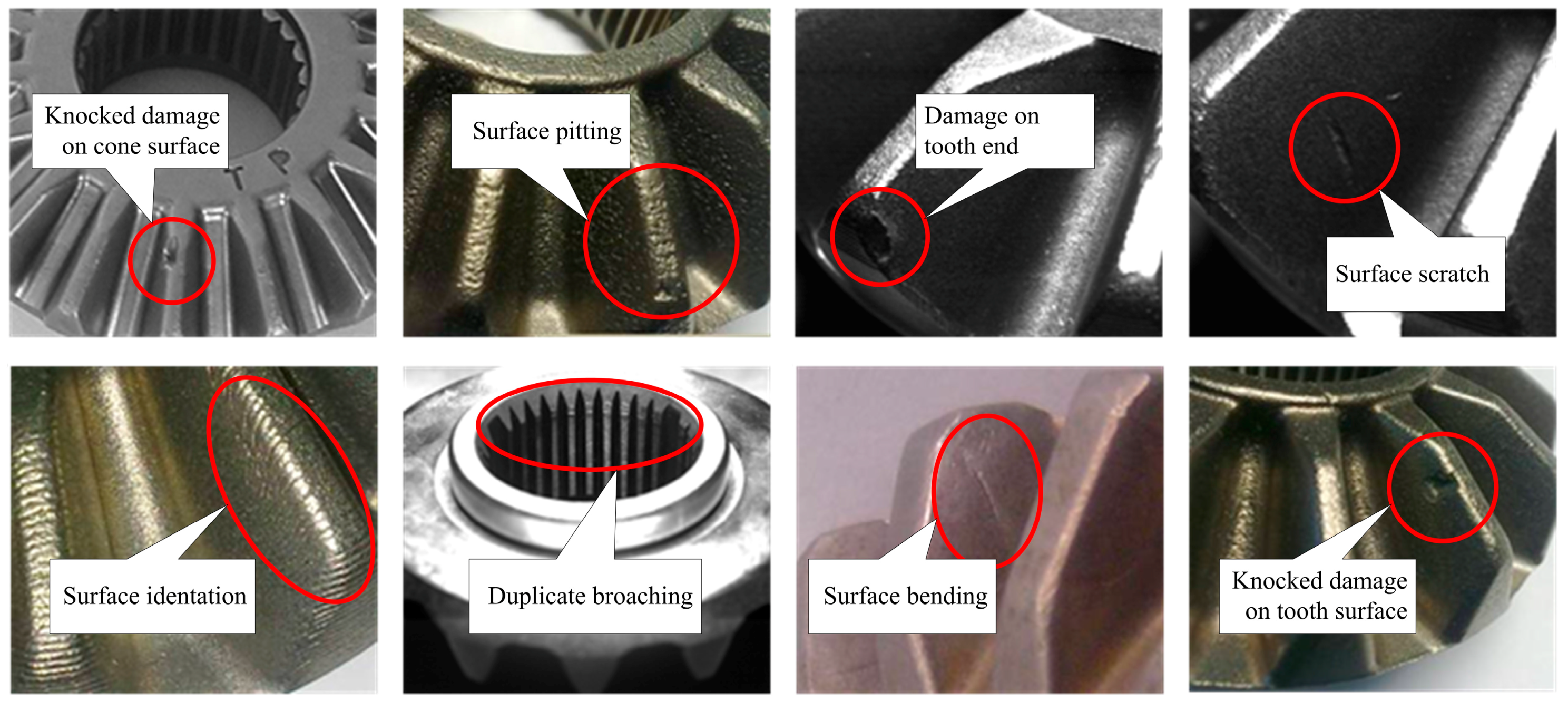

Because the defects of the bevel gears are complex and various, and the inspection time is short, the general algorithms cannot meet the requirements. In this system, we use multi-threading technology and propose several efficient image processing algorithms, which are NAD, CAM and FRP. The following introduces these key algorithms in detail.

3.1. Neighborhood Average Difference Method

From the point of texture, all kinds of defects are shown as waves, twists, undulations or roughness of the surface, thus defects can be detected by analyzing gear texture. Texture description operators based on gray-scale histograms include average, standard deviation, smoothness, third order moment, consistency and entropy, etc. A large number of experiments show that the combination of third order moment and smoothness do best in bevel gear defect detection, but these operators are sensitive to outside interference. The threshold setting is complicated and based on massive numbers of experiments and the results cannot show the characteristics of defects directly and comprehensively (such as area). In our system, we present an algorithm called Neighborhood Average Difference (NAD), which can extract the defects entirely and define larger ones as faults, ignoring tiny ones. The steps are as follows:

- Step 1:

Count the number of nonzero pixels in a neighborhood, denoted by N, given the neighborhood range is L × L pixels, here L = 30.

- Step 2:

Calculate the sum of gray values in the neighborhood: , in which p(i,j) is the pixel value of point (i,j).

- Step 3:

Calculate the average pixel value in a neighborhood: M = S/N.

- Step 4:

For each point p(i,j) in the neighborhood, if |p(i,j) − M| > δ, δ is a threshold, then the point is marked by setting p(i,j) = 255.

- Step 5:

Scan the marked points in the image. If they are in connected region and the size of the region is greater than a threshold, then the region is a defect. Single marked points and tiny connected regions are ignored.

In addition, interference such as the impurities, dust and dirt on the surface can be removed partly by image dilation and erosion processing.

3.2. Circle Approximation Method

Circle detection is a classical problem in image processing [

16,

17,

18,

19]. To detect the actual and virtual circles on the bevel gear fast and accurately, an algorithm named CAM is presented. The main idea is: Draw a circle with initialized center and radius, then expands or contracts it slowly and moves the center continuously until it is tangent to the circle to be detected. Then keep adjusting its radius and center on condition that they remain tangent. The drawn circle will move closer and closer to the circle to be detected until they match perfectly.

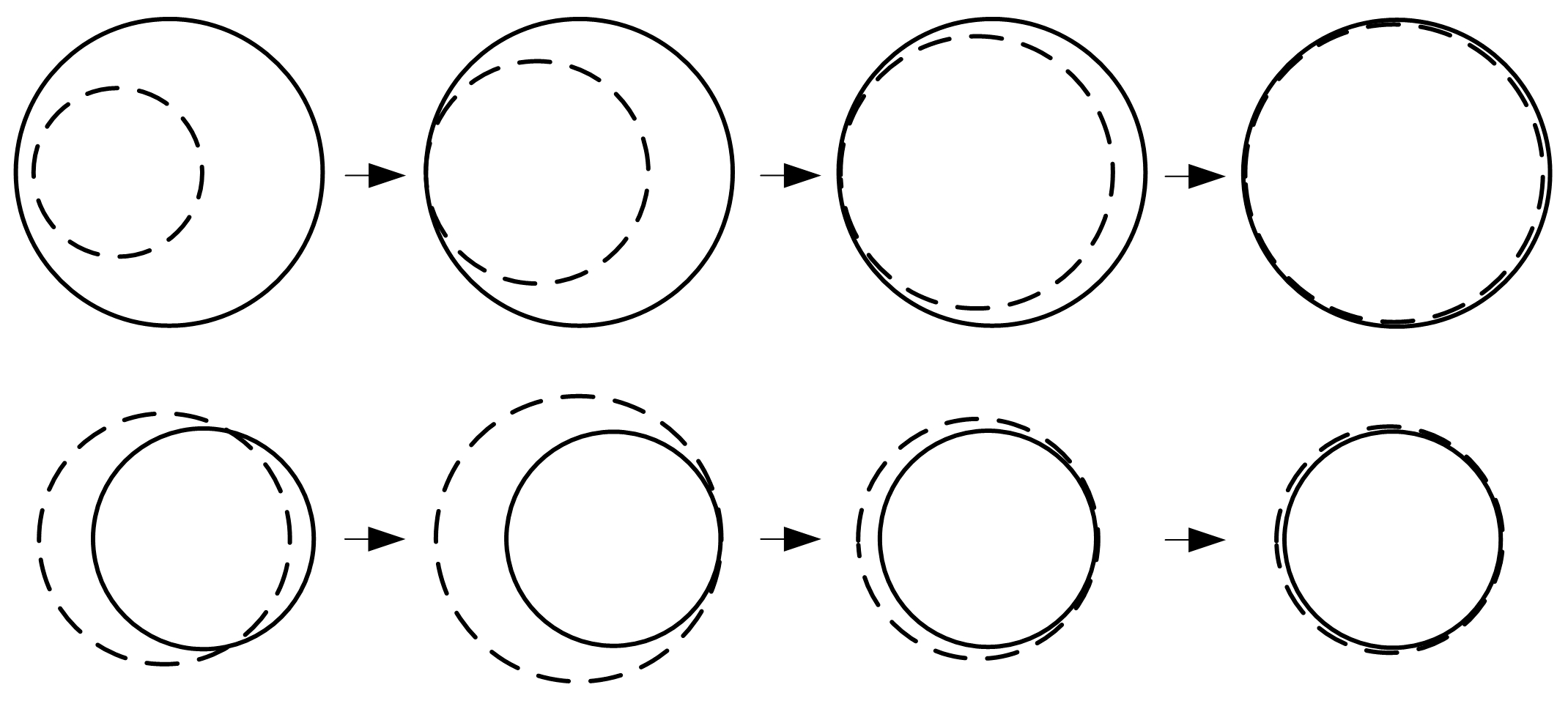

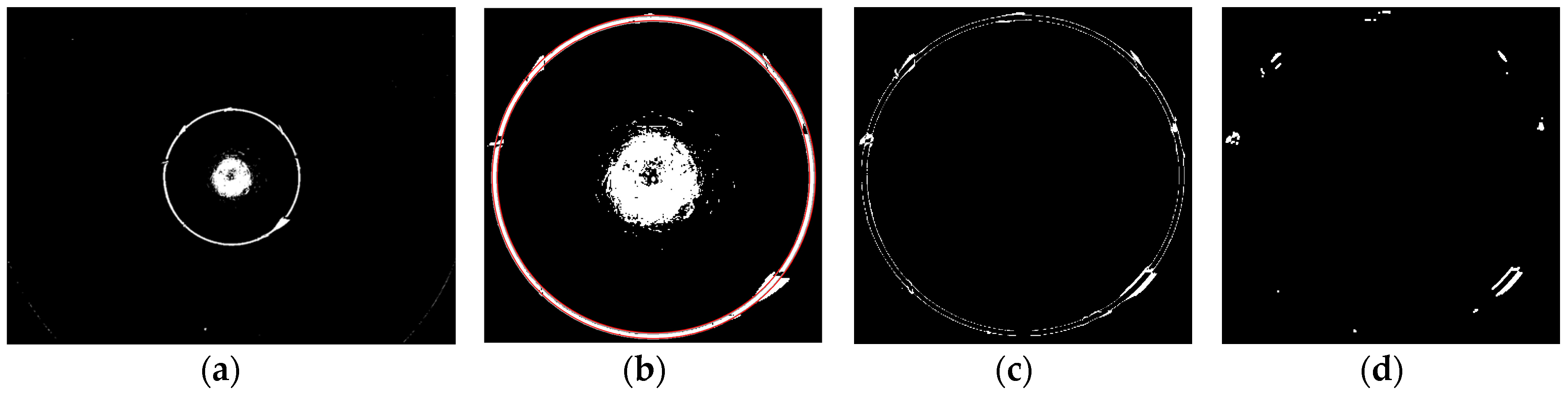

Figure 9 shows this process.

Circle center, radius and rotation angle step are three initial inputs of this method. The center and radius can be approximated only asking the drawn and the target circles have some common area. The more accurate the initial parameters are, the faster the method gets an idea result. It utilizes the positioning result in dimension measurement, and the steps are as follows:

- Step 1:

Extract the edge of the circle (actual or virtual) to be detected by threshold segmentation of the original image. Store the edge in target pixel set C.

- Step 2:

Set the initial center (x0, y0) and radius r0 of the drawn circle. Set the rotation angle step θ.

- Step 3:

Increase or decrease radius r0, r0 = r0 + δr, or r0 = r0 − δr, δr is the change value in each adjustment.

- Step 4:

Calculate the pixel set C’ on the drawn circle with the current center and radius. Find the intersection of C and C’, record as X. If X is empty, return to Step 3.

- Step 5:

If X is non-empty and the number of its elements is Xnum, judge whether Xnum satisfies the matching condition. If satisfies, output the center and radius information, otherwise move the center in its eight neighborhoods and find the position where X has the least elements, record and return to step 3.

The parameter

θ is used in calculation of set

X.

Figure 10 shows how it is defined.

R is the radius.

A and

B are the starting and ending point of a rotation. Line segment

L connects

A and

B. For computational convenience, the center coordinate is set to (0, 0),

B is set to (

R, 0),

A is set to (

x1,

y1), then:

Because the image is discrete, L ≥ 1, then across .

The method counts target pixels on the drawn circle based on the parameter θ, it searches step by step like the second hand of a clock. The value of θ is closely related to the cost of computation. Theoretically, the greater the θ is, the faster the algorithm is, but the robustness of the algorithm will be decreased and the detection accuracy will be reduced at the same time, so the detection accuracy, the execution speed and the robustness of the algorithm should be all taken into account to set the angle step θ. In addition, θ can be set dynamically. In early of the algorithm a bigger θ is used to approach the detected circle quickly. θ becomes smaller as soon as the drawn circle touches the detected circle which is then searched and fitted in a small range. The algorithm is efficient and accurate with a dynamic theta.

Similar to Hough Transform, our method is robust to image noise and disturbance in virtue of cumulative sum. It has a simple searching idea and only requires a preprocessing of threshold segmentation. While in Hough Transform, preprocessing of edge detection or skeleton extraction is very time consuming.

In order to verify the detection results of our algorithm, we compare it with Hough transform by fitting the moon in

Figure 11. The results of the two methods are almost identical and cannot be distinguished by naked eye. Details of the comparison are shown in

Table 1. The data show that CAM is about 50 times faster than Hough Transform, with little difference in initial parameter setting. In addition, the classical Hough Transform cannot be used in high resolution images because the parameter space matrix will increase dramatically with the increase of the image size, resulting in a large amount of computation and storage space. However, our circle approximation algorithm is not restricted in this aspect. It is simple and fast with less computation, and is very suitable for the high precision circle detection situation.

CAM is suitable for fitting circles when a good initialization is available. Hough is suitable for fitting circles in the presence of noise and multiple models (multiple circle arcs). A solution from Hough transform will generally require refinement using an iterative method like CAM.

Our method is more suitable for detection of circles which have been positioned approximately. In actually, with the auxiliary system composed by sensors and cameras, the location of bevel gear won’t deviate greatly. The gross location of the circle can be determined by software in advance. So our method can be successfully applied to most of the industrial circle detection occasions. The detection and production efficiency can be improved significantly with its speed advantage.

Like other circle detection methods, our method can detect solid circles and arcs. But it can also detect virtual circles such as gear spline circle, inscribed circle and circumscribed circle of a polygon.

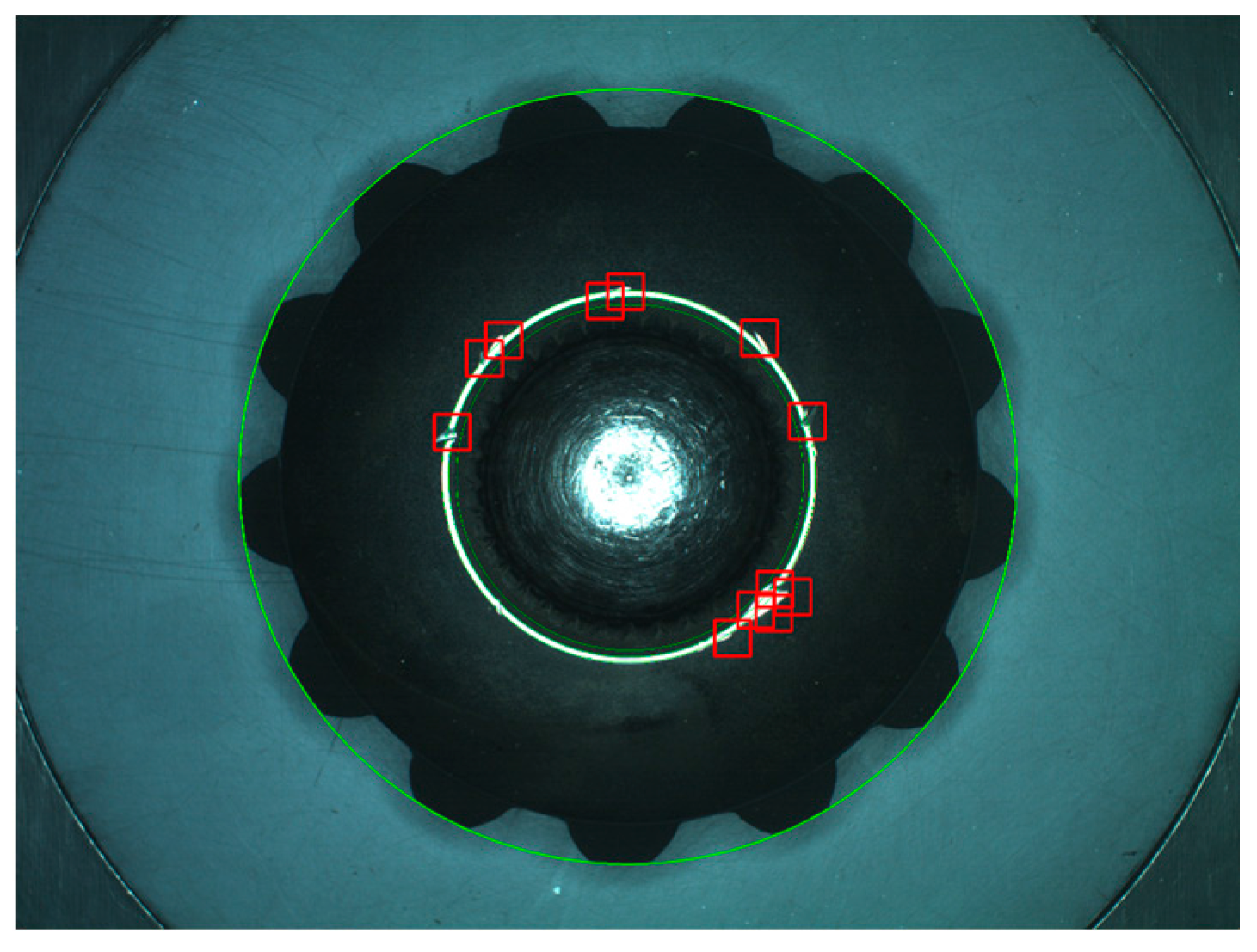

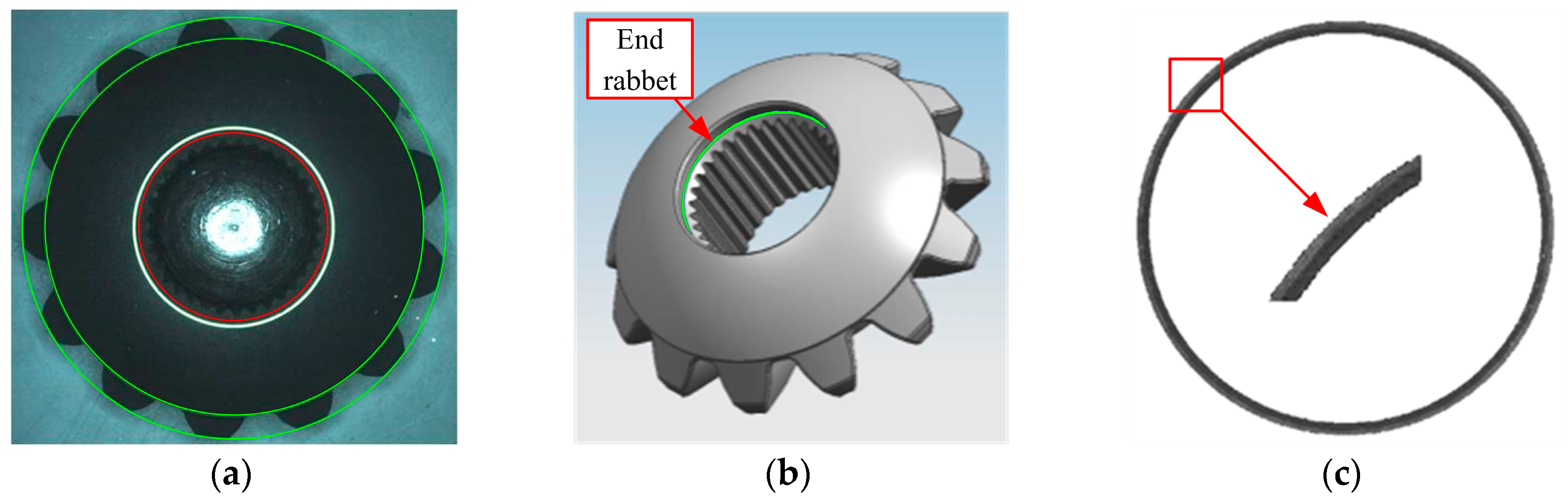

Figure 12 shows the fitting results of spline virtual circles on gear F

6 by our method.

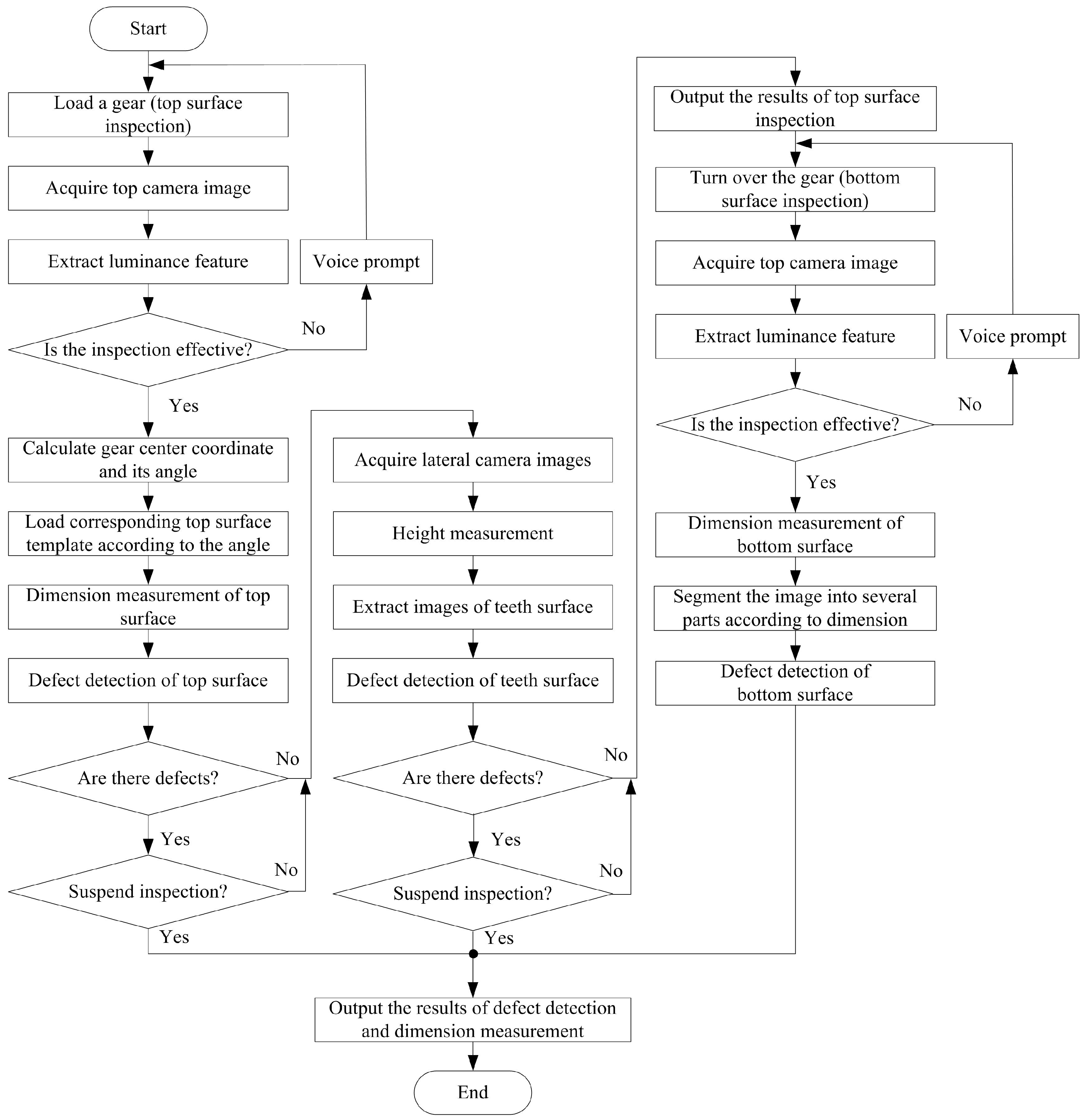

3.3. Fast Rotation-Position

In order to carry out accurate inspection of the bevel gear, the position of the workpiece should be determined quickly after loading. It includes horizontal, vertical and rotational position. This system uses a mechanical device to realize the horizontal and vertical position. Due to the complex gear structure and the short feeding time, it is difficult to achieve effective rotary position by hardware. We solve this problem by image processing method. Taking into account the center rotary symmetry of the bevel gear, the rotation position is divided into three steps which are center positioning, image acquisition of tooth surface and the rotary angle calculation:

- (1)

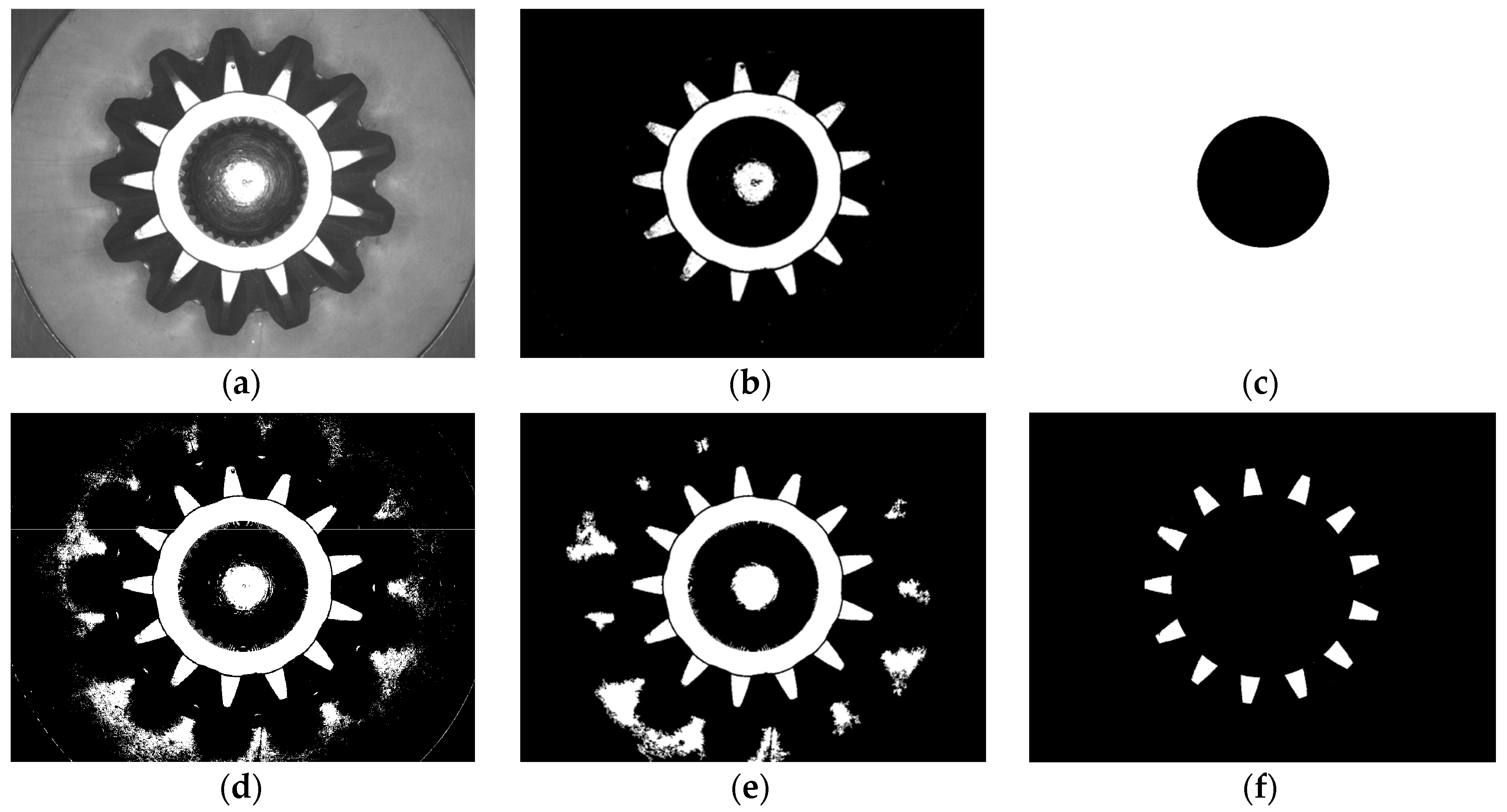

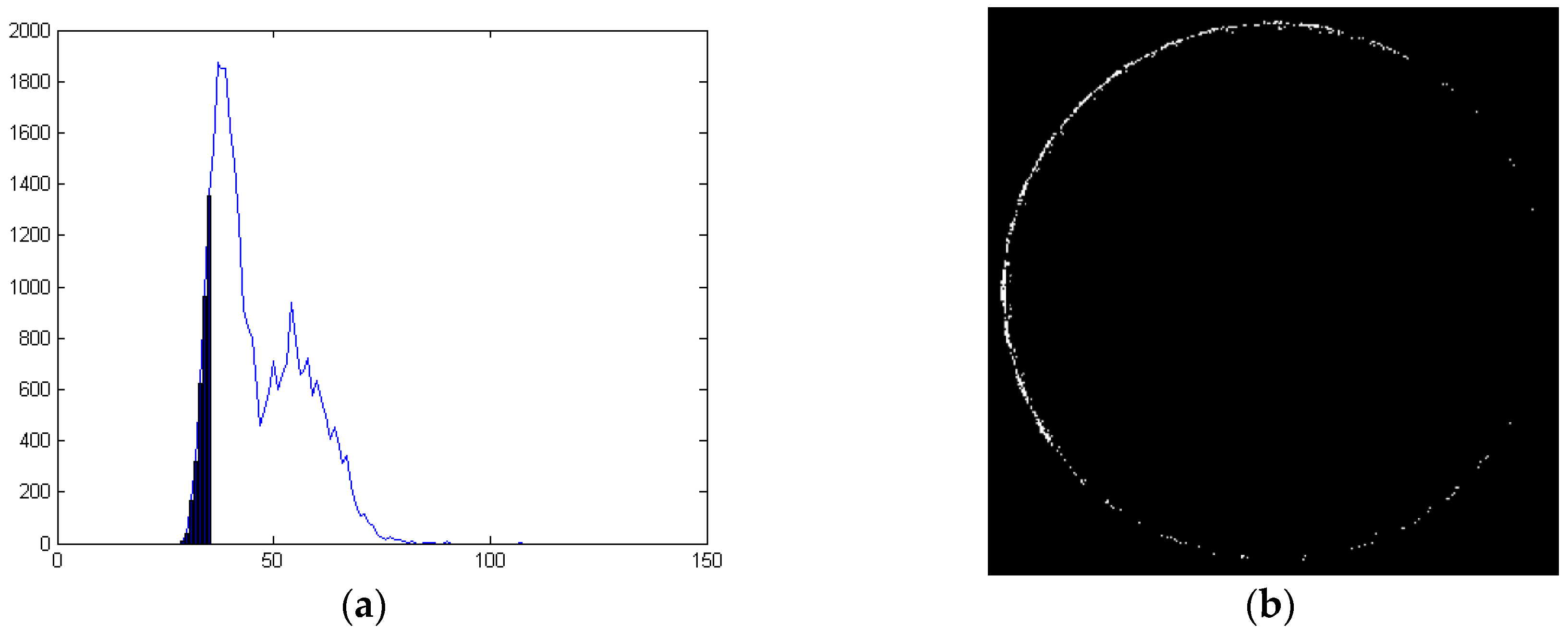

Center positioning. To cut out the image of the inner circle, first segment the top camera image with a certain threshold, then remove interference of impurity and inherent defects by foreground and background area filting. The circle center and diameter are extracted by area statistics and coordinates averaging.

Figure 13a–c show this process.

- (2)

Teeth-end image extraction. Segment

Figure 13a again with a smaller threshold value and cut out the entire teeth-end image. Remove interference of impurity and inherent defects by foreground and background area filtering. Then draw two circles with the center calculated above and proper radiuses, extract only the teeth-end surface, as shown in

Figure 13d–f.

- (3)

Calculate the rotation angle. In order to implement template matching algorithm in defect detection, the original image of the bevel gear should be transformed to a standard position to extract the matched temple. The following shows how to calculate the rotary angle .

For example, bevel gear A

4 has 13 teeth, which are distributed evenly. The angle between two teeth is 360°/13 = 27.69°, as shown in

Figure 14.

O is the center of the gear and

Pi is the geometric center of a tooth. The angle between

x-axis and line

OPi is defined as

αi. For each tooth,

αi is converted into the first quadrant and within 0°–27.69°. For gear A

4,

αi =

α1,

α1,…,

α13. We eliminate any

αi that has great difference with others, and calculate the mean of the rest, which is defined as the rotation angle

α of the gear to be detected. Experiments show that the rotation-position method provides excellent accuracy. The error is about 0.005°, which can meet the requirements of the gear position determination.

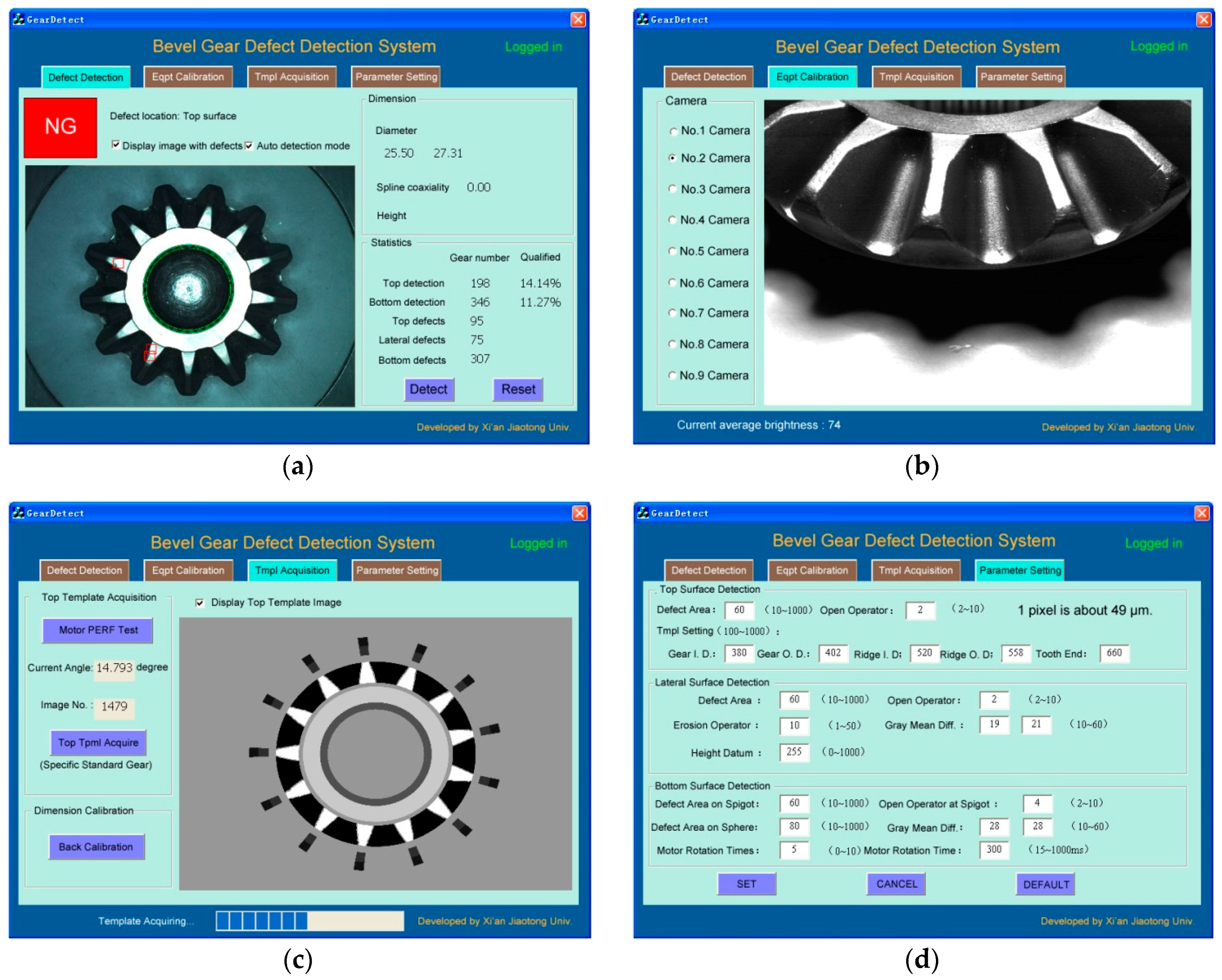

3.4. Template Matching and Collection

In machine vision, we often compare an input image with a standard image to find the difference or target, which is called template matching. It’s fast and efficient. In this system we use template matching a lot to extract the area to be detected, eliminating the interference of non-inspection areas and improving the inspection speed.

Figure 15a is the top surface image of bevel gear A

4 and

Figure 15b is the matching template. In

Figure 15b, the value of background and edge of the gear are set to 150, which means they are a non-inspection area. Black, white and some other gray colors indicate different parts to be detected.

The templates are collected from a standard and perfect gear. Here is the acquisition process of top surface template. First extract the gear’s center and rotation angle, and then divide target pixels into different parts according to their distance to the center and mark with different colors, remove background pixels completely. The templates are numbered and saved in order of rotation angle.

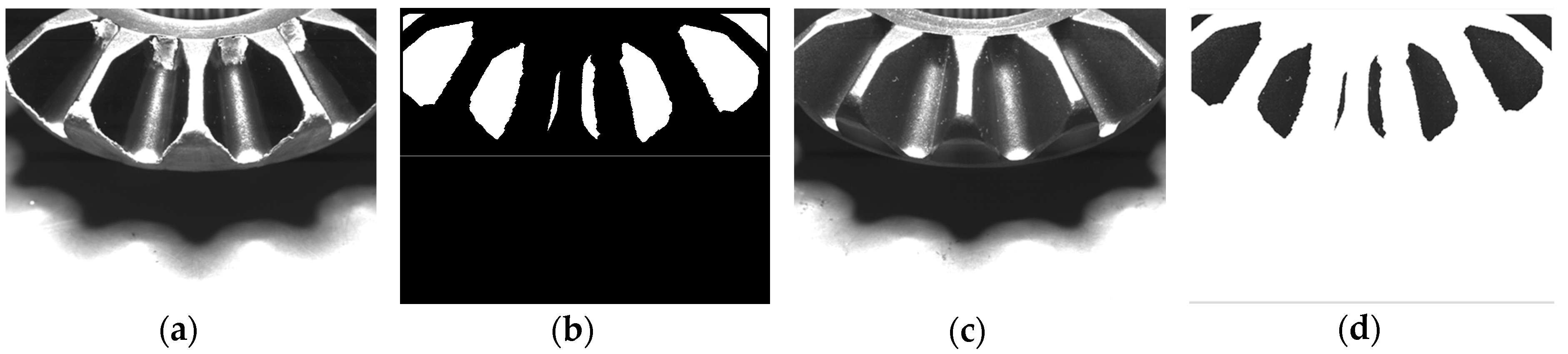

The lateral template is collected by the aid of a special gear painted with black and white matted coating, shown in

Figure 16a. This ensures that a perfect template can be extracted through a simple image processing, shown in

Figure 16b.

Figure 16c is an original lateral image and

Figure 16d is the extracted teeth surface by template matching.

In this system the templates collection and processing are completed automatically without artificial participation. Templates are automatically numbered and saved in order of rotation angle and camera. After a template is collected, the gear is rotated to another angle by the step-motor and the next collection begins. The angle interval is about 0.01°–0.02°. The total template image size is as large as 25 GB, that is to say, the system achieves ideal inspection speed by sacrificing storage space.