Relative Humidity Sensor Based on No-Core Fiber Coated by Agarose-Gel Film

Abstract

:1. Introduction

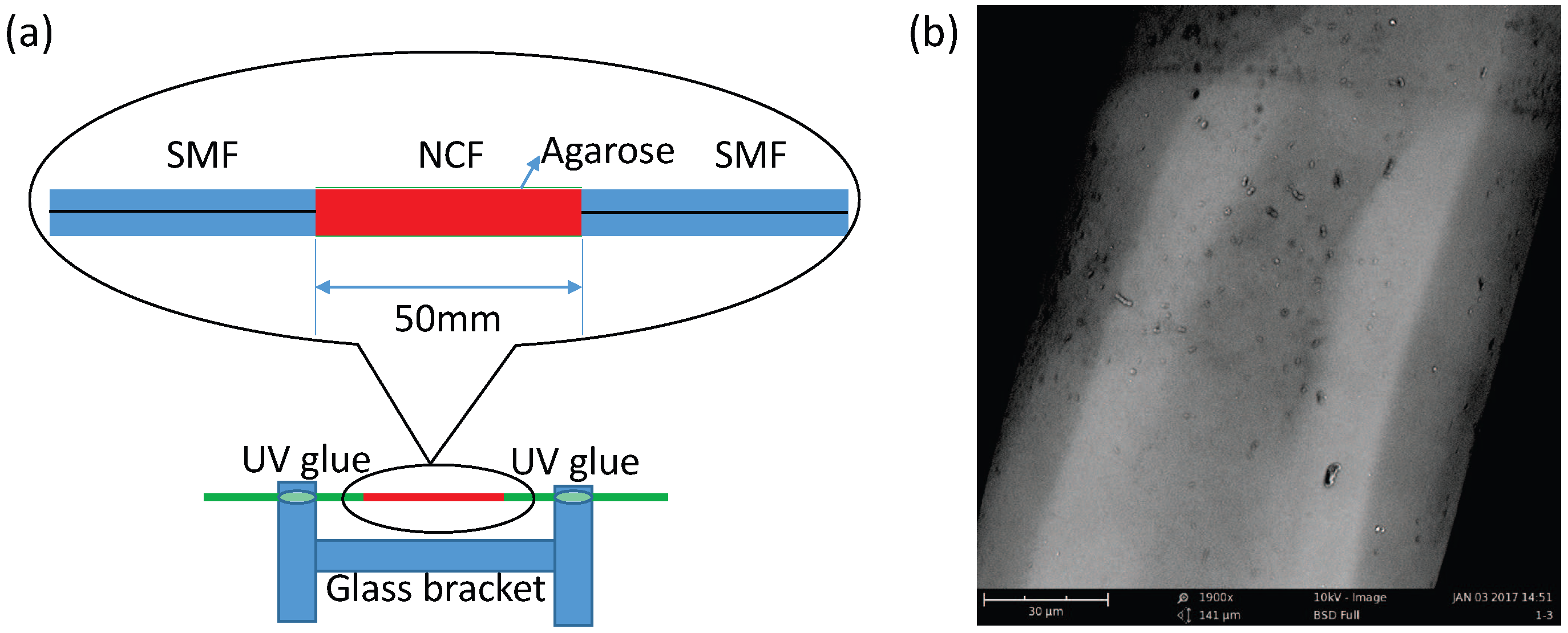

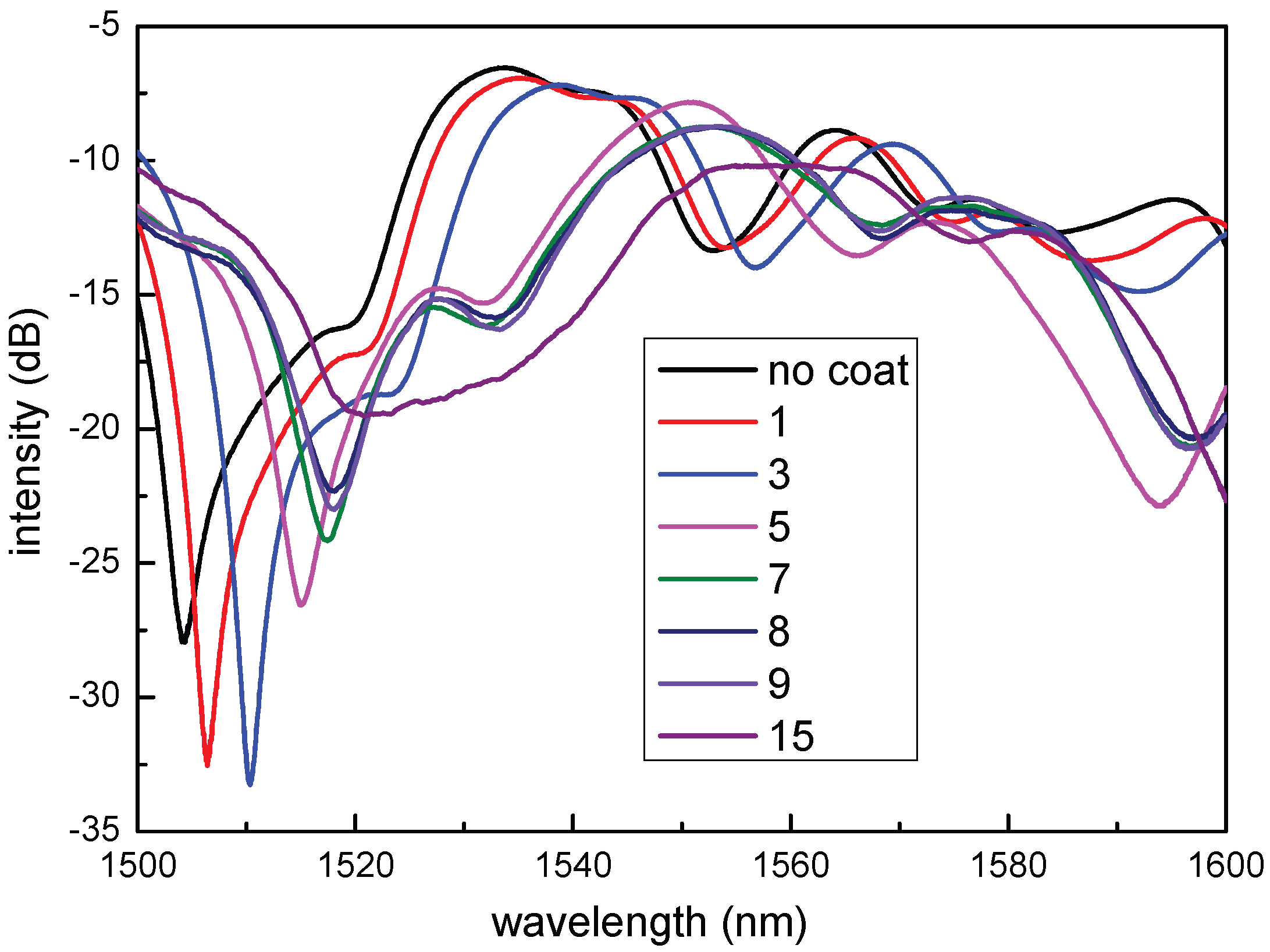

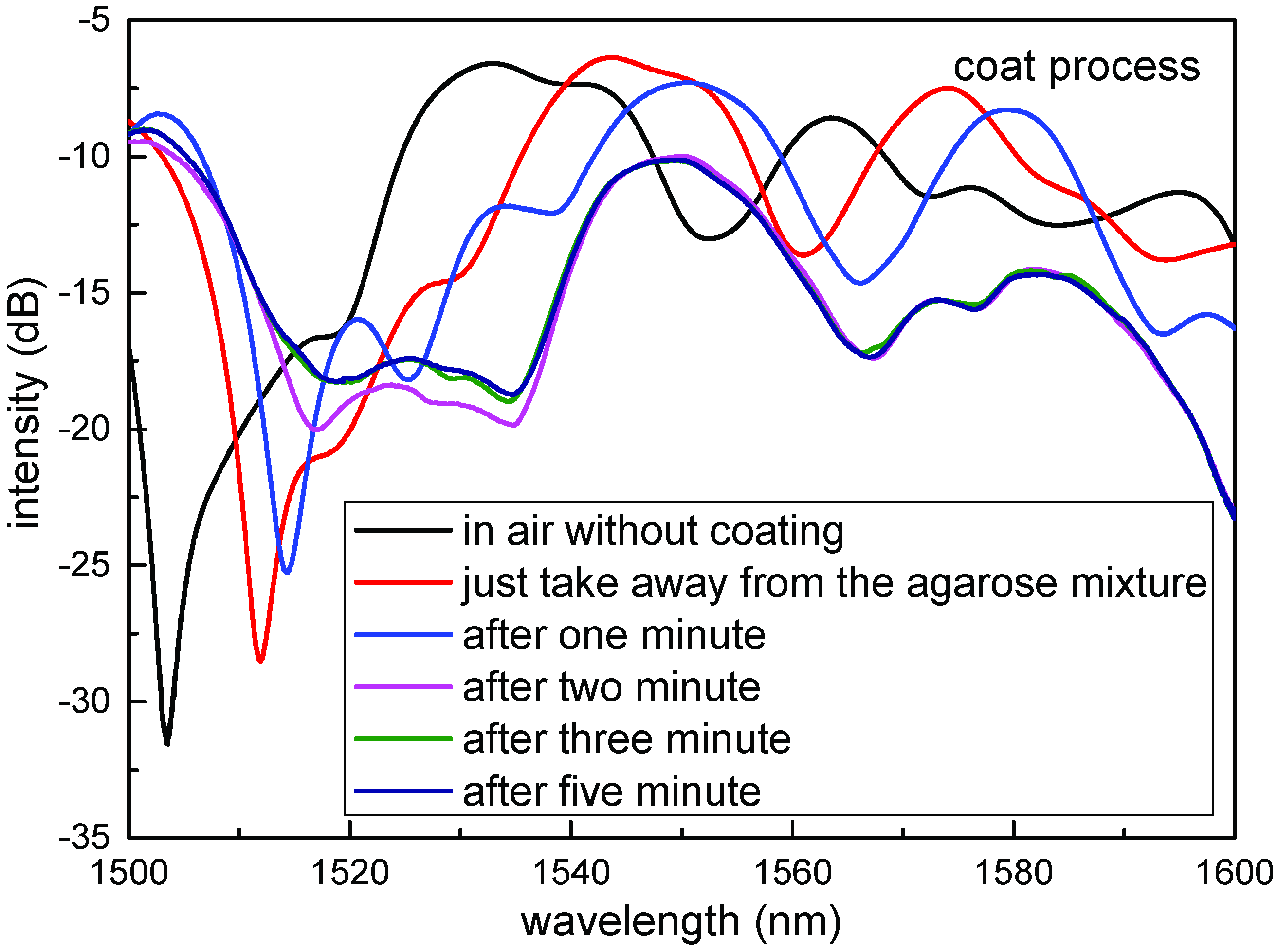

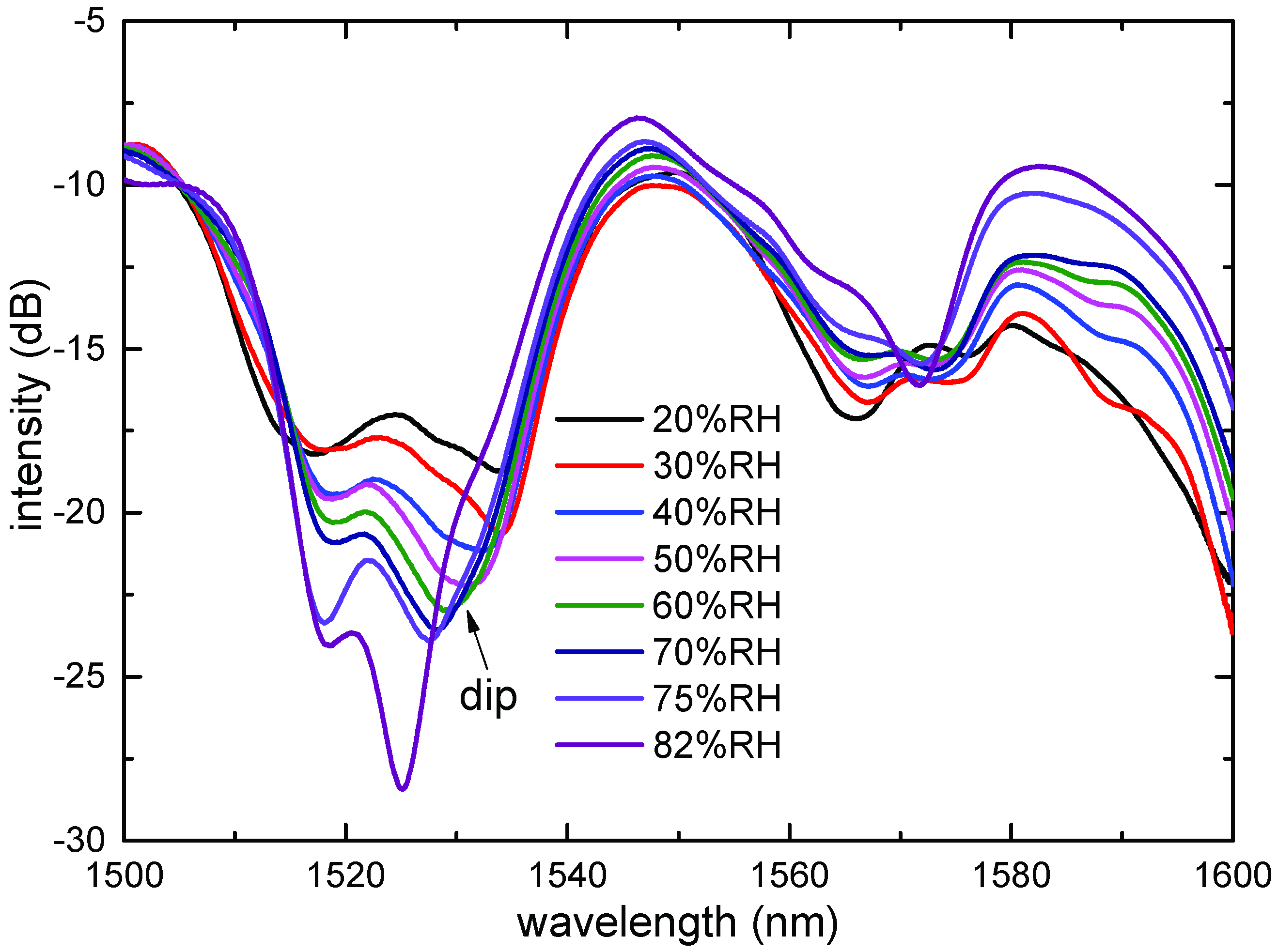

2. Principles and Fabrication

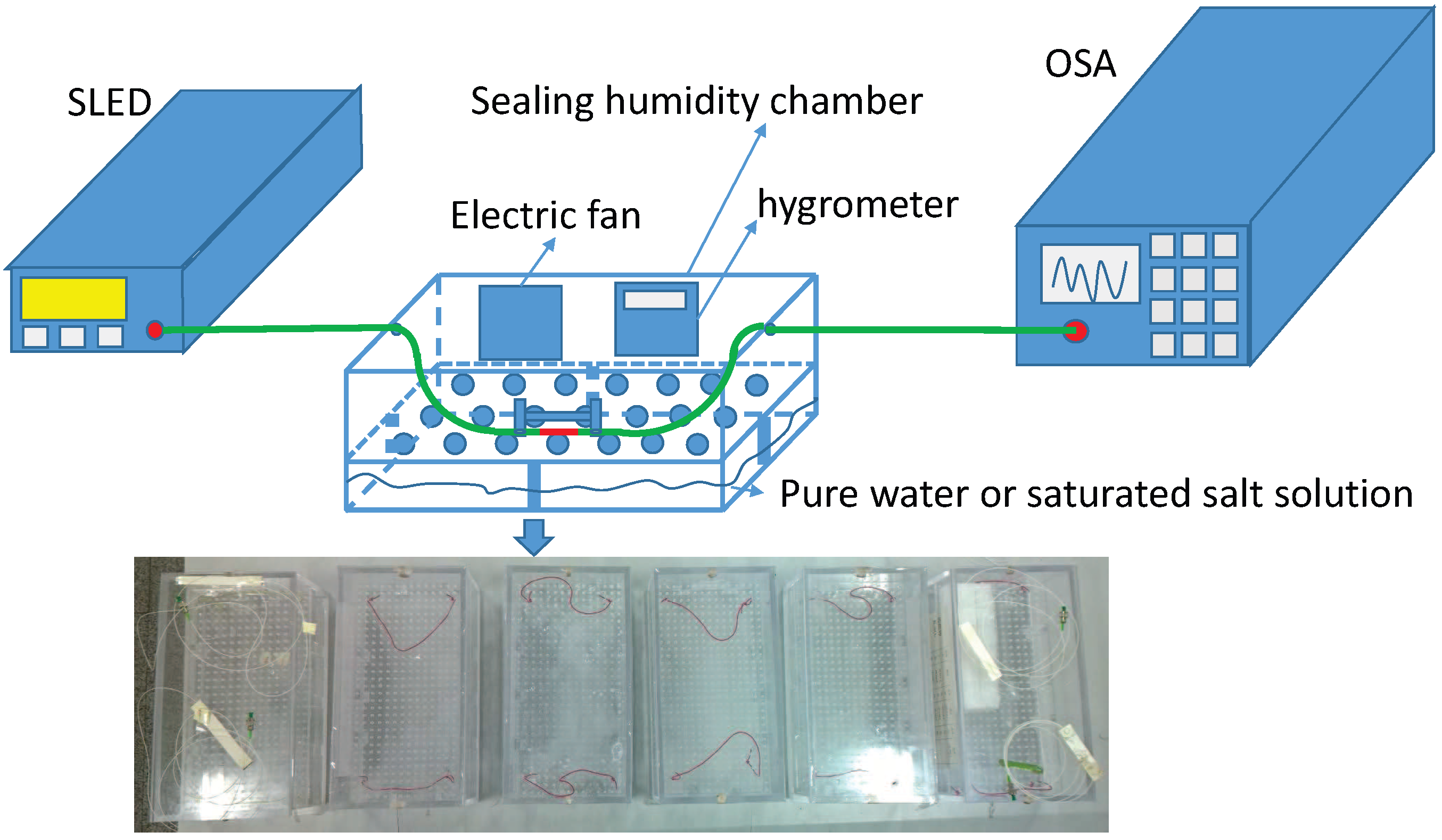

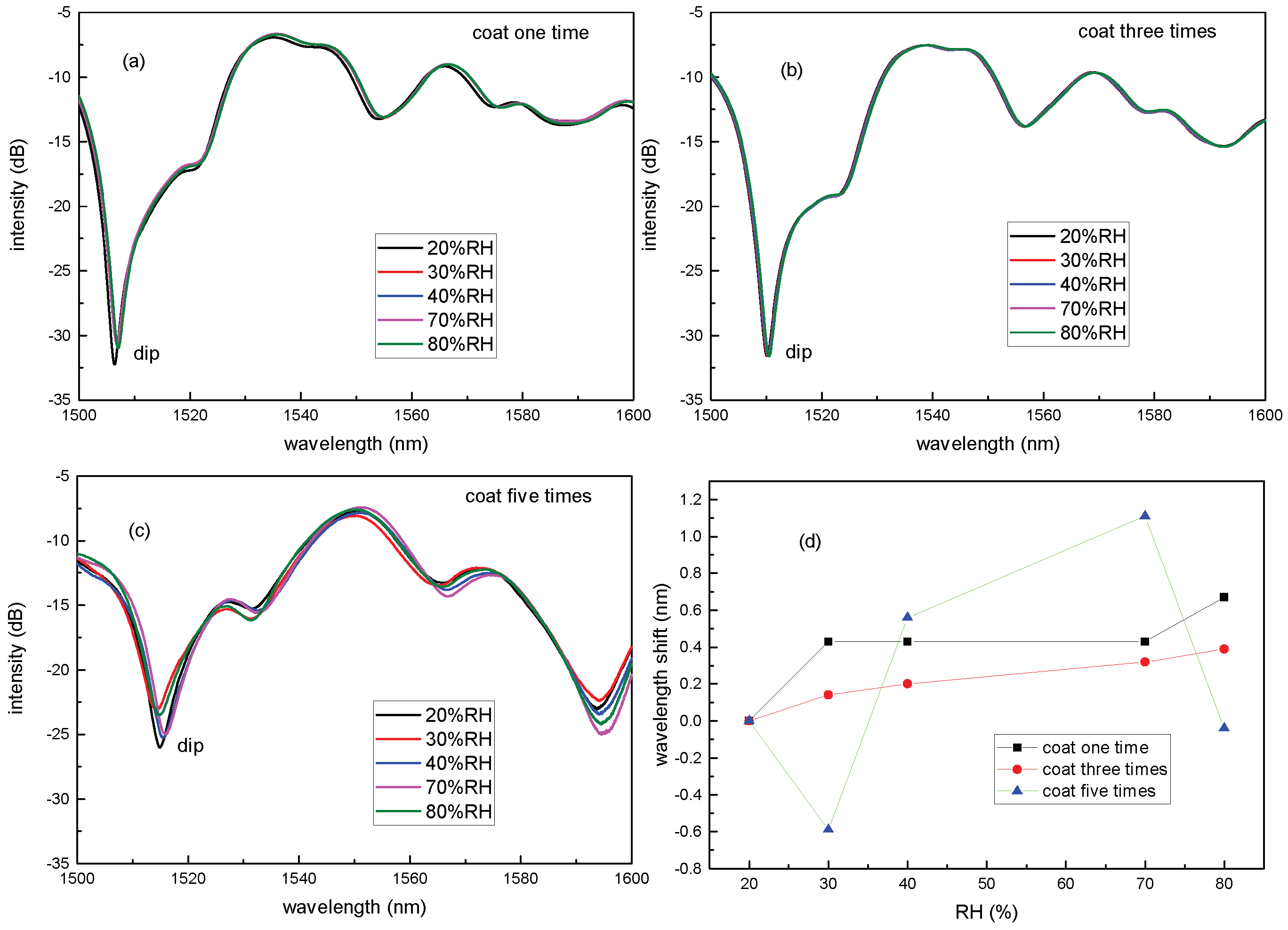

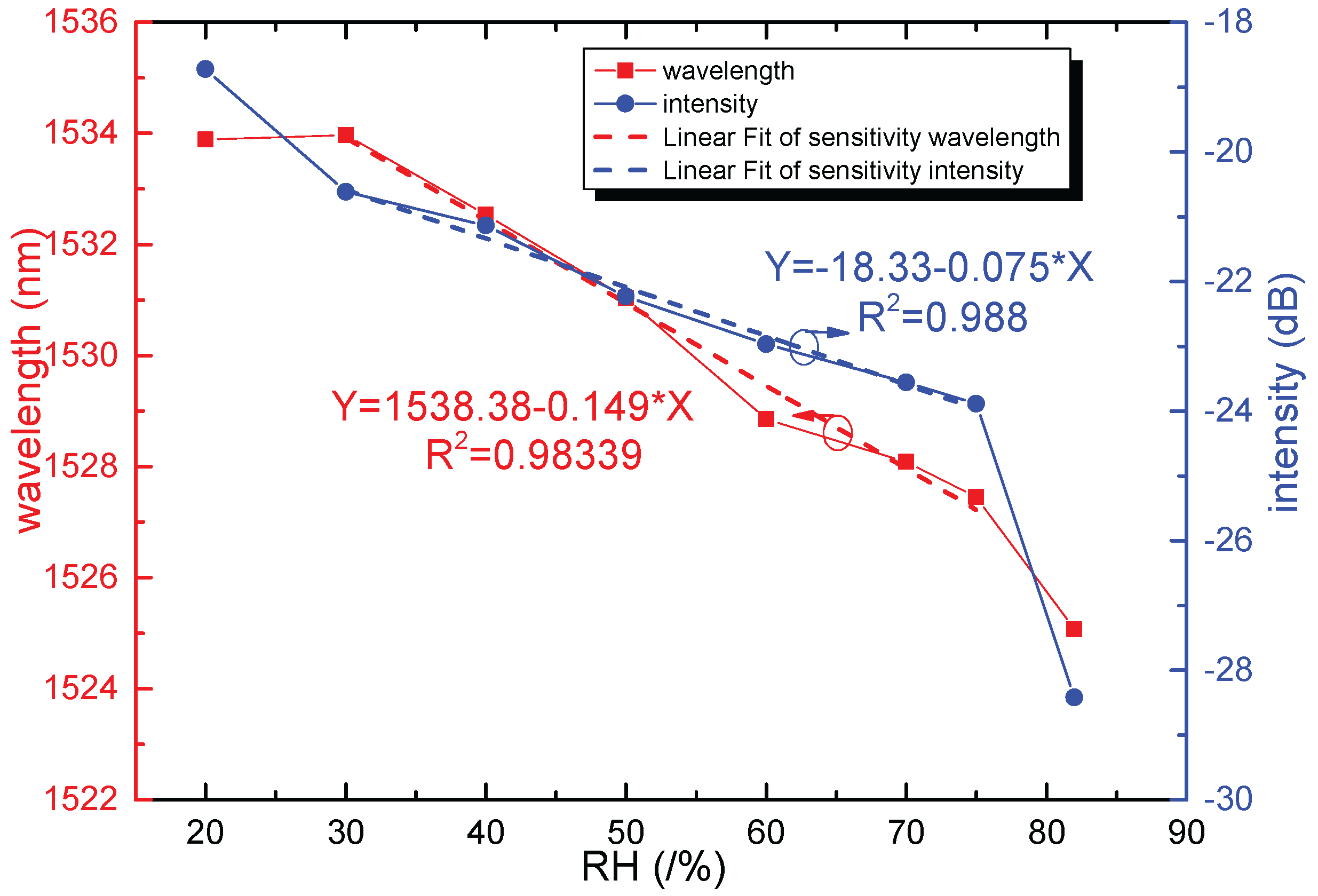

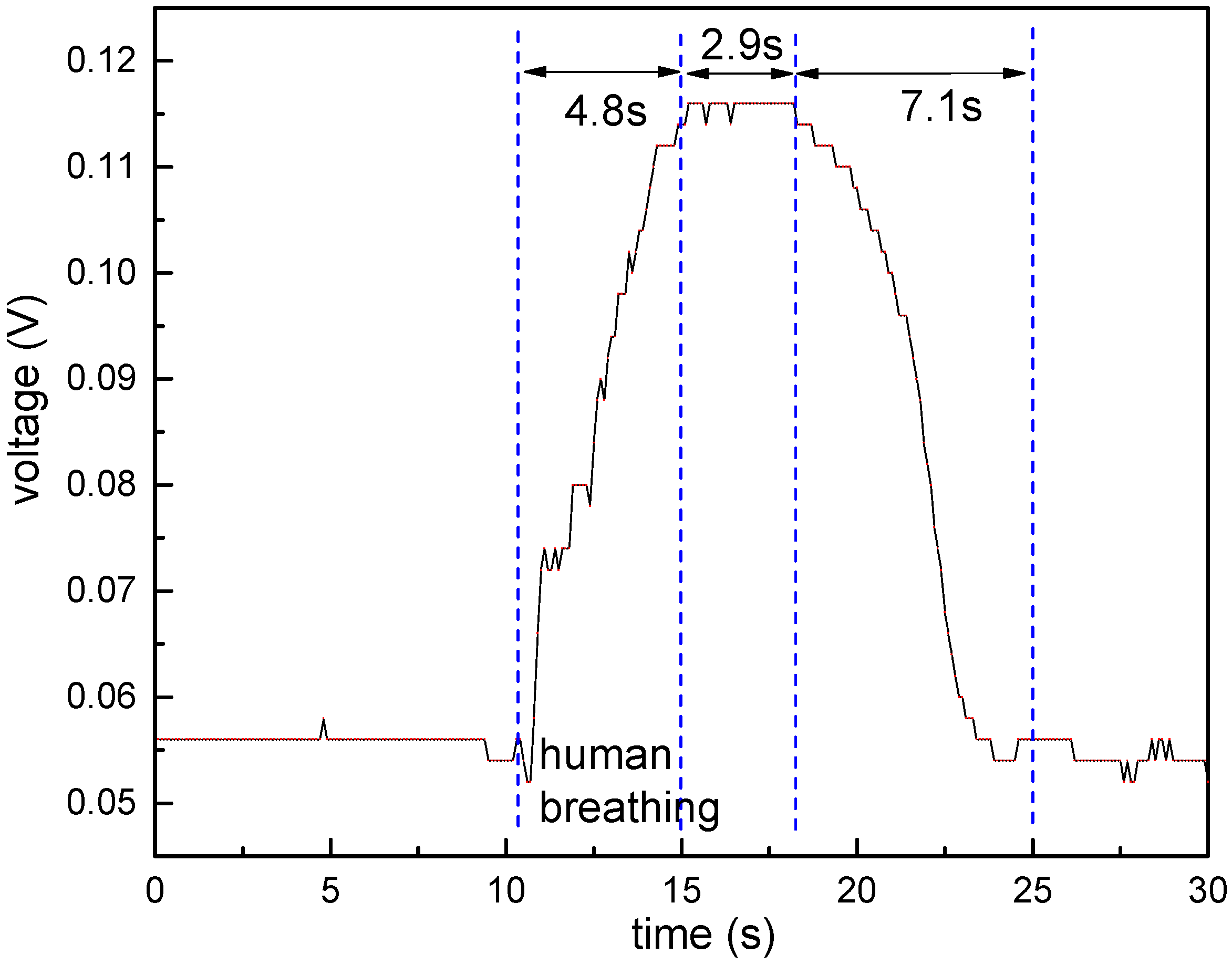

3. Experimental Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, X.F.; Farrell, G.; Lewis, E.; Tian, K.; Yuan, L.B.; Wang, P.F. A Humidity Sensor Based on a Singlemode-Side Polished Multimode–Singlemode Optical Fibre Structure Coated with Gelatin. J. Lightwave Technol. 2017, 35, 4087–4094. [Google Scholar] [CrossRef]

- Alvarez-Herrero, A.; Guerrero, H.; Levy, D. High-sensitivity sensor of low relative humidity based on overlay on side-polished fibers. IEEE Sens. J. 2004, 4, 52–56. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Farrell, G. Experimental demonstration of a high-sensitivity humidity sensor based on an Agarose-coated transmission-type photonic crystal fiber interferometer. Appl. Opt. 2013, 52, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Mallik, A.K.; Liu, D.; Kavungal, V.; Wu, Q.; Farrell, G.; Semenova, Y. Agarose coated spherical micro resonator for humidity measurements. Opt. Exp. 2016, 24, 21216–21227. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Miao, Y.; Liu, B.; Lin, W.; Zhang, H.; Song, B.; Huang, M.; Lin, L. Relative Humidity Sensor Based on S-Taper Fiber Coated with SiO2 Nanoparticles. IEEE Sens. J. 2015, 15, 3424–3428. [Google Scholar] [CrossRef]

- Batumalay, M.; Harun, S.W.; Irawati, N.; Ahmad, H.; Arof, H. A Study of Relative Humidity Fiber-Optic Sensors. IEEE Sens. J. 2015, 15, 1945–1950. [Google Scholar] [CrossRef]

- Korenko, B.; Rothhardt, M.; Hartung, A.; Bartelt, H. Novel Fiber-Optic Relative Humidity Sensor with Thermal Compensation. IEEE Sens. J. 2015, 15, 5450–5454. [Google Scholar] [CrossRef]

- Miao, Y.; Liu, B.; Zhang, H.; Li, Y.; Zhou, H.; Sun, H.; Zhang, W.; Zhao, Q. Relative Humidity Sensor Based on Tilted Fiber Bragg Grating with Polyvinyl Alcohol Coating. IEEE Photonics Tehnol. Lett. 2009, 21, 441–443. [Google Scholar] [CrossRef]

- Woyessa, G.; Nielsen, K.; Stefani, A.; Markos, C.; Bang, O. Temperature insensitive hysteresis free highly sensitive polymer optical fiber Bragg grating humidity sensor. Opt. Exp. 2016, 24, 1206–1213. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, L.; Zhang, M.; Tu, D.; Mao, X.; Liao, Y. Long-Period Grating Relative Humidity Sensor with Hydrogel Coating. IEEE Photonics Tehnol. Lett. 2007, 19, 880–882. [Google Scholar] [CrossRef]

- Xia, L.; Li, L.; Li, W.; Kou, T.; Liu, D. Novel optical fiber humidity sensor based on a no-core fiber structure. Sens. Actuators A Phys. 2013, 190, 1–5. [Google Scholar] [CrossRef]

- Zamarreño, C.R.; Hernaez, M.; Villar, I.D.; Matias, I.R.; Arregui, F.J. Tunable humidity sensor based on ITO-coated optical fiber. Sens. Actuators B Chem. 2010, 146, 414–417. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.; Cheng, J.; Jiang, Y.; Jiang, L.; Qi, Z. Humidity sensor based on power leakage at resonance wavelengths of a hollow core fiber coated with reduced graphene oxide. Sens. Actuators B Chem. 2016, 222, 618–624. [Google Scholar] [CrossRef]

- Wu, Q.; Semennova, Y.; Mathew, J.; Wang, P.; Farrell, G. Humidity sensor based on a single-mode hetero-core fiber structure. Opt. Lett. 2011, 36, 1752–1754. [Google Scholar] [CrossRef] [PubMed]

- Akita, S.; Sasaki, H.; Watanabe, K.; Seki, A. A humidity sensor based on a hetero-core optical fiber. Sens. Actuators B Chem. 2010, 147, 385–391. [Google Scholar] [CrossRef]

- Huang, C.; Xie, W.; Yang, M.; Dai, J.; Zhang, B. Optical Fiber Fabry-Perot Humidity Sensor Based on Porous Al2O3 Film. IEEE Photonics Tehnol. Lett. 2015, 27, 2127–2130. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, B.; Jiang, H.; He, S. Agarose Filled Fabry-Perot Cavity for Temperature Self-Calibration Humidity Sensing. IEEE Photonics Tehnol. Lett. 2016, 28, 2027–2030. [Google Scholar] [CrossRef]

- Sun, L.; Li, J.; Jin, L.; Ran, Y.; Guan, B. High-birefringence microfiber Sagnac interferometer based humidity sensor. Sens. Actuators B Chem. 2016, 231, 696–700. [Google Scholar] [CrossRef]

- Villar, I.D.; Socorro, A.B.; Corres, J.M.; Arregui, F.J. Optimization of Sensors Based on Multimode Interference in Single-Mode-Multimode-Single-Mode Structure. J. Lightwave Technol. 2013, 31, 3460–3468. [Google Scholar] [CrossRef]

- Rodriguez, A.J.R.; Baldovino-Pantaleon, O.; Cruz, R.F.D.; Zamarreno, C.R.; Matias, I.R.; May-Arrioja, D.A. Gasohol Quality Control for Real Time Applications by Means of a Multimode Interference Fiber Sensor. Sensors 2014, 14, 17817–17828. [Google Scholar] [CrossRef] [PubMed]

- Socorro, A.B.; Santamaría, E.; Fernández-Irigoyen, J.; Villar, I.D.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Fiber-Optic Immunosensor Based on an Etched SMS Structure. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 314–321. [Google Scholar] [CrossRef]

- Lan, X.; Huang, J.; Han, Q.; Wei, T.; Gao, Z.; Jiang, H.; Dong, J.; Xiao, H. Fiber ring laser interrogated zeolite-coated singlemode-multimode-singlemode structure for trace chemical detection. Opt. Lett. 2012, 37, 1998–2000. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.L.; Yang, L. Sensitivity enhancement of RI sensor based on SMS fiber structure with high refractive index overlay. J. Lightwave Technol. 2012, 30, 1463–1469. [Google Scholar] [CrossRef]

- Socorro, A.B.; Villar, I.D.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Sensitivity enhancement in a multimode interference-based SMS fibre structure coated with a thin-film: Theoretical and experimental study. Sens. Actuators B Chem. 2014, 190, 363–369. [Google Scholar] [CrossRef]

- Villar, I.D.; Socorro, A.B.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Refractometric sensors based on multimode interference in a thin-film coated single-mode-multimode-single-mode structure with reflection configuration. Appl. Opt. 2014, 53, 3913–3919. [Google Scholar] [CrossRef] [PubMed]

- Bariain, C.; Matias, I.R.; Arregui, F.J.; Lopez-Amo, M. Optical fiber humidity sensor based on a tapered fiber coated with agarose gel. Sens. Actuators B Chem. 2000, 69, 127–131. [Google Scholar] [CrossRef]

- Mathew, J.; Semenova, Y.; Farrell, G. Effect of coating thickness on the sensitivity of a humidity sensor based on an Agarose coated photonic crystal fiber interferometer. Opt. Exp. 2013, 21, 6313–6320. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Jiang, Y.; Ding, W. Agarose gel filled temperature-insensitive photonic crystal fibers humidity sensor based on the tunable coupling ratio. Sens. Actuators B Chem. 2014, 195, 313–319. [Google Scholar] [CrossRef]

| Saturated Salt Solution | Temperature (°C) | RH (%) |

|---|---|---|

| MgCl | 25 | 33 |

| K2CO3 | 25 | 43 |

| NaCl | 25 | 75 |

| KCl | 25 | 87 |

| K2SO4 | 25 | 98 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Shi, J.; Yang, X.; Xu, D.; Rong, F.; Zhao, J.; Yao, J. Relative Humidity Sensor Based on No-Core Fiber Coated by Agarose-Gel Film. Sensors 2017, 17, 2353. https://doi.org/10.3390/s17102353

Xu W, Shi J, Yang X, Xu D, Rong F, Zhao J, Yao J. Relative Humidity Sensor Based on No-Core Fiber Coated by Agarose-Gel Film. Sensors. 2017; 17(10):2353. https://doi.org/10.3390/s17102353

Chicago/Turabian StyleXu, Wei, Jia Shi, Xianchao Yang, Degang Xu, Feng Rong, Junfa Zhao, and Jianquan Yao. 2017. "Relative Humidity Sensor Based on No-Core Fiber Coated by Agarose-Gel Film" Sensors 17, no. 10: 2353. https://doi.org/10.3390/s17102353