Literature Review: Theory and Application of In-Line Inspection Technologies for Oil and Gas Pipeline Girth Weld Defection

Abstract

:1. Introduction

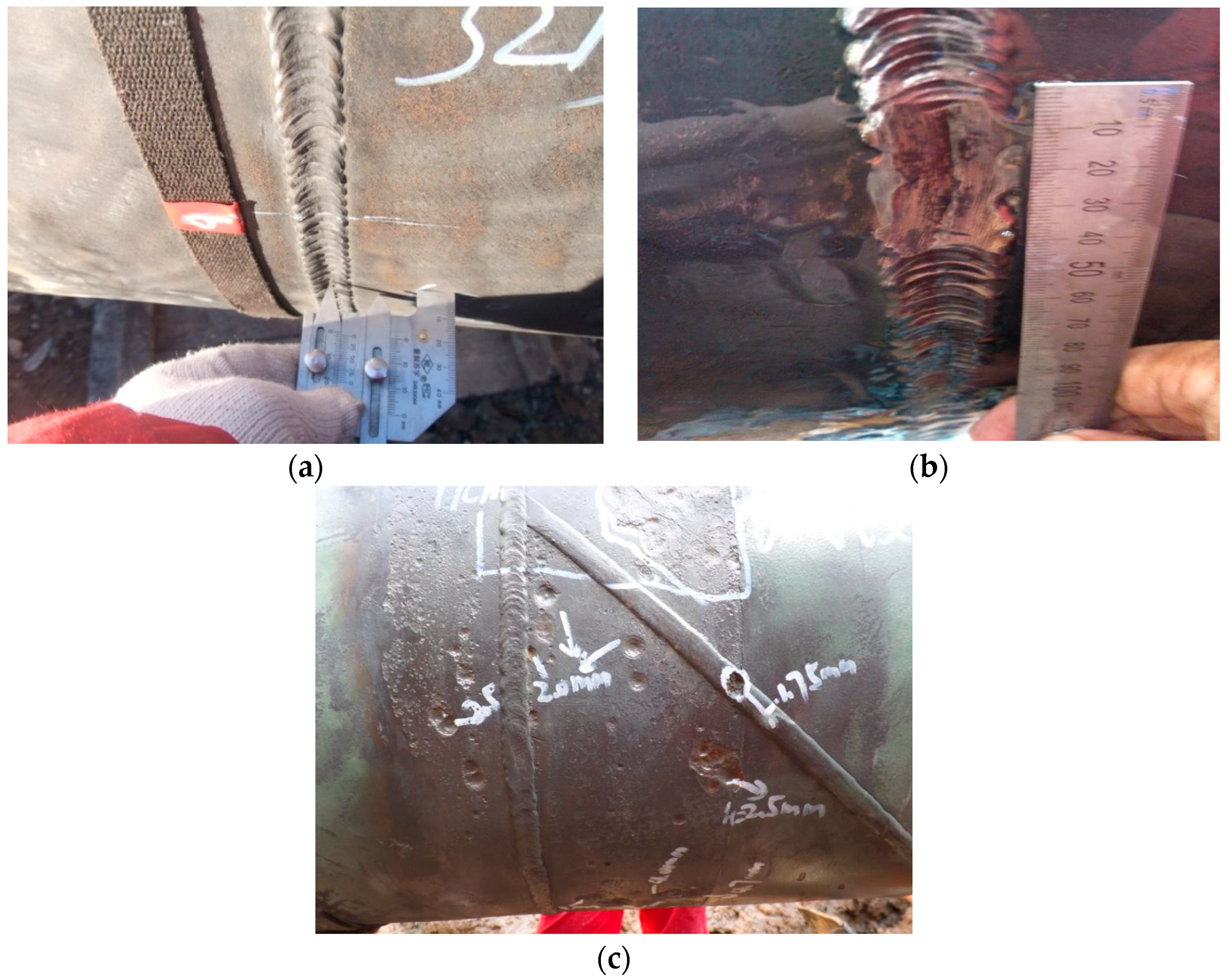

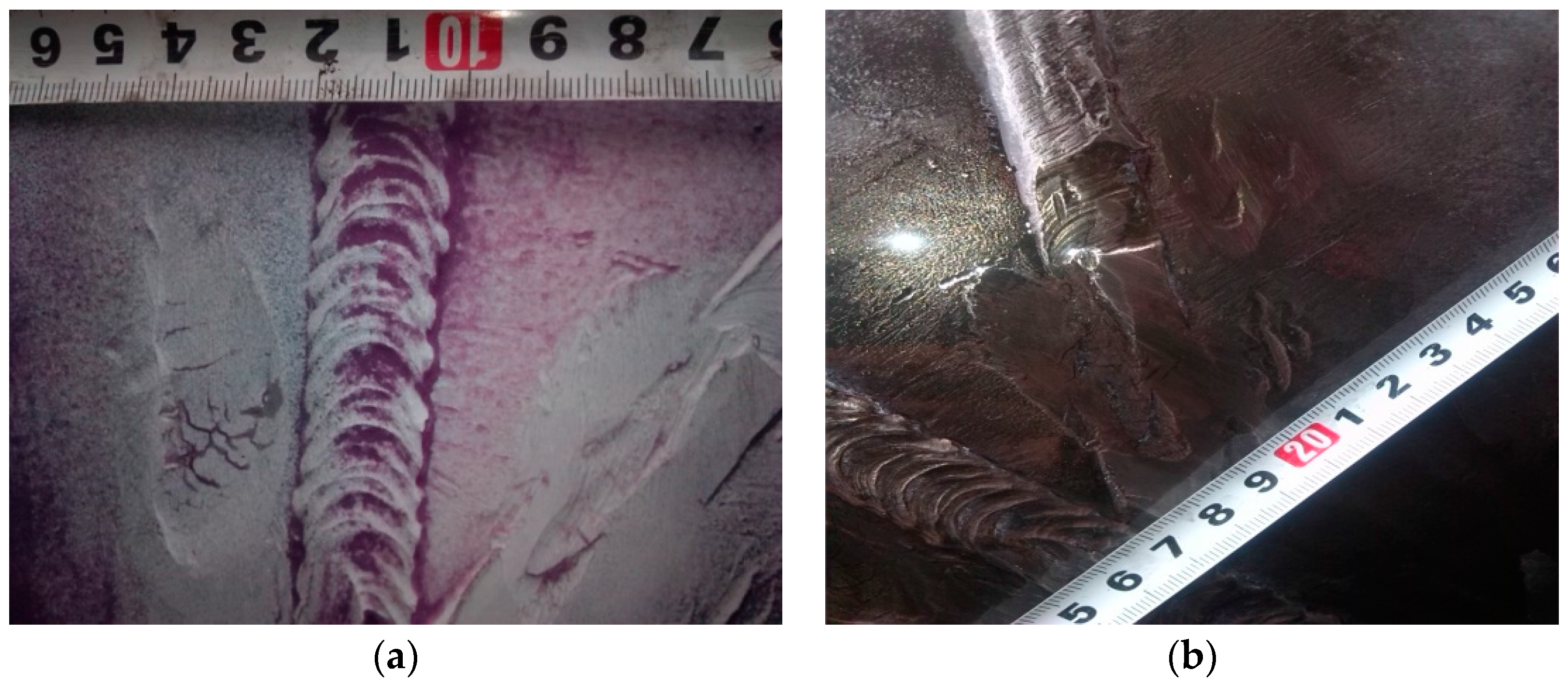

2. Oil and Gas Pipeline Girth Weld On-Site Inspection

3. Oil and Gas Pipeline Girth Weld Defect In-Line Inspection Technology

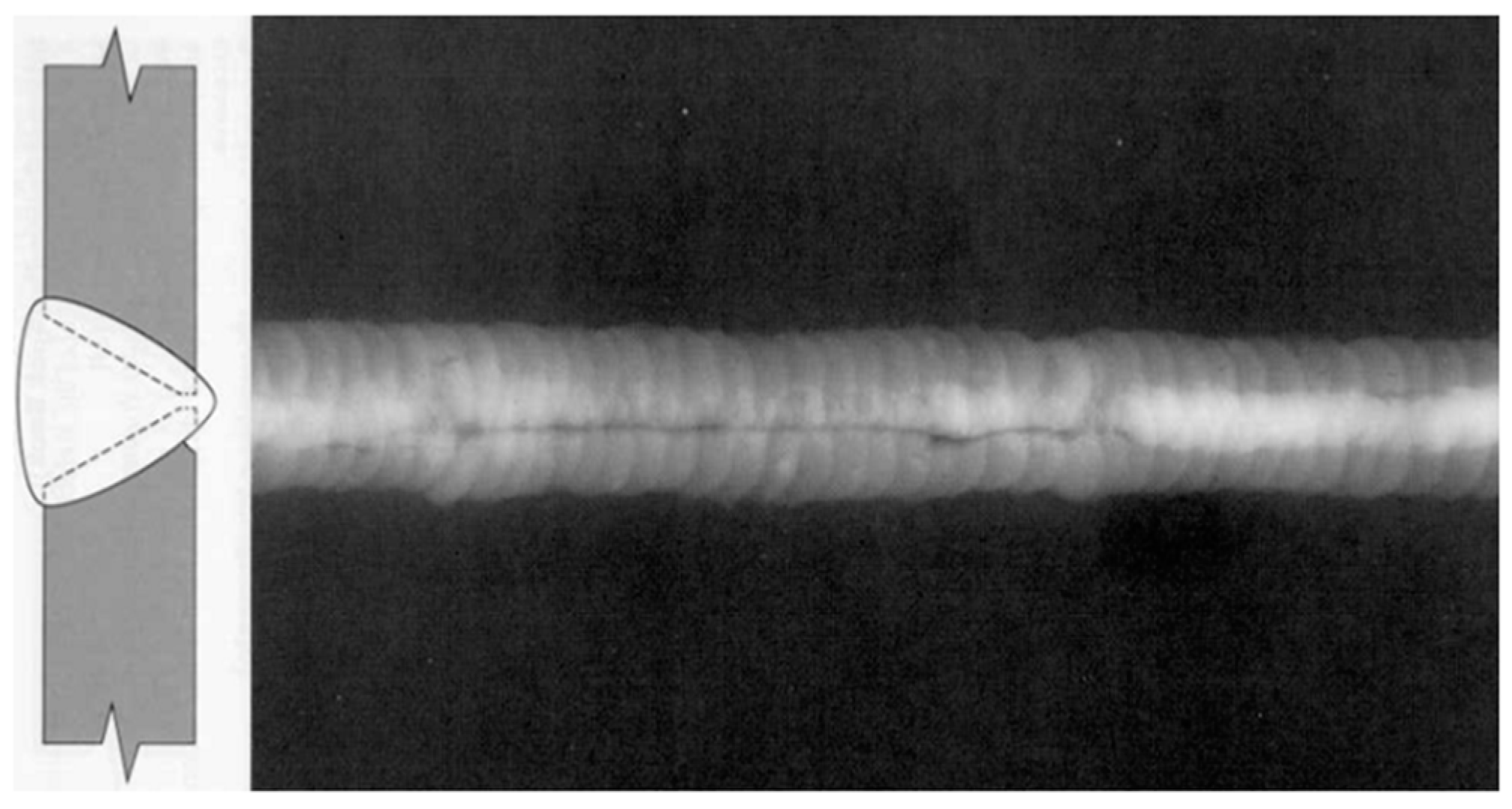

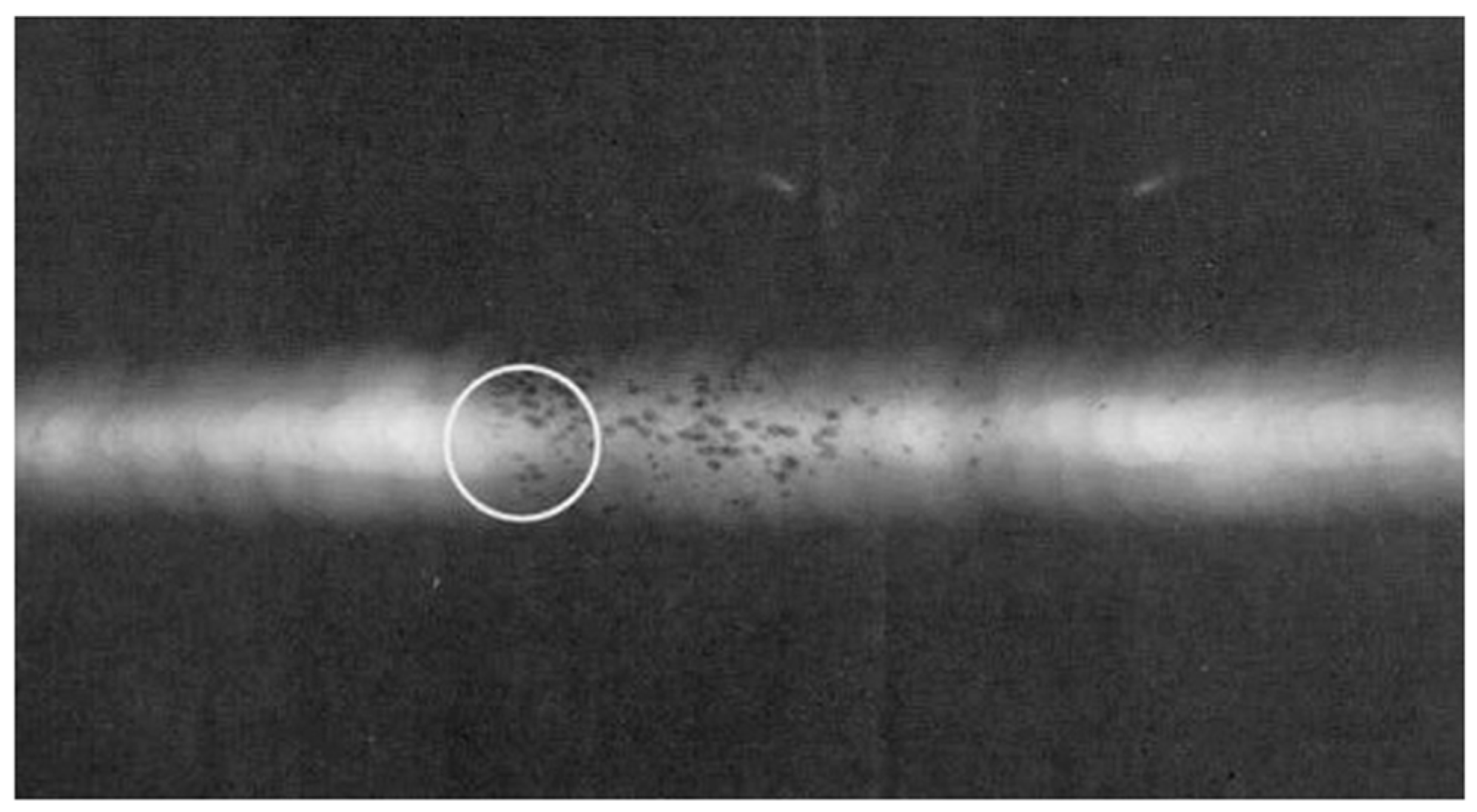

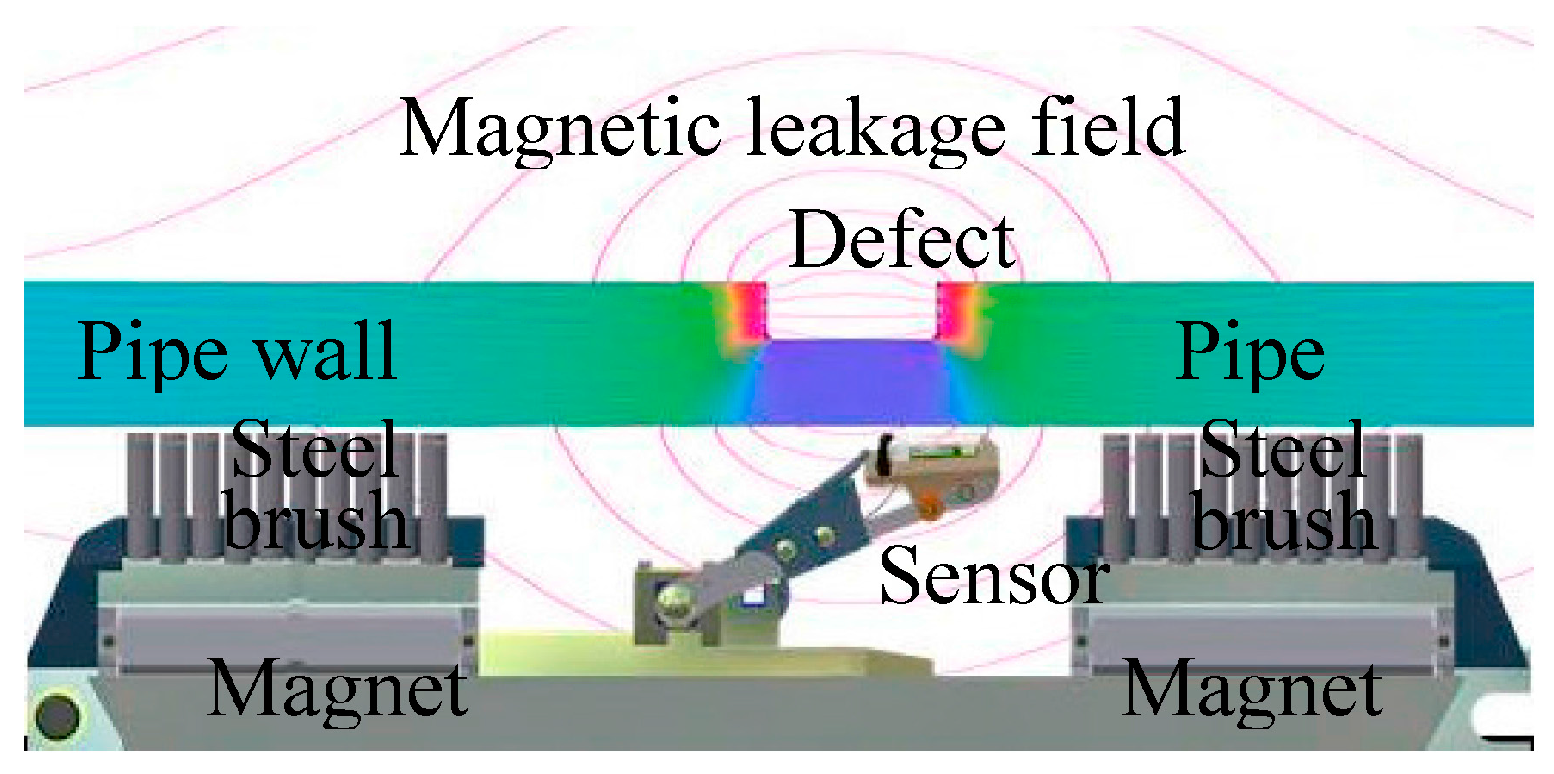

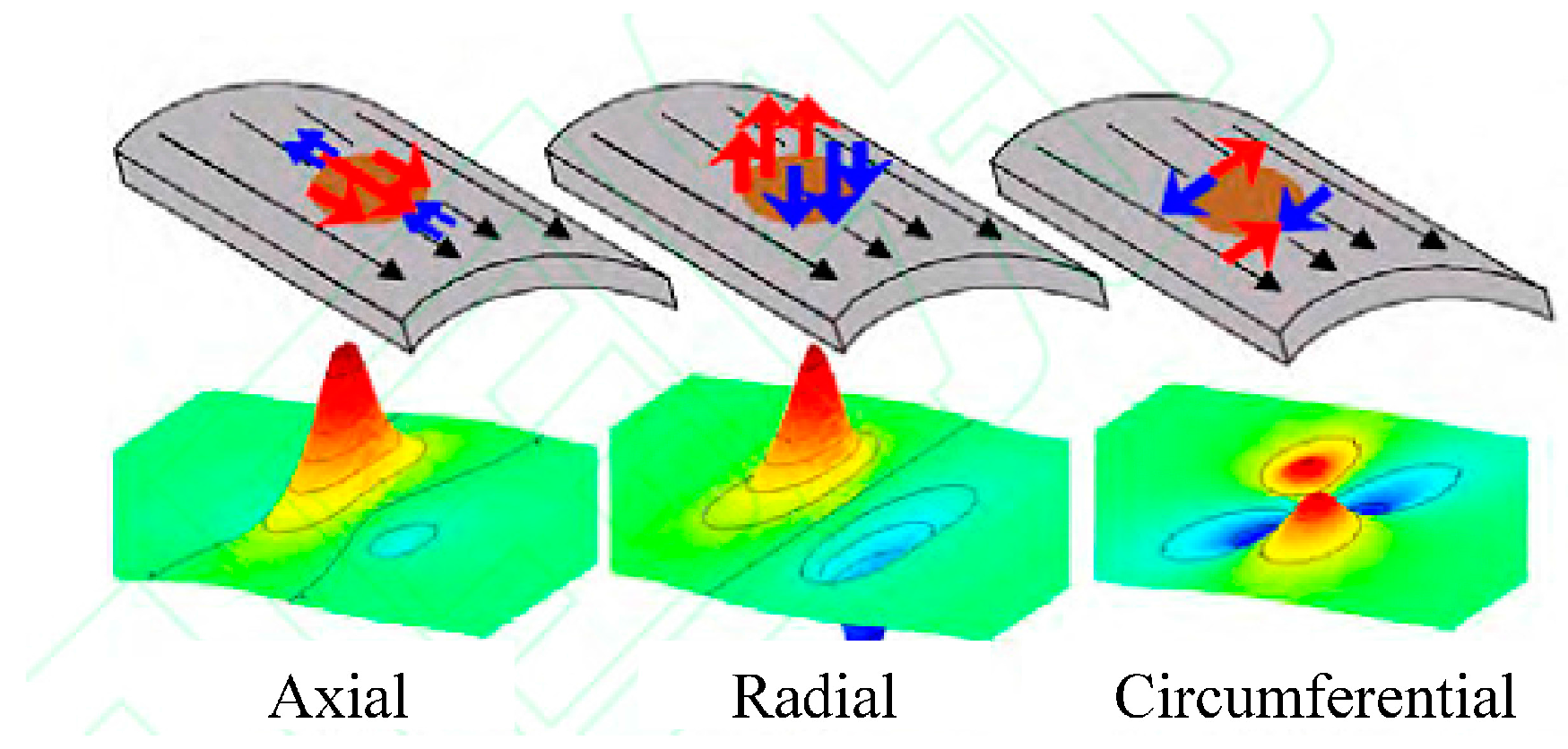

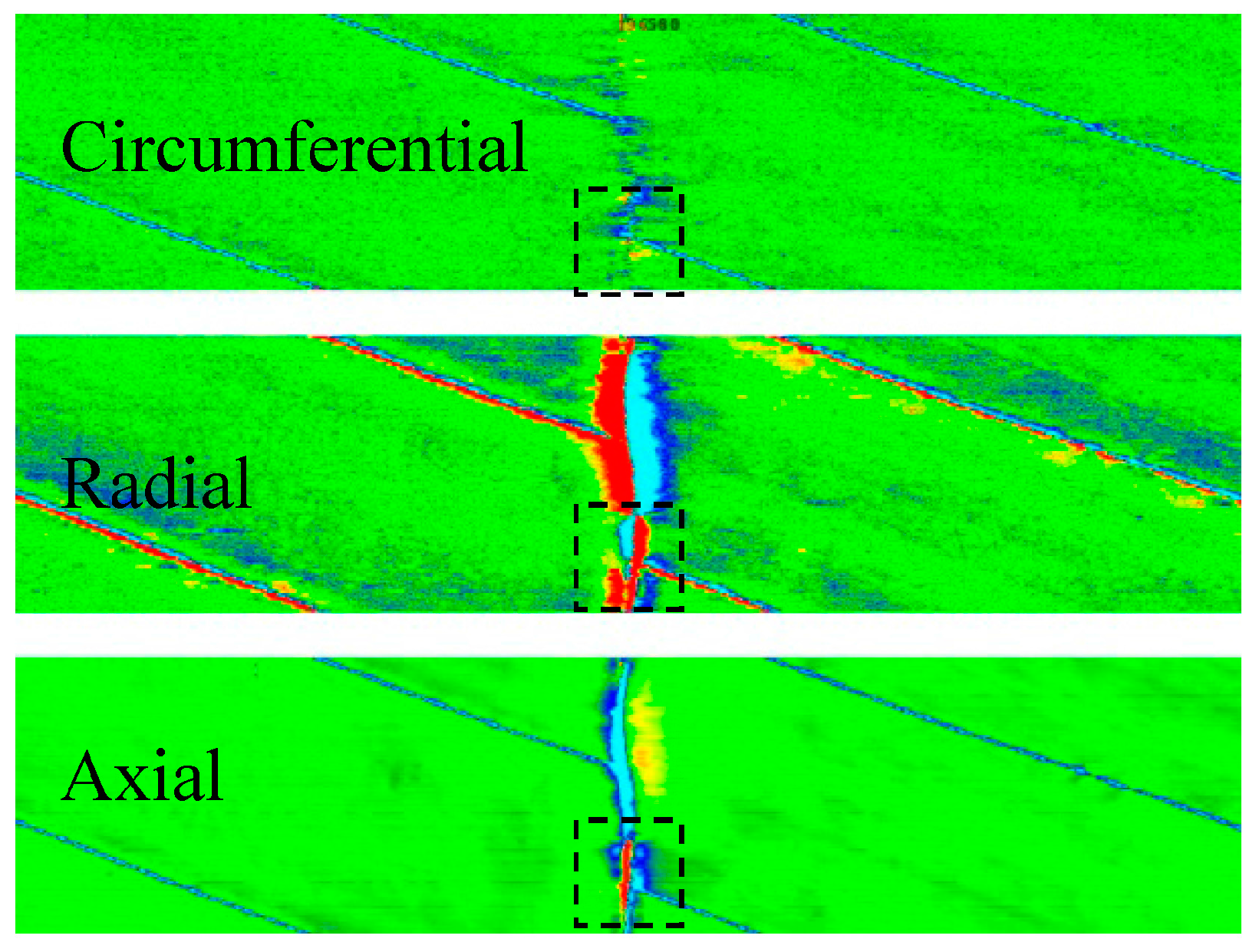

3.1. Three-Axis High-Resolution Magnetic Flux Leakage Inspection

3.1.1. Inspection Principle and Signal Analysis

3.1.2. Defect Sizing Methods

3.1.3. Inspection Reliability

3.2. Ultrasonic Inspection for Oil Transport Pipeline Girth Weld Cracks

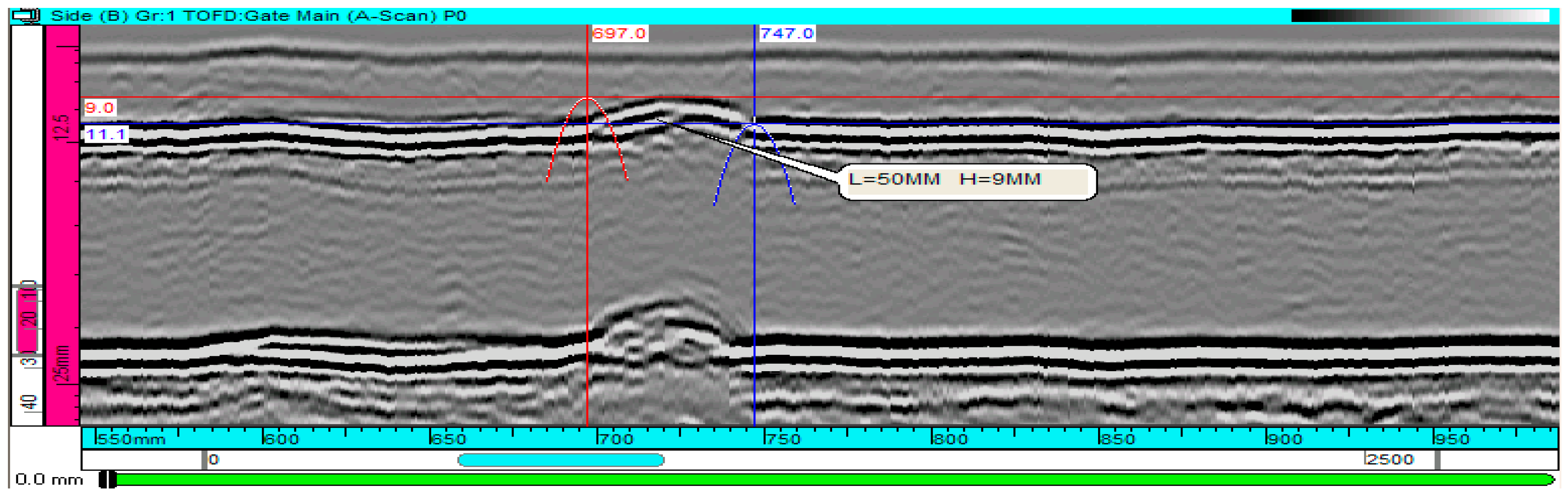

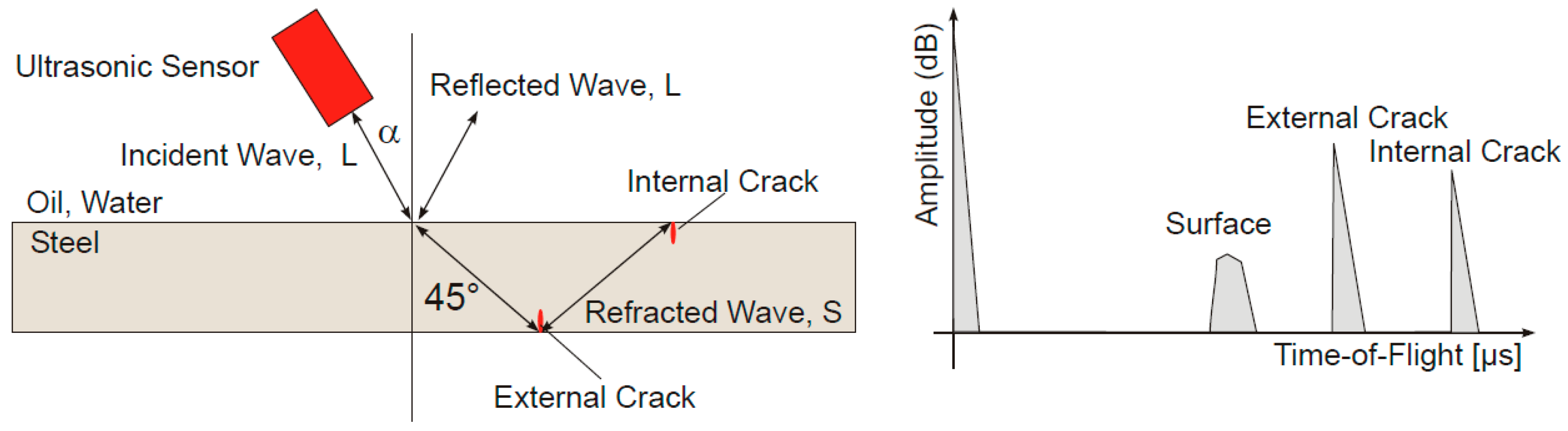

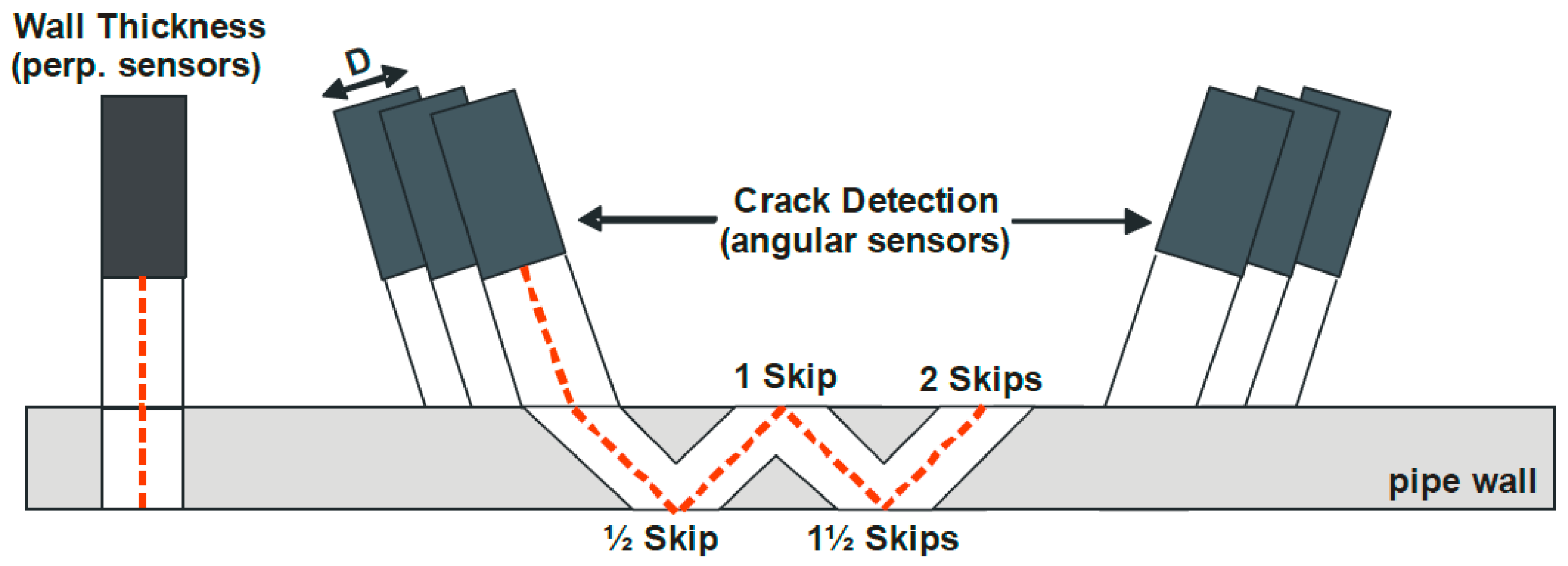

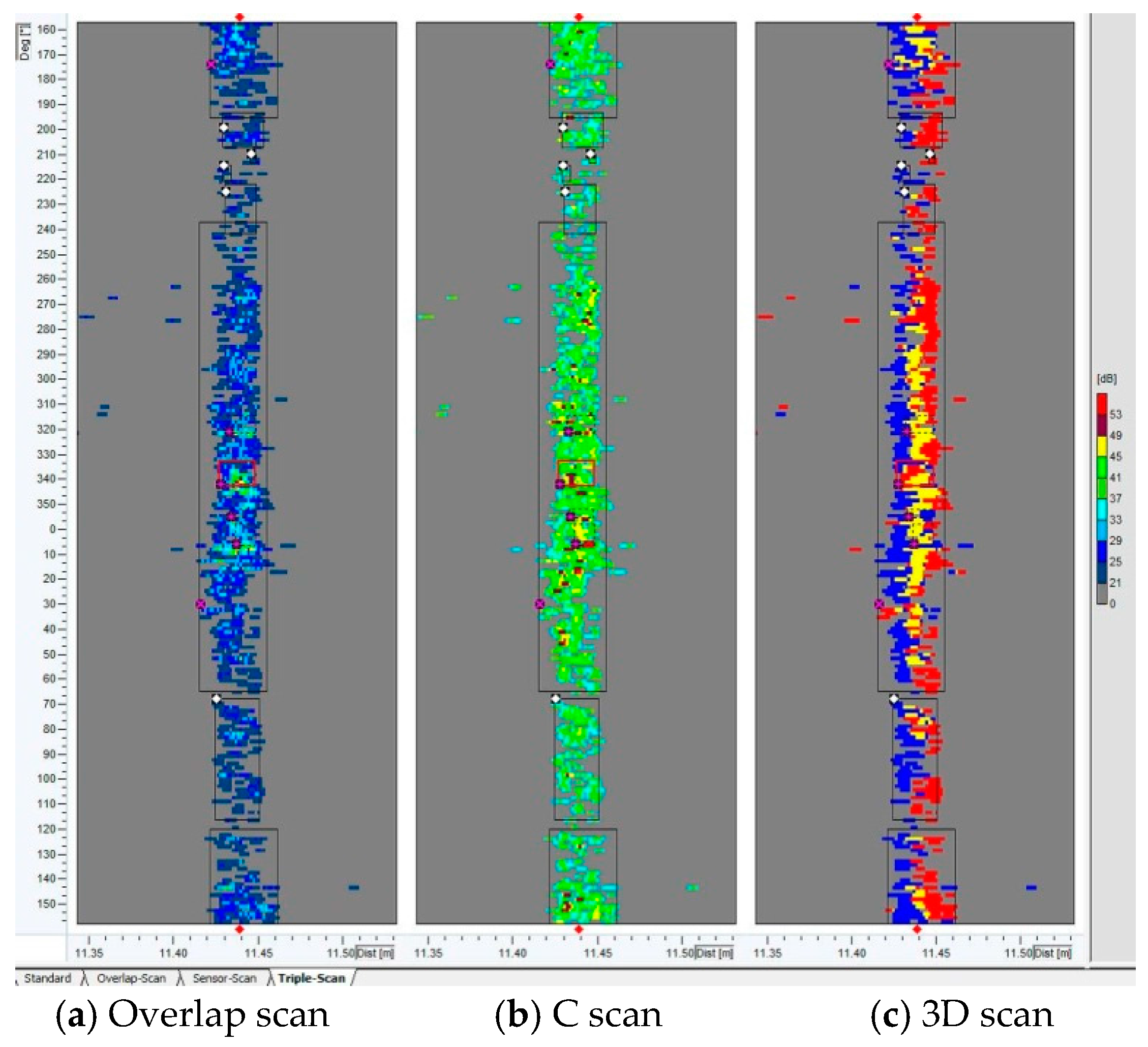

3.2.1. Inspection Principle and Signal Analysis

3.2.2. Defect Sizing Method

3.2.3. Inspection Reliability

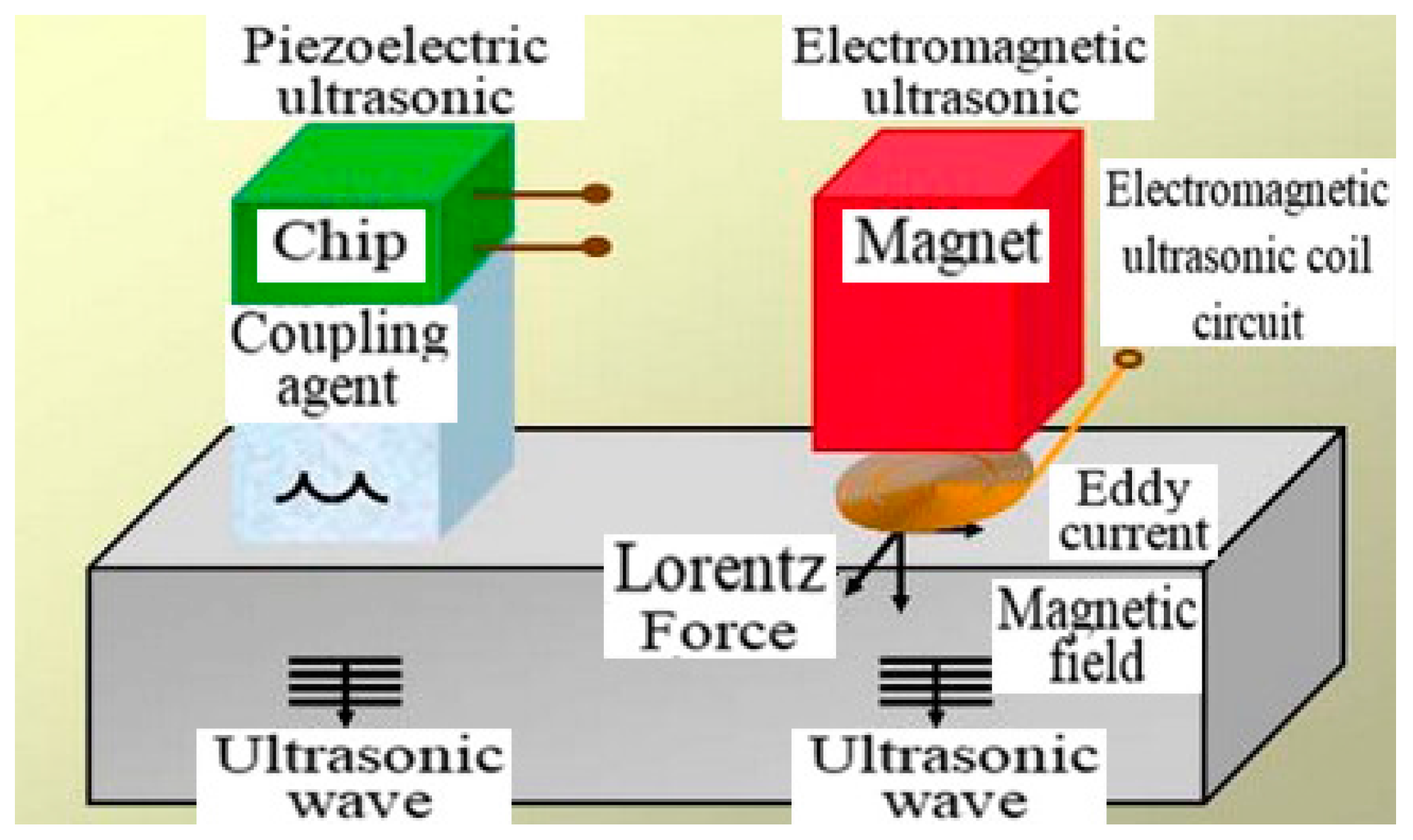

3.3. Electromagnetic Acoustic Transducer Inspection of Natural Gas Pipeline Girth Weld Defects

3.3.1. Inspection Principle

3.3.2. Signal Recognition and Defect Sizing

3.3.3. Inspection Reliability

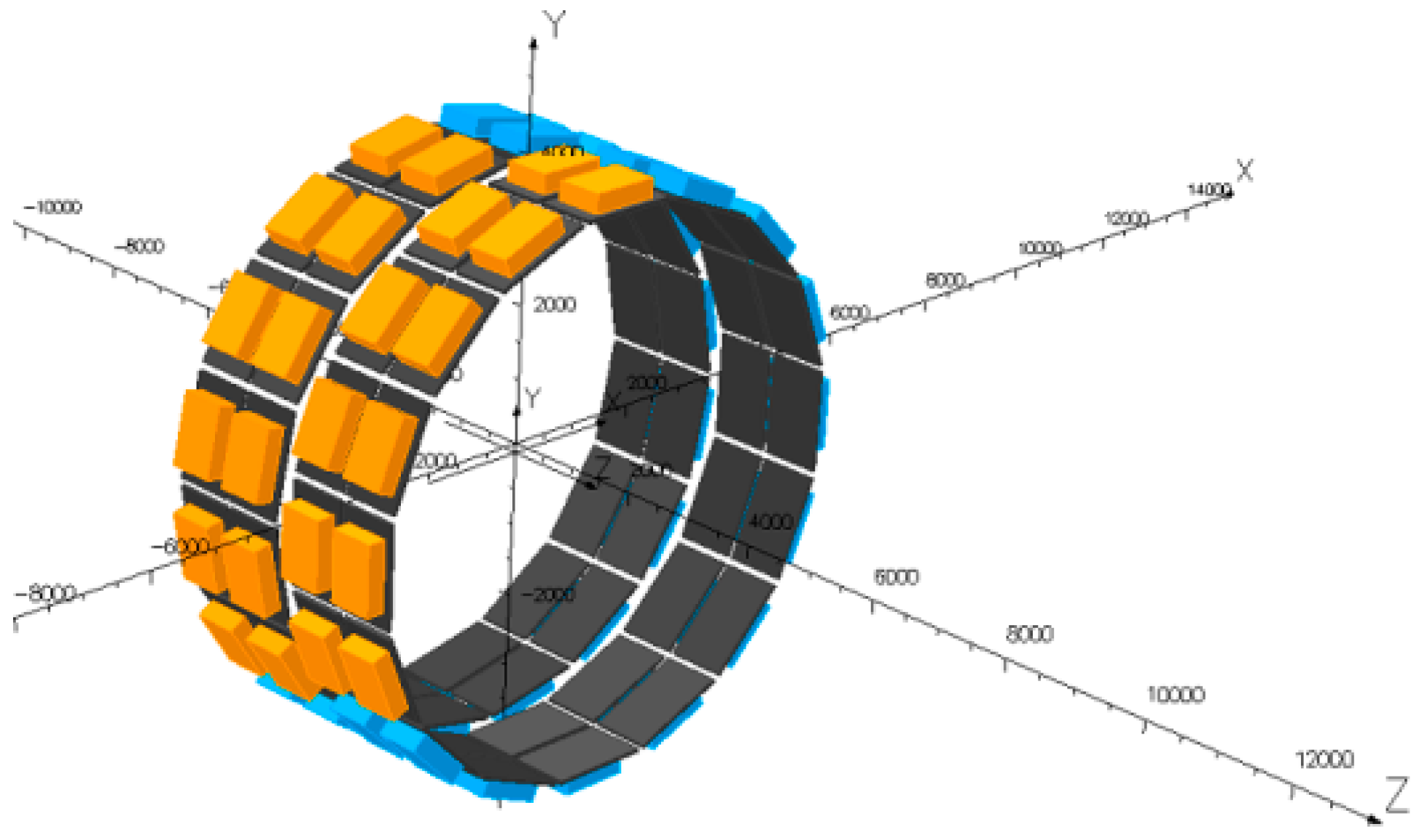

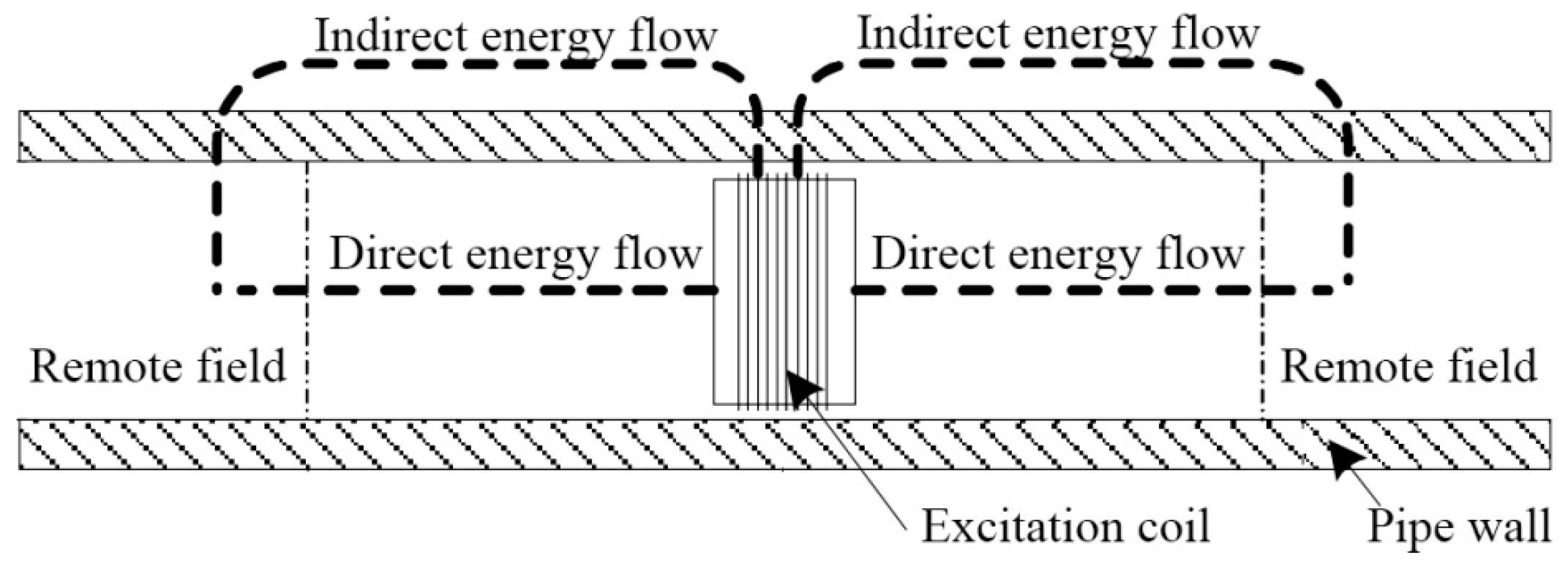

3.4. Electromagnetic Eddy Current Inspection

3.4.1. Inspection Principle

3.4.2. Defect Sizing Method

4. New Technologies for Pipeline Defect In-Line Inspection

4.1. Composite Ultrasonic Inspection

4.2. Laser Ultrasonic Inspection

4.3. Magnetostriction Inspection

5. Conclusions and Prospects

- Three-axis high-resolution MFL inspection technology can identify a lot of long-distance transport pipeline girth weld defects. It is highly adaptive and able to effectively detect the volumetric defects, but the accuracy of defect sizing is not high.

- Neither three-axis high-resolution MFL inspection nor liquid ultrasonic inspection can effectively detect the closed crack defect of long-distance transport pipeline girth weld, except the defects with a large opening (about >0.5 mm).

- The future development will focus on improving the existing electromagnetic ultrasonic crack inspection and RFEC inspection, developing and applying new crack inspection technology and realizing the effective inspection of girth weld crack defects.

- Due to the complexity of the on-line inspection condition and the principle of detection technologyfor long-distance transport pipeline girth weld, it is very difficult to detect and quantify the girth weld defects. The irregular outline of girth weld, surface condition of pipeline and other factors have inevitable influence on the inspection and sizing of girth weld defects, and attention should be paid to the actual pipeline inspection factors during inspection data analysis and sizing.

- At present, the finite element method and the neural network method are used to quantify the defects of girth welds, but the accuracy is far from satisfying the requirements. The type and sizing of defects need to be studied systematically.

- In order to improve the accuracy of pipeline defect inspection, the new technologies for contactless inspection have been applied in the in-line inspection of pipeline defects, including composite inspection, laser ultrasonic and magnetostriction.

Conflicts of Interest

References

- Pipeline and Hazardous Materials Safety Administration (PHMSA). Statistical Analysis of Pipeline Accidents. 14 December 2013. Available online: http://primis.phmsa.dot.gov/comm/reports/safety/ (accessed on 9 January 2015). [Google Scholar]

- Wang, T.; Yang, H.; Feng, Q.; Zhou, L.; Wang, F.; Xiang, X. Current status and prospect of inline inspection technologies for defects in girth weld of oil and gas pipeline. Oil Gas Storage Transp. 2015, 34, 694–698. [Google Scholar]

- Feng, Q. Practice and cogitation on pipeline integrity management. Oil Gas Storage Transp. 2014, 33, 229–232. [Google Scholar]

- Luo, H.; Ju, X.; Lu, Z.; Wang, S. Current Inspection Situation & Research Progress of Girth Welding Seam of Oil & Gas Transmission Pipeline. Welded Pipe Tube 2008, 32, 40–45. [Google Scholar]

- Wang, Y.; Yu, W.; Yang, G.; Cao, J. Research on X-ray detection technology of pressure pipeline containing medium. PetroChem. Equip. 2012, 41, 19–22. [Google Scholar]

- Huang, L.; Li, Y. Automatic UT phase array technology for girth welding of pipeline. Welded Pipe Tube 2006, 29, 40–45. [Google Scholar]

- Han, X.; Jiang, Z.; Han, S.; Ji, H. Application of Ultrasonic TOFD Inspection Technology to Girth Welding in Pipeline. Nondestruct. Test. 2008, 30, 61–63. [Google Scholar]

- Yeung, P.; Sporns, R.; Clouston, S.; Coleman, G.A.; Miller, S.; Mieila, C. Maximizing MFL ILI sizing confidence and accuracy using high-resolution field measurement data. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012.

- Lu, D.; Skow, J.; Keane, S. Assessing the probability of detecting crack features using ultrasonic in-line inspection tool run results and excavation data. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Sutherland, J.; Mann, A.; Vignal, G.; Maier, A.; Keane, S. Application and advancement of EMAT ILI technologies for the inspection of cracks in dents. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Wang, F.; Feng, Q.; Zhang, H.; Song, H.; Chen, J. Identification of Pipeline Features via Tri-Axial Magnetic Flux Leakage Technology for In-Line Inspection. Nondestruct. Test. 2011, 33, 79–84. [Google Scholar]

- Desjardins, G.; Nickle, R.; Skibinsky, D.; Yip, J. Comparison of In-Line Inspection Service Provider Magnetic Flux Leakage (MFL) Technology and Analytical Performance Based on Multiple Runs on Pipeline Segments. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012.

- Wang, F.; Feng, Q.; Wang, X.; Yan, B.; Chu, W. Signal analysis and application of tri-axial MFL sensors for pipeline in-line inspection. Oil Gas Storage Transp. 2010, 29, 815–817. [Google Scholar]

- Feng, Q. Three-axis high-resolution MFL internal inspection technology for in-service pipeline. Oil Gas Storage Transp. 2009, 28, 72–75. [Google Scholar]

- Clapham, L.; Babbar, V.; Chen, J.D. Understanding Magnetic Flux Leakage Signals From Gouges. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Co, V.; Ironside, S.; Ellis, C.; Wilkie, G. Characterization of Mechanical Damage through Use of the Tri-Axial Magnetic Flux Leakage Technology. In Proceedings of the 6th International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006.

- Feng, Q.; Sutherland, J.; Gu, B.; Wei, Y.; Tao, C. Evolution of Triax Magnetic Flux Leakage Inspection for Mitigation of Spiral Weld Anomalies. In Proceedings of the 28th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Feng, Q.; Ni, J. Feasibility analysis of internal detection technology for crack in spiral seam pipeline. Oil Gas Storage Transp. 2009, 28, 45–46. [Google Scholar]

- Feng, Q.; Song, H.; Wang, X.; Wang, F.; Li, B. The Triaxial Magnet IC Flux Leakage Signal Analysis of Spiral Weld Roof Topping and Hi-Low Defects. Nondestruct. Test. 2009, 31, 340–344. [Google Scholar]

- Cui, H.; Feng, Q.; Shui, B.; Zhang, Y. Origin analysis to the cracking of spiral welds in a crude oil pipeline. Oil Gas Storage Transp. 2008, 27, 47–49. [Google Scholar]

- Ireland, R.C.; Torres, C.R. Challenges in Circumferential Magnetisation II: A FEA Point of View. In Proceedings of the 6th International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006.

- Wang, F.; Chen, J. Technical Report on Identification and Evaluation Technology of Magnetic Flux Leakage Detection Signals for Girth Weld Defects; Technical Report QTSXJC-01; PetroChina Pipeline Company: Beijing, China, 2015. [Google Scholar]

- Liu, F.; Zheng, M.; Kong, S. Numerical Simulation and Experimental Research on Crack Magnetic Flux Leakage Field. In Proceedings of the 2011 Pressure Vessels and Piping Conference, Baltimore, MD, USA, 17–21 July 2011; pp. 731–737.

- Ting, W.; Sutherland, J.; Hui, Y. In-Line Inspection and Assessment for Pipeline Girth Weld Defects; PR-469-143508; Pipeline Research Council International: Calgary, AB, Canada, 2015; Volume 4. [Google Scholar]

- Nikolova, N.K.; Cronin, D.; Pasha, S.M.; Amineh, R.K.; Smith, I.; Thompson, R.; Hare, J.R. Electric Resistance Welded Seam Inspection Using Circumferential Flux. In Proceedings of the 7th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2008.

- Ding, Z.; He, R.; Liu, Z. The simulation analysis and quantity model of pipeline defect signals in magnetic flux leakage testing. Nondestruct. Test. 2013, 35, 30–33. [Google Scholar]

- Hari, K.C.; Nabi, M.; Kulkarni, S.V. Improved FEM model for defect-shape construction from MFL signal by using genetic algorithm. IET Sci. Meas. Technol. 2007, 1, 196–200. [Google Scholar] [CrossRef]

- Amineh, R.K.; Nikolova, N.K.; Reilly, J.P.; Hare, J.R. Characterization of Surface-Breaking Cracks Using One Tangential Component of Magnetic Leakage Field Measurements. IEEE Trans. Magn. 2008, 44, 516–524. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Feng, H. Research on intelligent pipeline magnetic flux leakage tester. Nondestruct. Test. 2002, 24, 100–102. [Google Scholar]

- Yang, L.; Xing, Y.; Gao, S. Research on high precision magnetic flux leakage in-line detection system. Non Destr. Test. 2005, 29, 20–22. [Google Scholar]

- Su, Y. Study on Three-Axis Magnetic Flux Leakage In-Line Inspection technology of Pipeline; Shenyang University of Technology: Shenyang, China, 2012. [Google Scholar]

- Park, G.S.; Park, S.H. Analysis of the Velocity-Induced Eddy Current in MFL Type NDT. IEEE Trans. Magn. 2004, 40, 663–666. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.Y.; Ward, S. Numerical simulation on magnetic flux leakage evaluation at high speed. NDTE Int. 2006, 39, 367–373. [Google Scholar] [CrossRef]

- Ma, F.; Yang, L. Speed Effect and Signal Compensation in High Speed Magnetic Flux Leakage Testing. Non Destr. Test. 2005, 29, 12–15. [Google Scholar]

- Ribes-Gomez, E.; Mcloone, S.; Irwin, G.W. Orthogonal wavelet network construction using local regularization. In Proceedings of the First International IEEE Symposium, Varna, Boulgaria, 10–12 September 2002; pp. 271–276.

- Christen, R.; Bergamini, A. Automatic flaw detection in NDE signals using a panel of neural networks. NDTE Int. 2006, 39, 547–553. [Google Scholar] [CrossRef]

- Kyungtae, H. 3-D Defectprofile Reconstruction from Magnetic Flux Leakage Signatures Using Wavelet Basis Function Neural Network. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2000. [Google Scholar]

- Joshi, A.; Udpa, L.; Udpa, S.; Tamburrino, A. Adaptive wavelets for characterizing magnetic flux leakage signals from pipeline inspection. IEEE Trans. Magn. 2006, 42, 3168–3170. [Google Scholar] [CrossRef]

- Ramuhalli, P.; Udpa, L.; Udpa, S.S. Electromagnetic NDE signal inversion by function-approximation neural networks. IEEE Trans. Magn. 2002, 38, 3633–3642. [Google Scholar] [CrossRef]

- Jiang, Q.; Wang, T.; Liu, Q.; Jiang, H. Analysis of the magnetic flux leakage field of pipeline defect based on radial basis function neural network. Nondestruct. Test. 2002, 24, 515–518. [Google Scholar]

- Wang, T.; Liu, X.; Qin, X.; Shang, T. Spectrum entropy and its application in characteristics abstraction of magnetic flux leakage signals. J. Tianjin Univ. 2004, 37, 216–220. [Google Scholar]

- Wei, M.; Jin, S.; Li, Y.; Cui, Q. Two dimensional profile reconstruction and process technology for Pipeline defect. Acta Pet. Sin. 2003, 24, 98–101. [Google Scholar]

- Wei, M.; Jin, S.; Li, Y.; Cui, Q. Study on wavelet compression technique for magnetic flux leakage image of oil and gas pipeline defects. OptoElectron. Eng. 2004, 31, 58–60. [Google Scholar]

- Yang, L.; Chen, X.; Wei, J. Signal processing technology in oil-gas pipeline magnetic flux leakage inspection. J. Shenyang Polytech. Univ. 1999, 21, 516–518. [Google Scholar]

- Yang, L.; Ma, F.; Gao, S. Quantitative recognition of pipeline defects based on neural network and data fusion. Nondestruct. Test. 2006, 28, 281–284. [Google Scholar]

- Salama, M.M.; Nestleroth, B.J.; Maes, M.A. Characterization of the accuracy of the MFL pipeline inspection tools. In Proceedings of the 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; Paper No. OMAE2012-83934. pp. 247–251.

- Bauer, S.; Brueske, H. Detection and Sizing of Subcritical Cracks Using Ultrasonic In-Line Inspection Methods. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Barkdull, L.; Willems, H. Post Assessment of Ultrasonic Crack Detection Inline Inspection Data. In Proceedings of the 7th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2008.

- Ohl, S.P.; Allison, R.E. Ultrasonic Inline Inspection of the Moomba to Sydney Pipeline. In Proceedings of the 6th International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006.

- Bates, N.; Lee, D.; Maier, C. A Review of Crack Detection In-Line Inspection Case Studies. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Xiang, X.; Jia, G. Study on Ultrasonic Inspection Technology of Cracks in Girth Welding of Liquid Pipeline; Technical Report MDJC-01; PetroChina Pipeline Company: Beijing, China, 2015. [Google Scholar]

- Masnata, A.; Sunseri, M. Neural network classification of flaws detected by ultrasonic means. NDTE Int. 1996, 29, 87–93. [Google Scholar] [CrossRef]

- Roy, A.; Barat, P.; Des, K. Material classification through neural networks. Ultrasonics 1995, 33, 175–180. [Google Scholar] [CrossRef]

- Zhao, J. Pipe Corrosion Cracking with Ultrasonic Detection Signal Processing Research; Beijing University of Chemical Technology: Beijing, China, 2008. [Google Scholar]

- Dai, B.; Zhao, J.; Zhou, Y. Research of Classification and Recognition of Pipeline Corrosion Defectson Ultrasonic In-line Inspection. Mach. Hydraul. 2008, 36, 194–199. [Google Scholar]

- Yang, Z. Research of Inner Inspection System in the Distance Pipelines; Beijing University of Chemical Technology: Beijing, China, 2007. [Google Scholar]

- Chen, G.; Zhang, X.; Xie, C.; He, X. Intelligent Recognition of Crack Depth in Ultrasonic Testing. J. South China Univ. Technol. 2005, 33, 1–5. [Google Scholar]

- Slaughter, M.; Spencer, K.; Dawson, J.; Senf, P. Comparison of Multiple Crack Detection In-Line Inspection Data to Assess Crack Growth. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Kresic, W.; Ironside, S. SCC Detection and Mitigation Based on In-line Inspection Tools. In Proceedings of the 5th International Pipeline Conference, Calgary, AB, Canada, 4–8 October 2004.

- Wilkie, G.H.; Elm, T.J.; Engen, D.L. Enbridge Comparison of Crack Detection In-Line Inspection Tools. In Proceedings of the 4th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2002.

- Li, Z. Development and Application of Electromagnetic Ultrasonic (EMAT) Technology. Non Destr. Test. 2006, 30, 13–14. [Google Scholar]

- Beuker, T.; Alers, R.; Brown, B.; Alers, G. SCC Detection and Coating Disbondment Detection Improvements Using the High Resolution EMAT ILI-Technology. In Proceedings of the 5th International Pipeline Conference, Calgary, AB, Canada, 4–8 October 2004.

- Huang, S.; Ye, C.; Wang, K.; Zhao, W.; Dong, J. Development of Oil and Gas Pipeline Crack Detector Based on EMAT. Nondestruct. Test. 2009, 31, 827–829. [Google Scholar]

- Wang, S.; Kang, L.; Zhao, Z.; Zhai, G. Overview of Research Advances in Electromagnetic Acoustic Transducer. Instrum. Tech. Sens. 2006, 5, 47–50. [Google Scholar]

- Yeomans, M.; Ashworth, B. Development of 36″ EmatScan® Crack Detection (CD) Tool. In Proceedings of the 4th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2002; pp. 1543–1548.

- Hilvert, M.; Beuker, T. High-Resolution EMAT as a Diagnostic Tool for Analysis of SCC and Crack-Like Pipelines Defects. In Proceedings of the ASME India International Oil and Gas Pipeline Conference, New Delhi, India, 17–18 April 2015.

- Kania, R.; Weber, R.; Klein, S. Investigation and Assessment of Low-Frequency ERW Seam Imperfections by EMAT and CMFL ILI. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Batte, A.D.; Fessler, R.R.; Marr, J.E.; Rapp, S.C. Managing the Threat of SCC in Gas Transmission Pipelines. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012.

- Kania, R.; Klein, S.; Marr, J.; Rosca, G.; Riverol, E.S.J.; Ruda, R.; Jansing, N.; Beuker, T.; Ronsky, N.D.; Weber, R. Validation of EMAT technology for gas pipeline crack inspection. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012.

- Sutherland, J.; Tappert, S.; Kania, R.; Kashammer, K.; Marr, J.; Mann, A.; Rosca, G.; Garth, C. The role of effective collaboration in the advancement of EMAT inline inspection technology for pipeline integrity management: A case study. In Proceedings of the 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012.

- Chao, G. Research and Experiment of Electromagnetic Ultrasonic Non-Destructive Testing Technology; Tianjin University: Tianjin, China, 2010. [Google Scholar]

- Zhang, J. Research of the Pipeline Long-Distance Detection Technology Based on Electromagnetic Acoustic Guided Wave; Shenyang University of Technology: Shenyang, China, 2015. [Google Scholar]

- Shu, D. Research of the Pipeline Defect Detection Technology Based on Electromagnetic Ultrasonic Guided Wave; Shenyang University of Technology: Shenyang, China, 2014. [Google Scholar]

- Li, S. Research on the Experiment System of Electro-Magnetic Ultrasonic in Pipelines’ Cracks Detection; Beijing University of Chemical Technology: Beijing, China, 2010. [Google Scholar]

- Canni, G.; McAughey, K.; Paige, D.; Giese, J. Feasibility of EMAT-Based Circumferential Crack Detection-Test Report; PR-437876; Pipeline Research Council International: Calgary, AB, Canada, 2015; Volume 12. [Google Scholar]

- Abbate, A.; Koay, J.; Frankel, J.; Schroeder, S.C.; Das, P. Signal detection and noise suppression using a wavelet transform signal processor: Application to ultrasonic flaw detection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 14–26. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jin, S.; Cao, L. Signal processing of electromagnetic ultrasonic detection for oil-gas pipelines. Acta Pet. Sin. 2006, 27, 112–115. [Google Scholar]

- Legendre, S.; Massicotte, D.; Goyette, J.; Bose, T.K. Neural classification of Lamb wave ultrasonic weld testing signals using wavelet coefficients. IEEE Trans. Instrum. Meas. 2001, 50, 672–678. [Google Scholar] [CrossRef]

- Case, T.J.; Wang, R.C. Flaw identification from time and frequency features of ultrasonic waveforms. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1996, 43, 592–600. [Google Scholar] [CrossRef]

- Ziarani, A.K. Extaction of Nonstationary Sinusoids; Toronto University: Toronto, ON, Canada, 2002. [Google Scholar]

- Yang, H.; Fu, D.; Cui, L. Experimental Study of Pipeline Crack Detection Based on Electromagnetic. Non Destr. Test. 2013, 37, 16–18. [Google Scholar]

- Kania, R.; Rosca, G.; Tandon, S.; Gao, M.; Krishnamurthy, R. Evaluation of EMAT tool performance and reliability. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Fore, T.; Klein, S.; Yoxall, C.; Cone, S. Validation of EMAT ILI for management of stress corrosion cracking in natural gas pipelines. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Tandon, S.; Gao, M.; Krishnamurthy, R.; Kania, R.; Piazza, M. SCC in-field inspection technology evaluation and its application to EMAT based pipeline integrity management programs. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Cao, J.; Li, Y.; Lin, L.; Li, K. NDT Technologies for In-line Inspection of Natural Gas Pipeline. Nondestruct. Test. 2013, 35, 20–25. [Google Scholar]

- Song, X.; Huang, S.; Zhao, W. Nondestructive testing technique for cracks in long-distance natural gas pipelines. Nat. Gas Ind. 2006, 26, 103–106. [Google Scholar]

- Fukutomi, H.; Takagi, T.; Nishikawa, M. Remote field eddy current technique applied to non-magnetic steam generator tubes. NDTE Int. 2001, 34, 17–23. [Google Scholar] [CrossRef]

- Goldfine, N.; Dunford, T.; Washabaugh, A.; Haque, S.; Denenberg, S. MWM®-Array Electromagnetic Techniques for Crack Sizing, Weld Assessment, Wall Loss/Thickness Measurement and Mechanical Damage Profilometry; TR_2012_05_02; Technical Document; Jentek Sensors Inc.: Waltham, MA, USA, 2012. [Google Scholar]

- Lian, J.; Shen, Y. The Development of Remote Field Eddy Current Testing Technique of Pipeline. Oil Gas Storage Transp. 2004, 23, 14–16. [Google Scholar]

- Guo, X. Research of Inner and Outer Surface defect Identification Technology Viaeddy Current Pipeline Internal Inspection; Shenyang University of Technology: Shenyang, China, 2013. [Google Scholar]

- Yang, L.; Guo, X.; Gao, S. Method of the Eddy Current Testing to Pipeline Inner Surface Defects. Instrum. Tech. Sens. 2014, 10, 78–81. [Google Scholar]

- Yang, B.F.; Li, X.C. Pulsed remote eddy current field array technique for nondestructive inspection of ferromagnetic tube. Nondestruct. Test. Eval. 2010, 25, 3–12. [Google Scholar] [CrossRef]

- Kasai, N.; Fujiwara, Y.; Sekine, K.; Sakamoto, T. Evaluation of back-side flaws of the bottom plates of an oil-storage tank by the RFECT. NDTE Int. 2008, 41, 525–529. [Google Scholar] [CrossRef]

- Wang, J. Research on the Theory and Technology of Pulsed Eddy Current Pipeline Detection Method; Shenyang University of Technology: Shenyang, China, 2014. [Google Scholar]

- Xu, X. Research on Remote Field Eddy Current Technique Used for Axial Crack Detection in Ferromagnetic Pipe; National University of Defense Technology: Changsha, China, 2007. [Google Scholar]

- Sophian, A.; Tian, G.Y.; Taylor, D.; Rudlin, J. Electromagnetic and eddy current NDT: A review. Insight NonDestr. Test. Cond. Monit. 2001, 3, 1–6. [Google Scholar]

- Wu, D.H.; Huang, S.L.; Zhao, W. Transient simulation analysis on magnetic flux leakage detection of cracks in long-distance oil and gas pipeline. Acta Pet. Sin. 2009, 30, 136–140. [Google Scholar]

- Wu, D.H.; Huang, S.L.; Zhao, W. Research on 3-D simulation of remote field eddy current detection for pipeline cracks. J. Syst. Simul. 2009, 21, 6626–6629. [Google Scholar]

- Liu, C. Simulation and Analysis of the Remote Filed Eddy Current Based on Finite Element Method; National University of Defense Technology: Changsha, China, 2005. [Google Scholar]

- Zhang, W.; Shi, Y.; Wang, Z.; Ao, Y. Research on the quantitative inverse method of RFEC inspection for pipe cracks. Chin. J. Sci. Instrum. 2013, 34, 1681–1689. [Google Scholar]

- Liu, H. Simulation and Research on Pipeline Crack Detection Based on Remote Field Eddy Current; Tsinghua University: Beijing, China, 2007. [Google Scholar]

- Yang, B.; Zhang, H.; Xing, Y.; Li, L.; Cui, W. Inspection Principle and Defect Quantitative Estimation of Pulsed Remote Field Eddy Current Technique. J. Air Force Eng. Univ. Nat. Sci. Ed. 2012, 13, 45–49. [Google Scholar]

- Zhang, H.; Yang, B.; Xing, Y.; Li, L.; Cui, W. Defect Quantification and Classification Based on Design of Connected Magnetic Core Pulsed Remote Field Eddy Current Probe. Chin. J. Sens. Actuators 2012, 25, 1371–1375. [Google Scholar]

- Yang, L.; Wang, G.; Gao, S. Ferromagnetic Tubes Testing Based Pulsed Remote Field Eddy Current Technique. Instrum. Tech. Sens. 2012, 11, 141–144. [Google Scholar]

- Willems, H.; Bjorgen, H.P.; Kristiansen, T.-S.; Wileme, G. Qualification of combined ultrasonic inspection tool for detection and sizing of circumferential weld cracks in offshore pipelines. In Proceedings of the 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014.

- Sato, H.; Hamajima, T.; Katayama, M.; Kanamaru, Y. Development of a 3D Ultrasonic Inspection Device for Pipeline Girth Welds. In Proceedings of the 6th International Pipeline Conference, Calgary, AB, Canada, 25–29 September 2006.

- Du, Y. Research on Synthetic Aperture Focusing Technology for Ultrasonic Imaging; Tianjin University: Tianjin, China, 2010. [Google Scholar]

- Shan, Q.; Dewhurst, R.J. Surface-breaking fatigue crack detection using laser ultrasound. Appl. Phys. 1993, 62, 14–18. [Google Scholar] [CrossRef]

- Levesque, D.; Ochiai, M.; Blouin, A.; Talbot, R.; Fukumoto, A.; Monchalin, J.P. Laser-ultrasonic inspection of surface-breaking tight cracks in metals using SAFT processing. In Proceedings of the IEEE Ultrasonics Symposium, Prague, Czech Republic, 8–11 October 2002; Volume 1, pp. 753–756.

- Rehman, H.; Klein, M.; Kania, R.; Rapp, S.; McNealy, R.; Fingerhut, M.; Ansari, H. Sizing Stress Corrosion Cracks Using Laser Ultrasonics. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Klein, M.B.; Ansari, H. Automated Laser Ultrasonic Inspection of Hybrid Laser Arc Welding for Pipeline Construction. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010.

- Tse, P.W.; Liu, X.C.; Wang, X.J.; Wang, D. A Novel and Flexible Design of Magnetostrictive Sensor for Strand/Rope Defect Inspection. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011.

- Ye, Y.; Xia, L. Experimental Research on High-Temperature Pipe Corrosion On-Line Monitoring. In Proceedings of the Pressure Vessels and Piping Conference, Toronto, ON, Canada, 15–19 July 2012.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Q.; Li, R.; Nie, B.; Liu, S.; Zhao, L.; Zhang, H. Literature Review: Theory and Application of In-Line Inspection Technologies for Oil and Gas Pipeline Girth Weld Defection. Sensors 2017, 17, 50. https://doi.org/10.3390/s17010050

Feng Q, Li R, Nie B, Liu S, Zhao L, Zhang H. Literature Review: Theory and Application of In-Line Inspection Technologies for Oil and Gas Pipeline Girth Weld Defection. Sensors. 2017; 17(1):50. https://doi.org/10.3390/s17010050

Chicago/Turabian StyleFeng, Qingshan, Rui Li, Baohua Nie, Shucong Liu, Lianyu Zhao, and Hong Zhang. 2017. "Literature Review: Theory and Application of In-Line Inspection Technologies for Oil and Gas Pipeline Girth Weld Defection" Sensors 17, no. 1: 50. https://doi.org/10.3390/s17010050