Indoor Positioning System Using Magnetic Field Map Navigation and an Encoder System

Abstract

:1. Introduction

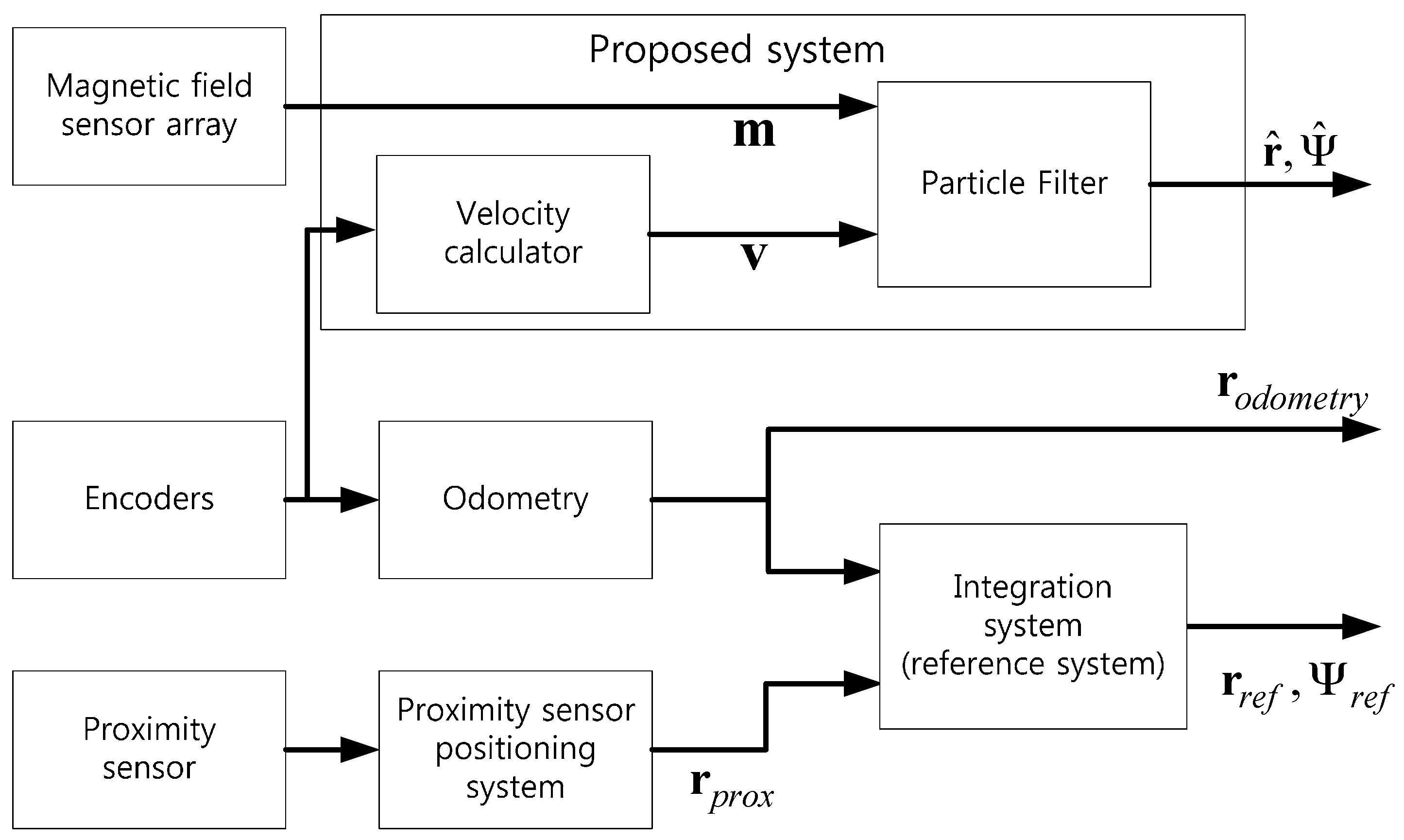

2. Positioning System

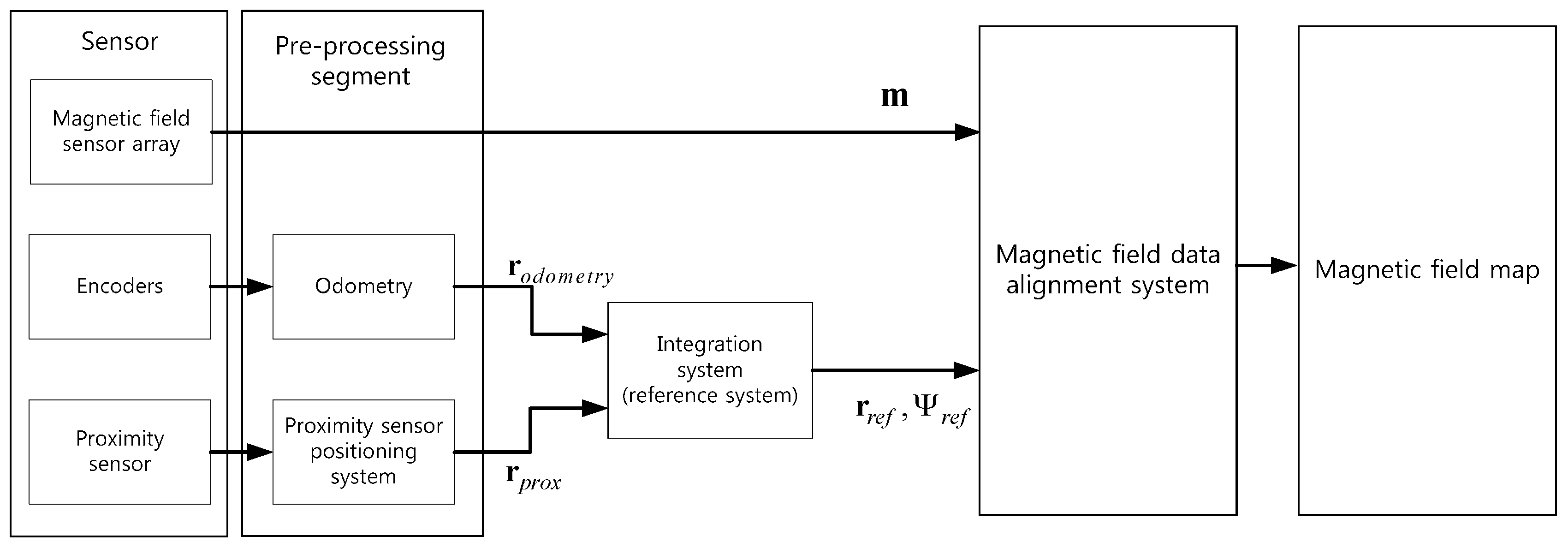

2.1. The Magnetic-Field Map-Building System

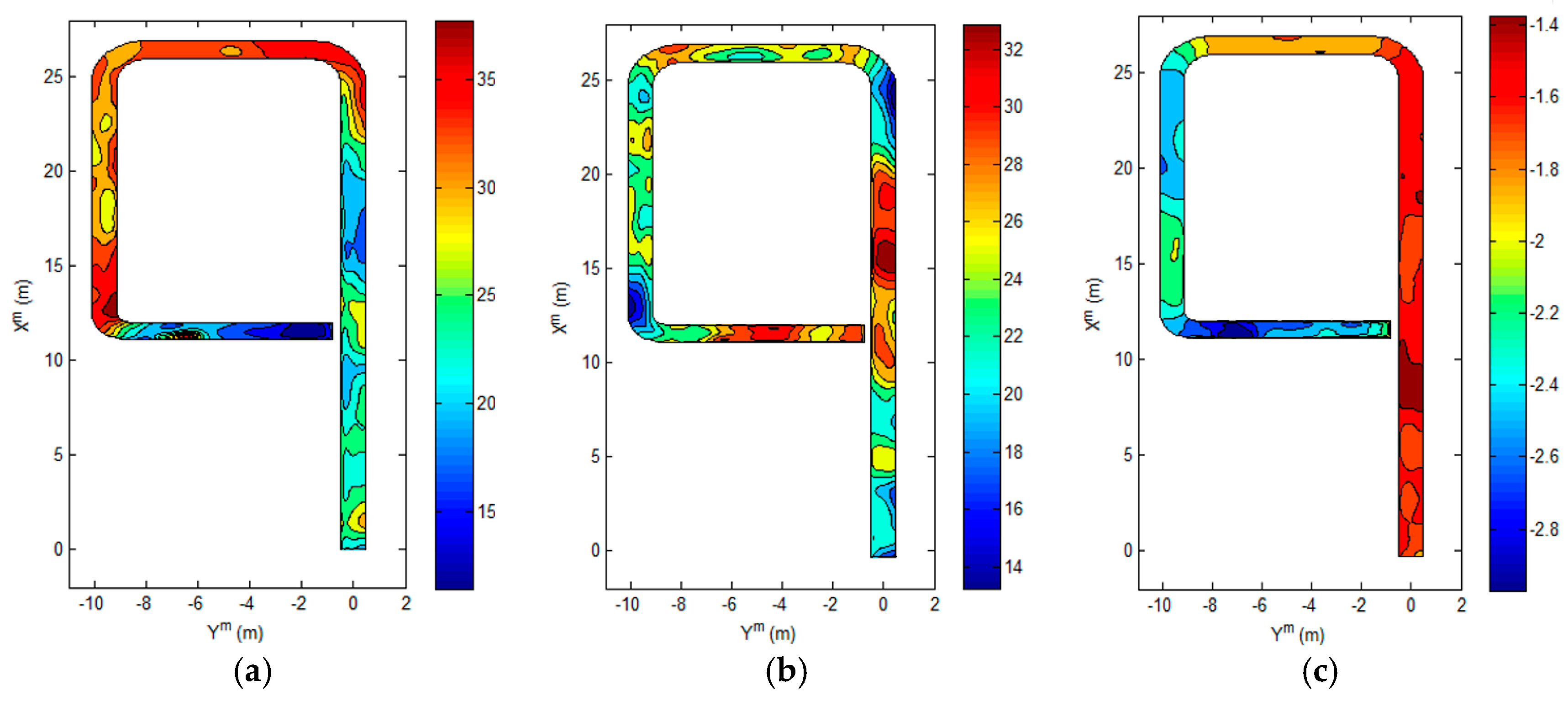

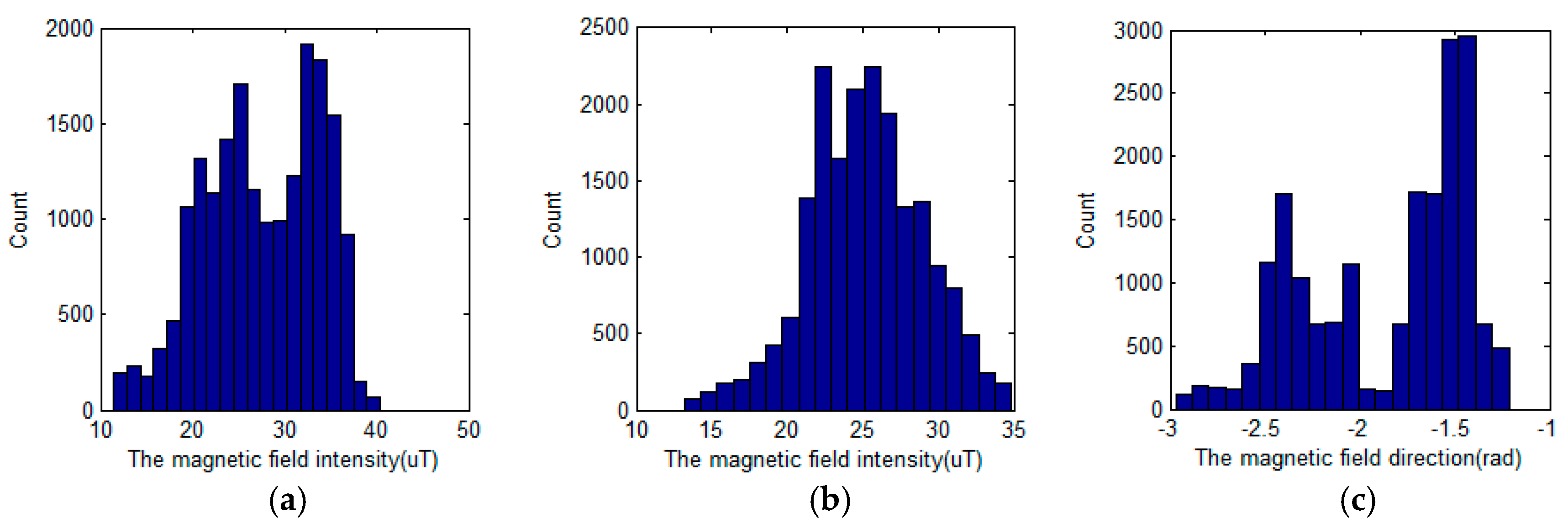

2.2. The Magnetic Field Map

2.3. Frame Definition

2.4. Particle Filter

3. Experiments and Results

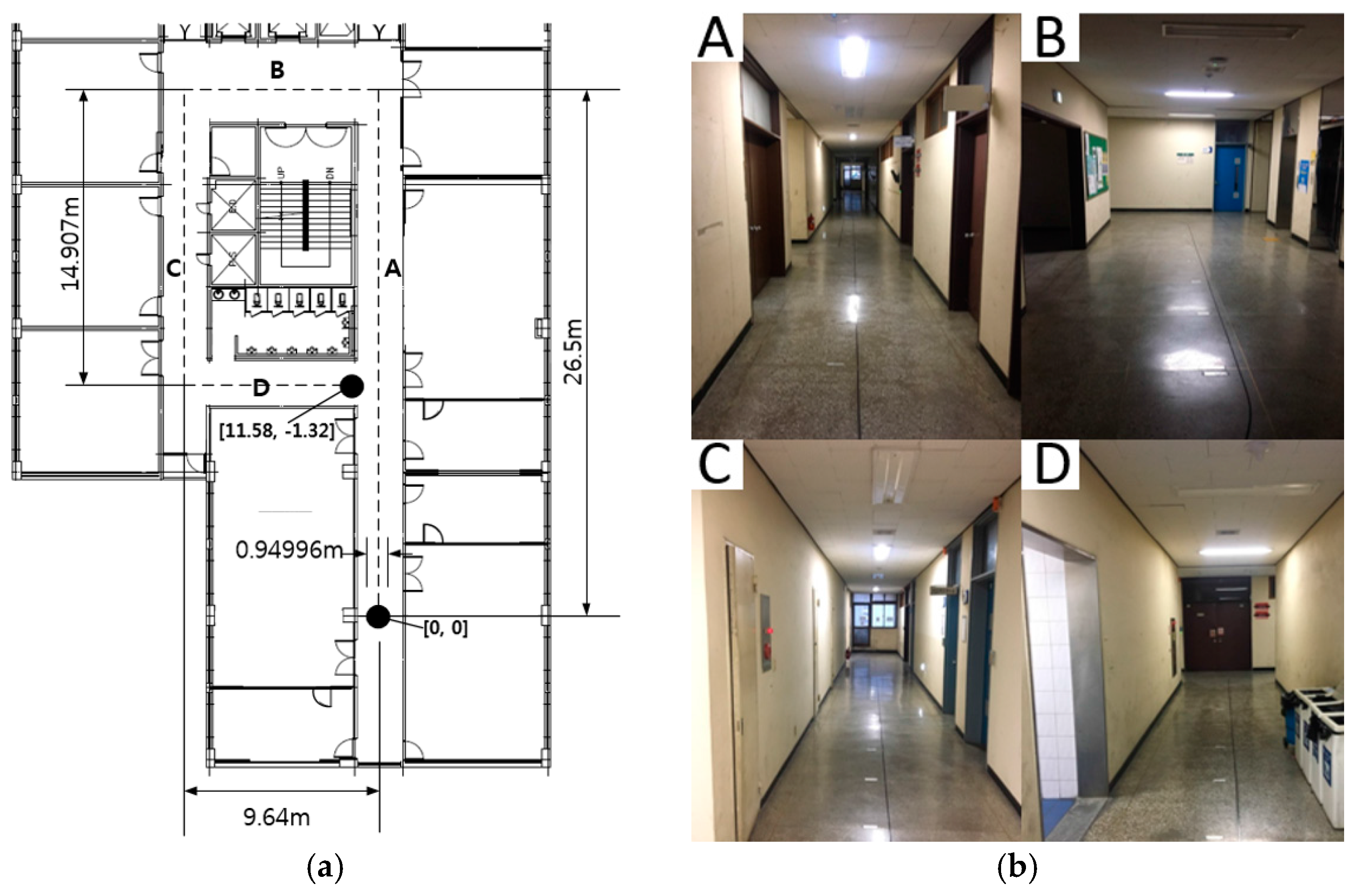

3.1. Experimental Environment

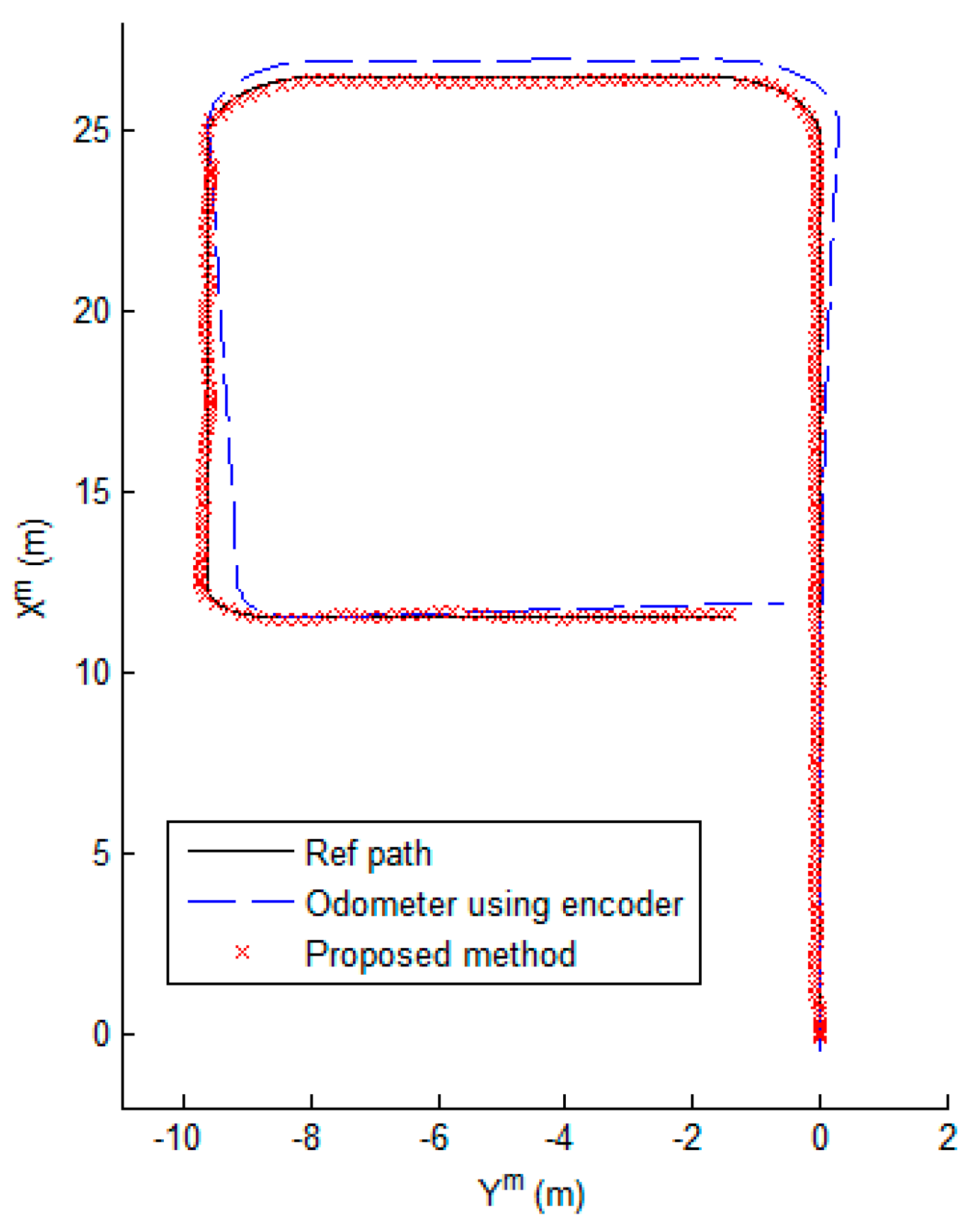

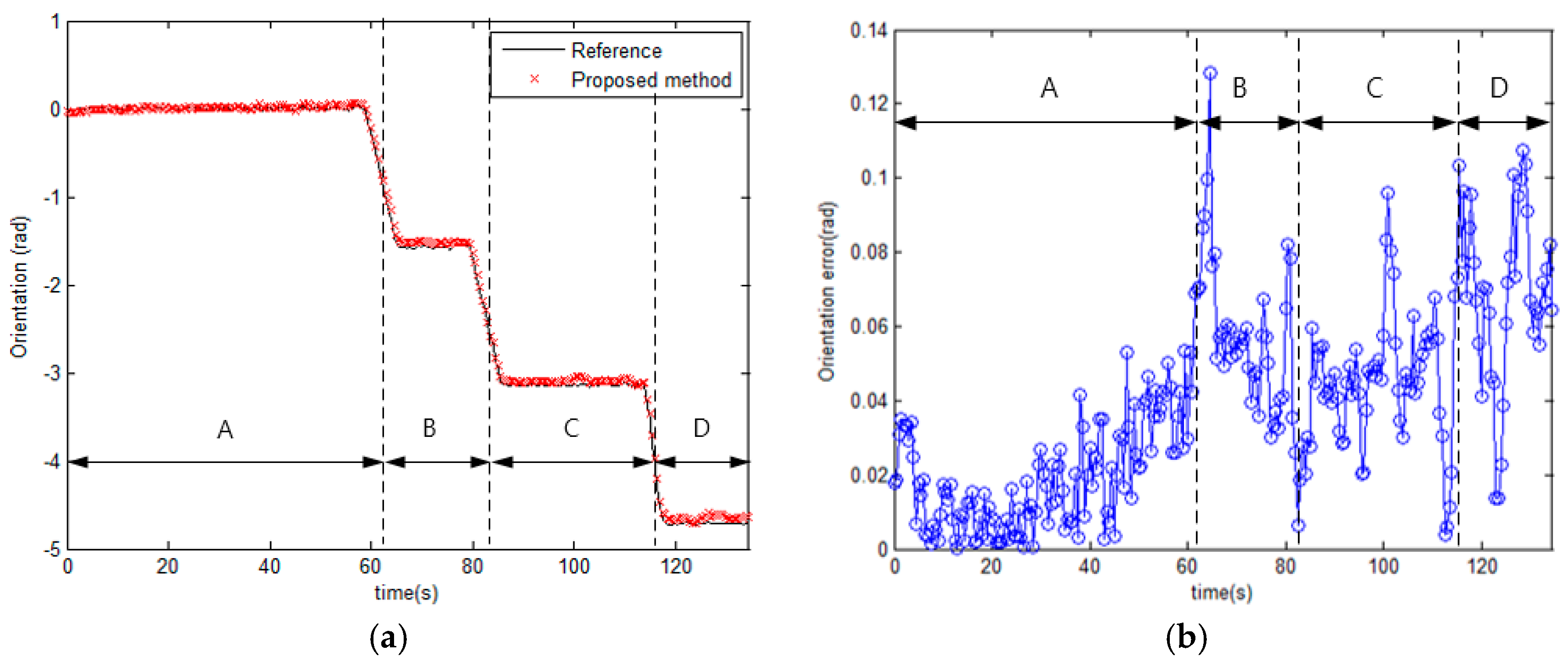

3.2. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cho, B.; Seo, W.; Moon, S.; Baek, K. Positioning of a Mobile Robot Based on Odometry and New Ultrasonic LPS. Int. J. Control Autom. Syst. 2013, 11, 333–345. [Google Scholar] [CrossRef]

- William, J. Global Positioning System (GPS) Standard Positioning Service (SPS) Performance Analysis Report; Report #93; Hughes Technical Center: Atlantic City, NJ, USA, April 2016. [Google Scholar]

- Misra, P.; Enge, P. Global Positioning System: Signals, Measurements, and Performance; Ganga-Jamuna Press: Lincoln, MA, USA, 2011. [Google Scholar]

- Villadangos, J.M.; Urena, J.; Mazo, M.; Hernandez, A.; Alvarez, F.; Garcia, J.J.; De Marziani, C.; Alonso, D. Improvement of ultrasonic beacon-based local position system using multi-access techniques. In Proceedings of the 2005 IEEE International Workshop on Intelligent Signal Processing, Faro, Portugal, 1–3 September 2005; pp. 352–357.

- Seo, W.; Cho, B.; Moon, S.; Baek, K. Position Estimation Using Time Difference of Flight of the Multi-coded Ultrasonic. In Intelligent Robotics and Applications; Springer: Berlin/Heidelberg, Germany, 2011; Volume 7101, pp. 604–609. [Google Scholar]

- Chawathe, S. Beacon Placement for Indoor Localization using Bluetooth. In Proceedings of the 11th International IEEE Conference on Intelligent Transportation Systems, Beijing, China, 12–15 October 2008; pp. 980–985.

- Wang, Y.; Ye1, Q.; Cheng, J.; Wang, L. RSSI-based Bluetooth Indoor Localization. In Proceedings of the 2015 11th International Conference on Mobile Ad-hoc and Sensor Networks (MSN), Shenzhen, China, 16–18 December 2015; pp. 165–171.

- Biswas, J.; Veloso, M. WiFi Localization and Navigation for Autonomous Indoor Mobile Robots. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–8 May 2010; pp. 4379–4384.

- Olivera, V.M.; Plaza, J.M.C.; Serrano, O.S. WiFi localization methods for autonomous robots. Robotica 2006, 24, 455–461. [Google Scholar] [CrossRef]

- Cho, B.; Moon, W.; Seo, W.; Baek, K. A dead reckoning localization system for mobile robots using inertial sensors and wheel revolution encoding. J. Mech. Sci. Technol. 2011, 25, 2907–2917. [Google Scholar] [CrossRef]

- Storms, W.; Shockley, J.; Raquet, J. Magnetic field navigation in an indoor environment. In Proceedings of the Ubiquitous Positioning Indoor Navigation and Location Based Service (UPINLBS), Kirkkonummi, Finland, 14–15 December 2010; pp. 1–10.

- Gozick, B.; Subbu, K.P.; Dantu, R.; Maeshiro, T. Magnetic Maps for Indoor Navigation. IEEE Trans. Instrum. Meas. 2011, 60, 3883–3891. [Google Scholar] [CrossRef]

- Shockley, J.A.; Raquet, J.F. Navigation of Ground Vehicles Using Magnetic Field Variations. Navigation 2014, 61, 237–252. [Google Scholar] [CrossRef]

- Doucet, A.; Freitas, N.; Gordon, N. Sequential Monte Carlo Methods in Practice-Statistics for Engineering and Information Science; Springer: New York, NY, USA, 2001. [Google Scholar]

- Gustafsson, F. Particle Filter Theory and Practice with Positioning Applications. IEEE Aerosp. Electron. Syst. Mag. 2010, 25, 53–82. [Google Scholar] [CrossRef]

- Haverinen, J.; Kemppainen, A. Global indoor self-localization based on the ambient magnetic field. Robot. Auton. Syst. 2009, 57, 1028–1035. [Google Scholar] [CrossRef]

- Grand, E.L.; Thrun, S. 3-Axis Magnetic Field Mapping and Fusion for Indoor Localization. In Proceedings of the 2012 IEEE Conference on Multisensor Fusion and Integration for Intelligent Systems (MFI), Hamburg, Germany, 13–15 September 2012; pp. 358–364.

- Abbas, T.; Arif, M.; Ahmed, W. Measurement and Correction of Systematic Odometry Errors Caused by Kinematics Imperfections in Mobile Robots. In Proceedings of the 006 SICE-ICASE International Joint Conference, Busan, Korea, 18–21 November 2006; pp. 2073–2078.

- Borenstein, J.; Feng, L. Measurement and Correction of Systematic Odometry Errors in Mobile Robots. IEEE Trans. Robot. Autom. 1996, 12, 869–880. [Google Scholar] [CrossRef]

- Choi, B.; Lee, J.; Lee, J. Localization and Map-building of Mobile Robot Based on RFID Sensor Fusion System. In Proceedings of the 6th IEEE International Conference on Industrial Informatics, Daejeon, Korea, 13–16 July 2008; pp. 412–417.

- Lee, S.; Song, J. Robust mobile robot localization using optical flow sensors and encoders. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (ICRA’04), Barcelona, Spain, 18–22 April 2004; Volume 11, pp. 1039–1044.

- Angermann, M.; Frassl, M.; Doniec, M.; Julian, B.J.; Robertson, P. Characterization of the Indoor Magnetic Field for Applications in Localization and Mapping. In Proceedings of the 2012 International Conference on Indoor Positioning and Indoor Navigation (IPIN), Sydney, Australia, 13–15 November 2012; pp. 1–9.

- Mohanalakshmi, K.; Arun, B. NFC Signals Based on an Effective Mobile Robot Localization. Elysium J. 2015, 2, 1–5. [Google Scholar]

- Goel, P.; Roumeliotis, S.I.; Sukhatme, G.S. Robust Localization Using Relative and Absolute Position Estimates. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and System, Lausanne, Switzerland, 30 September–4 October 2002; Volume 2, pp. 1134–1140.

- El-Sheimy, N.; Chiang, K.W.; Noureldin, A. The Utilization of Artificial Neural Networks for Multisensor System Integration in Navigation and Positioning Instruments. IEEE Trans. Instrum. Meas. 2006, 55, 1606–1615. [Google Scholar] [CrossRef]

- Navarro, D.; Benet, G. Magnetic Map Building for Mobile Robot Localization Purpose. In Proceedings of the IEEE Conference on Emerging Technologies & Factory Automation, Palma de Mallorca, Spain, 22–25 September 2009; pp. 1–4.

| XY (uT) | Z-Dir (uT) | Dir (rad) | |

|---|---|---|---|

| Std. | 6.24 | 3.83 | 0.43 |

| Mean | 27.55 | 25.18 | −1.86 |

| Max. | 40.38 | 34.84 | −1.21 |

| Min. | 11.41 | 13.19 | −2.97 |

| Distance (m) | Orientation (rad) | |

|---|---|---|

| Mean | 0.0948 | 0.0386 |

| Std. | 0.0618 | 0.0310 |

| Max. | 0.3736 | 0.1285 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-S.; Seo, W.; Baek, K.-R. Indoor Positioning System Using Magnetic Field Map Navigation and an Encoder System. Sensors 2017, 17, 651. https://doi.org/10.3390/s17030651

Kim H-S, Seo W, Baek K-R. Indoor Positioning System Using Magnetic Field Map Navigation and an Encoder System. Sensors. 2017; 17(3):651. https://doi.org/10.3390/s17030651

Chicago/Turabian StyleKim, Han-Sol, Woojin Seo, and Kwang-Ryul Baek. 2017. "Indoor Positioning System Using Magnetic Field Map Navigation and an Encoder System" Sensors 17, no. 3: 651. https://doi.org/10.3390/s17030651