Dynamic Calibration and Verification Device of Measurement System for Dynamic Characteristic Coefficients of Sliding Bearing

Abstract

:1. Introduction

2. Identification Theories and Methods for Dynamic Characteristic Coefficients of Sliding Bearing

3. Constitution and Dynamic Calibration Method of the Measurement System

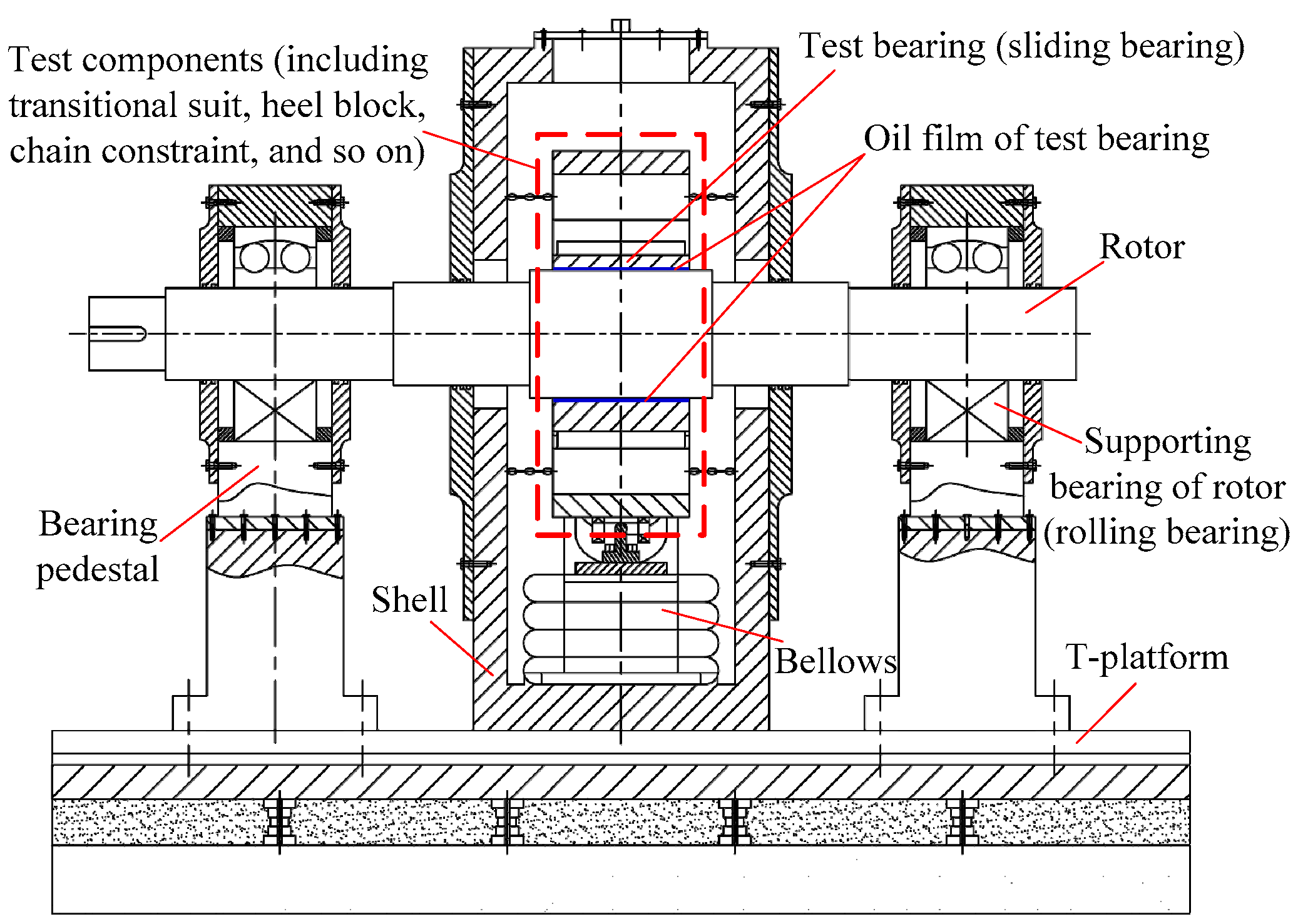

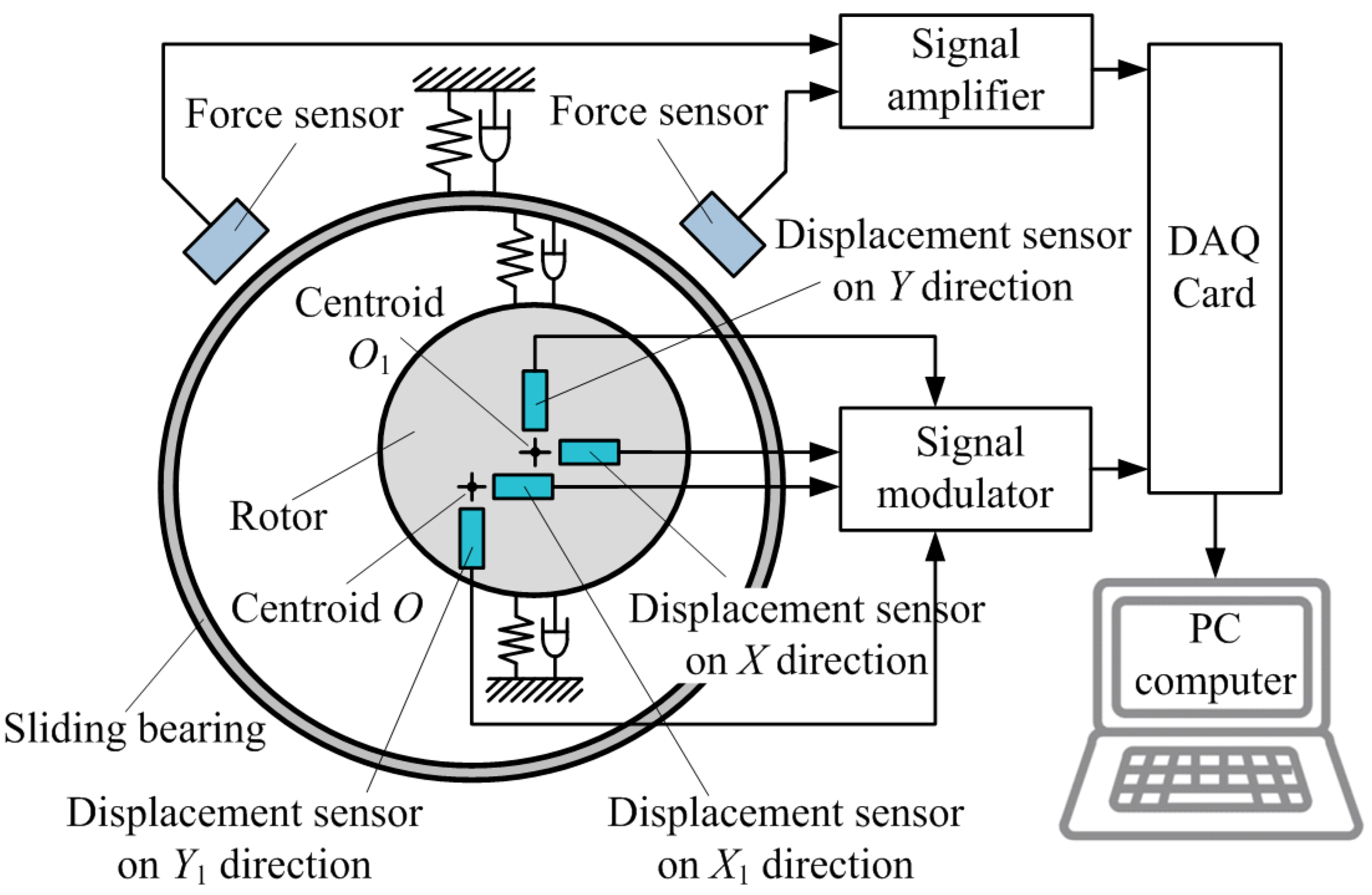

3.1. Constitution of the Measurement System

3.2. Error Propagation Analysis of Test Signals

3.3. Dynamic Calibration Method of Measurement System

4. Dynamic Calibration Device and Experiment

4.1. Dynamic Calibration Device

4.2. Analysis of Experiment Results Analysis

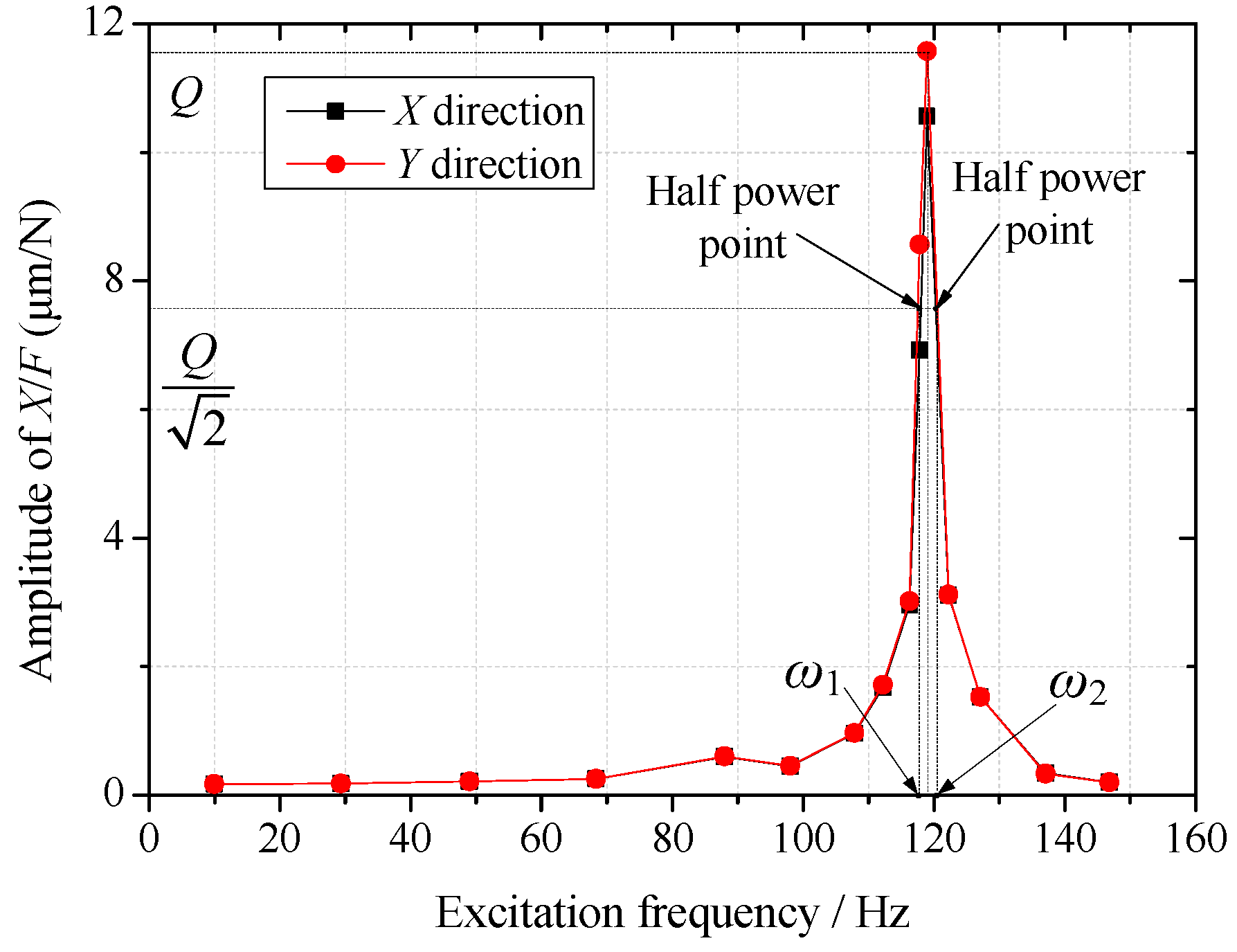

4.2.1. Damping Identification of Calibration Device

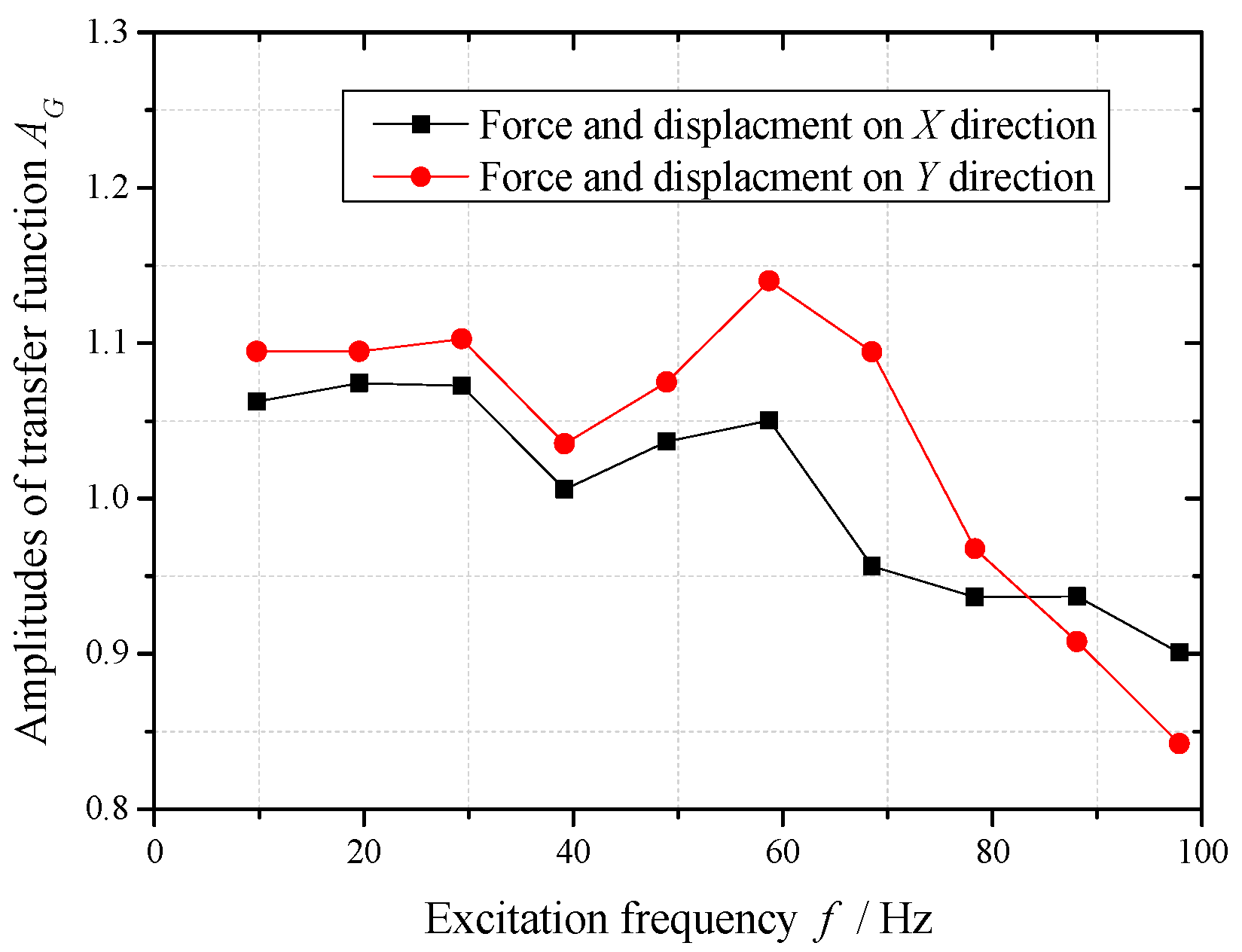

4.2.2. Calibration Data of the Measurement System under Different Frequencies

4.2.3. Identification Experiment of Dynamic Characteristic Coefficients Using the Calibration Data

5. Conclusions

- (1)

- For the measurement system for dynamic characteristics coefficients of sliding bearing, a novel dynamic calibration method by jointly calibrating multiple test channels is proposed in this paper. The calibration device contains a spring-mass system, which can simulate the dynamical characteristics of the sliding bearing.

- (2)

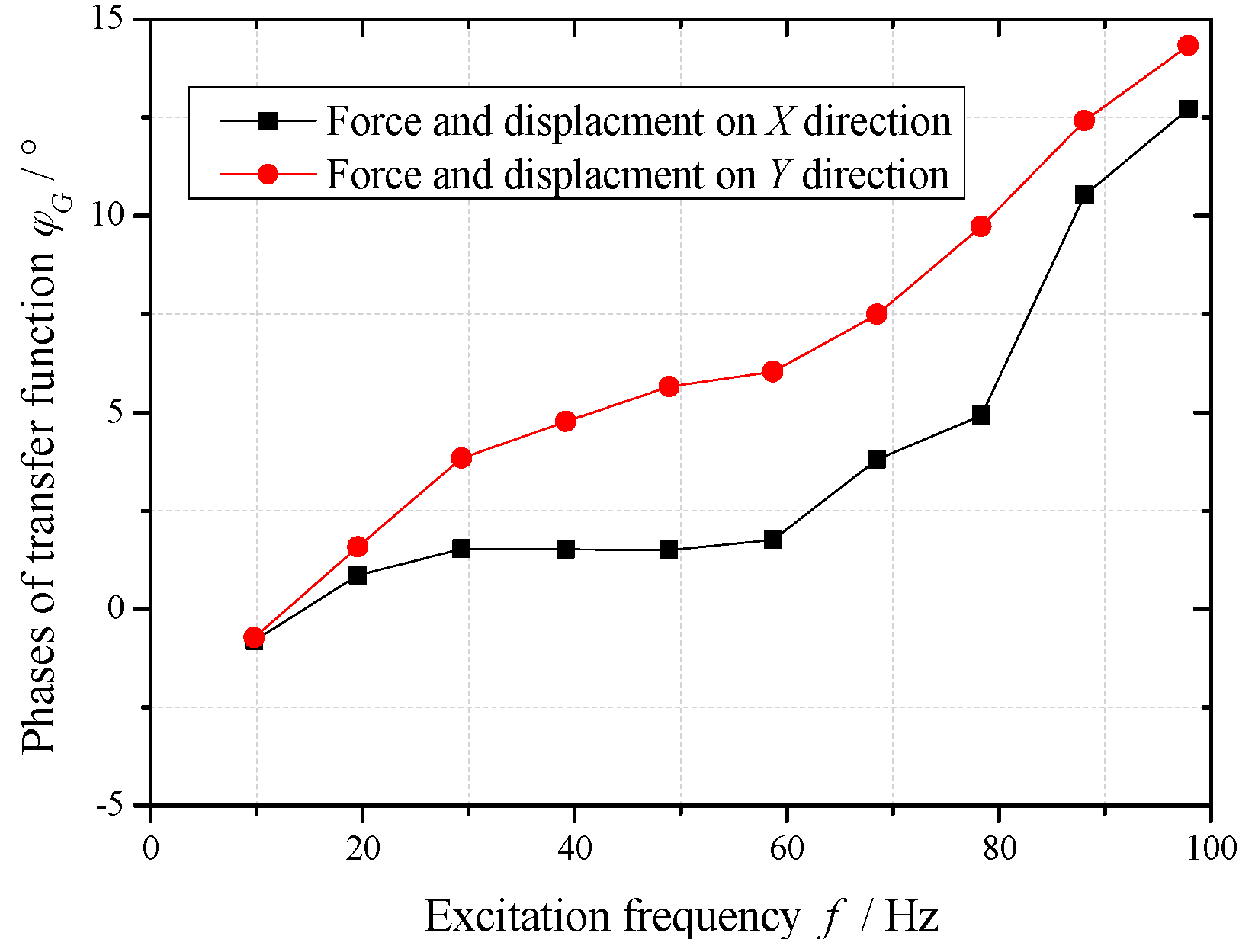

- The dynamic calibration device, including the piezo-actuator, force sensor and eddy current displacement sensor is designed and built. The dynamic calibration experiment in a wide frequency range simulating the bearing stiffness by disc springs is implemented. The experimental results show that the amplitude errors of this measurement system are small (less than ±15%) in the frequency range of 10 Hz–100 Hz, and the phase errors increase along with the increasing of frequency.

- (3)

- The simulated experiment of dynamic characteristics coefficients identification is implemented on this calibration device using the calibration data of this measurement system in the frequency range of 10 Hz–30 Hz. The identification errors of principal stiffnesses are respectively −2.36% and −3.58%, and the identification errors of principal dampings are 18.58% and 7.48%, which are all far smaller than the identification errors without calibration. It is preliminarily verified that the calibration data in this frequency range can support the dynamic characteristics test of sliding bearing in this frequency range well.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dowson, D.; Taylora, C.M. The state of knowledge in the field of bearing influenced rotor dynamics. Tribol. Int. 1980, 13, 196–198. [Google Scholar] [CrossRef]

- Nordmann, R. Identification of stiffness and damping coefficients of journal bearings by means of the impact method. Int. Cent. Mech. Sci. 1980, 273, 231–238. [Google Scholar]

- Lin, J.R. The influences of longitudinal surface roughness on sub-critical and super-critical limit cycles of short journal bearings. Appl. Math. Model. 2014, 38, 392–402. [Google Scholar] [CrossRef]

- Yuan, X.Y.; Wang, H.B.; Gao, Y.; Wang, S.H.; Qiu, D.M. A study on the oil film stiffness and damping coefficients of hydrodynamic journal bearings. Chin. J. Mech. Eng. 1992, 28, 83–87. (In Chinese) [Google Scholar]

- Li, Z.; Yuan, X.Y.; Zhu, J. A study of linear and non-linear dynamic performance for tilting-pad thrust bearing. Chin. Mech. Eng. 2000, 11, 560–562. (In Chinese) [Google Scholar]

- Sawicki, J.T.; Rao, T.V.V.L.N. Nonlinear prediction of rotor dynamic coefficients for a hydrodynamic journal bearing. Tribol. Trans. 2001, 44, 367–374. [Google Scholar] [CrossRef]

- Lin, J.R.; Lu, R.F.; Chu, L.M.; Hung, C.R. The effects of non-Newtonian rheology in the dynamic coefficients of wide slider bearings with a secant-shaped film profile. Ind. Lubr. Trib. 2013, 65, 351–356. [Google Scholar] [CrossRef]

- Yuan, X.Y. Research on the Dynamic Coefficients of Hydrodynamic Journal Bearing and Its Test Methods. Master’s Thesis, Xi’an Jiaotong University, Xi’an, China, June 1985. [Google Scholar]

- Yuan, X.Y.; Qiu, D.M. Measurement and application of the dynamic performances of oil-film of fixed-pad bearing by taking the perturbation frequency into consideration. J. Vib. Shock 1992, 11, 84–88. (In Chinese) [Google Scholar]

- Murphy, B.T.; Wagner, M.N. Measurement of rotor dynamic coefficients for a hydrostatic radial bearing. J. Trib. 1991, 11, 518–525. [Google Scholar] [CrossRef]

- Sun, W.L. Research on Recognition Methods of Oil-Film Dynamic Characteristics of Journal Bearing Based on Adaptive Signal Process. Master’s Thesis, Xi’an Jiaotong University, Xi’an, China, June 2002. [Google Scholar]

- Qiu, Z.L.; Tieu, A.K. Identification of sixteen force coefficients of two journal bearings from impulse responses. Wear 1997, 212, 206–212. [Google Scholar] [CrossRef]

- Chen, W.; Fan, H.J.; Wu, L.J. Review of water lubricated bearing for high speed spindle. Chin. Eng. Sci. 2013, 15, 21–27. (In Chinese) [Google Scholar]

- Jiang, G.D.; Xie, Y.B. The time domain multi-conditions identifying method of oil film coefficients of journal bearing. Shanghai Steam Turbine 1999, 1, 13–21. [Google Scholar]

- Zheng, T.S.; Xu, Q.Y. Identification of journal bearing oil-film dynamic coefficients by attaching additional masses to a rotor. J. Xi’an Jiaotong Univ. 1992, 26, 99–106. [Google Scholar]

- Xu, H.; Jiang, G.D.; Cong, H.; Xie, Y.B.; Wang, F.C. Experimental investigation on the dynamic properties of tilting pad journal bearing. Tribology 2001, 21, 385–389. [Google Scholar]

- Zhang, Y.Y.; Xie, Y.B.; Qiu, D.M. Identification of linearized oil-film coefficients in a flexible rotor-bearing system, Part II: Experiment. J. Sound Vib. 1992, 152, 549–559. [Google Scholar] [CrossRef]

- Sha, B.J.; Wang, J.P.; Li, H.C.; Yin, D.Z.; Guo, K.X. Experimental investigation on oil film dynamic properties of high speed sliding bearing. Shanghai Steam Turbine 1985, 4, 38–47. (In Chinese) [Google Scholar]

- Parkins, D.W. Measurement of oil film journal bearing damping coefficients: An extension of the selected orbit technique. J. Trib. 1995, 117, 696–701. [Google Scholar] [CrossRef]

- Khatri, R.; Childs, D.W. An experimental investigation of the dynamic performance of a vertical- application three-lobe bearing. J. Eng. Gas Turbines Power 2015, 137. [Google Scholar] [CrossRef]

- Tschoepe, D.P.; Childs, D.W. Measurements versus predictions for the static and dynamic characteristics of a four-pad, rocker-pivot, tilting-pad journal bearing. J. Eng. Gas Turbines Power 2014, 136. [Google Scholar] [CrossRef]

- Jiang, G.D.; Xie, Y.B.; Hu, H.; Xu, W.; Jin, Z.W. Identification of oil film coefficients of large journal bearings. Lubr. Eng. 1998, 1, 18–21. (In Chinese) [Google Scholar]

- Kozánek, J.; Šimek, J.; Steinbauer, P.; Bílkovský, A. Identification of stiffness and damping coefficients of aerostatic journal bearing. Eng. Mech. 2009, 16, 209–220. [Google Scholar]

- Peng, L. Model, Numerical Simulation and Test for Dynamic Characteristics Coefficients of Large Aspect Ratio Water Lubricated Journal Bearing. Master’s Thesis, Xi’an Jiaotong University, Xi’an, China, June 2013. [Google Scholar]

- Hu, X.N.; Dai, Y.M.; Wang, H.; Chen, S.Z.; Cheng, J.S.; Li, Y.; Cui, C.Y.; Li, L.K.; Yan, L.G. Design and fabrication of a conduction-cooled superconducting magnet for hall sensor calibration. IEEE Tran. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Lüken, M.; Misgeld, B.J.E.; Rüschen, D.; Leonhardt, S. Multi-sensor calibration of low-cost magnetic, angular rate and gravity systems. Sensors 2015, 15, 25919–25936. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cicco, M.D.; Iocchi, L.; Grisetti, G. Non-parametric calibration for depth sensors. Robot. Auton. Syst. 2015, 74, 309–317. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Wang, Y.; Fei, Y.T. Error modeling research of displacement dynamic measuring system. Tool Eng. 2006, 40, 53–56. [Google Scholar]

- Meyer, R.; Kühn, S.; Pokovic, K.; Bomholt, F.; Kuster, N. Novel sensor model calibration method for resistively loaded diode detectors. IEEE Trans. Electromagn. Compat. 2015, 57, 1345–1353. [Google Scholar] [CrossRef]

- Qin, H.H.; Song, A.G.; Liu, Y.Q.; Jiang, G.H.; Zhou, B.H. Design and calibration of a new 6 DOF haptic device. Sensors 2015, 15, 31293–31313. [Google Scholar] [CrossRef] [PubMed]

- Tang, T.S.; Chen, J.H.; Wu, F.J.; Zheng, W.F.; Zhang, H.F. Research and practice of time synchronization in kinematic measurement system. Hydrogr. Surv. Charting 2009, 29, 13–17. [Google Scholar]

- Zhang, W.; Zhang, J.; Qian, M.; Sun, B.Y.; Ren, Z.J. Research on small-force measuring system and its dynamic calibration equipment. Transducer Microsyst. Technol. 2008, 27, 8–10. [Google Scholar]

- Li, L.N.; Liu, H.Y.; Luo, Z.; Wang, F. LS-SVM-FLANN-based nonlinear dynamic compensation for virtual instrument system. J. Northeastern Univ. (Nat. Sci.) 2009, 30, 1305–1309. [Google Scholar]

- Deng, Q. Model, Instrument Systems and Experiment for Dynamic Characteristics Coefficients Identification of Journal Bearing. Master’s Thesis, Xi’an Jiaotong University, Xi’an, China, June 2012. [Google Scholar]

- Jiang, G.D.; Hu, H.; Xu, W.; Jin, Z.W.; Xie, Y.B. Identification of oil film coefficients of large journal bearings on a full scale journal bearing test rig. Tribolo. Int. 1997, 30, 789–793. [Google Scholar] [CrossRef]

- Guo, Y. Study on the Model for Tilting-Pad Bearing Stability in the Large Units and Performance Test. Ph.D. Thesis, Xi’an Jiaotong University, Xi’an, China, June 2012. [Google Scholar]

| Physical Quantities | First Excitation | Second Excitation | ||||

|---|---|---|---|---|---|---|

| Exciting Force F1 | Displacement on X Direction | Displacement on Y Direction | Exciting Force F2 | Displacement on X Direction | Displacement on Y Direction | |

| Units | N | μm | μm | N | μm | μm |

| Frequencies | 19.54 | 19.6 | 19.53 | 29.33 | 29.32 | 29.32 |

| Amplitudes | 22.1 | 4.54 | 4.72 | 90.87 | 16.95 | 17.52 |

| Phases | −83.82 | −83.43 | −82.72 | 150.9 | −27.85 | 154.56 |

| Simulated Dynamic Characteristic Coefficients | Units | Given Values | Identification Results | |||

|---|---|---|---|---|---|---|

| Not Calibrated | Error % | After Calibrated | Error % | |||

| kxx | (×106) N/m | 4.09 | 3.724 | −8.95 | 3.993 | −2.36 |

| kxy | (×106) N/m | 0 | −0.055 | - | −0.071 | - |

| kyx | (×106) N/m | 0 | −0.075 | - | −0.103 | - |

| kyy | (×106) N/m | 4.09 | 3.598 | −12.02 | 3.944 | −3.58 |

| cxx | N/(m∙s−1) | 146 | −347.463 | −337.99 | 173.126 | 18.58 |

| cxy | N/(m∙s−1) | 0 | 167.316 | - | 68.165 | - |

| cyx | N/(m∙s−1) | 0 | 343.945 | - | 87.227 | - |

| cyy | N/(m∙s−1) | 146 | −866.497 | −693.49 | 156.923 | 7.48 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Wei, Y.; Shi, Z.; Yuan, X. Dynamic Calibration and Verification Device of Measurement System for Dynamic Characteristic Coefficients of Sliding Bearing. Sensors 2016, 16, 1202. https://doi.org/10.3390/s16081202

Chen R, Wei Y, Shi Z, Yuan X. Dynamic Calibration and Verification Device of Measurement System for Dynamic Characteristic Coefficients of Sliding Bearing. Sensors. 2016; 16(8):1202. https://doi.org/10.3390/s16081202

Chicago/Turabian StyleChen, Runlin, Yangyang Wei, Zhaoyang Shi, and Xiaoyang Yuan. 2016. "Dynamic Calibration and Verification Device of Measurement System for Dynamic Characteristic Coefficients of Sliding Bearing" Sensors 16, no. 8: 1202. https://doi.org/10.3390/s16081202