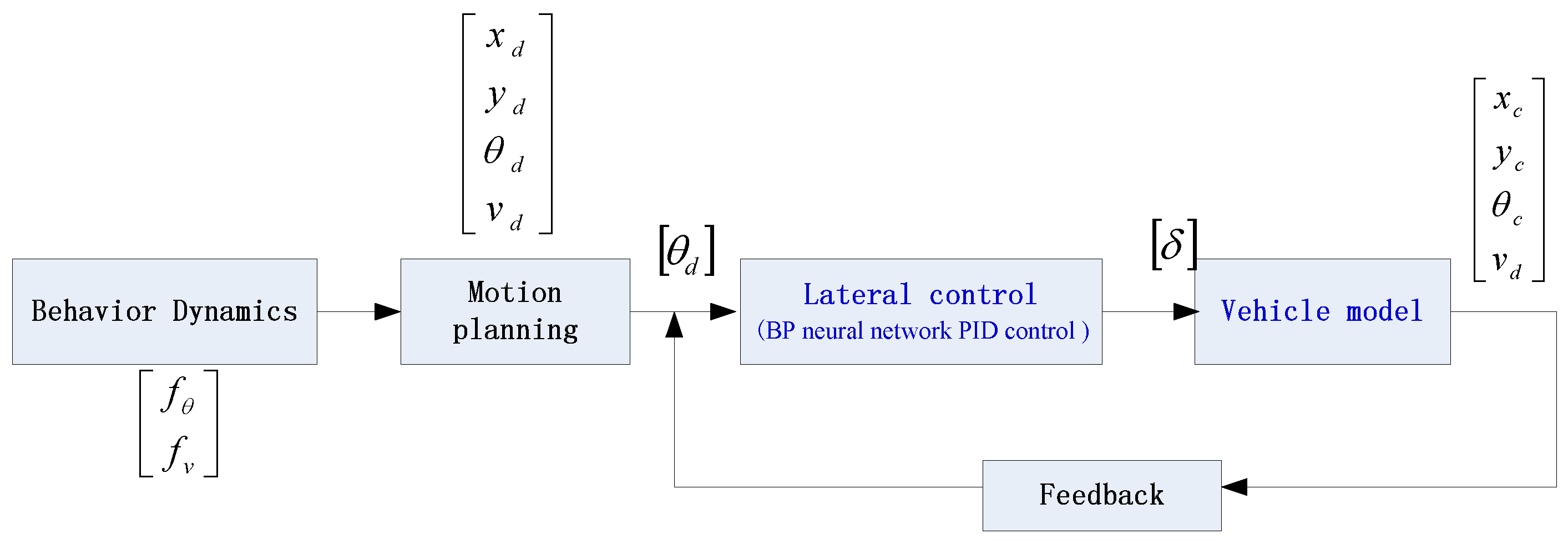

4.2. The Heading Angular Control

4.3. Adaptive PID Neural Network Controller Stability Analysis

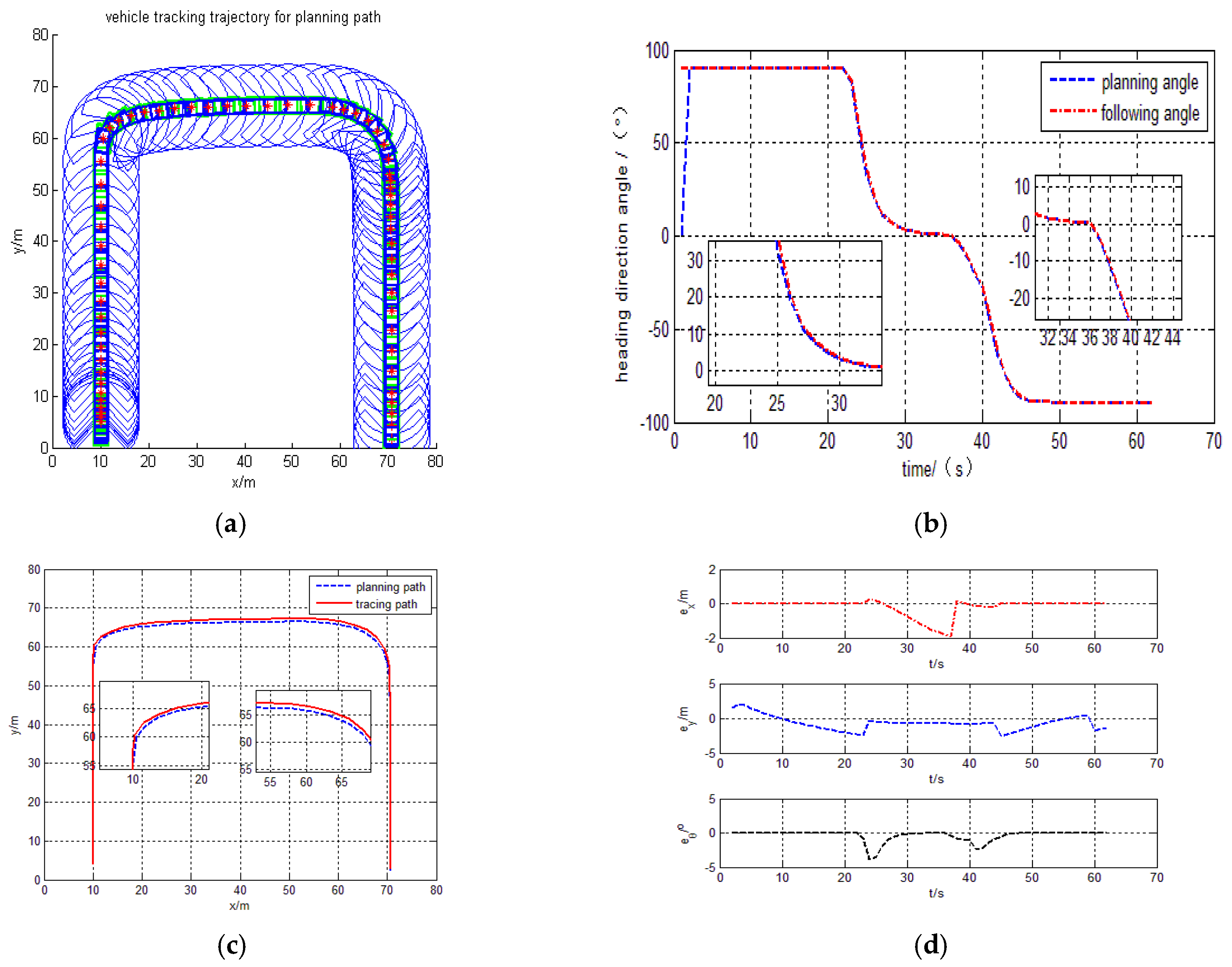

4.4.Simulation Experiments

4.4.1. Tracking the Curve

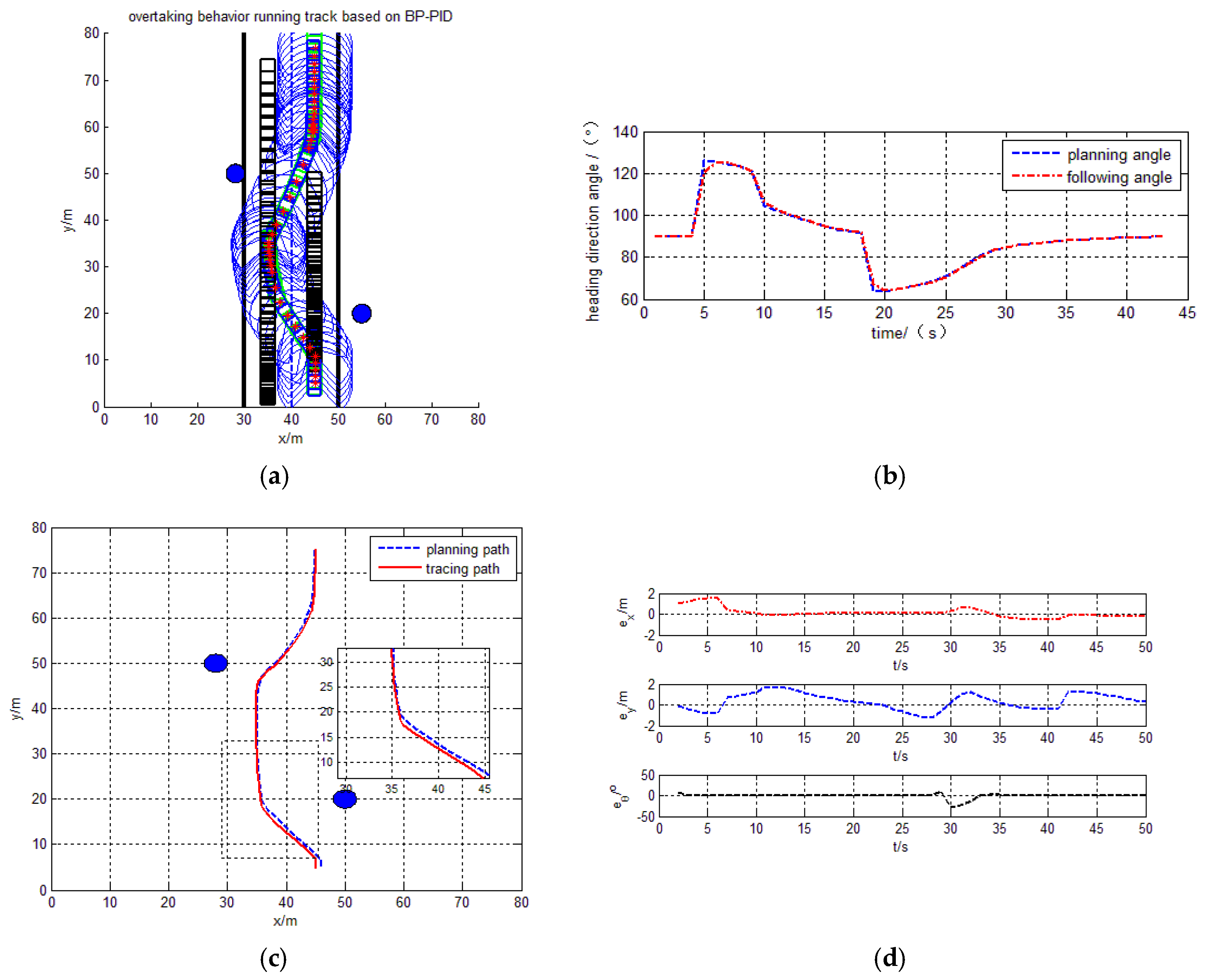

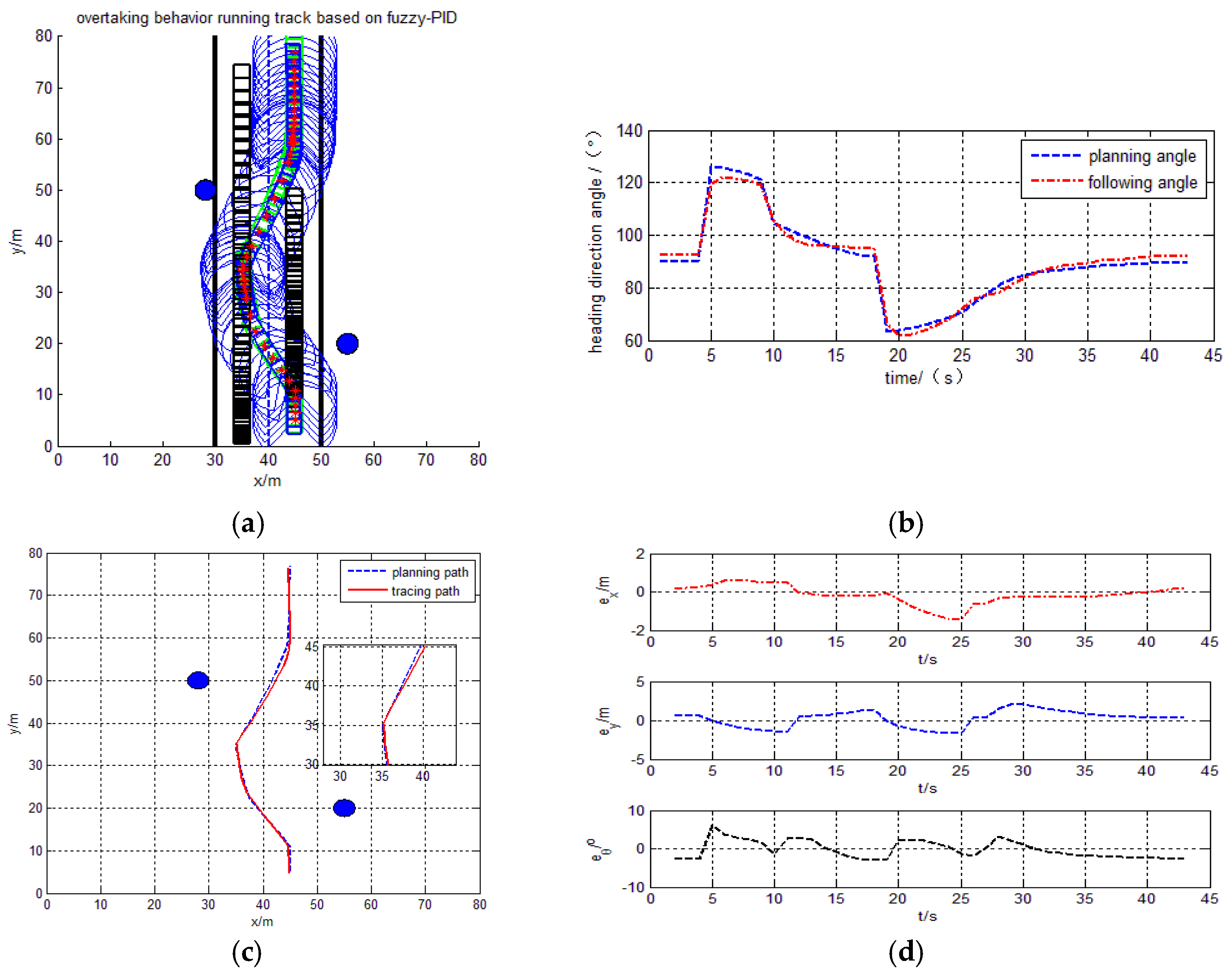

4.4.2. Tracking the Overtaking Behavior

5. Conclusions

- (1)

- The results of the pre-study behavioral dynamics motion planning are applied to the current motion tracking controller.

- (2)

- The model of intelligent vehicle steering system is built by using CARMA model and the parameters of steering system is trained by using FFRLS identify method. The vehicle model is set up according to the parameters of intelligent vehicle. The vehicle steering system model and vehicle model is connected to estimable a second-order control system.

- (3)

- The planning of the heading angle is input to the designed controller and output practices heading angle. An error between the planning path and tracing trajectory is calculated before feedback to the controller. The controller calculated the tracing heading angle in order to achieve zero path error.

- (4)

- The experimental results show that the identification algorithm and the BP neural network PID control model have real-time performance and reliability in path tracing, and the heading direction angle tracking effect is good; x, y direction and heading angle error is controllable and is close to zero. The method will lay a foundation for the lateral and the longitudinal coupling control.

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Wang, W.Y.; Li, I.H.; Chen, M.C.; Su, S.F. Dynamic Slip-Ratio Estimation and Control of Antilock Braking Systems Using an Observer-Based Direct Adaptive Fuzzy—Neural Controller. IEEE Trans. Ind. Electron. 2009, 56, 1746–1756. [Google Scholar] [CrossRef]

- Fukumura, T.; Iwata, T.; Murakami, T. The Method of Optimizing Traction Control System (TCS) and an Application to Vehicle Dynamics Control System. JSAE Rev. 1997, 18, 189. [Google Scholar]

- Arndt, D. Motor Vehicle Dynamic Regulation Method, e.g., for Use with an Electronic Stability Program (ESP), in Which Vehicle Yaw Rate and Velocity Vector are Determined and if Necessary a Braking Action Triggered. Patent DE10,247,994 A1, 29 April 2004. [Google Scholar]

- Dannöhl, C.; Müller, S.; Ulbrich, H. H∞-control of a rack-assisted electric power steering system. Veh. Syst. Dyn. 2012, 50, 527–544. [Google Scholar] [CrossRef]

- Nakayama, T.; Suda, E. Present and future of electric power steering. Int. J. Veh. Des. 1994, 15, 243–254. [Google Scholar]

- Hecker, F. Brake-Based Stability Assistance Functions for Commercial Vehicles. In Handbook of Driver Assistance Systems; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Miller, J.; Kienhofer, F.; Cebon, D. Design Concept for an Alternative Heavy Vehicle Slip Control Brake Actuator. Available online: http://road-transport-technology.org/Proceedings/HVTT%2010/Papers/Papers_HVTT/DESIGN%20CONCEPT%20FOR%20AN%20ALTERNATIVE%20HEAVY%20VEHICLE%20SLIP%20CONTROL%20BRAKE%20ACTUATOR%20-%20Miller.pdf (accessed on 29 May 2017).

- Schramm, H.; Stumpe, W. Anti-Lock Braking System (ABS) for Vehicles with an Additional Axle. U.S. Patent 020,030,130,781, 2 December 2002. [Google Scholar]

- Man, H.L.; Park, H.G.; Lee, S.H.; Kang, S.Y.; Lee, K.S. An adaptive cruise control system for autonomous vehicles. Int. J. Precis. Eng. Manuf. 2013, 14, 373–380. [Google Scholar]

- Krishnakumar, T.; Gireeshan, M.G. Anti-collision vehicles. Int. J. Pharm. Technol. 2015, 7, 8415–8418. [Google Scholar]

- Shafik, M.; Ijeh, I.C. An Intelligent Anti-Collision System for Electric Vehicle Industrial Applications. In Proceedings of the International Conference on Manufacturing Research, Loughborough, UK, 6–8 September 2016. [Google Scholar]

- Zungeru, A.M. Development of an Anti-collision Model for Vehicles. Int. J. Embed. Syst. Appl. 2012, 2, 21–34. [Google Scholar] [CrossRef]

- Hsu, T.H.; Liu, J.F.; Yu, P.N.; Lee, W.S. Development of an automatic parking system for vehicle. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Daza, I.G.; Bergasa, L.M.; Bronte, S.; Yebes, J.J.; Almazán, J.; Arroyo, R. Fusion of optimized indicators from Advanced Driver Assistance Systems (ADAS) for driver drowsiness detection. Sensors 2014, 14, 1106. [Google Scholar] [CrossRef] [PubMed]

- Durekovic, S.; Smith, N. Architectures of Map-Supported ADAS. In Proceedings of the Intelligent Vehicles Symposium, Baden-Baden, Germany, 5–9 June 2011; pp. 207–211. [Google Scholar]

- Lu, M.; Wevers, K.; Heijden, R.V.D. Technical Feasibility of Advanced Driver Assistance Systems (ADAS) for Road Traffic Safety. Transp. Plann. Technol. 2005, 8, 167–181. [Google Scholar] [CrossRef]

- Marchau, V.; Wiethoff, M.; Penttinen, M.; Molin, E. Stated preferences of European drivers regarding advanced driver assistance systems (ADAS). Eur. J. Transp. Infrastruct. Res. 2001, 43, 825–831. [Google Scholar]

- Nejad, H.T.N.; Do, Q.H.; Sakai, R.; Han, L. Real time localization, path planning and motion control for autonomous parking in cluttered environment with narrow passages. In Proceedings of the International IEEE Conference on Intelligent Transportation Systems, Anchorage, AK, USA, 16–19 September 2012; pp. 1357–1364. [Google Scholar]

- Tagne, G.; Talj, R.; Charara, A. Higher-order sliding mode control for lateral dynamics of autonomous vehicles, with experimental validation. In Proceedings of the Intelligent Vehicles Symposium, Gold Coast, QLD, Australia, 23–26 June 2013; pp. 678–683. [Google Scholar]

- Tagne, G.; Talj, R.; Charara, A. Design and validation of a robust immersion and invariance controller for the lateral dynamics of intelligent vehicles. Control Eng. Pract. 2015, 40, 81–92. [Google Scholar] [CrossRef]

- Takezawa, S.; Gulrez, T.; Herath, D.C.; Dissanayake, G. Environmental Recognition for Autonomous Robot using Simultaneous Localization and Map Building (SLAM) (Real Time Path Planning with Dynamical Localized Voronoi Division). Trans. Jpn. Soc. Mech. Eng. 2005, 71, 904–911. [Google Scholar] [CrossRef]

- Wang, X.; Fu, M.; Yang, Y.; Ma, H. Lateral Control of Autonomous Vehicles Based on Fuzzy Logic. In Proceedings of the Control and Decision Conference, Guiyang, China, 25–27 May 2013; pp. 237–242. [Google Scholar]

- Marino, R.; Tomei, P. Nonlinear Control Design: Gemetric, Adaptive and Robust; Prentice Hall International (UK) Ltd.: Hertfordshire, UK, 1995. [Google Scholar]

- Guo, L.; Feng, C. Robust H∞ controller design for a class of uncertain systems. Sci. China Technol. Sci. 1998, 41, 208–214. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M. Intelligent mixed H2/H∞ adaptive tracking control system design using self-organizing recurrent fuzzy-wavelet-neural-network for uncertain two-axis motion control system. Appl. Soft Comput. 2016, 41, 22–50. [Google Scholar] [CrossRef]

- Netto, M.S.; Chaib, S.; Mammar, S. Lateral adaptive control for vehicle lane keeping. In Proceedings of the American Control Conference, Boston, MA, USA, 30 June–2 July 2004; Volume 2693, pp. 2693–2698. [Google Scholar]

- Park, S.; Rakha, H.A.; Ahn, K.; Moran, K.; Saerens, B.; Bulck, E.V.D. Predictive Eco-cruise Control System: Model Logic and Preliminary Testing. Transp. Res. Rec. J. Transp. Res. Board 2012, 2270, 113–123. [Google Scholar] [CrossRef]

- Minorsky, N. Directional Stability of Automatically Steered Bodies. J. Am. Soc. Nav. Eng. 1922, 34, 280–309. [Google Scholar] [CrossRef]

- Jiao, J.; Chen, W.W.; Shao-Wen, L.I.; Wang, J.X. Self-adaptive PID control for intelligent vehicle steering system based on IPSO. J. Anhui Univ. 2008, 29, 1325–1327. [Google Scholar]

- Yamamoto, T.; Takao, K. Design and Experimental Evaluation of a Data-Driven PID Controller. IFAC Proc. Vol. 2010, 40, 391–396. [Google Scholar]

- Solea, R.; Filipescu, A.; Filipescu, S.; Dumitrascu, B. Sliding-mode controller for four-wheel-steering vehicle: Trajectory-tracking problem. In Proceedings of the Intelligent Control and Automation, Jinan, China, 7–9 July 2010; pp. 1185–1190. [Google Scholar]

- Yang, J.; Ma, R.; Zhang, Y.; Zhao, C. Sliding Mode Control for Trajectory Tracking of Intelligent Vehicle. Phys. Procedia 1999, 15, 578–587. [Google Scholar] [CrossRef]

- Economou, J.T.; Colyer, R.E.; Tsourdos, A.; White, B.A. Fuzzy logic approaches for wheeled skid-steer vehicles. In Proceedings of the 2002 IEEE Vehicular Technology Conference, Vancouver, BC, Canada, 24–28 September 2002; Volume 992, pp. 990–994. [Google Scholar]

- Ashraf, M.A.; Takeda, J.I.; Torisu, R. Neural Network Based Steering Controller for Vehicle Navigation on Sloping Land. Eng. Agric. Environ. Food 2010, 3, 100–104. [Google Scholar] [CrossRef]

- Rodrigo, H.A.; Govinda, G.V.L.; Tomás, S.J.; Alfonso, G.E.; Fernando, F.N. Neural Network-Based Self-Tuning PID Control for Underwater Vehicles. Sensors 2016, 16, 1429. [Google Scholar]

- Rout, R.; Subudhi, B. Inverse optimal self-tuning PID control design for an autonomous underwater vehicle. Int. J. Syst. Sci. 2016, 48, 367–375. [Google Scholar] [CrossRef]

- Aslam, J.; Qin, S.Y.; Alvi, M.A. Fuzzy sliding mode control algorithm for a four-wheel skid steer vehicle. J. Mech. Sci. Technol. 2014, 28, 3301–3310. [Google Scholar] [CrossRef]

- Dong, H.F.; Li, F.; Gao, Q.J.; Dong, B.L. Research on Intelligent Vehicle Steering System via Improved Fuzzy-PID Control Method Based on RSDA. Appl. Mech. Mater. 2012, 220–223, 958–963. [Google Scholar] [CrossRef]

- Kau, S.W.; Lee, H.J.; Yang, C.M.; Lee, C.H.; Hong, L.; Fang, C.H. Robust H∞ fuzzy static output feedback control of T-S fuzzy systems with parametric uncertainties. Fuzzy Sets Syst. 2007, 158, 135–146. [Google Scholar] [CrossRef]

- Zhenhai, G.; Bo, Z. Vehicle lane keeping of adaptive PID control with BP neural network self-tuning. In Proceedings of the Intelligent Vehicles Symposium, Las Vegas, NV, USA, 6–8 June 2005; pp. 84–87. [Google Scholar]

- Zhang, G.D.; Yang, X.H.; Lu, D.Q.; Liu, Y.X. Research on Pressurizer Pressure Control System Based on BP Neural Network Control of Self-Adjusted PID Parameters. Appl. Mech. Mater. 2013, 294, 2416–2423. [Google Scholar] [CrossRef]

- Han, G.; Fu, W.; Wang, W. The Study of Intelligent Vehicle Navigation Path Based on Behavior Coordination of Particle Swarm. Comput. Intell. Neurosci. 2016, 2016, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Han, G.; Fu, W.; Hao, D.; Wang, W. Research on Intelligent Vehicle Motion Planning Method Based on Behavior Dynamics. Mech. Sci. Technol. Aerosp. Eng. 2015, 34, 301–306. [Google Scholar]

- You, F.; Wang, R.B.; Zhang, R.H. Study of System Identification and Control Algorithm for Intelligent Vehicle. China J. Highw. Transp. 2008, 125, 749–752. [Google Scholar]

- Wang, X.; Ding, F. Performance analysis of the recursive parameter estimation algorithms for multivariable Box–Jenkins systems. J. Frankl. Inst. 2014, 351, 4749–4764. [Google Scholar] [CrossRef]

- Zhang, K.; Cui, S.M.; Wang, J.F. Intelligent vehicle’s path tracking control based on self-adaptive RBF network compensation. Kongzhi Yu Juece/Control Decis. 2014, 29, 627–631. [Google Scholar]

| Sign | Meaning | Value | Unit |

|---|---|---|---|

| L × D × H | Vehicle size | 3600 × 1600 × 1700 | mm × mm × mm |

| Road friction coefficient | 2 | ||

| Vehicle Mass | 1100 | kg | |

| Yaw moment of inertia | 2850 | kg m2 | |

| Front axle-COG distance | 1.15 | m | |

| Rear axle-COG distance | 1.05 | m | |

| Cornering stiffness of the front tire | 32000 | N/rad | |

| Cornering stiffness of the real tire | 32000 | N/rad | |

| Vehicle | ≤60 | km/h |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, G.; Fu, W.; Wang, W.; Wu, Z. The Lateral Tracking Control for the Intelligent Vehicle Based on Adaptive PID Neural Network. Sensors 2017, 17, 1244. https://doi.org/10.3390/s17061244

Han G, Fu W, Wang W, Wu Z. The Lateral Tracking Control for the Intelligent Vehicle Based on Adaptive PID Neural Network. Sensors. 2017; 17(6):1244. https://doi.org/10.3390/s17061244

Chicago/Turabian StyleHan, Gaining, Weiping Fu, Wen Wang, and Zongsheng Wu. 2017. "The Lateral Tracking Control for the Intelligent Vehicle Based on Adaptive PID Neural Network" Sensors 17, no. 6: 1244. https://doi.org/10.3390/s17061244