Using Custom Fiber Bragg Grating-Based Sensors to Monitor Artificial Landslides

Abstract

:1. Introduction

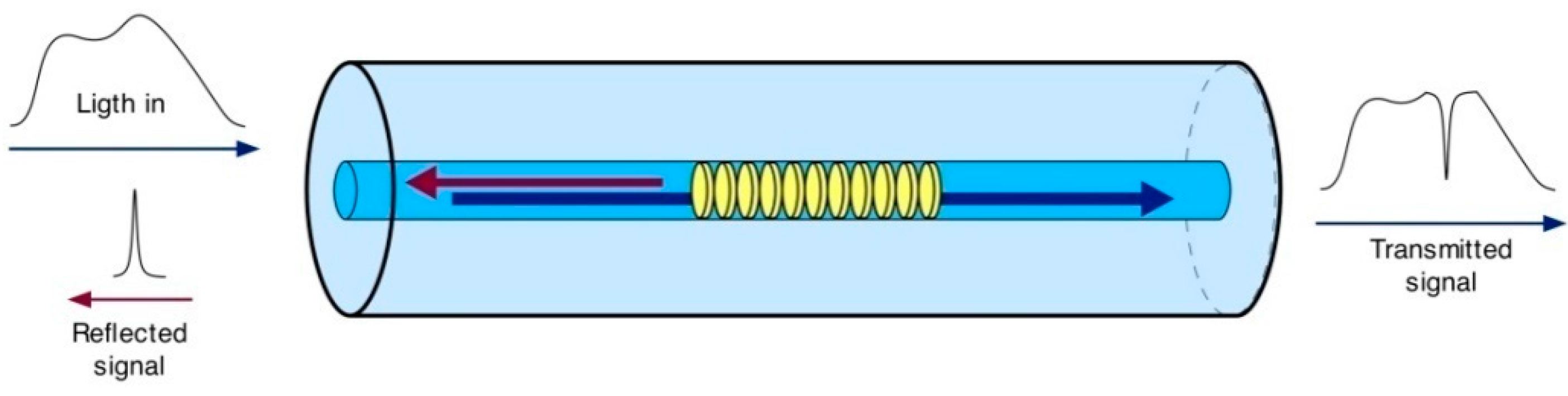

2. Principle of FBG Sensing Technology

3. Design and Calibration of FBG-Based Sensors

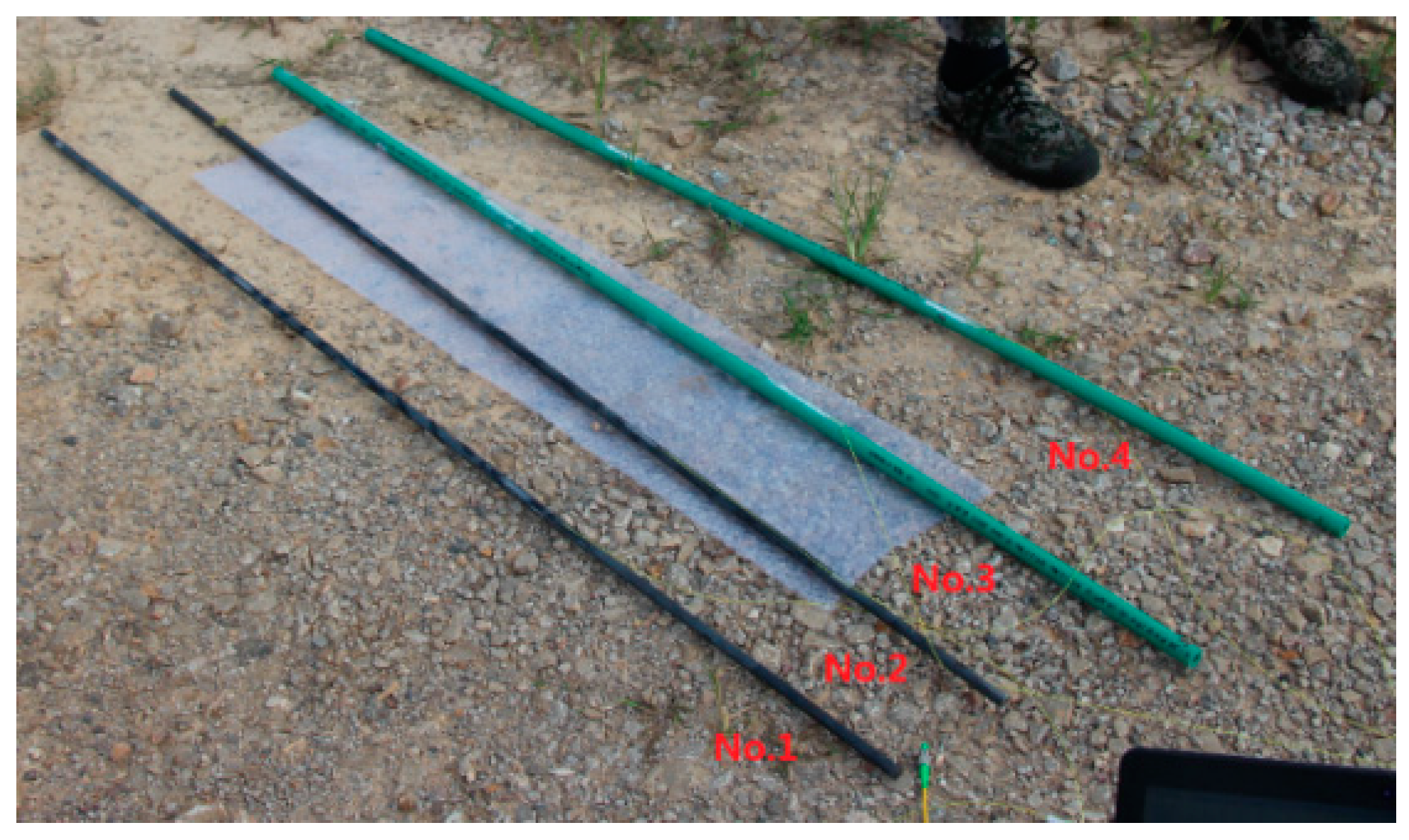

3.1. Design and Packaging Technology of FBG-Based Sensors

- Step1: Loctite 401 multi-purpose super strong instant adhesive glue is used to fix two fiber gratings onto the rod (steel/plastic) of a sensor.

- Step2: In order to prevent the sensors from being damaged during the experiment, any bare fiber is coated with epoxy resin as shown in Figure 3.

- Step3: After the solidification of the epoxy resin, nylon protective cloth is used to protect the rod of the sensor by using the winding reinforcement scheme shown in Figure 4.

- Step4: Lastly, adhesive tape is used to ensure the smoothness of each rod, as shown in Figure 5.

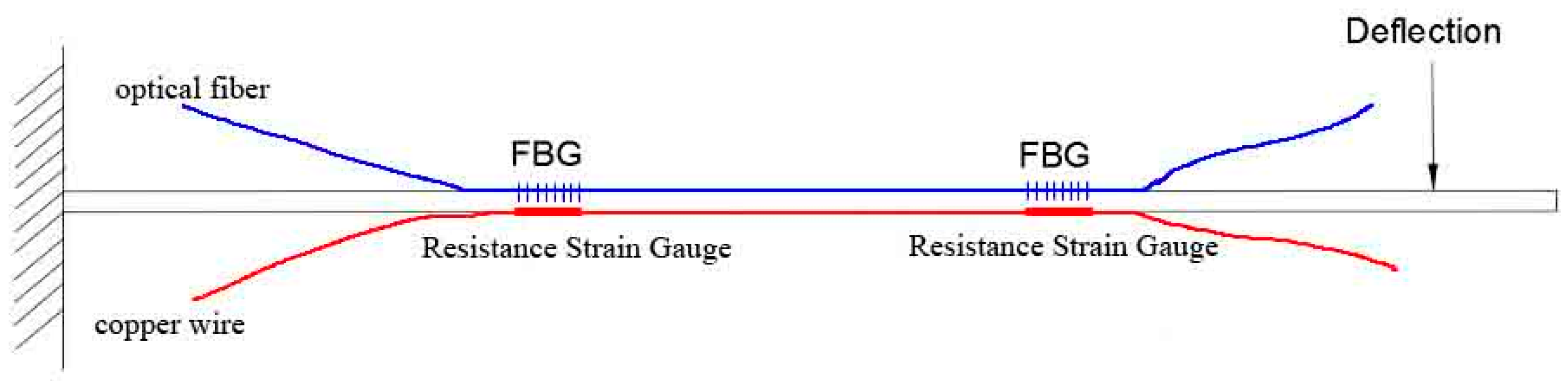

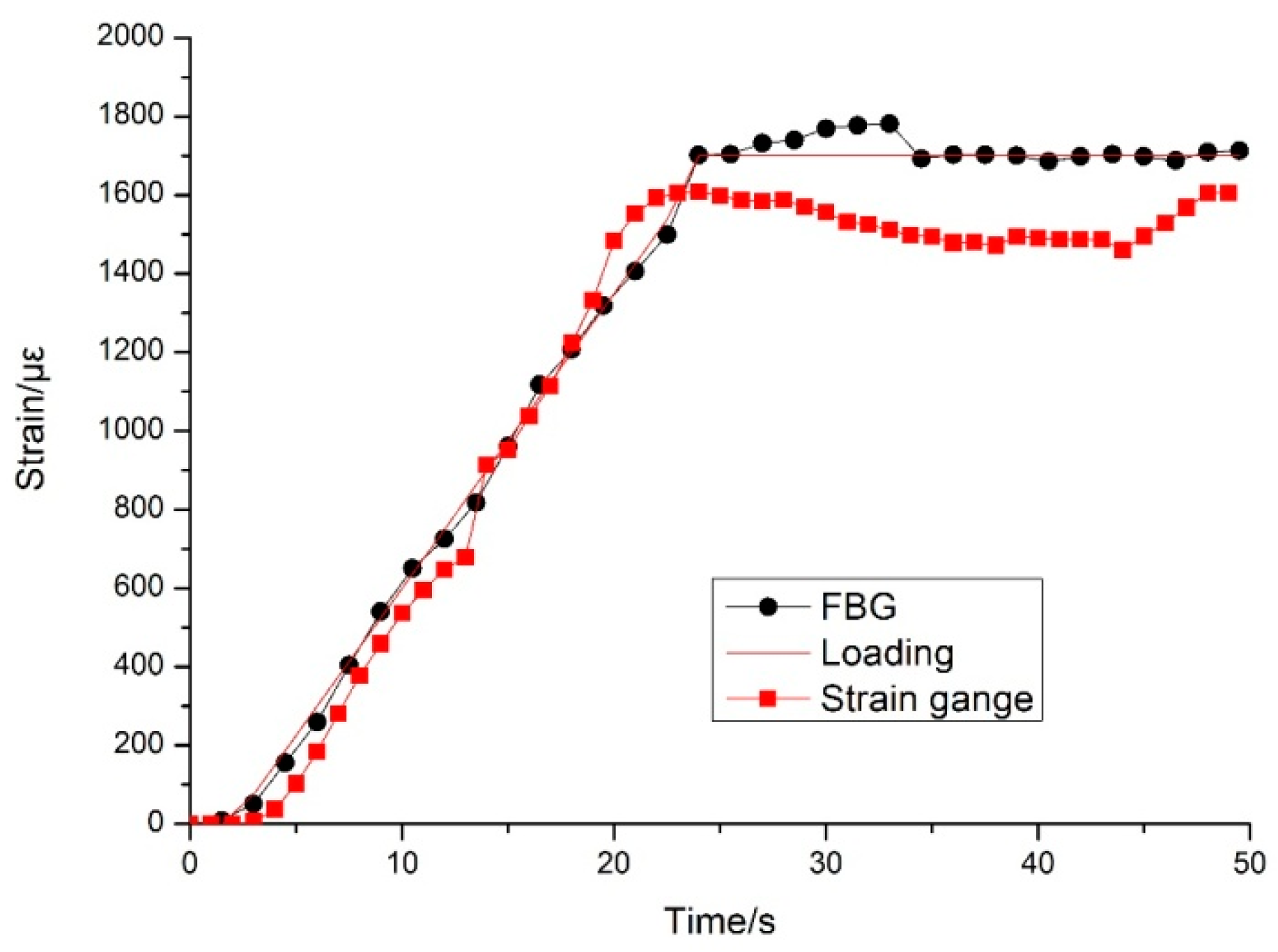

3.2. Sensor Calibration

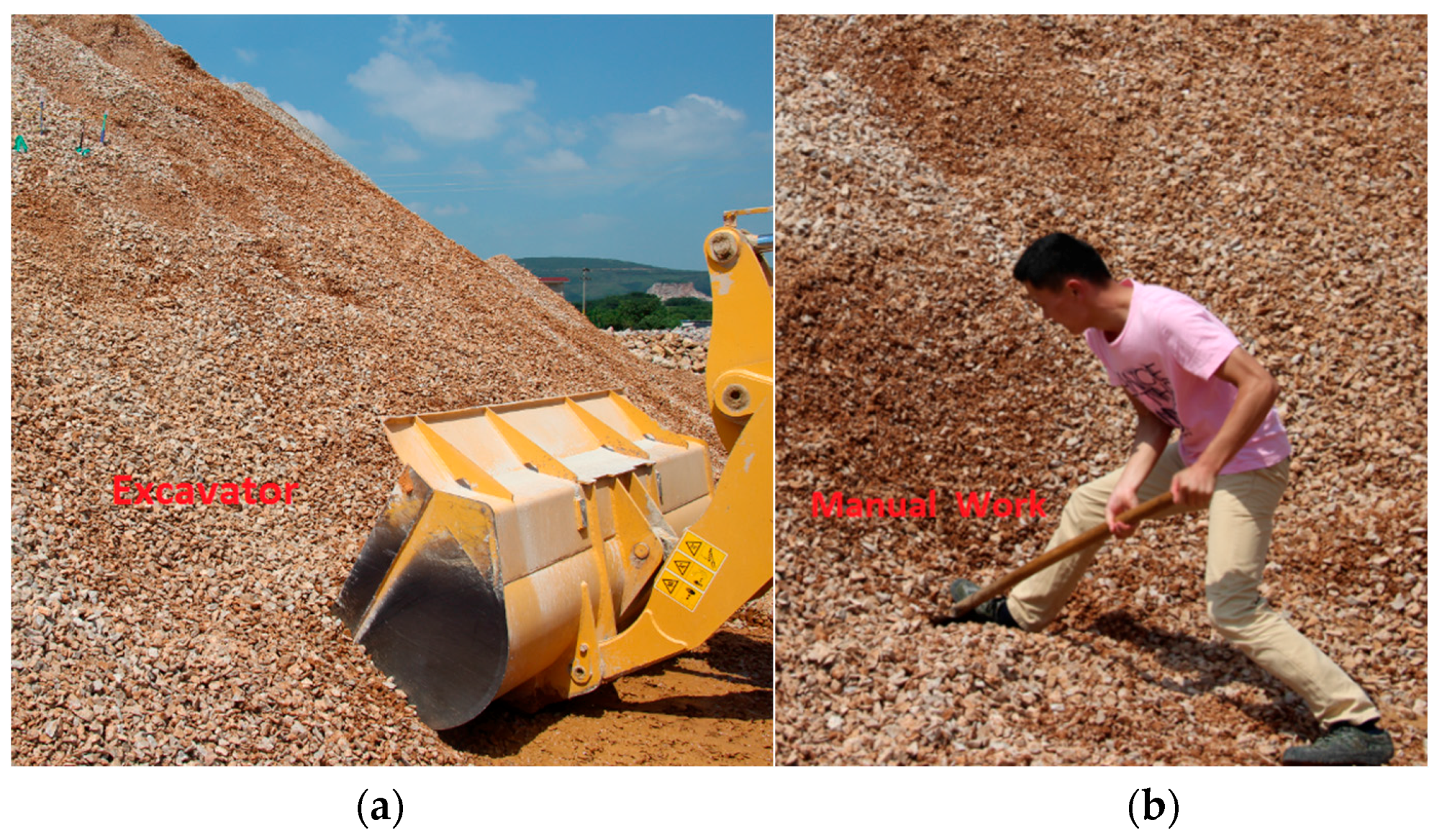

4. Experiment Results of Artificial Landslides Monitoring

- (1)

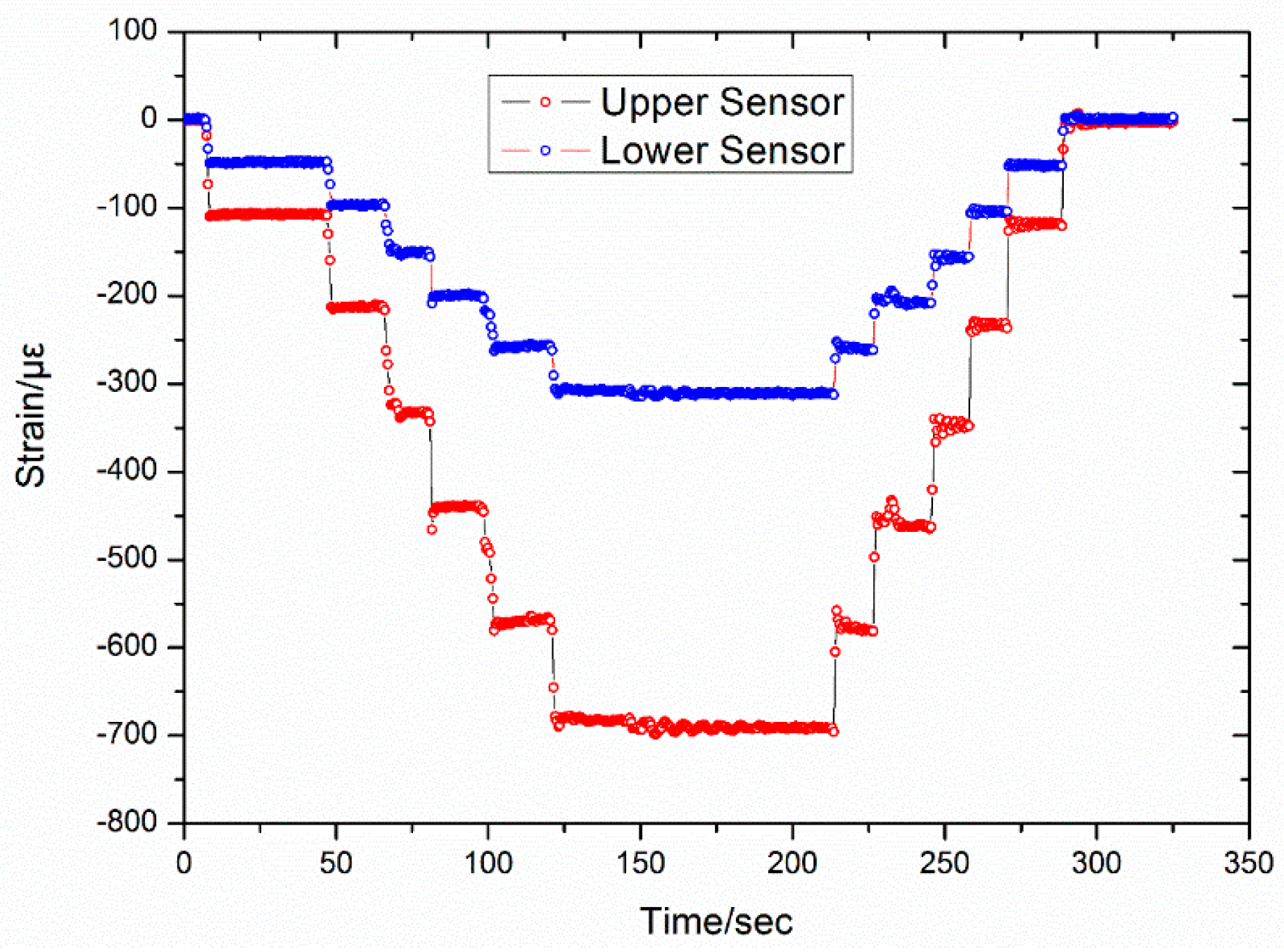

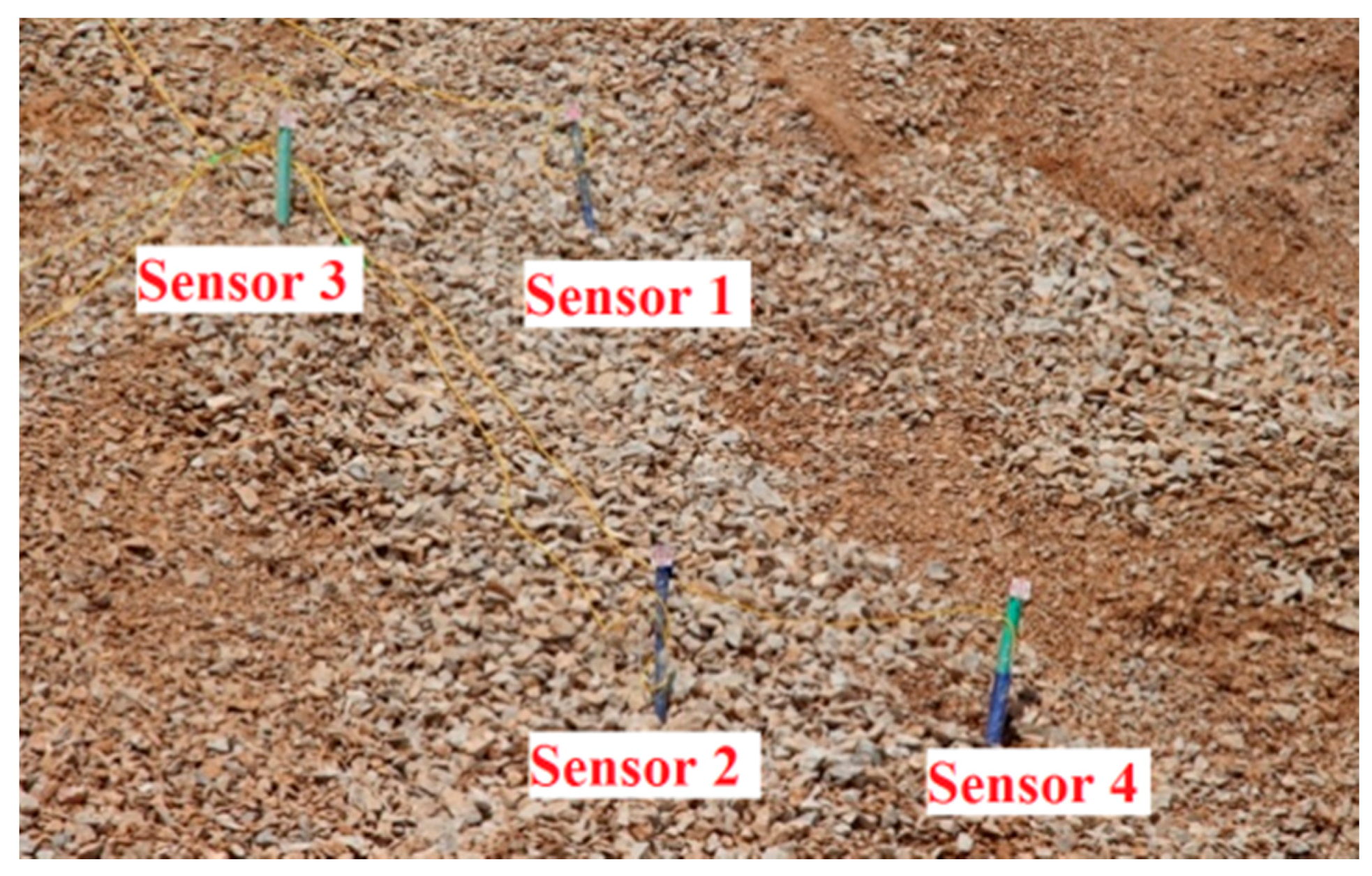

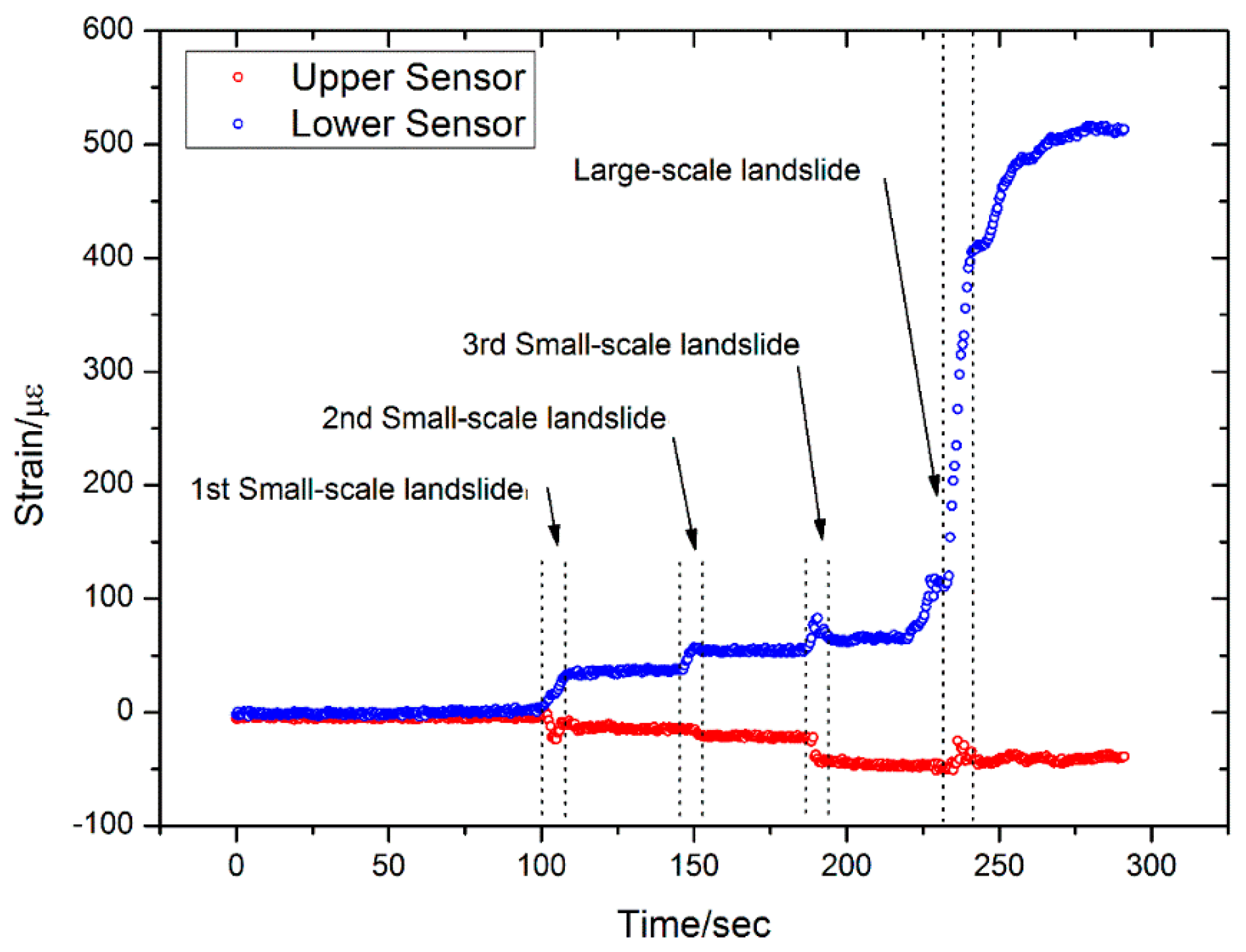

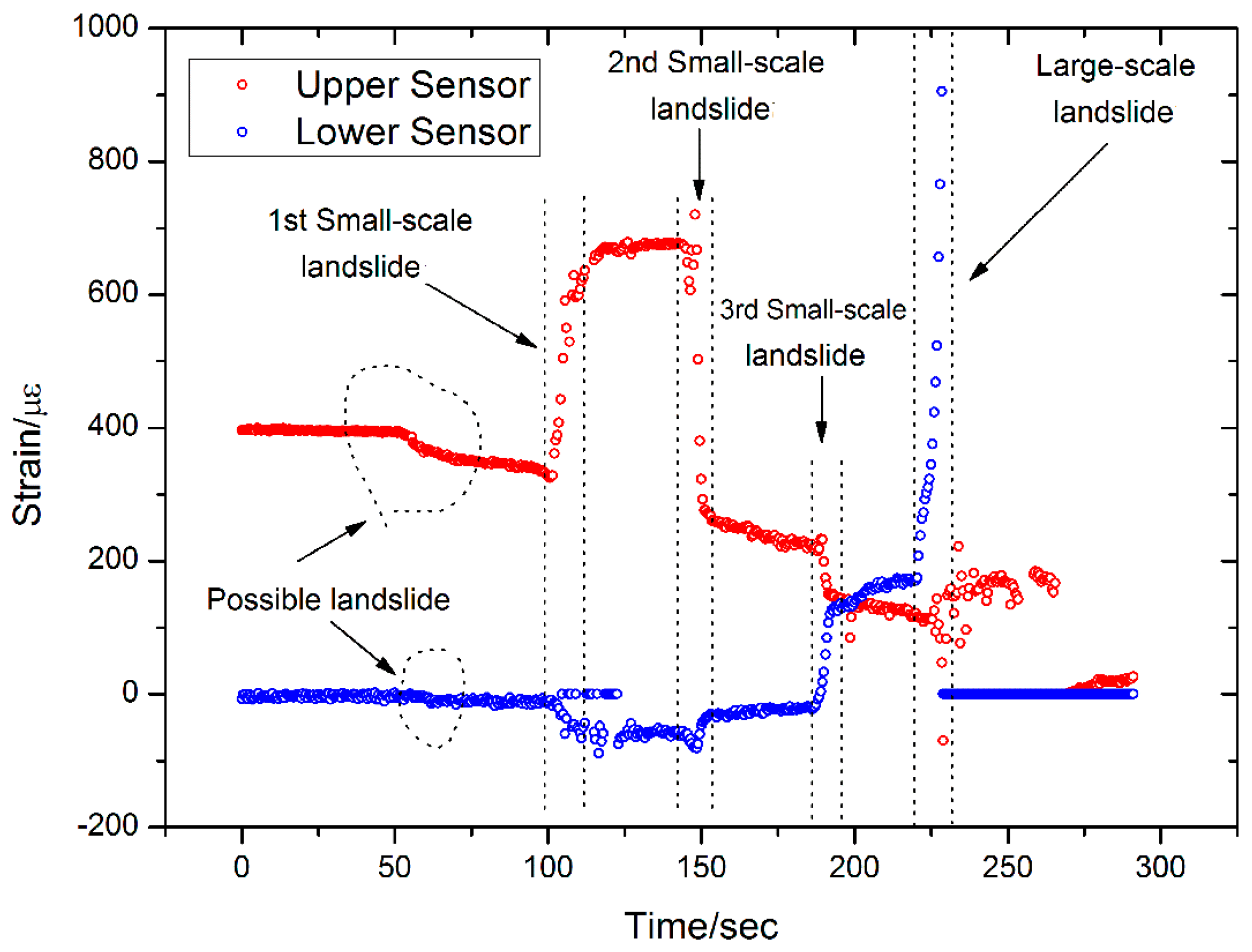

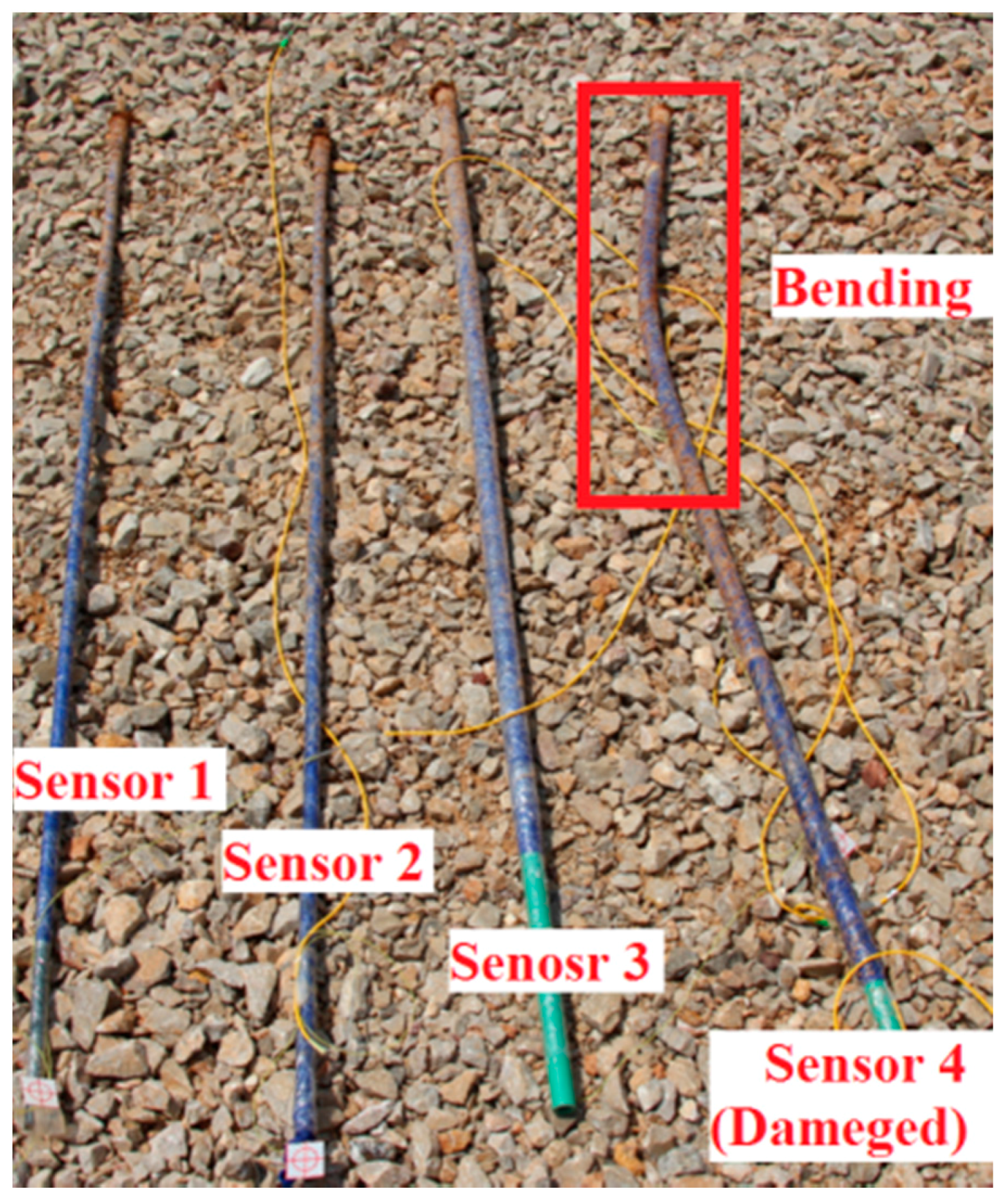

- Better results are obtained when monitoring small-scale landslides near the landslide body, such as with Sensors 2 and 4. In contrast, the sensors those are located some distance away from the landslide body can only detect the large-scale landslide. Several possible small-scale and large-scale landslides have been measured with Sensors 2 and 4.

- (2)

- (3)

- (4)

- When the sensor is located far away from the landslide body, small-scale landslides are almost impossible to detect with hard sensors. However, the soft sensors can be used as comparative devices as they can detect a varying trend of strain in the landslide body, which is very critical for early landslide warnings.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sassa, K.; Tsuchiya, S.; Ugai, K.; Wakai, A.; Uchimura, T. Landslides: A review of achievements in the first 5 years (2004–2009). Landslides 2009, 6, 275–286. [Google Scholar] [CrossRef]

- Yalcinkaya, M.; Bayrak, T. Dynamic model for monitoring landslides with emphasis on underground water in Trabzon Province, Northeastern Turkey. J. Surv. Eng. 2014, 129, 115–124. [Google Scholar] [CrossRef]

- Gili, J.A.; Corominas, J.; Rius, J. Using Global Positioning System techniques in landslide monitoring. Eng. Geol. 2000, 55, 167–192. [Google Scholar] [CrossRef]

- Teke, K.; Yalçınkaya, M.; Konak, H. Optimization of GPS networks for landslide areas. Fresen. Environ. Bull. 2008, 17, 664–675. [Google Scholar]

- Alizadeh-Khameneh, M.A.; Eshagh, M.; Sjöberg, L.E. Optimisation of Lilla Edet landslide GPS monitoring network. J. Geodetic Sci. 2015, 5, 57–66. [Google Scholar] [CrossRef]

- Liu, W.; Song, Y.; Tang, J.; Zhu, J. Mathematical model research on landslide monitoring through GPS. J. Cent. South Univ. Technol. 2006, 13, 456–460. [Google Scholar] [CrossRef]

- Tu, P.; Peng, H.; Li, H.; Xia, L. GPS monitoring and warning example of Bazimen landslide engineering. Adv. Mater. Res. 2012, 479–481, 2471–2476. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, Q.; Zhou, J.; Deng, M. Remote landslide observation system with differential GPS. Proc. Earth Planet. Sci. 2012, 5, 70–75. [Google Scholar] [CrossRef]

- Iwasaki, T.; Arakawa, T.; Nakazato, H.; Masunari, T.; Shimizu, N. Development of a displacement monitoring system using GPS for installation immediately after a large-scale landslide. Landslides 2011, 48, 100–106. [Google Scholar] [CrossRef]

- Abe, T.; Sato, H.; Oikawa, N.; Shoji, A.; Takami, T. Consideration of movement mechanism of YACHI landslide by GPS observation. Landslides 2005, 42, 343–349. [Google Scholar] [CrossRef]

- Bozzano, F.; Cipriani, I.; Mazzanti, P.; Prestininzi, A. Displacement patterns of a landslide affected by human activities: Insights from ground-based InSAR monitoring. Nat. Hazards 2011, 59, 1377–1396. [Google Scholar] [CrossRef]

- Colesanti, C.; Wasowski, J. Investigating landslides with space-borne Synthetic Aperture Radar (SAR) interferometry. Eng. Geol. 2006, 88, 173–199. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, H. Remote sensing of landslides: An analysis of the potential contribution to geo-spatial systems for hazard assessment in mountainous environments. Remote Sens. Environ. 2005, 98, 284–303. [Google Scholar]

- Tralli, D.; Blom, R.; Zlotnicki, V.; Donnellan, A.; Evans, D. Satellite remote sensing of earthquake, volcano, flood, landslide and coastal inundation hazards. ISPRS J. Photogramm. 2005, 59, 185–198. [Google Scholar] [CrossRef]

- Jaboyedoff, M.; Oppikofer, T.; Abellán, A.; Derron, M.; Loye, A.; Metzger, R.; Pedrazzini, A. Use of LIDAR in landslide investigations: A review. Nat. Hazards 2012, 61, 5–28. [Google Scholar] [CrossRef]

- Singleton, A.; Li, Z.; Hoey, T.; Muller, J. Evaluating sub-pixel offset techniques as an alternative to D-InSAR for monitoring episodic landslide movements in vegetated terrain. Remote Sens. Environ. 2014, 147, 133–144. [Google Scholar] [CrossRef]

- Xu, J.; Yang, D.; Qin, C.; Jiang, Y.; Sheng, L.; Jia, X.; Bai, Y.; Shen, X.; Wang, H.; Deng, X.; et al. Study and test of a new bundle-structure riser stress monitoring sensor based on FBG. Sensors 2015, 15, 29648–29660. [Google Scholar] [CrossRef] [PubMed]

- Pei, H.; Yin, J.; Zhu, H.; Cheng, Y.; Jin, Y.; Dong, S. Monitoring of lateral displacements of a slope using a series of special fibre Bragg grating-based in-place inclinometers. Meas. Sci. Technol. 2012, 23, 25007–25014. [Google Scholar] [CrossRef]

- Ho, Y.; Huang, A.; Lee, J. Development of a fibre Bragg grating sensored ground movement monitoring system. Meas. Sci. Technol. 2006, 17, 1733–1740. [Google Scholar] [CrossRef]

- Ramesh, M.; Vasudevan, N. The deployment of deep-earth sensor probes for landslide detection. Landslides 2012, 9, 457–474. [Google Scholar] [CrossRef]

- Pei, H.; Peng, C.; Yin, J.; Zhu, H.; Chen, X.; Pei, L. Monitoring and warning of landslides and debris flows using an optical fiber sensor technology. J. Mt. Sci. 2011, 8, 728–738. [Google Scholar] [CrossRef]

- Huntley, D.; Bobrowsky, P.; Zhang, Q.; Zhang, Q.; Slad, W.; Bunce, C.; Edwards, T.; Hendry, M.; Choi, E.; Martin, D. Fiber optic strain monitoring and evaluation of a slow-moving landslide near ashcroft, British Columbia, Canada. In Proceedings of the World Landslide Forum 3, Beijing, China, 2–6 June 2014; pp. 415–421.

- Liehr, S.; Wendt, M.; Krebber, K. Distributed strain measurement in perfluorinated polymer optical fibres using optical frequency domain reflectometry. Meas. Sci. Technol. 2010. [Google Scholar] [CrossRef]

- Zhu, H.; Ho, A.; Yin, J.; Hong, C. An optical fibre monitoring system for evaluating the performance of a soil nailed slope. Smart Struct. Syst. 2012, 9, 393–410. [Google Scholar] [CrossRef]

- Song, Z.; Shi, B.; Juang, H.; Shen, M.; Zhu, H. Soil strain-field and stability analysis of cut slope based on optical fiber measurement. Bull. Eng. Geol. Environ. 2016. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

| Radius/mm | 5–10 | 10–15 | 15–20 | 20–30 |

| Mass Percent/% | 8.2 | 20.4 | 31.9 | 39.5 |

| Landslide Type | Far from the Landslide Body | Near the Landslide Body | |||

|---|---|---|---|---|---|

| Sensor 1 | Sensor 3 | Sensor 2 | Sensor 4 | ||

| Possible | 1 | None | None | None | Detectable |

| Small-Scale | 2 | None | A trend of destruction | Detectable | Detectable |

| 3 | None | Detectable | Detectable | ||

| 4 | None | Detectable | Detectable | ||

| Large-Scale | 5 | Detectable | Detectable | Detectable | Detectable |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Wang, Y.; Sun, Y.; Gao, L.; Zhang, Z.; Zhang, W.; Zhao, P.; Yue, Y. Using Custom Fiber Bragg Grating-Based Sensors to Monitor Artificial Landslides. Sensors 2016, 16, 1417. https://doi.org/10.3390/s16091417

Zhang Q, Wang Y, Sun Y, Gao L, Zhang Z, Zhang W, Zhao P, Yue Y. Using Custom Fiber Bragg Grating-Based Sensors to Monitor Artificial Landslides. Sensors. 2016; 16(9):1417. https://doi.org/10.3390/s16091417

Chicago/Turabian StyleZhang, Qinghua, Yuan Wang, Yangyang Sun, Lei Gao, Zhenglin Zhang, Wenyuan Zhang, Pengchong Zhao, and Yin Yue. 2016. "Using Custom Fiber Bragg Grating-Based Sensors to Monitor Artificial Landslides" Sensors 16, no. 9: 1417. https://doi.org/10.3390/s16091417

APA StyleZhang, Q., Wang, Y., Sun, Y., Gao, L., Zhang, Z., Zhang, W., Zhao, P., & Yue, Y. (2016). Using Custom Fiber Bragg Grating-Based Sensors to Monitor Artificial Landslides. Sensors, 16(9), 1417. https://doi.org/10.3390/s16091417