This section details the procedure for designing an exciter-detector coil-based PEC sensor suitable for critical pipe inspection. The design example targets grey cast iron pipe assessment; the maximum thickness expected on pipes was 20 mm. The procedure includes the following steps: (1) identifying electrical and magnetic properties of the pipe material to be inspected; (2) numerically simulating a sensor to determine suitable sensor dimensions; and (3) sensor fabrication. The following subsections detail the three sub-steps of the design procedure.

3.1. Identification of Material Electrical and Magnetic Properties

Since becomes a function in the form of and predominantly depends on the electromagnetic properties and material thickness, it is in fact heavily independent of sensor dimensions. Practical limitations in sensor excitation and signal acquisition electronics dictate those dimensions, and they should be decided upon before fabrication in order to achieve sufficient penetration depth in the ferromagnetic material (grey cast iron in this case). Sensor dimensions are determined in this paper through numerical simulation, and to achieve that, knowing and beforehand is necessary.

Measuring electrical and magnetic properties was done by extracting a coupon (hot tapping [

24,

25,

26] is a viable option for coupon extraction from on-site critical pipes), making a specimen (dimensions = 3 mm × 2 mm × 2 mm) through Electric Discharge Machining (EDM) wire cutting [

27,

28,

29] (using cooling liquid) and feeding it to a Physical Property Measurement System (PPMS) [

30,

31,

32]. An average representation of properties is derived by performing measurements on multiple specimens. A total of 27 specimens made from coupons extracted from equally-spaced locations along a 1 km-long grey cast iron pipeline, with details provided in

Table 1, were tested by measuring their magnetization curve (i.e., BH curve where B is magnetic flux density and H is magnetic filed intensity) and electrical conductivity.

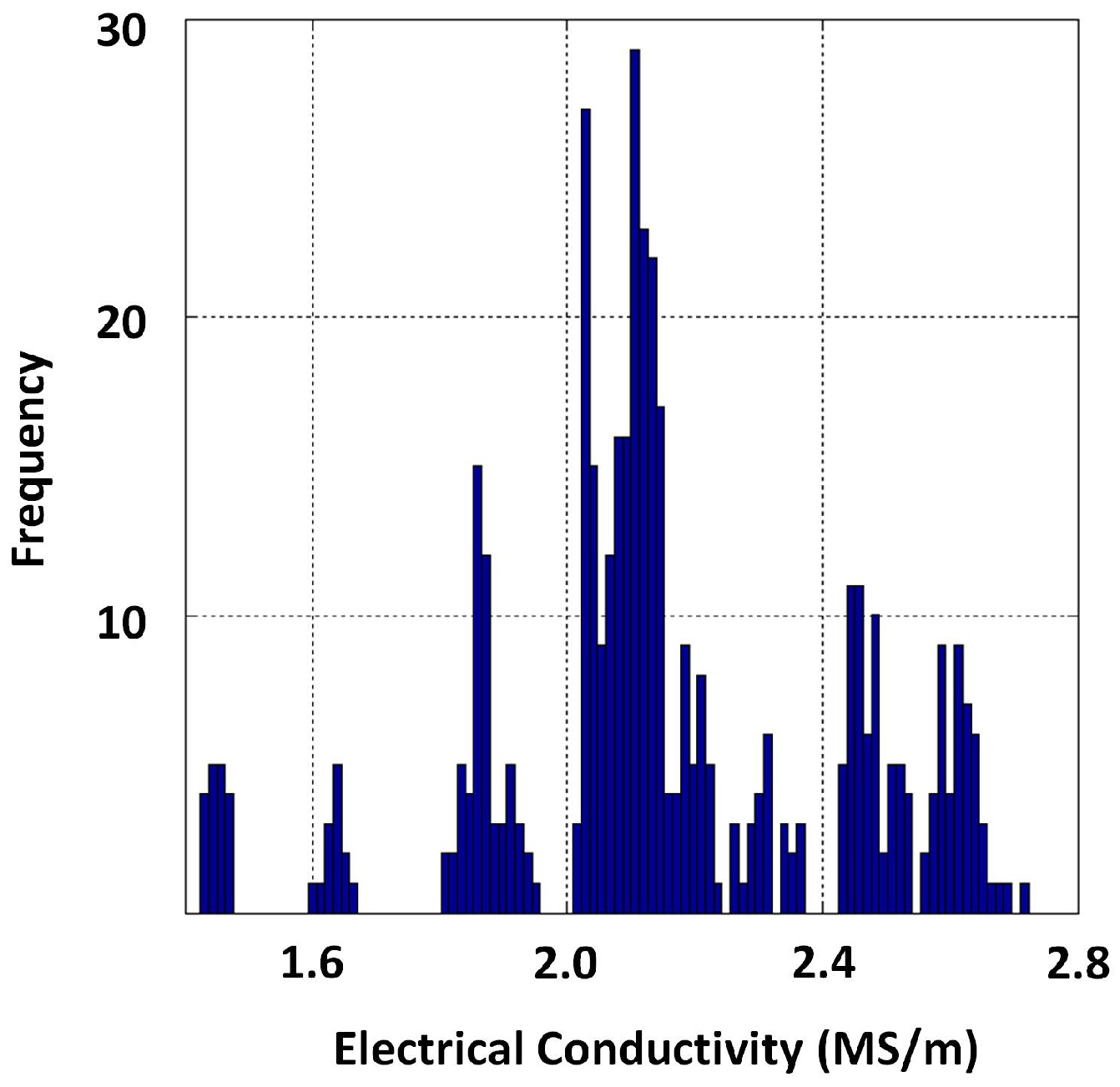

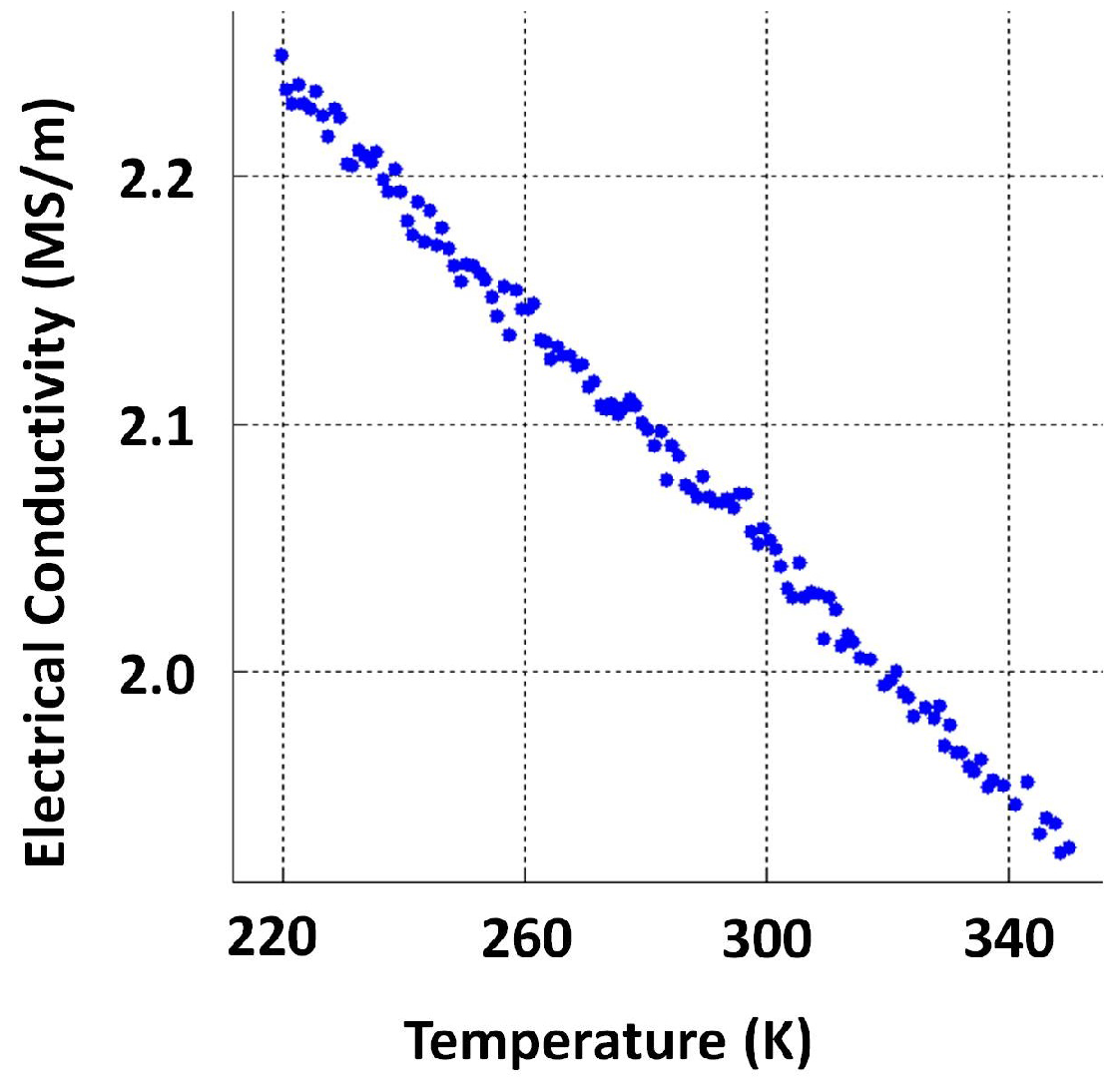

Since electrical conductivity is known to vary significantly with temperature, the dependence was captured by measuring the conductivity of each specimen across a range (220 K–350 K). The average representation for conductivity (i.e., 2.16

S/m, approximately) was obtained by computing the mean over temperature (between 283 K and 313 K to resemble atmospheric temperature variation in Sydney Australia), as well as specimens. Although the average value of

was considered for simulation, it was notable that

of cast iron is considerably variable. This can be seen in

Figure 3, which shows a histogram of conductivities resulting from all conductivity values (1097 in total) between temperatures 283 K and 313 K captured from all 27 specimens. The standard deviation (std) of this dataset was

S/m, and 94.8% of the data fell within

standard deviations. Such a variation in conductivity creates a unique difficulty in calibrating PEC sensors for critical pipe assessment. Conductivity data from which the statistics were calculated are provided as

Supplementary Material.

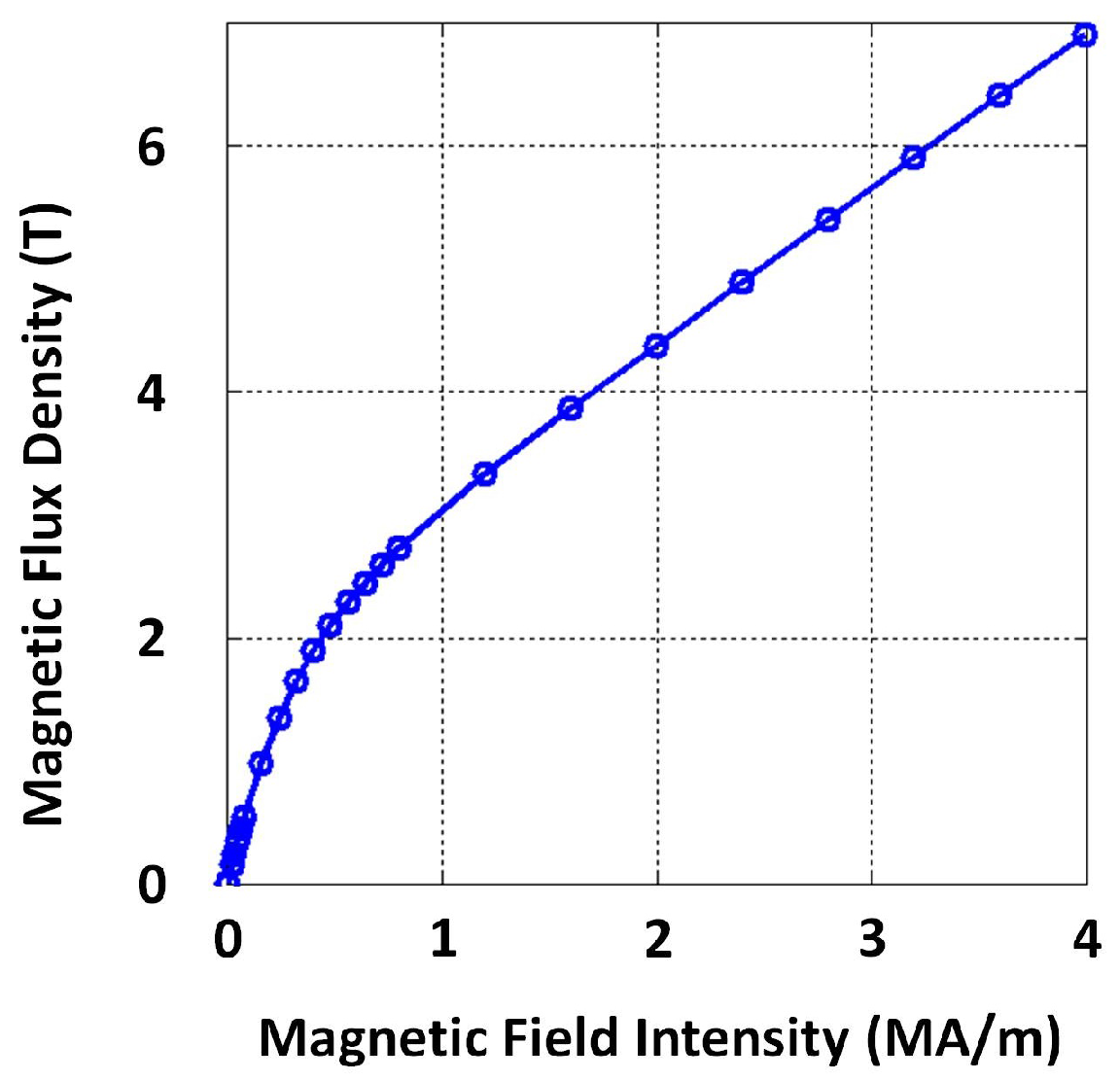

Significant variation in magnetic properties within atmospheric temperature conditions and a correlation between electrical conductivity and magnetic permeability were not evident from the available data; therefore a magnetization curve per specimen was measured while magnetizing and demagnetizing. Resulting curves were averaged eventually across samples.

Figure 4 and

Figure 5 depict a magnetization curve and conductivity measurements performed on a particular grey cast iron specimen, respectively, and raw data are provided as

Supplementary Material. A fine sampling resolution to measure the magnetization curve region covering low magnetic fields is recommended in order to capture the typical non-linear behaviour present. A sampling interval of 10 A/m was used when magnetic field intensity ≤100 A/m. The relative permeability value

calculated from the low magnetic field region of the magnetization curve in

Figure 4 (considering the sensor excitation strength, high magnetic fields are not expected inside the pipe material) and the averaged conductivity value

S/m were used to numerically simulate a PEC sensor and determine suitable dimensions for the application, the process is described in subsequent

Section 3.2.

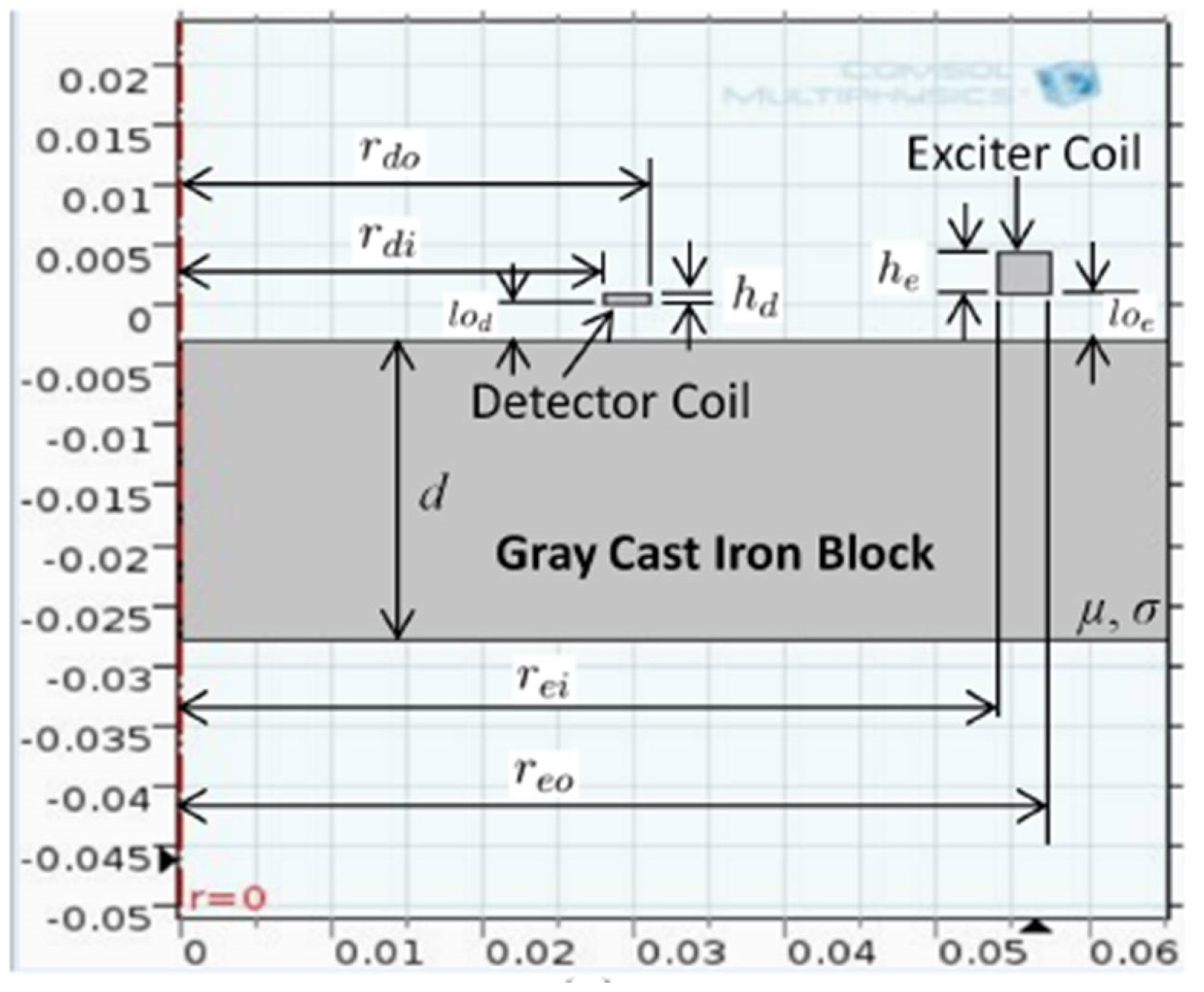

3.2. Numerical Simulation of the PEC Sensor

Due to the simplicity of modelling, and the common use for ferromagnetic material thickness estimation [

2,

3,

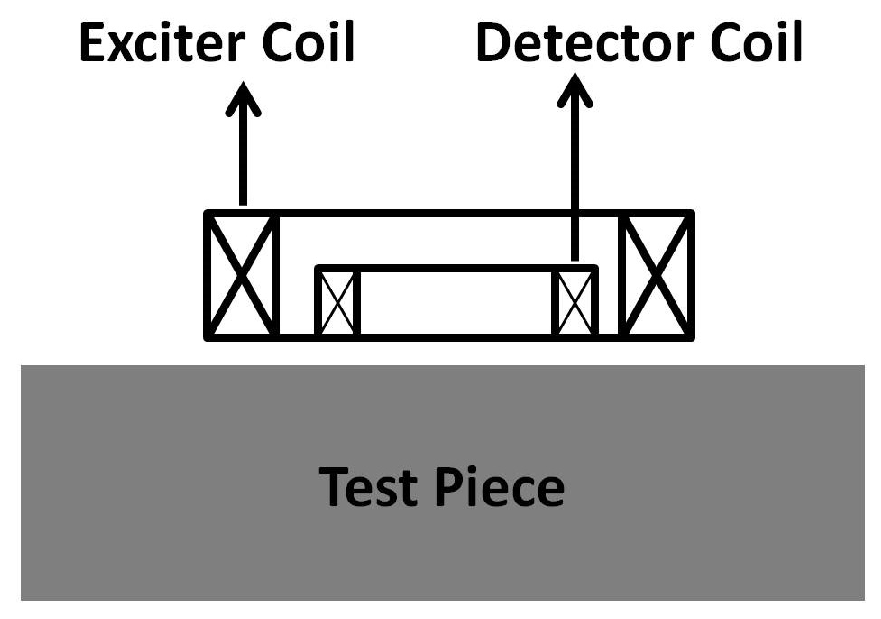

5], a circular-shaped PEC sensor having concentrically-wound air cored coils as shown in the cross-section in

Figure 1 was selected for this work. For a fixed excitation, the sensor size has been observed to be a dominant factor influencing the sensor’s penetration capability (i.e., the maximum thickness of a particular material to which the sensor will be sensitive) [

16]. Therefore, before fabrication, the sensor interaction with grey cast iron was numerically simulated using FEA. A 2D axisymmetric model of the sensor placed above a grey cast iron (shown in

Figure 6) was developed using COMSOL Multiphysics

®. The input parameters required for simulation are defined in

Table 2. The simulation model outputs the detector coil voltage

as a function of many input variables as shown in Equation (

12).

is calculated using the magnetic vector potential, which is determined by solving the magnetic vector potential equation shown in Equation (

13) for any given location in the model, where

is the magnetic potential at any location,

t is time and

is the source current.

To narrow down the suitable set of sensor dimensions, the heights of exciter and detector coils (

and

) and vertical offsets of the two coils (

and

) are fixed. Copper wires are used to wind coils; thus, we use the standard permeability and conductivity of copper (

,

,

and

) for simulation. In addition, rough estimates of permeability (

) and electrical conductivity (

) of grey cast iron are required.

Table 3 shows the fixed parameters for simulation. As per the estimated value in

Section 3.1, the approximated electrical conductivity used for grey cast iron was

S/m. Since the magnetic properties of grey cast iron are non-linear, the relative permeability value

calculated from the low magnetic field region of the experimentally-measured BH curve in

Section 3.1 was used to represent

. The amplitude of the excitation current pulse was also considered to be fixed at 200 mA. The sensor excitation circuit was designed to produce a voltage pulse having a 10-V amplitude and current amplitude of 200 mA; thus, the exciter coil resistance was required to be

. Due to availability, standard copper wire of

mm diameter (AWG 28 wire class) was chosen to wind both exciter and detector coils. As discussed in

Section 3.3, the detector coil output is directly connected to an instrumentation amplifier having high input impedance. This results in the effective impedance (

) felt as the load by the detector coil to be high (indicative of ∞).

Given the constraints, the objective was to select suitable inner and outer radii of both exciter and detector coils (i.e.,

,

,

and

) along with their respective number of coil turns (i.e.,

and

) in order to have cast iron thickness sensitivity from about 5–20 mm. While parameter selection can be formulated as an optimisation problem, similar to the work in [

19] related to a distributed EC inspection system, solving it for this case would require time-consuming stochastic optimisation due to deriving closed-form equations to perform a quicker convex optimisation being difficult. Therefore the parameters in

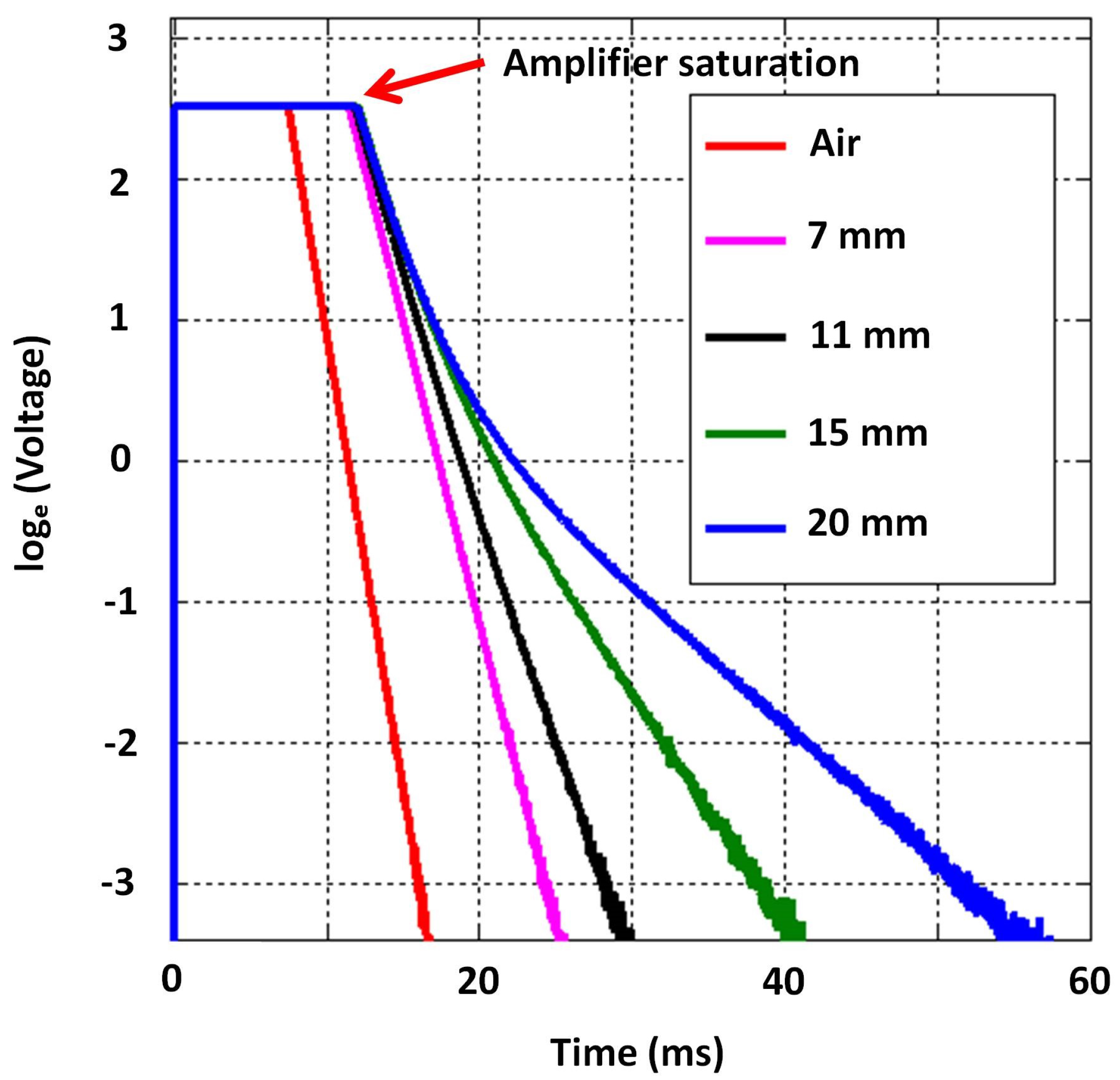

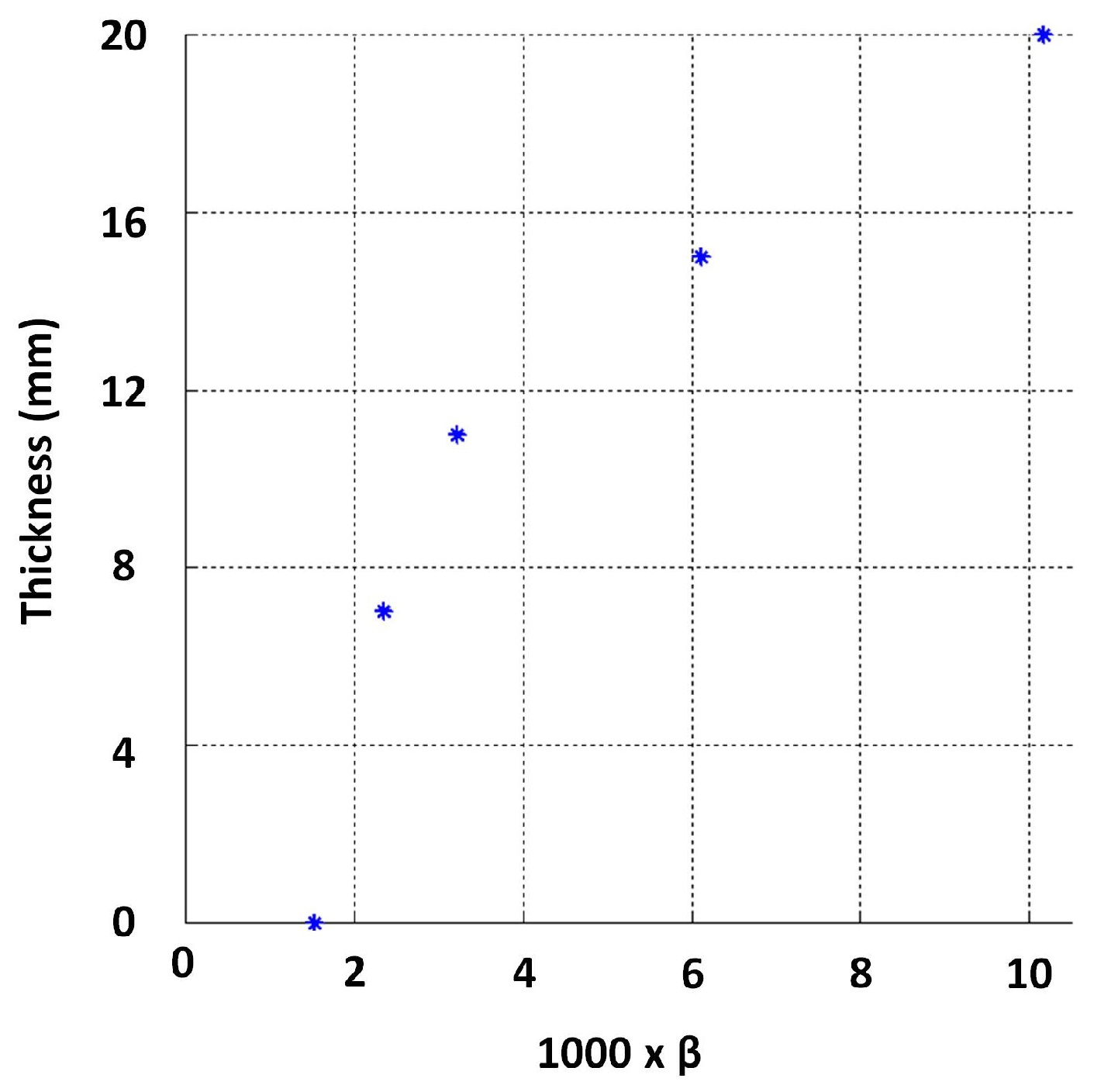

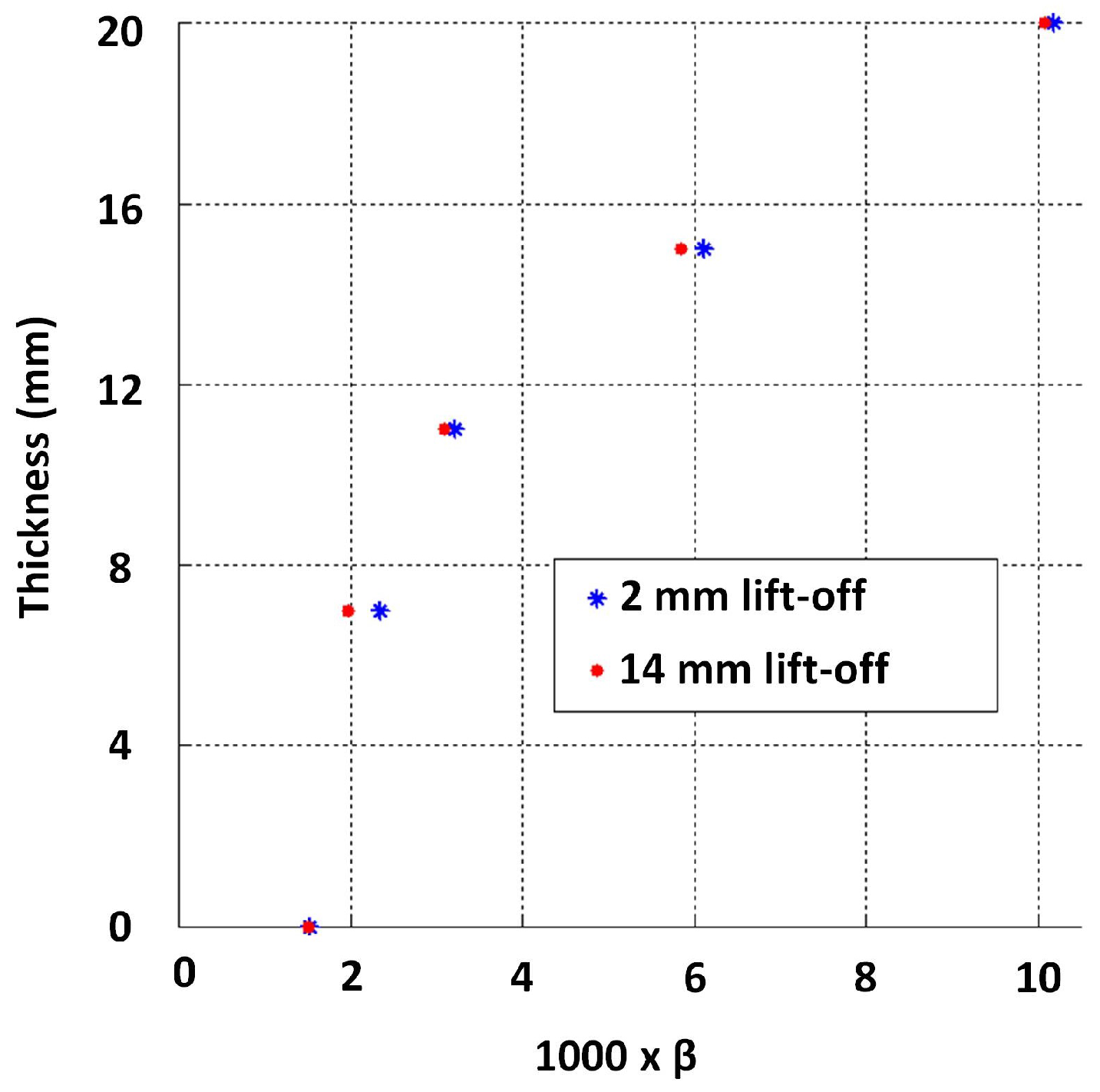

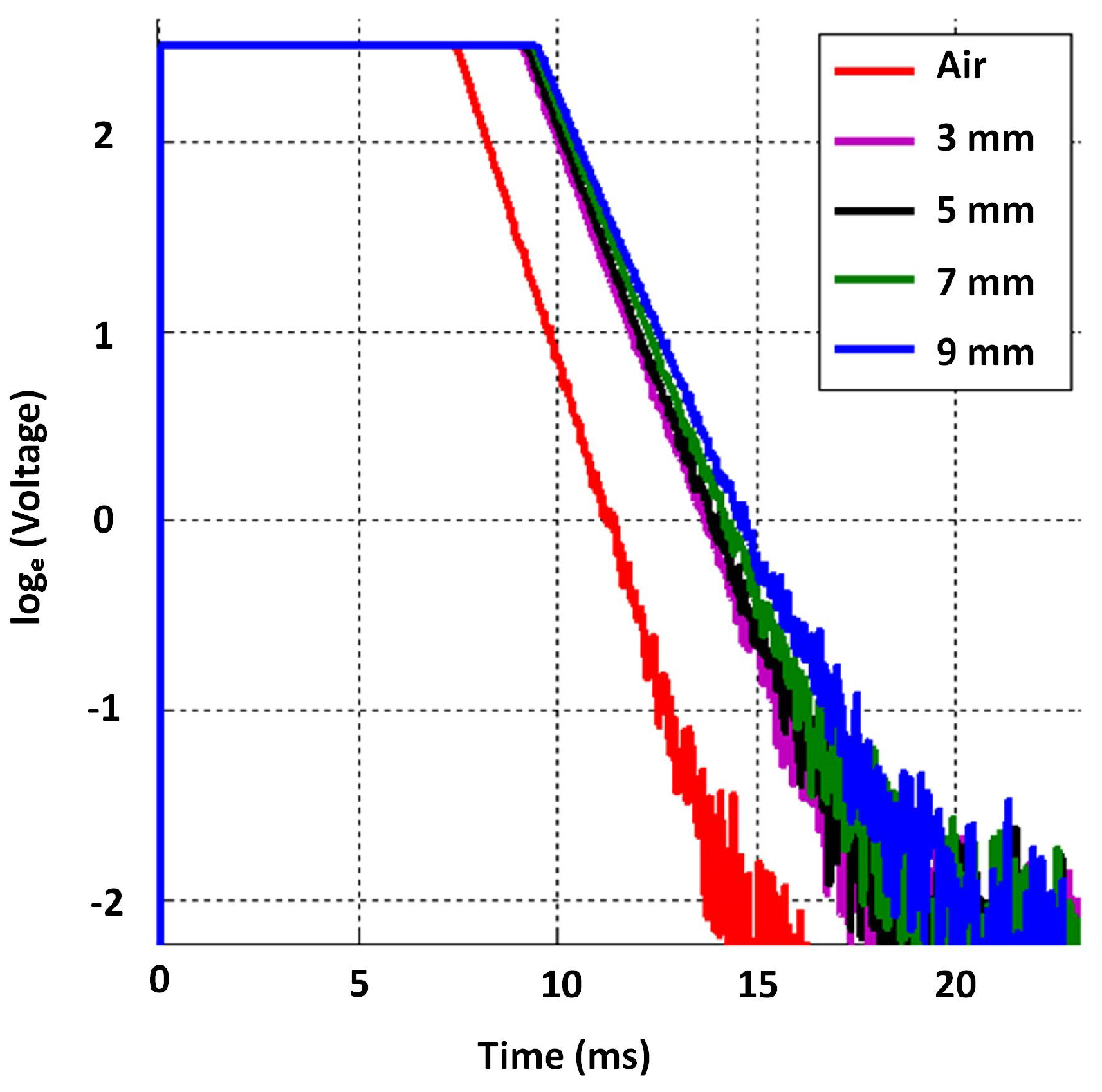

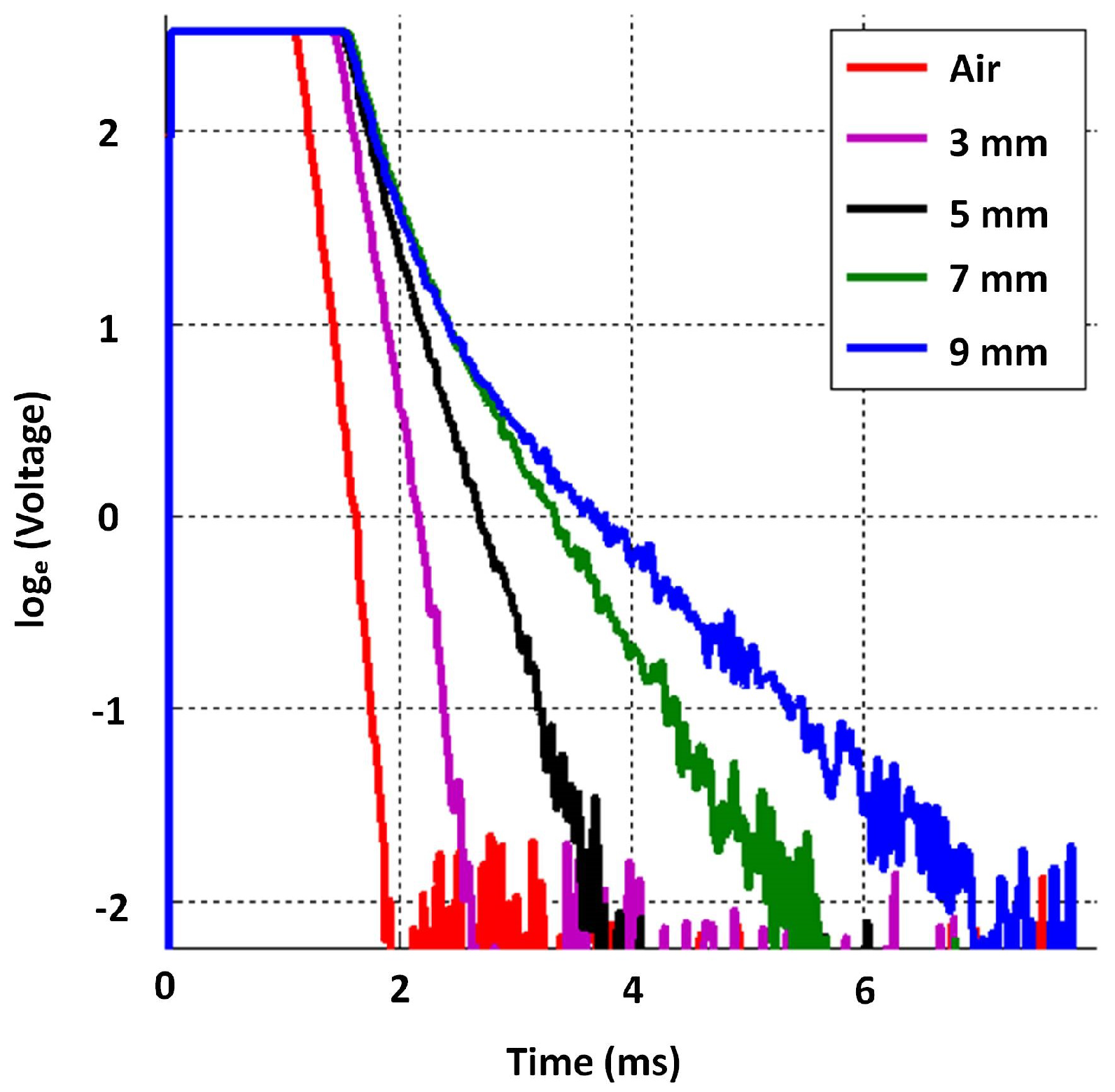

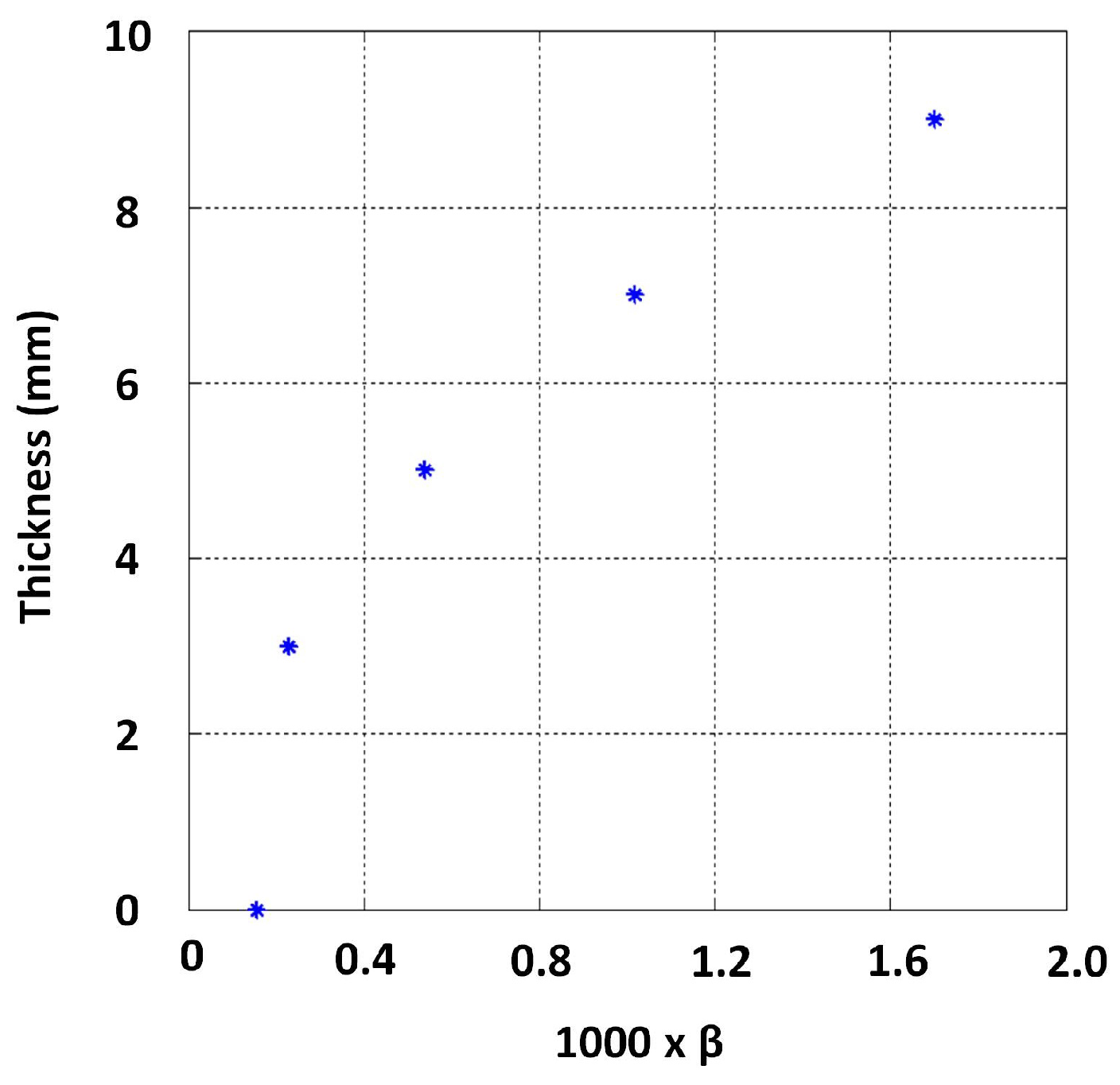

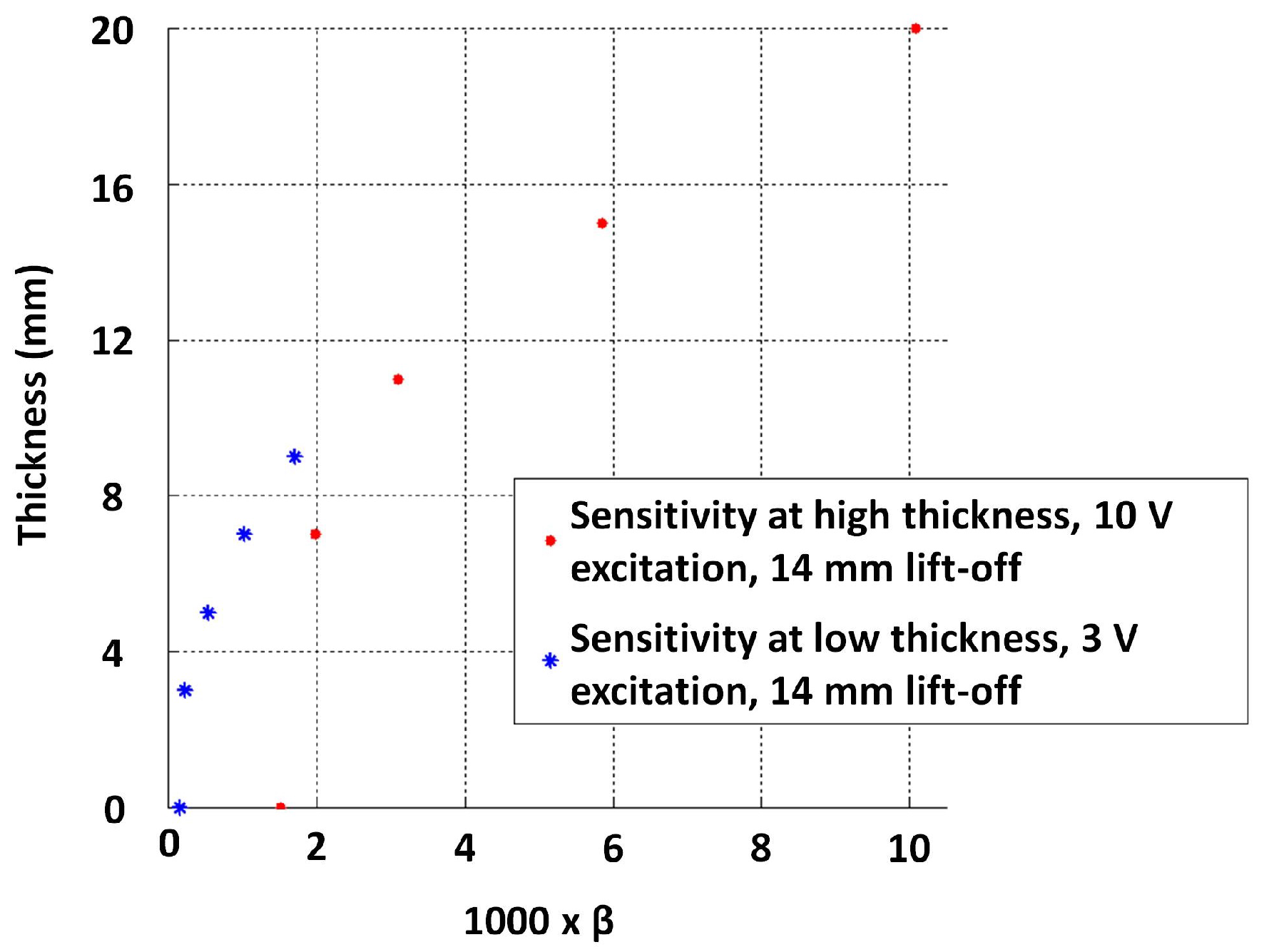

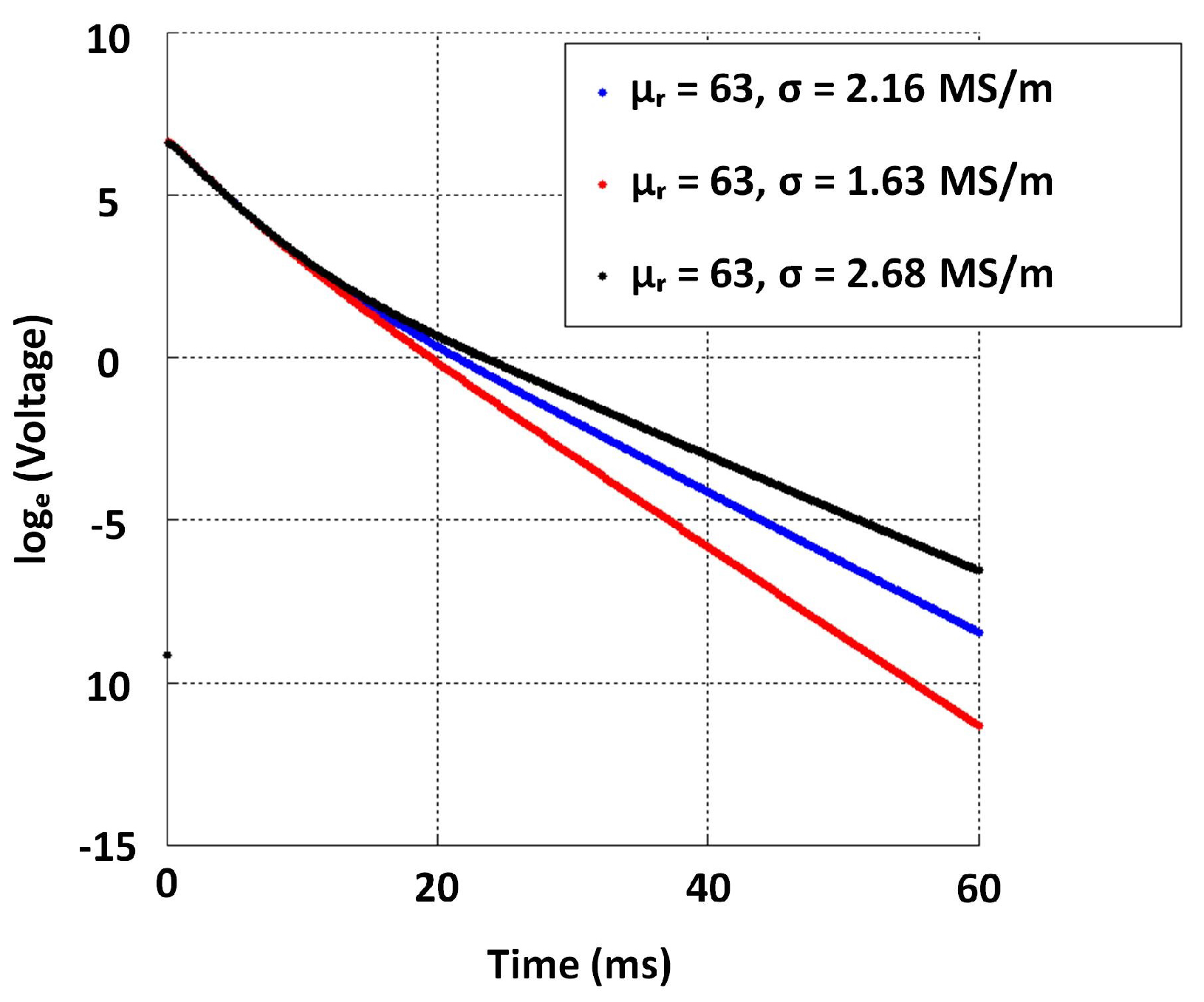

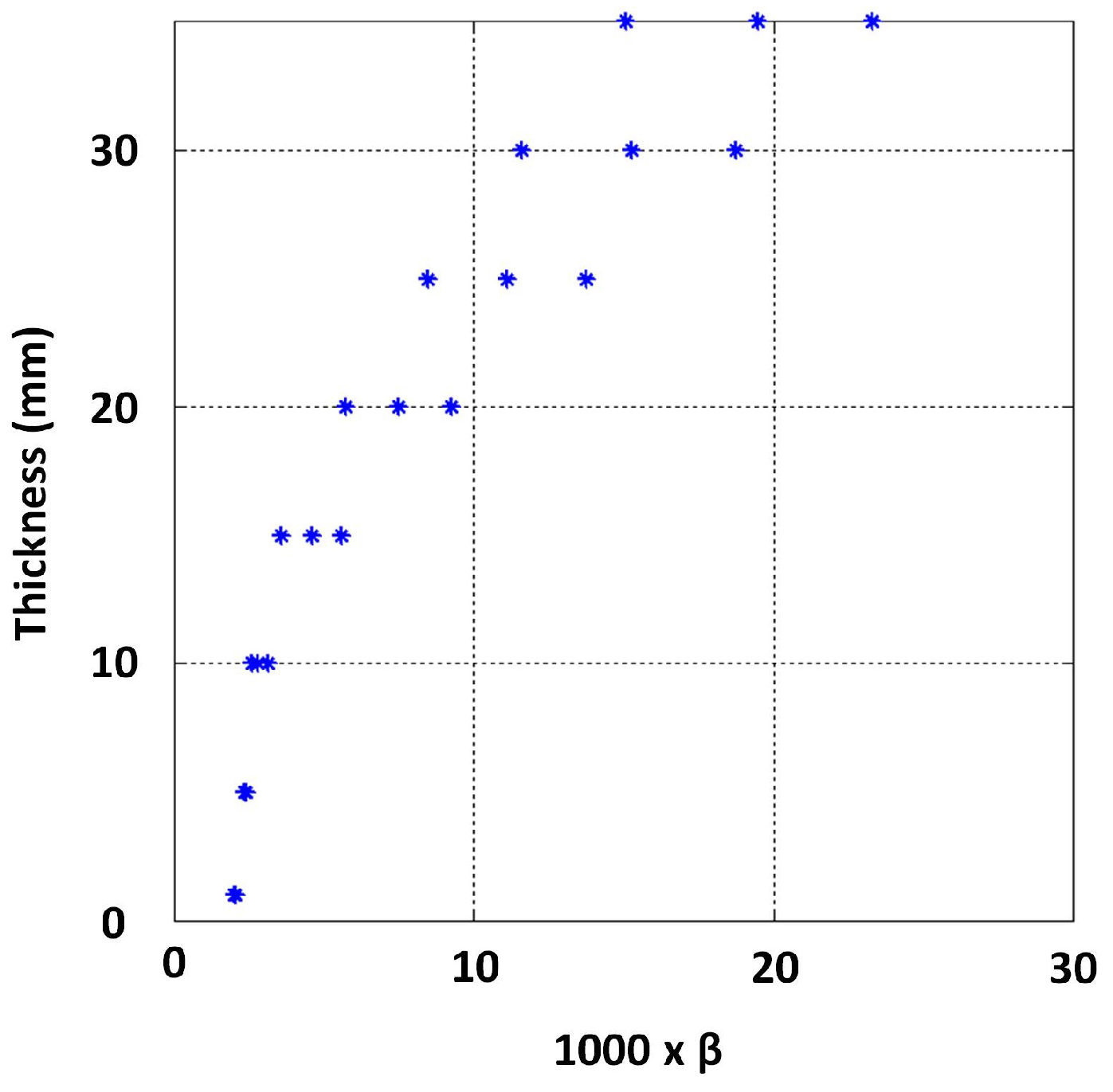

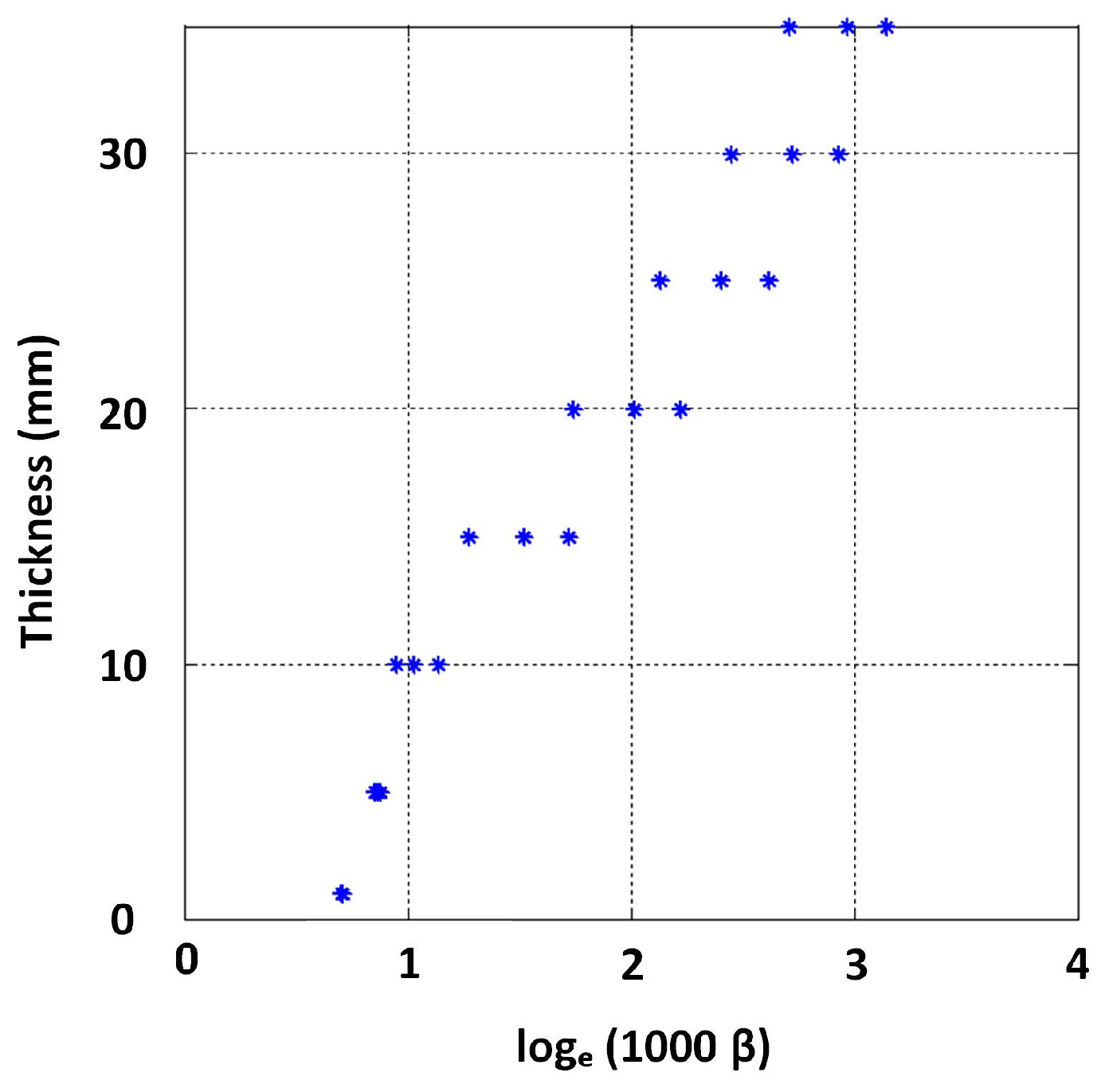

Table 4 were selected through simulation and experimentally validated to yield sufficient sensitivity to thickness with both low and high lift-off, as shown in

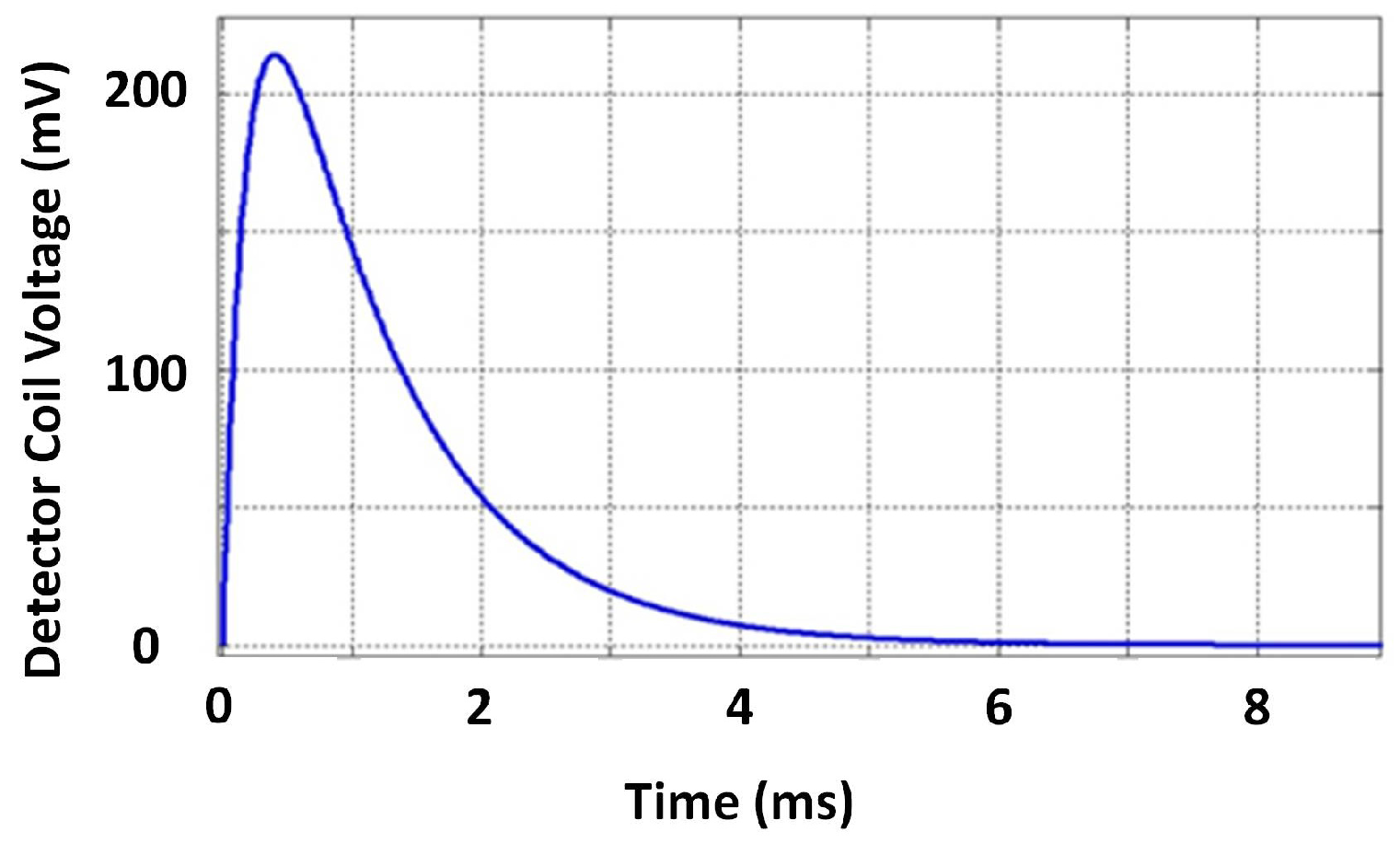

Figure 7. The later stage of all signals in

Figure 7 behaves as a straight line with a negative gradient; this behaviour is expected as per the formulation in Equation (

4) and validates the straight line behaviour theorized in

Section 2.1. Raw data plotted in

Figure 7 and the relevant COMSOL simulation model are provided with the

Supplementary Material for interested readers to use and with which to experiment.

Due to operational practicalities, water utilities are interested in robotic tools, which can autonomously inspect pipes internally; a development related to the purpose is presented in [

13]. As in the case with the pipe in

Table 1, critical pipes usually have an insulated internal protection, typically made of cement. Therefore, when inspecting internally, it is necessary for PEC sensors to assess a pipe wall with a 10–15 mm lift-off. Motivated by this need, and for the sensor to be suitable for both external and internal inspection, the dimensions in

Table 4 were chosen for the sensor to be sufficiently sensitive to thickness with a lift-off ranging from 2–14 mm, as indicated by the signals in

Figure 7.

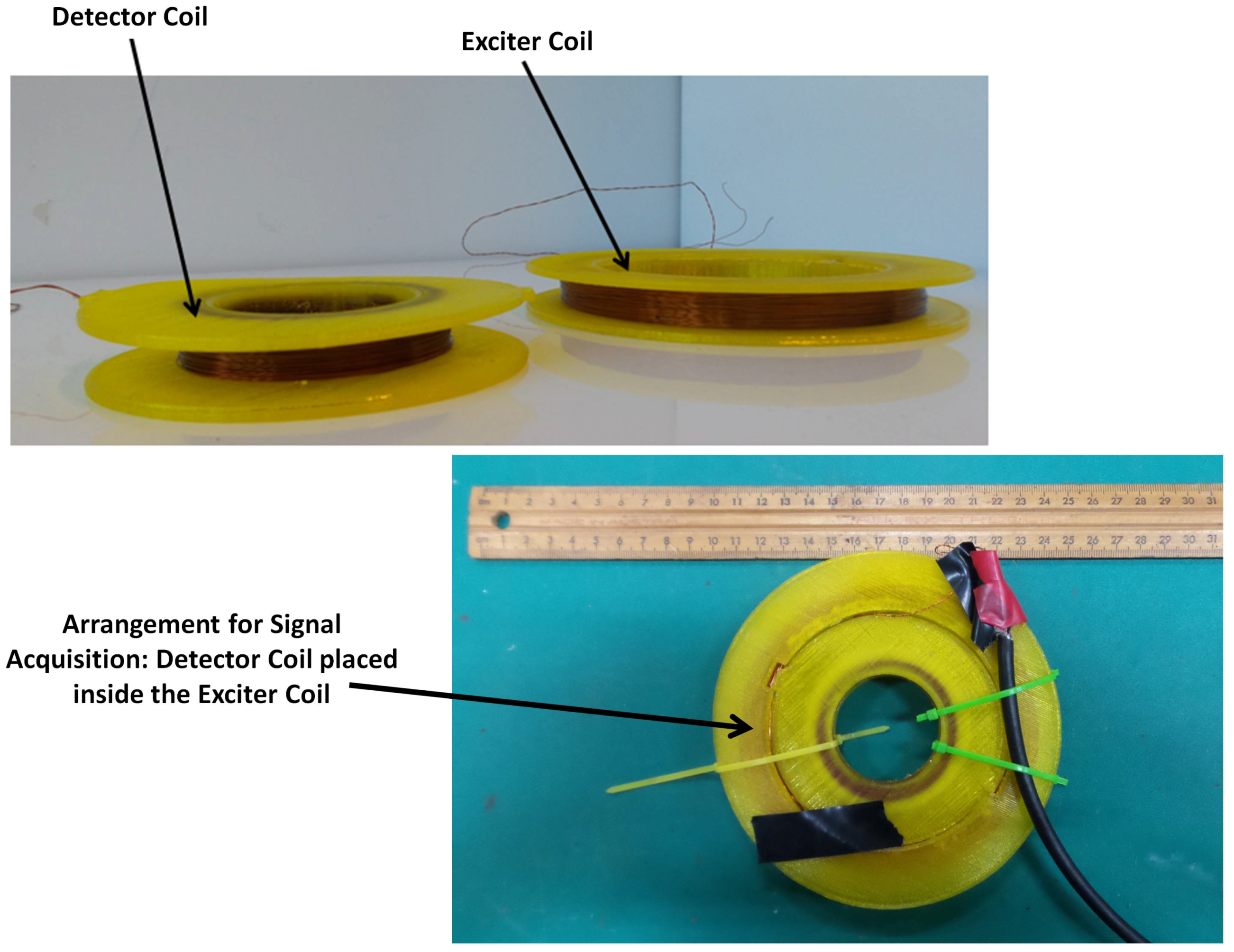

3.3. Sensor Fabrication

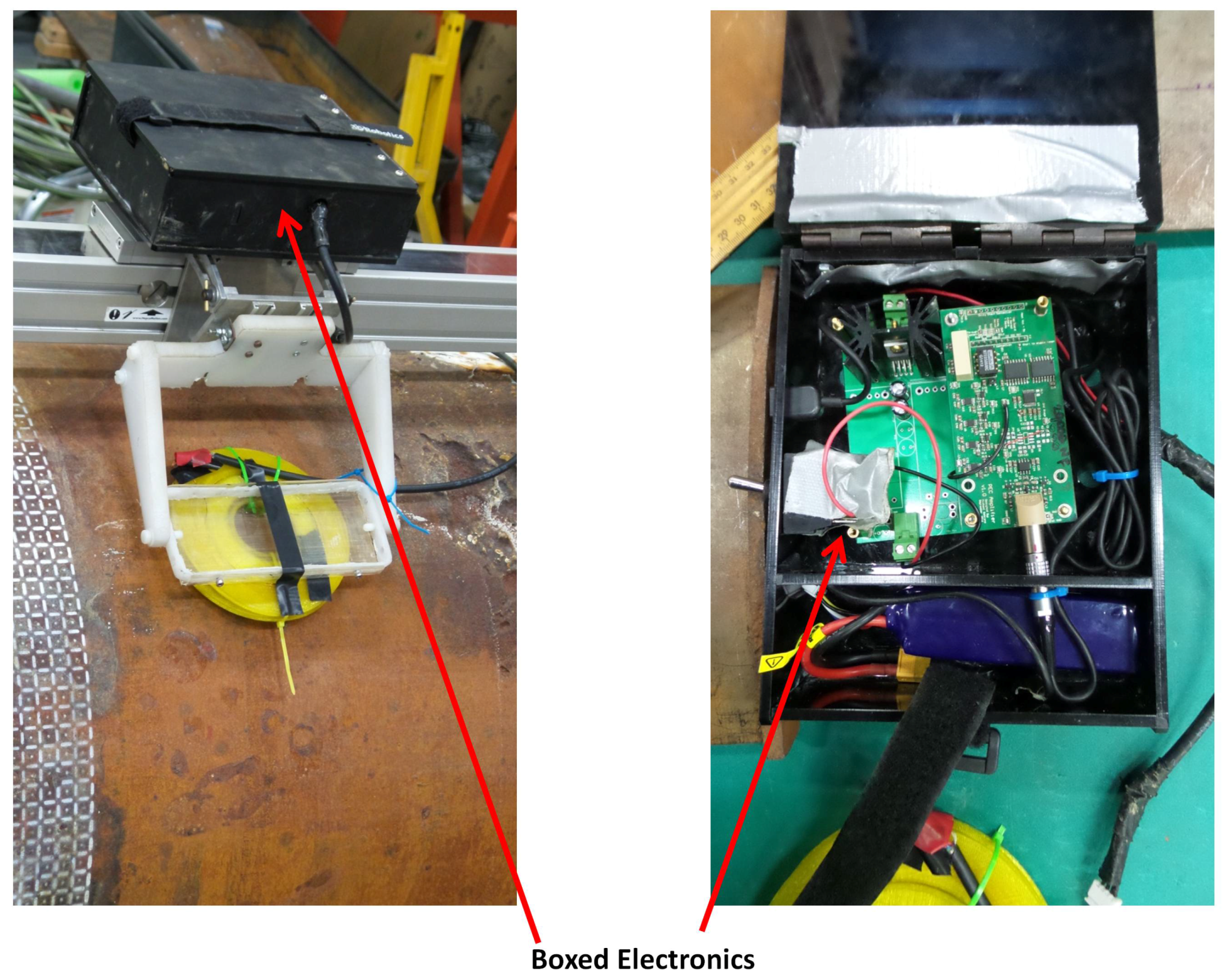

Figure 8 shows the PEC sensor fabricated using the values provided in

Table 4. Both exciter and detector coils were wound using AWG 28 wires having an approximate diameter of 0.315 mm. The sensor core was designed in SOLIDWORKS

©software and was 3D printed using Polylactide (PLA) biodegradable polyester.

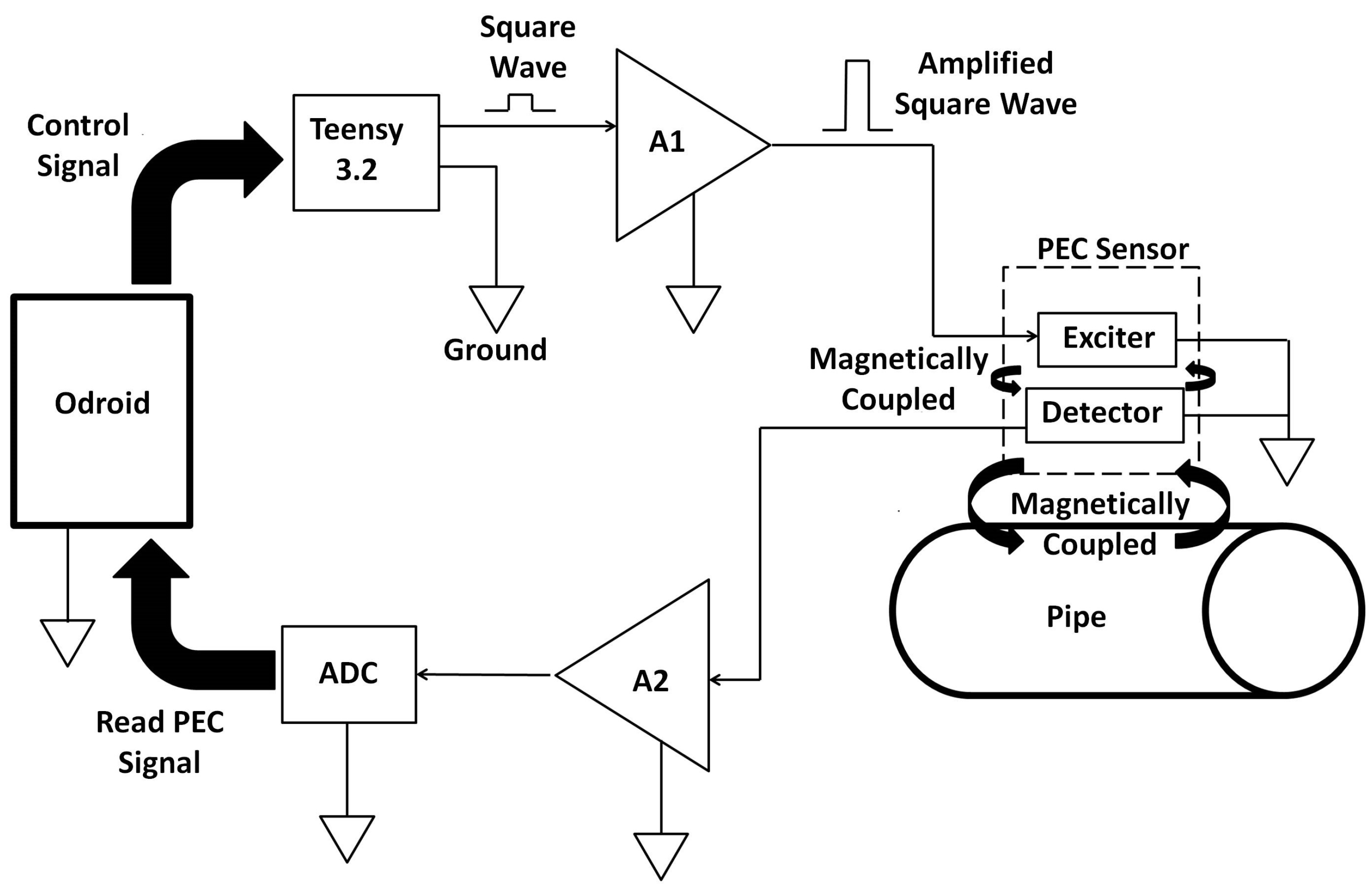

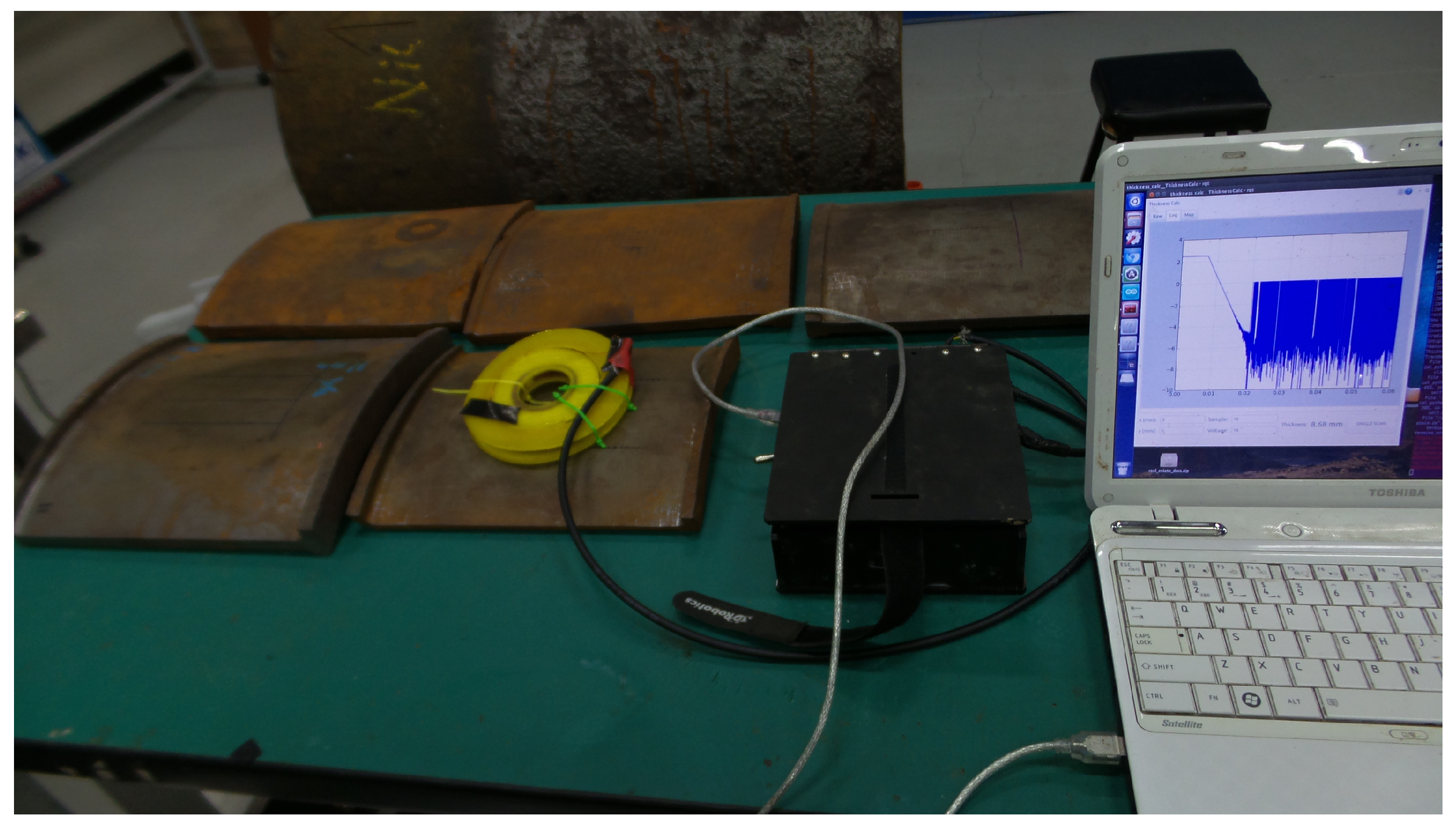

The block diagram of the sensing setup composed by integrating the sensor with driving and receiving electronics is shown in

Figure 9. An Odroid XU4 (Arm-based single board computer) is used to control a Teensy 3.2 generating the square wave (voltage pulse), which drives the sensor. The low power square wave generated by the Teensy is passed through an OPA548T fast Operational Amplifier-based non-inverting amplifier (A1) with a voltage gain of four to generate the desired powerful sensor excitation voltage pulse of 10 V, 50% duty ratio with a 60 ms pulse width. The induced detector coil voltage (i.e., PEC signal), which is in millivolt scale, is passed through an AD8428BRZ-based high performance instrumentation amplifier (A2) with a voltage gain of 2000. The amplified signal is sampled by a 16-bit ADS8681 integrated data acquisition system at a sampling rate of 15

s per sample and transferred via the Odroid to a PC. Capturing multiple signals at a given location and considering their average as the measurement was applied for noise reduction. To be specific, following experimental observations, obtaining a measurement by averaging 10 signals resulting from falling edges of the pulse is implemented. Alternatively, the signal processing method in [

33] using only one signal per measurement is also implemented in case quicker data acquisition is desired. The fabricated PCB for sensor excitation and signal reception is shown in

Figure 10, while

Figure 11 shows the sensing setup with cased up electronics being used to externally scan a pipe with the aid of an automated rig for sensor placement.