High-Precision Registration of Point Clouds Based on Sphere Feature Constraints

Abstract

:1. Introduction

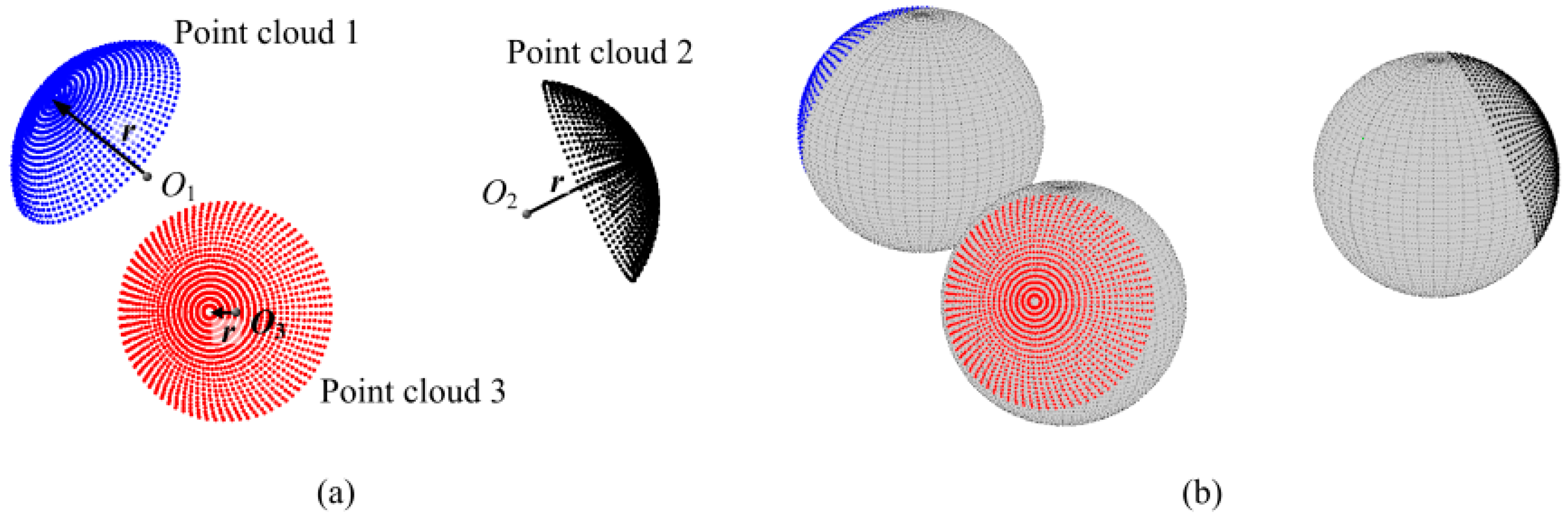

2. Principle of Registration

2.1. Constructing Virtual Overlapping Areas

2.2. Selection of Accurate Corresponding Point Pairs

2.3. Solution of the Transformation Matrices R and T

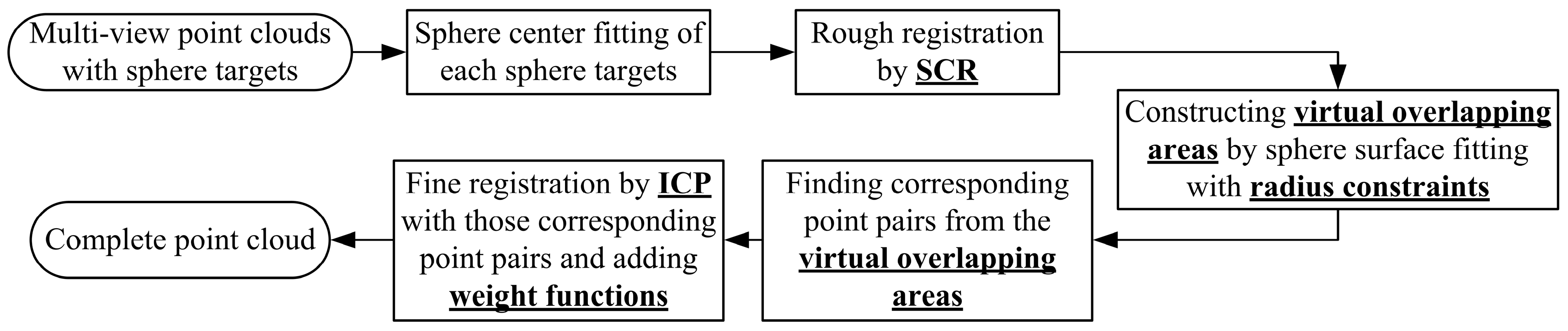

3. Algorithm Procedure

- (1)

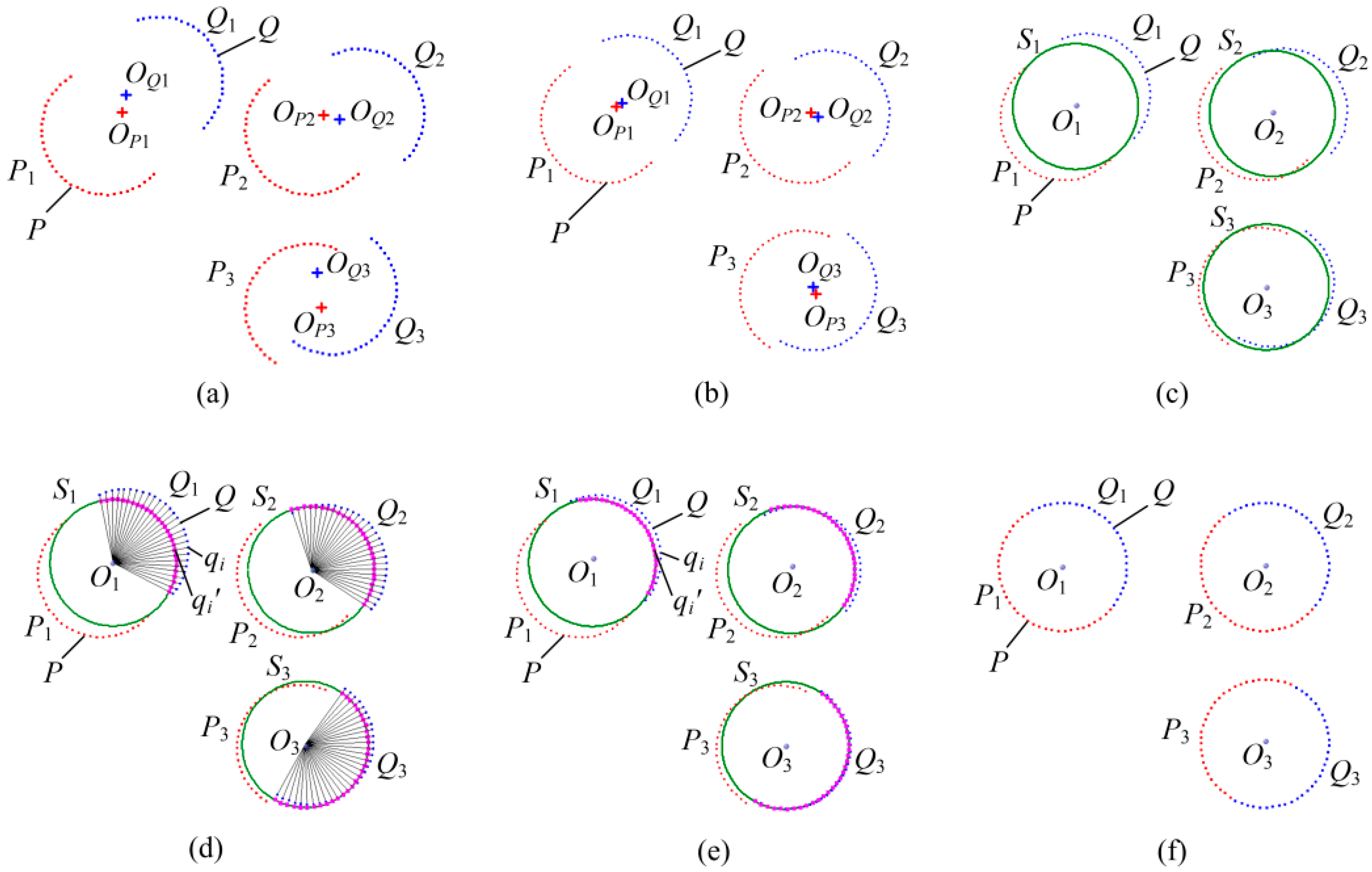

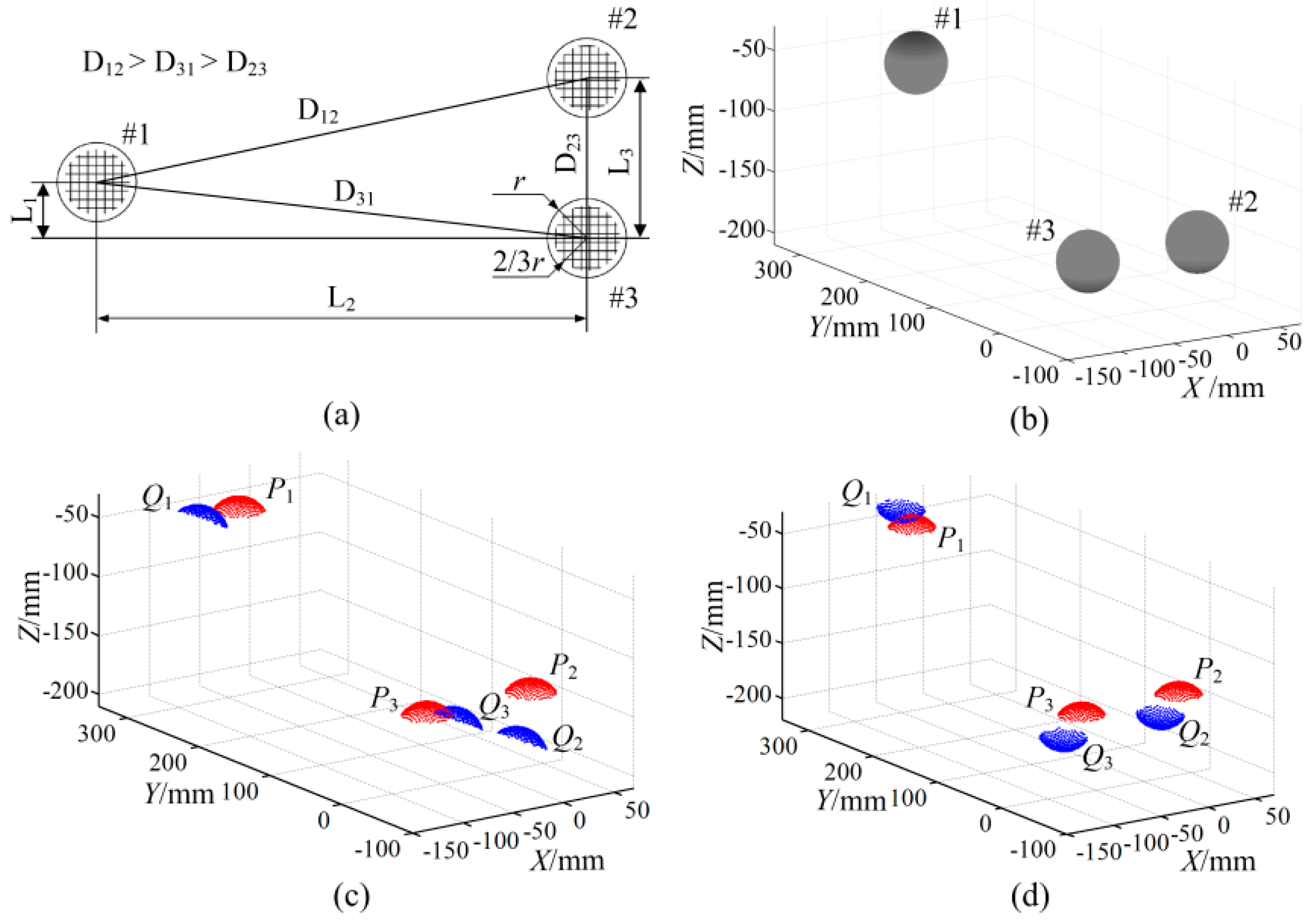

- Identification of the sphere point clouds. Use Hough transform to automatically detect the sphere point clouds from measurement point clouds [23], such as the sphere point clouds P and Q as shown in Figure 3a. P1, P2, P3, in P and Q1, Q2, Q3, in Q represent measurement point set from three different sphere targets, respectively. The radius of sphere targets is measured by Coordinate Measuring Machine (CMM) in advance. For each sphere point cloud, the coordinates of sphere center are fitted by Equation (2). The distances between those centers are calculated with the solved center coordinates, and the distance differences are applied to distinguishing the targets, such as (DP1P3 ≈ DQ1Q3) > (DP2P3 ≈ DQ2Q3) > (DP1P2 ≈ DQ1Q2), shown in Figure 3a. That means P1 and Q1 from a same sphere target, P2 and Q2 from a same sphere target and P3 and Q3 from a same sphere target.

- (2)

- (3)

- Construction of sphere surface. The coordinates of sphere center O1~O3 are obtained by fitting the point clouds of the same target to a common sphere surface by Equation (2) respectively, while the radius is set to a known value. The fitting residual is obtained by following Equation (7) and saved as Err_Fit.where, pi, qi denote the vectors in point clouds P and Q, respectively; c0 is the fitting sphere center; |·| denotes calculating the absolute value.

- (4)

- Selection of corresponding point pairs. Fix one point cloud, such as P. Each point qi in Q is connected to the corresponding fitting sphere center Oj (j = 1, 2, and 3), respectively. The connecting line intersects the sphere surface Sj (j = 1, 2 and 3) at qi', which is regarded as the corresponding point of qi, as shown in Figure 3d. The coordinates of the intersection point qi' are calculated by Equation (3).

- (5)

- Solution of the rotation matrix R and translation vector T. With corresponding point pairs obtained in (4), a rotation matrix R and a translation vector T are solved by minimizing the Equation (5) (Improved-ICP). Then the point cloud Q is aligned to the constructed sphere surface with the solution of R and T, as shown in Figure 3e. In fact, the fixed point cloud P can also be registered to the constructed surface simultaneously to accelerate the registration speed.

- (6)

- Determination of iteration termination. Re-calculate the new fitting residuals (saved as Err_Fit_New) by Equation (7) with the point cloud P and the new point cloud Q obtained in (5), and calculate the variation of the fitting residuals Vari_Fit = |Err_Fit_New − Err_Fit|. Then determine whether the variation of fitting residuals or the solving residuals of Equation (5) in Step (5) is less than the setting value, or the number of iteration is larger than a setting number. When those happen, the iteration is terminated; otherwise return to Step (3). The final registration result is shown in Figure 3f.

4. Experiments and Analysis

4.1. Impact Analysis of Main Factors by Simulation

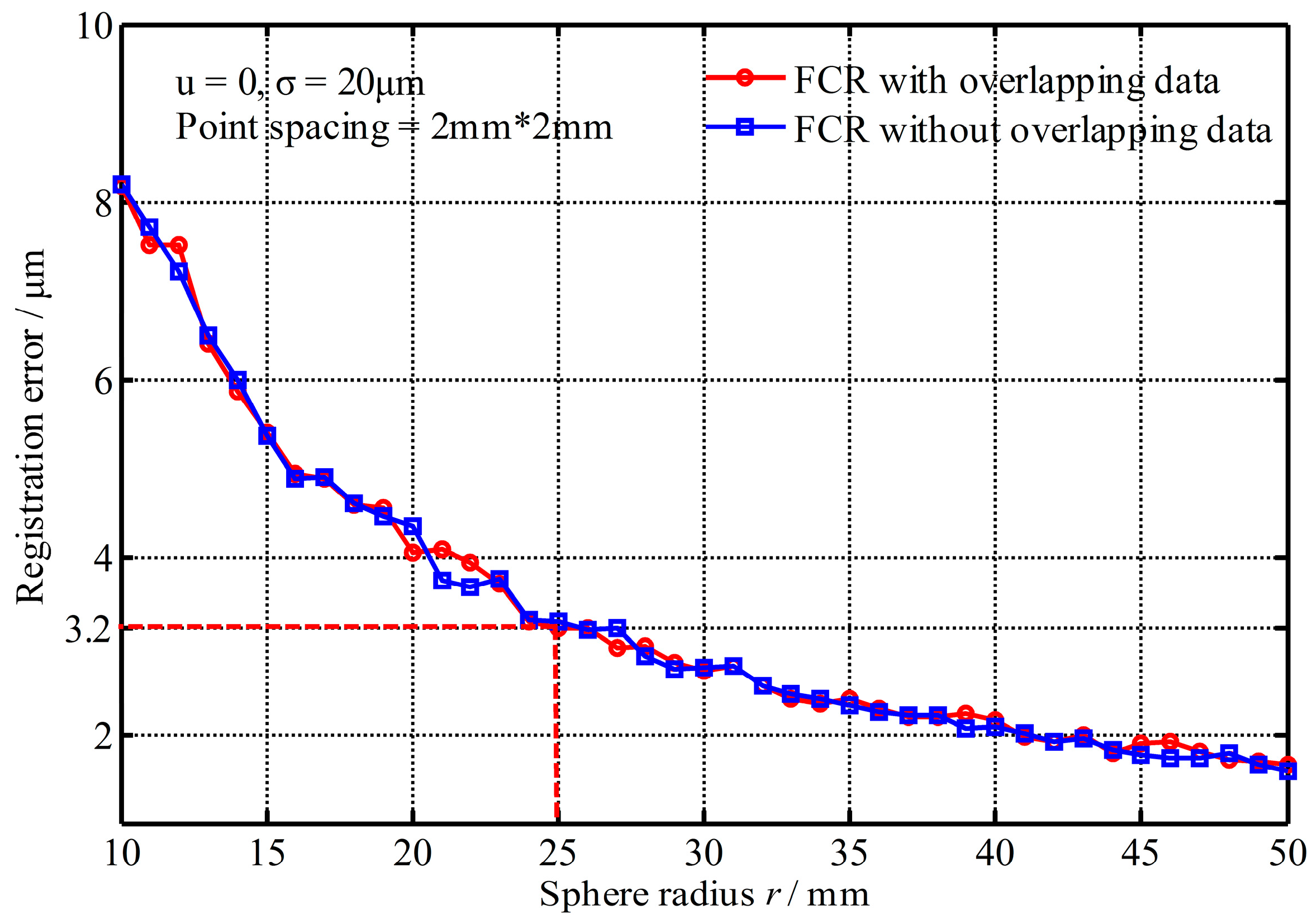

4.1.1. Impact of the Target Size

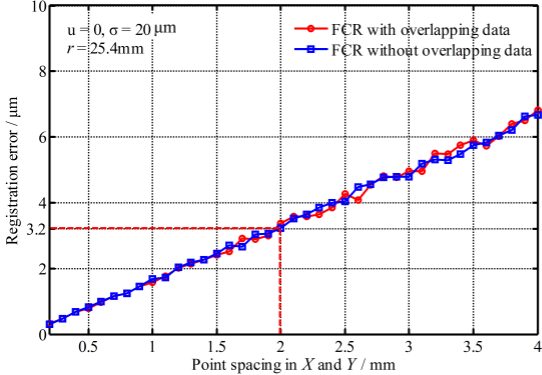

4.1.2. Impact of the Point Density

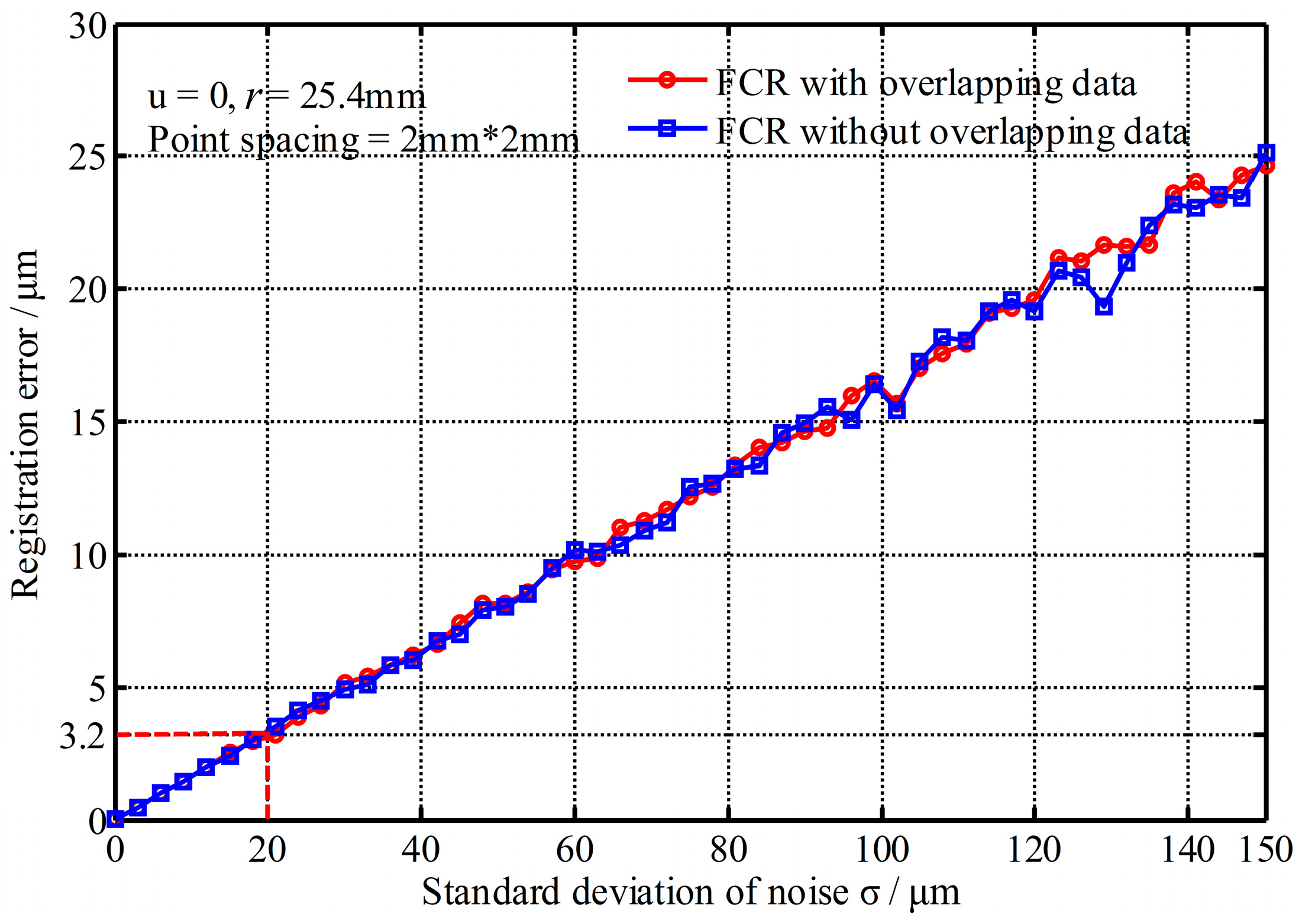

4.1.3. Impact of the Noise

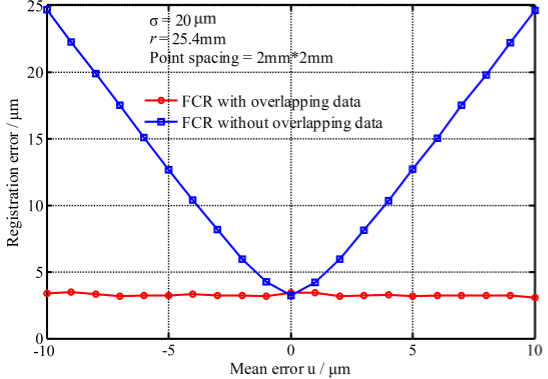

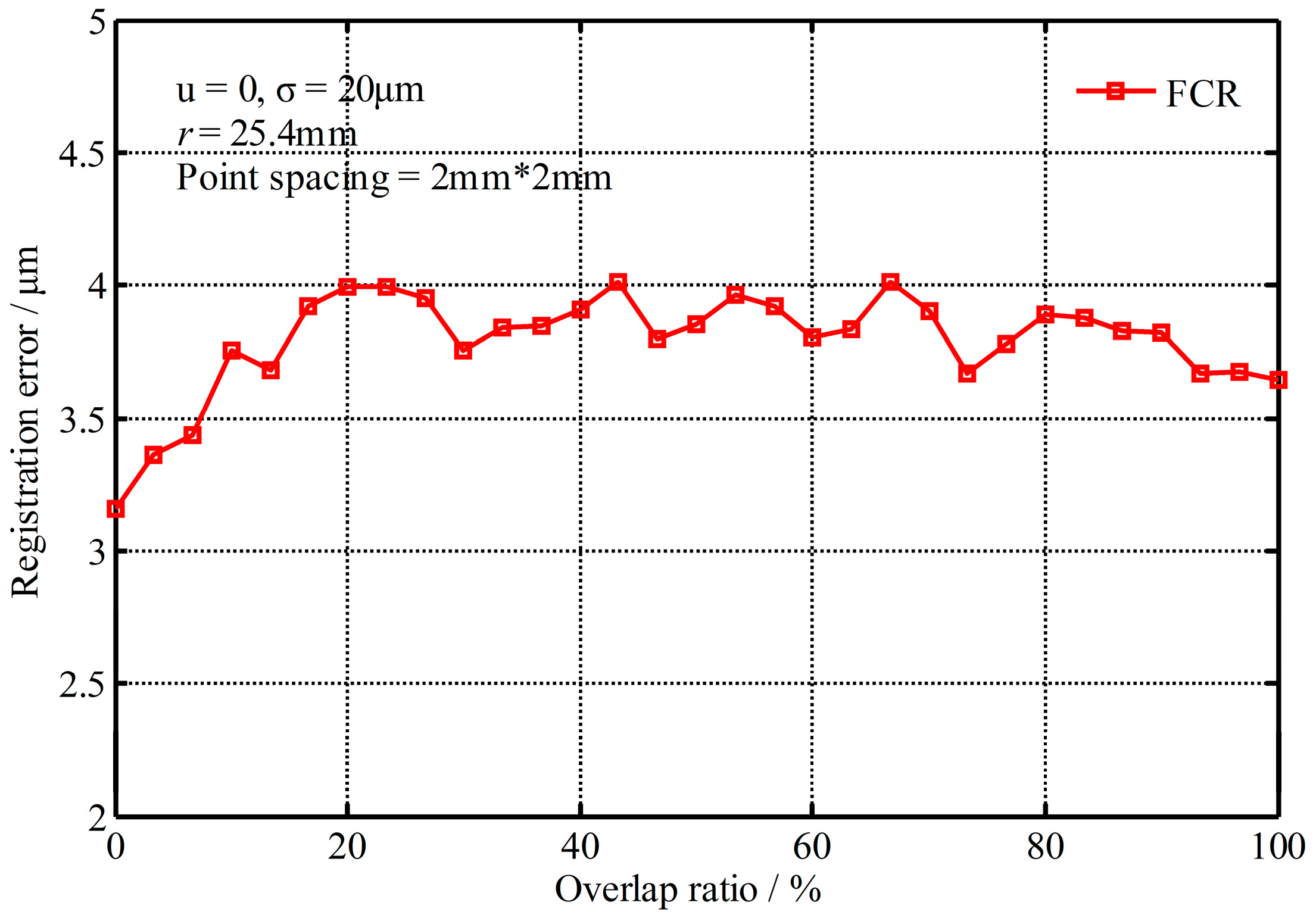

4.1.4. Impact of the Overlap Ratio

4.2. Comparison of Registration Precision with Typical Methods

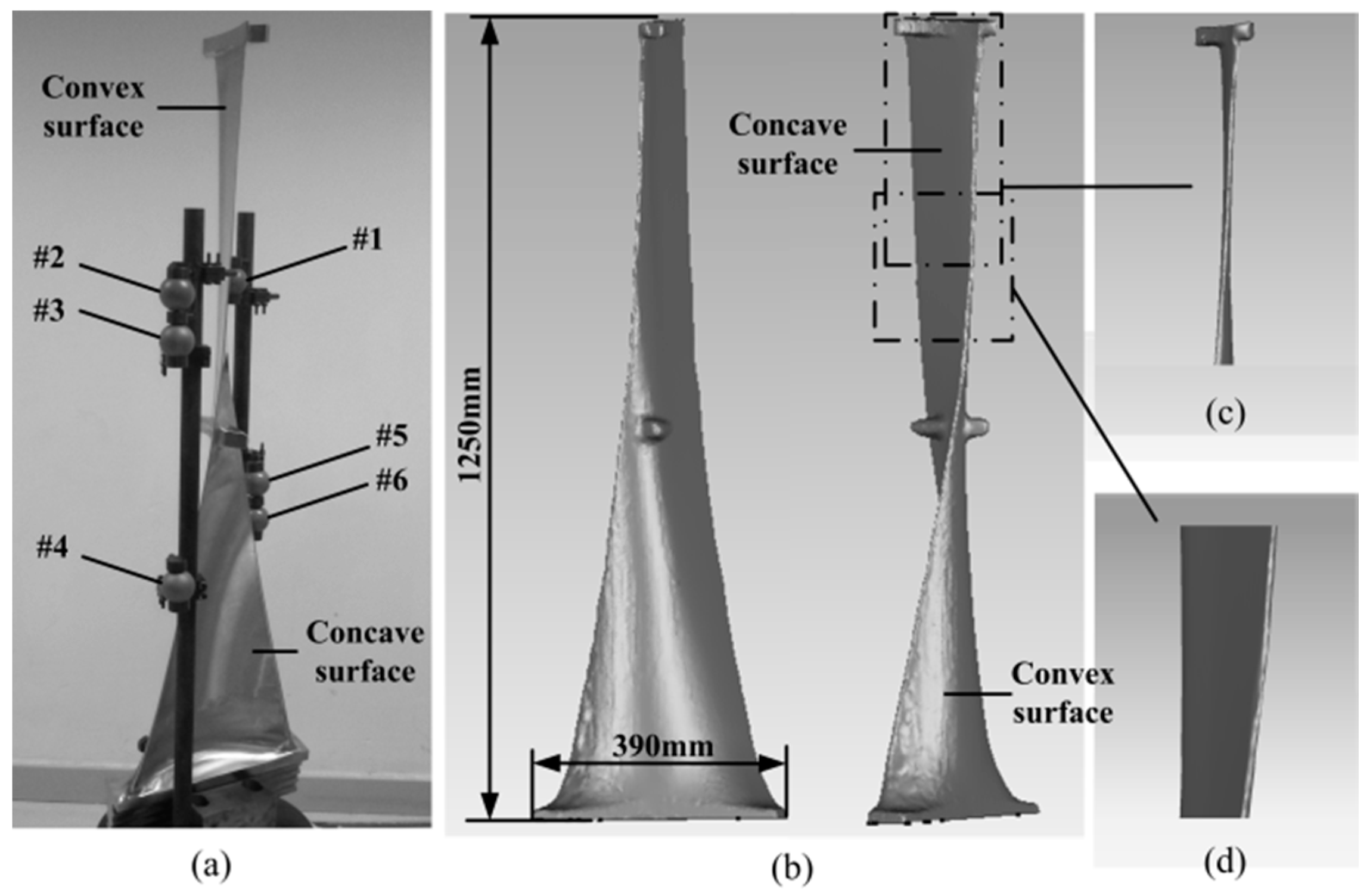

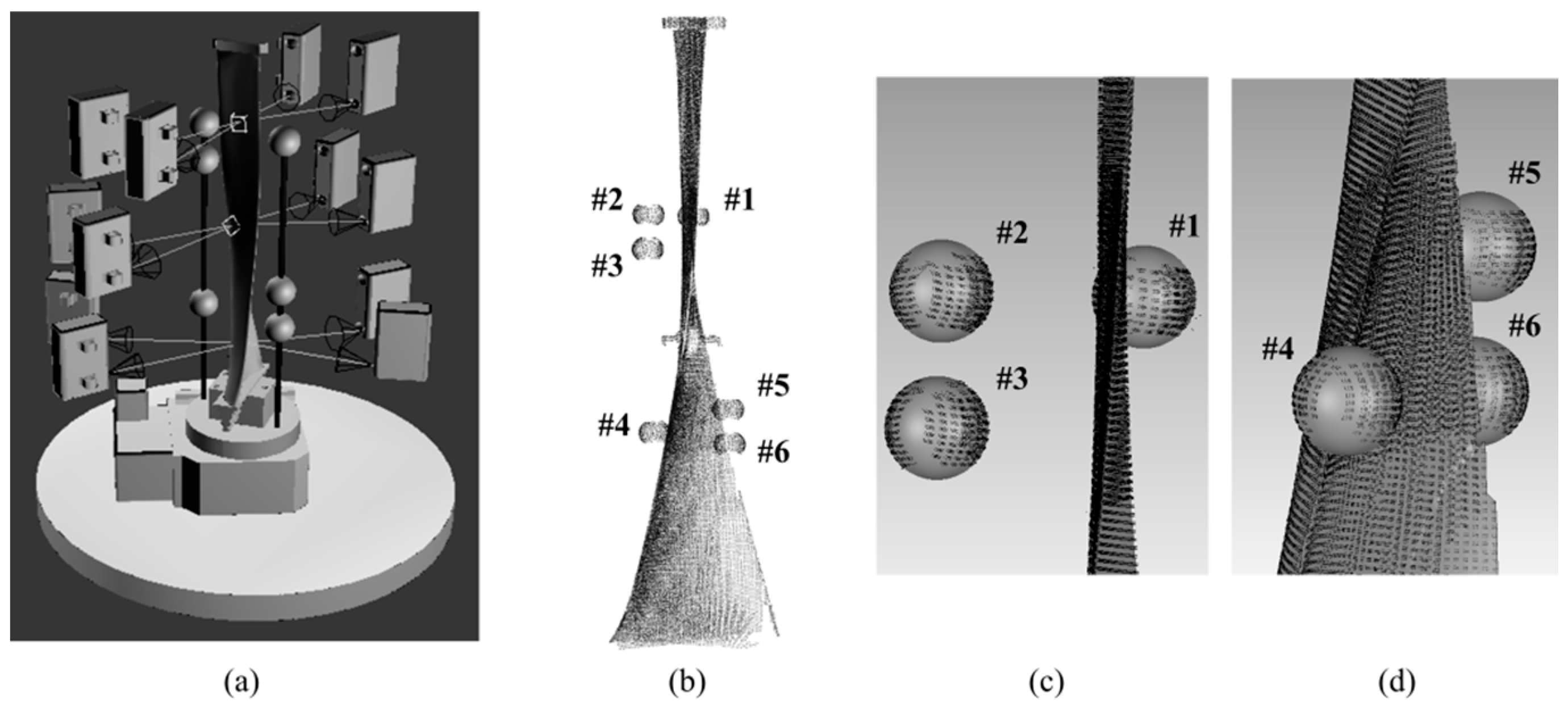

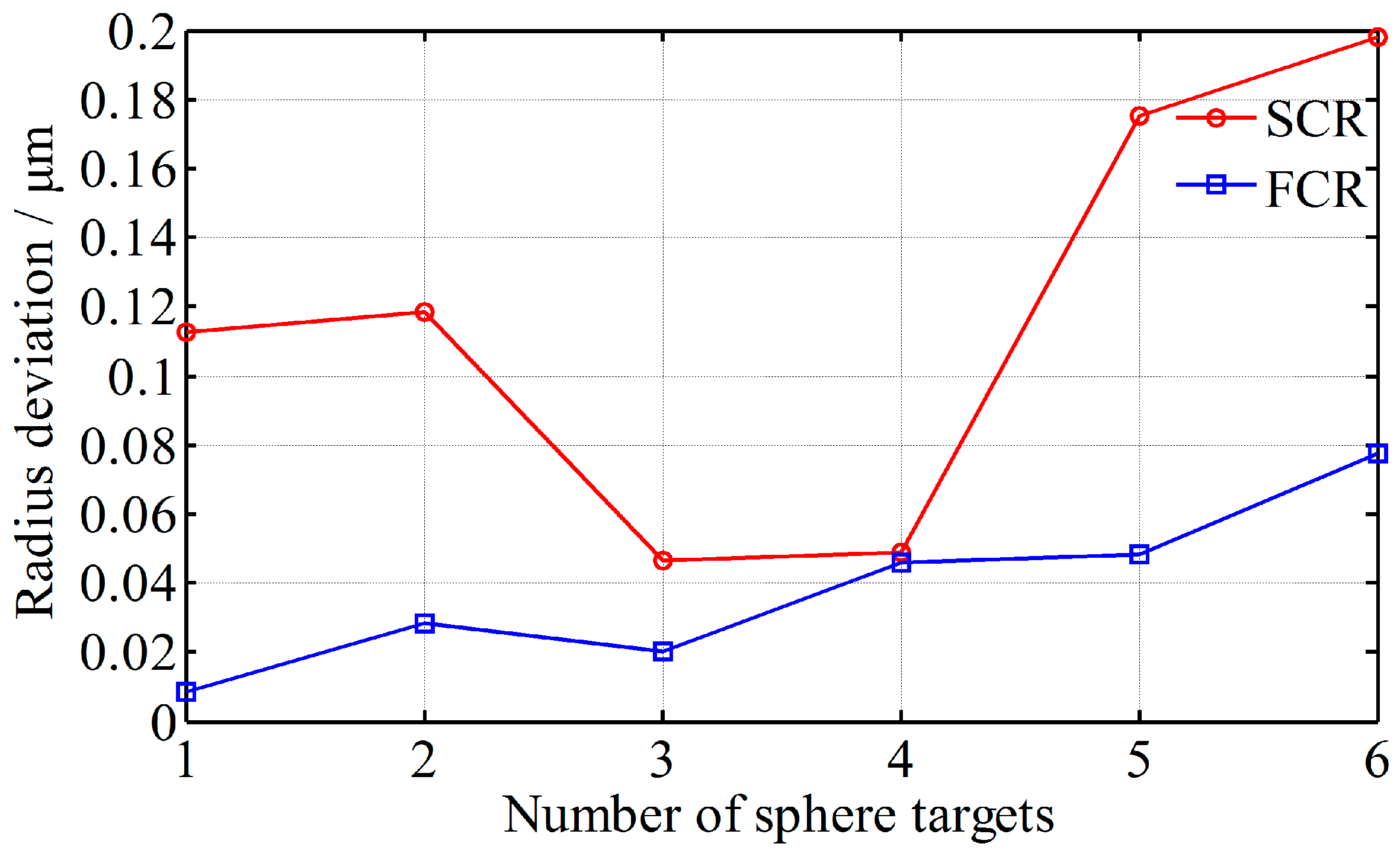

4.3. Real Blade Registration

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| ICP | Iterative Closest Point |

| SCR | Sphere Center Registration |

| FCR | Feature Constraints Registration |

| CMM | Coordinates Measuring Machine |

References

- Herráeza, J.; Martíneza, J.; Colla, E.; Martínb, M.; Rodríguezb, J. 3D modeling by means of videogrammetry and laser scanners for reverse engineering. Measurement 2016, 87, 216–227. [Google Scholar] [CrossRef]

- Alsadik, B.; Gerke, M.; Vosselman, G.; Daham, A.; Jasim, L. Minimal camera networks for 3D image based modeling of cultural heritage objects. Sensors 2014, 14, 5785–5804. [Google Scholar] [CrossRef] [PubMed]

- Gardner, J.; Kiderlen, M. A new algorithm for 3D reconstruction from support functions. IEEE Trans. Pattern Anal. 2009, 31, 556–562. [Google Scholar] [CrossRef] [PubMed]

- Van der Jeught, S.; Dirckx, J. Real-time structured light profilometry: A review. Opt. Laser Eng. 2015, 87, 18–31. [Google Scholar] [CrossRef]

- Vázquez, D.; Crespo, D.; Quiroga, J. New method for three-dimensional shape registration of prismatic objects. Opt. Eng. 2006, 45, 023603. [Google Scholar] [CrossRef]

- Hedjazi, M.; Purang, A. Distribution of target registration error for anisotropic and inhomogeneous fiducial localization error. IEEE Trans. Med. Imaging 2009, 28, 799–813. [Google Scholar]

- Yang, Y.; Ong, S.; Foong, K. A robust global and local mixture distance based non-rigid point set registration. Pattern Recogn. 2015, 48, 156–173. [Google Scholar] [CrossRef]

- Chen, H.; Bir, B. Global-to-local non-rigid shape registration. In Proceedings of the 18th International Conference on Pattern Recognition, Hong Kong, China, 20–24 August 2006; Volume 4, pp. 57–60.

- Ijaz, U.; Prager, R.; Gee, A.; Treece, G. Optimization strategies for ultrasound volume registration. Meas. Sci. Technol. 2010, 21, 085803. [Google Scholar] [CrossRef]

- Zeng, S. Fast optimal joint tracking-registration for multisensor systems. IEEE Trans. Instrum. Meas. 2011, 60, 3461–3470. [Google Scholar] [CrossRef]

- Besl, P.; Mckay, N. A method for registration of 3D shapes. IEEE Trans. Pattern Anal. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Magnusson, M.; Lilienthal, A.; Duckett, T. Scan registration for autonomous mining vehicles using 3D-NDT. J. Field Robot. J. Field Robot. 2007, 24, 803–827. [Google Scholar] [CrossRef]

- Horaud, R.; Forbes, F.; Yguel, M.; Dewaele, G.; Zhang, J. Rigid and Articulated Point Registration with Expectation Conditional Maximization. IEEE Trans. Pattern Anal. 2011, 33, 587–602. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Li, H.; Campbell, D.; Jia, Y. Go-ICP: A Globally Optimal Solution to 3D ICP Point-Set Registration. IEEE Trans. Pattern Anal. 2016, 38, 2241–2254. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Yin, P.; He, Y.; Gu, F. Enhanced ICP for the registration of large-scale 3D environment models: An experimental study. Sensors 2016, 16, 228. [Google Scholar] [CrossRef] [PubMed]

- Jorge, R.; Eduardo, B. Medical image segmentation, volume representation and registration using spheres in the geometric algebra framework. Pattern Recogn. 2007, 40, 171–188. [Google Scholar] [CrossRef]

- Franaszek, M.; Cheok, G.; Witzgall, C. Fast automatic registration of range images from 3D imaging systems using sphere targets. Automat. Constr. 2009, 18, 265–274. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, H.; Zhang, Y.; Zhang, D. Automatic registration of laser point cloud using precisely located sphere targets. J Appl. Remote Sens. 2014, 8, 083588. [Google Scholar] [CrossRef]

- Yun, D.; Kim, S.; Heo, H.; Ko, K. Automated registration of multi-view point clouds using sphere targets. Adv. Eng. Inform. 2015, 29, 930–939. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.; Gao, J.; Bao, W. A High-precision Registration Method Based on Auxiliary Sphere Targets. In Proceedings of the International Conference on Digital Image Computing: Techniques and Applications (DICTA), Wollongong, Australia, 25–27 November 2014; pp. 25–27.

- Moré, J. The Levenberg-Marquardt algorithm: Implementation and theory. Numer. Anal. Lect. Notes Math. 1978, 630, 105–116. [Google Scholar]

- Horn, B. Closed-form solution of absolute orientation using unit quaternions. J. Opt. Soc. Am. A 1987, 4, 629–642. [Google Scholar] [CrossRef]

- Ogundana, O.; Coggrave, C.; Burguete, R.; Huntley, J. Fast Hough transform for automated detection of spheres in three-dimensional point clouds. Opt. Eng. 2007, 46, 051002. [Google Scholar]

- Huang, J.; Wang, Z.; Gao, J.; Xue, Q. Projector calibration with error surface compensation method in the structured light 3D measurement system. Opt. Eng. 2013, 52, 1–10. [Google Scholar] [CrossRef]

- Huang, J.; Xue, Q.; Wang, Z.; Gao, J. Analysis and Compensation for Lateral Chromatic Aberration in a Color Coding Structured Light 3D Measurement System. Sensors 2016, 16, 1426. [Google Scholar] [CrossRef] [PubMed]

| Method | Running Time | Registration Error with Overlapping Data | Registration Error with Non-Overlapping Data | ||||

|---|---|---|---|---|---|---|---|

| Mean | RMS | Max | Mean | RMS | Max | ||

| SCR | 3 s | 10.1 μm | 6.7 μm | 53.4 μm | 11.4 μm | 6.9 μm | 60.2 μm |

| ICP | 104 s | 22.4 μm | 11.1 μm | 62.1 μm | / | / | / |

| FCR | 96 s | 3.3 μm | 1.7 μm | 11.6 μm | 3.2 μm | 1.7 μm | 11.5 μm |

| Object | Method | Registration Error with Overlapping Data | Registration Error with Non-Overlapping Data | ||||

|---|---|---|---|---|---|---|---|

| Mean | RMS | Max | Mean | RMS | Max | ||

| Ball | SCR | 0.036 mm | 0.028 mm | 0.144 mm | 0.048 mm | 0.033 mm | 0.112 mm |

| ICP | 0.260 mm | 0.130 mm | 0.433 mm | / | / | / | |

| FCR | 0.012 mm | 0.023 mm | 0.107 mm | 0.009 mm | 0.028 mm | 0.119 mm | |

| Plate | SCR | 0 | 0.041 mm | 0.121 mm | / | / | / |

| ICP | 0 | 0.104 mm | 0.224 mm | / | / | / | |

| FCR | 0 | 0.020 mm | 0.069 mm | / | / | / | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Wang, Z.; Gao, J.; Huang, Y.; Towers, D.P. High-Precision Registration of Point Clouds Based on Sphere Feature Constraints. Sensors 2017, 17, 72. https://doi.org/10.3390/s17010072

Huang J, Wang Z, Gao J, Huang Y, Towers DP. High-Precision Registration of Point Clouds Based on Sphere Feature Constraints. Sensors. 2017; 17(1):72. https://doi.org/10.3390/s17010072

Chicago/Turabian StyleHuang, Junhui, Zhao Wang, Jianmin Gao, Youping Huang, and David Peter Towers. 2017. "High-Precision Registration of Point Clouds Based on Sphere Feature Constraints" Sensors 17, no. 1: 72. https://doi.org/10.3390/s17010072

APA StyleHuang, J., Wang, Z., Gao, J., Huang, Y., & Towers, D. P. (2017). High-Precision Registration of Point Clouds Based on Sphere Feature Constraints. Sensors, 17(1), 72. https://doi.org/10.3390/s17010072