Before using the Trimble SX10 in various projects to investigate the geometric quality of the data it delivers, in this section some of its technical specifications are confronted to those of other instruments offering similar functionalities.

2.1. Overview of Image-Assisted and Scanning Total Stations

Despite the diversity of surveying instruments available to land surveyors, the total station is still a staple instrument in recording punctual and precise measurements. From the initial theodolites allowing the user to measure horizontal and vertical angles, to the instrument known as tacheometer or total station including an Electronic Distance Measurement (EDM) unit to record distances, the electronics have contributed to the improvement of hardware. Today total stations are moving towards robotic multi-sensor systems which combine ever more sophisticated functionalities. Thus the broad range of instruments available on the market may appear staggering, as described in the recent report in [

10]. Scherer and Lerma [

2] provide a comprehensive and thorough review about the historic and constant evolution of this technology, as also do [

11]. It shows that not only the EDM has evolved, allowing for example reflectorless distance measurements, but also the adjunction of built-in sensors has contributed to changing the hardware. In fact, most of the current total stations are robotic and motorized, achieving among other features the automatic recognition and tracking of reflector prisms or the remote steering of the device by the user. All these new functionalities offered by total stations have triggered further improvements and innovations in these surveying instruments.

Total stations which are equipped with one or more built-in digital camera(s) for targeting and steering operations are reported in the literature as Image-Assisted Total Stations (IATS), see for example [

2,

12,

13]. Even if the idea of combining theodolite and camera does not have a recent origin as explained in [

2], the first prototypes of a modern device combination were constructed in the 2000s. Prototypes applying this major improvement are described notably in projects from universities [

1,

12,

14,

15,

16]. While dealing with such an instrument, its calibration is highly important. Calibration models for the on-board cameras are described in [

12,

17,

18]. The calibration ensures the perfect coaxiality between the built-in camera and the telescope line of sight, so that the observed image corresponds to the targeted area containing the point to be measured. Ehrhart and Lienhart [

18] specifically analyze different error sources related to the use of an IATS as well as their impact on experimental geodetic network measurements.

More recently a few manufacturers of surveying instruments have introduced scanning functions into their total station hardware. This innovation was driven by the generalized use of TLS in surveying activities, and made possible by the combination of instrument motorization and reflectorless distance measurement. First releases of such modern total stations offer some pre-built scanning modules such as line or grid scanning. This is the case of the Topcon Imaging Station series launched on the market in 2008 and illustrated by the Topcon IS-3 [

19] in

Table 1. In addition to imaging facilities and the possible creation of 360° panoramas, this instrument also offers simple scanning functions with a measuring rate lower than 20 points per second. This means that points are captured in a defined window area along a grid interval specified by the user, but without user intervention during measurements and in particular no need to aim at each individual point.

There is quite a significant gap between scanning rates of total stations such as the previous Trimble VX Spatial Station or more recently Trimble S9 (Trimble Inc., Sunnyvale, CA, USA) (15 pts/s) but also Topcon IS-3 (Topcon Positioning Systems Inc., Livermore, CA, USA) (20 pts/s, see

Table 1), and scanning rates of current TLS which are able to capture millions of points a second. This gap was slightly reduced as Leica introduced its Nova series total stations. The Leica Nova MS50 (Leica Geosystems, Heerbrugg, Switzerland) was launched in 2013 and a new release called Leica MS60 has been marketed since 2015 [

20]. They present the same scanning speed of about 1000 points per second as indicated in

Table 1. The very latest release of Trimble SX10 in October 2016 shows a promising improvement since it offers an increased scanning rate of 26,600 points per second [

9]. Further specifications of Topcon IS-3 (Topcon Positioning Systems Inc., Livermore, CA, USA), Leica MS60 (Leica Geosystems, Heerbrugg, Switzerland) and Trimble SX10 (Trimble Inc., Sunnyvale, CA, USA) are listed in

Table 1. Besides, because the capability of total stations to feature scanning facilities is a quite recent improvement, the names given by manufacturers or stated in the literature for this technology can vary. Leica often calls its instruments of Nova series

multi-stations, whereas Trimble refers to SX10 device as a

scanning total station. Since the second acronym is more general, it will be used in the remaining parts of this article to refer to this technology.

Wagner [

13] presents the specifications of two other modern total stations in a table similar to

Table 1. When having a look at these two tables, it appears that all major surveying instrument manufacturers (Leica, Trimble and Topcon among others) currently develop IATS which integrate some scanning functions. Nevertheless regarding scanning specifications and more particularly the scanning rate, one can say that actually only Leica MS50 or MS60 and Trimble SX10 total stations are capable of efficient scanning. A big advantage of these devices is the possibility to measure all point coordinates in a same unique reference system. It should be noticed that, nowadays, the high difference of scanning rate between scanning total stations and TLS is mainly due to the mass of the total station telescope that has to be moved during the scanning process [

2,

13]. The considerably higher measuring speed of Trimble SX10 compared to Leica MS60 is due to the absence of telescope on the SX10 device, which is one of the most original features of this instrument. Since most of the total station users are used to manually aiming by looking through a telescope, this is a daring decision of the manufacturer which clearly benefits the scanning rate. As explained later in

Section 3.1, the telescope functionality is replaced by the presence of cameras and the use of a remote controller shown in the corresponding picture in

Table 1.

2.2. Related Work

A literature review shows that IATS and scanning total stations have been adopted in several fields which usually apply conventional tacheometry. The advantages related to the use of modern devices is often underlined in these papers. Unfortunately most of the time contributions do not focus on the assessment of the devices but rather on their use in specific case studies, except when considering contributions related to prototypes of IATS. This is even more true for scanning total stations which were released later on. Besides, it appears that scanning total stations are sometimes only applied for the cameras they contain. In the following subsection an overview of contributions from different application fields using IATS and scanning total stations is proposed. It mainly encompasses contributions where the devices of

Table 1 were used.

A first application field where the results are promising deals with the monitoring of civil engineering structures. Examples of bridge monitoring [

21], dam monitoring [

22] as well as chimney deformation monitoring [

23] are reported. The main advantage mentioned of IATS is the possibility of automatically detecting targets thanks to the camera-based views without the necessary use of reflective prisms, as do [

21] to investigate vibrations and displacements on a footbridge. While this previous work only uses the camera capabilities of the Leica MS50 to prevent structural failure, in [

22] the grid scanning module of this same device was used to model a dam surface. The dam surface was scanned as well as specific cross-sections using the line scanning module to carry out subsidence analysis during loading experiments on the dam. It appears that the data captured by the scanning total station was valuable to investigate the overall deformation behavior since the acquired point clouds enabled the identification of different deformation patterns. For industrial chimney deformation monitoring, Zheng et al. [

23] use a Topcon IS to capture oriented images from several stations distributed in a network around the chimney. Outlines of the chimney are extracted from these pictures after different image processing steps, and a model of the surveyed object is finally reconstructed. A last example related to civil engineering reports on the survey of reservoirs with UAV photogrammetry [

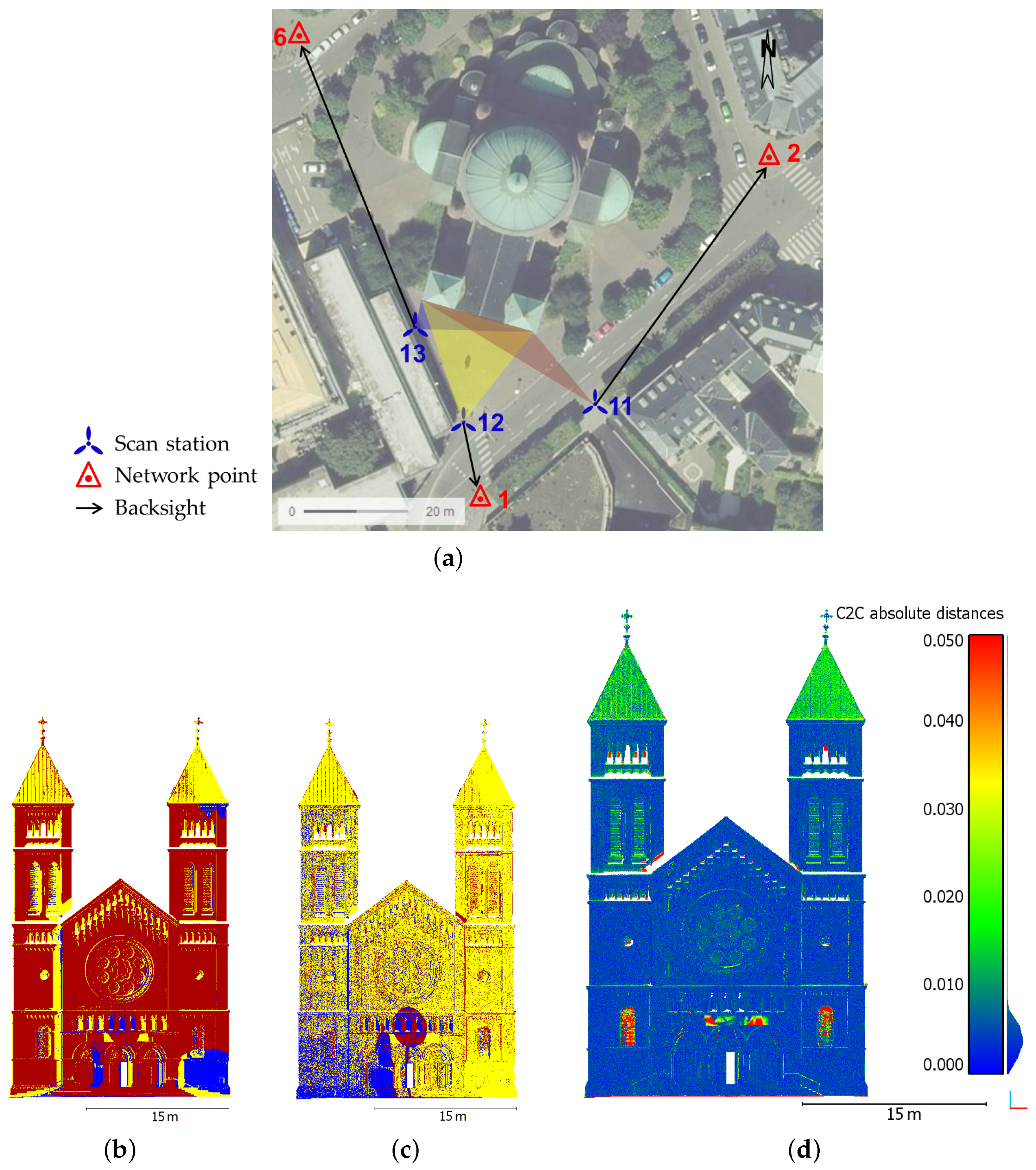

24]. To validate the photogrammetry-based model, a reference model of the reservoirs is created thanks to a Leica MS60. This kind of instrument appears as a suitable solution to the authors since a station network is necessary to obtain a complete model thanks to multiple scan stations.

In the field of geosciences, deformations or changes of natural areas are often monitored using GNSS and conventional tacheometry. An example of a project whose aim is the development of an early warning system for alpine instable slopes is presented in Thuro et al. [

25]. In this context, monitoring of landslides is performed thanks to an IATS prototype based on a conventional Leica total station. The authors use this prototype since the control of the mounted camera with external devices is required. Indeed the video frames are used for the automatic detection of natural targets such as surface rocks or debris in this case, rather than artificial marks or reflectors used in conventional methods. A flowchart that recaps the steps of natural or artificial target detection with an IATS is also proposed in [

25]. Looking at a similar topic, Gomez-Vasconcelos et al. [

26] do not only use pictures captured by a Leica Nova MS50 but also the georeferenced point clouds it delivers to investigate tectonic areas. The authors explain that after meshing the point clouds they are able to create a digital outcrop model, and fault displacements are measured within this model. This data is combined with information coming from other sensors in order to predict potential interactions between volcanism and seismic hazards in these areas. Then regarding change detection, erosion of a beach is surveyed in [

27]. The changed areas within a determined time interval are studied thanks to the grid scanning module of a Topcon IS. Wagner [

13] describes an application example of geo-monitoring that is also related to the study of changes. In this application, displacement vectors between two periods in a mountainous terrain have been computed thanks to a Leica MS50. In such a challenging terrain, the authors highlight the advantage of carrying only one surveying instrument up to the observation point.

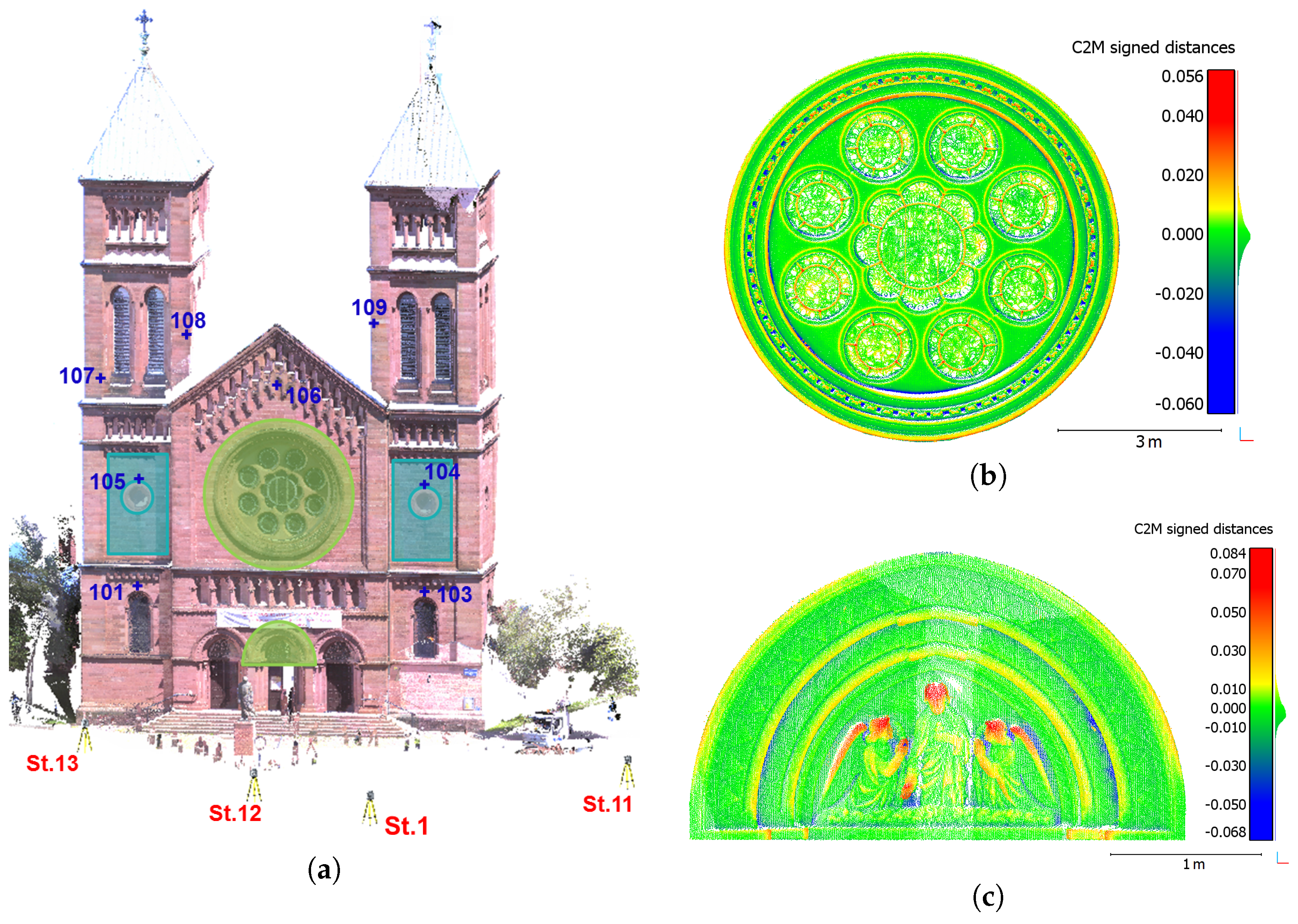

Some contributions report the use of modern total stations for building survey and cultural heritage applications. Wozniak et al. [

28] present results obtained for the creation of a building facade 3D model using data from a Topcon IS-3 as well as images acquired with a conventional digital camera. In this study aiming at documenting geometrical features of buildings, the Topcon Imaging Station is used in its standard scanning mode for reflectorless point acquisition. Despite a stated advantage of requiring one unique device capable of multiple survey tasks, some main limitations of the device are underlined, such as the low measurement speed or the low image resolution. In the context of Building Information Modeling (BIM), Sepasgozar et al. [

29] relate on mobile and static acquisition methods for as-built modeling, given that point clouds are increasingly used as data in construction. Static acquisitions performed with a Leica MS50 are compared with data obtained based on mobile technologies, providing a better spatial accuracy than mobile data, although requiring more time. The same Leica MS50 is used to provide reference data in a similar approach described in [

30]. In this second work the authors aim at evaluating a mobile mapping system on a larger scale test field, in which control points on building facades and street profiles were previously captured with the multi-station. Some more examples rather related to cultural heritage are reported in [

31,

32] which both use the Topcon IS. Evgenikou and Georgopoulos [

31] investigate the 3D modeling of small artifacts thanks to different sensors, and a brief overview of results obtained for architectural survey of a bridge are shown in [

32]. Even if point density seems to be the major issue in both cases, the device could be adapted for documenting objects of similar size as a bridge whereas it is visibly not adapted for small artifacts reconstruction.

Metrology applications can finally be reported, considering leveling capabilities with a Leica MS60 [

33], or collimation measurements with an experimental camera module on a total station [

14].