1. Introduction

Two-phase flow is widespread in the petroleum industry, chemical engineering, pharmacy and nuclear reaction fields, etc. The study of liquid-liquid/gas-liquid two-phase flow in horizontal pipes and the individual phase concentration measurement of liquid-liquid/gas-liquid two-phase flow are of great importance for diverse industrial applications and the optimization of the oil production process [

1,

2]. Electrical methods (the capacitance method and conductance method) are widely used for gas-liquid/liquid-liquid two-phase flow measurements because they are characterized by their clarity of principle, simple structure, easy implementation, low cost, on-line measurement, fast response, and lack of fluid interference, etc. [

3,

4,

5,

6,

7,

8,

9]. In particular the conductance method [

8,

9] is mainly dependent on the conductive properties of the flow components, which means that a direct measurement of phase holdup could be made if the two flow components are both electrically conductive and have contrasting conductivity. Therefore, it is very important and meaningful to measure the water holdup of oil-water two-phase flow in horizontal wells by using the conductance method [

10].

The measurement principle of water holdup [

1,

11,

12] indicates that water holdup can be determined by oil-water mixture phase conductivity and continuous water phase conductivity. Water holdup, which can be obtained according to Maxwell analytic model [

13], can be converted into a water volume fraction, with an interpretation chart for slip correction. The value of oil-water mixture phase conductivity is mainly dependent on the dispersed oil-phase volume fraction and continuous water phase conductivity; meanwhile it is influenced by the space distribution of the discrete phase.

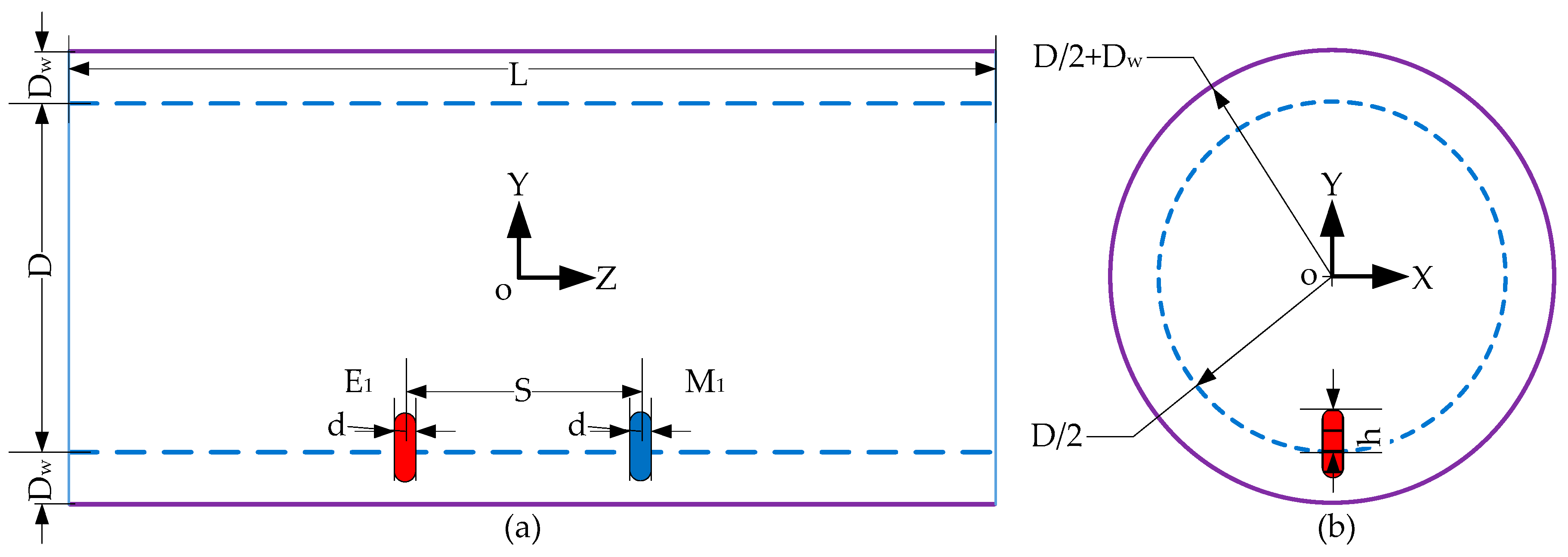

In terms of the ring-shaped conductance probe (RSCP) geometry optimization, Lucas et al. [

14,

15] used the FEM to investigate the sensitivity field distribution for the geometry optimization of electrodes. Fossa and Devia [

16,

17] optimized the RSCP geometry, and investigated the effects of the RSCP geometry on the response of the measuring device in annular, segregated and bubble flows, and improved the RSCP response both in terms of linearity and spatial resolution by means of the numerical solution of Laplace problem. Using the FEM, Jin et al. [

18] designed and optimized a conductivity probe with a vertical multiple electrode array (VMEA), proposed the content of the spatial sensitivity and effective information, and then, constructed an optimized VMEA which could be used to measure cross-correlation velocity and predict volume fraction in vertical upward gas-water two-phase flow with satisfactory accuracy.

Although progress has been made on the conductance method in previous research, the early work mainly focused on the investigation of the sensitivity distribution of the electric field for vertical small diameter pipes, and paid little attention to the effects of various flow patterns in horizontal pipes on the output response both in terms of linearity and spatial resolution. The oil-water two-phase flow patterns of long distance undulating horizontal wells have a mixed flow pattern which is mainly horizontal segregated flow as opposed to vertical wells [

2,

19]. The flow pattern and flow velocity are influenced by the inclination of the long distance undulating horizontal well, so the pre-existing profile parameters measuring sensor production for vertical wells cannot be directly used for horizontal wells.

Early experimental investigations on the horizontal oil-water two-phase flow patterns were conducted in acrylic pipes with a small diameter, and the flow patterns were primarily defined by simple observations [

20,

21]. Arirachakaran et al. [

22] observed stratified flow, mixed flow, annular flow, intermittent flow and dispersed flow in a 25.1 mm inner-diameter (ID) horizontal pipe. Trallero et al. [

23] comprehensively performed an experimental and theoretical study in a 50.1 mm ID pipe, and then classified the flow patterns into segregated flow and dispersed flow, the segregated flow includes stratified flow (ST) and stratified flow with mixing at the interface (ST & MI), the dispersed flow includes dispersion of oil in water and water flow (DO/W & W), dispersion of water in oil and oil in water flow (DW/O & DO/W), dispersion of oil in water flow (DO/W), and dispersion of water in oil flow (DW/O). Zhai et al. [

24] conducted an experimental under various flow conditions in a 20 mm ID horizontal pipe by using the radial mini-conductance probes and RSCP, analyzed and obtained the same result of flow patterns classification

.In vertical production profile logging wells, the RSCWCM measures oil-water mixture phase conductivity online when the fluid flows through the RSCP measuring pipelines. The pure-water phase conductivity could be obtained by the RSCP connected with a sampler for oil-water two-phase separation [

1,

12]. In horizontal production profile logging wells, the oil-water mixture phase conductivity could be measured online in the process of fluid flow by using the RSCWCM [

25]. However, due to the characteristics of the horizontal well structure and limitations of the ring-shaped electrode structure of the RSCWCM, the RSCP must still be immersed in the oil-water segregated flow when sampling [

26], so it is impossible to realize pure-water result sampling calibration, and the RSCWCM cannot be applied in horizontal wells.

In this study, we designed and optimized a MCP for measuring pure-water phase conductivity of oil-water two-phase segregated flows in horizontal pipes. We also present the experimental results to verify the validity of pure-water phase conductivity measurement using our new MCP.

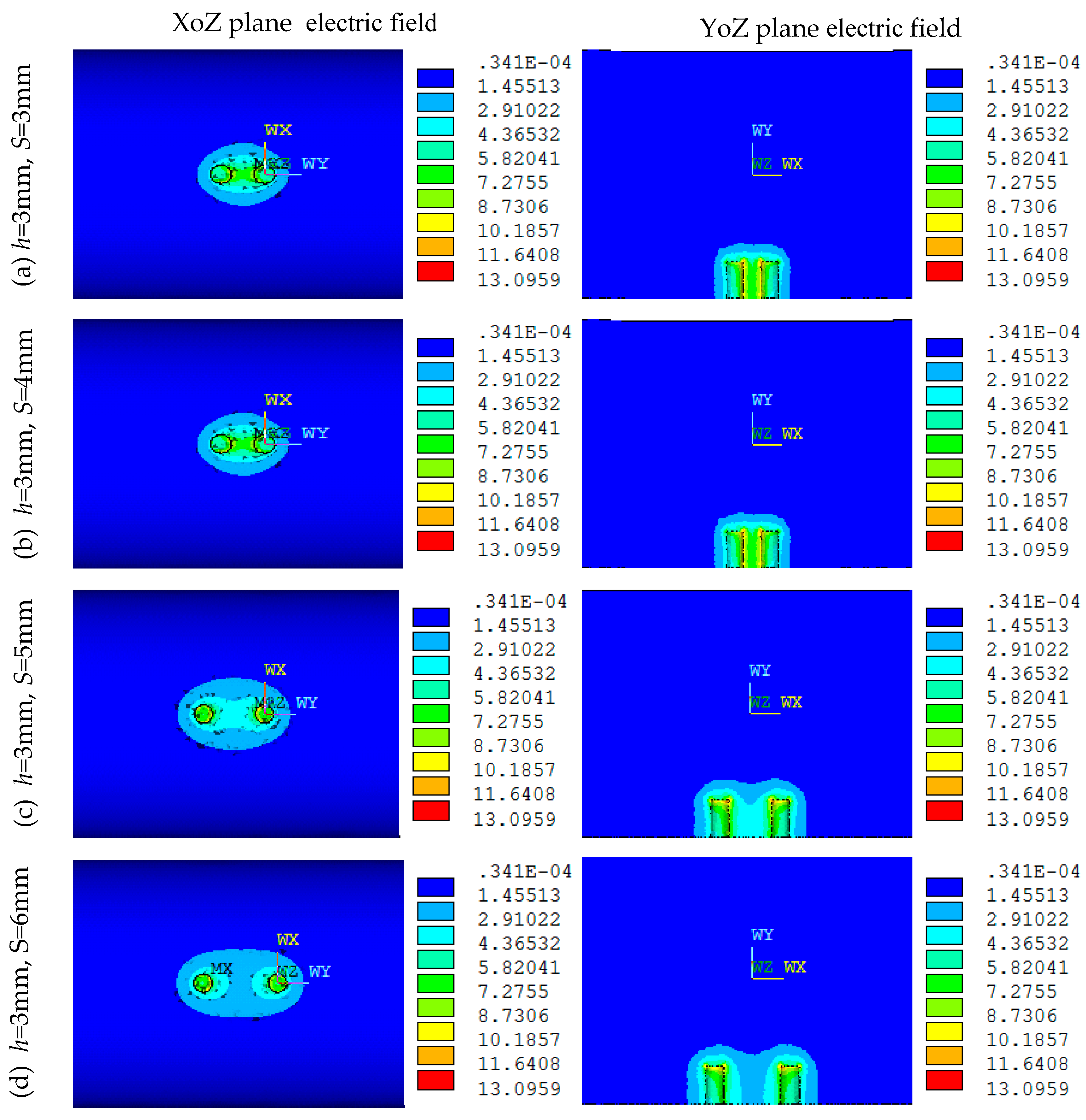

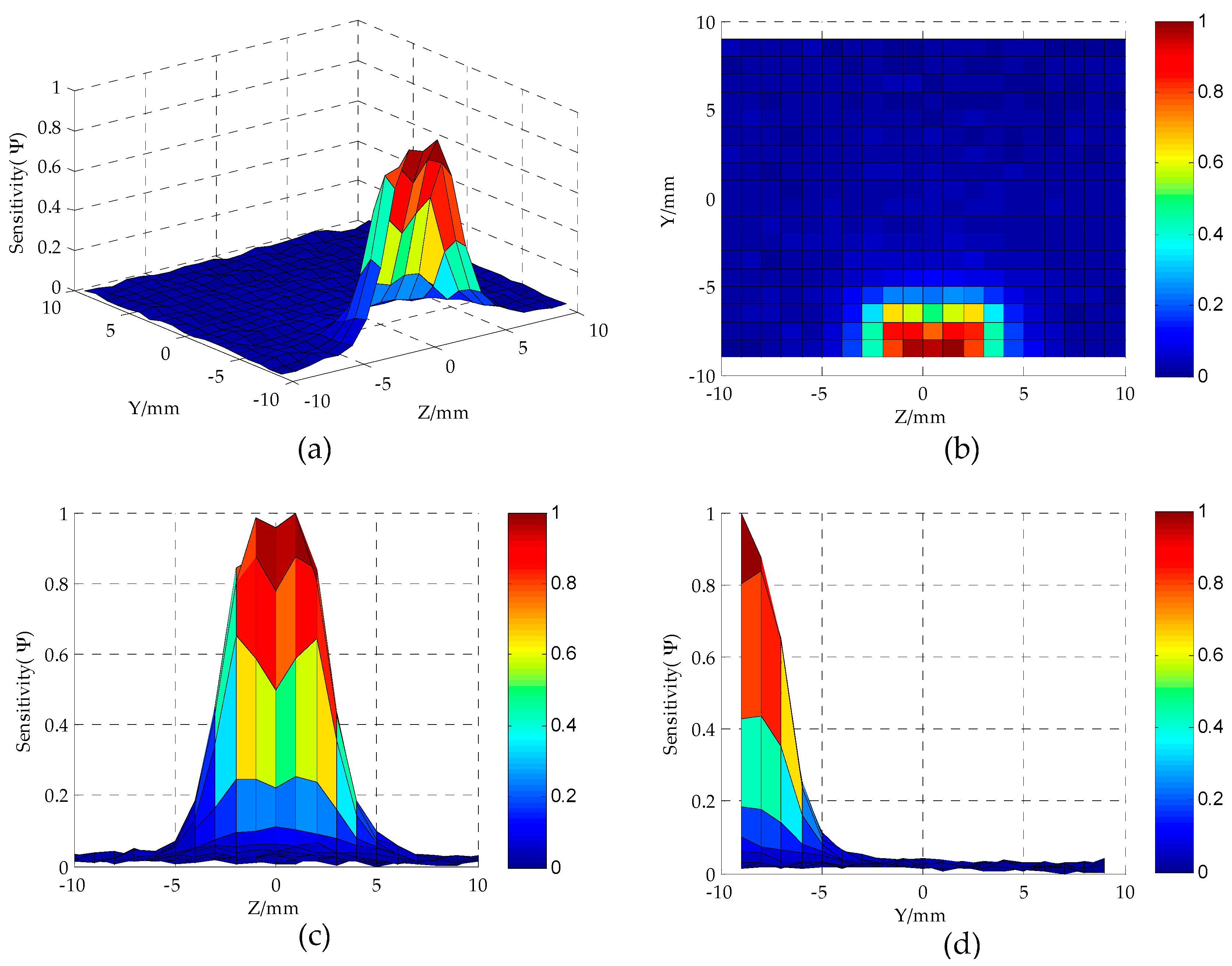

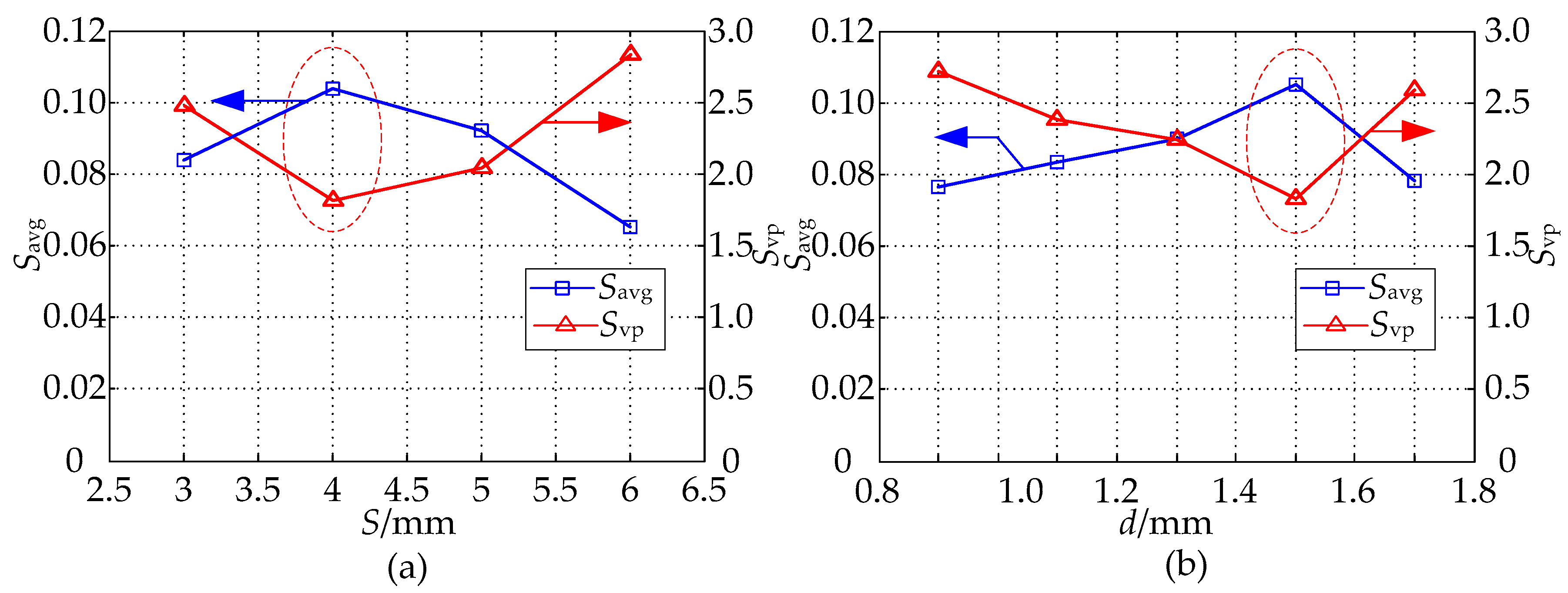

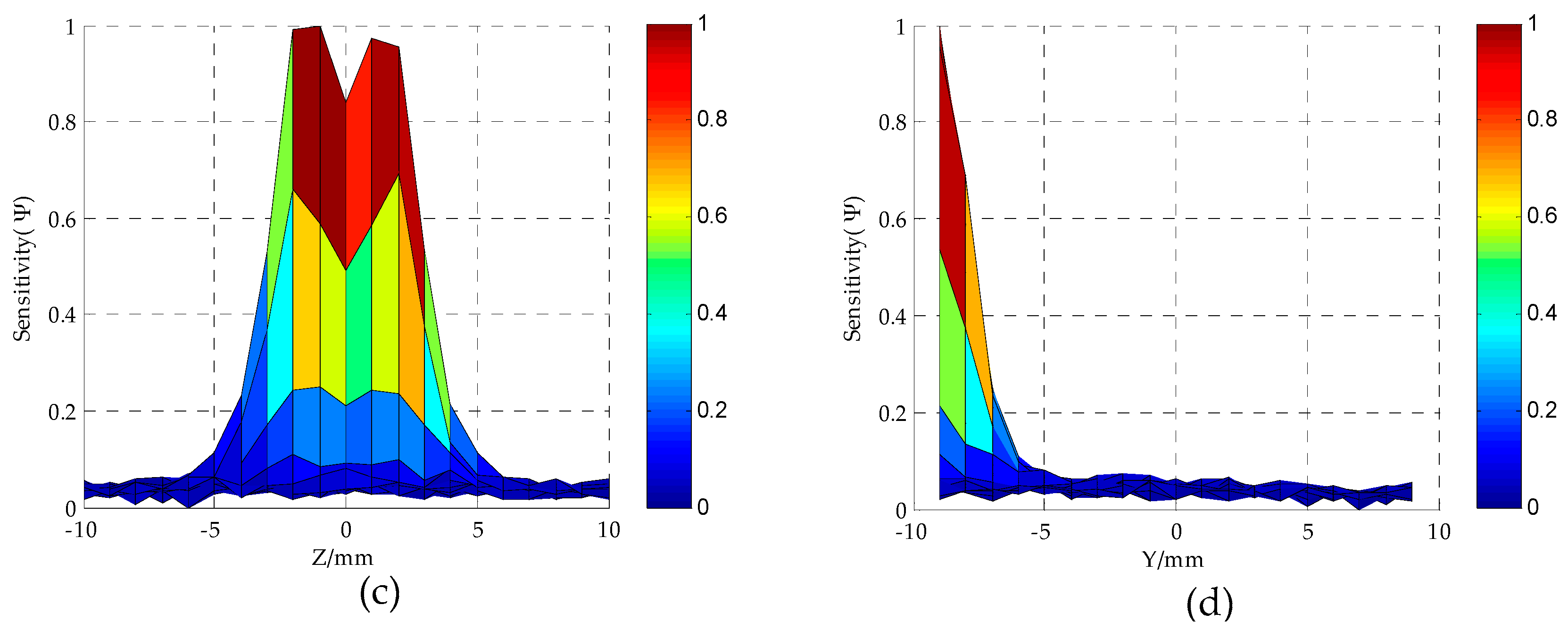

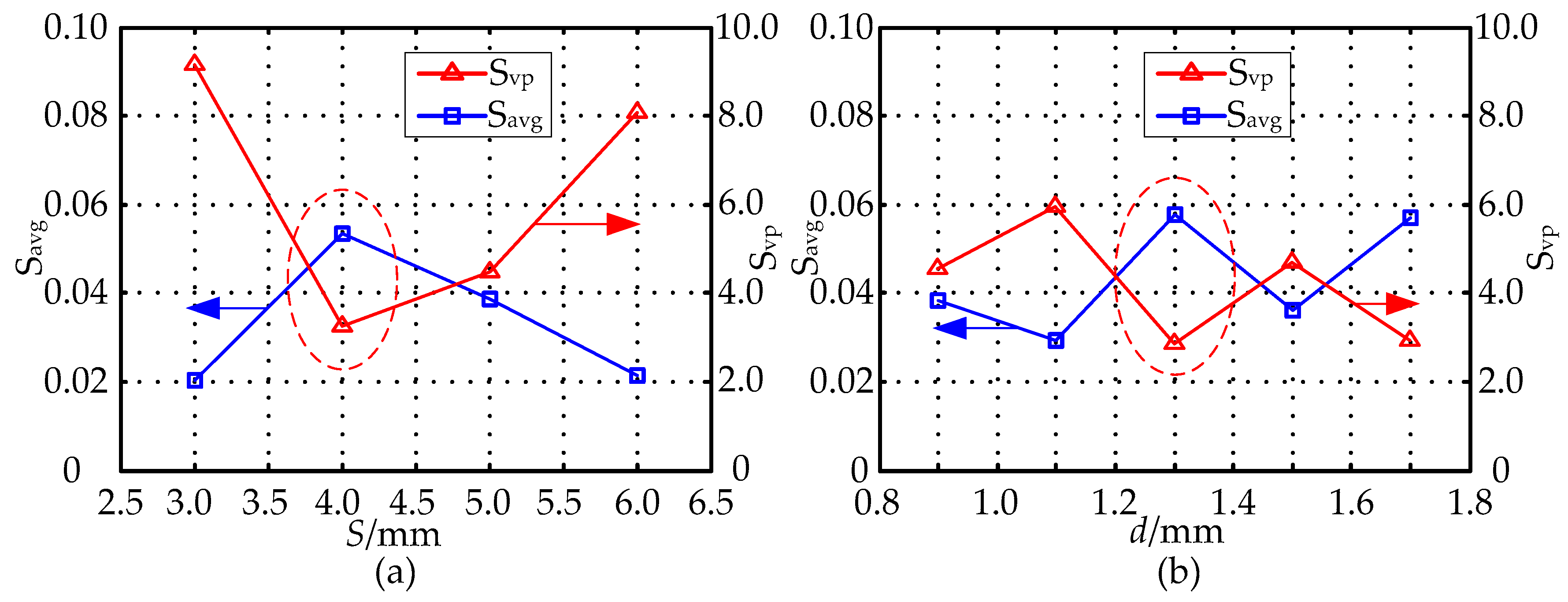

3. Simulation Calculated Response for Segregated Flow

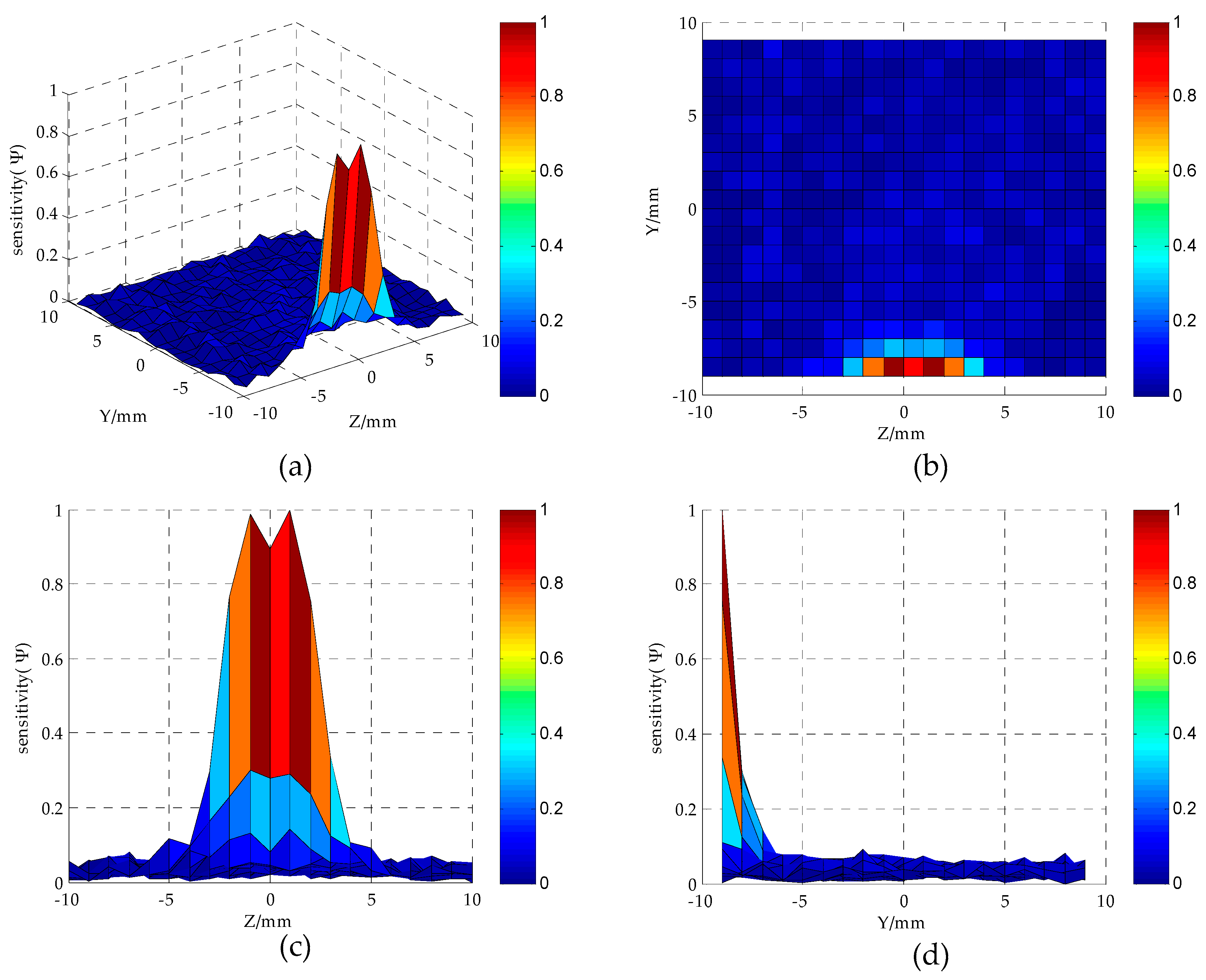

From

Section 2, the sensitive fields of the MCP with different values of

h have some differences when the parameters

S and

d are constant, especially with the increase of the parameter

h, the sensitive field of sensor along the

Y-axis shows a continuous expanding tendency. Consequently, to measure the pure-water phase conductivity in the condition of the horizontal oil-water segregated flow, the effect degree of the MCP in the measurement field along the

Y-axis by the non-conducting materials such as oil phase and so on needs further investigation. From the analysis of

Figure 5,

Figure 8 and

Figure 11, under the condition of the parameter

D = 20 mm, the geometry parameters

h,

S and

d of the MCP after optimization value

h = 3 mm,

S = 4 mm,

d = 1.5 mm and

h = 2 mm,

S = 4 mm,

d = 1.3 mm and

h = 1 mm,

S = 3 mm,

d = 1.3 mm, respectively.

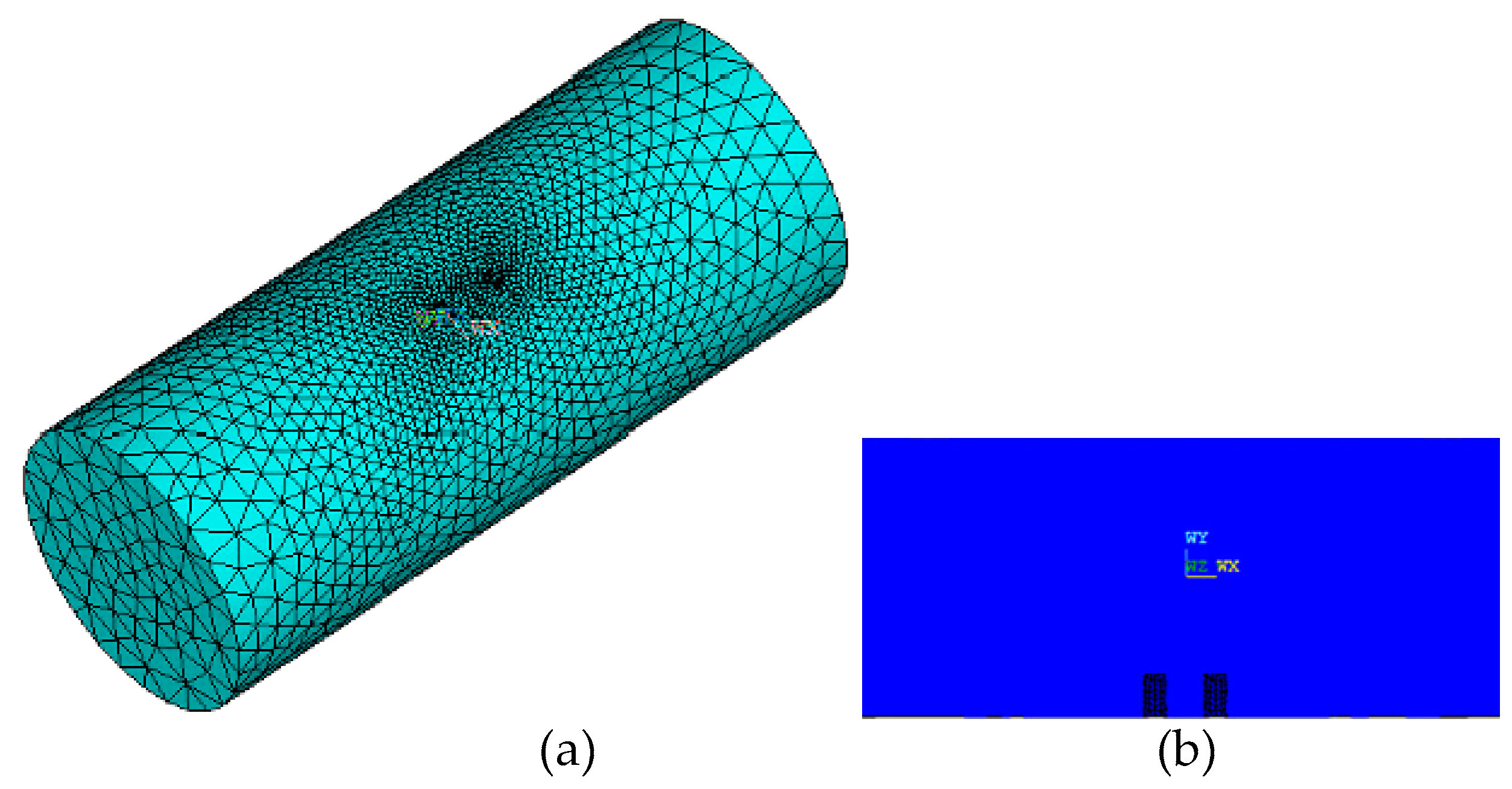

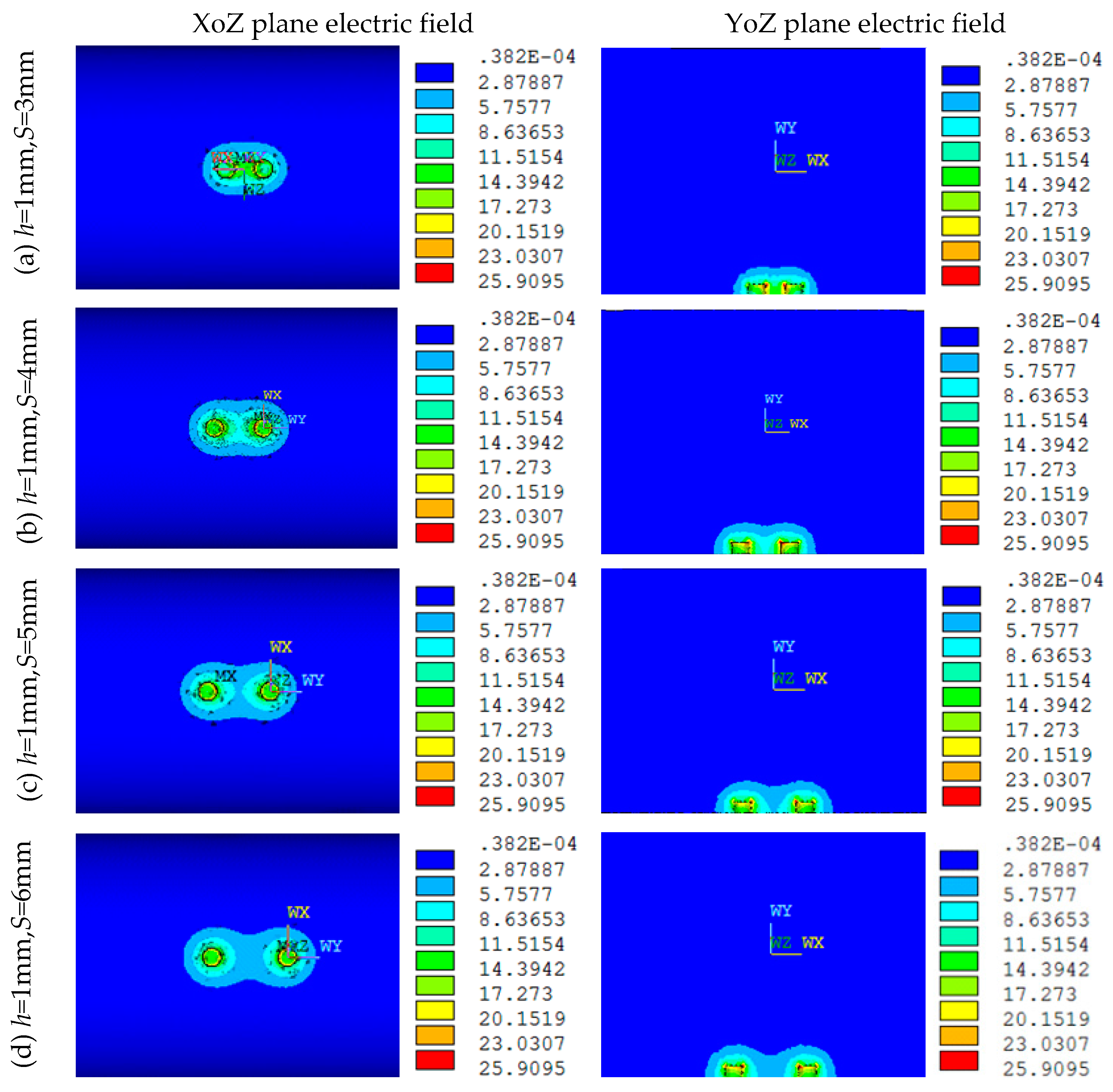

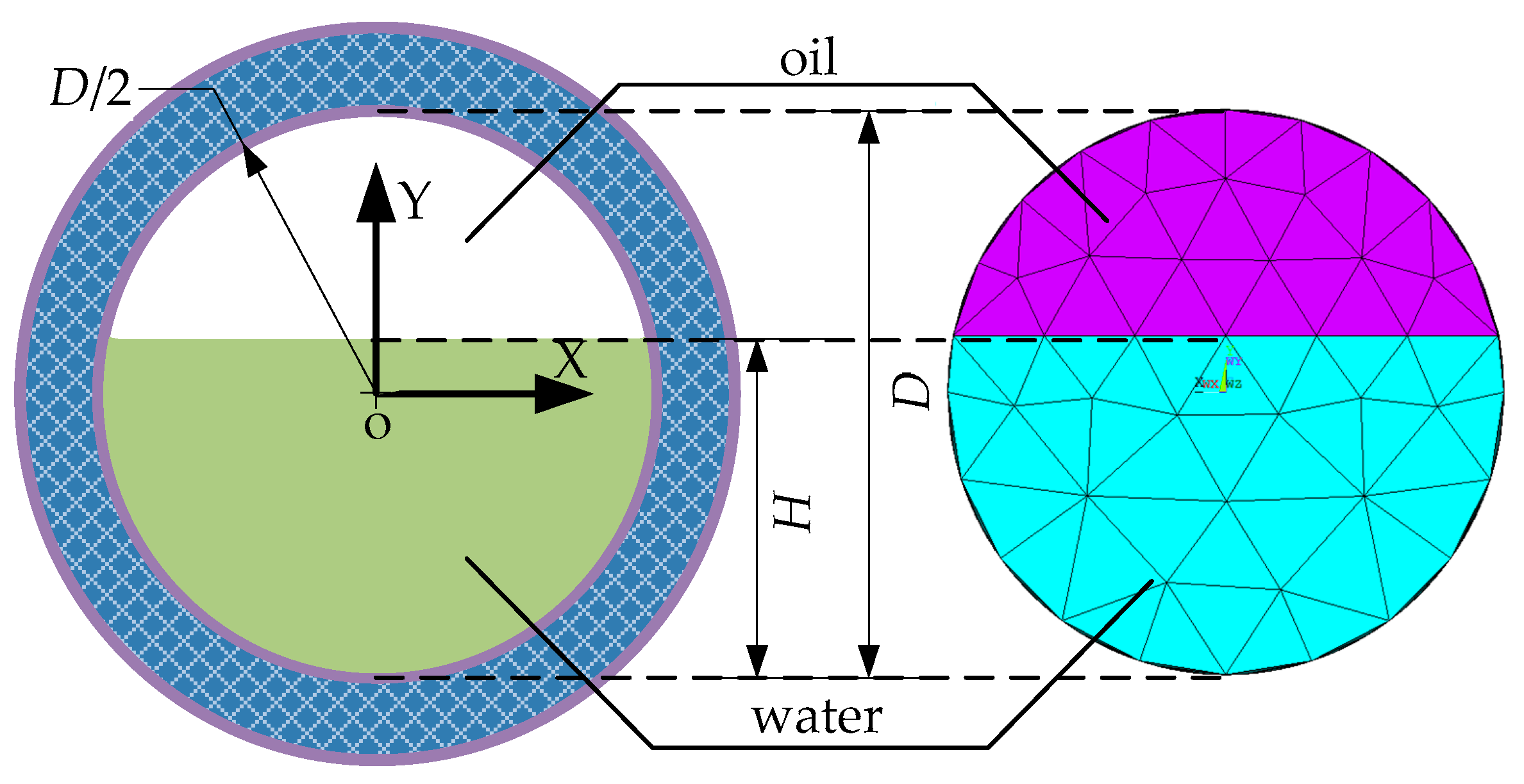

In this simulation, the response of the MCP for oil-water segregated flow is calculated using a 3D finite element model.

Figure 12 shows the 2D view of the meshed model for segregated flow.

H is the thickness of the water layer,

D is the inner diameter of the insulated flow pipe. The simulation conditions, which are also same as the condition in

Section 2, are that the water resistivity

σw = 100 Ω·m, oil resistivity

σo = 1.0

E + 13 Ω·m, a direct current of 0.1 mA is supplied to the electrode E

1, a current of −0.1 mA is supplied to M

1, and the voltage of electrode M

1 is simultaneously set to 0 V.

Figure 13 shows the curve between water holdup

ym and height of water layer (

H/

D), and it is a nonlinear curve between the

ym and the (

H/

D), the range of both

ym and (

H/

D) are from 0 to 1. When

ym = 0 or (

H/

D) = 0, the insulated flow pipe is filled with pure oil; when

ym = 1 or (

H/

D) = 1, the insulated flow pipe is filled with pure water; when 0 <

ym < 1 or 0 <

H/

D < 1, the insulated flow pipe is filled with oil-water mixture.

Under the condition of the parameter

D = 20 mm, the response signals of the MCP are analyzed in terms of

ym and

H/

D, respectively, the range of both

ym and

H/

D are from 0 to 1, and the change interval with 0.05 was used as an experimental point. The calculated response values of the MCP are shown in

Table 2 and

Figure 14 in which

Vm is the measured voltage and can be expressed as:

where

kσ is resistance correction coefficient,

σm is resistivity of oil-water mixture in measurement field,

Ie represents exciting current.

As can be seen from

Table 2, the response values of the MCP have obvious differences under the pure oil and pure water conditions, which can be attributed to the distinctive difference of water and oil resistivity. Meanwhile, the response values of sensor structure with different parameters are different, which can be attributed to the different electric field generated by two electrodes in measurement field.

As can be seen from

Figure 14, the range of both

ym and

H/

D are from 0.05 to 1, and with the increase of

ym or

H/

D, under the condition of lower

ym or

H/

D, the measured voltage value

Vm shows an obvious difference and decreasing tendency, which can be attributed to the stronger electric field in the measurement region, where the non-conducting oil phase is located in the high sensitivity sensitive area analyzed from

Figure 4,

Figure 7 and

Figure 10. Therefore, the response result is seriously affected by the non-conducting oil phase and the pure-water result cannot be obtained. When

ym or

H/

D is greater than or equal to a constant value, the response result of the MCP is approximately equal to pure-water value, and it is almost not influenced by oil phase, which can be attributed to the non-conducting fluid away from the high sensitivity sensitive area. Under the conditions of higher

ym or

H/

D, the MCP can obtain a reliable and accurate pure-water value, and it can be used as the pure-water correction for water content measurement. As can be seen from

Figure 14a, in the condition of the MCP with

D = 20 mm,

h = 3 mm,

d = 1.5 mm and

S = 4 mm, the response result is approximately equal to the pure-water value when

ym is greater than or equal to 0.25. In the condition of the MCP with

D = 20 mm,

h = 2 mm,

d = 1.3 mm and

S = 4 mm, the response result is approximately equal to the pure-water value when

ym is greater than or equal to 0.20. In the condition that the MCP with

D = 20 mm,

h = 1 mm,

d = 1.3 mm and

S = 3 mm, the response result is approximately equal to the pure-water value when

ym is greater than or equal to 0.15. As well, in

Figure 14b, in the condition of the MCP with

D = 20 mm,

h = 3 mm,

d = 1.5 mm and

S = 4 mm, the response result is approximately equal to the pure-water value when

H/

D is greater than or equal to 0.30.

In the condition ofthe MCP with

D = 20 mm,

h = 2 mm,

d = 1.3 mm and

S = 4 mm, the response result is approximately equal to the pure-water value when

H/

D is greater than or equal to 0.25. In the condition of the MCP with

D = 20 mm,

h = 1 mm,

d = 1.3 mm and

S = 3 mm, the response result is approximately equal to the pure-water value when

H/

D is greater than or equal to 0.2. In

Figure 4d,

Figure 7d,

Figure 10d and

Figure 14, it is found that the MCP has good measurement characteristics for oil-water segregated flow in case of high

ym or

H/

D in simulated calculation. Meanwhile, the MCP response result tends to be constant, i.e., pure-water correction for water content measurement, under the condition of

H/

D ((

h + 3)/20, 1) or

ym ((

h + 2)/20, 1), which shows that the smaller the parameter

h of the MCP is, the larger the low sensitivity sensitive area along the

Y-axis in the sensor measurement field is, the smaller the critical value of

ym or

H/

D which is needed for getting the pure water correction, and the easier obtaining the pure-water phase conductivity is.

4. Static Experiment for Oil-Water Segregated Flow

In order to avoid the polarization phenomenon, an alternating voltage source is adopted as the exciting signal in actual application, and the two electrodes are connected with a sinusoidal 20 kHz exciting signal in the measurement system. Meanwhile, in order to avoid the voltage loss on the distance line, the V/F conversion circuit is adopted to construct the pure-water frequency measurement system.The instrument output is expressed by the frequency signal

Fm which can be described as:

where

kV is correction coefficient,

Vm is the measuring voltage for pure water, pure oil or water-oil mixture, respectively.

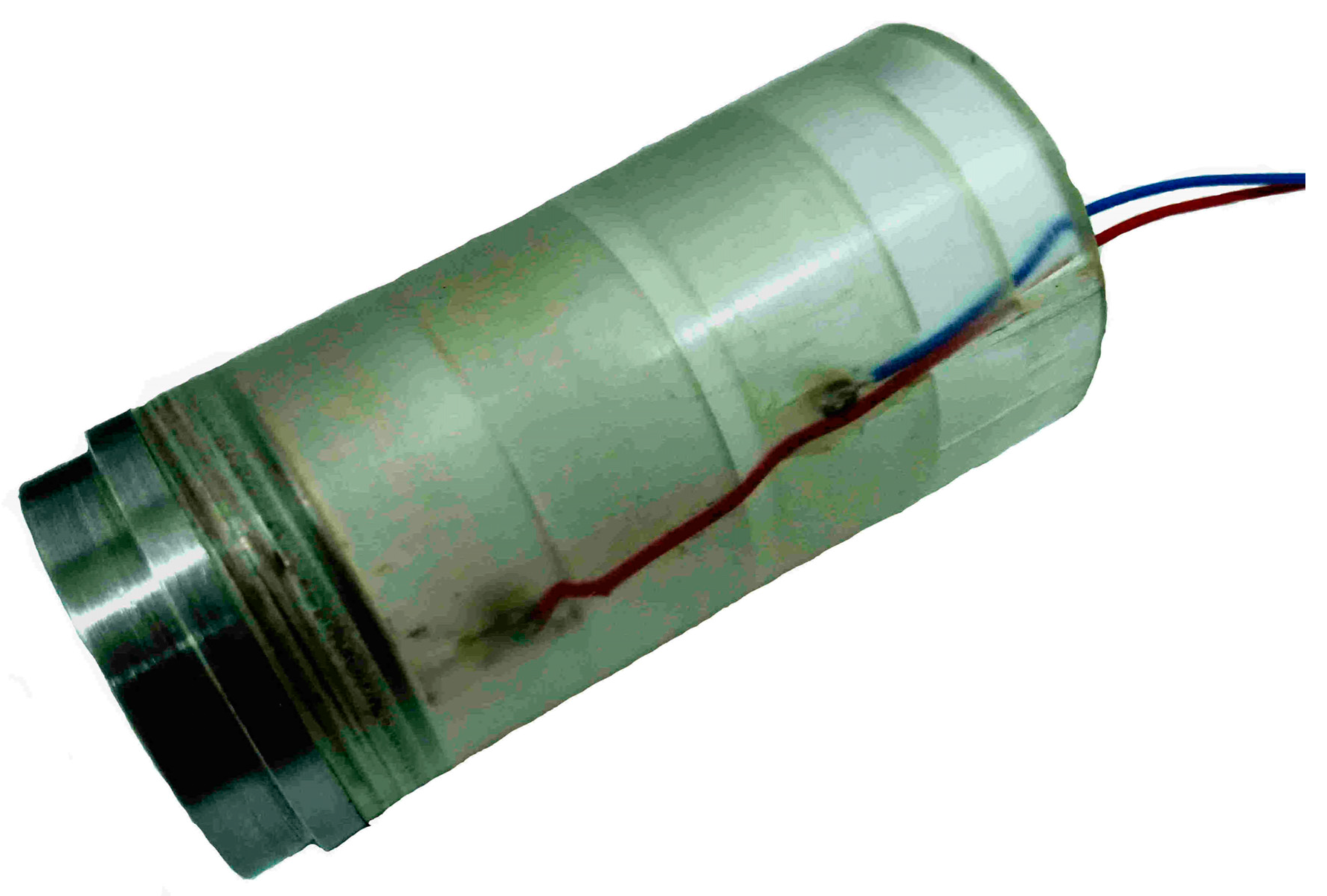

Figure 15 shows images of the MCP. In

Figure 15, it can be seen that the structures of the MCP are axially separated and flush-mounted on the inside wall of the insulated flow pipe with

D = 20 mm.

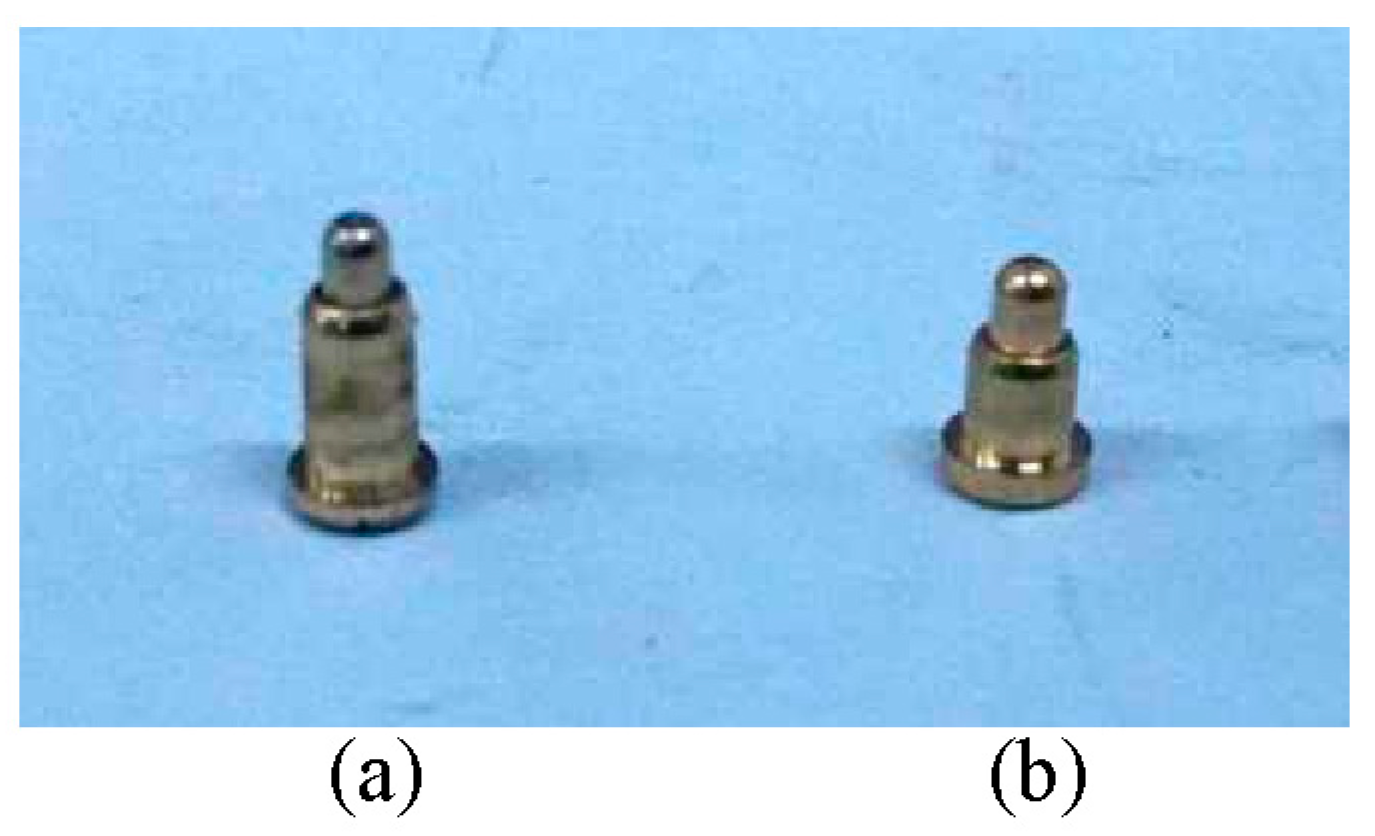

Figure 16 shows images of the gold-plated electrodes with different parameters. In

Figure 16a, the gold-plated electrode

h is equal to 3 mm and

d is equal to 1.5 mm. In

Figure 16b, the gold-plated electrode

h is equal to 2 mm and

d is equal to 1.3 mm.

To calibrate the MCP in the water-layer thickness measurement, the calibration test for oil-water segregated flow is carried out. The experimental mediums are tap water and industrial white oil. In the experiment, the fluid is forced into the insulated flow pipe of the MCP with D = 20 mm from a large diameter horizontal plexiglass pipe (the value of inner diameter is 50 mm). The different values of ym are matched in horizontal plexiglass pipe, and the range of oil holdup y0 is from 0% to 100% which is corresponding to the different values of H/D.

Considering that the measurement results of the instruments are influenced by the repeatability errors of the measurements and system errors during long time continuous operation, this paper employed horizontal oil-water two-phase flow experimental equipment to carry out the multiple (three or more times)repeated oil-water segregated experiments using an experimental point where ym and H/D change from 0 to 1, increasing 0.05 every time, whose result is recorded every 5 minutes and each experimental point is recorded 10 times.

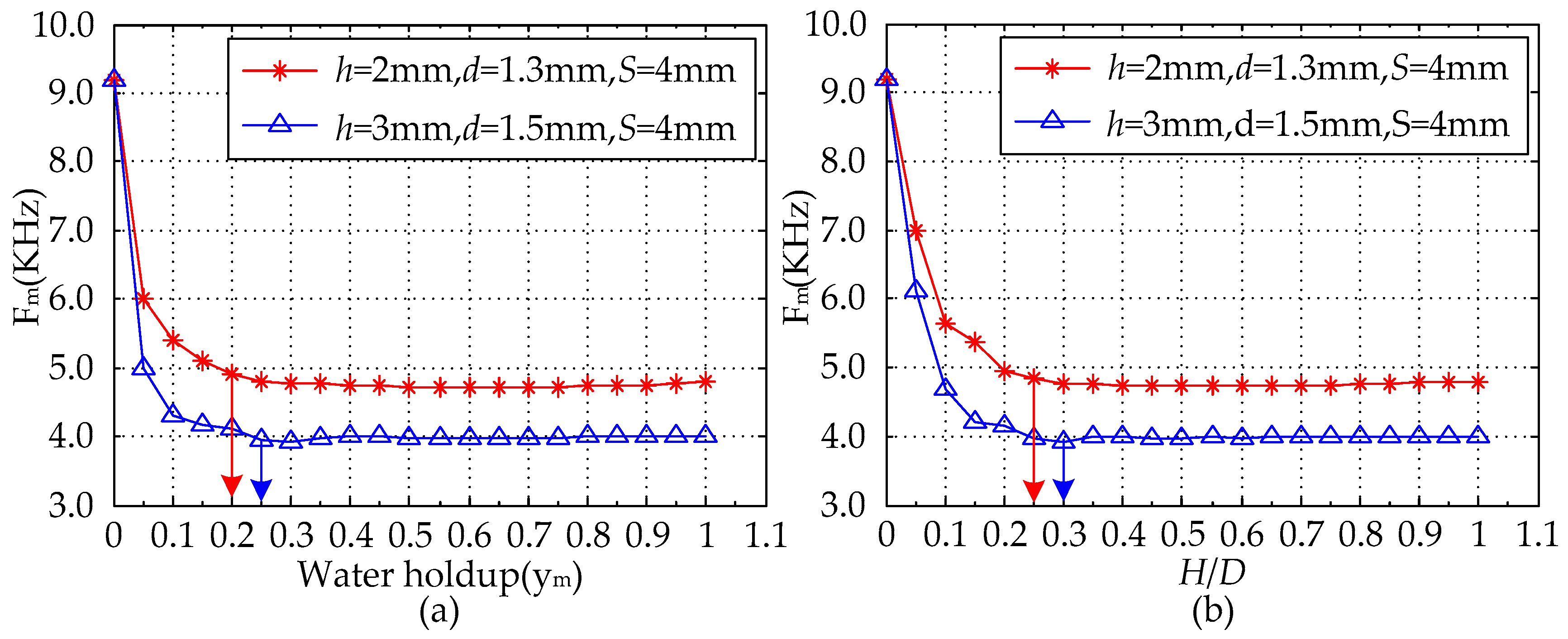

Figure 17 shows the comparison of the MCP with different structure parameters measuring the horizontal oil-water segregated distribution response results. As can be observed from

Figure 17, the range of both

ym and

H/

D are from 0 to 1, which can be described as: when

ym = 0 or

H/

D = 0, the measured result of the MCP is the pure-oil value; when

ym = 1 or

H/

D = 1, the measured result of the MCP is pure-water value; and when 0 <

ym < 1 or 0 <

H/

D < 1, the measured result of the MCP is between the pure-oil value and the pure-water value. The measured values of the MCP with different structure parameters in the conditions of pure oil and pure water are shown in

Table 3. As can be seen, the measured MCP values have obvious differences for the conditions of pure oil and pure water, which can be attributed to the distinctive resistivity differences of water and oil. Meanwhile, when

ym = 0 or

H/

D = 0, i.e., the condition of pure oil, the measured values of sensors with different structure parameters are exactly the same, which can be attributed to the fact that the measured voltage reaches saturation in the actual circuit system. When

ym = 1 or

H/

D = 1, i.e., the condition of pure water, the measured values of the sensors with different structure parameters are different, which can be attributed to the different electric field or high sensitivity sensitive area generated by the two electrodes in the measurement field. With the increase of

ym or

H/

D, under the conditions of lower

ym or

H/

D, the measured frequency signal

Fm of the MCP with two different structure parameters shows obvious differences and decreasing tendency, which could be attributed to the stronger electric field in the measurement region, where the non-conducting oil phase is located in the high sensitivity sensitive area analyzed from

Figure 4,

Figure 7 and

Figure 10. When

ym or

H/

D is greater than or equal to a constant value, the response result of the MCP is pretty close to the pure-water value, and it is gently influenced by the non-conducting oil phase, which can be attributed to the non-conducting oil phase being away from the high sensitivity sensitive area. Therefore, under the conditions of higher

ym or

H/

D, the MCP can obtain a reliable and accurate pure-water value, which can be used as the pure-water correction for water content measurements in horizontal oil-water segregated flow. As can be seen from

Figure 17a, in the condition of the MCP with

D = 20 mm,

h = 3 mm,

d = 1.5 mm and

S = 4 mm, the response result

Fm is pretty close to pure-water value when

ym is greater than or equal to 0.25. In the condition of the MCP with

D = 20 mm,

h = 2 mm,

d = 1.3 mm and

S = 4 mm, the response result

Fm is pretty close to pure-water value when

ym is greater than or equal to 0.20. As can be seen from

Figure 17b, in the condition ofthe MCP with

D = 20 mm,

h = 3 mm,

d = 1.5 mm and

S = 4 mm, the response result

Fm is pretty close to the pure-water value when

H/

D is greater than or equal to 0.30. In the condition of the MCP with

D = 20 mm,

h = 2 mm,

d = 1.3 mm and

S = 4 mm, the response result

Fm is pretty close to pure-water value when

H/

D is greater than or equal to 0.25.

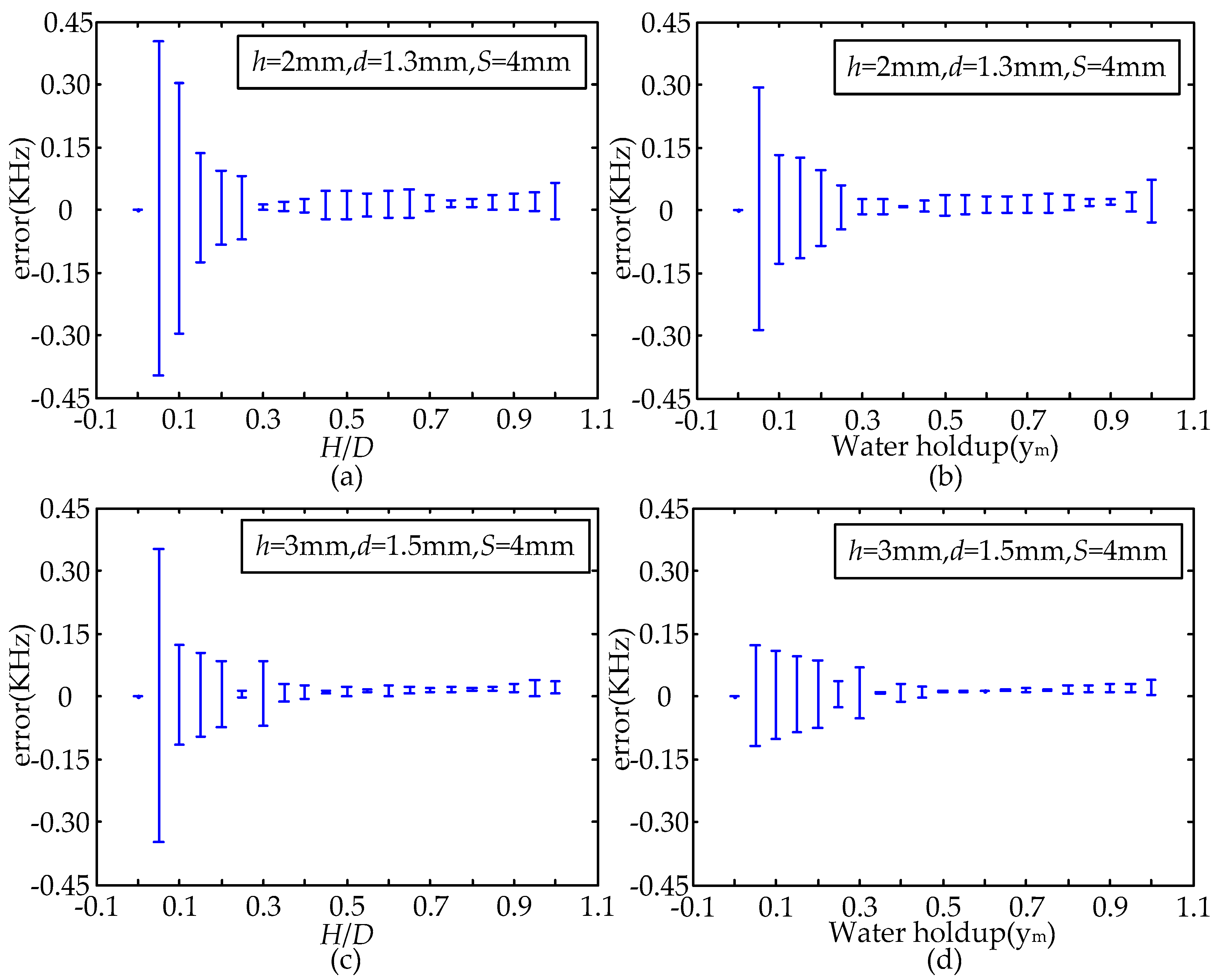

Considering the influence of the repeatability errors of measurement and system errors comprehensively, the measurement error of the experimental point can be obtained by calculating the mean square error for the data set of the repeated experiments and long time records to the corresponding experimental point. The error bars of the MCP with two different structure parameters in the conditions of

ym and

H/

D are shown in

Figure 18. As can be seen from

Figure 18, the measured error of each structure sensor has obvious difference in the conditions of

ym or

H/

D, under the condition of lower

ym or

H/

D, the distribution of measured error has a great fluctuation, which can be attributed to the weak fluctuation of the fluid in the measurement region, where the non-conducting oil phase is located in the high sensitivity sensitive area. When

ym or

H/

D is greater than or equal to a constant value, the measured error of the MCP is very small, which can be attributed to the fact that the non-conducting oil phaseis away from the high sensitivity sensitive area, and it indicates that the MCP can obtain an accurate pure-water value in horizontal oil-water segregated flow.

In

Figure 4d,

Figure 7d,

Figure 10d and

Figure 17, it is found that the MCP with

D = 20 mm has good measurement characteristics for oil-water segregated flow in case of high

ym or

H/

D in static experiments. Meanwhile, the MCP measured result tends to be constant, i.e., the pure-water value, in the conditions of

H/

D ((

h + 3)/20, 1) or

ym ((

h + 2)/20, 1), which shows that the smaller the parameter

h of the MCP is, the larger the low or non-sensitive area along the

Y-axis in the sensor measurement field is, the smaller the critical value of

ym or

H/D which is needed for getting pure-water correction, and the easier obtaining pure-water phase conductivity is.

From the comprehensive analysis of the simulation calculation and static experiment, under the condition of H/D ((h + 3)/20, 1) or ym ((h + 2)/20, 1), the measured value of the MCP in the horizontal oil-water segregated flow is approximately equal to the pure-water value, the MCP has good characteristics such as being stable and reliable for pure-water correction measurements with the continuous water phase, and the sensors whose value of the parameter h is minor have great adaptability in horizontal oil-water segregated flow.

Therefore, the response result of the MCP could be given as the calibration result of pure-water phase conductivity works satisfactorily in static experiments of oil-water segregated flow. Furthermore, the critical value of ym or H/D which is needed for getting the pure-water correction is not only related to the parameter h, but also the parameter D, simultaneously. Therefore, it is necessary to further investigate the effect of the parameter D on the performance of MCP in the future. Also the flow loop test will be carried out in the future to further examine the performance of the MCP.