Uncertainty Analysis in Humidity Measurements by the Psychrometer Method

Abstract

:1. Introduction

2. Theoretical Background

Equations for Determining Psychrometric Constant

3. Materials and Methods

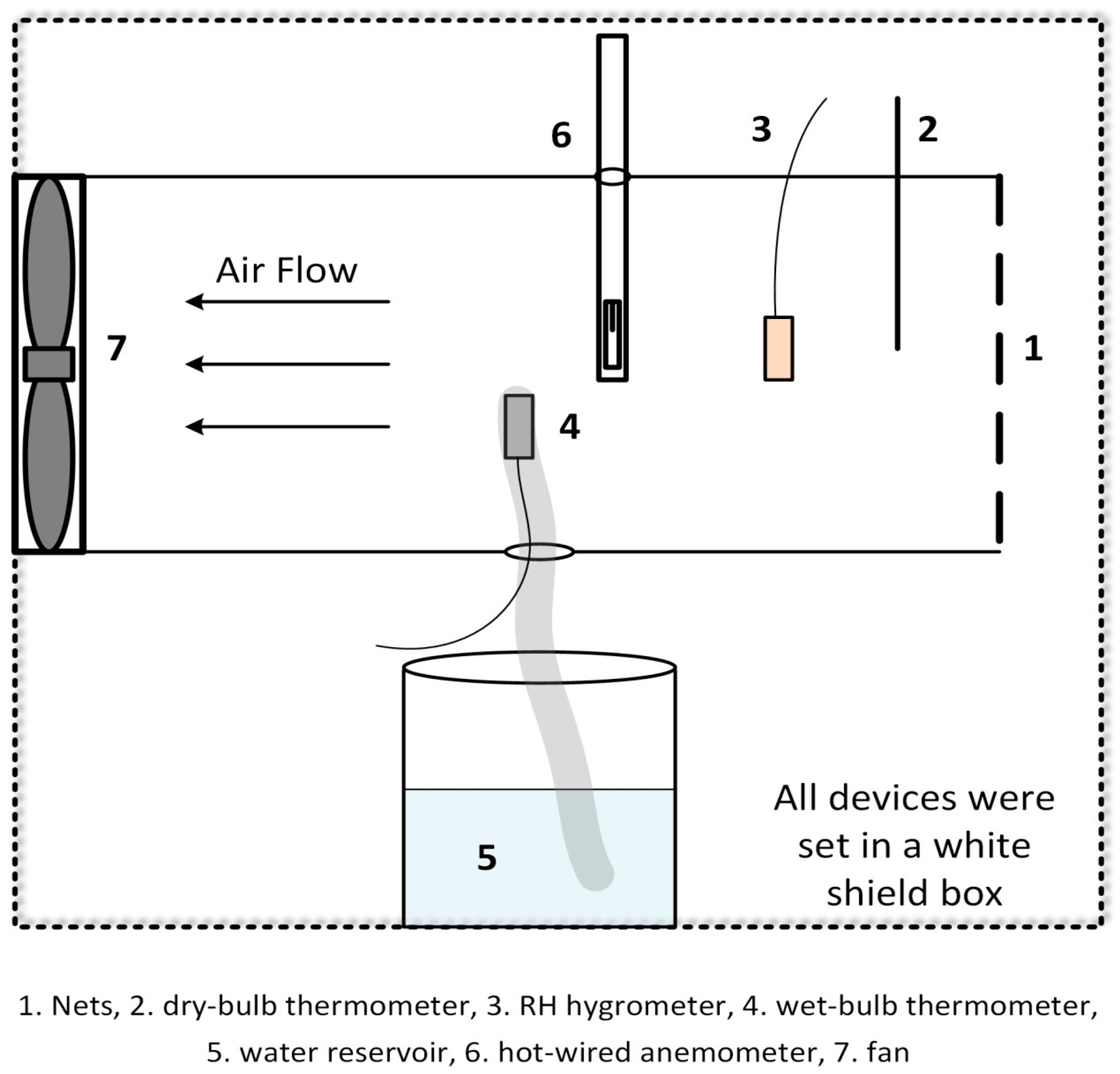

3.1. Equipment

3.2. Sensors

3.3. Experimental Method

4. Results

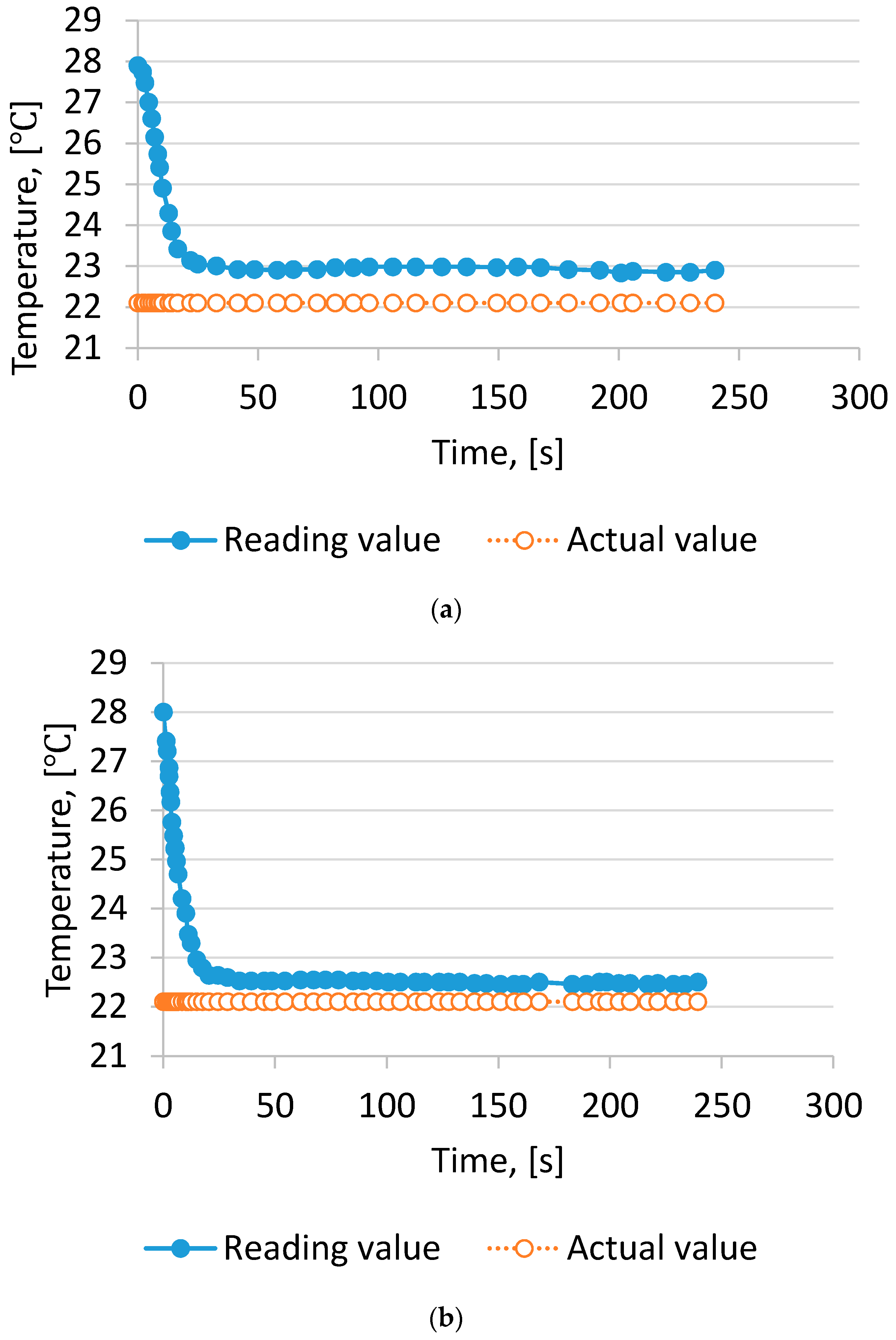

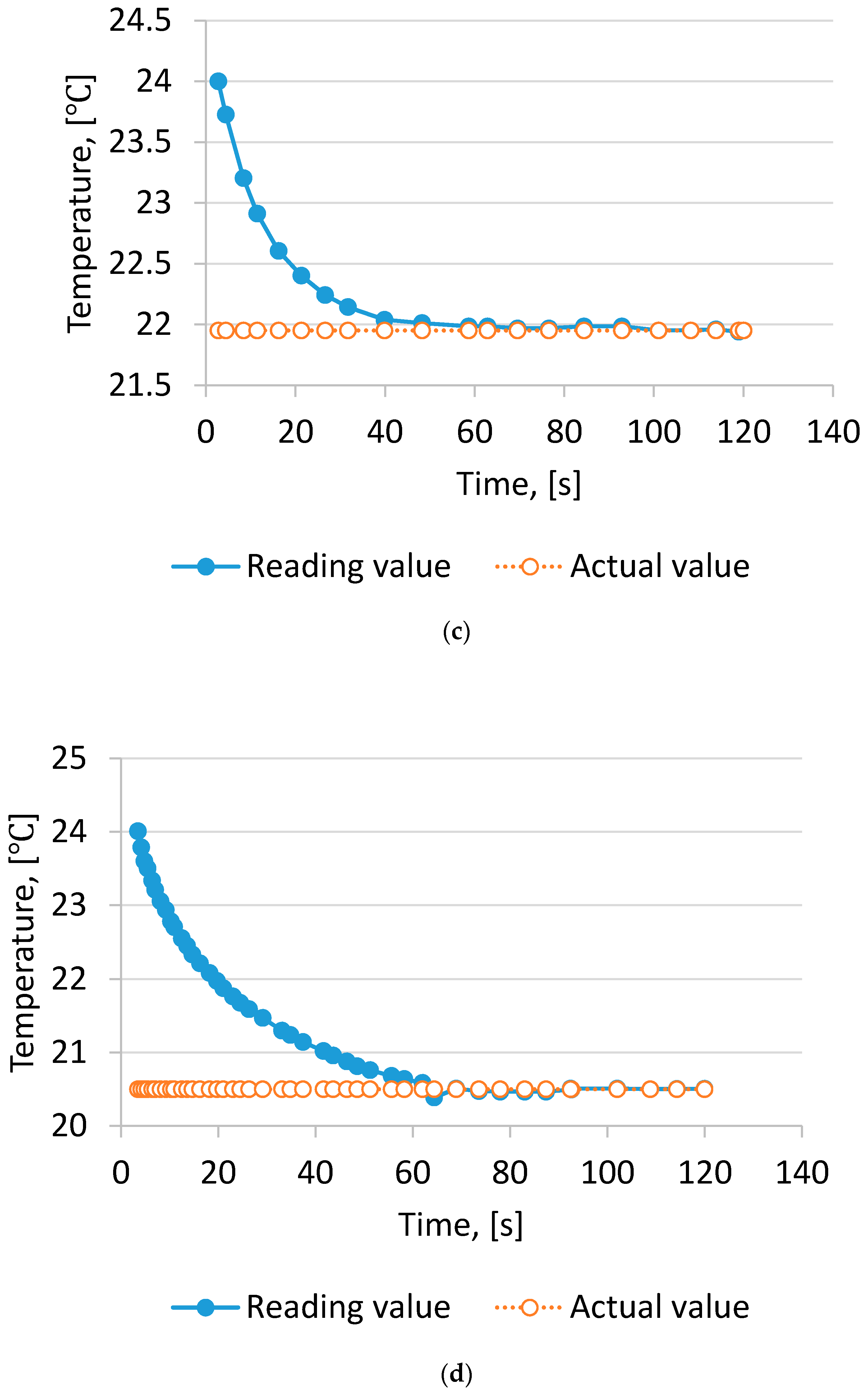

4.1. Effect of Air Velocity on Tw

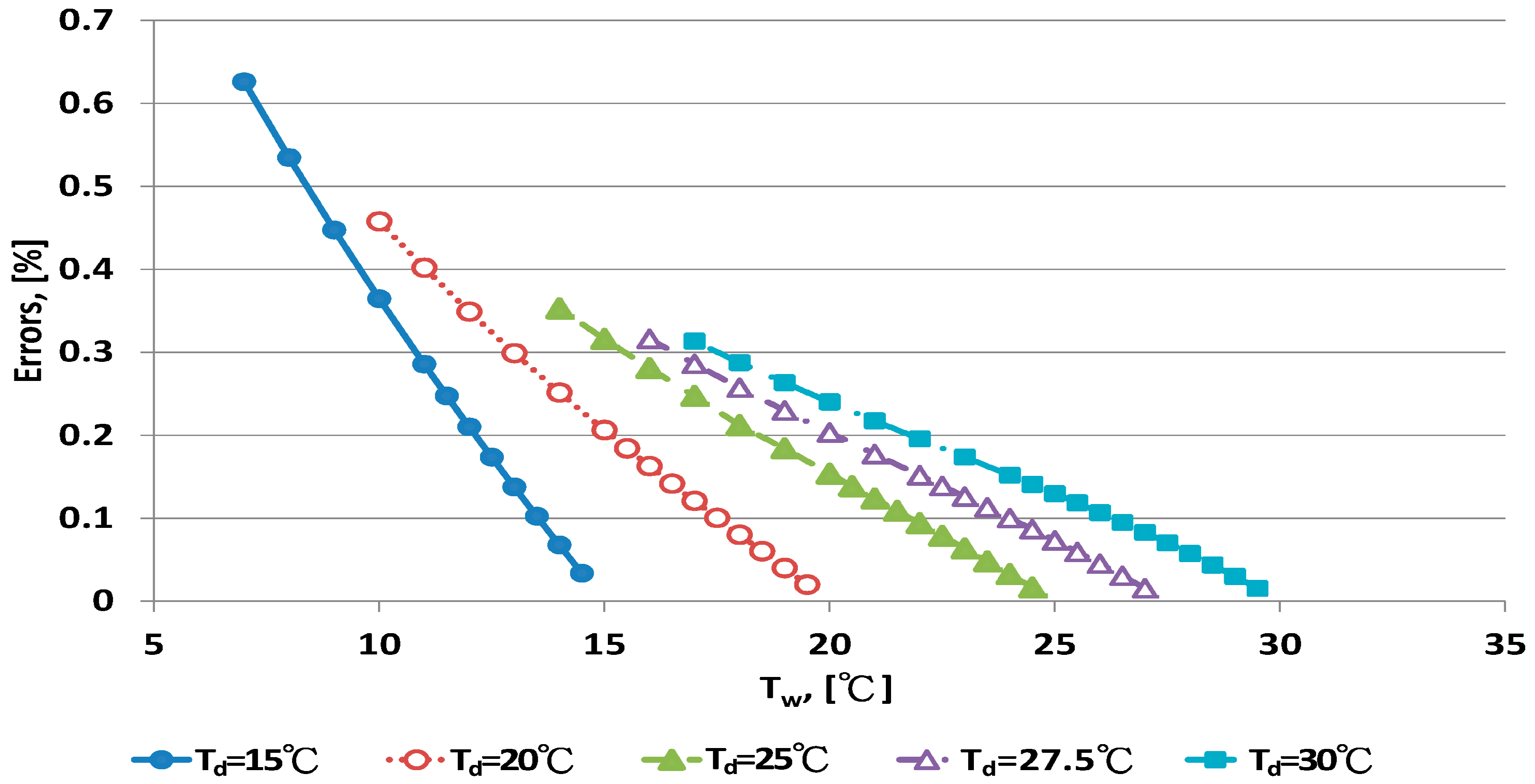

4.2. Comparison of Predictive Performance of Six Empirical Equations

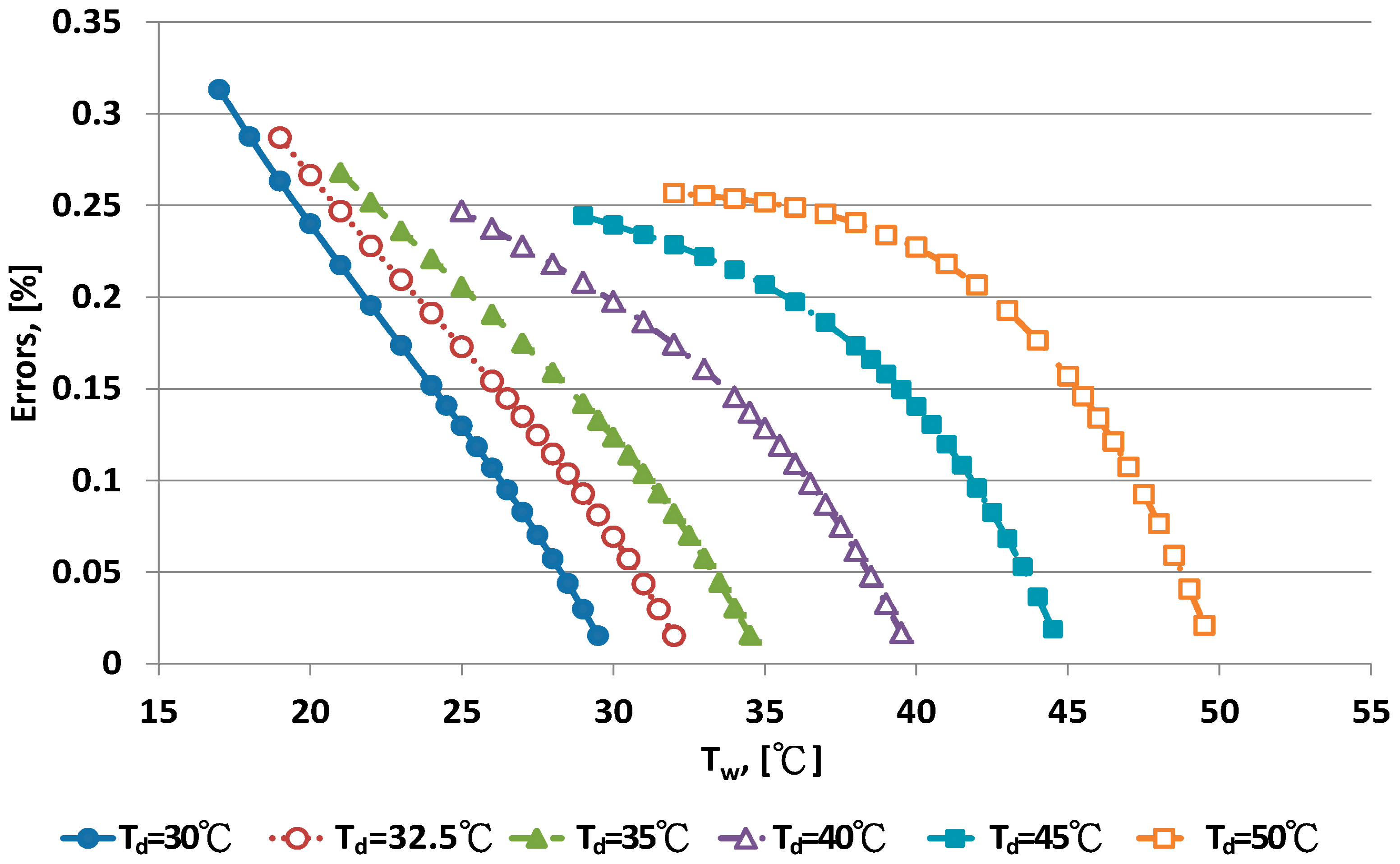

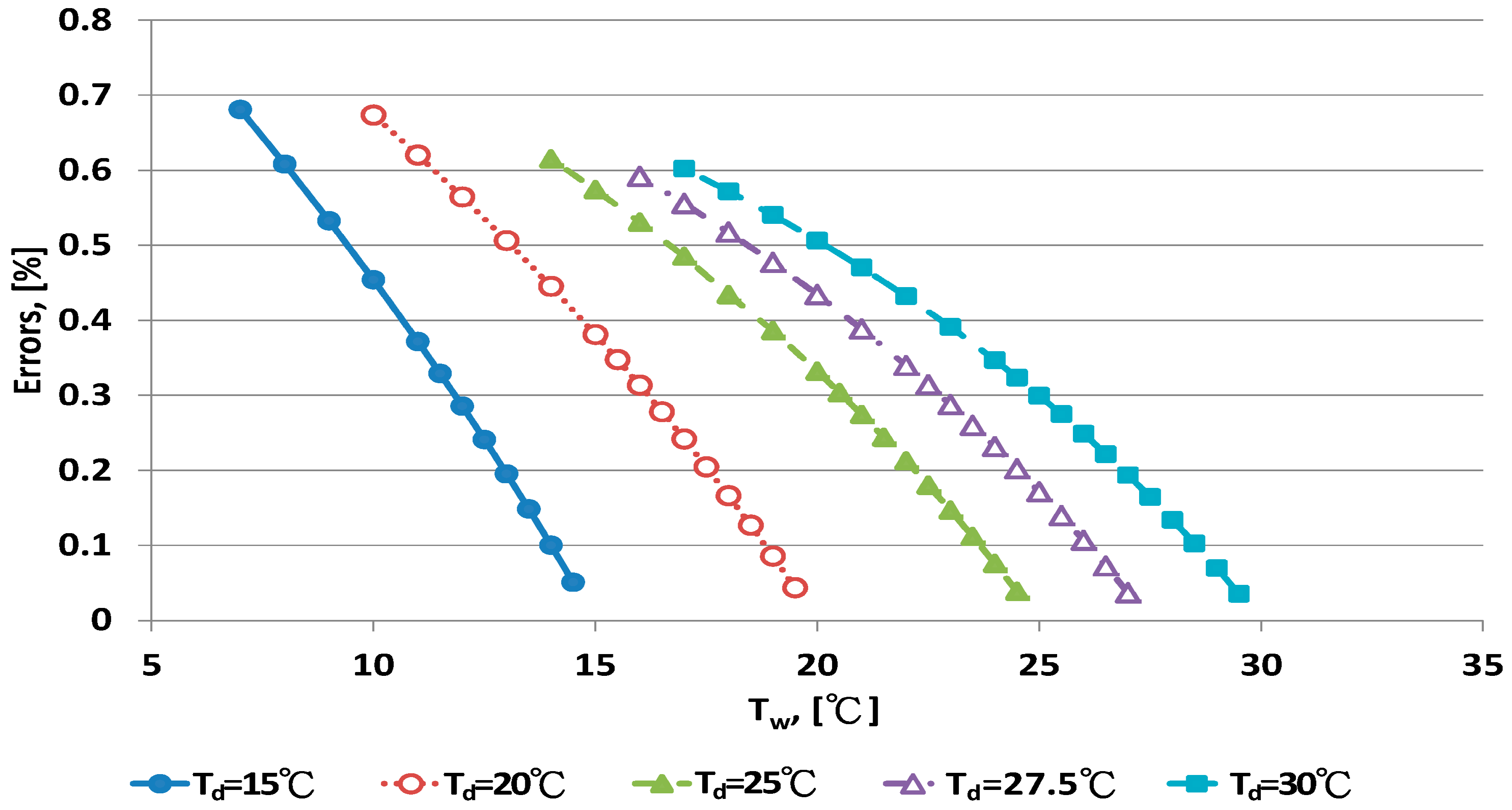

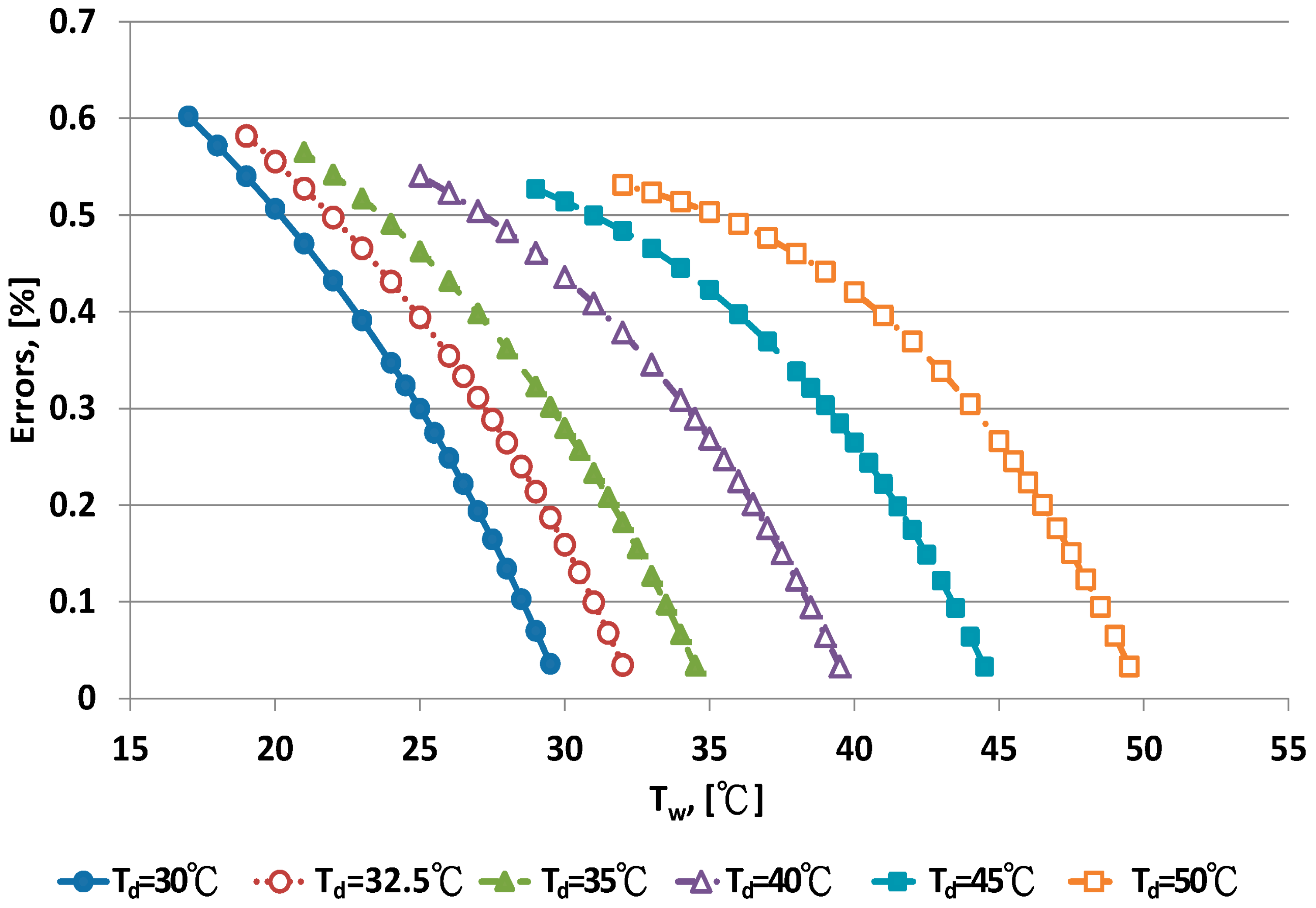

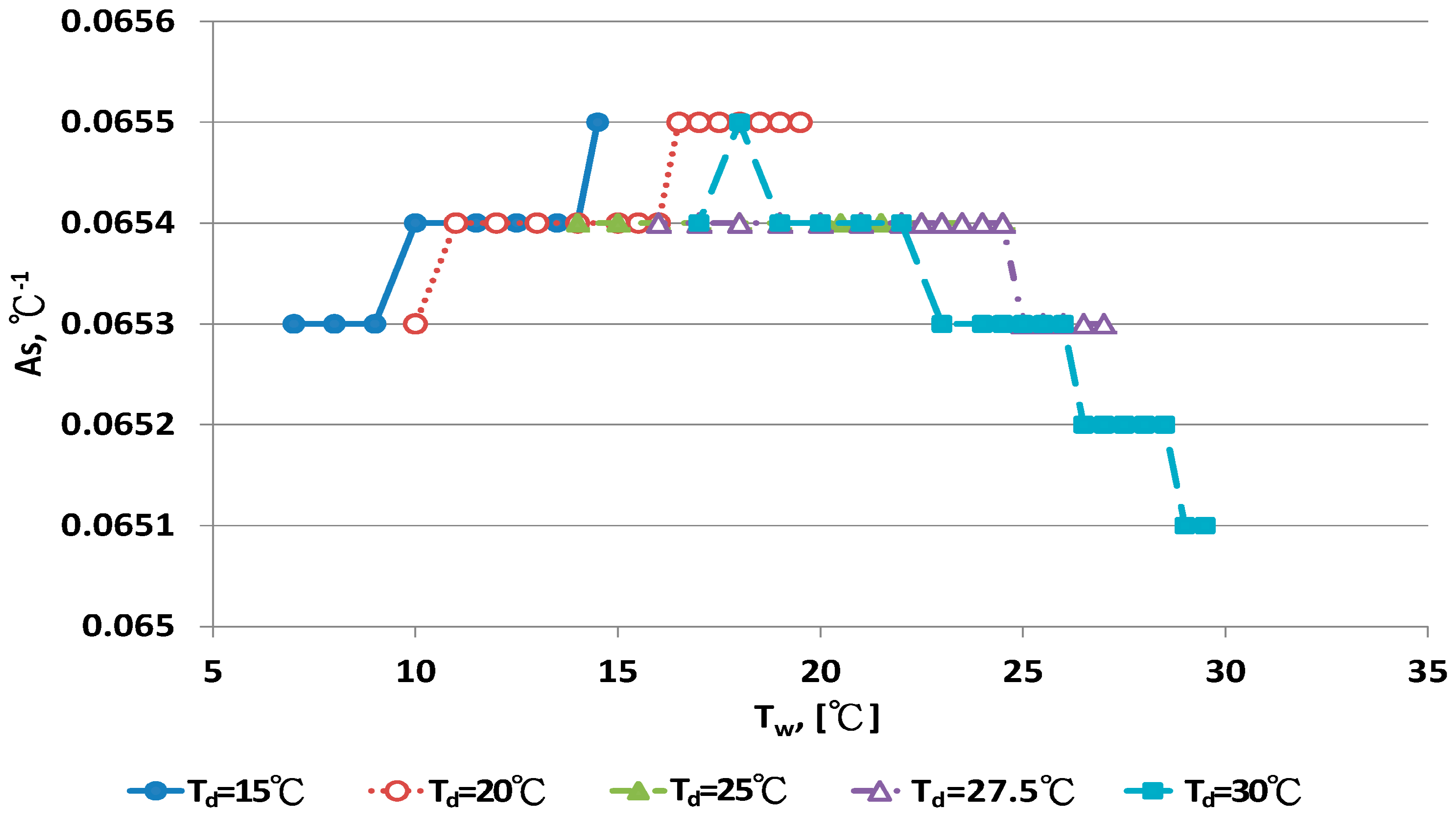

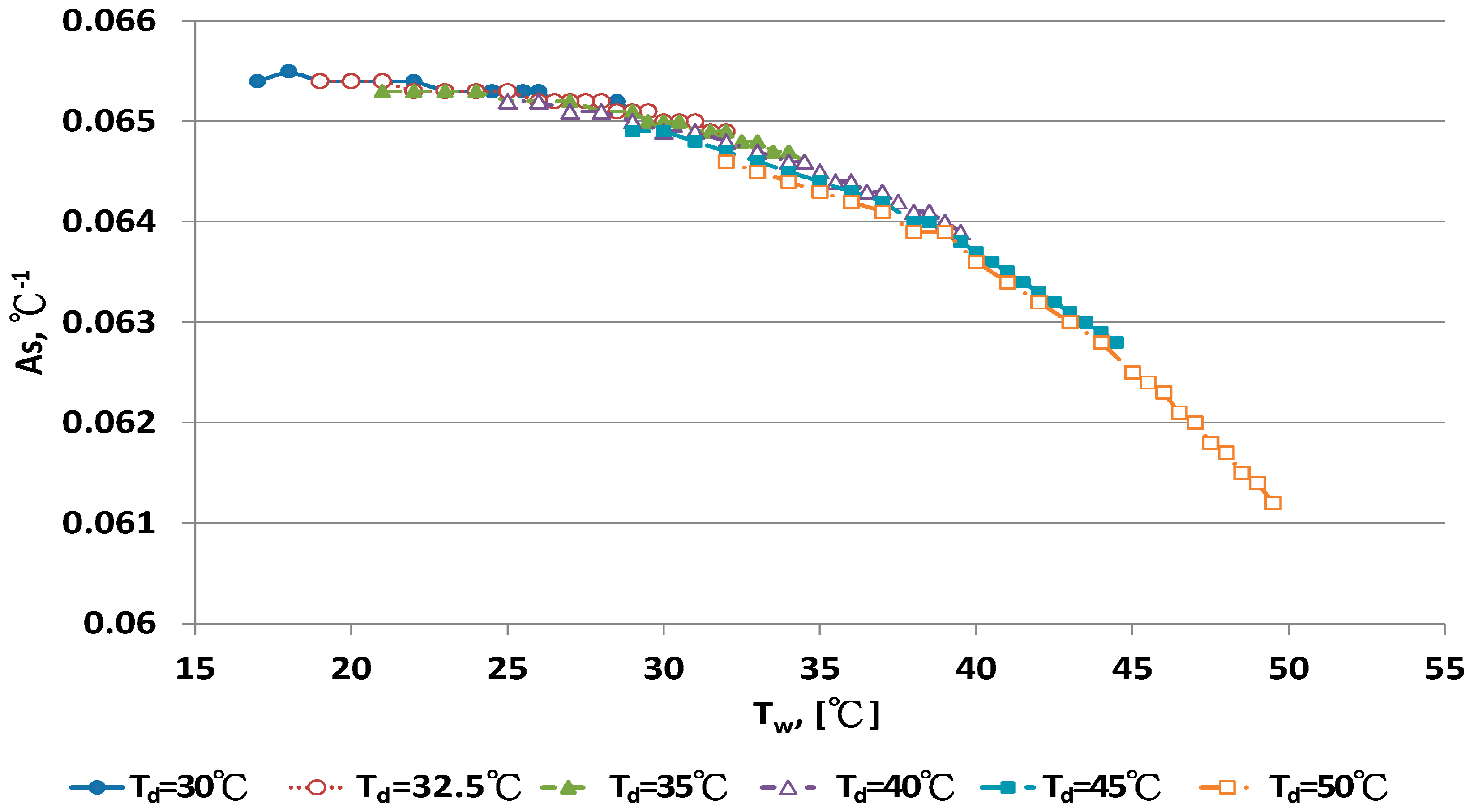

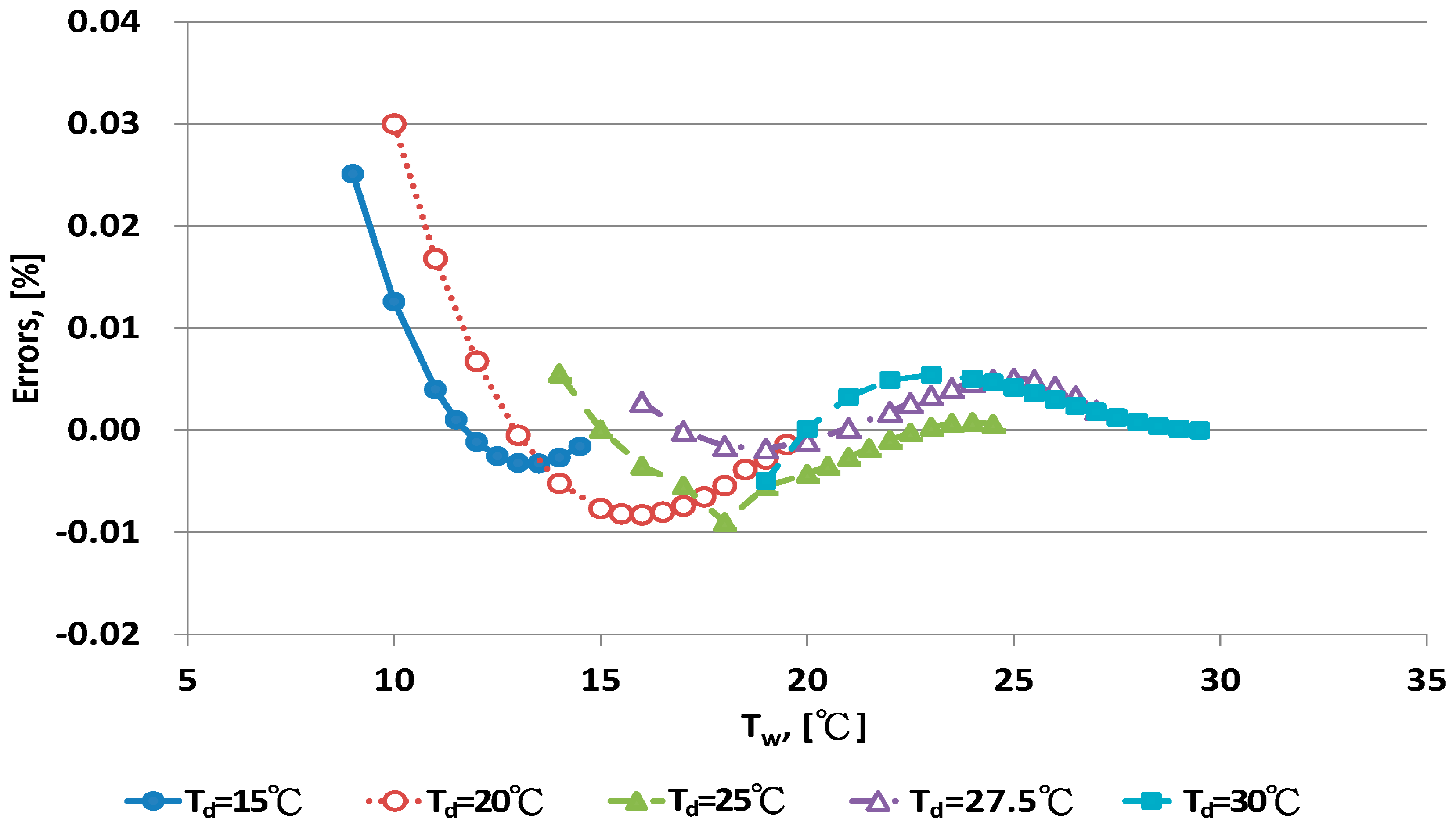

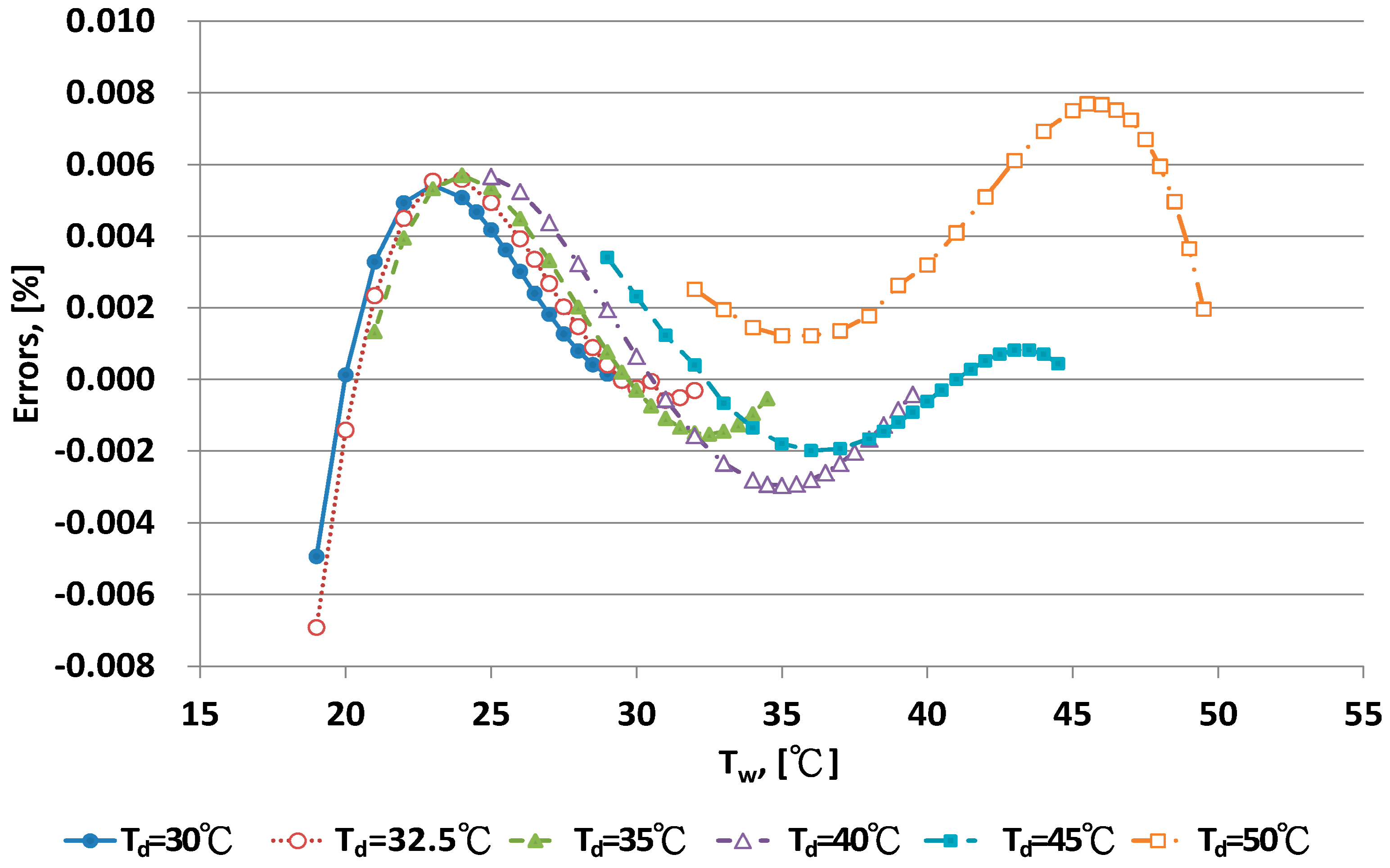

4.3. Development of a New As Equation

R2 = 0.99483, s = 4.73762 × 10−5, Td > 30 °C,

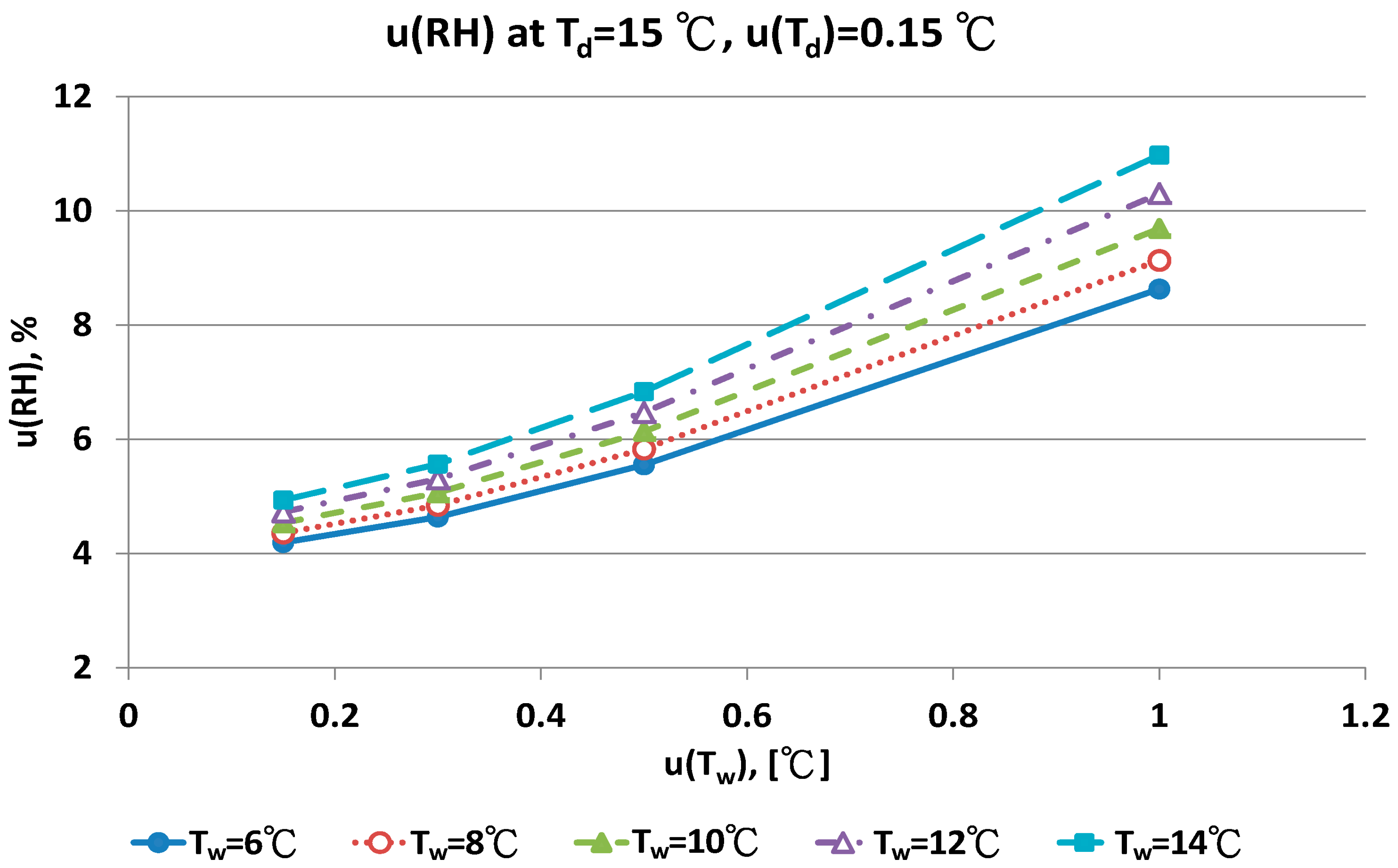

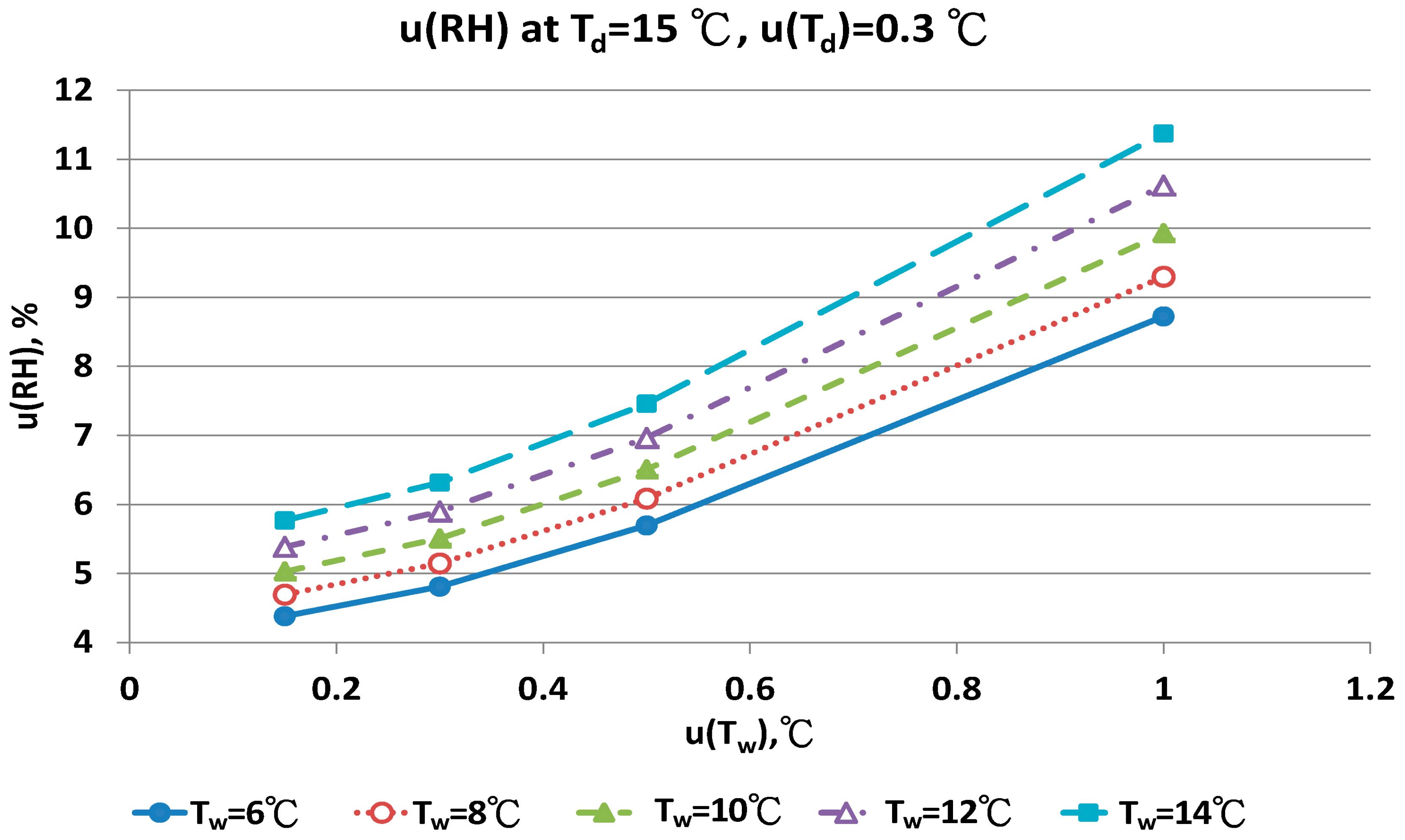

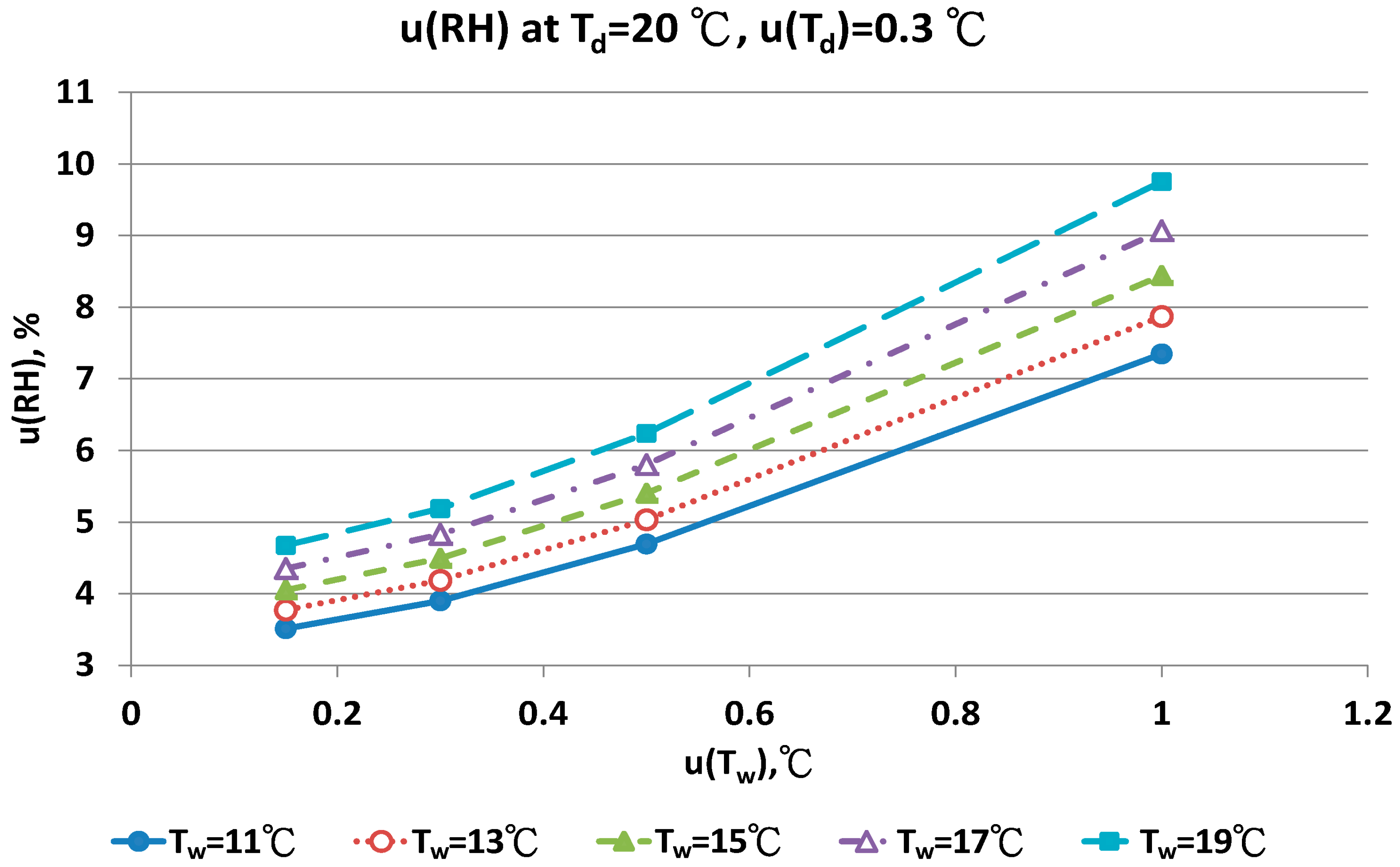

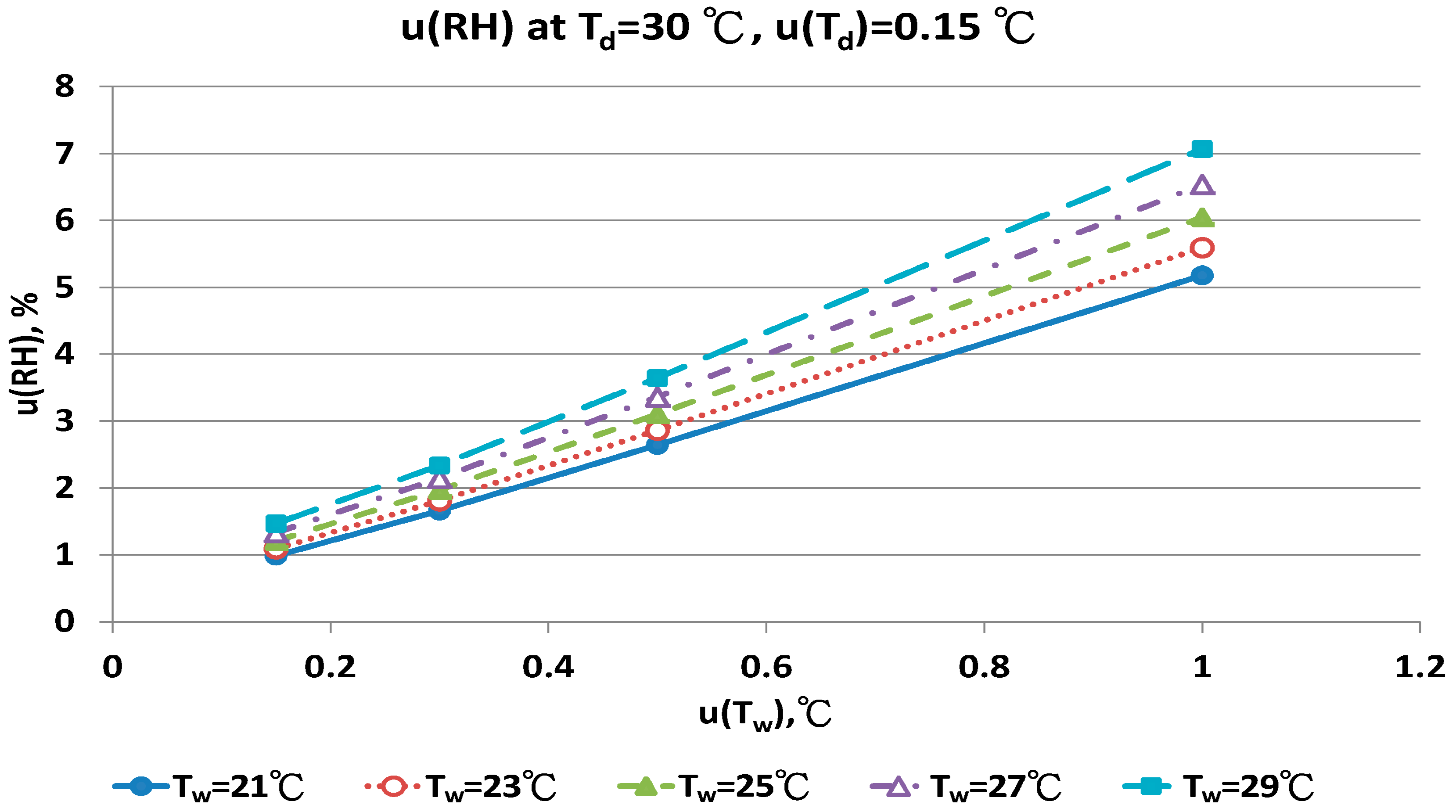

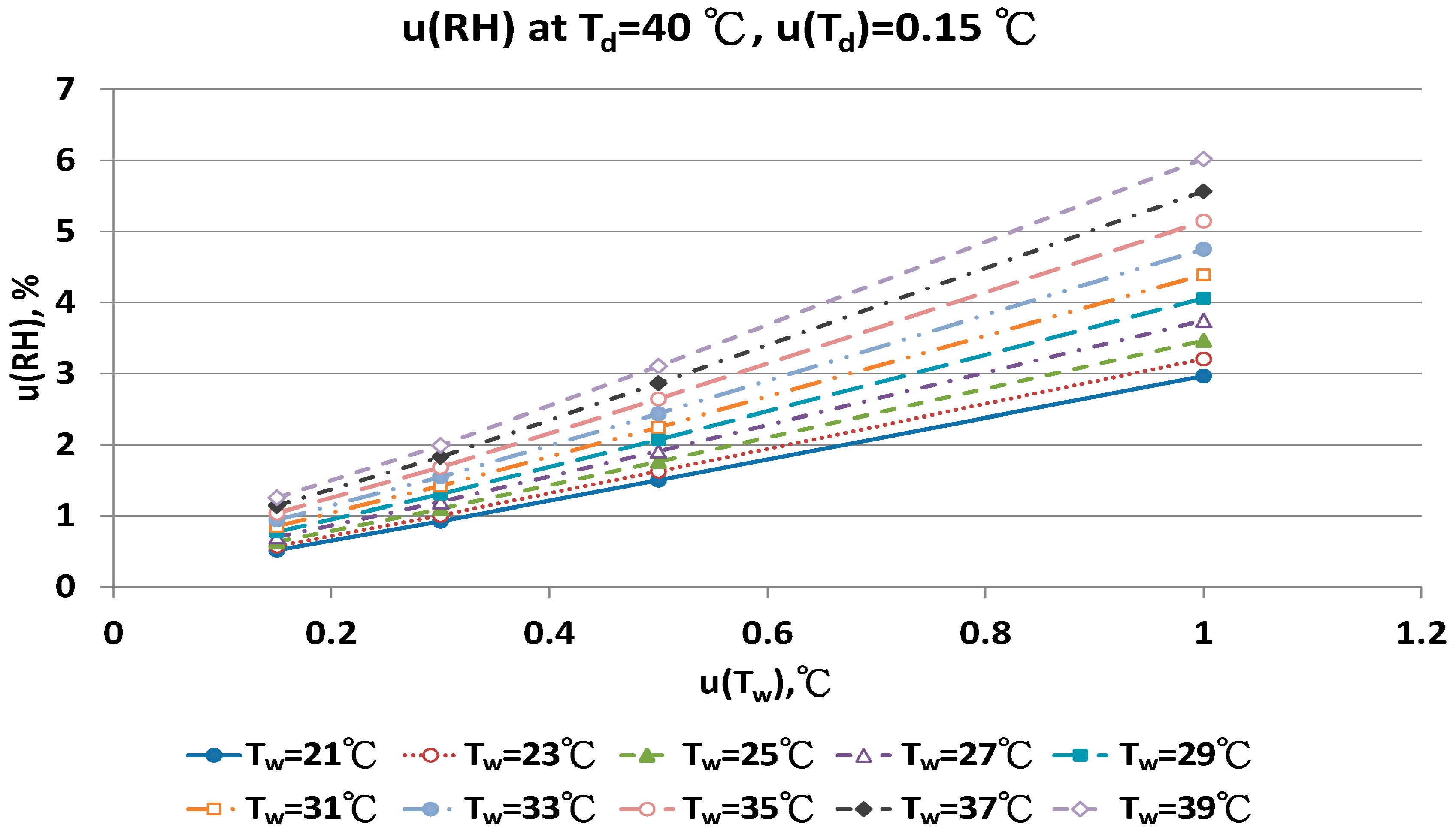

4.4. Measurement Uncertainty of Humidity Calculated by Td and Tw Values

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | psychrometric coefficient °C−1·kPa−1 |

| As | psychrometric constant incorporated air atmosphere term, °C−1 |

| e | vapor pressure, kPa |

| es | saturated vapor pressure, kPa |

| E | error of predictive performance, % |

| Emax | maximum error of predictive performance, % |

| Emin | minima error of predictive performance, % |

| absolute error of predictive performance, % | |

| ave | average of |

| n | number of data |

| P | atmosphere air pressure, kPa |

| RHcal | calculated RH value from empirical equation |

| RHsta | standard RH value from ASHRAE Handbook |

| T | temperature of air, °C |

| Td | dry bulb temperature, °C |

| Tw | wet bulb temperature, °C |

| u(RH) | uncertainty of relative humidity |

| u(Td) | uncertainty of dry bulb temperature |

| u(Tw) | uncertainty of wet bulb temperature |

Appendix A. Evaluation of the Measurement Uncertainty

- 1

- Model the measurementy is not measured directly and is determined from K quantities ,The functional relationship is as follows:

- 2

- Ensure the uncertainty source and calculate the estimated values ofwhere is the combined uncertainty and y is the output quantity.

- 3

- Evaluate the uncertainty classified as A and B types.

- 4

- Estimate the covariance of each .

- 5

- Calculate the sensitivity coefficient,

- 6

- Calculate the combining uncertainty and effective degree of freedom.

- 7

- Determine a coverage factor and expanded uncertainty.

- 8

- Report the uncertainty.The uncertainty of RH value that calculated from Td and Tw values.By Equation (A2), the uncertainty of RH can be calculated follows:If As is a constant,If ,

References

- Wernecke, R.; Wernecke, J. Industrial Moisture and Humidity Measurement: A Practical Guide; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- EN 15251. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- ASHRAE. The ASHRAE Guide for Buildings in Hot and Humid Climates; ASHRAE: Atlanta, GA, USA, 2009. [Google Scholar]

- D’Ambrosio Alfano, F.; Malchaire, J.; Palella, B.I.; Riccio, G. The WBGT index revisited after 60 years of use. Ann. Occup. Hyg. 2014, 58, 955–970. [Google Scholar] [PubMed]

- Kjellstrom, T.; Holmér, I.; Lemke, B. Workplace heat stress, health and productivity an increasing challenge for low and middle-income countries during climate change. Glob. Health Action 2009, 2, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Dell'Isola, M.; Frattolillo, A.; Palella, B.I.; Riccio, G. Influence of measurement uncertainties on the thermal environment assessment. Int. J. Thermophys. 2012, 33, 1616–1632. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.; Palella, B.I.; Riccio, G. The role of measurement accuracy on the heat stress assessment according to ISO 7933: 2004. WIT Trans. Biomed. Health 2007, 11, 115–124. [Google Scholar]

- Wiederhold, P.R. Water Vapor Measurement; Marcel Dekker, Inc.: New York, NY, USA, 1997. [Google Scholar]

- Pallas-Areny, R.; Webster, J.G. Sensors and Signal Conditioning; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Fleming, R.J. A note on temperature and relative humidity corrections for humidity sensors. J. Atmos. Ocean. Technol. 1998, 15, 1511–1515. [Google Scholar] [CrossRef]

- Lu, T.; Chen, C. Uncertainty evaluation of humidity sensors calibrated by saturated salt solutions. Measurement 2007, 40, 591–599. [Google Scholar] [CrossRef]

- ISO. Ergonomics of the Thermal Environment: Instruments for Measuring Physical Quantities; ISO: Geneva, Switzerland, 2002. [Google Scholar]

- D’Ambrosio Alfano, F.; Palella, B.I.; Riccio, G. On the problems related to natural wet bulb temperature indirect evaluation for the assessment of hot thermal environments by means of WBGT. Ann. Occup. Hyg. 2012, 56, 1063–1079. [Google Scholar] [PubMed]

- ASHRAE. Brochure on Psychrometer; ASHRAE: Atlanta, GA, USA, 1977. [Google Scholar]

- ASHRAE. ASHRAE Handbook: Fundamentals; ASHRAE: Atlanta, GA, USA, 2013. [Google Scholar]

- Singh, A.K.; Singh, H.; Singh, S.P.; Sawhney, R.L. Numerical calculation of psychrometric properties on a calculator. Build. Environ. 2002, 37, 415–419. [Google Scholar] [CrossRef]

- Bahadori, A.; Zahedi, G.; Zendehboudi, S.; Hooman, K. Simple predictive tool to estimate relative humidity using wet bulb depression and dry bulb temperature. Appl. Therm. Eng. 2013, 50, 511–515. [Google Scholar] [CrossRef]

- Harrison, R.G.; Wood, C.R. Ventilation effects on humidity measurements in thermometer screens. Q. R. Meteorol. Soc. 2012, 138, 1114–1120. [Google Scholar] [CrossRef]

- Ustymczuk, A.; Giner, S.A. Relative humidity errors when measuring dry and wet bulb temperatures. Biosyst. Eng. 2012, 110, 106–111. [Google Scholar] [CrossRef]

- Mathioulakis, E.; Panaras, G.; Belessiotis, V. Estimation of uncertainties in indirect humidity measurements. Energy Build. 2011, 43, 2806–2812. [Google Scholar] [CrossRef]

- The Sensirion Company. Introduction to Humidity—Basic Principles on Physics of Water Vapor; The Sensirion Company: Staefa, Switzerland, 2009. [Google Scholar]

- Penman, H.L. Humidity; Reinhold Publishing Co.: New York, NY, USA, 1958. [Google Scholar]

- Goff, J.A.; Gratch, S. Thermodynamic properties of moist air. Trans. ASHVE 1945, 51, 125–164. [Google Scholar]

- British United Turkeys Ltd. Measurement of Incubation Humidity; British United Turkeys Ltd.: Cheshire, UK, 2005. [Google Scholar]

- Harrison, L.D. Fundamental Concepts and Definitions Relating to Humidity. In Humidity and Moisture; Wexler, A., Ed.; Reinhold Publishing Co.: New York, NY, USA, 1963; Volume 3. [Google Scholar]

- WMO. Guide to Meteorological Instruments and Methods of Observation; WMO-No. 8; World Meteorological Organisation: Geneva, Switzerland, 2006. [Google Scholar]

- De, B.; Neiva, A.C.; dos Reis, E.; Sanchez, C.G. Calibration and Validation of a New Aspirated Psychrometer for Technological Development of Humidifier. In Proceedings of the XVIII IMEKO World Congress, Rio de Janeiro, Brazil, 17–22 September 2006.

- ISO/IEC 98–3. Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement; ISO Edition: Geneva, Switzerland, 2010. [Google Scholar]

- National Aeronautics and Space Administration. Measurement Uncertainty Analysis Principles and Methods, NASA Measurement Quality Assurance Handbook—Annex 3; National Aeronautics and Space Administration: Washington, DC, USA, 2010.

- Grabe, M. Measurement Uncertainties in Science and Technology, 2nd ed.; Springer: Heidelberg, Germany, 2005. [Google Scholar]

- Barber, E.M.; Gu, D. Performance of an aspirated psychrometer and three hygrometers in livestock barns. Appl. Eng. Agric. 1988, 5, 595–599. [Google Scholar] [CrossRef]

- Simoes-Moreira, J.R. A thermodynamic formulation of the psychrometer constant. Meas. Sci. Technol. 1999, 10, 302–311. [Google Scholar] [CrossRef]

- Chen, C. Evaluation of measurement uncertainty for thermometers with calibration equations. Accredit. Qual. Assur. 2006, 11, 75–82. [Google Scholar] [CrossRef] [Green Version]

| 1 | Penman equation [22] |

| Pw = Pws (Tw) − 0.0664 × (Td – Tw) | |

| 2 | Goft-Cratch equation [23] |

| Pw = Pws (Tw) − 0.067193 × (Td – Tw) | |

| 3 | British United Turkeys (BUT) equation [24] |

| Pw = Pws (Tw) − 0.066 × (Td – Tw) | |

| 4 | Harrison equation [25] |

| Pw = Pws (Tw) − 0.067 × (1 + 0.00115Tw) × (Td – Tw) | |

| 5 | World meteorological Organisation (WMO) equation [26] |

| Pw = Pws (Tw) − 0.0662795 × (1 + 0.000944Tw) × (Td – Tw) | |

| 6 | Nevia et al. equation [27] |

| Pw = Pws (Tw) − 0.0647164 × (1 + 0.00504Tw) × (Td – Tw) |

| Temp. (°C) | Criteria | As (This Study) °C−1 | Penman | BUT | Goff-Cratch | Harrison | WMO | Neiva et al. |

|---|---|---|---|---|---|---|---|---|

| 15 | Emin | −0.0032 | 0.0278 | 0.0336 | 0.0510 | 0.2783 | 0.0508 | 0.1171 |

| Emax | 0.0476 | 0.5321 | 0.6259 | 0.1041 | 0.9483 | 0.6808 | 0.8323 | |

| ave | 0.0988 | 0.2261 | 0.2691 | 0.3966 | 0.6492 | 0.3331 | 0.5575 | |

| 20 | Emin | −0.00823 | 0.1999 | 0.0115 | 0.0370 | 0.2353 | 0.0435 | 0.1200 |

| Emax | 0.0300 | 0.4577 | 0.2866 | 0.7969 | 0.9548 | 0.6735 | 1.3476 | |

| ave | 0.0079 | 0.1917 | 0.1947 | 0.3443 | 0.6330 | 0.3332 | 0.7268 | |

| 25 | Emin | −0.0090 | 0.0164 | 0.0195 | 0.0289 | 0.0557 | 0.0387 | 0.1161 |

| Emax | 0.0056 | 0.3528 | 0.4223 | 0.6282 | 0.9358 | 0.6150 | 1.3540 | |

| ave | 0.0448 | 0.1531 | 0.1841 | 0.2759 | 0.4612 | 0.3091 | 0.8033 | |

| 27.5 | Emin | −0.0018 | 0.0156 | 0.0183 | 0.0264 | 0.2815 | 0.0370 | 0.1126 |

| Emax | 0.0051 | 0.3161 | 0.3187 | 0.5645 | 0.9617 | 0.5918 | 1.4235 | |

| ave | 0.0029 | 0.1418 | 0.1696 | 0.2523 | 0.6542 | 0.3016 | 0.8282 | |

| 30 | Emin | −0.0423 | 0.0153 | 0.0176 | 0.0246 | 0.2474 | 0.0356 | 0.1080 |

| Emax | 0.0054 | 0.3132 | 0.3745 | 0.5562 | 0.9635 | 0.6021 | 1.4964 | |

| ave | 0.0058 | 0.1422 | 0.1693 | 0.2494 | 0.6368 | 0.3205 | 0.8774 | |

| 32.5 | Emin | −0.0069 | 0.0153 | 0.0174 | 0.0234 | 0.2603 | 0.0346 | 0.1048 |

| Emax | 0.0056 | 0.2870 | 0.3423 | 0.5060 | 0.9651 | 0.5818 | 1.5331 | |

| ave | 0.0024 | 0.1384 | 0.1628 | 0.2349 | 0.6418 | 0.3068 | 0.8004 | |

| 35 | Emin | −0.0015 | 0.0156 | 0.0174 | 0.0267 | 0.2715 | 0.0338 | 0.1008 |

| Emax | 0.0057 | 0.2679 | 0.3119 | 0.4654 | 0.9665 | 0.5649 | 1.5543 | |

| ave | 0.00216 | 0.1576 | 0.1576 | 0.2224 | 0.6474 | 0.3015 | 0.8851 | |

| 40 | Emin | −0.0030 | 0.0170 | 0.0183 | 0.0223 | 0.0411 | 0.0329 | 0.0929 |

| Emax | 0.0057 | 0.2470 | 0.2877 | 0.4083 | 0.7609 | 0.5406 | 1.5631 | |

| ave | 0.0024 | 0.1388 | 0.1566 | 0.2095 | 0.4017 | 0.3015 | 0.8751 | |

| 45 | Emin | −0.0020 | 0.0188 | 0.0199 | 0.0230 | 0.0399 | 0.0327 | 0.0858 |

| Emax | 0.0034 | 0.2444 | 0.2778 | 0.3768 | 0.7177 | 0.5271 | 1.5428 | |

| ave | 0.0011 | 0.1511 | 0.1656 | 0.2088 | 0.3910 | 0.3016 | 0.8592 | |

| 50 | Emin | −0.0076 | 0.0210 | 0.0218 | 0.0242 | 0.0389 | 0.0331 | 0.0797 |

| Emax | 0.0077 | 0.2568 | 0.2859 | 0.3725 | 0.7041 | 0.5313 | 1.5342 | |

| ave | 0.0046 | 0.1719 | 0.1848 | 0.2232 | 0.4015 | 0.3190 | 0.8706 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Chen, C. Uncertainty Analysis in Humidity Measurements by the Psychrometer Method. Sensors 2017, 17, 368. https://doi.org/10.3390/s17020368

Chen J, Chen C. Uncertainty Analysis in Humidity Measurements by the Psychrometer Method. Sensors. 2017; 17(2):368. https://doi.org/10.3390/s17020368

Chicago/Turabian StyleChen, Jiunyuan, and Chiachung Chen. 2017. "Uncertainty Analysis in Humidity Measurements by the Psychrometer Method" Sensors 17, no. 2: 368. https://doi.org/10.3390/s17020368