Vibration Sensor Monitoring of Nickel-Titanium Alloy Turning for Machinability Evaluation

Abstract

:1. Introduction

- detection of machining process variables through sensorial perception methods;

- sensor signals processing;

- relevant sensorial features extraction and selection;

- implementation of decision making paradigms for diagnosis on machining process conditions;

- activation of corrective actions.

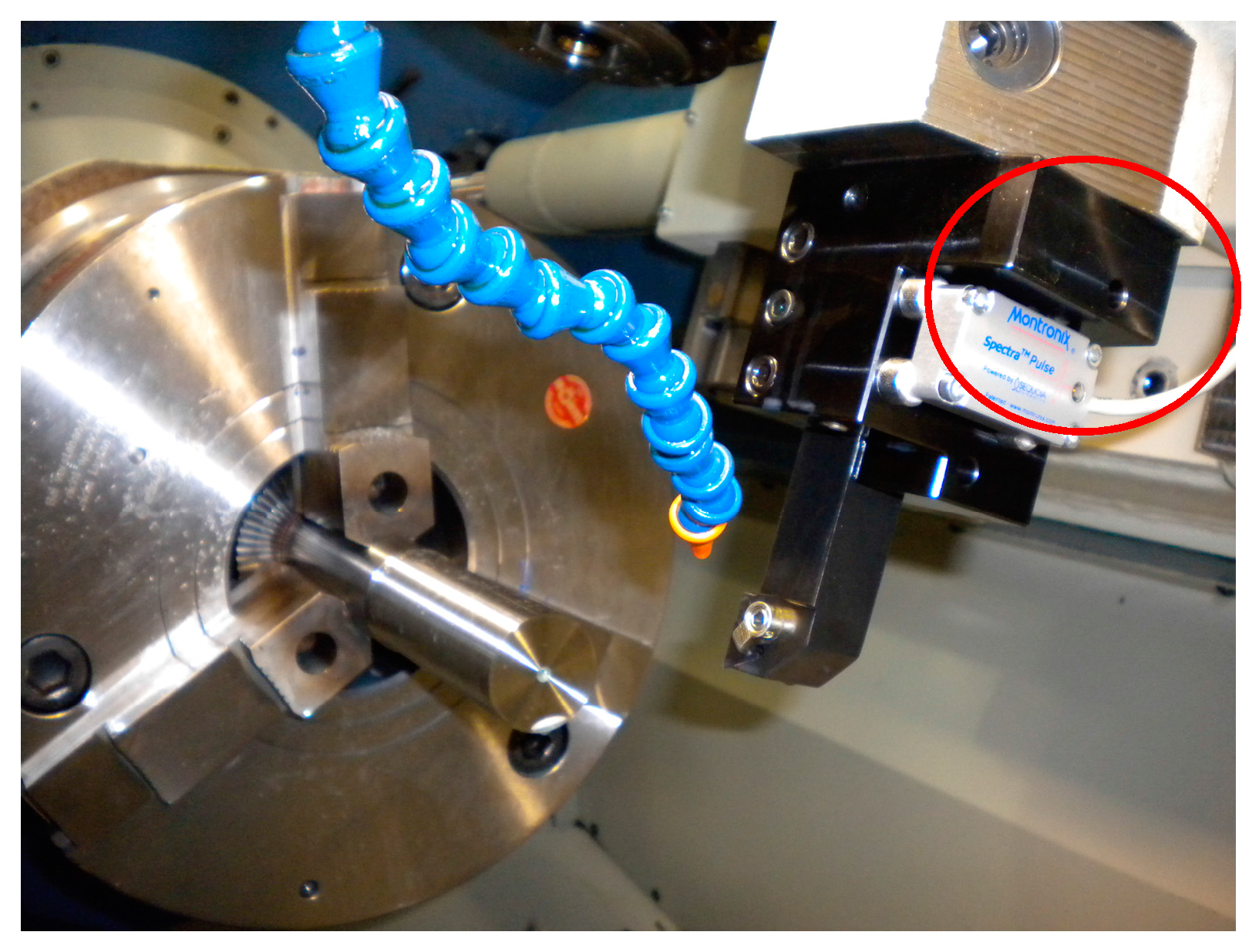

2. Experimental Setup and Vibration Sensor Signals Acquisition

3. Vibration Sensor Signal Processing

4. Feature Extraction through Wavelet Packet Transform

5. Machinability Classification

6. Cognitive Pattern Recognition via Neural Networks

- -

- input layer with five nodes, according to the number of input feature vector elements (the five statistical features for each packet);

- -

- hidden layer with a number of nodes equal to 5, 10 or 15;

- -

- output layer with only one node, providing a binary target value associated to machinability condition: 0 = Acceptable; 1 = Poor.

7. Results and Discussion

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shimizu, K.; Tadaki, T. Shape Memory Alloys; Funakubo, H., Ed.; Gordon and Breach Science Publishers: Abingdon-on-Thames, UK, 1987. [Google Scholar]

- Duerig, T.W.; Melton, K.N.; Stöckel, D.; Wayman, C.M. Engineering Aspects of Shape Memory Alloys; Butterworth Heinemann: London, UK, 1990; p. 130. [Google Scholar]

- Turner, J.D. Memory-metal Actuators for Automotive Applications. Proc. Inst. Mech. Eng. 1994, 208, 299–302. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Ding, H. Tool wear characteristics in machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2013, 64, 60–77. [Google Scholar] [CrossRef]

- Mussot-Hoinarda, G.; Elmay, W.; Peltier, L.; Laheurte, P. Fatigue performance evaluation of a Nickel-free titanium-based alloy for biomedical application—Effect of thermomechanical treatments. J. Mech. Behav. Biomed. Mater. 2017, 71, 32–42. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.H.; Sealy, M.P.; Guo, Y.B.; Wei, X.T. Austenite—Martensite phase transformation of biomedical Nitinol by ball burnishing. J. Mater. Process. Technol. 2014, 214, 3122–3130. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Pressas, I.S.; Manolakos, D.E. A Review on the machining of Nickel-Titanium shape memory alloys. Rev. Adv. Mater. Sci. 2015, 42, 28–35. [Google Scholar]

- Ulutan, D.; Özel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Guo, Y.; Klink, A.; Fu, C.; Snyder, J. Machinability and surface integrity of Nitinol shape memory alloy. CIRP Ann. 2013, 62, 83–86. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, H.E.; Noebe, R.D.; Jawahir, I.S. Analysis of Tool-wear and Cutting Force Components in Dry, Preheated, and Cryogenic Machining of NiTi Shape Memory Alloys. Procedia CIRP 2013, 8, 498–503. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, H.E.; Jawahir, I.S. Surface integrity characteristics of NiTi shape memory alloys resulting from dry and cryogenic machining. Procedia CIRP 2014, 13, 393–398. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V. Machining of NiTi based shape memory alloys. Mater. Sci. Eng. A 2004, 378, 180–184. [Google Scholar] [CrossRef]

- Weinert, K.; Petzoldt, V.; Kötter, D. Turning and Drilling of NiTi Shape Memory Alloys. CIRP Ann. 2004, 53, 65–68. [Google Scholar] [CrossRef]

- Zailani, Z.A.; Mativenga, P.T. Effects of Chilled Air on Machinability of NiTi Shape Memory Alloy. Procedia CIRP 2016, 45, 207–210. [Google Scholar] [CrossRef]

- Kaynak, Y.; Karaca, H.E.; Noebe, R.D.; Jawahir, I.S. Tool-wear analysis in cryogenic machining of NiTi shape memory alloys: A comparison of tool-wear performance with dry and MQL machining. Wear 2013, 306, 51–63. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Caggiano, A.; Napolitano, F.; Teti, R. Dry Turning of Ti6Al4V: Tool Wear Curve Reconstruction Based on Cognitive Sensor Monitoring. Procedia CIRP 2017, 62, 209–214. [Google Scholar] [CrossRef]

- Dimla, D.E. Sensor signals for tool-wear monitoring in metal cutting: A review of methods. Int. J. Mach. Tools Manuf. 2000, 40, 1073–1098. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P.; Doukas, C.; Foteinopoulos, P.; Chryssolouris, G. Acoustic emission signal through turning tools: A computational study. Procedia CIRP 2013, 8, 426–431. [Google Scholar] [CrossRef]

- Er, P.V.; Teo, C.S.; Tan, K.K. Approach towards sensor placement, selection and fusion for real-time condition monitoring of precision machines. Mech. Syst. Signal Process. 2016, 68–69, 105–124. [Google Scholar] [CrossRef]

- Aouabdi, S.; Taibi, M.; Bouras, S.; Boutasseta, N. Using multi-scale entropy and principal component analysis to monitor gears degradation via the motor current signature analysis. Mech. Syst. Signal Process. 2017, 90, 298–316. [Google Scholar] [CrossRef]

- Segreto, T.; Simeone, A.; Teti, R. Principal component analysis for feature extraction and NN pattern recognition in sensor monitoring of chip form during turning. CIRP J. Manuf. Sci. Technol. 2014, 7, 202–209. [Google Scholar] [CrossRef]

- Segreto, T.; Simeone, A.; Teti, R. Chip form classification in carbon steel turning through cutting force measurement and principal components analysis. Procedia CIRP 2012, 2, 49–54. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, H.T.; Wu, Y.; Zhu, T.; Ding, H. Bayesian learning-based model predictive vibration control for thin-walled workpiece machining processes. IEEE/ASME Trans. Mechatron. 2017, 22, 509–520. [Google Scholar] [CrossRef]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef]

- Lauro, C.H.; Brandão, L.C.; Baldo, D.; Reis, R.A.; Davim, J.P. Monitoring and processing signal applied in machining processes—A review. Measurement 2014, 58, 73–86. [Google Scholar] [CrossRef]

- Möhring, H.-C.; Litwinski, K.M.; Gümmer, O. Process monitoring with sensory machine tool components. CIRP Ann. Manuf. Technol. 2010, 59, 383–386. [Google Scholar] [CrossRef]

- Segreto, T.; Caggiano, A.; Teti, R. Neuro-fuzzy system implementation in multiple sensor monitoring for Ni-Ti alloy machinability evaluation. Procedia CIRP 2015, 37, 193–198. [Google Scholar] [CrossRef]

- Teti, R. Advanced IT methods of signal processing and decision making for zero defect manufacturing in machining. Procedia CIRP 2015, 28, 3–15. [Google Scholar] [CrossRef]

- Wang, H.; To, S.; Chan, C.Y. Investigation on the influence of tool-tip vibration on surface roughness and its representative measurement in ultra-precision diamond turning. Int. J. Mach. Tools Manuf. 2013, 69, 20–29. [Google Scholar] [CrossRef]

- Segreto, T.; Karam, S.; Simeone, A.; Teti, R. Residual stress assessment in Inconel 718 machining through wavelet sensor signal analysis and sensor fusion pattern recognition. Procedia CIRP 2013, 9, 103–108. [Google Scholar] [CrossRef]

- Viktor Skrickij, V.; Bogdevičius, M.; Junevičius, R. Diagnostic features for the condition monitoring of hypoid gear utilizing the wavelet transform. Appl. Acoust. 2016, 106, 51–62. [Google Scholar] [CrossRef]

- Xu, S.; Jiang, X.; Huang, J.; Yang, S.; Wang, X. Bayesian wavelet PCA methodology for turbomachinery damage diagnosis under uncertainty. Mech. Syst. Signal Process. 2016, 80, 1–18. [Google Scholar] [CrossRef]

- Segreto, T.; Teti, R. Applications of intelligent sensor monitoring for machining processes. In Laser Metrology & Machine Performance VIII; Proceedings of the 8th International Conference on Laser Metrology, Machine Tool, CMM & Robotic Performance; Lamdamap 2007, Cardiff, UK, 28 June 2007; Euspen: Bedford, UK, 2007; pp. 388–399. [Google Scholar]

- Wang, L.; Gao, R.X. Condition Monitoring and Control for Intelligent Manufacturing; Springer: London, UK, 2006. [Google Scholar]

- Peng, Z.; Chu, F.; He, Y. Vibration signal analysis and feature extraction based on reassigned wavelet scalogram. J. Sound Vib. 2002, 253, 1087–1100. [Google Scholar] [CrossRef]

- Upadhyay, V.; Jain, P.K.; Mehta, N.K. In-process prediction of surface roughness in turning of Ti–6Al–4V alloy using cutting parameters and vibration signals. Measurement 2013, 46, 154–160. [Google Scholar] [CrossRef]

- Abouelatta, O.B.; Madl, J. Surface roughness prediction based on cutting parameters and tool vibrations in turning operations. J. Mater. Process. Technol. 2001, 118, 269–277. [Google Scholar] [CrossRef]

- Dimla, D.E. The correlation of vibration signal features to cutting tool wear in a metal turning operation. Int. J. Adv. Manuf. Technol. 2002, 19, 705–713. [Google Scholar] [CrossRef]

- Bishop, C.M. Neural Networks for Pattern Recognition; Clarendon Press: Oxford, UK, 1995. [Google Scholar]

- D’Addona, D.; Segreto, T.; Simeone, A.; Teti, R. ANN tool wear modelling in the machining of Nickel superalloy industrial products. CIRP J. Manuf. Sci. Technol. 2011, 4, 33–37. [Google Scholar] [CrossRef]

- Gokhale, M.Y.; Khanduja, D.K. Time domain signal analysis using wavelet packet decomposition approach. Int. J. Commun. Netw. Syst. Sci. 2010, 3, 321–329. [Google Scholar] [CrossRef]

- Misiti, M.; Misiti, Y.; Oppenheim, G.; Poggi, J.M. (1997–2014) Wavelet Toolbox for Use with MATLAB; The MathWorks, Inc.: Natick, MA, USA, 2014. [Google Scholar]

| Cutting Parameters | Experimental Test Values | ||||

|---|---|---|---|---|---|

| Cutting speed vc (m/min) | 40 | 55 | 75 | 100 | 130 |

| Feed rate f (mm/rev) | 0.10 | 0.15 | 0.20 | ||

| Depth of cut ap (mm) | 0.50 | ||||

| Test ID | Cutting Speed | Feed Rate | Flank Wear | Crater Wear | Vibrations Level | Overall Classification |

|---|---|---|---|---|---|---|

| 1 | 40 | 0.10 | 1 | 1 | 2 | Acceptable |

| 2 | 40 | 0.15 | 1 | 1 | 2 | Acceptable |

| 3 | 40 | 0.20 | 1 | 1 | 3 | Acceptable |

| 4 | 55 | 0.10 | 1 | 1 | 2 | Acceptable |

| 5 | 55 | 0.15 | 1 | 1 | 3 | Acceptable |

| 6 | 55 | 0.20 | 1 | 1 | 3 | Acceptable |

| 7 | 75 | 0.10 | 2 | 2 | 2 | Acceptable |

| 8 | 75 | 0.15 | 1 | 1 | 3 | Acceptable |

| 9 | 75 | 0.20 | 1 | 1 | 4 | Poor |

| 10 | 100 | 0.10 | 1 | 1 | 2 | Acceptable |

| 11 | 100 | 0.15 | 1 | 1 | 4 | Poor |

| 12 | 100 | 0.20 | 1 | 1 | 4 | Poor |

| 13 | 130 | 0.10 | 5 | 5 | 3 | Poor |

| 14 | 130 | 0.15 | 5 | 4 | 4 | Poor |

| 15 | 130 | 0.20 | 5 | 2 | 5 | Poor |

| Vibration Component—ax | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NN Configuration | 5-5-1 | 5-10-1 | 5-15-1 | ||||||

| Wavelet Packet | Success Rates (%) for Features Extracted from Each WPT Packet | ||||||||

| Acceptable | Poor | Overall | Acceptable | Poor | Overall | Acceptable | Poor | Overall | |

| A | 82.2 | 70.0 | 77.3 | 82.2 | 70.0 | 77.3 | 82.2 | 73.3 | 78.7 |

| D | 77.8 | 63.3 | 72.0 | 73.3 | 80.0 | 76.0 | 86.7 | 76.7 | 82.7 |

| AA | 84.4 | 73.3 | 80.0 | 80.0 | 63.3 | 73.3 | 84.4 | 60.0 | 74.7 |

| DA | 84.4 | 73.3 | 80.0 | 91.1 | 73.3 | 84.0 | 80.0 | 66.7 | 74.7 |

| AD | 77.8 | 70.0 | 74.7 | 82.2 | 66.7 | 76.0 | 82.2 | 63.3 | 74.7 |

| DD | 77.8 | 60.0 | 70.7 | 84.4 | 73.3 | 80.0 | 82.2 | 80.0 | 81.3 |

| AAA | 86.7 | 80.0 | 84.0 | 84.4 | 70.0 | 78.7 | 86.7 | 66.7 | 78.7 |

| DAA | 80.0 | 80.0 | 80.0 | 80.0 | 70.0 | 76.0 | 82.2 | 73.3 | 78.7 |

| ADA | 82.2 | 63.3 | 74.7 | 82.2 | 70.0 | 77.3 | 88.9 | 70.0 | 81.3 |

| DDA | 82.2 | 70.0 | 77.3 | 80.0 | 50.0 | 68.0 | 88.9 | 73.3 | 82.7 |

| AAD | 88.9 | 70.0 | 81.3 | 84.4 | 70.0 | 78.7 | 82.2 | 63.3 | 74.7 |

| DAD | 91.1 | 83.3 | 88.0 | 80.0 | 73.3 | 77.3 | 80.0 | 70.0 | 76.0 |

| ADD | 93.3 | 63.3 | 81.3 | 84.4 | 66.7 | 77.3 | 80.0 | 70.0 | 76.0 |

| DDD | 86.7 | 70.0 | 80.0 | 82.2 | 73.3 | 78.7 | 82.2 | 60.0 | 73.3 |

| Vibration Component—ay | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NN Configuration | 5-5-1 | 5-10-1 | 5-15-1 | ||||||

| Wavelet Packet | Success Rates (%) for Features Extracted from Each WPT Packet | ||||||||

| Acceptable | Poor | Overall | Acceptable | Poor | Overall | Acceptable | Poor | Overall | |

| A | 84.4 | 73.3 | 80.0 | 77.8 | 53.3 | 68.8 | 84.4 | 80.0 | 82.7 |

| D | 86.7 | 50.0 | 72.0 | 93.3 | 50.0 | 76.0 | 88.9 | 60.0 | 77.3 |

| AA | 86.7 | 66.7 | 78.7 | 82.2 | 63.3 | 74.7 | 86.7 | 60.0 | 76.0 |

| DA | 86.7 | 60.0 | 76.0 | 86.7 | 63.3 | 77.3 | 86.7 | 56.7 | 74.7 |

| AD | 88.9 | 56.7 | 76.0 | 93.3 | 56.7 | 78.7 | 91.1 | 60.0 | 78.7 |

| DD | 86.7 | 60.0 | 76.0 | 84.4 | 70.0 | 78.7 | 91.1 | 63.3 | 80.0 |

| AAA | 84.4 | 60.0 | 74.7 | 80.0 | 66.7 | 74.7 | 80.0 | 60.0 | 72.0 |

| DAA | 77.8 | 70.0 | 74.7 | 97.8 | 63.3 | 84.0 | 88.9 | 63.3 | 78.7 |

| ADA | 86.7 | 63.3 | 77.3 | 88.9 | 63.3 | 78.7 | 84.4 | 70.0 | 78.7 |

| DDA | 97.8 | 66.7 | 85.3 | 95.6 | 70.0 | 85.3 | 88.9 | 60.0 | 77.3 |

| AAD | 91.1 | 53.3 | 76.0 | 91.1 | 60.0 | 78.7 | 91.1 | 66.7 | 81.3 |

| DAD | 86.7 | 56.7 | 74.7 | 82.2 | 56.7 | 72.0 | 88.9 | 60.0 | 77.3 |

| ADD | 88.9 | 60.0 | 77.3 | 91.1 | 56.7 | 77.3 | 75.6 | 70.0 | 77.3 |

| DDD | 88.9 | 66.7 | 80.0 | 88.9 | 63.3 | 78.7 | 93.3 | 70.0 | 84.0 |

| Vibration Component—az | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| NN Configuration | 5-5-1 | 5-10-1 | 5-15-1 | ||||||

| Wavelet Packet | Success Rates (%) for Features Extracted from Each WPT Packet | ||||||||

| Acceptable | Poor | Overall | Acceptable | Poor | Overall | Acceptable | Poor | Overall | |

| A | 88.9 | 73.3 | 82.7 | 93.3 | 66.7 | 82.7 | 88.9 | 63.3 | 78.7 |

| D | 86.7 | 66.7 | 78.7 | 86.7 | 63.3 | 77.3 | 88.9 | 63.3 | 78.7 |

| AA | 86.7 | 76.7 | 82.7 | 88.9 | 63.3 | 81.3 | 91.1 | 66.7 | 81.3 |

| DA | 95.6 | 73.3 | 86.7 | 91.1 | 70.0 | 84.0 | 95.6 | 76.7 | 88.0 |

| AD | 86.7 | 60.0 | 76.0 | 86.7 | 73.3 | 78.7 | 86.7 | 63.3 | 77.3 |

| DD | 88.9 | 70.0 | 81.3 | 93.3 | 66.7 | 85.3 | 93.3 | 80.0 | 88.0 |

| AAA | 84.4 | 76.7 | 81.3 | 86.7 | 73.3 | 78.7 | 77.8 | 66.7 | 73.3 |

| DAA | 86.7 | 60.0 | 76.0 | 84.4 | 66.7 | 76.0 | 93.3 | 63.3 | 81.3 |

| ADA | 95.6 | 66.7 | 84.0 | 93.3 | 63.3 | 88.0 | 88.9 | 66.7 | 80.0 |

| DDA | 82.2 | 70.0 | 77.3 | 88.9 | 80.0 | 76.0 | 84.4 | 66.7 | 77.3 |

| AAD | 88.9 | 60.0 | 77.3 | 84.4 | 56.7 | 73.3 | 86.7 | 56.7 | 74.7 |

| DAD | 91.1 | 63.3 | 80.0 | 93.3 | 66.7 | 82.7 | 84.4 | 63.3 | 76.0 |

| ADD | 88.9 | 76.7 | 84.0 | 97.8 | 70.0 | 86.7 | 88.9 | 76.7 | 84.0 |

| DDD | 88.9 | 56.7 | 76.0 | 88.9 | 60.0 | 77.3 | 80.0 | 70.0 | 76.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segreto, T.; Caggiano, A.; Karam, S.; Teti, R. Vibration Sensor Monitoring of Nickel-Titanium Alloy Turning for Machinability Evaluation. Sensors 2017, 17, 2885. https://doi.org/10.3390/s17122885

Segreto T, Caggiano A, Karam S, Teti R. Vibration Sensor Monitoring of Nickel-Titanium Alloy Turning for Machinability Evaluation. Sensors. 2017; 17(12):2885. https://doi.org/10.3390/s17122885

Chicago/Turabian StyleSegreto, Tiziana, Alessandra Caggiano, Sara Karam, and Roberto Teti. 2017. "Vibration Sensor Monitoring of Nickel-Titanium Alloy Turning for Machinability Evaluation" Sensors 17, no. 12: 2885. https://doi.org/10.3390/s17122885