The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating

Abstract

:1. Introduction

- (1)

- The resolution needs to be improved for small ice load measuring. In the initial icing on the phase conductor, the increment of load caused by ice is only several hundred Newtons. Thus, the sensor resolution needs to be improved.

- (2)

- The load error caused by temperature variation should be reduced. Theoretically, the wavelength shifts of two FBGs mounted on one elastic element is the same under temperature variation. However, field experiments indicate that the wavelength shift difference is about 10 pm under temperature variation [8,12]. In addition, the difference may approach 30 pm in special conditions of strong, cold wind or intense sunlight. Since the load error caused by temperature variation depends on product of the load sensitivity (N/pm) and wavelength shift difference, the load error should be reduced by improving load sensitivity.

- (3)

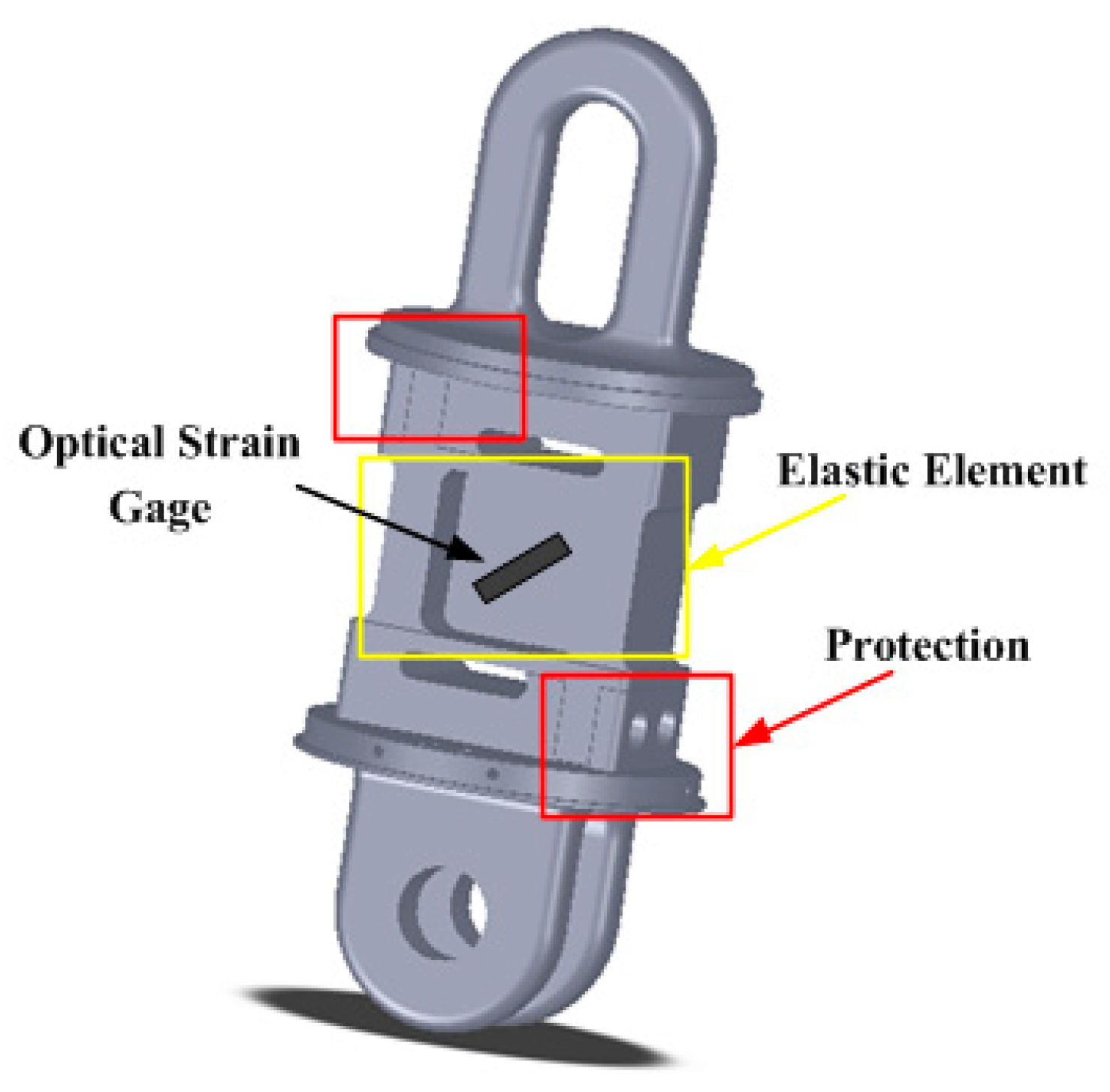

- Load protection needs to be added to avoid failure under heavy ice load. The mechanical strength request of the FBG load cell is the same as the fitting on the tower of high-voltage overhead transmission lines. For example, the failure load of a sample load cell should be larger than 160 kN according the standard of 110 kV fittings [13], and the effective strain range and sensitivity of a commercial FBG strain gauge is ±2000 µε and 1.4 pm/µε. Thus, the resolution of a sensor without protection is not able to be lower than 57.14 N, otherwise the FBG gauge will fail under heavy load. However, according to (1) the resolution needs to be improved for small ice load measurement. Therefore, load protection needs to be added to balance the resolution and safety range. In addition, for the conventional load cell without protection, the plastic deformation of the elastic element begins after a heavy load impulse, and the repeatability of the load cell is hard to maintain.

2. Principle of the Load Cell

2.1. Principle of FBG Sensing

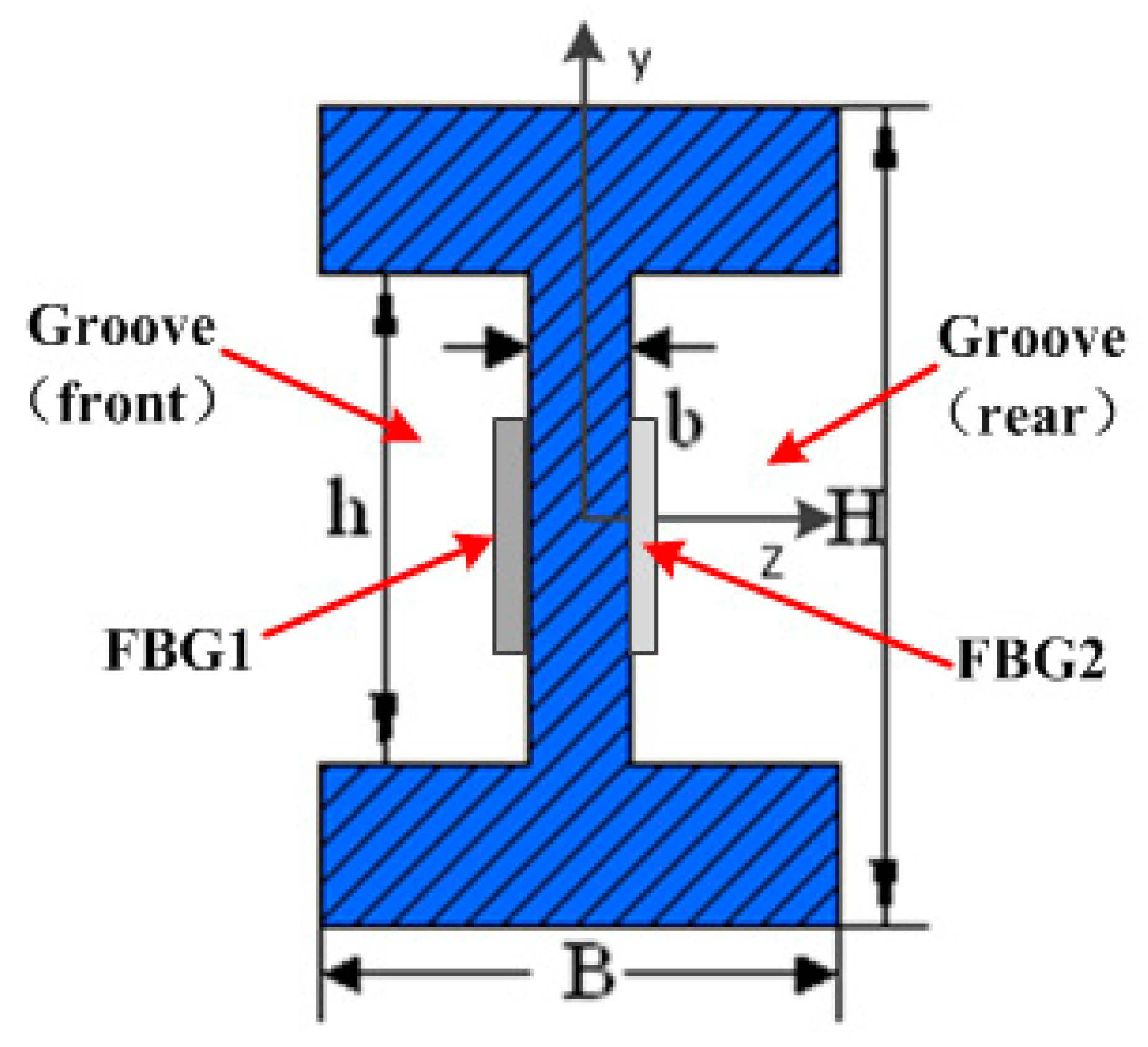

2.2. Design of the Load Cell

2.3. Theoretical Calculation of Elastic Element

- (a)

- The direction of shearing stress is in consistent with shearing force; and

- (b)

- The distribution of shearing stress on the cross-section is uniform.

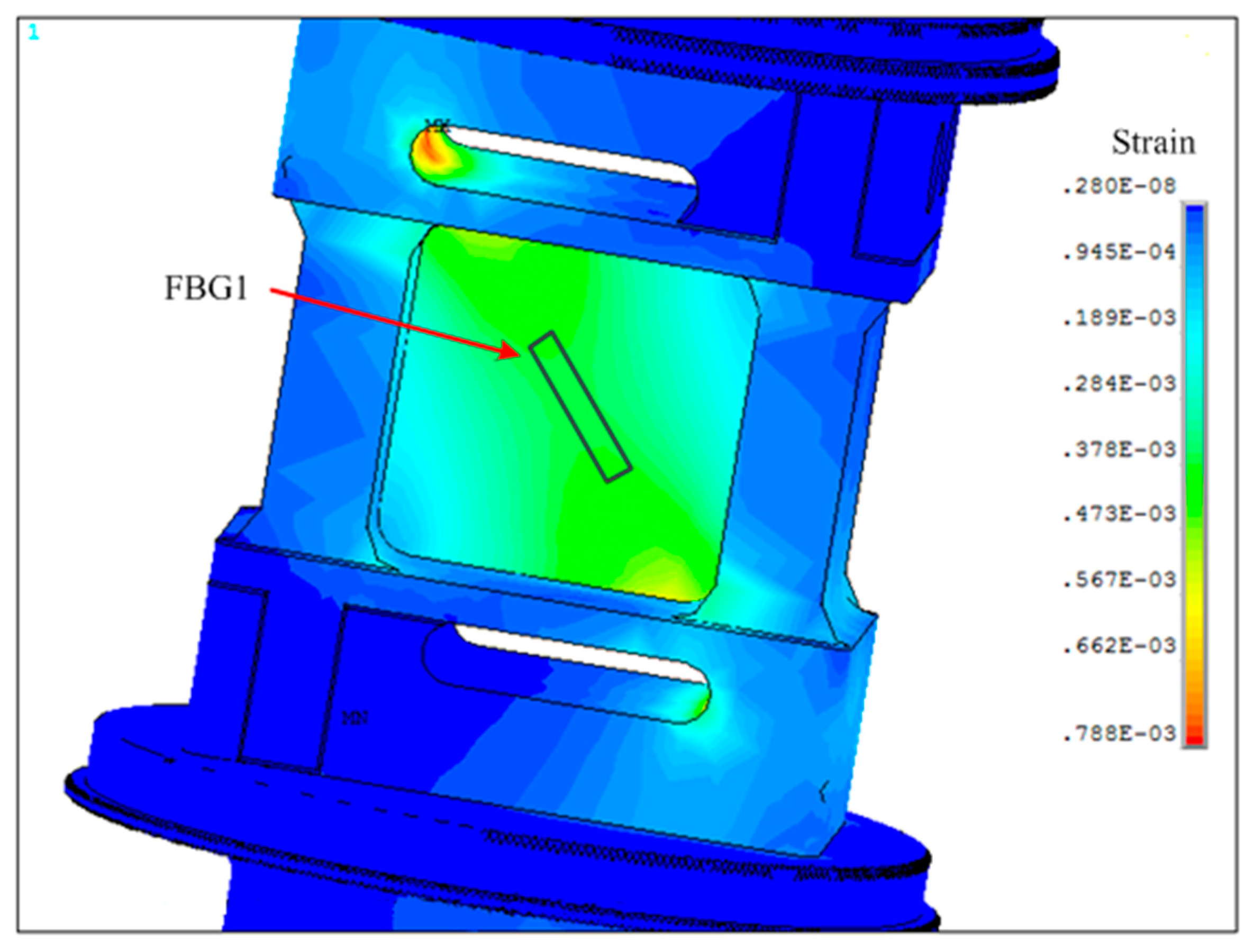

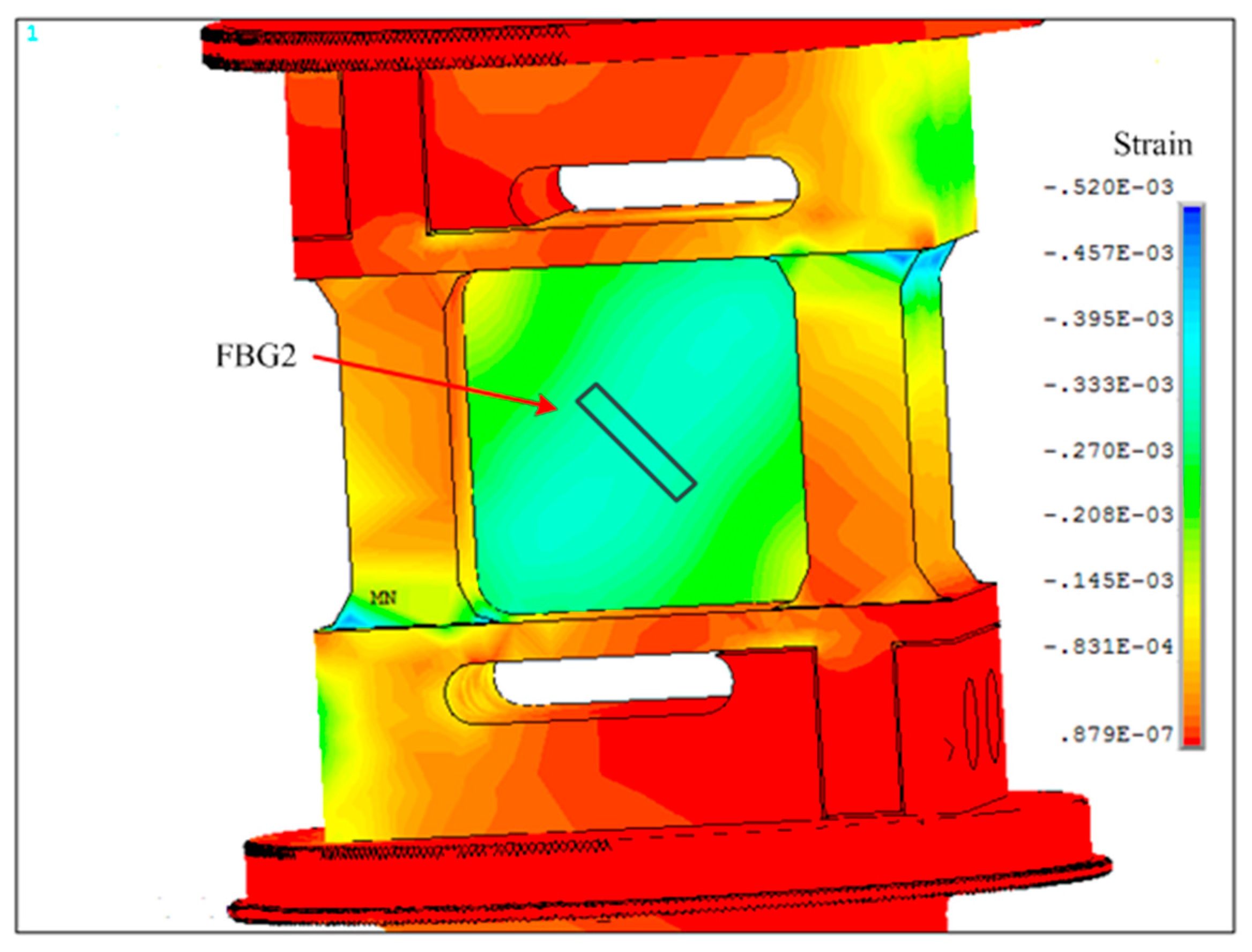

2.4. FEM (Finite-Element Method) Analysis of the Elastic Element

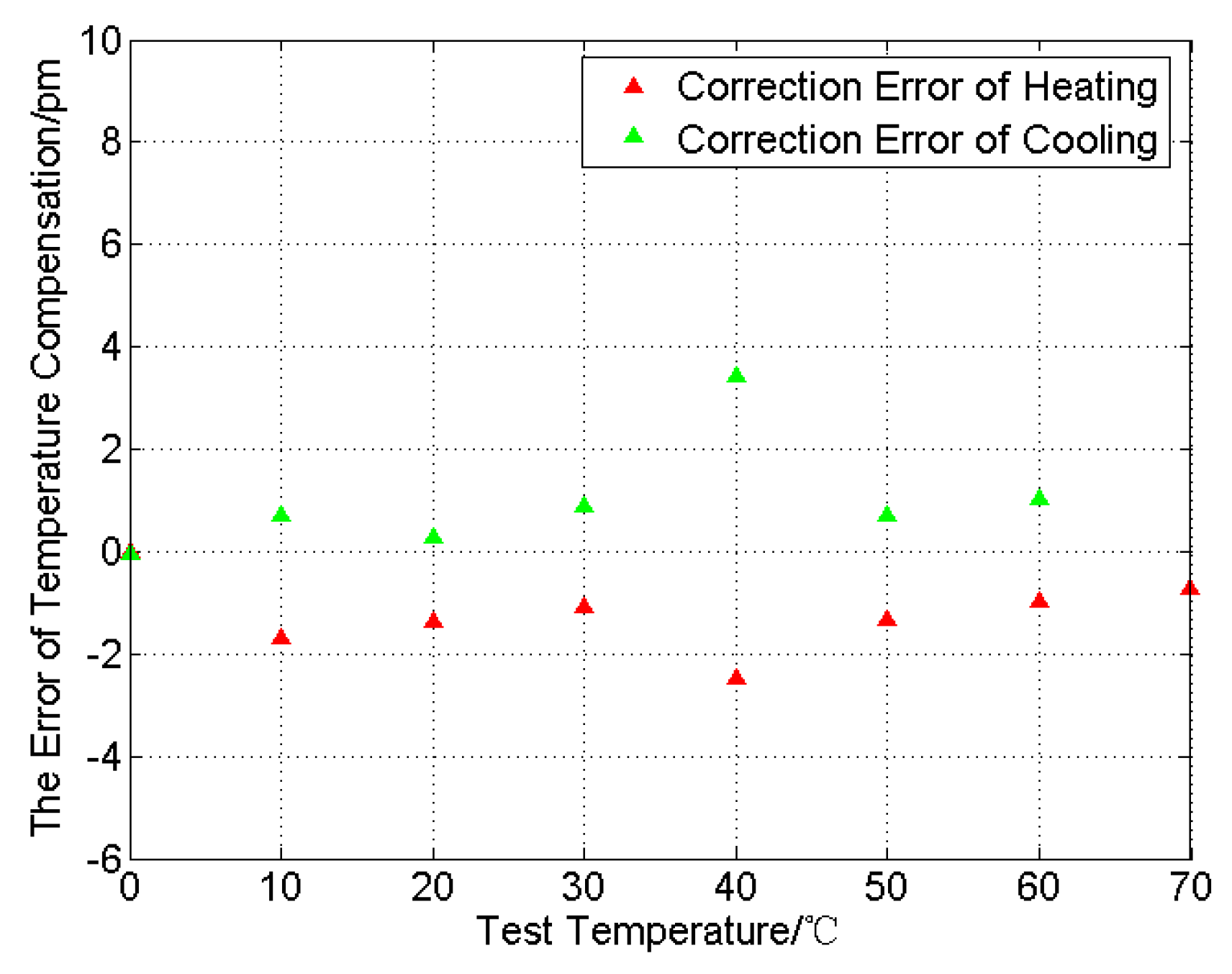

3. Temperature Experiment of Load Cell

3.1. The Arrangement of Temperature Compensation Experiment

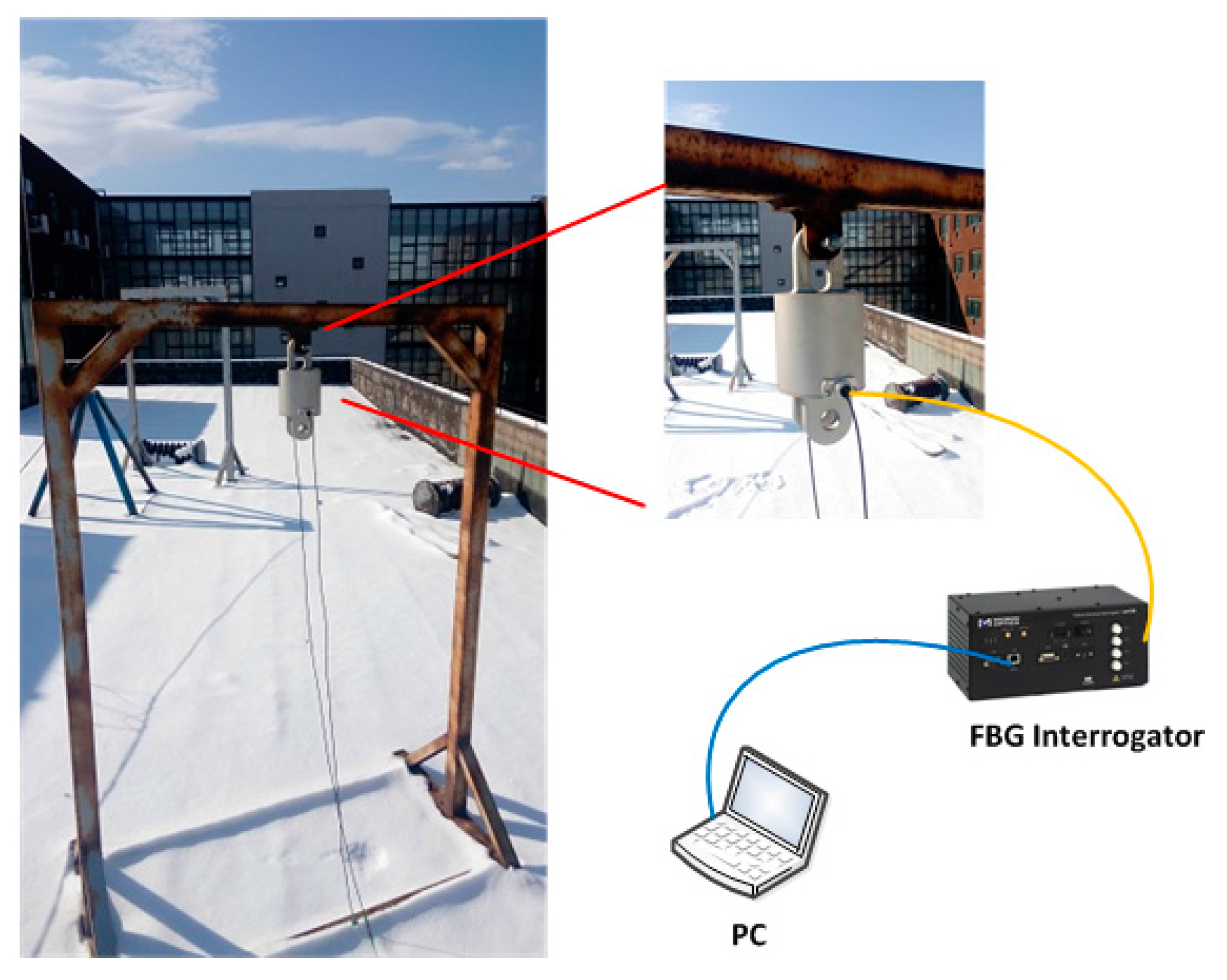

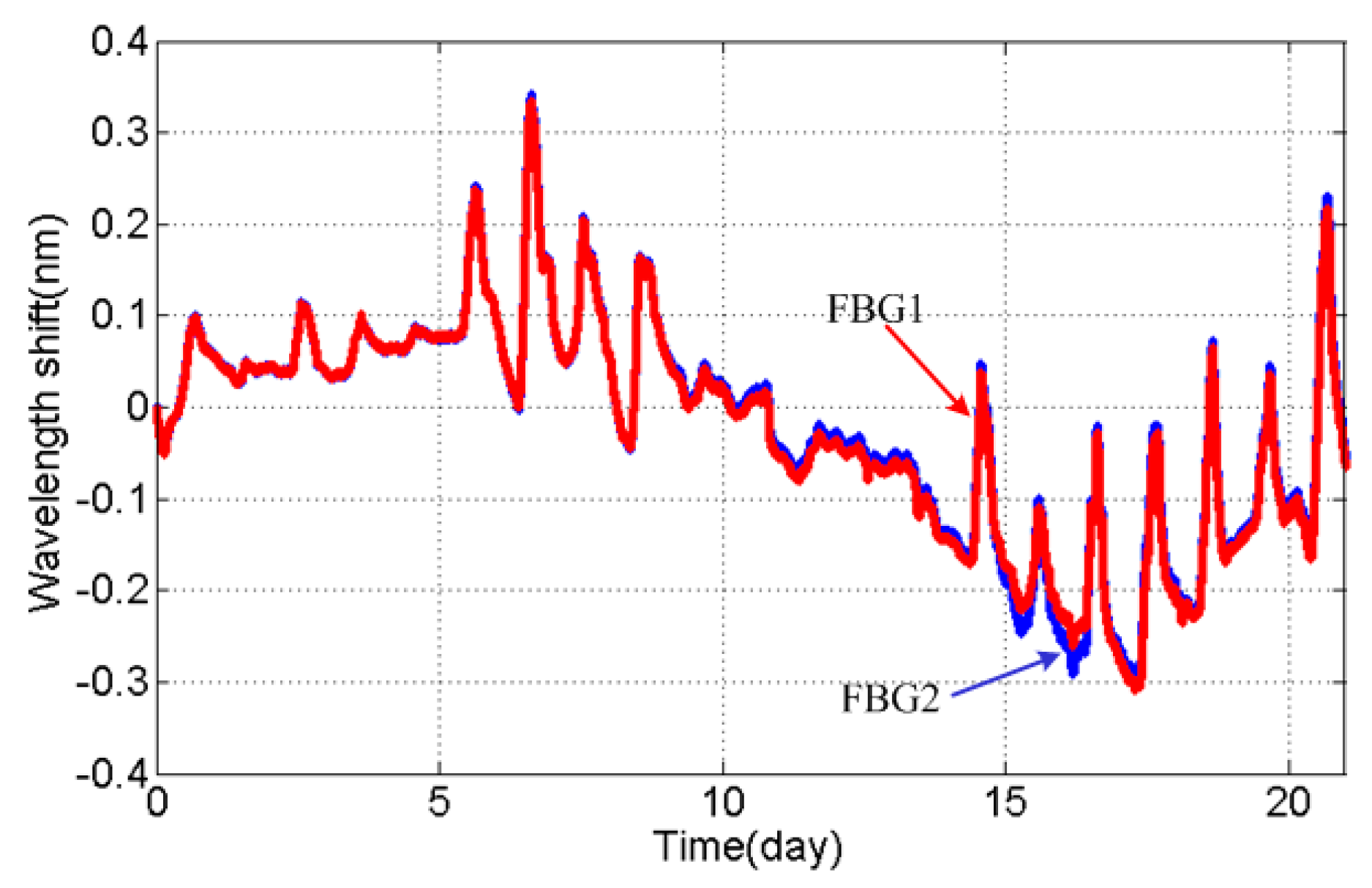

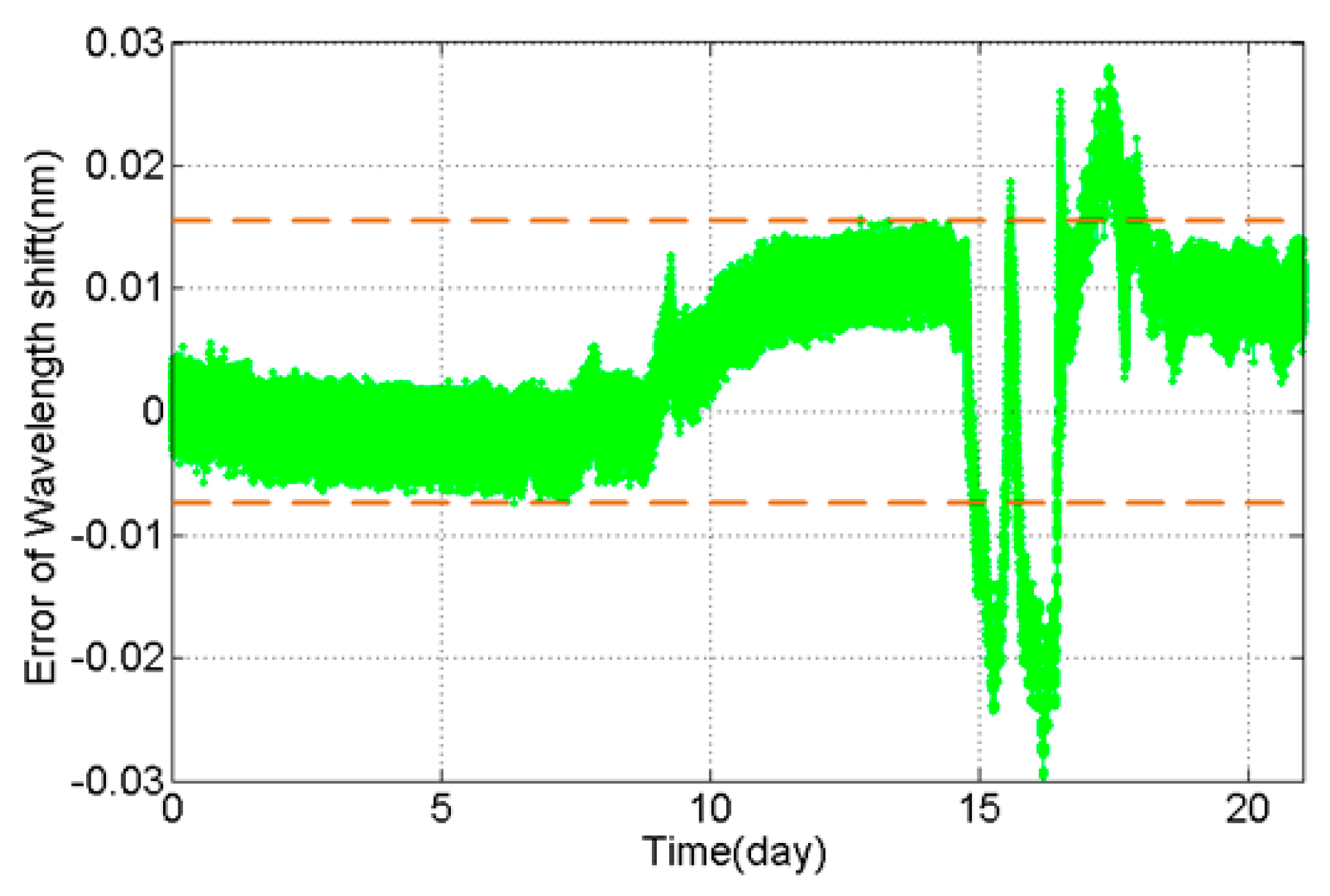

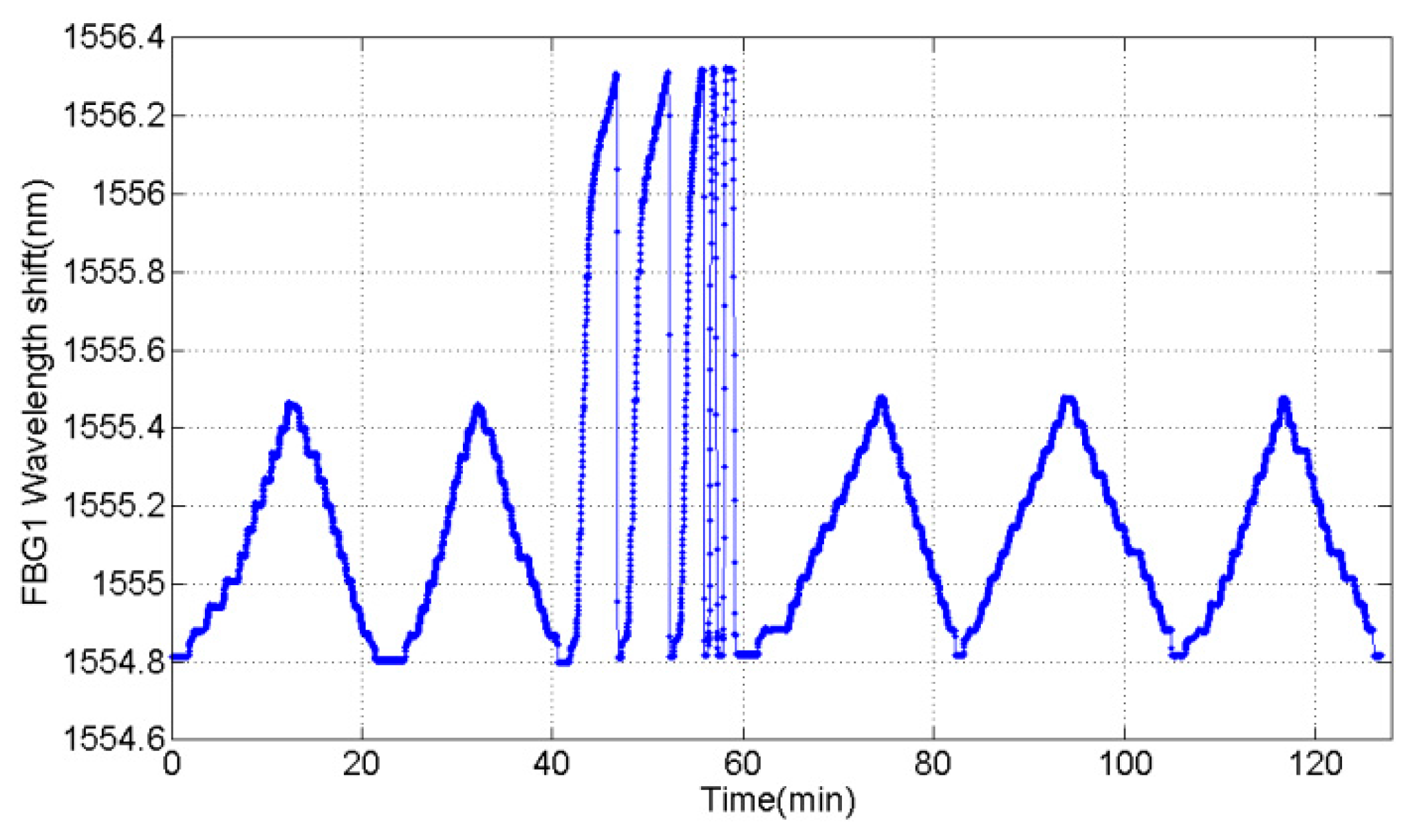

3.2. Outdoor Tempereture Experiment

4. Tension Experiment of Load Cell

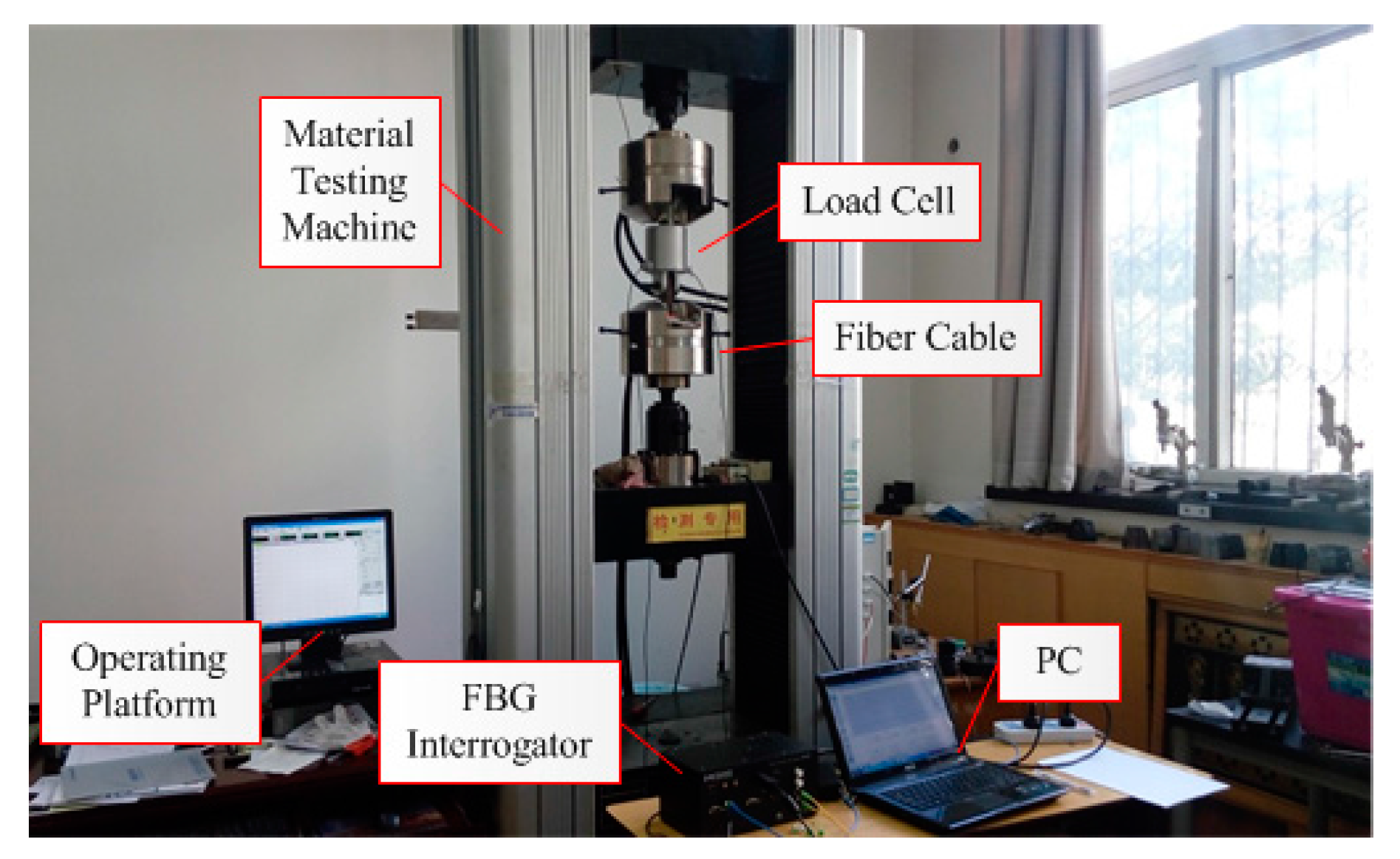

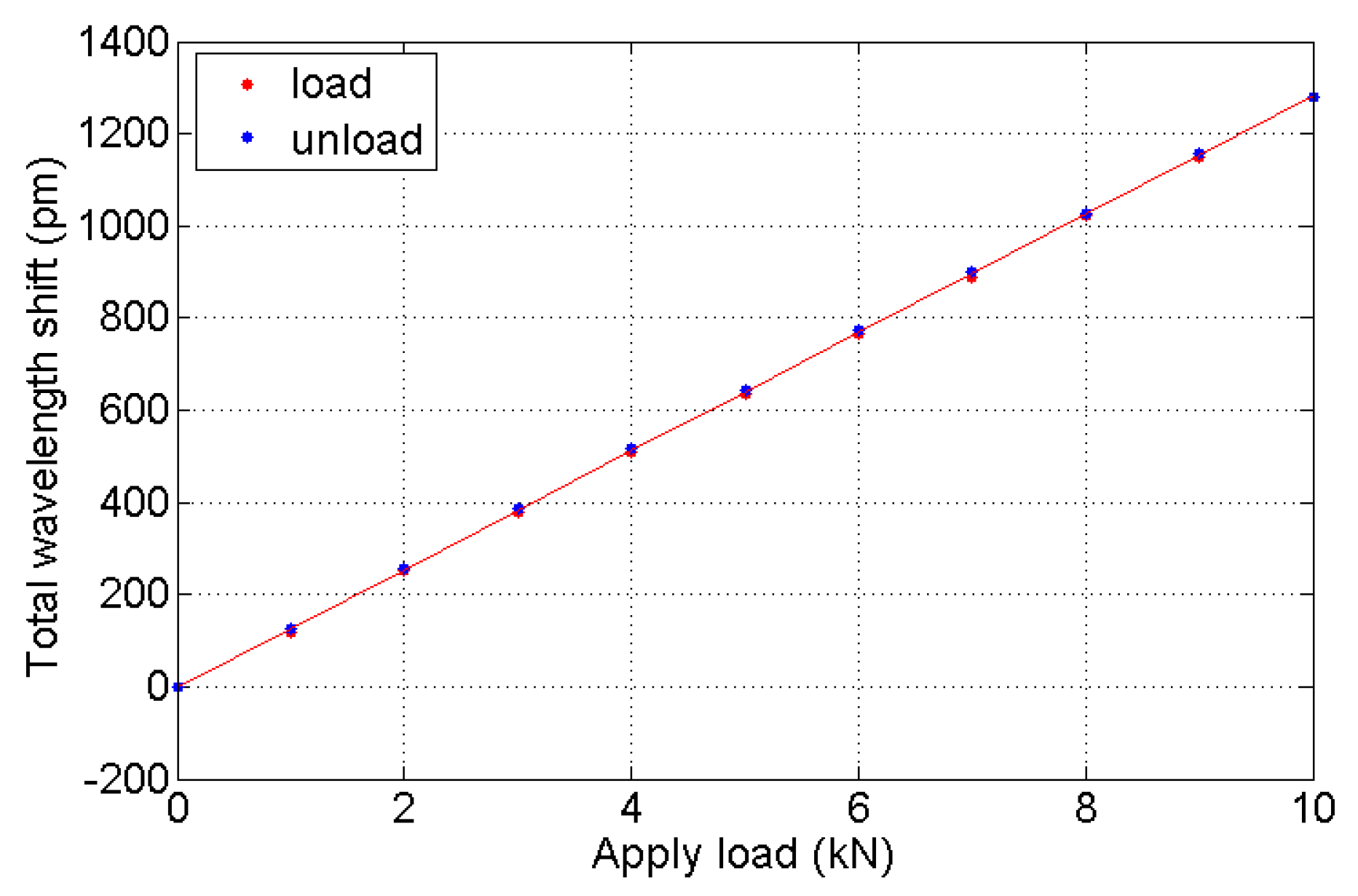

4.1. The Arrangement of the Tension Sensing Experiment

4.2. The Overload Examination of Load Cell

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- CIGRE Working Group B2.06. Big Storm Events: What We Have Learned (TB 344); CIGRE: Paris, France, 2009; pp. 28–30. [Google Scholar]

- CIGRE Working Group B2.29. Systems for Prediction and Monitoring of Ice Shedding, Anti-Icing and De-Icing for Overhead Lines (TB 438); CIGRE: Paris, France, 2010; pp. 9–15. [Google Scholar]

- Lu, J.Z.; Zeng, M.; Zeng, X.J.; Fang, Z.; Yuan, J. Analysis of Ice-Covering Characteristics of China Hunan Power Grid. IEEE Trans. Ind. Appl. 2015, 51, 1997–2002. [Google Scholar] [CrossRef]

- Savadjiev, K.; Farzaneh, M. Modeling of icing and ice shedding on overhead power lines based on statistical analysis of meteorological data. IEEE Trans. Power Deliv. 2004, 19, 715–721. [Google Scholar] [CrossRef]

- Kalinowski, H.J.; Chaves, R.C.; Abe, I. Multiplexed fiber optic Bragg grating sensors for strain and temperature measurements in power systems. In Proceedings of the International Conference on Fiber Optics and Photonics, New Delhi, India, 14–18 December 1999; pp. 544–553.

- Bjerkan, L. Application of fiber-optic Bragg grating sensors in monitoring environmental loads of overhead power transmission lines. Appl. Opt. 2000, 39, 554–560. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, Y.; Iwasaki, J.-I.; Nakamura, K. A Multiplexing Load Monitoring System of Power Transmission Lines using Fiber Bragg Grating. In Proceedings of the 12th International Conference on Optical Fiber Sensors, Williamsburg, VA, USA, 28–31 October 1997; pp. 468–471.

- Ma, G.M.; Li, C.R.; Quan, J.T.; Jiang, J.; Cheng, Y.C. A fiber Bragg grating tension and tilt sensor applied to icing monitoring on overhead transmission lines. IEEE Trans. Power Deliv. 2011, 26, 2163–2170. [Google Scholar] [CrossRef]

- Xue, Z.H.; Huang, Q.; Zhang, C.H.; Cao, Y.X.; Zhang, R. Icing monitoring system based on fiber Bragg grating sensor for overhead transmission lines. In Proceedings of the 2013 IEEE International Conference on Smart Instrumentation, Measurement and Applications, Kuala Lumpur, Malaysia, 26–27 November 2013; pp. 1–4.

- Zhang, M.; Xing, Y.M.; Zhang, Z.G.; Chen, Q.G. Design and experiment of FBG-based icing monitoring on overhead transmission lines with an improvement trial for windy weather. Sensors 2014, 14, 23954–23969. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.B.; Hao, Y.P.; Ye, Q.; Hao, Y.Q.; Li, L.C. Development of optical fiber sensors based on Brillouin scattering and FBG for on-line monitoring in overhead transmission lines. J. Lightwave Technol. 2013, 31, 1559–1565. [Google Scholar] [CrossRef]

- Ma, G.M.; Li, C.R.; Jiang, J.; Luo, Y.T.; Cheng, Y.C. A novel optical load cell used in icing monitoring on overhead transmission lines. Cold Reg. Sci. Technol. 2012, 71, 67–72. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China. Nominal Failing Load Series and Coupling Dimensions for Electric Power Fitting (GB/T 2315-2008), 3rd ed.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; pp. 1–2.

- Lee, B. Review of the present status of optical fiber sensors. Opt. Fiber Technol. 2003, 9, 57–79. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, W.G.; Zhang, H.; Liu, B.; Zhao, J. An embedded FBG sensor for simultaneous measurement of stress and temperature. IEEE Photonic Technol. Lett. 2006, 18, 154–156. [Google Scholar] [CrossRef]

- Li, K. Review of the strain modulation methods used in fiber bragg grating sensors. J. Sens. 2016, 2016, 8. [Google Scholar] [CrossRef]

- Aneesh, R.; Maharana, M.; Munendhar, P.; Tam, H.Y.; Khijwania, S.K. Simple temperature insensitive fiber bragg grating based tilt sensor with enhanced tunability. Appl. Opt. 2011, 50, E172–E176. [Google Scholar] [CrossRef]

- Kisała, P.; Cięszczyk, S. Method of simultaneous measurement of two direction force and temperature using fbg sensor head. Appl. Opt. 2015, 54, 2677–2687. [Google Scholar] [CrossRef] [PubMed]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Verification Regulation of Load Cell (JJG 669–2003), 2nd ed.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2003; pp. 27–28.

| T (°C) | λ1 (nm) | λ1 (nm) | Δλ1 (nm) | Δλ2 (nm) |

|---|---|---|---|---|

| 0 | 1554.161 | 1549.845 | 0 | 0 |

| 10 | 1554.402 | 1550.082 | 0.241 | 0.237 |

| 20 | 1554.644 | 1550.318 | 0.483 | 0.473 |

| 30 | 1554.888 | 1550.556 | 0.727 | 0.711 |

| 40 | 1555.075 | 1550.740 | 0.914 | 0.895 |

| 50 | 1555.325 | 1550.983 | 1.164 | 1.138 |

| 60 | 1555.567 | 1551.219 | 1.406 | 1.374 |

| 70 | 1555.812 | 1551.458 | 1.651 | 1.613 |

| 60 | 1555.568 | 1551.218 | 1.407 | 1.373 |

| 50 | 1555.326 | 1550.982 | 1.165 | 1.137 |

| 40 | 1555.085 | 1550.744 | 0.924 | 0.899 |

| 30 | 1554.849 | 1550.516 | 0.688 | 0.671 |

| 20 | 1554.618 | 1550.291 | 0.457 | 0.446 |

| 10 | 1554.387 | 1550.065 | 0.226 | 0.220 |

| 0 | 1554.162 | 1549.846 | 0.001 | 0.001 |

| F/kN | /pm | /pm | /pm |

|---|---|---|---|

| 0 | 0 | 0 | 0 |

| 1 | 119 | 120 | 118 |

| 2 | 253 | 253 | 251 |

| 3 | 382 | 379 | 377 |

| 4 | 510 | 511 | 509 |

| 5 | 637 | 636 | 636 |

| 6 | 764 | 762 | 766 |

| 7 | 893 | 891 | 890 |

| 8 | 1021 | 1023 | 1023 |

| 9 | 1149 | 1152 | 1150 |

| 10 | 1281 | 1279 | 1281 |

| 9 | 1157 | 1156 | 1158 |

| 8 | 1033 | 1031 | 1027 |

| 7 | 901 | 905 | 902 |

| 6 | 775 | 774 | 774 |

| 5 | 649 | 649 | 644 |

| 4 | 522 | 522 | 518 |

| 3 | 390 | 391 | 386 |

| 2 | 262 | 259 | 257 |

| 1 | 129 | 127 | 125 |

| 0 | 0 | 0 | 0 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, G.; Mao, N.; Li, Y.; Jiang, J.; Zhou, H.; Li, C. The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating. Sensors 2016, 16, 922. https://doi.org/10.3390/s16060922

Ma G, Mao N, Li Y, Jiang J, Zhou H, Li C. The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating. Sensors. 2016; 16(6):922. https://doi.org/10.3390/s16060922

Chicago/Turabian StyleMa, Guoming, Naiqiang Mao, Yabo Li, Jun Jiang, Hongyang Zhou, and Chengrong Li. 2016. "The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating" Sensors 16, no. 6: 922. https://doi.org/10.3390/s16060922

APA StyleMa, G., Mao, N., Li, Y., Jiang, J., Zhou, H., & Li, C. (2016). The Reusable Load Cell with Protection Applied for Online Monitoring of Overhead Transmission Lines Based on Fiber Bragg Grating. Sensors, 16(6), 922. https://doi.org/10.3390/s16060922