Quartz Crystal Microbalance Electronic Interfacing Systems: A Review

Abstract

:1. Introduction

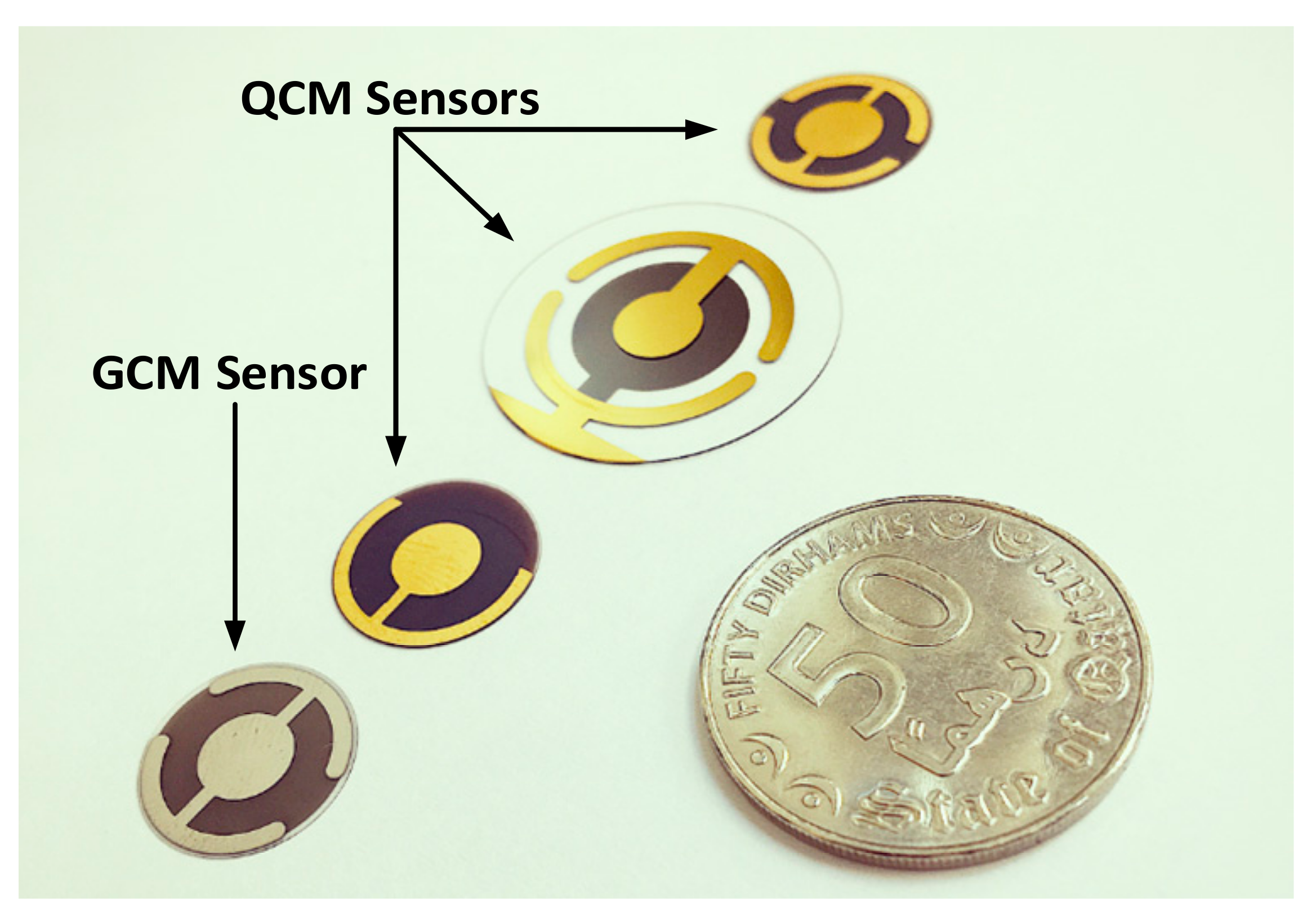

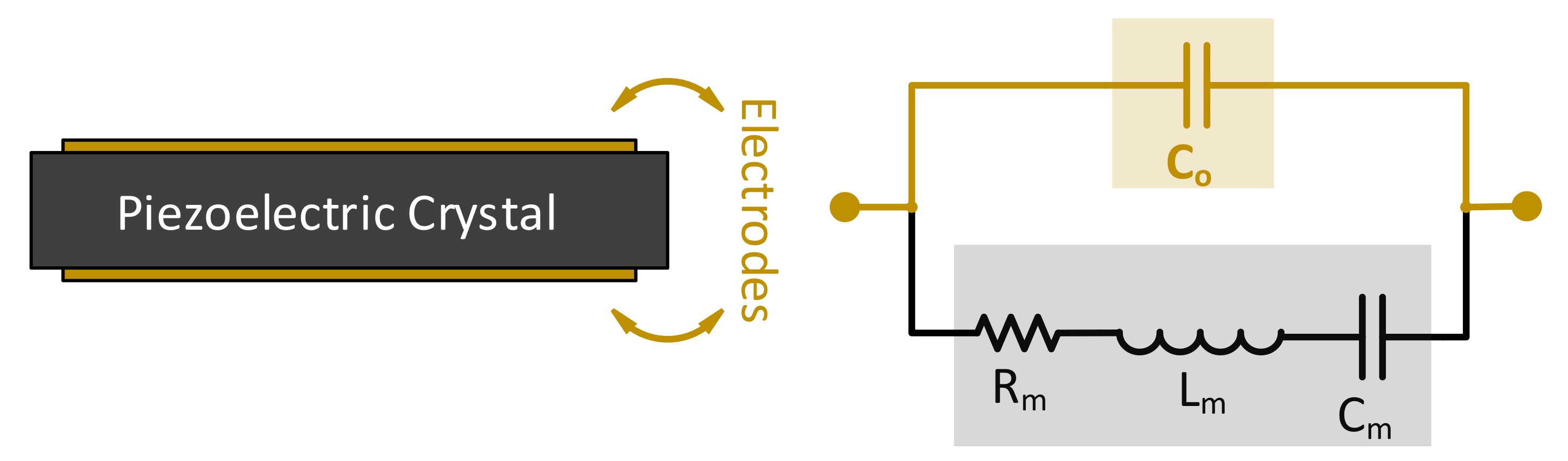

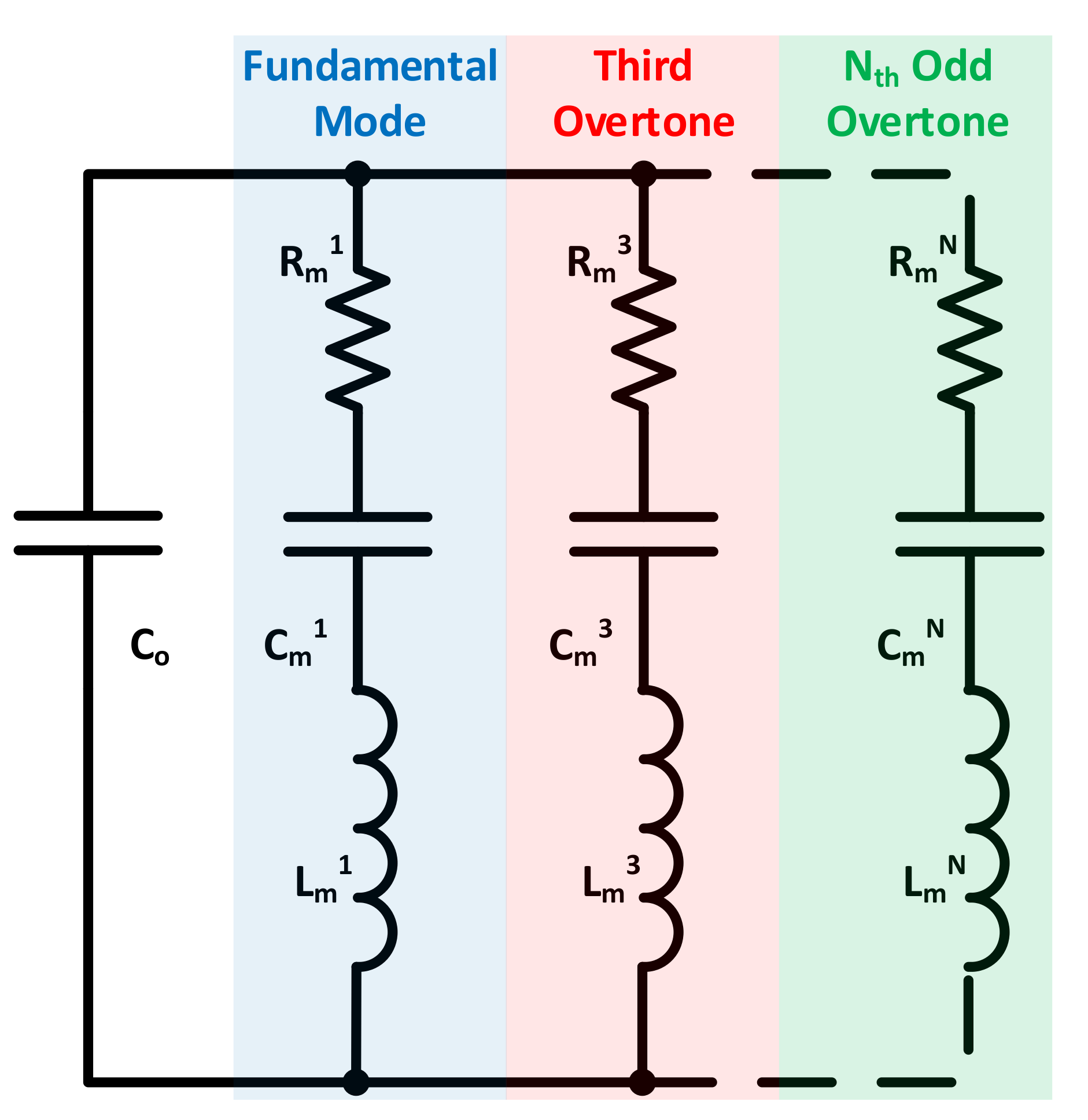

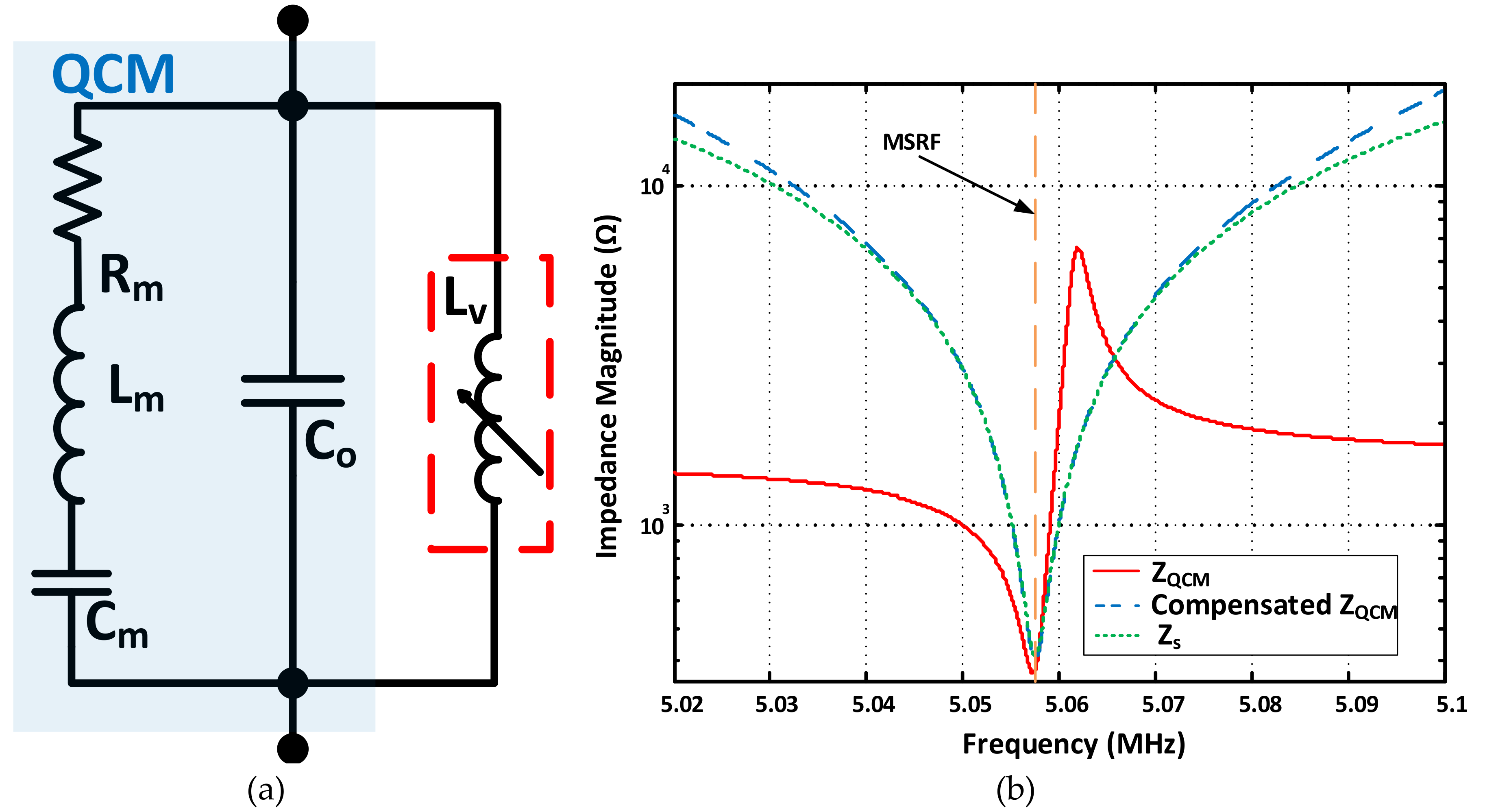

2. Electrical Modeling of QCM Resonators

3. QCM Electronic Interfacing Systems for Sensing Applications

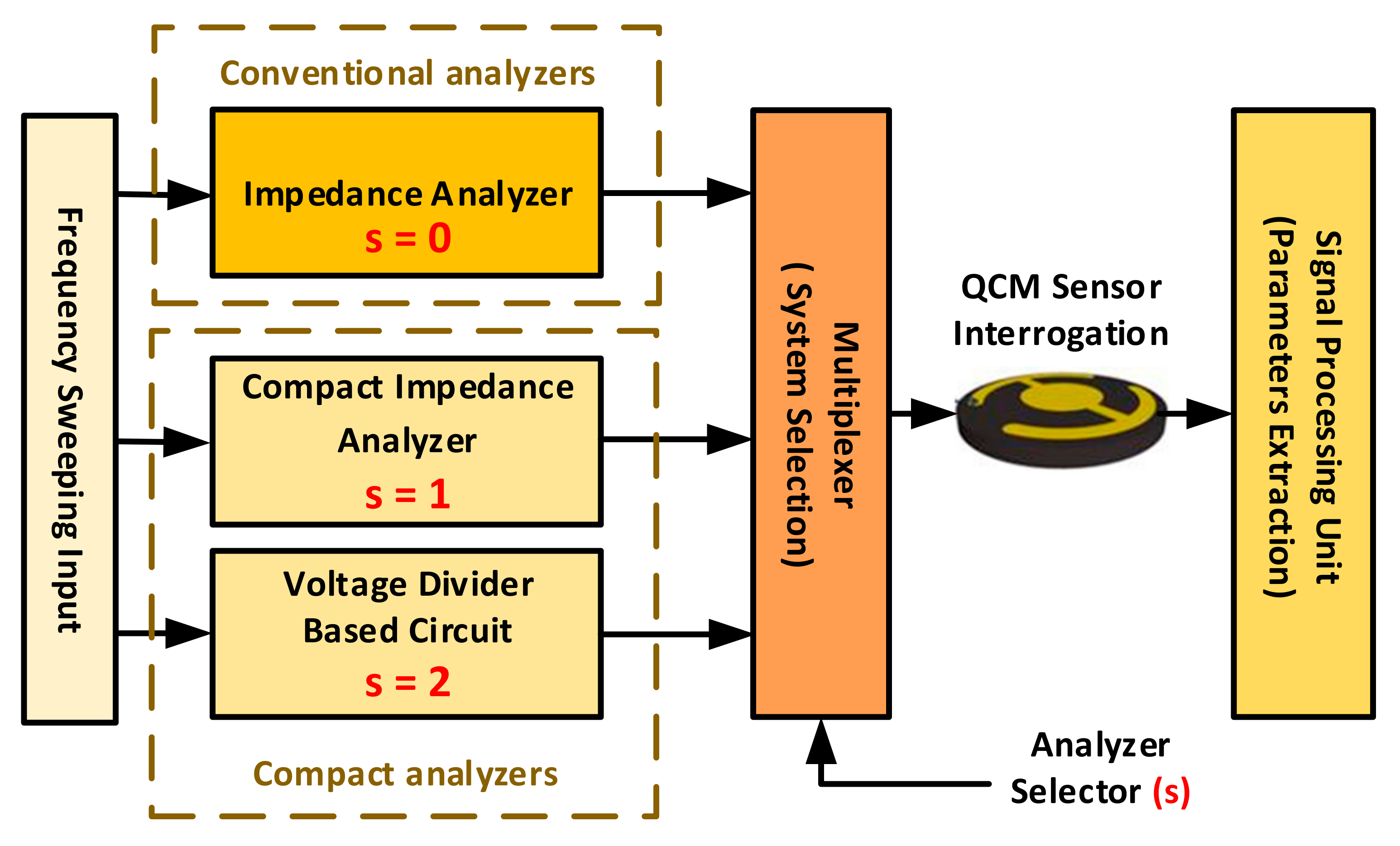

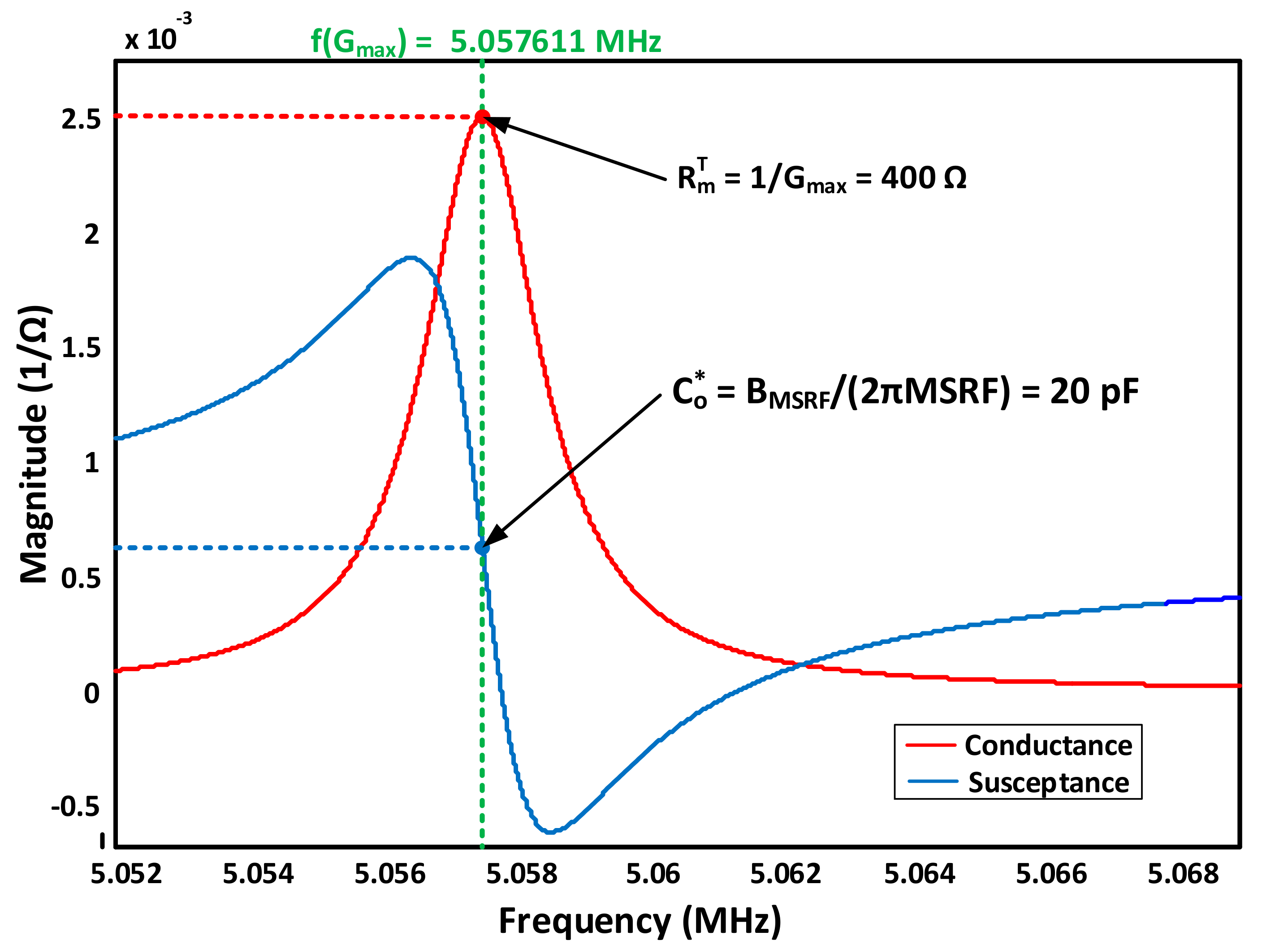

3.1. Impedance-Analysis Based Measurements

3.1.1. Conventional Impedance Analyzers Based Measurements

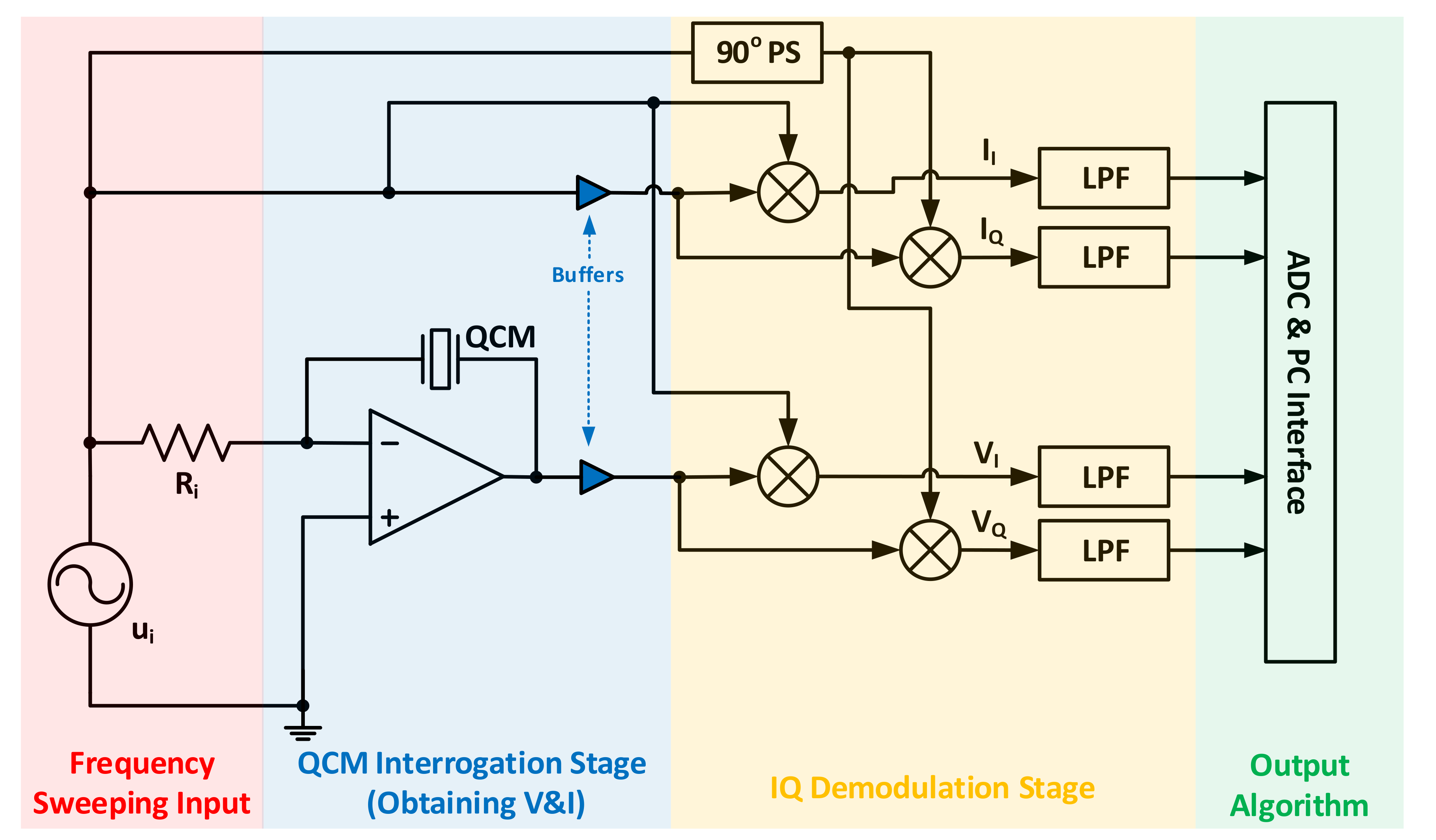

3.1.2. Voltage-Divider Based Impedance Measurements

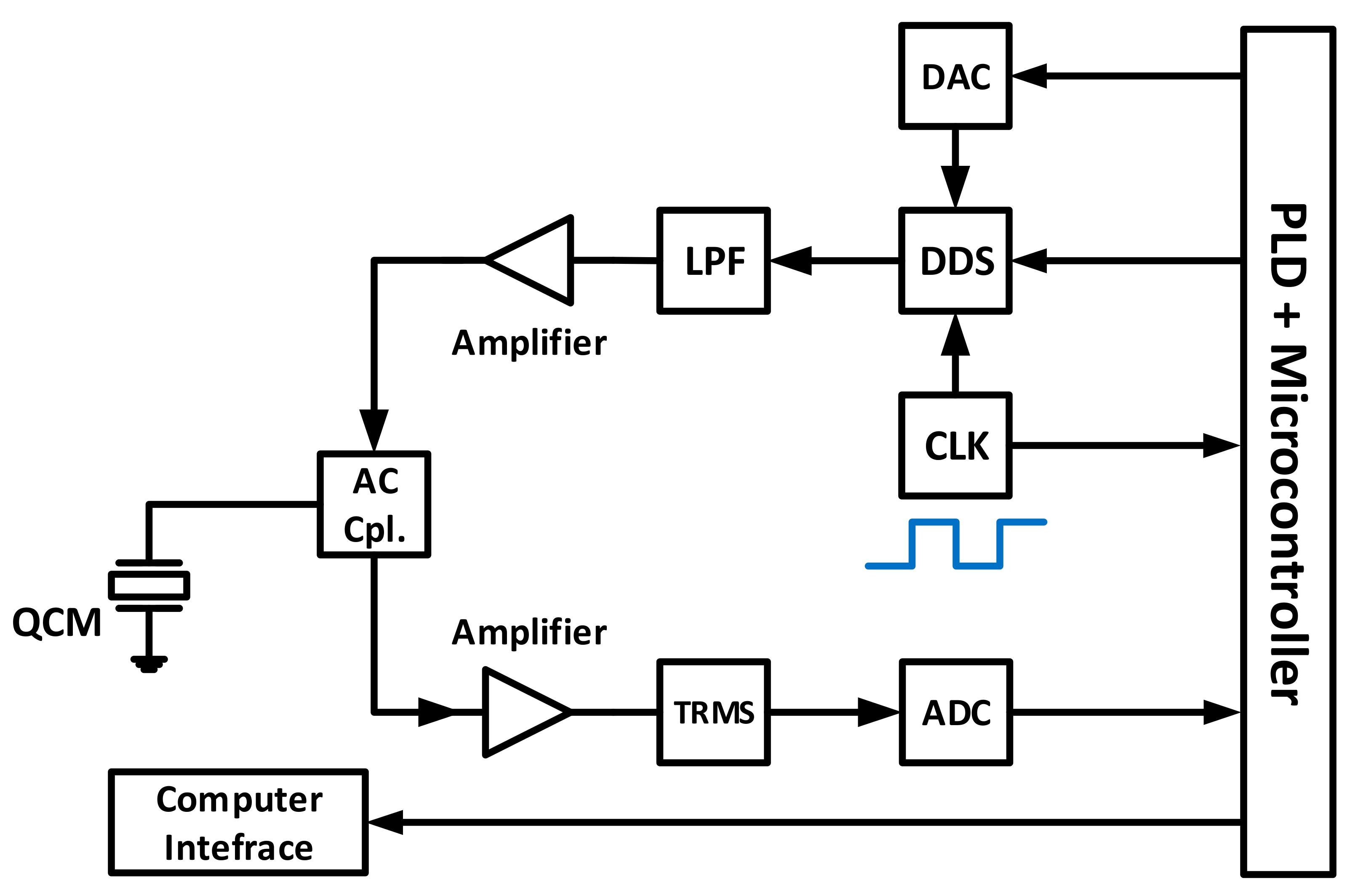

3.1.3. Compact Impedance Analyzers

3.2. Electronic Oscillators Based Measurement Systems

3.2.1. QCM Based Oscillators

Miller Oscillator

Commercial QCM200 Oscillator-Based Instrumentation

Other QCM Oscillators

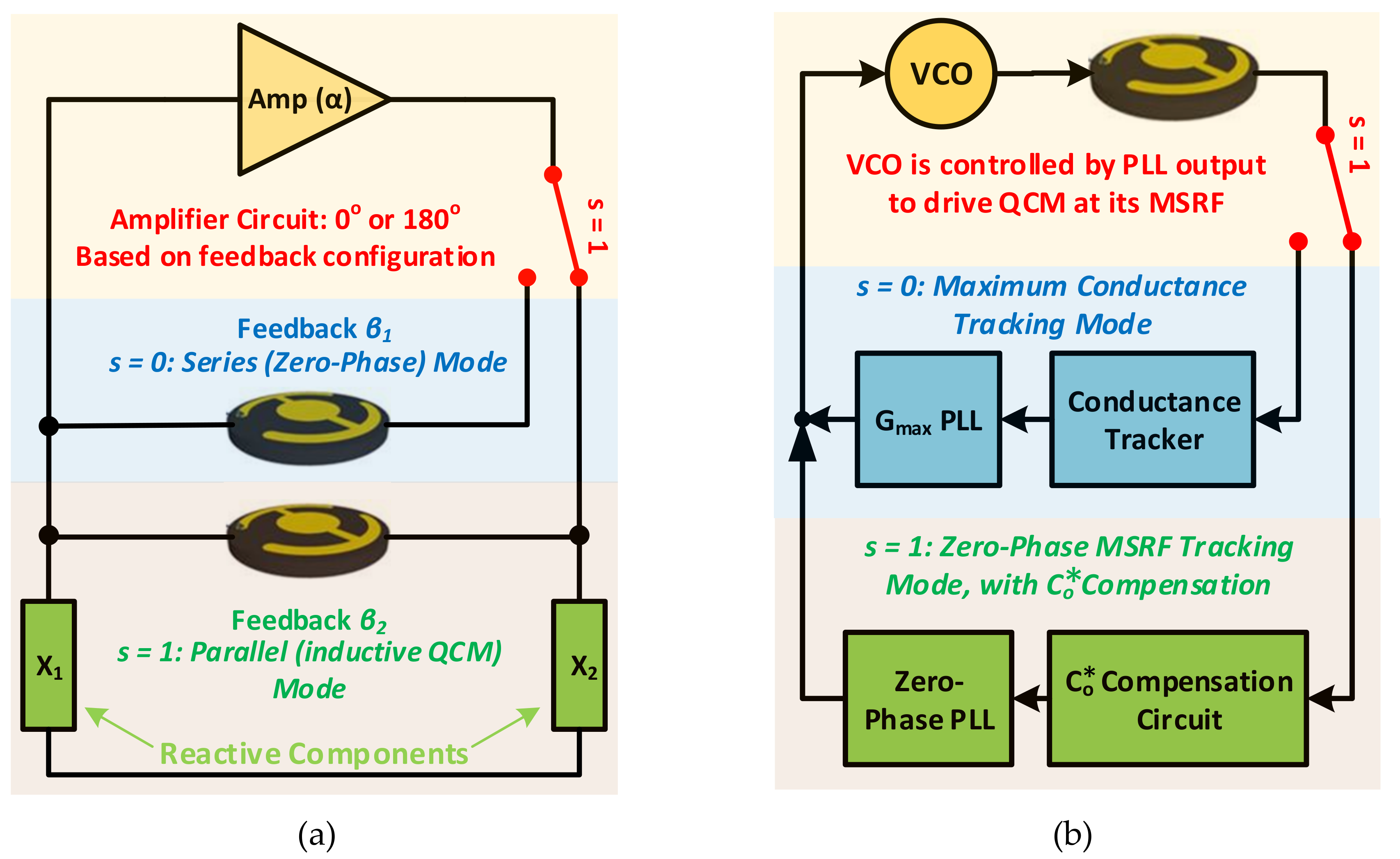

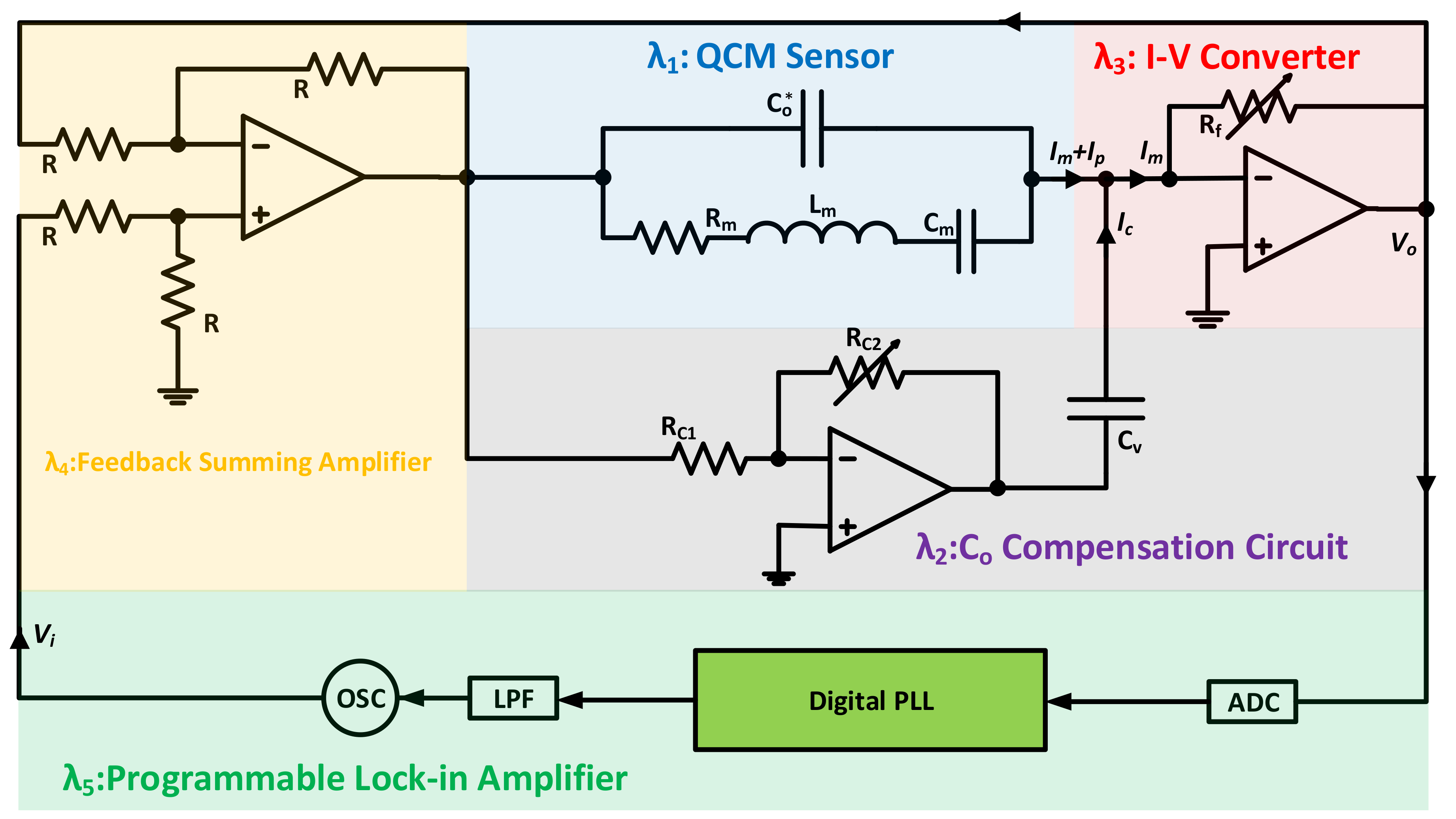

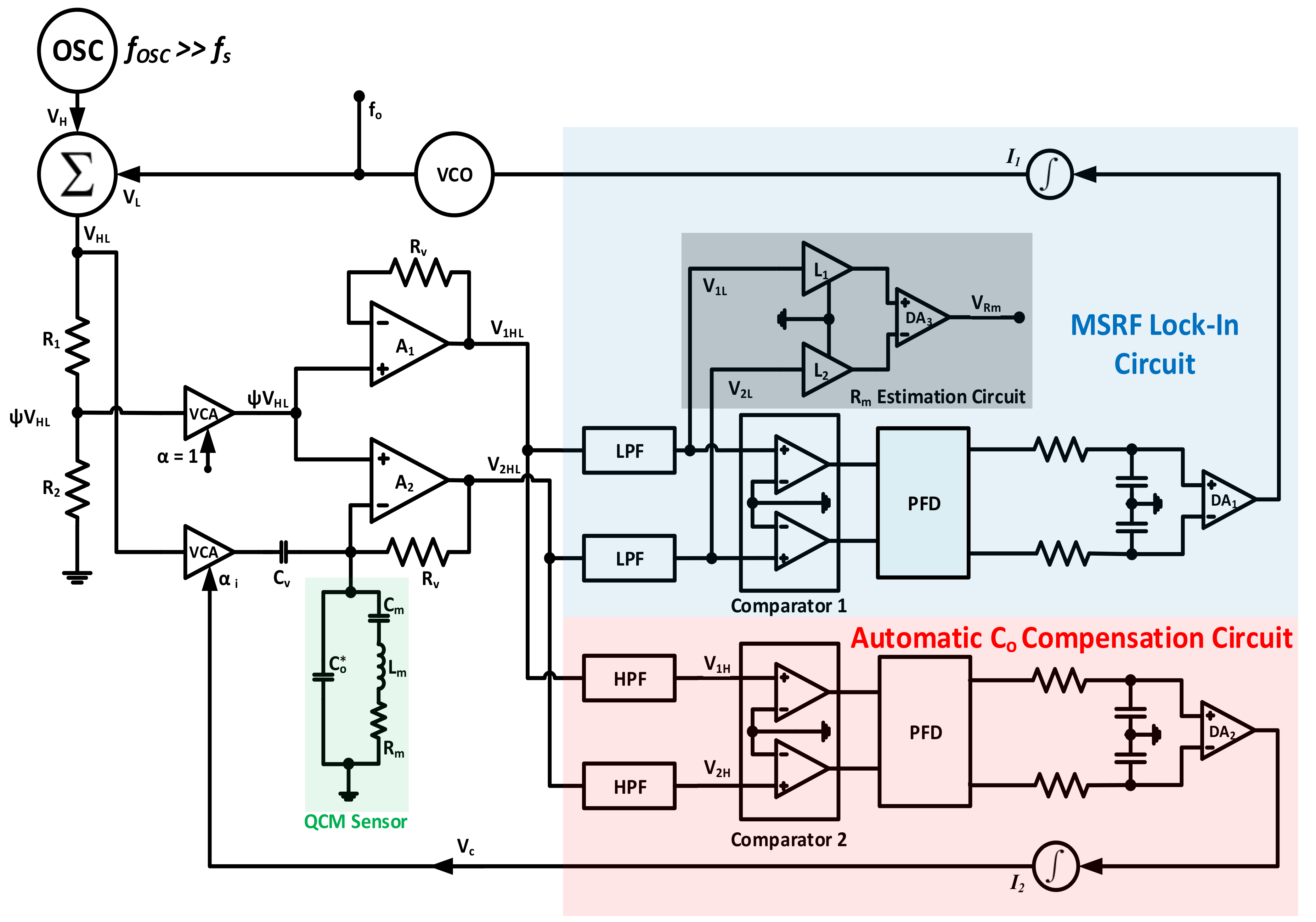

3.2.2. Controlled (Lock-In) Based Oscillators

Zero-Phase Lock-In Circuits

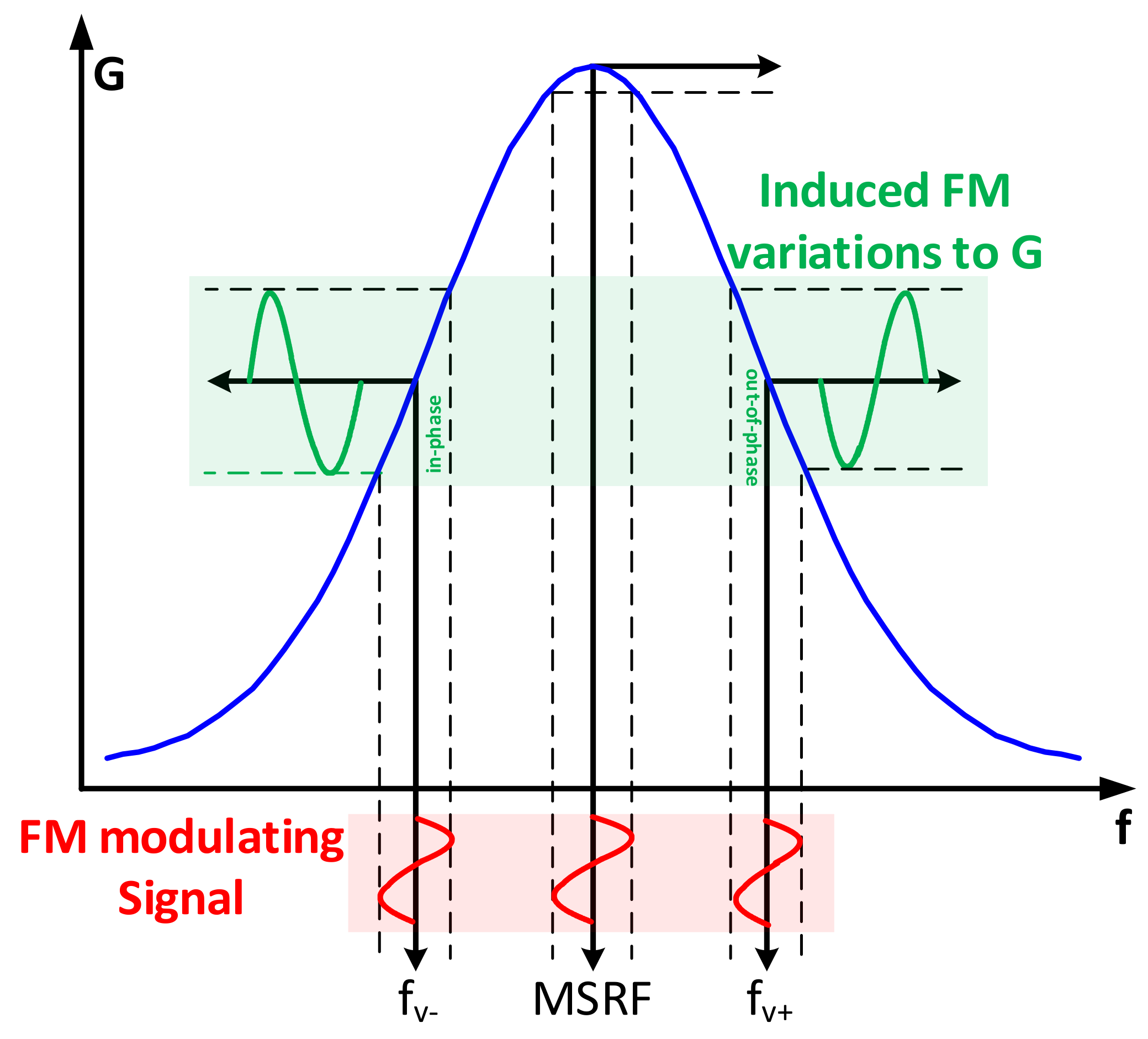

Maximum Conductance Lock-In Circuits

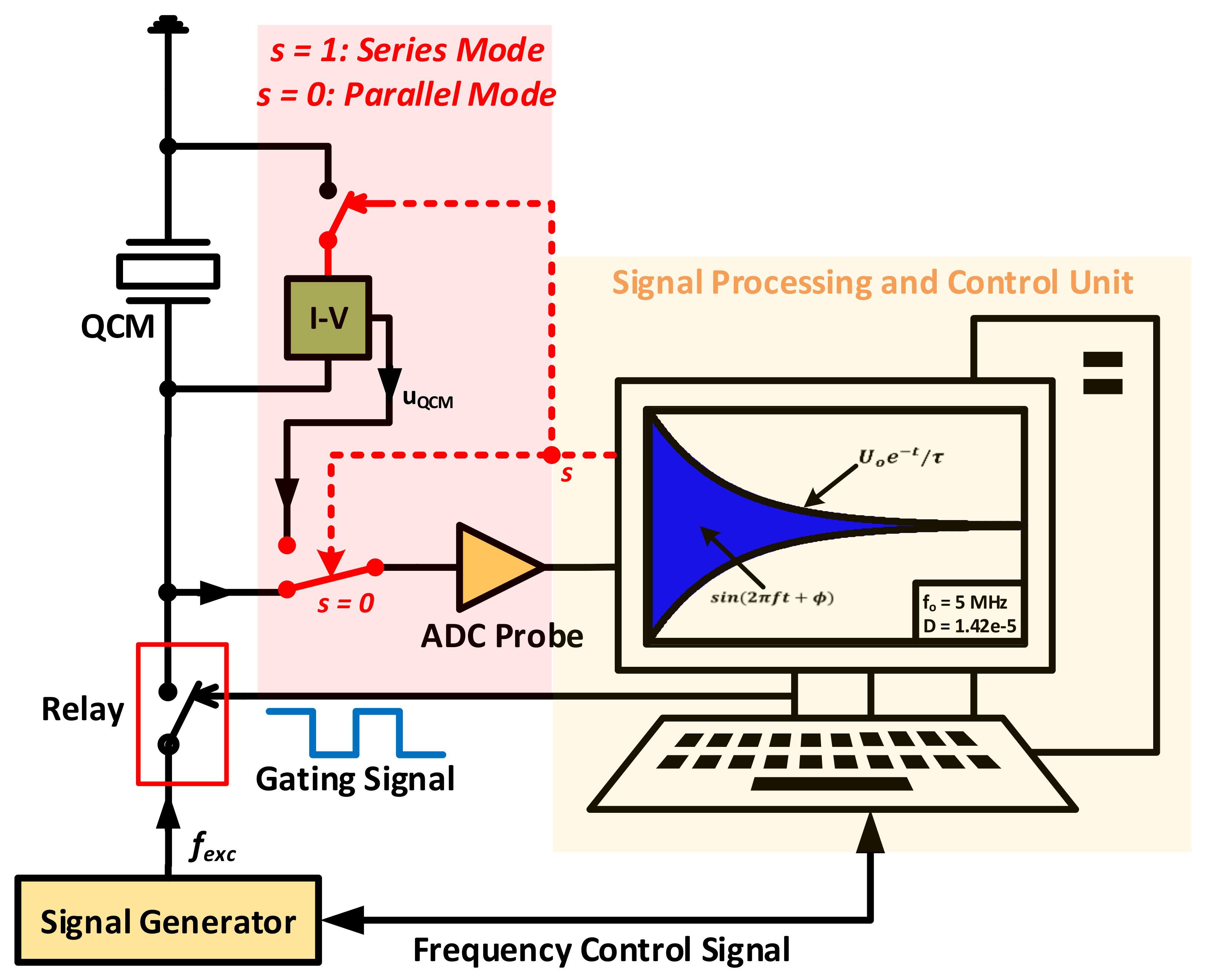

3.3. Exponential Decay Based Characterization

3.3.1. Conventional Exponential Decay Technique

3.3.2. Contactless QCM-D Based Systems

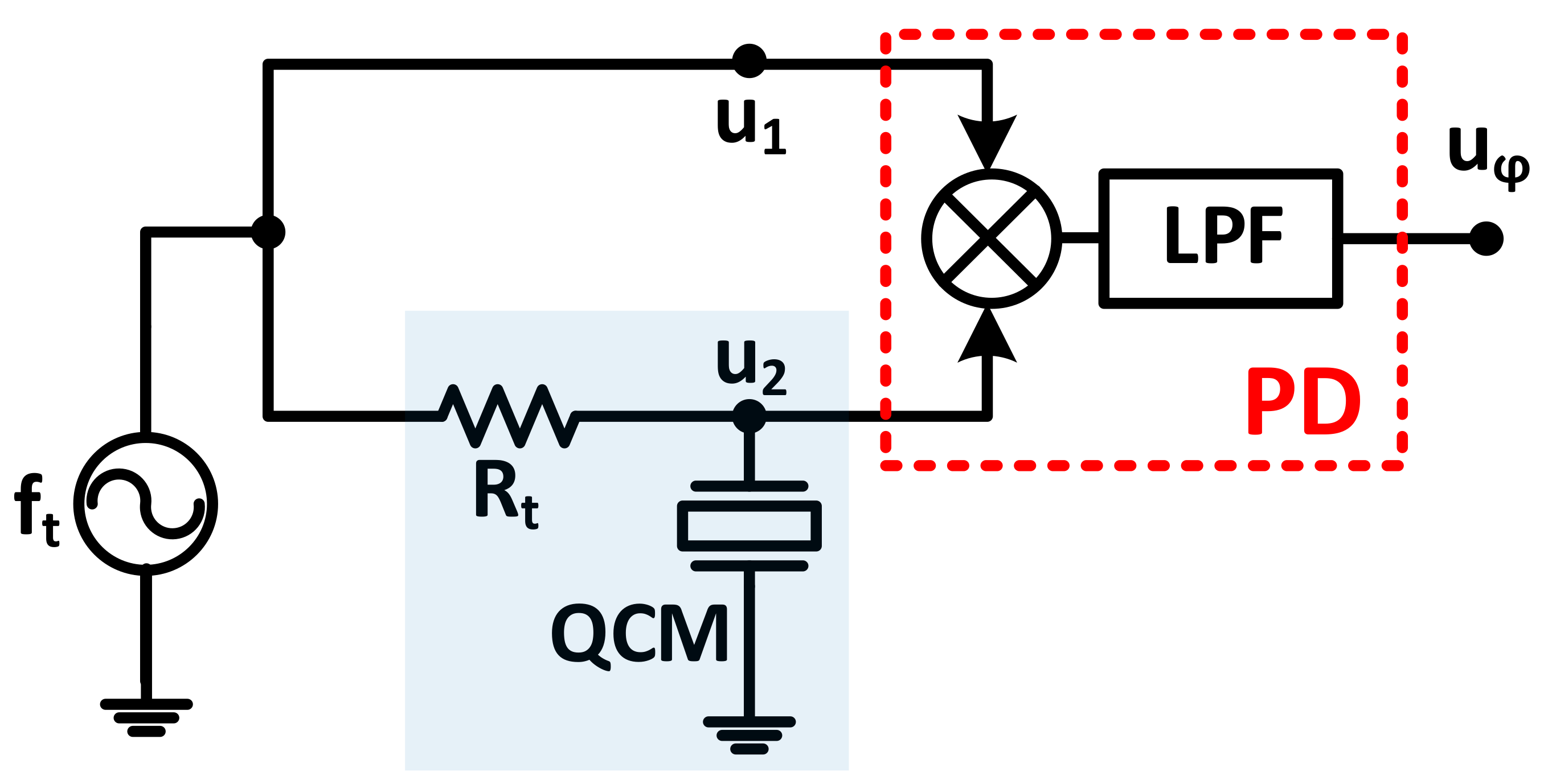

3.4. Phase-Shift Based Characterization

4. High Temperature Applications Design Considerations

4.1. High-Temperature QCM Based Systems

4.2. High-Temperature Quartz-Alternatives Crystals

5. Electronic Interfacing Systems Comparison

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| ABO | Active Bridge Oscillator | Motional inductance | |

| ACC | Automatic Capacitance Compensation | LPF | Low-Pass Filter |

| ADC | Analog to Digital Converter | M | Mutual Inductance |

| Effective Surface Area | MSRF | Motional Series Resonance Frequency | |

| AGC | Automatic Gain Control | N | Odd harmonic overtone (N = 1,3,...) |

| ALD | Atomic Layer Deposition | NCO | Numeric Control Oscillator |

| B | Electrical Susceptance | OCXO | Oven-Controlled Crystal Oscillator |

| BPF | Band-Pass Filter | OTA | Operational Transconductance Amplifier |

| BVD | Butterworth-Van-Dyke crystal model | PFD | Phase-Frequency Detector |

| External wiring/parasitic capacitance | PLD | Programmable Logic Device | |

| Motional capacitance | PLL | Phase-Locked Loop | |

| Parallel electrodes capacitance | Q | Crystal’s Quality Factor | |

| Effective total parallel capacitance | QCM | Quartz Crystal Microbalance | |

| Piezoelectric material elastic constant | Liquid-load damping resistance | ||

| D | Crystal’s Dissipation Factor | Motional resistance | |

| DAC | Digital to Analog Converter | Total crystal’s series resistance | |

| DDS | Direct Digital Synthesizer | SNR | Signal to Noise Ratio |

| Operating frequency, angular form | t | time | |

| FBAR | Film Bulk Acoustic Resonators | TSM | Thickness Shear Mode |

| Unloaded crystal resonance frequency | u, V | Voltage | |

| Maximum impedance parallel resonance | VCO | Voltage Controlled Oscillator | |

| Zero-phase series resonance frequency | Electrical Reactance | ||

| Minimum impedance series resonance | Y | Electrical Admittance | |

| G | Electrical Conductance | Z | Electrical Impedance |

| GCM | Crystal Microbalance | variation, induced by factor x | |

| h | Crystal Electrodes separation | Exponential-Decay time constant | |

| HFF | High-Fundamental Frequency | Density | |

| HPF | High-Pass Filter | Piezoelectric material permittivity | |

| I | Current | Crystal’s shear modulus | |

| Piezoelectric electrochemical constant | Viscosity | ||

| LCM | Langasite Crystal Microbalance | Oscillator’s Amplifier gain | |

| LEM | Lumped Element Model | Oscillator’s Feedback gain |

References

- Curie, J.; Curie, P. An oscillating quartz crystal mass detector. Rendu 1880, 91, 294–297. [Google Scholar]

- Sauerbrey, G. Verwendung von schwingquarzen zur wägung dünner schichten und zur mikrowägung. Z. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Rodahl, M.; Kasemo, B. Frequency and dissipation-factor responses to localized liquid deposits on a QCM electrode. Sens. Actuators B Chem. 1996, 37, 111–116. [Google Scholar] [CrossRef]

- Calvo, E.; Etchenique, R.; Bartlett, P.; Singhal, K.; Santamaria, C. Quartz crystal impedance studies at 10 MHz of viscoelastic liquids and films. Faraday Discuss. 1997, 107, 141–157. [Google Scholar] [CrossRef]

- Reed, C.E.; Kanazawa, K.K.; Kaufman, J.H. Physical description of a viscoelastically loaded AT-cut quartz resonator. J. Appl. Phys. 1990, 68, 1993–2001. [Google Scholar] [CrossRef]

- Sen, K.; Ashbolt, N. Environmental Microbiology, 1st ed.; Caister Academic Press: Norfolk, UK, 2011. [Google Scholar]

- Lu, C.S.; Lewis, O. Investigation of film-thickness determination by oscillating quartz resonators with large mass load. J. Appl. Phys. 1972, 43, 4385–4390. [Google Scholar] [CrossRef]

- Millichamp, J. Development of a Novel High Temperature Crystal Microbalance In-Situ Sensor for the Study of Electrode Processes in Solid Oxide Fuel Cells. Ph.D. Thesis, University College London (UCL), London, UK, 2013. [Google Scholar]

- QCM200 Digital Controller: Operation and Service Manual; Stanford Research Systems: Sunnyvale, CA, USA, 2011.

- Wang, D.; Mousavi, P.; Hauser, P.J.; Oxenham, W.; Grant, C.S. Quartz crystal microbalance in elevated temperature viscous liquids: Temperature effect compensation and lubricant degradation monitoring. Colloids Surf. A Physicochem. Eng. Asp. 2005, 268, 30–39. [Google Scholar] [CrossRef]

- Rahtu, A.; Ritala, M. Compensation of temperature effects in quartz crystal microbalance measurements. Appl. Phys. Lett. 2002, 80, 521–523. [Google Scholar] [CrossRef]

- Konash, P.L.; Bastiaans, G.J. Piezoelectric crystals as detectors in liquid chromatography. Anal. Chem. 1980, 52, 1929–1931. [Google Scholar] [CrossRef]

- Nomura, T.; Okuhara, M. Frequency shifts of piezoelectric quartz crystals immersed in organic liquids. Anal. Chim. Acta. 1982, 142, 281–284. [Google Scholar] [CrossRef]

- Keiji Kanazawa, K.; Gordon, J.G. The oscillation frequency of a quartz resonator in contact with liquid. Anal. Chim. Acta 1985, 175, 99–105. [Google Scholar] [CrossRef]

- Mecea, V.M.; Carlsson, J.O.; Bucur, R.V. Extensions of the quartz-crystal-microbalance technique. Sens. Actuators A Phys. 1996, 53, 371–378. [Google Scholar] [CrossRef]

- Ishay, R.B.; Kapp-Barnea, Y.; Grigoriantz, I.; Teblum, E.; Lellouche, J.-P. Real time acoustic profiling of a live cancerous cell monolayer using QCM. Sens. Actuators B Chem. 2015, 215, 373–381. [Google Scholar] [CrossRef]

- Wang, P.; Su, J.; Gong, L.; Shen, M.; Ruths, M.; Sun, H. Numerical simulation and experimental study of resonance characteristics of QCM-P devices operating in liquid and their application in biological detection. Sens. Actuators B Chem. 2015, 220, 1320–1327. [Google Scholar] [CrossRef]

- Tai, H.; Bao, X.; He, Y.; Du, X.; Xie, G.; Jiang, Y. Enhanced formaldehyde-sensing performances of mixed polyethyleneimine-multiwalled carbon nanotubes composite films on quartz crystal microbalance. IEEE Sens. J. 2015, 15, 6904–6911. [Google Scholar] [CrossRef]

- Sharma, P.; Ghosh, A.; Tudu, B.; Sabhapondit, S.; Baruah, B.D.; Tamuly, P.; Bhattacharyya, N.; Bandyopadhyay, R. Monitoring the fermentation process of black tea using QCM sensor based electronic nose. Sens. Actuators B Chem. 2015, 219, 146–157. [Google Scholar] [CrossRef]

- Masdor, N.A.; Altintas, Z.; Tothill, I.E. Sensitive detection of Campylobacter jejuni using nanoparticles enhanced QCM sensor. Biosens. Bioelectron. 2016, 78, 328–336. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, S.; Simon, S.; Gao, B.; Sjöblom, J. Asphaltene fractionation based on adsorption onto calcium carbonate: Part 1. Characterization of sub-fractions and QCM-D measurements. Colloids Surf. A Physicochem. Eng. Asp. 2016, 495, 136–148. [Google Scholar] [CrossRef]

- Jia, Y.; Yu, H.; Cai, J.; Li, Z.; Dong, F. Explore on the quantitative analysis of specific surface area on sensitivity of polyacrylic acid-based QCM ammonia sensor. Sens. Actuators B Chem. 2017, 243, 1042–1045. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, W.; Guo, Z.; Zhang, Z.; Zhu, H.; Yan, R.; Zhou, L. Stability enhanced, repeatability improved Parylene-C passivated on QCM sensor for aPTT measurement. Biosens. Bioelectron. 2017, 98, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Speller, N.C.; Siraj, N.; McCarter, K.S.; Vaughan, S.; Warner, I.M. QCM virtual sensor array: Vapor identification and molecular weight approximation. Sens. Actuators B Chem. 2017, 246, 952–960. [Google Scholar] [CrossRef]

- Sobiepanek, A.; Milner-Krawczyk, M.; Lekka, M.; Kobiela, T. AFM and QCM-D as tools for the distinction of melanoma cells with a different metastatic potential. Biosens. Bioelectron. 2017, 93, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Zajforoushan Moghaddam, S.; Zhu, K.; Nyström, B.; Thormann, E. Thermo-responsive diblock and triblock cationic copolymers at the silica/aqueous interface: A QCM-D and AFM study. J. Colloid Interface Sci. 2017, 505, 546–555. [Google Scholar] [CrossRef] [PubMed]

- Lay, B.; Kandjani, A.E.; Amin, M.H.; Kabir, K.M.M.; Ippolito, S.J.; Sabri, Y.M.; Bhargava, S.K. Galvanic replacement of colloidal monolayer crystal on a QCM device for selective detection of mercury vapor. Sens. Actuators B Chem. 2017, 250, 383–392. [Google Scholar] [CrossRef]

- Li, Q.; Gu, Y.; Wang, N.F. Application of random forest classifier by means of a QCM-based e-nose in the identification of Chinese liquor flavors. IEEE Sens. J. 2017, 17, 1788–1794. [Google Scholar] [CrossRef]

- Speller, N.C.; Siraj, N.; Vaughan, S.; Speller, L.N.; Warner, I.M. QCM virtual multisensor array for fuel discrimination and detection of gasoline adulteration. Fuel 2017, 199, 38–46. [Google Scholar] [CrossRef]

- Yoo, H.Y.; Ju, M.; Bruckenstein, S. Increasing QCM sensitivity based on high molecular weight porous polymer films. Sens. Actuators B Chem. 2018, 254, 573–577. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Li, N.; Ding, X.; Zhao, X. A QCM humidity sensors based on GO/Nafion composite films with enhanced sensitivity. IEEE Sens. J. 2016, 16, 8874–8883. [Google Scholar] [CrossRef]

- Yao, Y.; Zhang, H.; Sun, J.; Ma, W.; Li, L.; Li, W.; Du, J. Novel QCM humidity sensors using stacked black phosphorus nanosheets as sensing film. Sens. Actuators B Chem. 2017, 244, 259–264. [Google Scholar] [CrossRef]

- Yao, Y.; Xue, Y. Impedance analysis of quartz crystal microbalance humidity sensors based on nanodiamond/graphene oxide nanocomposite film. Sens. Actuators B Chem. 2015, 211, 52–58. [Google Scholar] [CrossRef]

- Ma, W.; Tang, S.; Wei, Y.; Xie, G. Simple biosensing method to detect DMMP based on QCM transducer and acetylcholine esterase sensitive film. Micro Nano Lett. 2017, 12, 113–116. [Google Scholar] [CrossRef]

- Zhu, Y.; Cheng, Z.; Xiang, Q.; Chen, X.; Xu, J. Synthesis of functionalized mesoporous TiO2-SiO2 with organic fluoroalcohol as high performance DMMP gas sensor. Sens. Actuators B Chem. 2017, 248, 785–792. [Google Scholar] [CrossRef]

- Cooper, M.A.; Singleton, V.T. A survey of the 2001 to 2005 quartz crystal microbalance biosensor literature: Applications of acoustic physics to the analysis of biomolecular interactions. J. Mol. Recognit. 2007, 20, 154–184. [Google Scholar] [CrossRef] [PubMed]

- Becker, B.; Cooper, M.A. A survey of the 2006–2009 quartz crystal microbalance biosensor literature. J. Mol. Recognit. 2011, 24, 754–787. [Google Scholar] [CrossRef] [PubMed]

- Casteleiro-Roca, J.L.; Calvo-Rolle, J.L.; Meizoso-Lopez, M.C.; Piñón-Pazos, A.; Rodríguez-Gómez, B.A. New approach for the QCM sensors characterization. Sens. Actuators A Phys. 2014, 207, 1–9. [Google Scholar] [CrossRef]

- Lucklum, R.; Eichelbaum, F. Interface circuits for QCM sensors. In Piezoelectric Sensors; Janshoff, A., Steinem, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 3–47. [Google Scholar]

- Fernández, R.; García, P.; García, M.; García, V.J.; Jiménez, Y.; Arnau, A. Design and validation of a 150 MHz HFFQCM sensor for bio-sensing applications. Sensors 2017, 17, 2057. [Google Scholar] [CrossRef] [PubMed]

- Montagut, Y.; García, J.V.; Jiménez, Y.; March, C.; Montoya, Á.; Arnau, A. Validation of a phase-mass characterization concept and interface for acoustic biosensors. Sensors 2011, 11, 4702–4720. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Sun, X.; Zhang, K.; Fan, G.; Wang, Y.; Li, G.; Hu, R. A Noncontact dibutyl phthalate sensor based on a wireless-electrodeless QCM-D modified with nano-structured nickel hydroxide. Sensors 2017, 17, 1681. [Google Scholar] [CrossRef] [PubMed]

- Ogi, H. Wireless-electrodeless quartz-crystal-microbalance biosensors for studying interactions among biomolecules: A review. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2013, 89, 401–417. [Google Scholar] [CrossRef]

- Ogi, H.; Fukunishi, Y.; Nagai, H.; Okamoto, K.; Hirao, M.; Nishiyama, M. Nonspecific-adsorption behavior of polyethylenglycol and bovine serum albumin studied by 55-MHz wireless-electrodeless quartz crystal microbalance. Biosens. Bioelectron. 2009, 24, 3148–3152. [Google Scholar] [CrossRef] [PubMed]

- Ogi, H.; Motohisa, K.; Hatanaka, K.; Ohmori, T.; Hirao, M.; Nishiyama, M. Concentration dependence of IgG-protein A affinity studied by wireless-electrodeless QCM. Biosens. Bioelectron. 2007, 22, 3238–3242. [Google Scholar] [CrossRef] [PubMed]

- Ogi, H.; Yanagida, T.; Hirao, M.; Nishiyama, M. Replacement-free mass-amplified sandwich assay with 180-MHz electrodeless quartz-crystal microbalance biosensor. Biosens. Bioelectron. 2011, 26, 4819–4822. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Bai, Q.; Hu, J.; Hou, D. A practical model of quartz crystal microbalance in actual applications. Sensors 2017, 17, 1785. [Google Scholar] [CrossRef] [PubMed]

- Edvardsson, M.; Rodahl, M.; Kasemo, B.; Höök, F. A dual-frequency QCM-D setup operating at elevated oscillation amplitudes. Anal. Chem. 2005, 77, 4918–4926. [Google Scholar] [CrossRef] [PubMed]

- Tembhare, P.C.; Rangaree, P.H. A review on: Design of 2.4GHz FBAR filter using MEMS technology for RF applications. Imp. J. Interdiscip. Res. 2017, 3, 939–941. [Google Scholar]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Colangeli, L.; Lopez-Moreno, J.J.; Nørnberg, P.; Della Corte, V.; Esposito, F.; Mazzotta Epifani, E.; Merrison, J.; Molfese, C.; Palumbo, P.; Rodriguez-Gomez, J.F.; et al. MEDUSA: The ExoMars experiment for in-situ monitoring of dust and water vapour. Planet. Space Sci. 2009, 57, 1043–1049. [Google Scholar] [CrossRef]

- Battaglia, R.; Palomba, E.; Palumbo, P.; Colangeli, L.; Della Corte, V. Development of a micro-balance system for dust and water vapour detection in the Mars atmosphere. Adv. Space Res. 2004, 33, 2258–2262. [Google Scholar] [CrossRef]

- Elam, J.W.; Pellin, M.J. GaPO4 sensors for gravimetric monitoring during atomic layer deposition at high temperatures. Anal. Chem. 2005, 77, 3531–3535. [Google Scholar] [CrossRef] [PubMed]

- Thanner, H.; Krempl, P.W.; Wallnöfer, W.; Worsch, P.M. GaPO4 high temperature crystal microbalance with zero temperature coefficient. Vacuum 2002, 67, 687–691. [Google Scholar] [CrossRef]

- Devine, T.M.; Chakravarti, R.; Patrick, B.N.; Giheny, K.P.E. Method and Application of GaPO4 Crystal Microbalance to High Acid Crude Corrosion Testing. U.S. Patent 20,160,025,614 A1, 28 January 2016. [Google Scholar]

- Jakab, S.; Picart, S.; Tribollet, B.; Rousseau, P.; Perrot, H.; Gabrielli, C. Study of the dissolution of thin films of cerium oxide by using a GaPO4 crystal microbalance. Anal. Chem. 2009, 81, 5139–5145. [Google Scholar] [CrossRef] [PubMed]

- Millichamp, J.; Ali, E.; Brandon, N.P.; Brown, R.J.C.; Hodgson, D.; Kalyvas, C.; Manos, G.; Brett, D.J.L. Application of a GaPO4 crystal microbalance for the detection of coke formation in high-temperature reactors and solid oxide fuel cells. Ind. Eng. Chem. Res. 2011, 50, 8371–8375. [Google Scholar] [CrossRef]

- Thanner, H.; Krempl, P.W.; Selic, R.; Wallnöfer, W.; Worsch, P.M. GaPO4 high temperature crystal microbalance demonstration up to 720 °C. J. Therm. Anal. Calorim. 2003, 71, 53–59. [Google Scholar] [CrossRef]

- Zu, H.; Wu, H.; Wang, Q.M. High-temperature piezoelectric crystals for acoustic wave sensor applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 486–505. [Google Scholar] [CrossRef] [PubMed]

- Cernosek, R.W.; Martin, S.J.; Hillman, A.R.; Bandey, H.L. Comparison of lumped-element and transmission-line models for thickness-shear-mode quartz resonator sensors. In Proceedings of the IEEE International Frequency Control Symposium, Orlando, FL, USA, 30 May 1997; pp. 96–104. [Google Scholar] [CrossRef]

- Arbuckle-Keil, G.A. The quartz crystal microbalance in electrochemistry. In Characterization of Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Martin, S.J.; Granstaff, V.E.; Frye, G.C. Characterization of a quartz crystal microbalance with simultaneous mass and liquid loading. Anal. Chem. 1991, 63, 2272–2281. [Google Scholar] [CrossRef]

- Arnau, A. A review of interface electronic systems for AT-cut quartz crystal microbalance applications in liquids. Sensors 2008, 8, 370–411. [Google Scholar] [CrossRef] [PubMed]

- Rodahl, M.; Höök, F.; Kasemo, B. QCM operation in liquids: An explanation of measured variations in frequency and Q factor with liquid conductivity. Anal. Chem. 1996, 68, 2219–2227. [Google Scholar] [CrossRef] [PubMed]

- Auge, J.; Hauptmann, P.; Eichelbaum, F.; Rösler, S. Quartz crystal microbalance sensor in liquids. Sens. Actuators B Chem. 1994, 19, 518–522. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, S.; Liu, Q.; Masliyah, J.; Xu, Z. QCM-D study of nanoparticle interactions. Adv. Colloid Interface Sci. 2016, 233, 94–114. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Bai, Q.; Zhou, Q.; Hu, J. The resistance-amplitude-frequency effect of in—Liquid quartz crystal microbalance. Sensors 2017, 17, 1476. [Google Scholar] [CrossRef] [PubMed]

- Johannsmann, D. The Quartz Crystal Microbalance in Soft Matter Research, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Saha, T.; Guo, N.Q.; Ramakrishnan, N. Zinc oxide nanostructure-based langasite crystal microbalance ultraviolet sensor. IEEE Sens. J. 2016, 16, 2964–2970. [Google Scholar] [CrossRef]

- Astrid, P.; Arne, L.; Diethelm, J. Coupled resonances allow studying the aging of adhesive contacts between a QCM surface and single, micrometer-sized particles. Nanotechnology 2015, 26, 484001. [Google Scholar] [CrossRef]

- Furusawa, H.; Sekine, T.; Ozeki, T. Hydration and viscoelastic properties of high- and low-density polymer brushes using a quartz-crystal microbalance based on admittance analysis (QCM-A). Macromolecules 2016, 49, 3463–3470. [Google Scholar] [CrossRef]

- Wudy, F.; Multerer, M.; Stock, C.; Schmeer, G.; Gores, H.J. Rapid impedance scanning QCM for electrochemical applications based on miniaturized hardware and high-performance curve fitting. Electrochim. Acta. 2008, 53, 6568–6574. [Google Scholar] [CrossRef]

- Mills, C.A.; Chai, K.T.C.; Milgrew, M.J.; Glidle, A.; Cooper, J.M.; Cumming, D.R.S. A multiplexed impedance analyzer for characterizing polymer-coated QCM sensor arrays. IEEE Sens. J. 2006, 6, 996–1002. [Google Scholar] [CrossRef] [Green Version]

- Kang, Q.; Qi, Y.; Zhang, P.; Shen, D. Improve the signal-to-noise ratio of a quartz crystal microbalance in an impedance analysis method. Talanta 2007, 72, 1474–1480. [Google Scholar] [CrossRef] [PubMed]

- Torres, R.; García, J.V.; Arnau, A.; Perrot, H.; Kim, L.T.T.; Gabrielli, C. Improved frequency/voltage converters for fast quartz crystal microbalance applications. Rev. Sci. Instrum. 2008, 79. [Google Scholar] [CrossRef] [PubMed]

- Marco, F.; Vittorio, F. An oscillator circuit for dual-harmonic tracking of frequency and resistance in quartz resonator sensors. Meas. Sci. Technol. 2009, 20, 124005. [Google Scholar] [CrossRef]

- Cassiède, M.; Paillol, J.H.; Pauly, J.; Daridon, J.L. Electrical behaviour of AT-cut quartz crystal resonators as a function of overtone number. Sens. Actuators A Phys. 2010, 159, 174–183. [Google Scholar] [CrossRef]

- Kasper, M.; Traxler, L.; Salopek, J.; Grabmayr, H.; Ebner, A.; Kienberger, F. Broadband 120 MHz impedance quartz crystal microbalance (QCM) with calibrated resistance and quantitative dissipation for biosensing measurements at higher harmonic frequencies. Biosensors 2016, 6, 23. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.-P.; Bao, Y.; Lin, Q.; Pang, R.-S.; Wang, L.-M.; Niu, L. A new quartz crystal microbalance measuring method with expansive frequency range and broadband adaptive response capacity. Chin. J. Anal. Chem. 2014, 42, 773–778. [Google Scholar] [CrossRef]

- Kankare, J.; Loikas, K.; Salomäki, M. Method for measuring the losses and loading of a quartz crystal microbalance. Anal. Chem. 2006, 78, 1875–1882. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.J.; Liang, T.; Han, K. Development of a real-time QCM bond-rupture system for POCT applications. IEEE Sens. J. 2016, 16, 8731–8735. [Google Scholar] [CrossRef]

- Antonio, A.; Yeison, M.; José, V.G.; Yolanda, J. A different point of view on the sensitivity of quartz crystal microbalance sensors. Meas. Sci. Technol. 2009, 20, 124004. [Google Scholar] [CrossRef]

- Chagnard, C.; Gilbert, P.; Watkins, A.N.; Beeler, T.; Paul, D.W. An electronic oscillator with automatic gain control: EQCM applications. Sens. Actuators B Chem. 1996, 32, 129–136. [Google Scholar] [CrossRef]

- Chao, Z.; Guanping, F. Contributions of amplitude measurement in QCM sensors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1996, 43, 942–947. [Google Scholar] [CrossRef]

- Matthys, R.J. Crystal Oscillator Circuits, revised ed.; Krieger Publishing Company: Malabar, FL, USA, 1992. [Google Scholar]

- Barnes, C. Development of quartz crystal oscillators for under-liquid sensing. Sens. Actuators A Phys. 1991, 29, 59–69. [Google Scholar] [CrossRef]

- Barnes, C. Some new concepts on factors influencing the operational frequency of liquid-immersed quartz microbalances. Sens. Actuators A Phys. 1992, 30, 197–202. [Google Scholar] [CrossRef]

- Arnau, A.; García, J.V.; Jimenez, Y.; Ferrari, V.; Ferrari, M. Improved electronic interfaces for AT-cut quartz crystal microbalance sensors under variable damping and parallel capacitance conditions. Rev. Sci. Instrum. 2008, 79, 075110. [Google Scholar] [CrossRef] [PubMed]

- Arnau, A.; Sogorb, T.; Jimenez, Y. A new method for continuous monitoring of series resonance frequency and simple determination of motional impedance parameters for loaded quartz-crystal resonators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 617–623. [Google Scholar] [CrossRef] [PubMed]

- Arnau, A.; Jimenez, Y.; Sogorb, T. Circuit for continuous monitoring of quartz-crystal resonators in sensor applications. Electron. Lett. 2002, 38, 365–367. [Google Scholar] [CrossRef]

- Sell, J.K.; Niedermayer, A.O.; Jakoby, B. A digital PLL circuit for resonator sensors. Sens. Actuators A Phys. 2011, 172, 69–74. [Google Scholar] [CrossRef]

- Koçum, C.; Erdamar, A.; Ayhan, H. Design of temperature controlled quartz crystal microbalance system. Instrum. Sci. Technol. 2009, 38, 39–51. [Google Scholar] [CrossRef]

- OpenQCM. OpenQCM Electronics Circuit—Pierce Oscillator. Available online: http://openqcm.com/electronics (accessed on 30 November 2017).

- Satoh, T.; Ruslan, R.I.; Gotoh, S.; Akitsu, T. Double-resonance quartz crystal oscillator and excitation of a resonator immersed in liquid media. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Ruslan, R.I.B.; Satoh, T.; Akitsu, T. Voltage-controlled double-resonance quartz oscillator using variable-capacitance diode. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 738–745. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Pardo, L.; Farina, J.; Gabrielli, C.; Perrot, H.; Brendel, R. Design considerations of miller oscillators for high-sensitivity QCM sensors in damping media. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 1965–1976. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Pardo, L.; Rodriguez, J.F.; Gabrielli, C.; Perrot, H.; Brendel, R. TSM-AW sensors based on miller XCOs for microgravimetric measurements in liquid media. IEEE Trans. Instrum. Meas. 2008, 57, 2309–2319. [Google Scholar] [CrossRef]

- García-Martinez, G.; Bustabad, E.A.; Perrot, H.; Gabrielli, C.; Bucur, B.; Lazerges, M.; Rose, D.; Rodriguez-Pardo, L.; Fariña, J.; Compère, C.; et al. Development of a mass sensitive quartz crystal microbalance (QCM)-based DNA biosensor using a 50 MHz electronic oscillator circuit. Sensors 2011, 11, 7656–7664. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Pardo, L.; Farina, J.; Gabrielli, C.; Perrot, H.; Brendel, R. Methodology of design of electronic circuit oscillators for QCM sensors in liquid media. In Proceedings of the IEEE International Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 800–805. [Google Scholar] [CrossRef]

- Rodriguez-Pardo, L.; Cao-Paz, A.; Fariña, J. QCM oscillator sensors: Comparison between miller and ABO topologies. Procedia Eng. 2011, 25, 1257–1260. [Google Scholar] [CrossRef]

- Pinheiro, A.C.; Bourbon, A.I.; Cerqueira, M.A.; Maricato, É.; Nunes, C.; Coimbra, M.A.; Vicente, A.A. Chitosan/fucoidan multilayer nanocapsules as a vehicle for controlled release of bioactive compounds. Carbohydr. Polym. 2015, 115, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Muckley, E.S.; Lynch, J.; Kumar, R.; Sumpter, B.; Ivanov, I.N. PEDOT: PSS/QCM-based multimodal humidity and pressure sensor. Sens. Actuators B Chem. 2016, 236, 91–98. [Google Scholar] [CrossRef]

- Liu, N.; Han, J.; Liu, Z.; Qu, L.; Gao, Z. Rapid detection of endosulfan by a molecularly imprinted polymer microsphere modified quartz crystal microbalance. Anal. Methods 2013, 5, 4442–4447. [Google Scholar] [CrossRef]

- Trotochaud, L.; Young, S.L.; Ranney, J.K.; Boettcher, S.W. Nickel—Iron oxyhydroxide oxygen-evolution electrocatalysts: The role of intentional and incidental iron incorporation. J. Am. Chem. Soc. 2014, 136, 6744–6753. [Google Scholar] [CrossRef] [PubMed]

- Beißner, S.; Thies, J.W.; Bechthold, C.; Kuhn, P.; Thürmann, B.; Dübel, S.; Dietzel, A. Low-cost, in-liquid measuring system using a novel compact oscillation circuit and quartz-crystal microbalances (QCMs) as a versatile biosensor platform. J. Sens. Sens. Syst. 2017, 6, 341–350. [Google Scholar] [CrossRef]

- Jakoby, B.; Art, G.; Bastemeijer, J. Novel analog readout electronics for microacoustic thickness shear-mode sensors. IEEE Sens. J. 2005, 5, 1106–1111. [Google Scholar] [CrossRef]

- Hu, Z.; Hedley, J.; Keegan, N.; Spoors, J.; Gallacher, B.; McNeil, C. One-port electronic detection strategies for improving sensitivity in piezoelectric resonant sensor measurements. Sensors 2016, 16, 1781. [Google Scholar] [CrossRef] [PubMed]

- Arnau, A.; Garcia, J.V.; Jimenez, Y.; Ferrari, V.; Ferrari, M. Improved electronic interfaces for heavy loaded AT cut quartz crystal microbalance sensors. In Proceedings of the IEEE International Frequency Control Symposium Joint with the 21st European Frequency and Time Forum, Geneva, Switzerland, 29 May–1 June 2007; pp. 357–362. [Google Scholar] [CrossRef]

- Narbón, J.V.G. Improved Characterization Systems for Quartz Crystal Microbalance Sensors: Parallel Capacitance Compensation for Variable Damping Conditions and Integrated Platform for High Frequency Sensors in High Resolution Applications. Ph.D. Thesis, Polytechnic University of Valencia, Valencia, Spain, 2016. [Google Scholar]

- Rodahl, M.; Höök, F.; Krozer, A.; Brzezinski, P.; Kasemo, B. Quartz crystal microbalance setup for frequency and Q-factor measurements in gaseous and liquid environments. Rev. Sci. Instrum. 1995, 66, 3924–3930. [Google Scholar] [CrossRef]

- Rodahl, M.; Kasemo, B. A simple setup to simultaneously measure the resonant frequency and the absolute dissipation factor of a quartz crystal microbalance. Rev. Sci. Instrum. 1996, 67, 3238–3241. [Google Scholar] [CrossRef]

- Dixon, M.C. Quartz crystal microbalance with dissipation monitoring: Enabling real-time characterization of biological materials and their interactions. J. Biomol. Tech. 2008, 19, 151–158. [Google Scholar] [PubMed]

- Rodahl, M.; Höök, F.; Krozer, A.; Kasemo, B. A Piezoelectric Crystal Microbalance Device. W.O. Patent 1,996,035,103 A1, 7 November 1996. [Google Scholar]

- Baù, M.; Ferrari, M.; Ferrari, V. Analysis and validation of contactless time-gated interrogation technique for quartz resonator sensors. Sensors 2017, 17, 1264. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M.; Baù, M.; Pagnoni, M.; Ferrari, V. Compact DDS-based system for contactless interrogation of resonant sensors based on time-gated technique. In Proceedings of the IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 907–910. [Google Scholar] [CrossRef]

- Ferrari, M.; Baù, M.; Masud, M.; Ferrari, V. A Time-gated contactless interrogation system for frequency and quality factor tracking in QCR to investigate on liquid solution microdroplets. Procedia Eng. 2016, 168, 704–707. [Google Scholar] [CrossRef]

- Drees, D.M.; Shanks, H.R.; Van Deusen, R.A.; Landin, A.R. Method and System for Detecting Material Using Piezoelectric Resonators. U.S. Patent 5,932,953 A, 3 August 1999. [Google Scholar]

- Montagut, Y.J.; García, J.V.; Jiménez, Y.; March, C.; Montoya, A.; Arnau, A. Frequency-shift vs. phase-shift characterization of in-liquid quartz crystal microbalance applications. Rev. Sci. Instrum. 2011, 82, 064702. [Google Scholar] [CrossRef] [PubMed]

- March, C.; García, J.V.; Sánchez, Á.; Arnau, A.; Jiménez, Y.; García, P.; Manclús, J.J.; Montoya, Á. High-frequency phase shift measurement greatly enhances the sensitivity of QCM immunosensors. Biosens. Bioelectron. 2015, 65, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Antonio, A.; Mollá, P.G.; Narbon, J.V.G.; Jiménez, Y.J.; Ferizzola, Y.M.; Fabado, A.R. Method and Device for Nanogravimetry in Fluid Media Using Piezoelectric Resonators. U.S. Patent 8,869,617 B2, 28 October 2014. [Google Scholar]

- Ferrari, V.; Marioli, D.; Taroni, A. Improving the accuracy and operating range of quartz microbalance sensors by a purposely designed oscillator circuit. IEEE Trans. Instrum. Meas. 2001, 50, 1119–1122. [Google Scholar] [CrossRef]

- Rocha-Gaso, M.-I.; García, J.-V.; García, P.; March-Iborra, C.; Jiménez, Y.; Francis, L.-A.; Montoya, Á.; Arnau, A. Love wave immunosensor for the detection of carbaryl pesticide. Sensors 2014, 14, 16434–16453. [Google Scholar] [CrossRef] [PubMed]

- Cao-Paz, A.; Rodriguez-Pardo, L.; Fariña, J. Temperature compensation of QCM sensors in liquid media. Sens. Actuators B Chem. 2014, 193, 78–81. [Google Scholar] [CrossRef]

- Kakalis, A.; Panayiotou, C. The temperature effect of AT-cut input quartz parameters on QCM effective properties calculated with equivalent circuit models. J. Electroceram. 2017, 1–13. [Google Scholar] [CrossRef]

- Saha, T.; Guo, N.; Ramakrishnan, N. A novel langasite crystal microbalance instrumentation for UV sensing application. Sens. Actuators A Phys. 2016, 252, 16–25. [Google Scholar] [CrossRef]

- Habuka, H.; Matsui, M. Langasite crystal microbalance frequency behavior over wide gas phase conditions for chemical vapor deposition. Surf. Coat. Technol. 2013, 230, 312–315. [Google Scholar] [CrossRef]

- Nosek, J.; Pustka, M. Determination of the electromechanical coupling factor of gallium orthophosphate (GaPO4) and its influence on resonance-frequency temperature dependencies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 10–14. [Google Scholar] [CrossRef] [PubMed]

- Aubert, T.; Elmazria, O.; Assouar, M.B. Wireless and batteryless surface acoustic wave sensors for high temperature environments. In Proceedings of the 9th International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009; pp. 890–898. [Google Scholar] [CrossRef]

- PiezoCryst. High Temperature Microbalance Sensor Crystals: Type R-30. Available online: http://piezocryst.com/fileadmin/user_upload/pdf/R-30_Datenblatt_Rev.01.pdf (accessed on 30 November 2017).

- Millichamp, J.; Mason, T.J.; Brandon, N.P.; Brown, R.J.C.; Maher, R.C.; Manos, G.; Neville, T.P.; Brett, D.J.L. A study of carbon deposition on solid oxide fuel cell anodes using electrochemical impedance spectroscopy in combination with a high temperature crystal microbalance. J. Power Sources 2013, 235, 14–19. [Google Scholar] [CrossRef]

| Characterization Technique | Advantages | Limitations | ||

|---|---|---|---|---|

| Impedance Analysis | Conventional Impedance Analyzers |

|

| |

| Compact Circuitry | VD Based |

|

| |

| Compact Analyzers |

|

| ||

| Oscillator Circuits | QCM Oscillators |

|

| |

| PLL Based | 0-Phase Tracking |

|

| |

| Tracking |

| |||

| Exponential Decay (QCM-D) | Conventional |

|

| |

| Contactless |

|

| ||

| Phase-Mass Characterization |

|

| ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alassi, A.; Benammar, M.; Brett, D. Quartz Crystal Microbalance Electronic Interfacing Systems: A Review. Sensors 2017, 17, 2799. https://doi.org/10.3390/s17122799

Alassi A, Benammar M, Brett D. Quartz Crystal Microbalance Electronic Interfacing Systems: A Review. Sensors. 2017; 17(12):2799. https://doi.org/10.3390/s17122799

Chicago/Turabian StyleAlassi, Abdulrahman, Mohieddine Benammar, and Dan Brett. 2017. "Quartz Crystal Microbalance Electronic Interfacing Systems: A Review" Sensors 17, no. 12: 2799. https://doi.org/10.3390/s17122799