Dispersion Curve Engineering of TiO2/Silver Hybrid Substrates for Enhanced Surface Plasmon Resonance Detection

Abstract

:1. Introduction

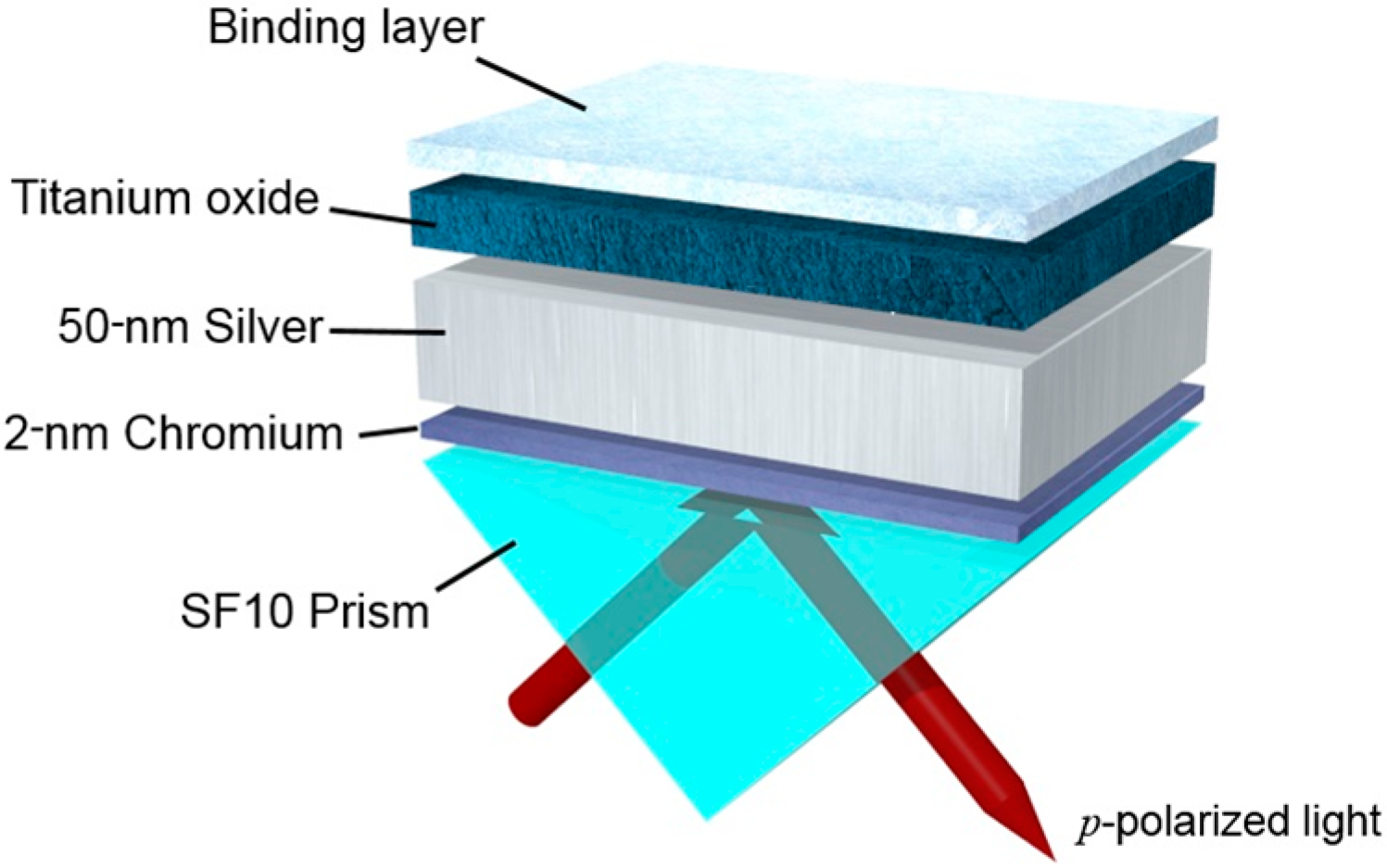

2. Numerical Methods

3. Experimental Details

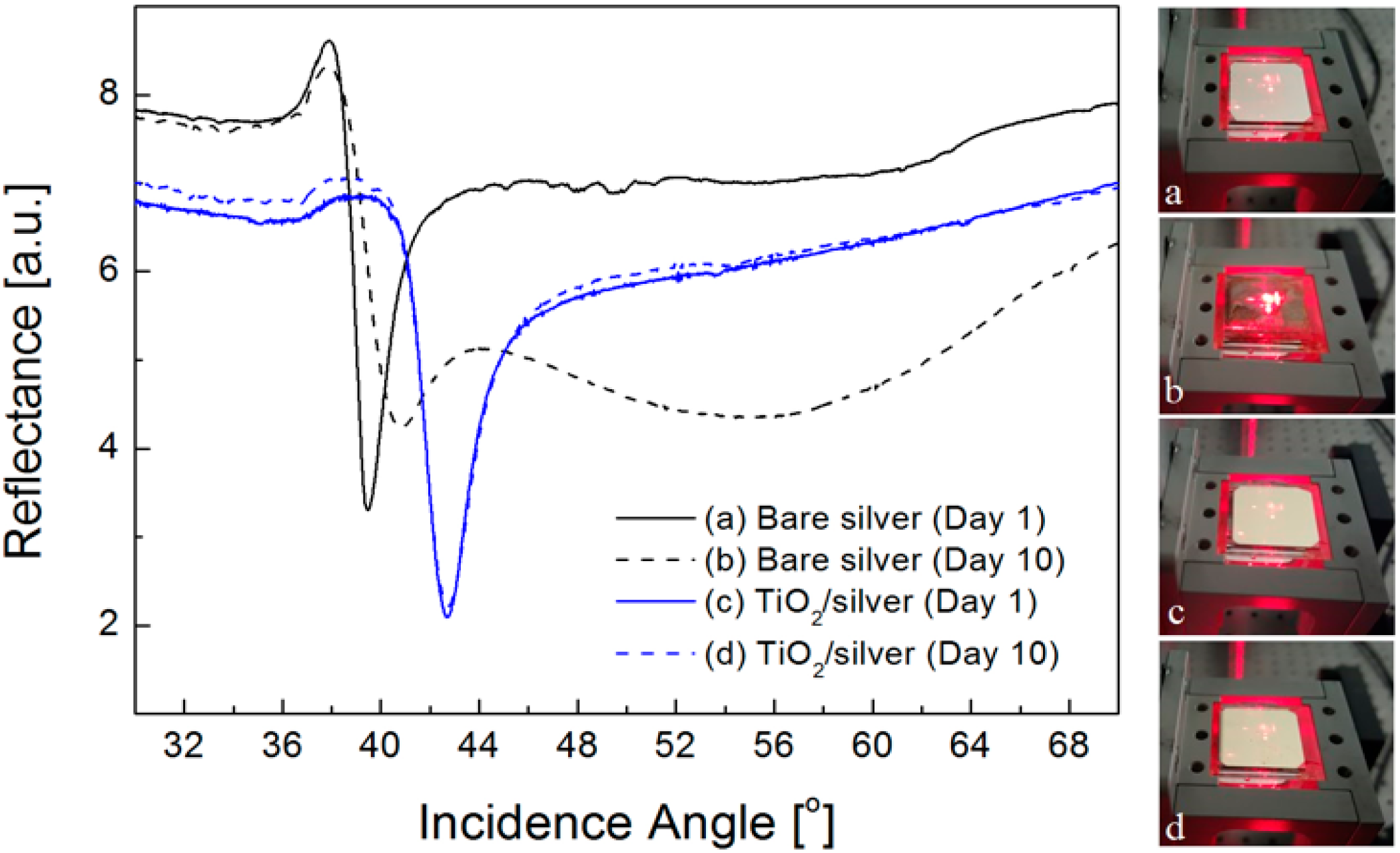

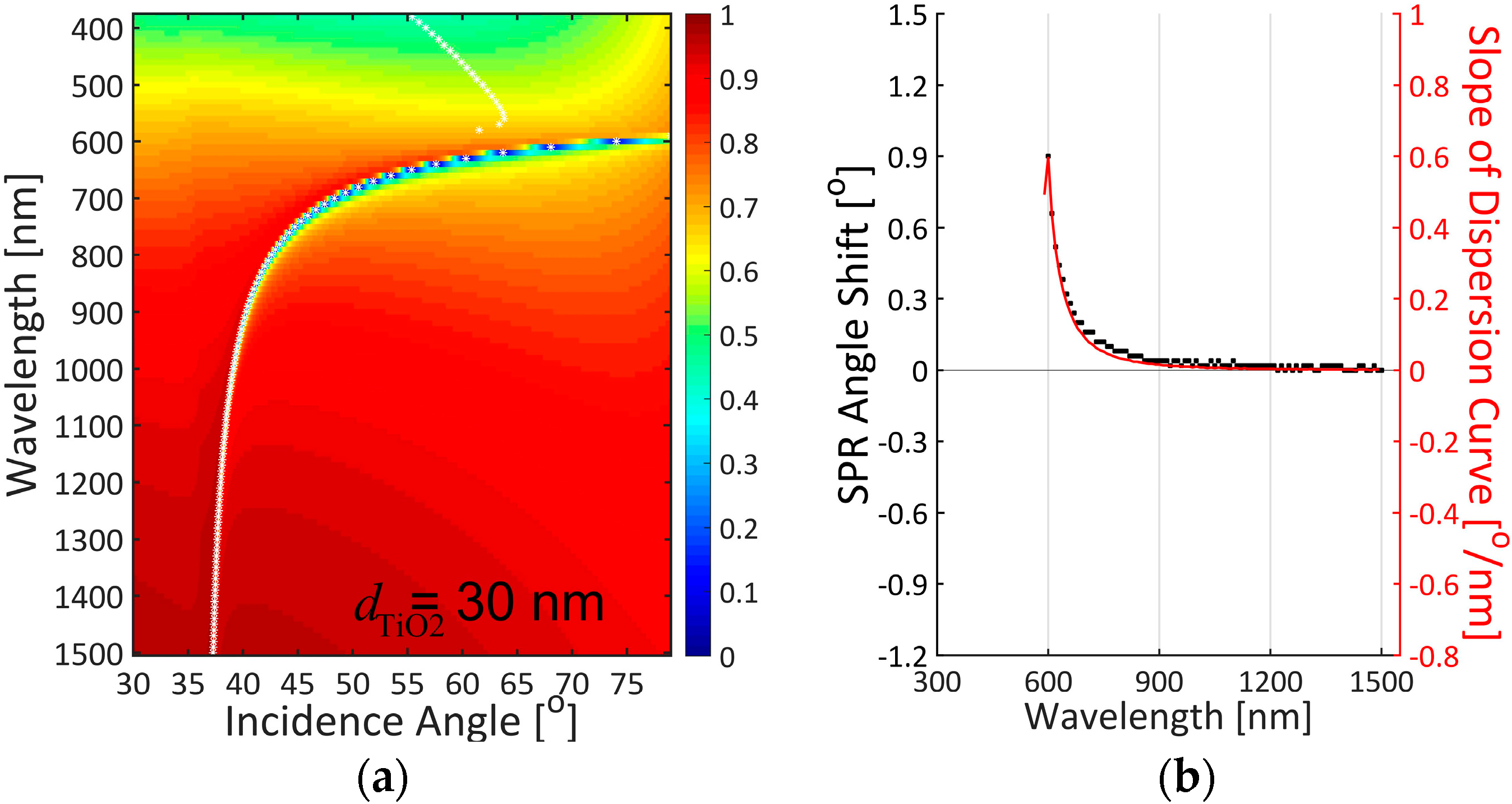

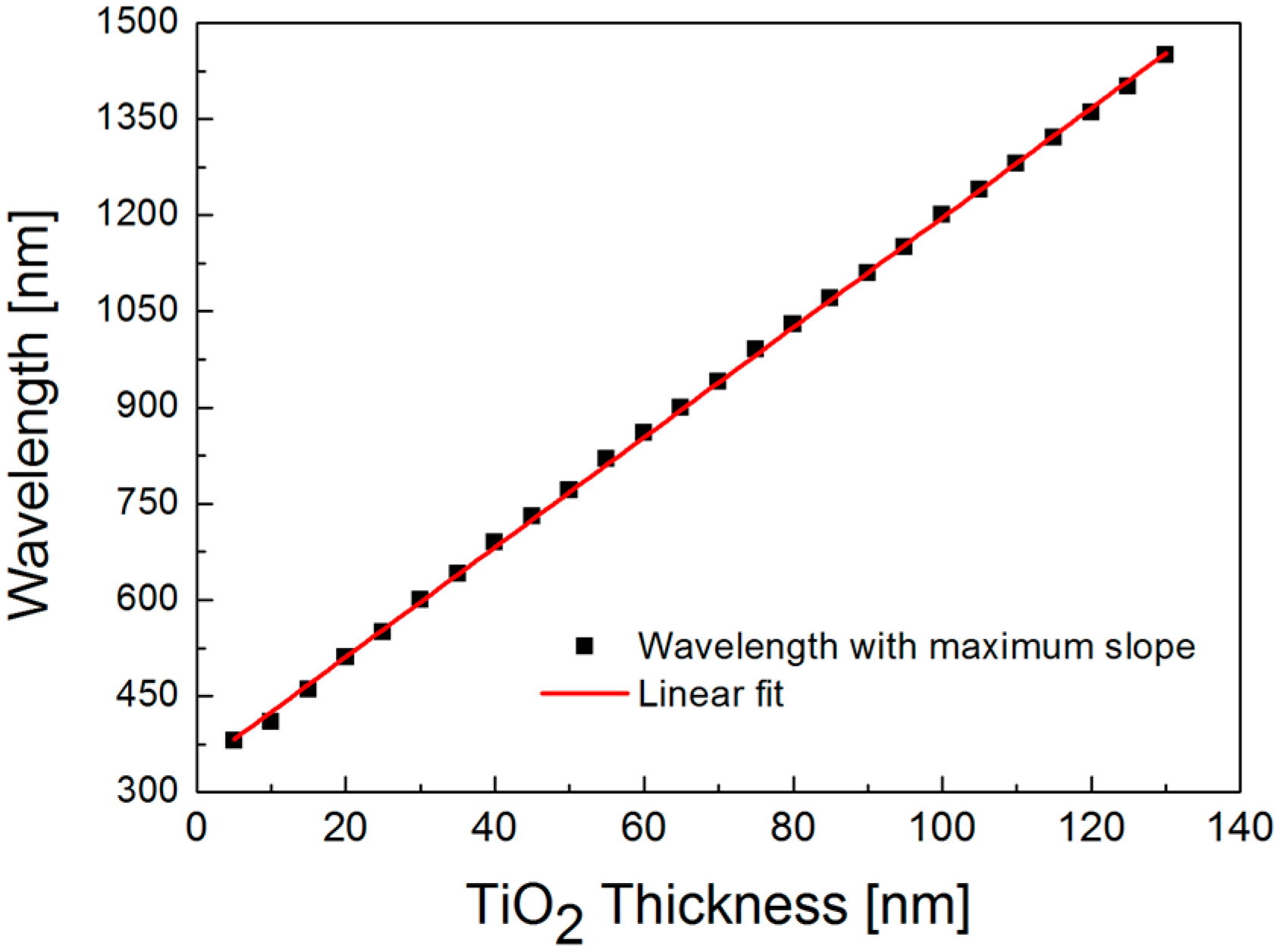

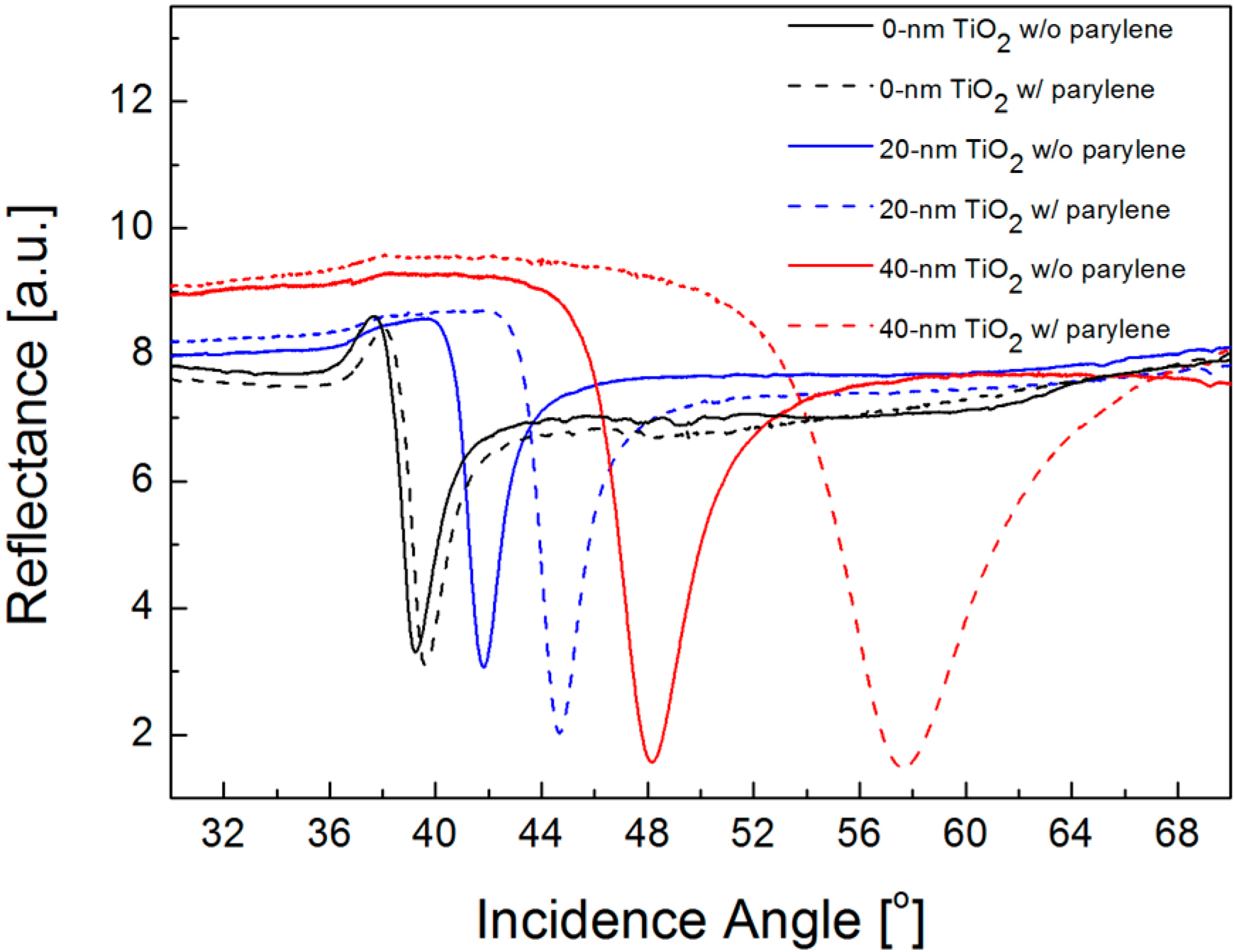

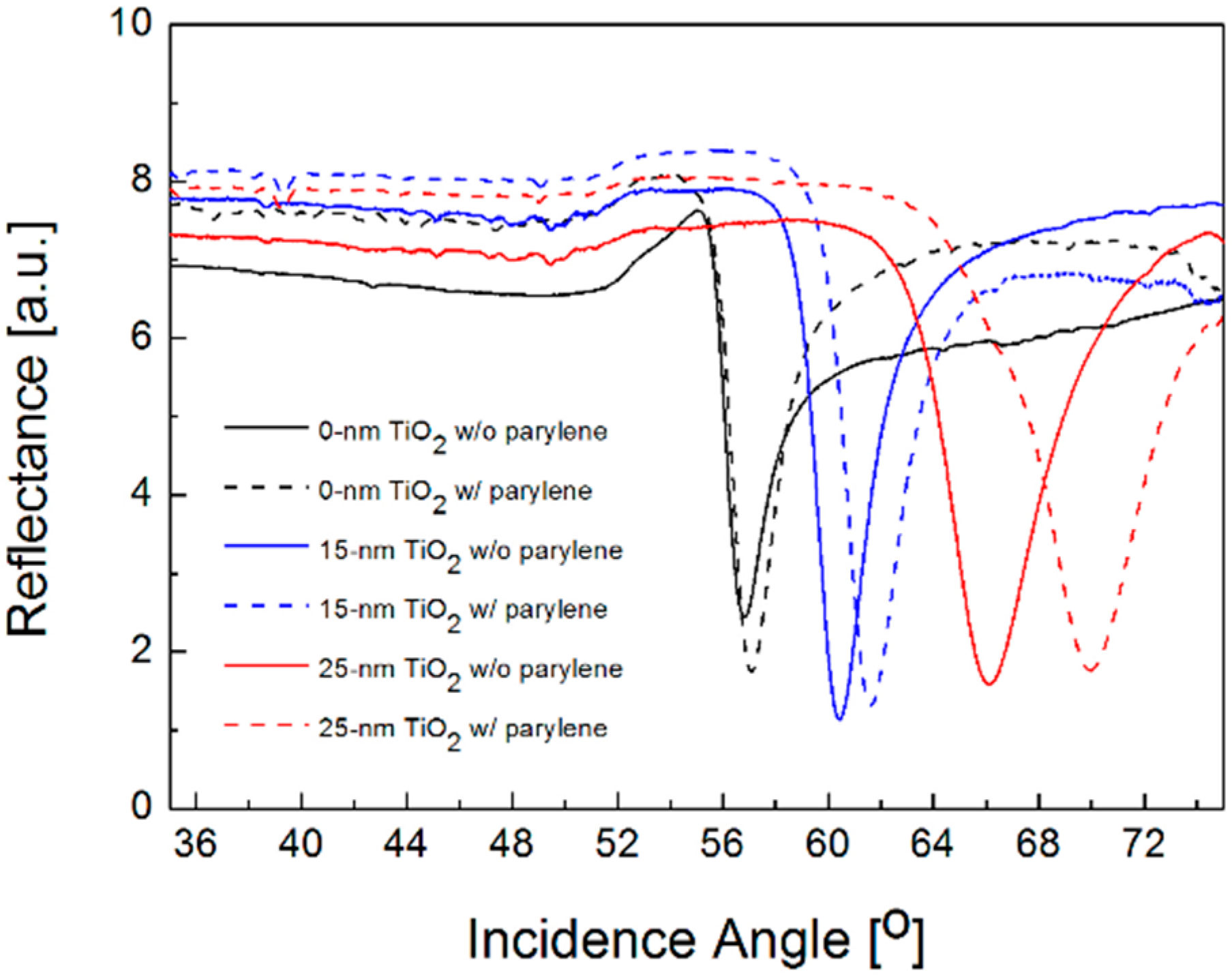

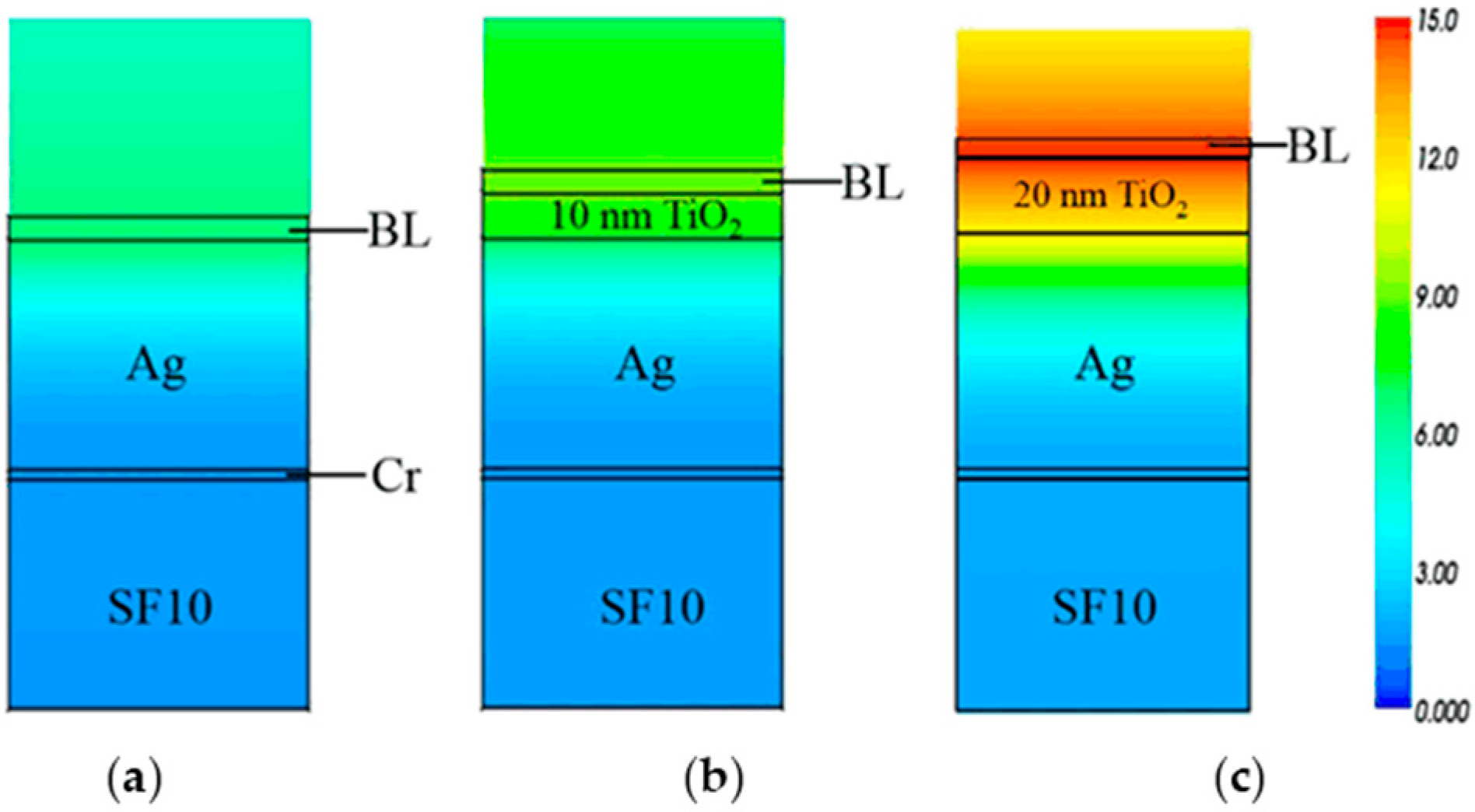

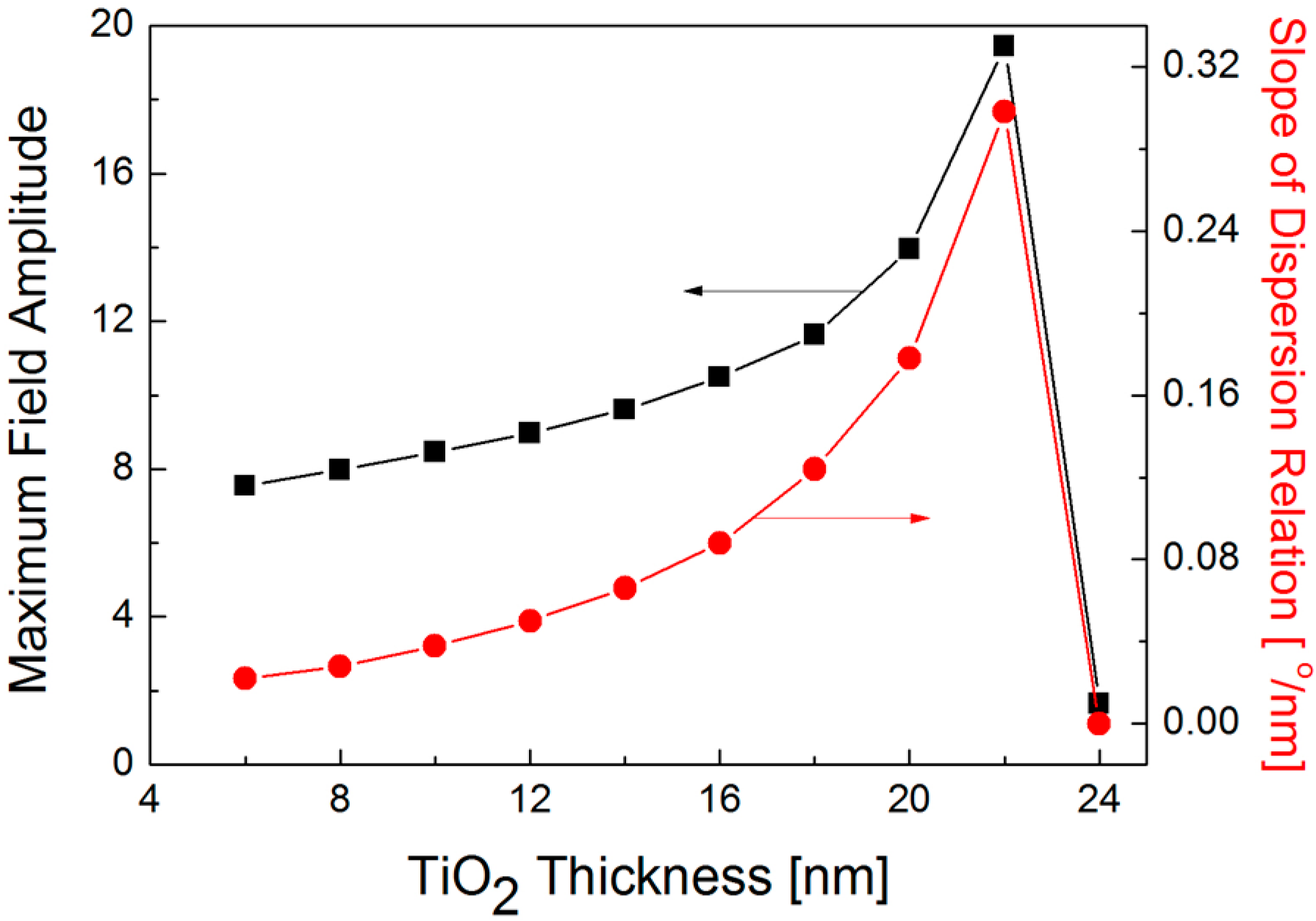

4. Results and Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Homola, J.; Yee, S.S.; Gauglitz, G. Surface Plasmon Resonance Sensors: Review. Sens. Actuators B Chem. 1999, 54, 3–15. [Google Scholar] [CrossRef]

- Lahav, A.; Auslender, M.; Abdulhalim, I. Sensitivity Enhancement of Guide-Wave Surface-Plasmon Resonane Sensors. Opt. Lett. 2008, 33, 2539–2541. [Google Scholar] [CrossRef] [PubMed]

- Ciminelli, C.; Campanella, C.M.; Dell’Olio, F.; Campanella, C.E.; Armenise, M.N. Label-Free Optical Resonant Sensors for Biochemical Applications. Prog. Quantum Electron. 2013, 37, 51–107. [Google Scholar] [CrossRef]

- Guo, X. Surface Plasmon Resonance Based Biosensor Technique: A Review. J. Biophotonics 2012, 5, 483–501. [Google Scholar] [CrossRef] [PubMed]

- Rich, R.L.; Myszka, D.G. Advances in Surface Plasmon Resonance Biosensor Analysis. Curr. Opin. Biotechnol. 2000, 11, 54–61. [Google Scholar] [CrossRef]

- Adamczyk, M.; Moore, J.A.; Yu, Z. Application of Surface Plasmon Resonance toward Studies of Low-Molecular-Weight Antigen-Antibody Binding Interactions. Methods 2000, 20, 319–328. [Google Scholar] [CrossRef] [PubMed]

- Englebienne, P.; Van Hoonacker, A.; Verhas, M. Surface Plasmon Resonance: Principles, Methods and Applications in Biomedical Sciences. Spectroscopy 2003, 17, 255–273. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Sensitivity Enhancement Methods for Surface Plasmon Sensors. Lasers Photonics Rev. 2011, 5, 571–606. [Google Scholar] [CrossRef]

- Homola, J. Surface Plasmon Resonance Sensors for Detection of Chemical and Biological Species. Chem. Rev. 2008, 108, 462–493. [Google Scholar] [CrossRef] [PubMed]

- Nelson, S.G.; Johnston, K.S.; Yee, S.S. High Sensitivity Surface Plasmon Resonance Sensor Based on Phase Detection. Sens. Actuators B Chem. 1996, 35, 187–191. [Google Scholar] [CrossRef]

- Kooyman, R.P.H.; Kolkman, H.; Van Gent, J.; Greve, J. Surface Plasmon Resonance Immunosensors: Sensitivity Considerations. Anal. Chim. Acta 1988, 213, 35–45. [Google Scholar] [CrossRef]

- Zynio, S.; Samoylov, A.V.; Surovtseva, E.R.; Mirsky, V.M.; Shirshov, Y.M. Bimetallic Layers Increase Sensitivity of Affinity Sensors Based on Surface Plasmon Resonance. Sensors 2002, 2, 62–70. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, R.S.; Zhang, D.G.; Lu, Y.H.; Wang, P.; Ming, H.; Luo, Z.F.; Kan, Q. Bimetallic Chips for a Surface Plasmon Resonance Instrument. Appl. Opt. 2011, 50, 387–391. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.H.; Kim, Y.L.; Byun, K.M. Graphene-on-Silver Substrates for Sensitive Surface Plasmon Resonance Imaging Biosensors. Opt. Express 2011, 19, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Szunerits, S.; Castel, X.; Boukherroub, R. Surface Plasmon Resonance Investigation of Silver and Gold Films Coated with Thin Indium Tin Oxide Layers: Influence on Stability and Sensitivity. J. Phys. Chem. C 2008, 112, 15813–15817. [Google Scholar] [CrossRef]

- Franzen, S.; Rhodes, C.; Cerruti, M.; Gerber, R.W.; Losego, M.; Maria, J.-P.; Aspnes, D.E. Plasmonic Phenomena in Indium Tin Oxide and ITO-Au Hybrid Films. Opt. Lett. 2009, 34, 2867–2869. [Google Scholar] [CrossRef] [PubMed]

- Lahav, A.; Shalabaney, A.; Abdulhalim, I. Surface Plasmon Sensor with Enhanced Sensitivity Using Top Nano Dielectric Layer. J. Nanophotonics 2009, 3, 031501. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Figure of Merit Enhancement of Surface Plasmon Resonance Sensors in the Spectral Interrogation. Opt. Lett. 2012, 37, 1175–1177. [Google Scholar] [CrossRef] [PubMed]

- Szunerits, S.; Shalabney, A.; Boukherroub, R.; Abdulhalim, I. Dielectric Coated Plasmonic Interfaces: Their Interest for Sensitive Sensing of Analyte-Ligand Interactions. Rev. Anal. Chem. 2012, 31, 15–28. [Google Scholar] [CrossRef]

- Jin, Z.; Guanb, W.; Liu, C.; Xue, T.; Wanga, Q.; Zheng, W.; Cui, X. A Stable and High Resolution Optical Waveguide Biosensor Based on Dense TiO2/Ag Multilayer Film. App. Surf. Sci. 2016, 377, 207–212. [Google Scholar] [CrossRef]

- El-Gohary, S.H.; Eom, S.; Lee, S.Y.; Byun, K.M. Dispersion Curve-Based Sensitivity Engineering for Enhanced Surface Plasmon Resonance Detection. Opt. Commun. 2016, 370, 299–305. [Google Scholar] [CrossRef]

- El-Gohary, S.H.; Kim, N.-H.; Byun, K.M. Optical Determination of Thick Graphene Layer Number Based on Surface Plasmon Resonance. J. Nanophotonics 2013, 7, 073799. [Google Scholar] [CrossRef]

- Devore, J.R. Refractive indices of rutile and sphalerite. J. Opt. Soc. Am. 1951, 41, 416–419. [Google Scholar] [CrossRef]

- Rakic, D.; Djurisic, B.; Elazar, J.M.; Majewski, M.L. Optical Properties of Metallic Films for Vertical-Cavity Optoelectronic Devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef] [PubMed]

- Jahanshahi, P.; Ghomeishi, M.; Adikan, F.R.M. Study on Dielectric Function Models for Surface Plasmon Resonance Structure. Sci. World J. 2014, 1, 503749–503755. [Google Scholar] [CrossRef] [PubMed]

- Bareiß, M.; Kälblein, D.; Jirauschek, C.; Exner, A.; Pavlichenko, I.; Lotsch, B.; Zschieschang, U.; Klauk, H.; Scarpa, G.; Fabel, B.; et al. Ultra-Thin Titanium Oxide. Appl. Phys. Lett. 2012, 101, 083113. [Google Scholar] [CrossRef]

- Jeon, B.J.; Kim, M.H.; Pyun, J.C. Application of a Functionalized Parylene Film as a Linker Layer of SPR Biosensor. Procedia Chem. 2009, 1, 1035–1038. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Lee, G.-Y.; Ko, H.; Chang, Y.W.; Kang, M.-J.; Pyun, J.C. Development of SPR Biosensor for the Detection of Human Hepatitis B Virus Using Plasma-Treated Parylene-N Film. Biosens. Bioelectron. 2014, 56, 286–294. [Google Scholar] [CrossRef] [PubMed]

- Read, T.; Olkhov, R.V.; Shaw, A.M. Measurement of the Localized Plasmon Penetration Depth for Gold Nanoparticles Using a Non-Invasive Bio-Stacking Method. Phys. Chem. Chem. Phys. 2013, 15, 6122–6129. [Google Scholar] [CrossRef] [PubMed]

- Zheludkevich, M.L.; Gusakov, A.G.; Voropaev, A.G.; Vecher, A.A.; Kozyrski, E.N.; Raspopov, S.A. Oxidation of Silver by Atomic Oxygen. Oxid. Met. 2004, 61, 39–48. [Google Scholar] [CrossRef]

- Choi, S.H.; Byun, K.M. Investigation on an Application of Silver Substrates for Sensitive Surface Plasmon Resonance Imaging Detection. J. Opt. Soc. Am. A 2010, 27, 2229–2236. [Google Scholar] [CrossRef] [PubMed]

- Ozaki, M.; Kato, J.; Kawata, S. Surface-Plasmon Holography with White-Light Illumination. Science 2011, 332, 218–220. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.-H.; Jung, W.K.; Byun, K.M. Correlation Analysis between Plasmon Field Distribution and Sensitivity Enhancement in Reflection- and Transmission-Type Localized Surface Plasmon Resonance Biosensors. Appl. Opt. 2011, 50, 4982–4988. [Google Scholar] [CrossRef]

- Ma, X.-C.; Dai, Y.; Yu, L.; Huang, B.-B. Energy Transfer in Plasmonic Photocatalytic Composites. Light 2016, 5, e16017. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Gohary, S.H.; Choi, M.; Kim, Y.L.; Byun, K.M. Dispersion Curve Engineering of TiO2/Silver Hybrid Substrates for Enhanced Surface Plasmon Resonance Detection. Sensors 2016, 16, 1442. https://doi.org/10.3390/s16091442

El-Gohary SH, Choi M, Kim YL, Byun KM. Dispersion Curve Engineering of TiO2/Silver Hybrid Substrates for Enhanced Surface Plasmon Resonance Detection. Sensors. 2016; 16(9):1442. https://doi.org/10.3390/s16091442

Chicago/Turabian StyleEl-Gohary, Sherif H., Munsik Choi, Young L. Kim, and Kyung Min Byun. 2016. "Dispersion Curve Engineering of TiO2/Silver Hybrid Substrates for Enhanced Surface Plasmon Resonance Detection" Sensors 16, no. 9: 1442. https://doi.org/10.3390/s16091442

APA StyleEl-Gohary, S. H., Choi, M., Kim, Y. L., & Byun, K. M. (2016). Dispersion Curve Engineering of TiO2/Silver Hybrid Substrates for Enhanced Surface Plasmon Resonance Detection. Sensors, 16(9), 1442. https://doi.org/10.3390/s16091442