1. Introduction

The structural maintenance of large civil, aeronautic and wind turbine structures is difficult to establish with periodic verification methods. Maintenance works of these structures are conducted by non-destructive testing (NDT) most of the time [

1]. Material development in these sectors demands high technology equipment and qualified man power, which increase the maintenance process cost. The real-time monitoring method provides the structural behavior and eases the maintenance work. This method is called structural health monitoring (SHM). SHM can alert the operators to anomalies and failures. Online, continuous and global SHM can reduce maintenance and component replacement cost by monitoring structures under harsh environments in remote sites. SHM offers robust real-time monitoring, because necessary maintenance or repairs could be addressed based on this technology [

1]. Life fatigue and economic issues are arising in industrial composite structures with age. SHM could offer a vital tool to inspect continuously for potential failures in the systems.

In SHM, the sensors are the fundamental compound to provide information about the performance of the structure. Important procedures in SHM are the selection and placement of suitable sensors for measuring key parameters. There are several parameters to monitor in large structures, like: pressure, temperature, strain and humidity. The strain sensors provide more information about structure and material properties [

2]. In multiple commercial applications, FOSs have been already selected for health monitoring. The greatest advantage of FOSs is their intrinsic link to other optical fibers. The links allow the sensor to keep the quality of the signal with low loss. Therefore, the sensor functions can extend for long distances. In almost all FOS applications, the optical fiber is a thin glass fiber that is protected mechanically with a polymer coating and inserted in a cable [

3]. The sensors can be placed on the surface of the structure or embedded within the structure.

The light signals travel inside the optical fiber. The transmitted and reflected light is modulated by its amplitude, phase, frequency or polarization state. If the structure undergoes the strain effect, there is a change in light transmission parameters, which is converted to the strain rate applied to the structure [

4]. The most commonly-used sensors are grating based (FBG (Fiber Bragg grating)) and distributed sensors. The distributed sensor works by the back-scatter method. The strain can be measured by the time-domain technique (OTDR) or the frequency-domain technique (OFDR). Sensing solutions based on back-scatter make the use of off-the-shelf low cost telecom-grade fiber as a sensor possible.

FOS is very small in size and flexible. The addition of polymers around the glass core provides additional flexibility to FOS. This characteristic allows the optical fibers to be inserted successfully inside the composite structures. The perturbation of the surrounding field in the host due to the presence of the sensor is often termed the ‘obtrusivity’ of the sensor. Excessive obtrusivity will not only perturb the values of the field variables being measured, but affect the integrity of the host, sensor and the interface between them. The resulting degradation can compromise the accuracy of measurements and the long-term reliability of the sensor-host interaction [

5]. While embedding FOS between the composite plies, it creates a resin concentration called ‘resin pockets’ that disturbs the obtrusivity of the sensors. This will modify the stress transfer between composite plies and FOS. The sensors are positioned in the composite material parallel to the composite fiber alignment directions to reduce the dimension of the resin pockets [

6]. However, laminate orientations may vary to reinforce the composite structure. Accordingly, the resin concentration is more than the expected level, and that affects the stress transfer between the FOS and composite material [

7]. The possible embedded optical fibers to use in anisotropic materials have already been demonstrated [

8,

9]. There are two main coating materials used in industrial applications without considering outer buffer coats: acrylate and polyimide. They both have different mechanical properties and cost effects. Polyimide has a higher modulus than the acrylate, so it withstands high mechanical loads and harsh environments like salt and temperature [

10]. On the contrary, the cost of the polyimide is higher than acrylate; therefore, it is difficult to choose a suitable solution for large-scale structures.

In this paper, we will discuss the stress transfer between the coating material and epoxy material. We consider the epoxy material as a bonding between two composite thin parts in order to make the proper stress analysis about the coating influence. Several previous studies do not investigate in detail the out-of-plane strain, which is a key parameter of structural integrity in anisotropic materials. Castellucci et al. [

11] studied the out-of-plane sensitivity in a 3D-woven cloth configuration with distributed strain sensors. Their study is concentrated on sensor spacing and gauge length to collect the strain all the way through the FOS. In recent years, substantial research efforts also attempted developing multi-parameter FBG sensors [

12,

13]. They worked on multi-axial strain observation in grating sensors. A change in axial strain or temperature will not affect the birefringence of the fiber, but that will cause an overall shift of the Bragg spectrum towards higher or lower values. A change in transverse strain leads to a change of the birefringence of the fiber, which results in a change of the peak separation. Therefore, they proposed capillary configuration for the Bragg grating sensor obtains axial and transversal strain. The sensitivity to transversal strain also remained considerably lower than the sensitivity to axial strain in that solution. Several reports described the characterization of gratings subjected to transversal strains [

14,

15]. Disbond area and crack prediction under fatigue loadings are also possible by FBG sensors [

16,

17]. Changing the sensitivity property of coating and cladding also allows the multi-parameter strains’, physical and chemical properties’ (gas, humidity) detection in grating sensors [

18,

19,

20]. We are using the distributed FOS in our study; the multi-axial strains can be identified by the optimal positioning of the sensors in the composites. This alignment of FOS is assumed as the sinusoidal form. Therefore, we make a numerical study of the embedded sensor [

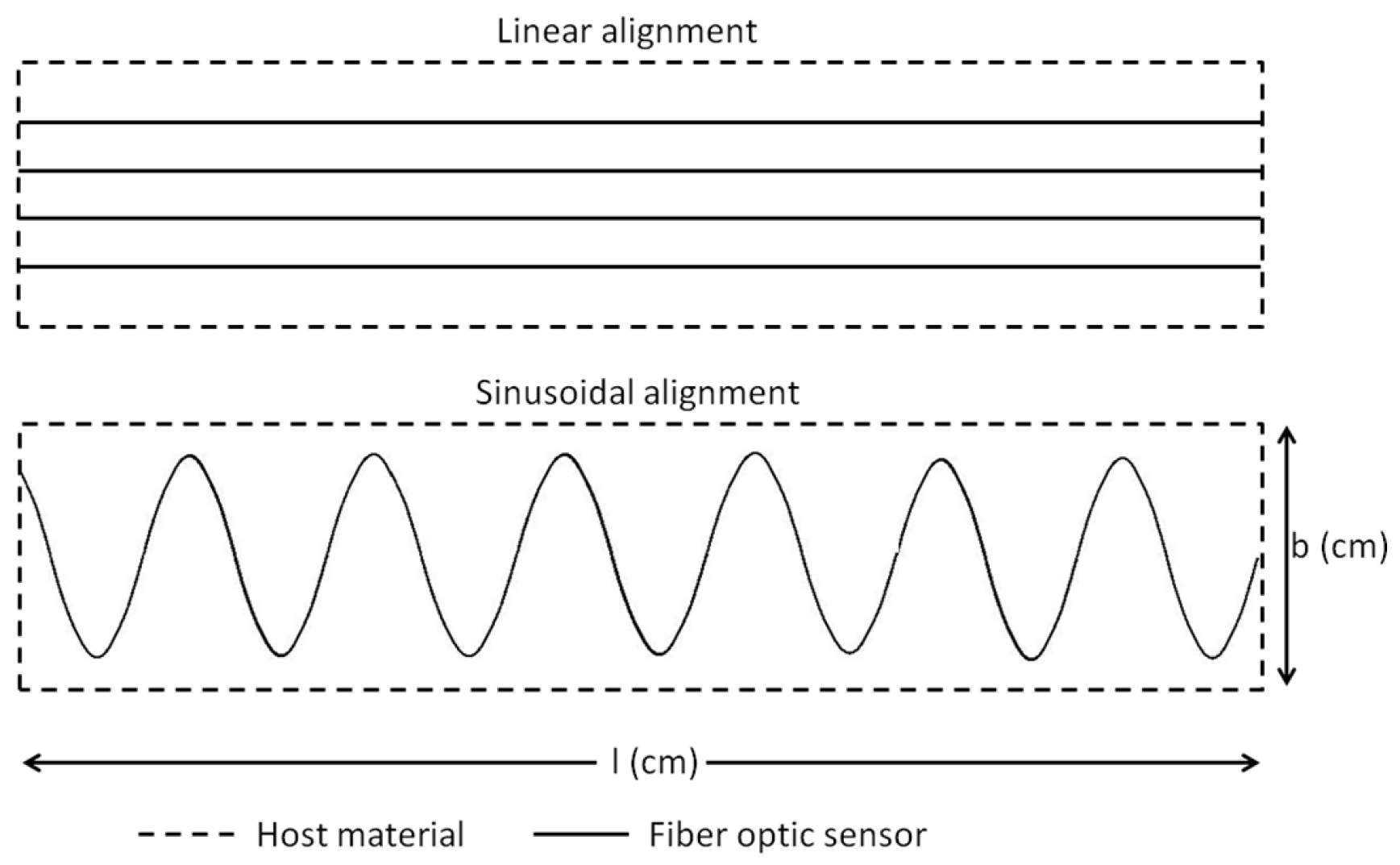

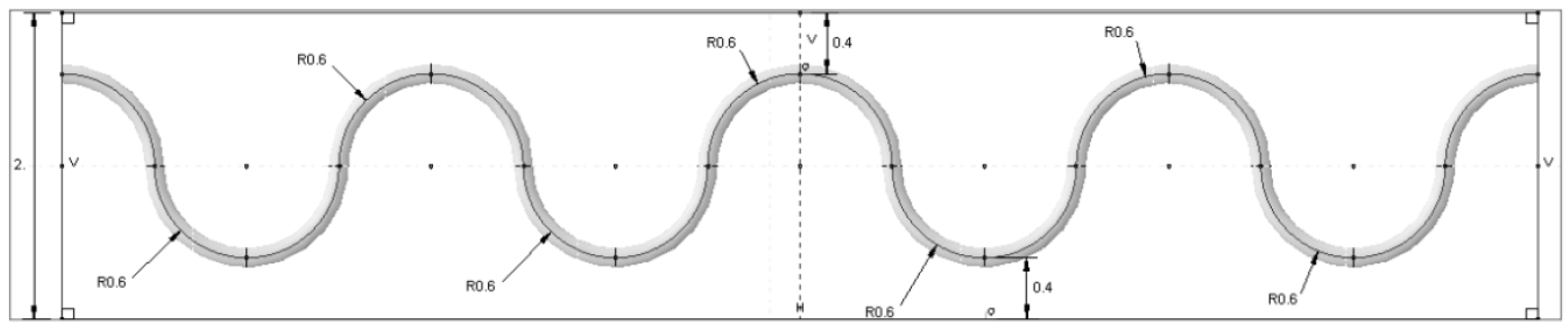

21] in the composite material bonding. The same sinusoidal fiber alignment model is difficult to design with the resin pocket effect. Fibers have their own limit of the bending angle to avoid fiber breakage [

22]. The optimal sinusoidal profile should be selected in the simulation. In this study, we will see the strain detection in different directions by various optical fiber alignment methods. As two coating materials are considered in this work, their presence was taken into account during stress transfer analysis. Once the multi-axial strains are proven by the numerical model, the experiments were established for the alignment method study. The distributed FOS is bonded over the composite specimens by epoxy bonding material to check the effectiveness of the fiber optic alignment.

4. Experimental Preparation

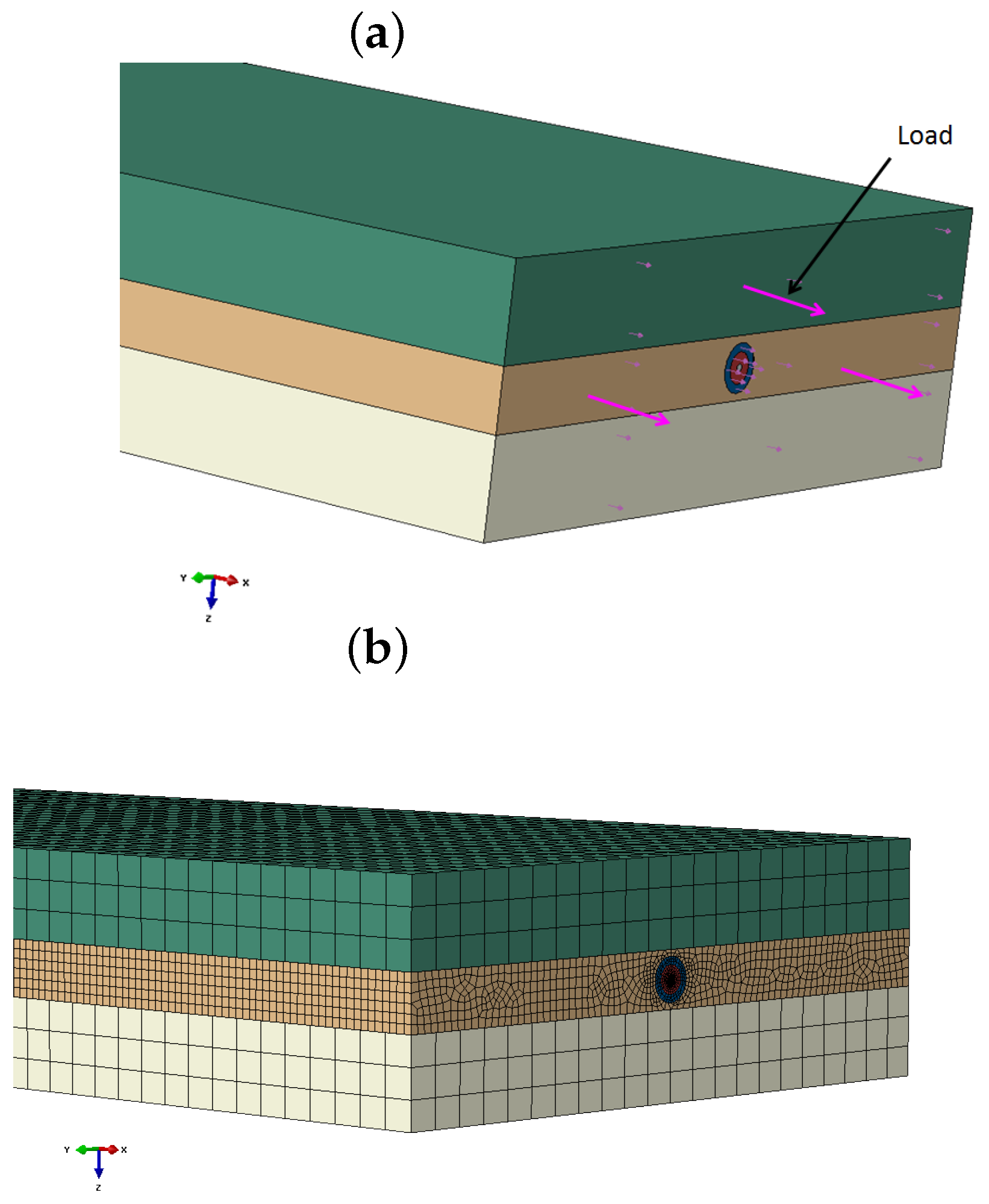

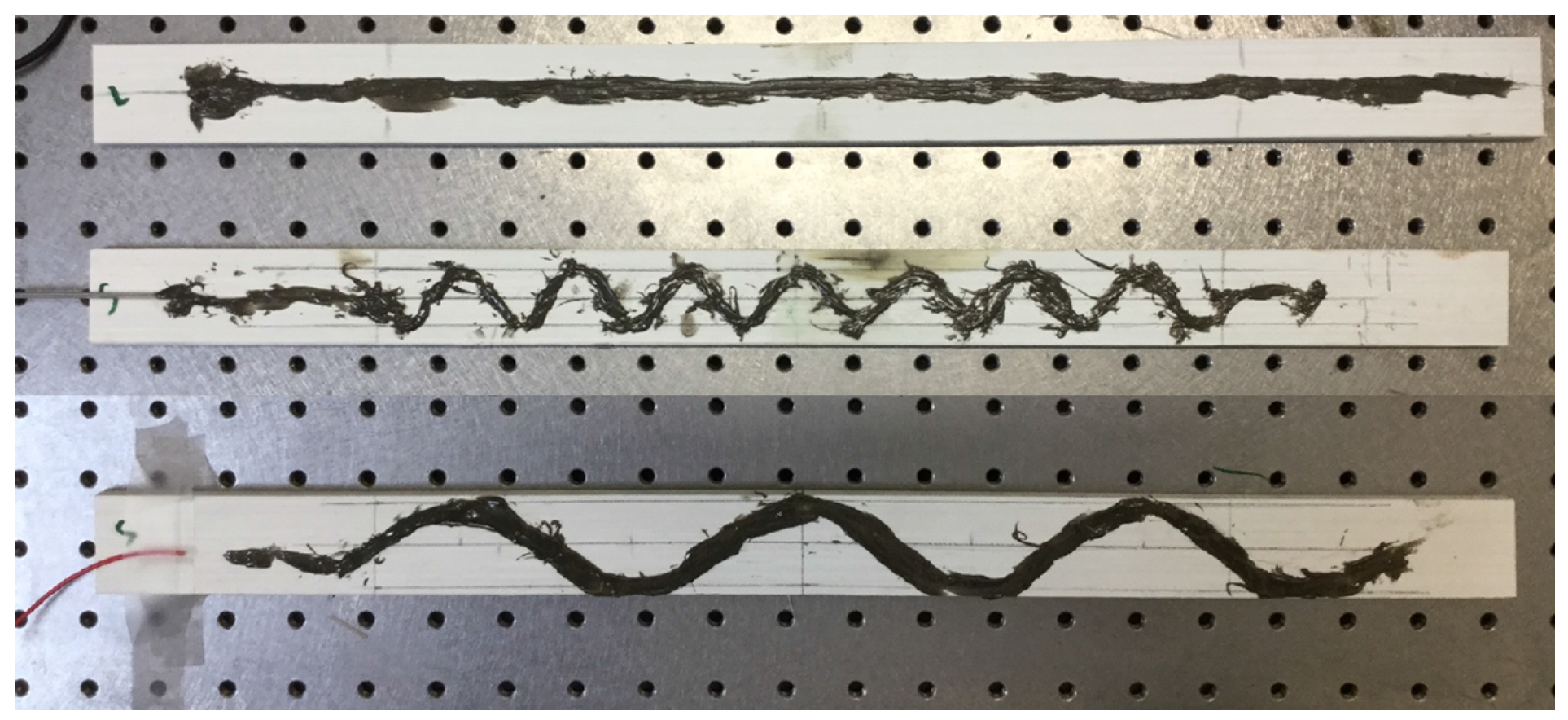

The effectiveness of FOS alignment is also tested in mechanical test under three-point bending load. The specimen was prepared with bonded FOS. The glass fiber-reinforced composite material made by the pultrusion method is used for the experiment. The specimen was cut in the dimensions of (500 × 35 × 7) mm. The FOS with a 0.08-mm cladding diameter surrounded by a 0.125-mm diameter acrylate coating is bonded over the composite material specimen. The bi-component epoxy resin is used for the bonding. The FOS is bonded as shown in

Figure 7 with equal intervals. The peak is maintained at the middle of the specimen and spread towards the tip of the specimen linearly. Two different diameters are considered for the sinusoidal form; they have 2-cm period waves (small sinusoidal alignment) and 6-cm period waves (extended sinusoidal alignment). This period change is collected from edge effect study of the numerical simulation that will be mentioned in

Section 5.1. For the linear model, the optical fiber is positioned exactly at the middle (width wise) of the specimen. To maintain the optical fiber’s position, they are bonded initially on the work bench, as well as the composite specimens. This helps to avoid the fiber fault and misalignment during the bonding. Once the bonding is realized with a small wooden stick at ambient temperature, they were sent to an industrial ovenunder 40

C temperatures as recommended by the adhesive’s producer. After one day of being completely placed in the oven, the specimen was checked for the state of fiber bonding. Afterwards, another composite plate was kept over this and sent to mechanical experiments. Once again, the quality of the specimen is checked; the fiber optic connectors are linked with the FOS. For the mechanical loading, the specimen was subjected to an imposed displacement controlled load at the middle of the specimen to get the bending behavior. The torsion is applied on the specimen by the help of the wedge support. The wedge angle provides the quantity of torsion displacement. The imposed displacement is 3.5 mm, and the wedge angle is maintained as 45

.

The distributed FOS is treated with LUNA OBR-4600 type optical back-scatter reflectometry equipment. The OFDR is used with the Rayleigh scatter signal in a single mode fiber. We have considered a distributed Rayleigh sensor for both the numerical and experimental study. The strain value is measured with the continuous monitoring method. The sensor was functioning with a 1550-nm wavelength, and the frequency of strain acquisition is 1 Hz. The equipment spatial length is 0.5 cm.

6. Discussion

The comparison between the linear and sinusoidal configuration is shown in the figures from the numerical simulation and experiments. Additionally, these figures compare fiber optic strain sensing properties. The strain observed in the epoxy is assumed as the strain seen by the fiber optics; because the host material provides the external stress to the FOS structure to modify the wavelength or the travel time of the waves. This modification is converted to the strain value during the signal treatment of FOSs. Therefore, this study can clearly present the FOS’s sensing capability according to the host material. The sinusoidal and linear alignment should have provided different intrusive properties, which would lead to the modification in the mechanical property of the material. However, this intrusive characteristic is more effective while embedded between composite plies. In our case, we insert the sensor in the bonding material. Therefore, the material property variation produced by this insertion characteristic is negligible.

As we bond the sensor over a structure, the host composite material became unimportant for this study; however, the consideration of the composite material provides the orthotropic condition to check the approximate behavior of the real condition. Therefore, the carbon fiber-reinforced composite material is considered for the numerical study and glass fiber-reinforced composite for the experimental method. The composite materials’ variation affects the strain value comparison between the numerical and experimental method, but we are interested in the strain component rather than the strain values during this comparison. The strain values are compared while the same materials are in use (comparison within the numerical model and comparison within the experiment). In addition, the future detailed study of the strain value comparison would help to create the analytic function about alignment.

In the linear numerical model, the sensor is not valuable with respect to collecting linear and shear strains, because the tensile load does not provide enough stress to the sensor. It acts to extend the composite and epoxy towards the longitudinal direction. In the same way, shear load does not make any section variation to provide the

strain in the normal direction, which is along the lengthwise direction. Therefore, no visible high valued shear strain is observed around the fiber optic zone. However, epoxy has a high Poisson ratio that provides a high lateral strain. This lateral strain transformed to the FOS, which is embedded in epoxy. Therefore, the lateral strain is clearly visible in the linear FOS alignment configuration. The coating material acrylate and polyimide do not change this functionality, but they can vary the strain values by changing the transfer of stress between the FOS and the epoxy, as coatings have different modulus and material properties. The FOS with acrylate coating provides more strain values in all directions compared to the FOS with polyimide coating. This proves the advantage of polyimide coating over acrylate; because the high strain value in epoxy may lead to damage in the composite material assembly. On the other hand, the strain values are observed with minor variation between acrylate and polyimide coating. This should be compared with the cost of the FOS based on the coating material. The polyimide-coated FOS costs 15% more than the one with acrylate coating [

2].

The coating difference creates less variation of the strain value observed in the numerical simulation. Therefore, the users should take into account this factor based on the application. If the application is large scale with atmospheric temperature, the small strain modification will not play a big role in material damage. Therefore, the acrylate-coated FOS is preferable. On the contrary, for a micro-scale study or a high temperature-based application, this small variation makes a big difference, so the polyimide-coated sensor is preferable.

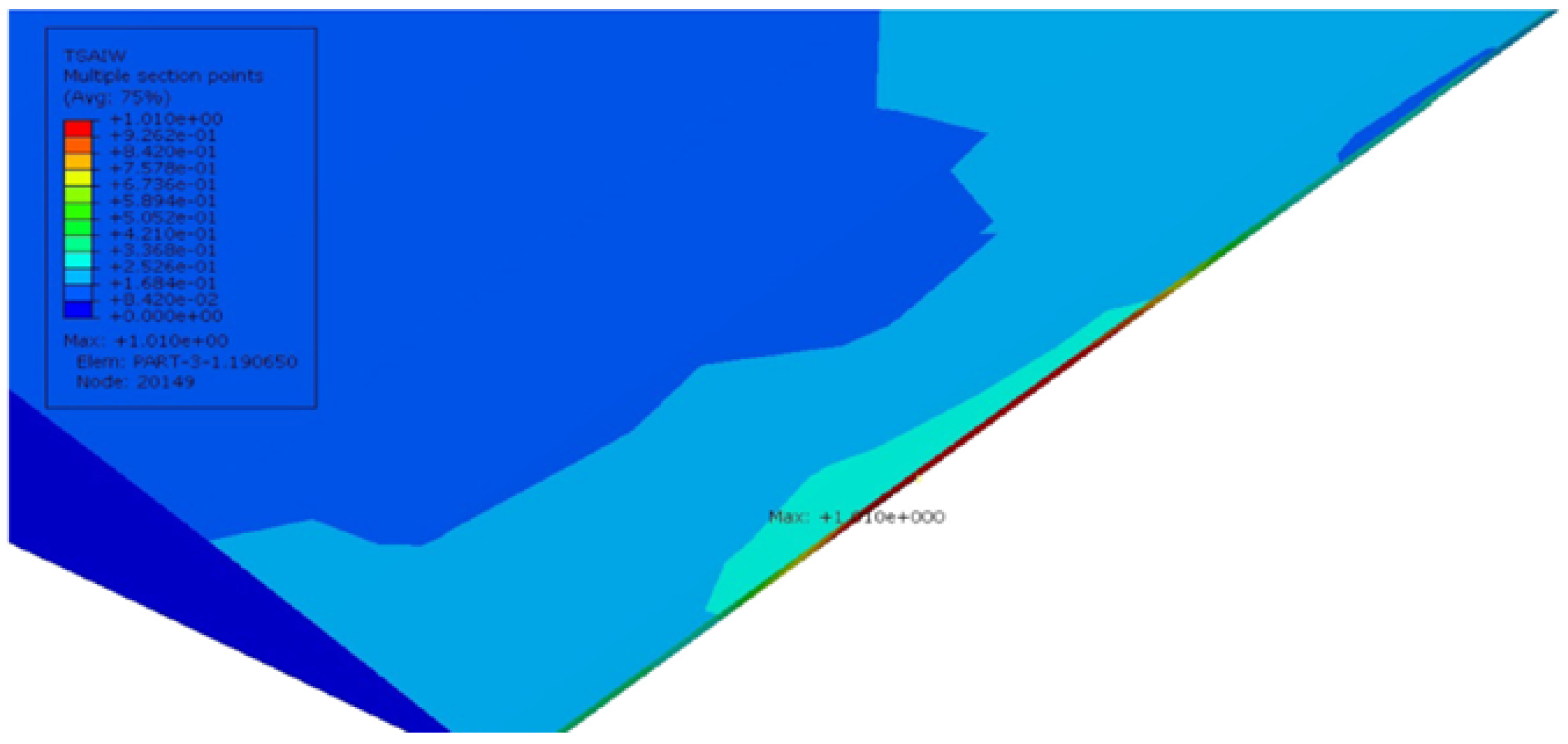

From the strain values in the numerical model sinusoidal configuration, we observed that the

took place by the tensile strain component around the curvature of the sinusoidal alignment (reddish color,

Figure 10a); shear strain

came off with the combination of compression and tensile combined strains (red and blue,

Figure 10).

provides lateral tensile strains (reddish,

Figure 10) and a small amount of compression strain in the curvatures (bluish,

Figure 10). The value of the strain varies based on the coating material used in the FOSs. This proves that the sinusoidal FOS alignment is better for the multi-axial sensing for a large structure. Some structures expect specified axis strain sensing rather than single axis strain. For those cases, the linear alignment FOS might not be effective. Therefore, the multi-parameter strain sensing characteristic sinusoidal alignment is preferable.

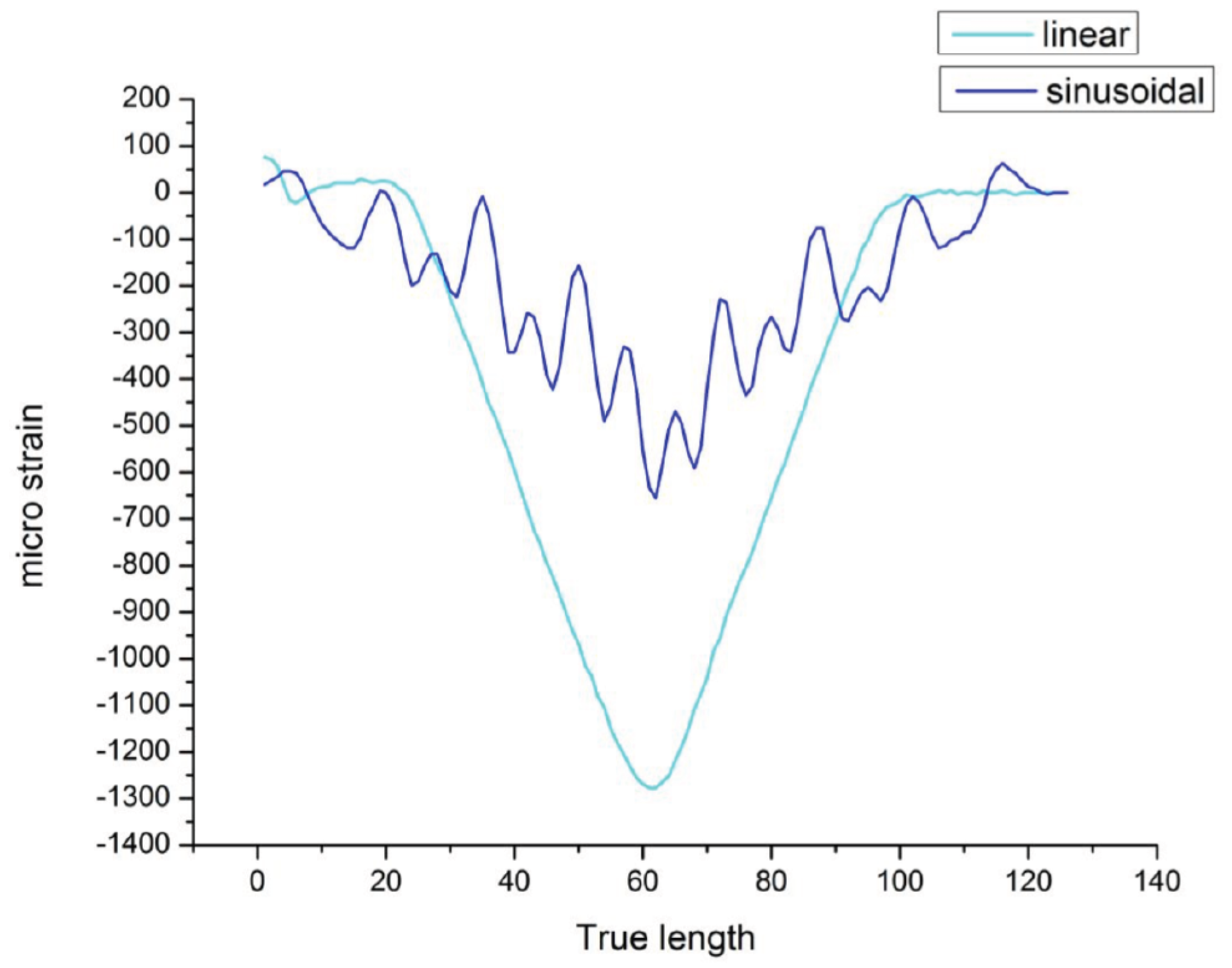

Once the directional strain is proven, it is important to analyze the strain values during the monitoring of the structure; because sensors strain values should reflect clearly the amount of anomalies to identify the risk in the structure. The sinusoidal alignment can reduce the strain range or value when embedded in the structure. While comparing linear alignment with small sinusoidal alignment FOS, the strain value is noticed to be exactly half from 1300

m/m to 600

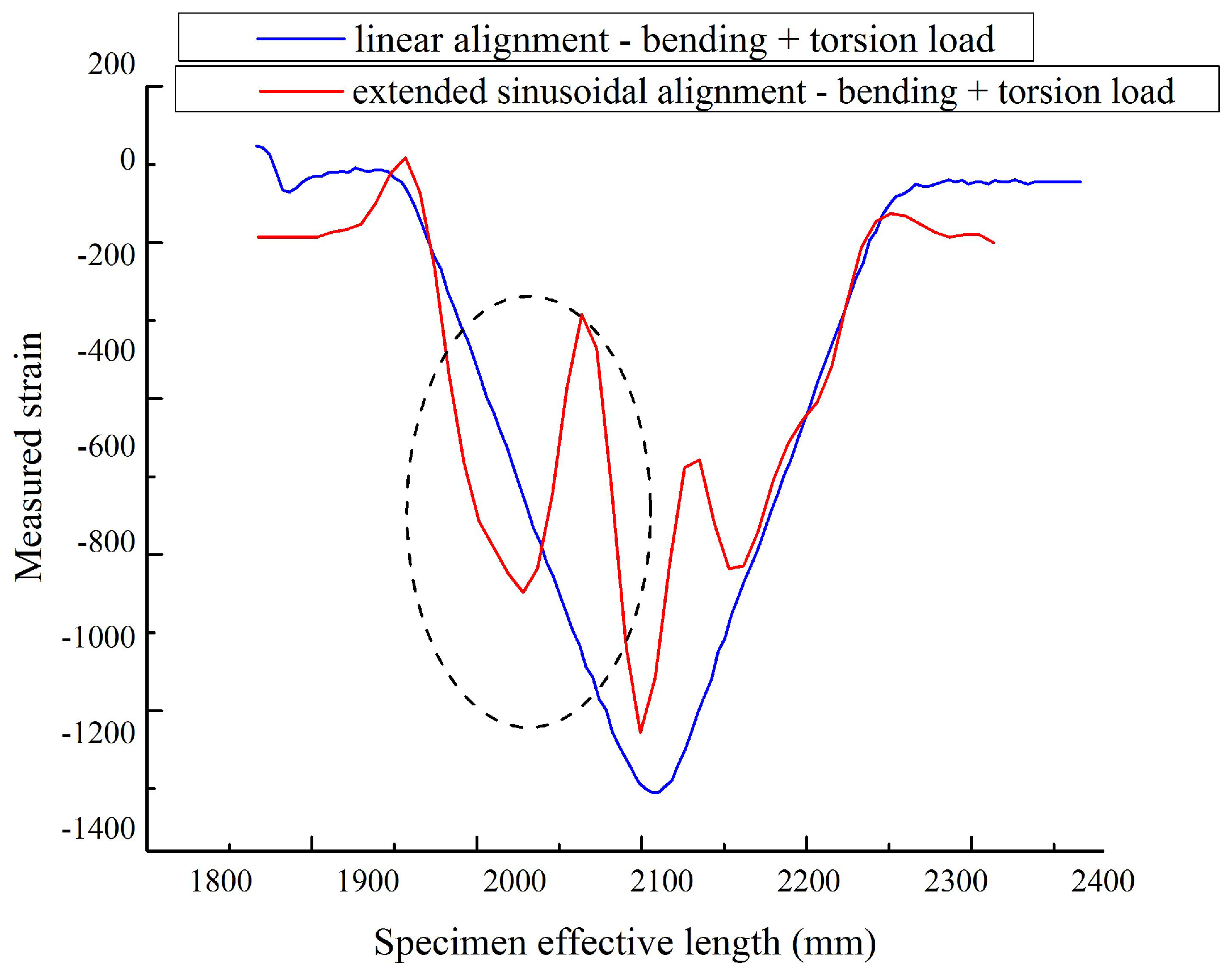

m/m. However, we are able to detect the strain by peaks under torsional load by sinusoidal alignment. In

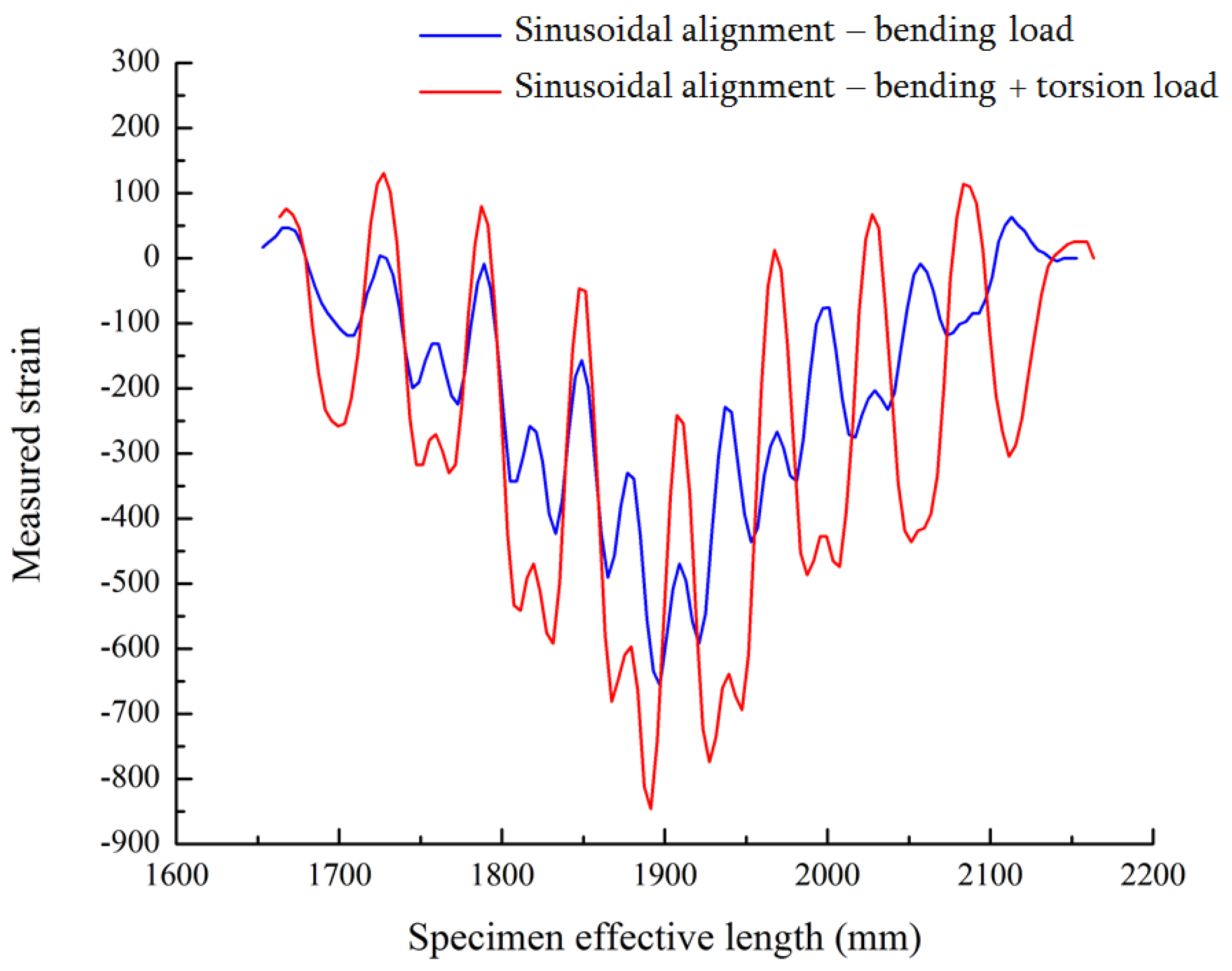

Figure 15, strain by bending load values jumps from 100

m/m to 250

m/m while applying the additional torsion load. This torsional effect is observed in the peaks mentioned in

Figure 15. The torsional strain can represent the shear strain observed in the numerical simulation part, and it works also under bending load.

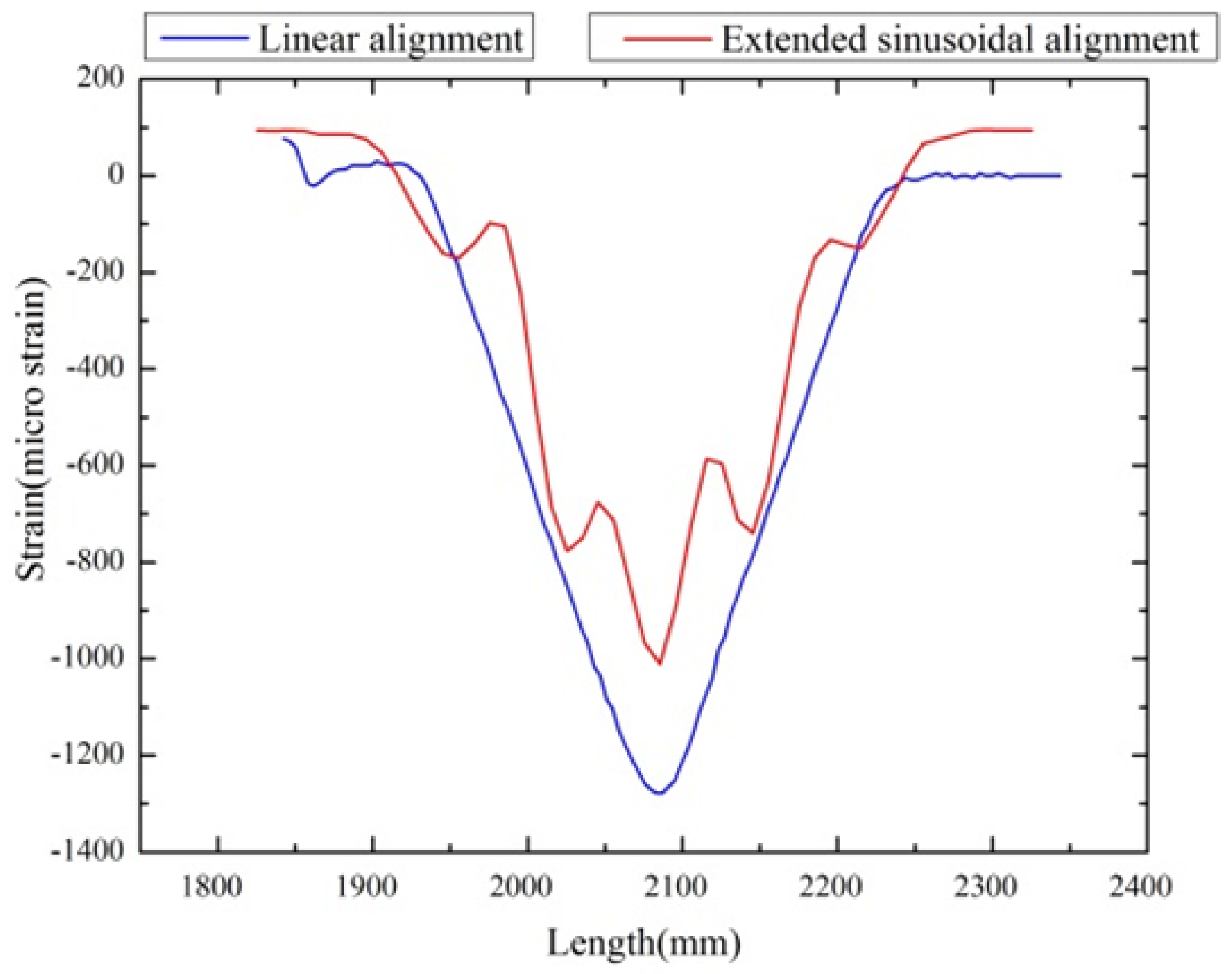

Our objective is to reach the strain value close to the linear alignment configuration by keeping the torsional load strain sensing. Therefore, the extended sinusoidal FOS alignment is considered, and they are tested under the same boundary condition to check the strain by the optical back scatter method. The strain value from this novelty positioning method (1050

m/m) approaches the strain value of the linear positioning (1300

m/m) method for a given boundary condition. This proves that it is possible to recover the strain value range with the multi-parameter sensing. Additionally, torsional strain is also observed with peak variation (see

Figure 17). This provides an outlook that the large-scale composite structure SHM is possible with multi-directional strain sensing by using our proposed fiber optical sinusoidal alignment procedure.

7. Conclusions

FOSs are preferable for the SHM of large structures like wind turbine blades. However, they have a difficulty in identifying multi-axial strains while embedded in the structure. It is also hard to distinguish the strain coordinates, if the loading direction is random. In this study, we have discussed the optimal solution for multi-axial strain sensing by working on distributed FOS alignment in fiber-reinforced composite with epoxy bonding.

From our numerical study, the multi-parameter strain is clearly visible in the sinusoidal alignment method compared to the linear alignment method. Linear alignment FOS shows only lateral strains, while the sinusoidally-aligned FOS provides the strain information in the linear, shear and lateral directions. This strain value varies based on the coating material considered. Acrylate coating permits high strain to the host material compared to the polyimide coating.

The multi-axial strain sensing of FOS was also proven by the experiment method under bending and torsion loads. The sinusoidal aligned FOSs are able to measure the strain results by bending and torsion load. In contrast, linear alignment FOS only detects the strain components of bending load. However, the strain value (1300 m/m) collected by linear (or straight) alignment FOS was higher than the one of sinusoidal alignment FOS (600 m/m), for similar boundary conditions. The linear alignment’s strain range was 55% higher than the simple sinusoidal configuration. To approach the strain range towards the linear alignment FOS’s strain, the periods of sinusoidal alignment were extended. This extended sinusoidal alignment FOS helps to come closer to the strain magnitude (1050 m/m) observed in linear alignment FOS. The difference between linear and sinusoidal configuration’s strain values was reduced to 20%. This study proves that it is possible to have a multi-parameter strain sensing in distributed FOS without affecting the strain magnitude. In addition, it gives the overview to the users for making an optimal SHM system for large-scale structures and bonding.