A Smart Power Electronic Multiconverter for the Residential Sector

Abstract

:1. Introduction

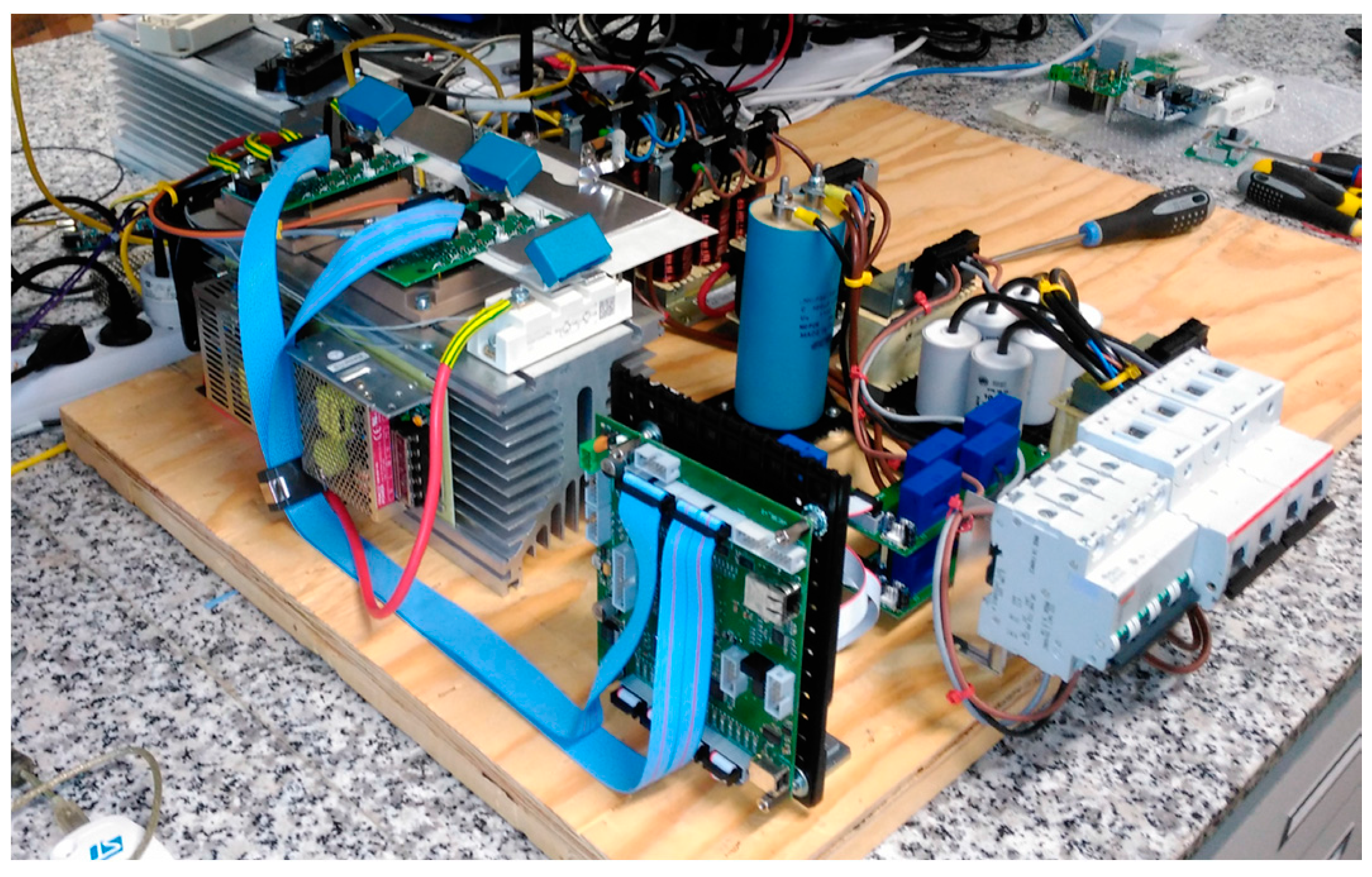

- the proposal of a general-purpose robust and compact multiconverter system, designed for smart grid applications. It includes one renewable energy source and up to two energy storage elements which can be controlled independently or cooperatively. A 3 kVA three-phase multiconverter laboratory prototype has been built for experimental tests. The design of the measurement stage is described in detail.

- the application of the multiconverter system to a local energy unit installed in homes of a smart community operating according to the active power set-points received from the community EMS.

- the validation by simulation and experimental tests of the proper operation of the multiconverter in the proposed residential sector application.

- the performance of this multiconverter presents several improvements compared with traditional converters, such as:

- -

- tracking an active power set-point, demanding or injecting into the community grid sinusoidal and balanced currents although the grid voltage is distorted or unbalanced,

- -

- energy storage based on a hybrid configuration, composed by batteries and supercapacitors, managed cooperatively in order to improve the efficiency and extend the lifetime of the storage elements,

- -

- integration into a common platform equipped with real-time communication systems of a local power unit capable of adapting MPPT PV generation, hybrid storage and consumption following instantaneous set-points sent by the EMS of the community.

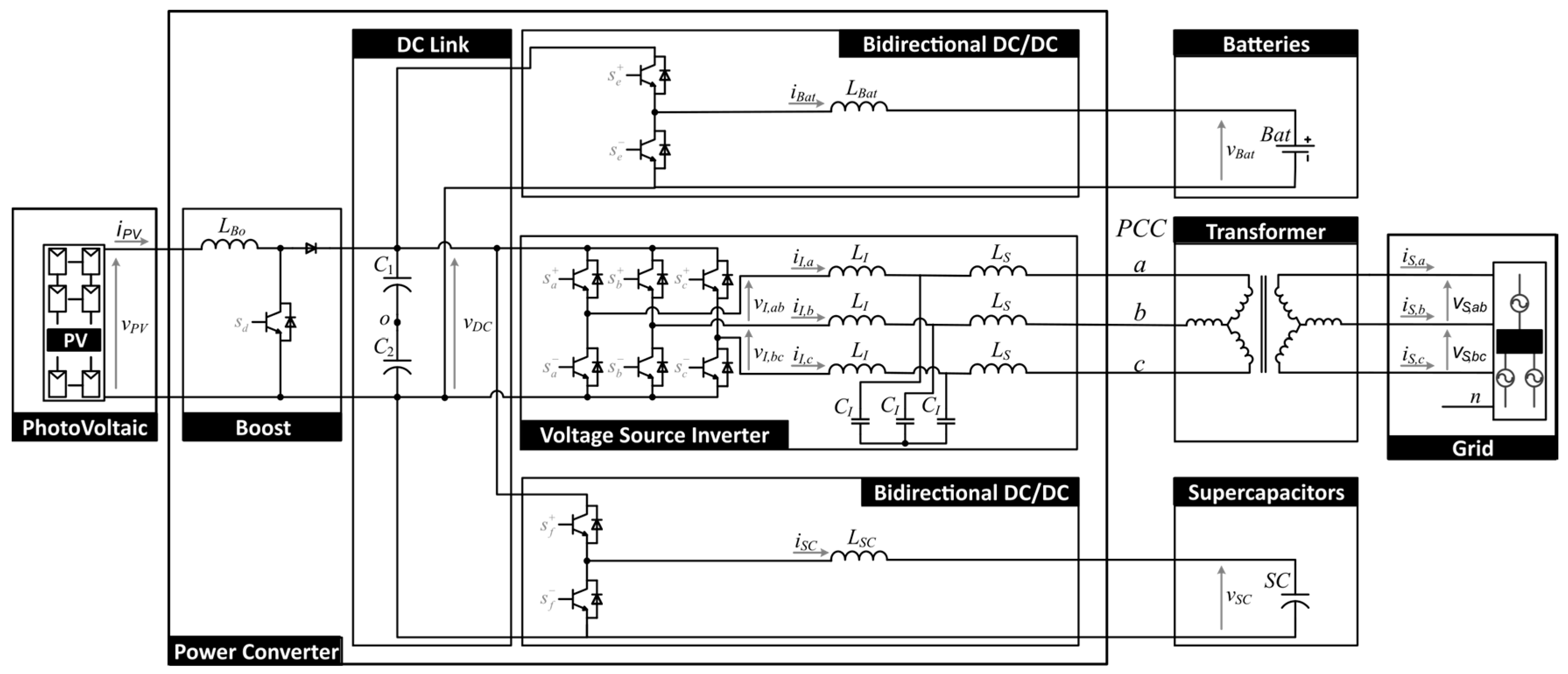

2. Topology of the Multiconverter System

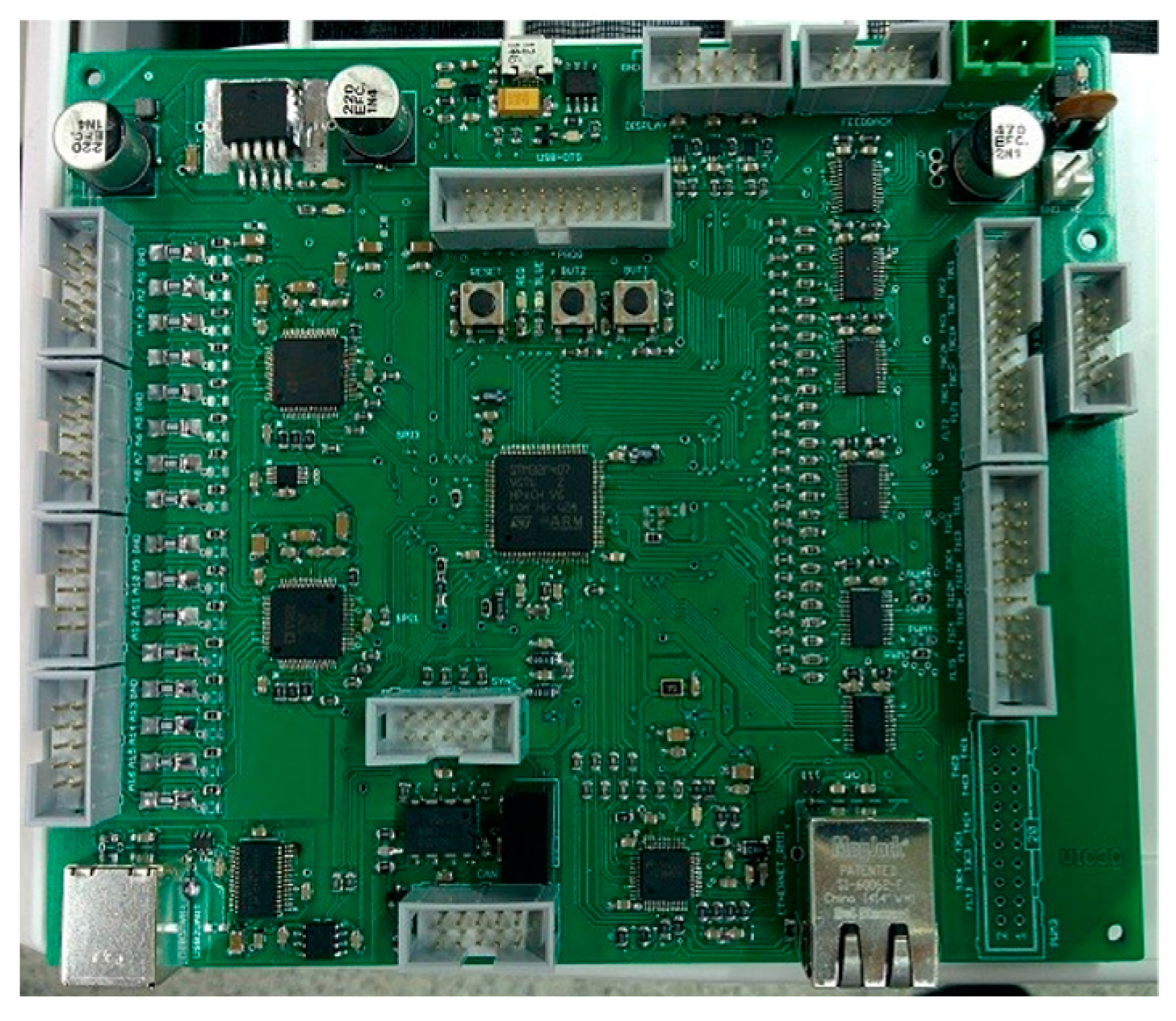

3. Control System: Control Board and Measurement Stage

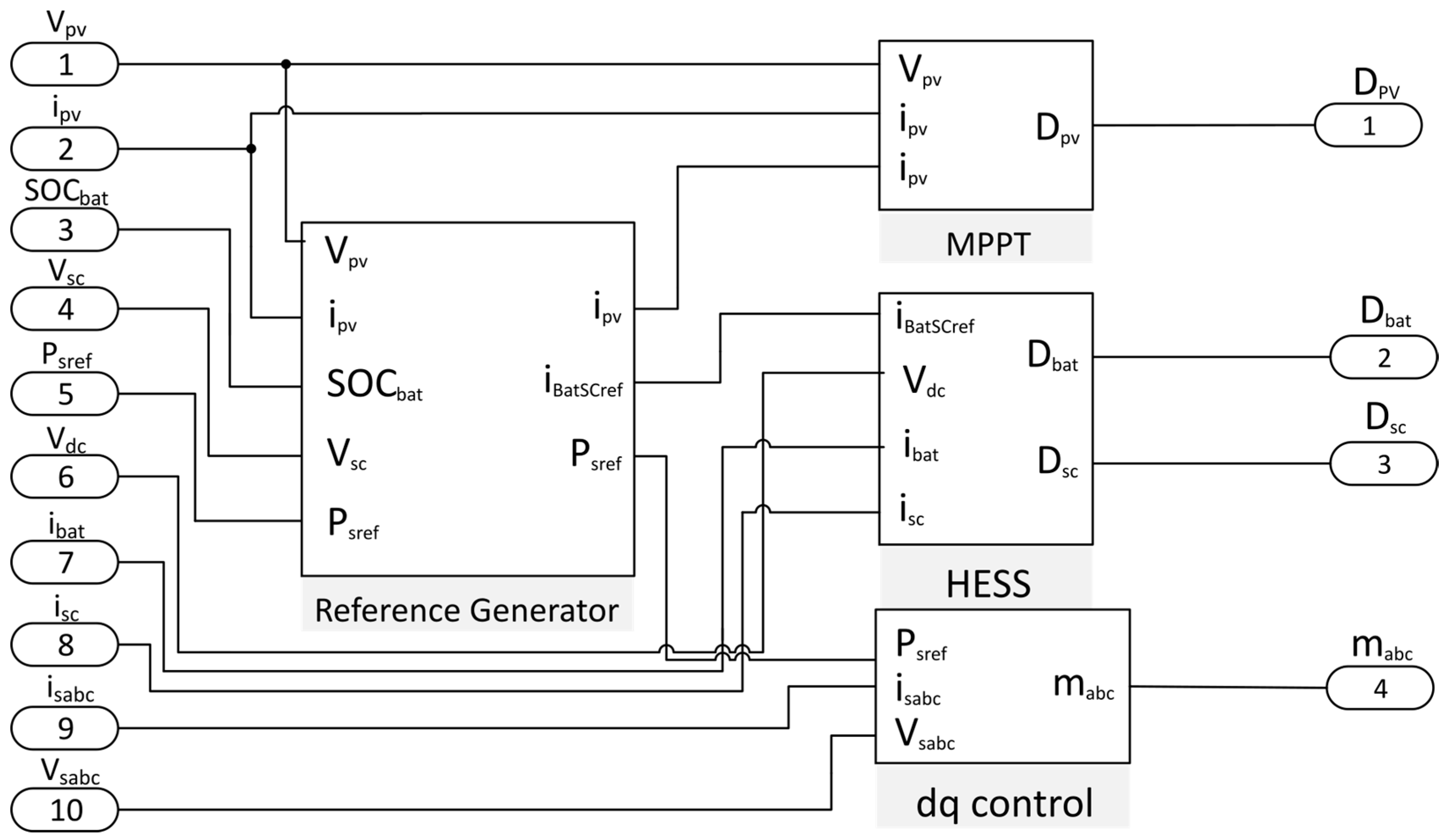

4. Control Algorithm

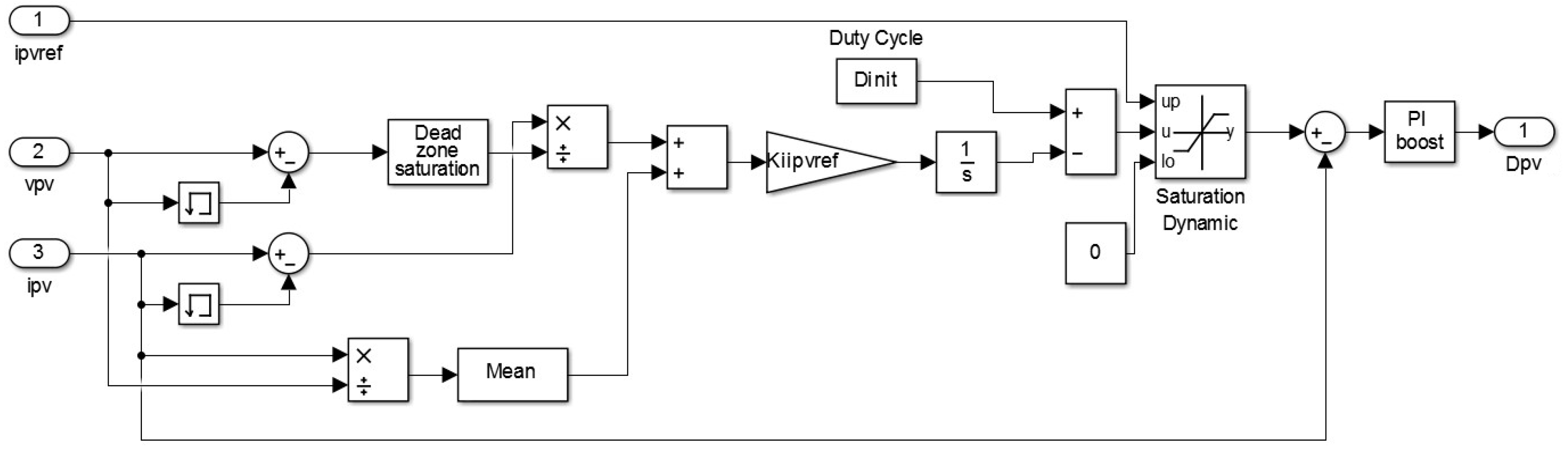

4.1. MPPT Control Logic

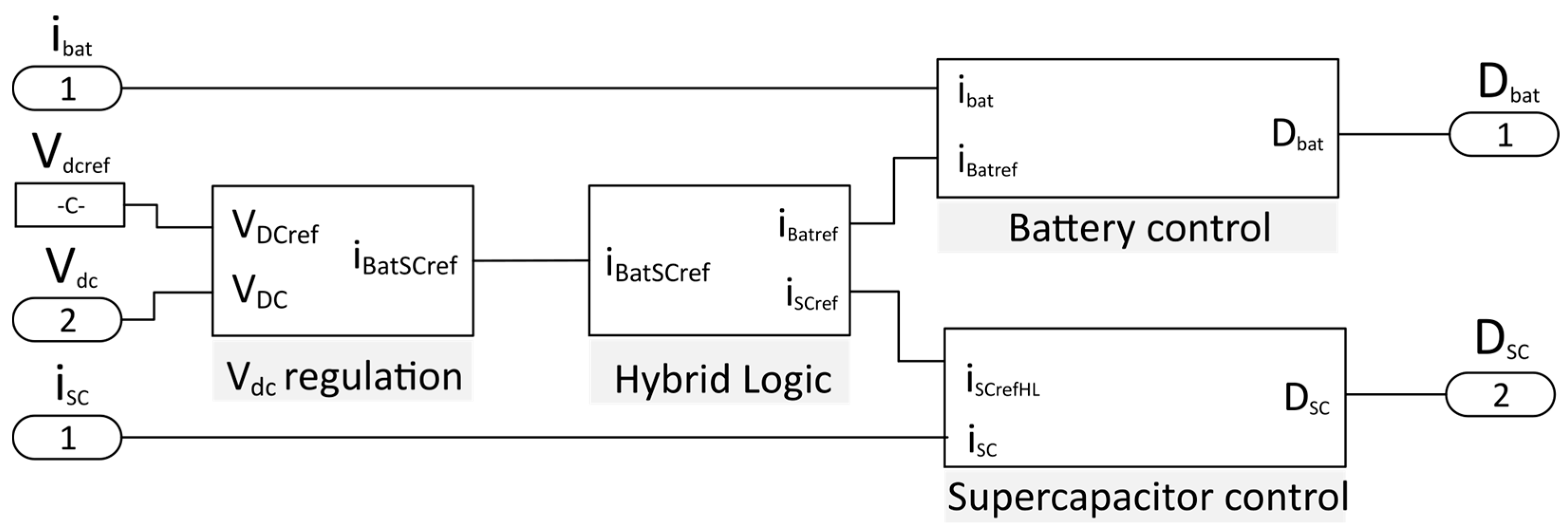

4.2. HESS Control

4.3. d-q Inverter Control

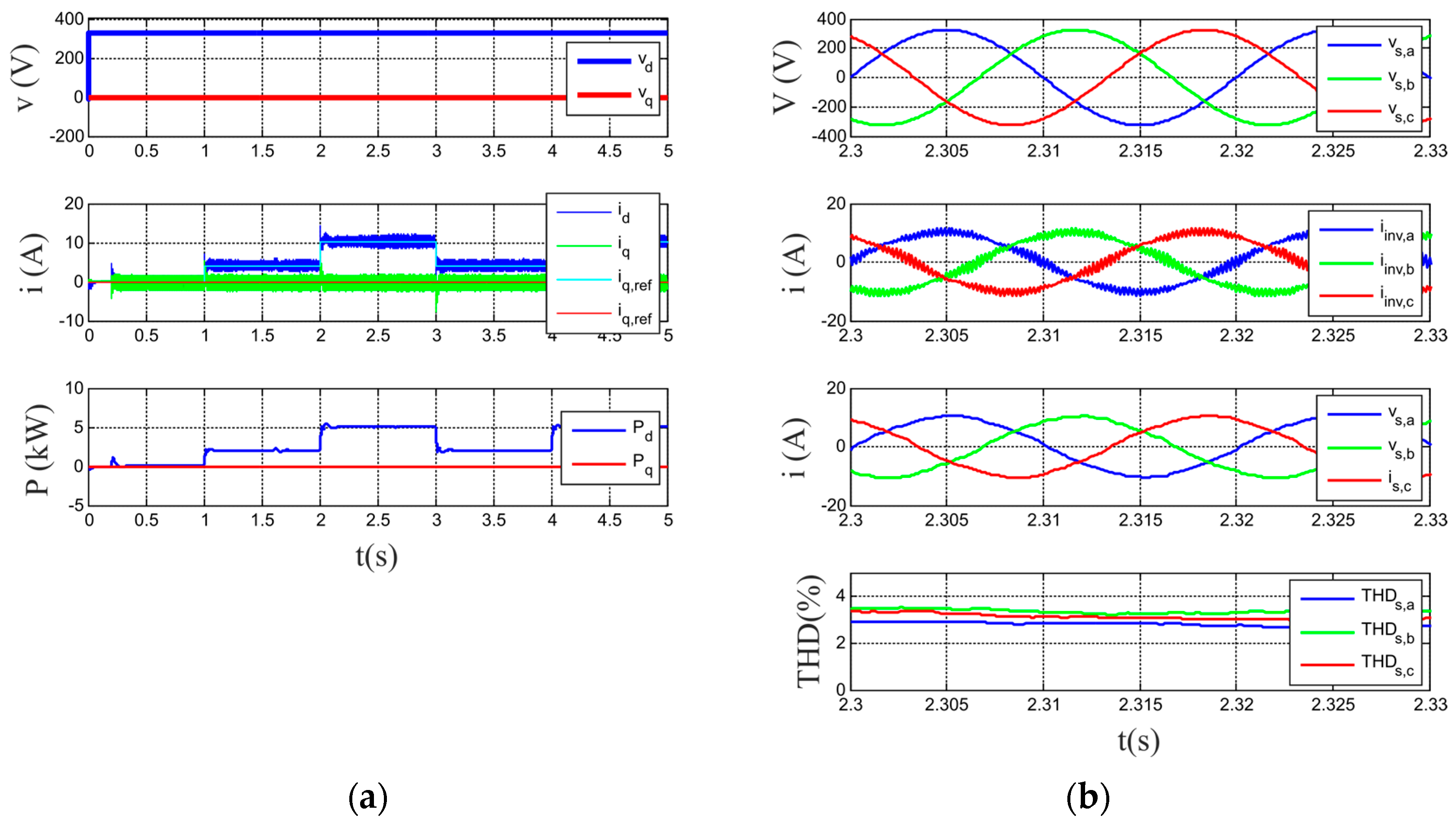

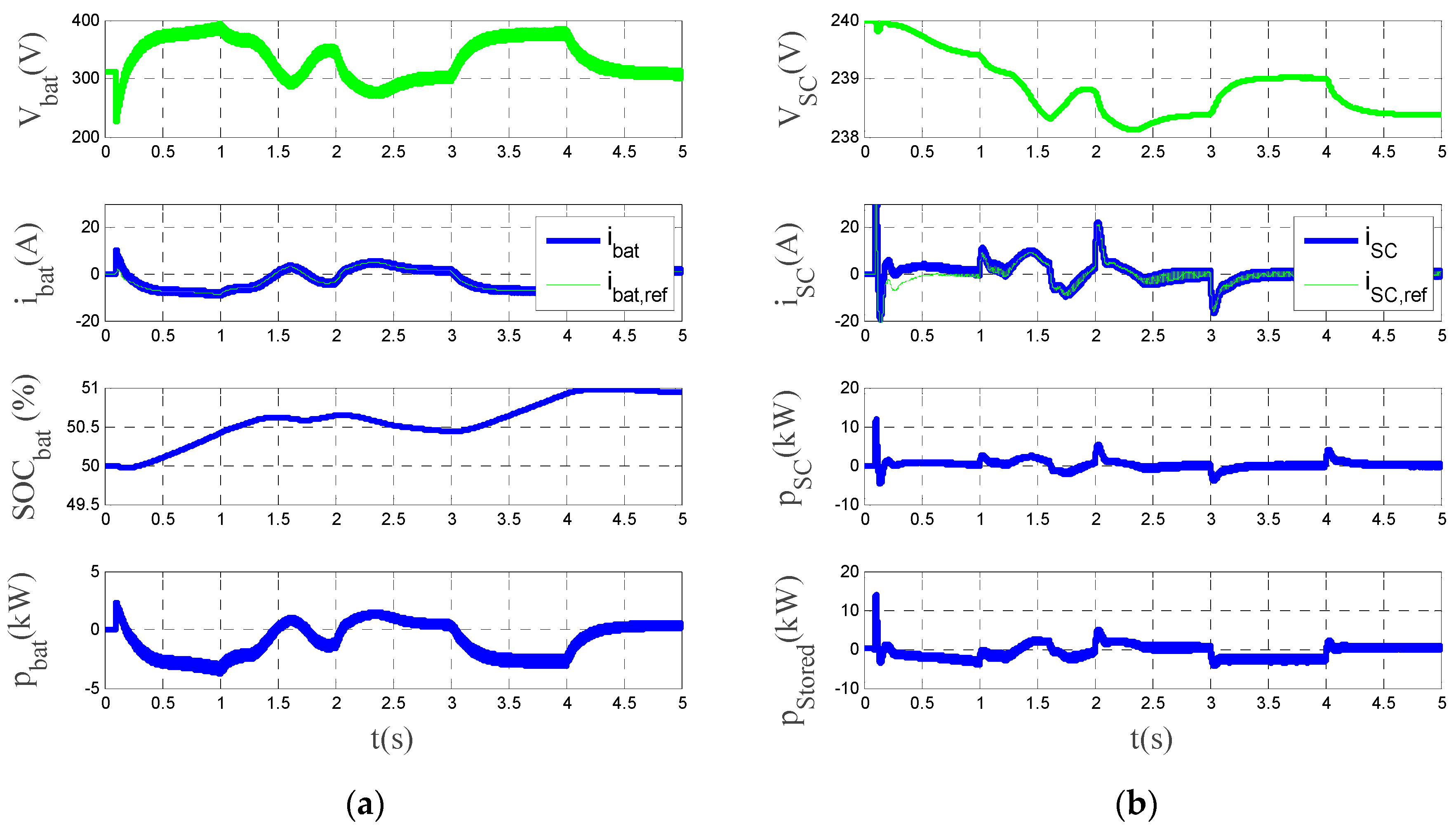

5. Simulation Analysis

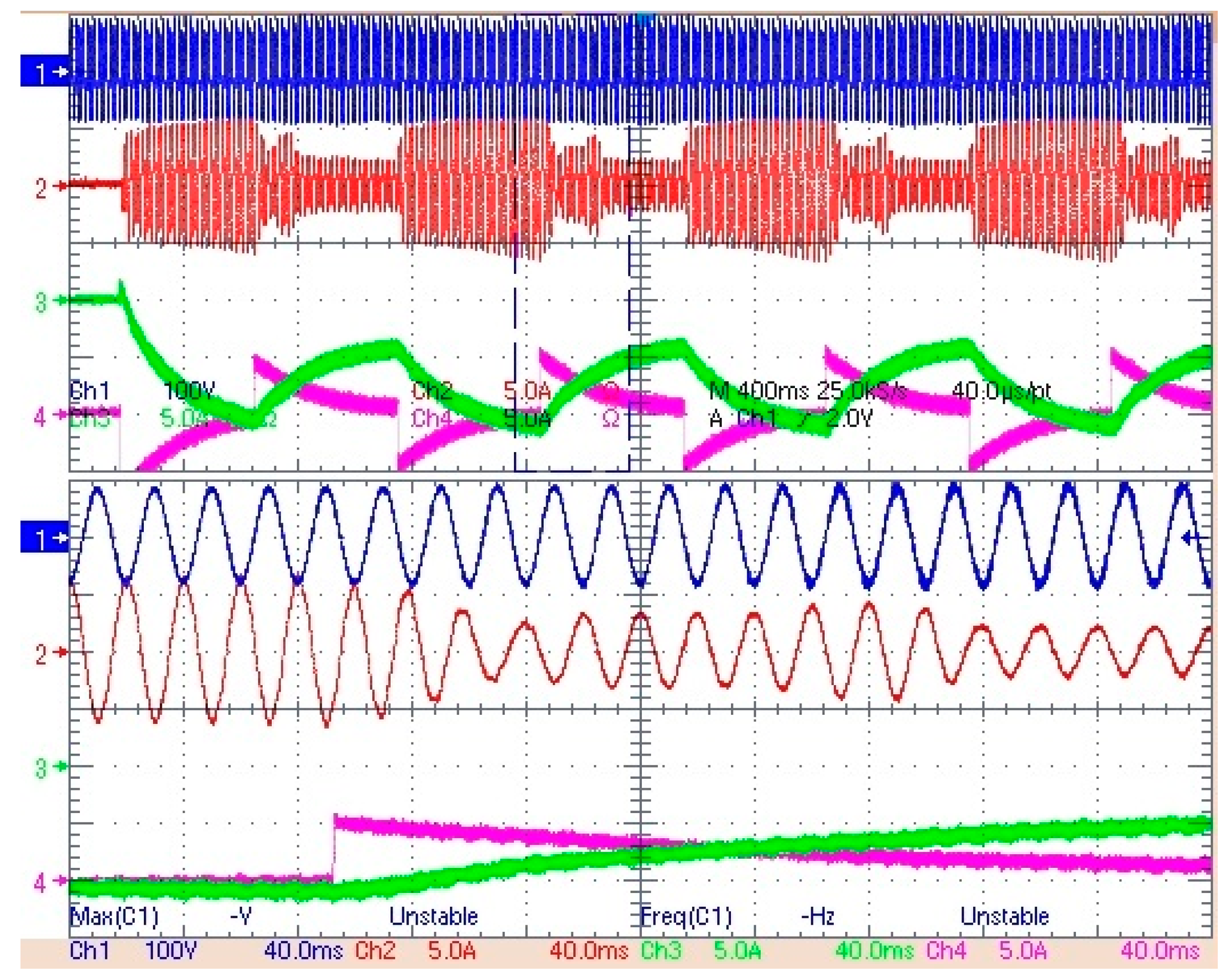

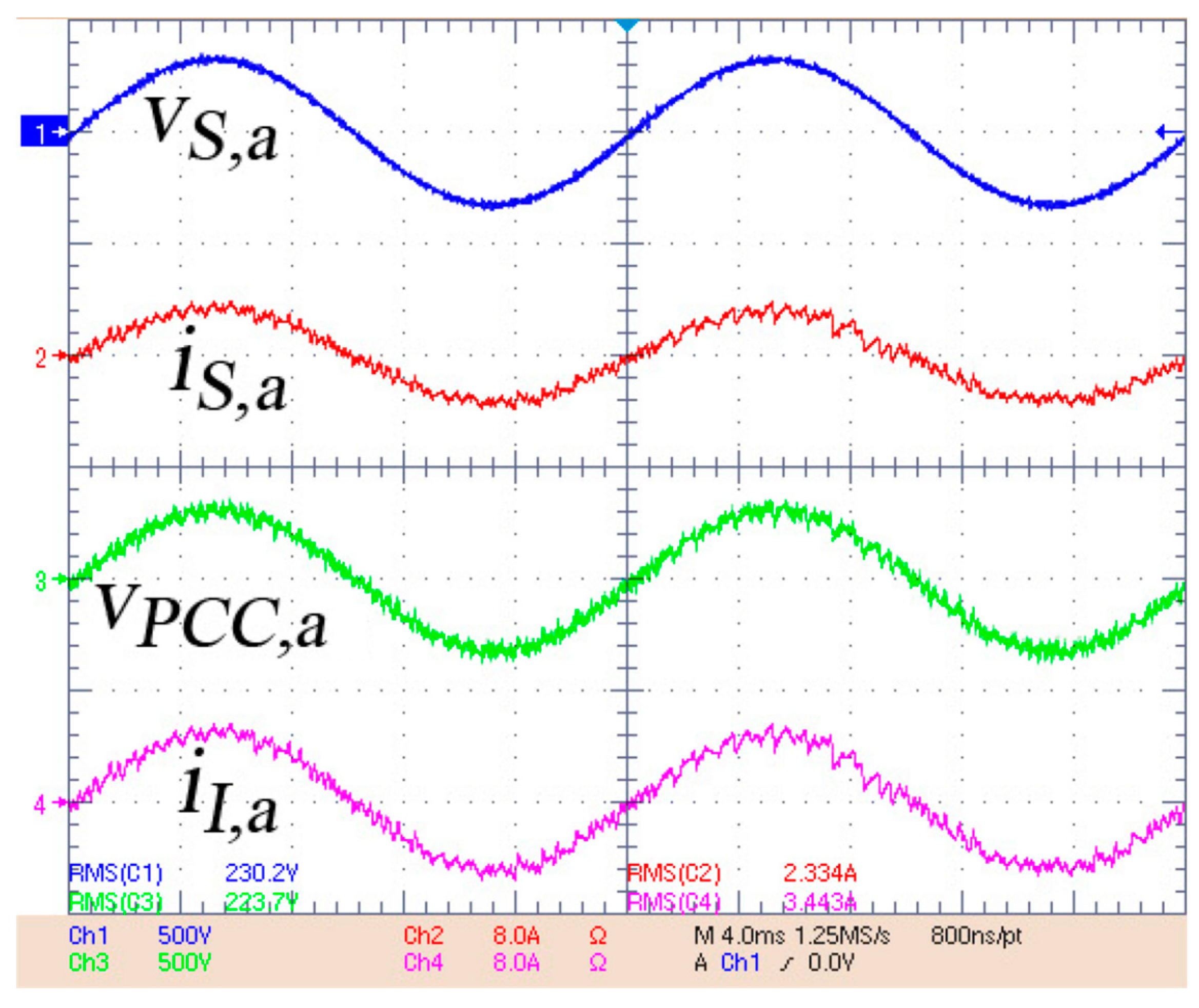

6. Experimental Results

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| , | DC link capacitors |

| Inverter output filter capacitors | |

| Boost converter duty cycle | |

| DC/DC supercapacitor converter duty cycle | |

| DC/DC battery converter duty cycle | |

| DC/DC battery converter inductance | |

| Boost converter inductance | |

| Inverter output filter inductances (inverter side) | |

| Inverter output filter inductances (grid side) | |

| DC/DC supercapacitor converter inductance | |

| Battery power | |

| PV module power | |

| Super-capacitor power | |

| Total HESS power | |

| Reference active power set-point | |

| ; ; ; ; ; | Inverter switching signals |

| Boost converter switching signal | |

| ; | DC/DC battery converter switching signals |

| ; | DC/DC supercapacitor converter switching signals |

| Battery current | |

| ; ; | Inverter output currents |

| PV module current | |

| ; ; | Grid currents |

| Supercapacitor converter current | |

| Inverter duty cycle | |

| Battery voltage | |

| DC link voltage reference value | |

| DC link voltage | |

| ; ; | Inverter output voltages |

| PV module voltage | |

| ; ; | Grid Voltages |

| Supercapacitor voltage | |

| Low-pass filter time constant |

References

- World Energy Outlook 2013. Available online: worldenergyoutlook.org (accessed on 12 November 2013).

- Renewables to Surpass Gas by 2016 in the Global Power Mix. Available online: iea.org (accessed on 26 June 2013).

- SmartGrids: European Technology Platform. Available online: www.smartgrids.eu (accessed on 18 July 2016).

- Etherden, N.; Bollen, M.H. Increasing the hosting capacity of distribution networks by curtailment of renewable energy resources. In Proceedings of the 2011 IEEE Trondheim PowerTech, Trondheim, Norway, 19–23 June 2011; pp. 1–7. [Google Scholar]

- Pepermans, G.; Driesen, J.; Haeseldonckx, D.; Belmans, R.; D’haeseleer, Y.W. Distributed Generation: Definition, Benefits and Issues. Energy Policy 2005, 33, 787–798. [Google Scholar] [CrossRef]

- Dugan, C.; McDermott, T.E.; Ball, G.J. Planning for distributed generation. IEEE Ind. Appl. Mag. 2001, 7, 80–88. [Google Scholar] [CrossRef]

- Dugan, R.C.; Price, S.K. Including distributed resources in distribution planning. In Proceedings of the IEEE PES Power Systems Conference Exposition, New York, NY, USA, 10–13 October 2004; pp. 1694–1698. [Google Scholar]

- Koutsopoulos, I.; Hatzi, V.; Tassiulas, L. Optimal energy storage control policies for the smart power grid. In Proceedings of the IEEE SmartGridComm, Brussels, Belgium, 17–20 October 2011; pp. 475–480. [Google Scholar]

- Rahbar, K.; Xu, J.; Zhang, R. Real-time energy storage management for renewable integration in microgrids: An off-line optimization approach. IEEE Trans. Smart Grid 2015, 6, 124–134. [Google Scholar] [CrossRef]

- Ackermann, T.; Knyazkin, V. Interactionof distributed generation and the distribution network: Operation aspects. In Proceedings of the PES T&D Asia Pacific Conference, Yokohama, Japan, 6–10 October 2002; Volume 2, pp. 1357–1362. [Google Scholar]

- Lui, T.J.; Stirling, W.; Marcy, H.O. Get Smart. IEEE Power Energy Mag. 2010, 8, 66–78. [Google Scholar] [CrossRef]

- Majstrovic, G. Electricity Transmission and Distribution Network; European Energy Institute: Florence, Italy, June–July 2009. [Google Scholar]

- Güngör, V.C.; Sahin, D.; Kocak, T.; Ergüt, S.; Buccella, C.; Cecati, C.; Hancke, G.P. Smart grid technologies: Communication technologies and standards. IEEE Trans. Ind. Inform. 2011, 7, 529–539. [Google Scholar]

- Shadmand, M.B.; Balog, R.S. Multi-objective optimization and design of photovoltaic-wind hybrid system for community smart DC microgrid. IEEE Trans. Smart Grid 2014, 5, 2635–2643. [Google Scholar] [CrossRef]

- Tushar, M.H.K.; Assi, C. Distributed Real-Time Electricity Allocation Mechanism for Large Residential Microgrid. IEEE Trans. Smart Grid 2015, 6, 1353–1363. [Google Scholar] [CrossRef]

- Tian, P.; Xiao, X.; Wang, K.; Ding, R. A hierarchical energy management system based on hierarchical optimization for microgrid community economic operation. IEEE Trans. Smart Grid. 2016, 7, 2230–2241. [Google Scholar] [CrossRef]

- Tushar, W.; Chai, B.; Yuen, C.; Huang, S.; Smith, D.B.; Poor, H.V.; Yang, Z. Energy storage sharing in smart grid: A modified auction-based approach. IEEE Trans. Smart Grid 2016, 7, 1462–1475. [Google Scholar] [CrossRef]

- Tushar, W.; Chai, B.; Yuen, C.; Smith, D.B.; Wood, K.L.; Yang, Z.; Poor, H.V. Three-party energy management with distributed energy resources in smart grid. IEEE Trans. Ind. Electron. 2015, 62, 2487–2498. [Google Scholar] [CrossRef]

- Mediwaththe, C.P.; Stephens, E.R.; Smith, D.B.; Mahanti, A. A dynamic game for electricity load management in neighborhood area networks. IEEE Trans. Smart Grid 2016, 7, 1329–1336. [Google Scholar] [CrossRef]

- Croce, D.; Giuliano, F.; Tinnirello, I.; Galatioto, A.; Bonomolo, M.; Beccali, M.; Zizzo, G. Overgrid: A fully distributed demand response architecture based on overlay networks. IEEE Trans. Autom. Sci. Eng. 2017, 14, 471–481. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Adinolfi, G.; Graditi, G.; Saretta, E. Photovoltaics in Net Zero Energy Buildings and Clusters: Enabling the smart city operation. Energy Procedia 2014, 61, 1171–1174. [Google Scholar] [CrossRef]

- Wang, G.; Ciobotaru, M.; Agelidis, V.G. Power smoothing of large solar PV plant using hybrid energy storage. IEEE Trans. Sustain. Energy 2014, 5, 834–842. [Google Scholar] [CrossRef]

- Abeywardana, D.B.W.; Hredzak, B.; Agelidis, V.G. Single-phase grid-connected lifepo4 battery–supercapacitor hybrid energy storage system with interleaved boost inverter. IEEE Trans. Power Electron. 2015, 30, 5591–5604. [Google Scholar] [CrossRef]

- Choudar, A.; Boukhetala, D.; Barkat, S.; Brucker, J. A local energy management of a hybrid PV-storage based distributed generation for microgrids. Energy Convers. Manag. 2015, 90, 21–33. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, P.; Setyawan, L. Multilevel energy management system for hybridization of energy storages in dc microgrids. IEEE Trans. Smart Grid 2016, 7, 847–856. [Google Scholar] [CrossRef]

- Jiang, W.; Zhang, L.; Zhao, H.; Huang, H.; Hu, R. Research on power sharing strategy of hybrid energy storage system in photovoltaic power station based on multi-objective optimization. IET Renew. Power Gener. 2016, 10, 575–583. [Google Scholar] [CrossRef]

- Wang, G.; Ciobotaru, M.; Agelidis, V. Power management for improved dispatch of utility-scale PV plants. IEEE Trans. Power Syst. 2016, 31, 2297–2306. [Google Scholar] [CrossRef]

- Roncero-Clemente, C.; Romero-Cadaval, E.; Roncero-Sanchez, P.; Gonzalez-Romera, E. Comparison of two power flow control strategies for photovoltaic inverters. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society (IECON), Montreal, QC, Canada, 25–28 October 2012; pp. 5167–5172. [Google Scholar]

- Esram, T.; Chapman, P.L. Comparison of photovoltaic array maximum power point tracking techniques. IEEE Trans. Energy Convers. 2007, 22, 439–449. [Google Scholar] [CrossRef]

- Cecati, C.; Khalid, H.; Tinari, M.; Adinolfi, G.; Graditi, G. DC nanogrid for renewable sources with modular DC/DC LLC converter building block. IET Power Electron. 2017, 10, 536–544. [Google Scholar] [CrossRef]

- Kuperman, A.; Aharon, I. Battery–ultracapacitor hybrids for pulsed current loads: A review. Renew. Sustain. Energy Rev. 2011, 15, 981–992. [Google Scholar] [CrossRef]

- Zandi, M.; Payman, A.; Martin, J.; Pierfederici, S.; Davat, B.; Meibody-Tabar, F. Energy management of a fuel cell/supercapacitor/battery power source for electric vehicular applications. IEEE Trans. Veh. Technol. February 2011, 60, 433–443. [Google Scholar] [CrossRef]

- Guerrero-Martínez, M.A.; Romero-Cadaval, E.; González, F.B.; Montero, M.I.M.; Romera, E.G. Supercapacitors: Alternative energy storage systems. Prz. Elektrotech. Electr. Rev. 2009, 85, 188–195. [Google Scholar]

- Kim, Y.; Raghunathan, V.; Raghunathan, A. Design and management of battery-supercapacitor hybrid electrical energy storage systems for regulation services. IEEE Trans. Multi-Scale Comput. Syst. 2017, 3, 12–24. [Google Scholar] [CrossRef]

- Jing, W.; Lai, C.H.; Wong, S.H.W.; Wong, M.L.D. Battery-supercapacitor hybrid energy storage system in standalone DC microgrids: A review. IET Renew. Power Gener. 2017, 11, 461–469. [Google Scholar] [CrossRef]

- Zhao, N.; Schofield, N.; Niu, W. Energy storage system for a port crane hybrid power-train. IEEE Trans. Transp. Electrification 2016, 2, 480–492. [Google Scholar] [CrossRef]

- Miñambres, V.; Milanés, M.I.; Vinagre, B.; Romero, E. Phase locked loop for distorted three-phase systems tested with a PI, a PID and a Fractional PI. Prz. Elektrotech. Electr. Rev. 2009, 85, 201–207. [Google Scholar]

- Miñambres-Marcos, V.; Guerrero-Martínez, M.Á.; Romero-Cadaval, E.; González-Castrillo, P. Grid-connected photovoltaic power plants for helping node voltage regulation. IET Renew. Power Gener. 2014, 9, 236–244. [Google Scholar] [CrossRef]

- Gallardo-Lozano, J.; Milanés-Montero, M.I.; Guerrero-Martínez, M.A.; Romero-Cadaval, E. Electric vehicle battery charger for smart grids. Electr. Power Syst. Res. 2012, 90, 18–29. [Google Scholar] [CrossRef]

- Hamza, K.A.E.; Linda, H.; Cherif, L. LCL filter design with passive damping for photovoltaic grid connected systems. In Proceedings of the 6th International Renewable Energy Congress (IREC), Sousse, Tunisia, 24–26 March 2015; pp. 1–4. [Google Scholar]

- Institute of Electrical and Electronics Engineers (IEEE). IEEE Std 1547: IEEE Standard for Interconnecting Distributed Resources with the Electric Power System; IEEE: Piscataway, New Jersey, USA, 28 July 2003. [Google Scholar]

- The International Electrotechnical Commission (IEC). IEC 61727 ed2.0: Photovoltaic (PV) Systems—Characteristics of the Utility Interface; IEC: Geneva, Switzerland, 2004. [Google Scholar]

| Current Transducers | Specification | Voltage Transducers |

|---|---|---|

| 0 ... ±100 A | Measuring range | 0 ... ±14 mA (10 mA/500 V) |

| 25 mA | Secondary nominal current rms | 25 mA |

| ±12 ... 15 V | Supply voltage | ±15 V (±5%) |

| 200 kHz | Frequency bandwith | 200 kHz |

| 2.5 kV rms | Isolation | 2.5 kV rms |

| 1:2000 | Conversion ratio | 2500:1000 |

| ±0.9% | Accuracy | ±0.9% |

| −40 °C ... 85 °C | Operating temperature | 0 °C ... 70 °C |

| Parameter | Value |

|---|---|

| PV nominal power | 5 kW |

| DC reference voltage | 720 V |

| Battery storage capacity | 3 kWh |

| Nominal battery voltage | 48 V |

| Supercapacitor storage capacity | 0.3 kWh |

| Supercapacitor equivalent circuit capacitance | 37.5 F |

| Low pass filter time constant | 0.2 s |

| PWM switching frequency | 5 kHz |

| Parameter | Value |

|---|---|

| C1, C2 | 2.2 mF |

| LBo | 10 mH |

| LBat | 20 mH |

| LSC | 20 mH |

| LI, CI, LS | 5 mH, 10 µF, 5 mH |

| PV Panels | HP E4351B Solar Array Simulator |

| Power Electronics | Fuji IGBT-IPM 6MBP50RA120 |

| Battery | Li-ion batteries BMZ energy storage 6.74 kWh (Li-Ion NMC) Nominal voltage 55.5 V, Charge end voltage 61.5 V, discharge end voltage 41.0 V, Maximum Charge 80 A, Maximum discharge 300 A, Full cycles 5000 |

| Supercapacitor | Maxwell BMOD0165 P048 B01 Rate capacitance 165 F, nominal voltage 48 V, Maximum Voltage 51 V, Maximum current 1900 A, Equivalent series resistance initial 6.3 mΩ |

| C1, C2 | 2.2 mF |

| LBo | 10 mH |

| LBat | 20 mH |

| LSC | 20 mH |

| LI, CI, LS | 5 mH, 10 µF, 5 mH |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerrero-Martinez, M.A.; Milanes-Montero, M.I.; Barrero-Gonzalez, F.; Miñambres-Marcos, V.M.; Romero-Cadaval, E.; Gonzalez-Romera, E. A Smart Power Electronic Multiconverter for the Residential Sector. Sensors 2017, 17, 1217. https://doi.org/10.3390/s17061217

Guerrero-Martinez MA, Milanes-Montero MI, Barrero-Gonzalez F, Miñambres-Marcos VM, Romero-Cadaval E, Gonzalez-Romera E. A Smart Power Electronic Multiconverter for the Residential Sector. Sensors. 2017; 17(6):1217. https://doi.org/10.3390/s17061217

Chicago/Turabian StyleGuerrero-Martinez, Miguel Angel, Maria Isabel Milanes-Montero, Fermin Barrero-Gonzalez, Victor Manuel Miñambres-Marcos, Enrique Romero-Cadaval, and Eva Gonzalez-Romera. 2017. "A Smart Power Electronic Multiconverter for the Residential Sector" Sensors 17, no. 6: 1217. https://doi.org/10.3390/s17061217