Mechanical Strength and Broadband Transparency Improvement of Glass Wafers via Surface Nanostructures

Abstract

:1. Introduction

2. Materials and Methods

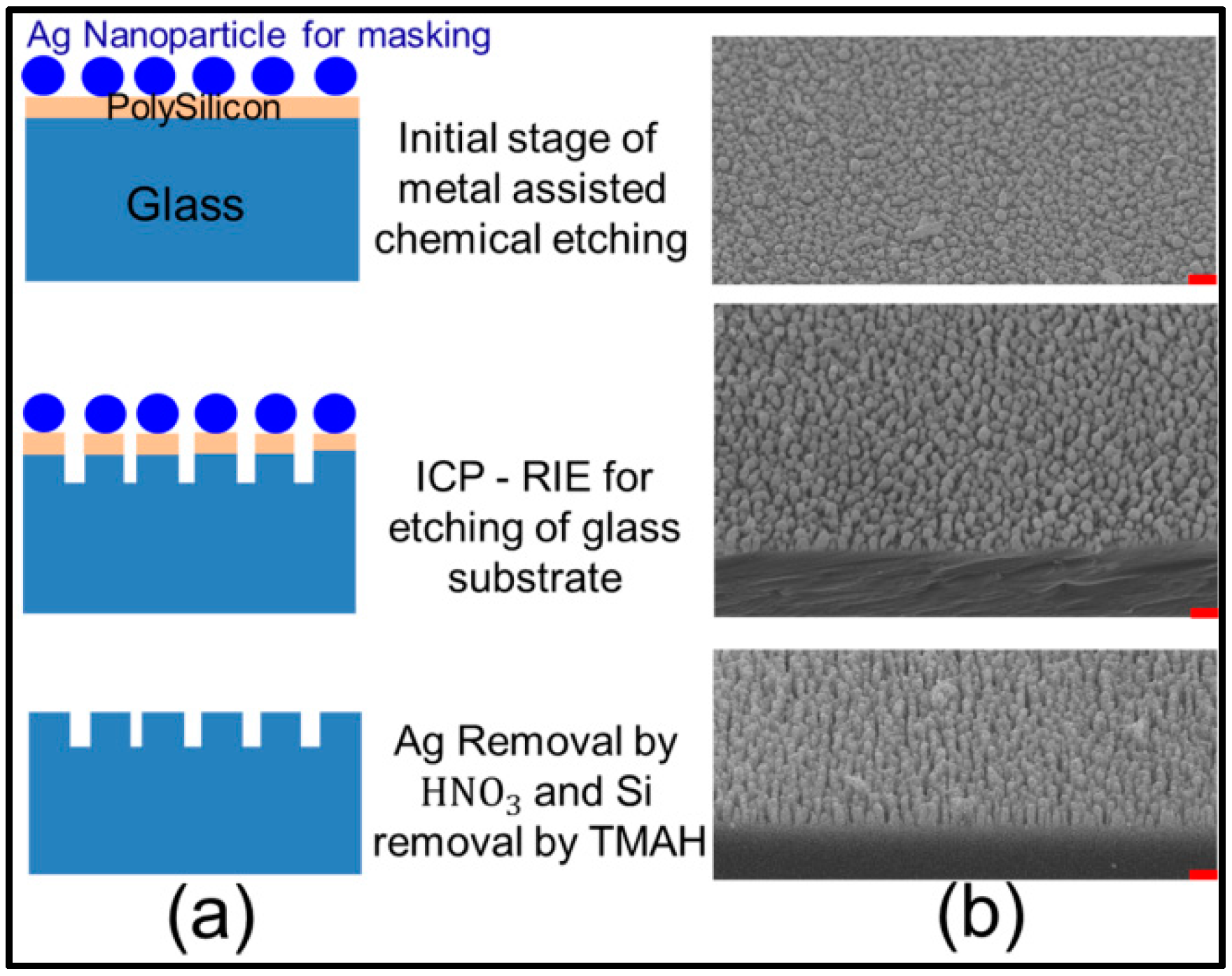

2.1. Nanostructure Fabrication

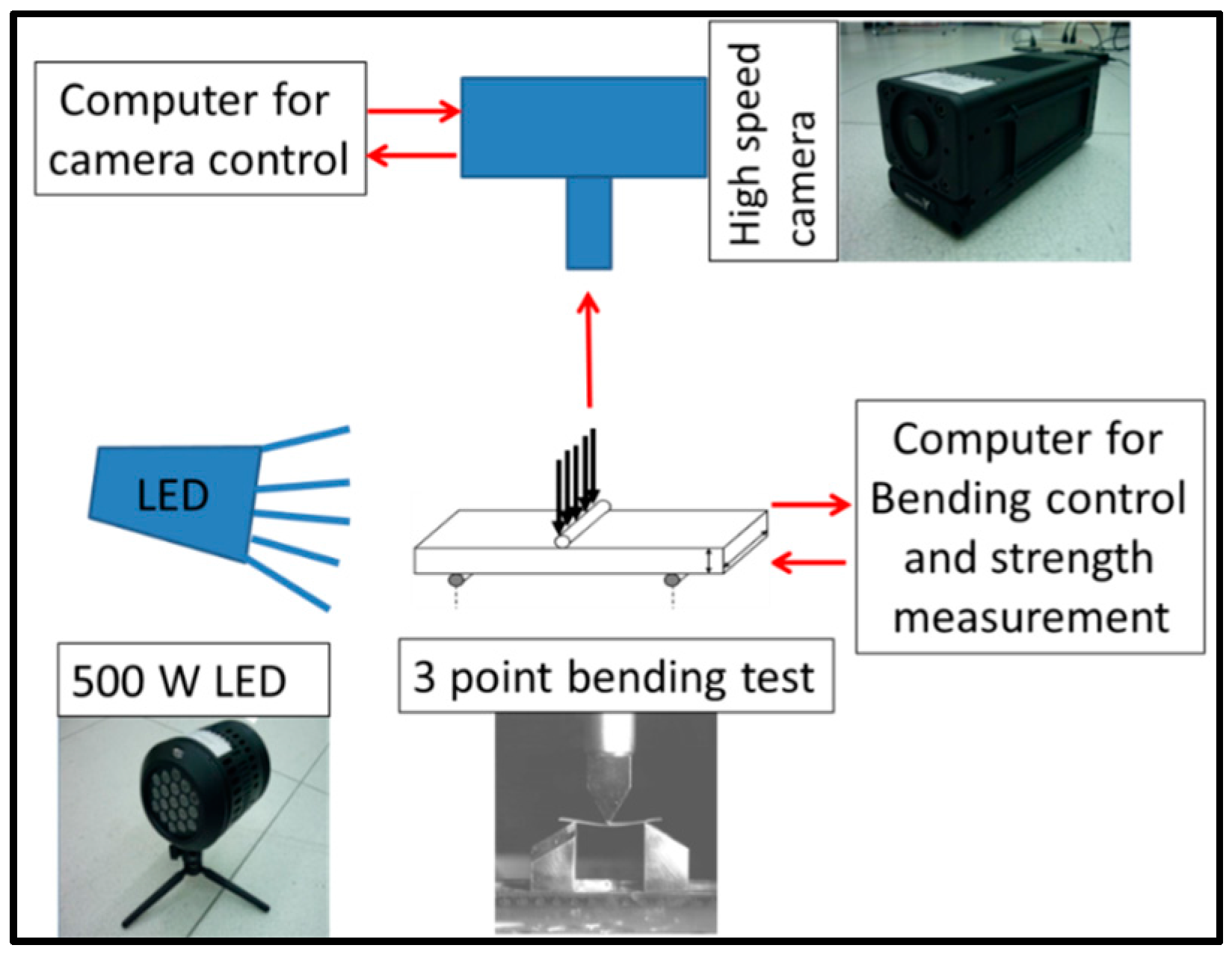

2.2. Three-Point Bending Test

2.3. Fragmentation Analysis Using High Speed Camera

2.4. Transparency and Reflection Measurement

3. Results

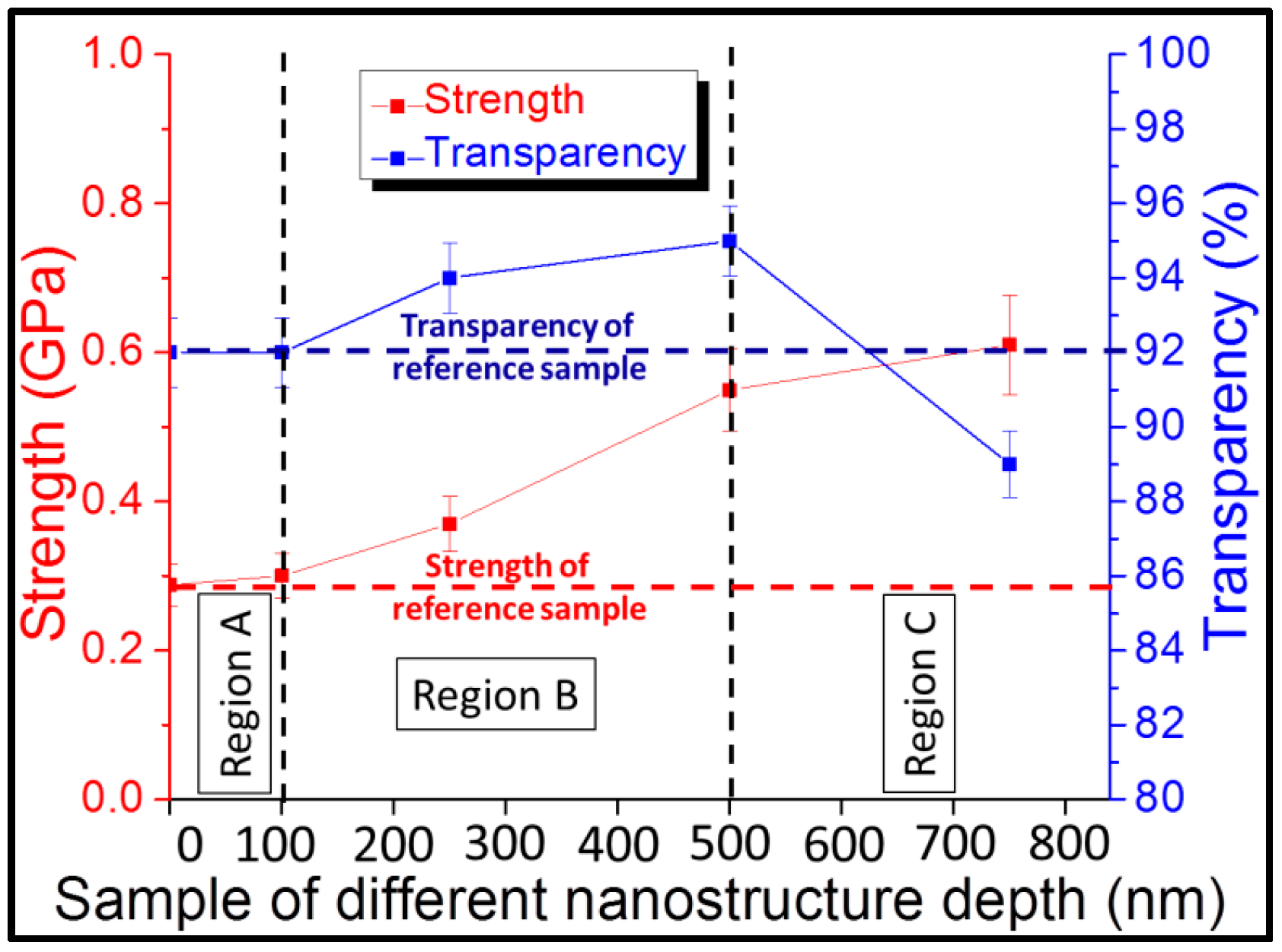

3.1. Bending Strength Measurement for Different Depths of Nanostructure Borosilicate Glass

3.2. Comparison of Load-Displacement Curve Before and After Nanostructure Fabrication

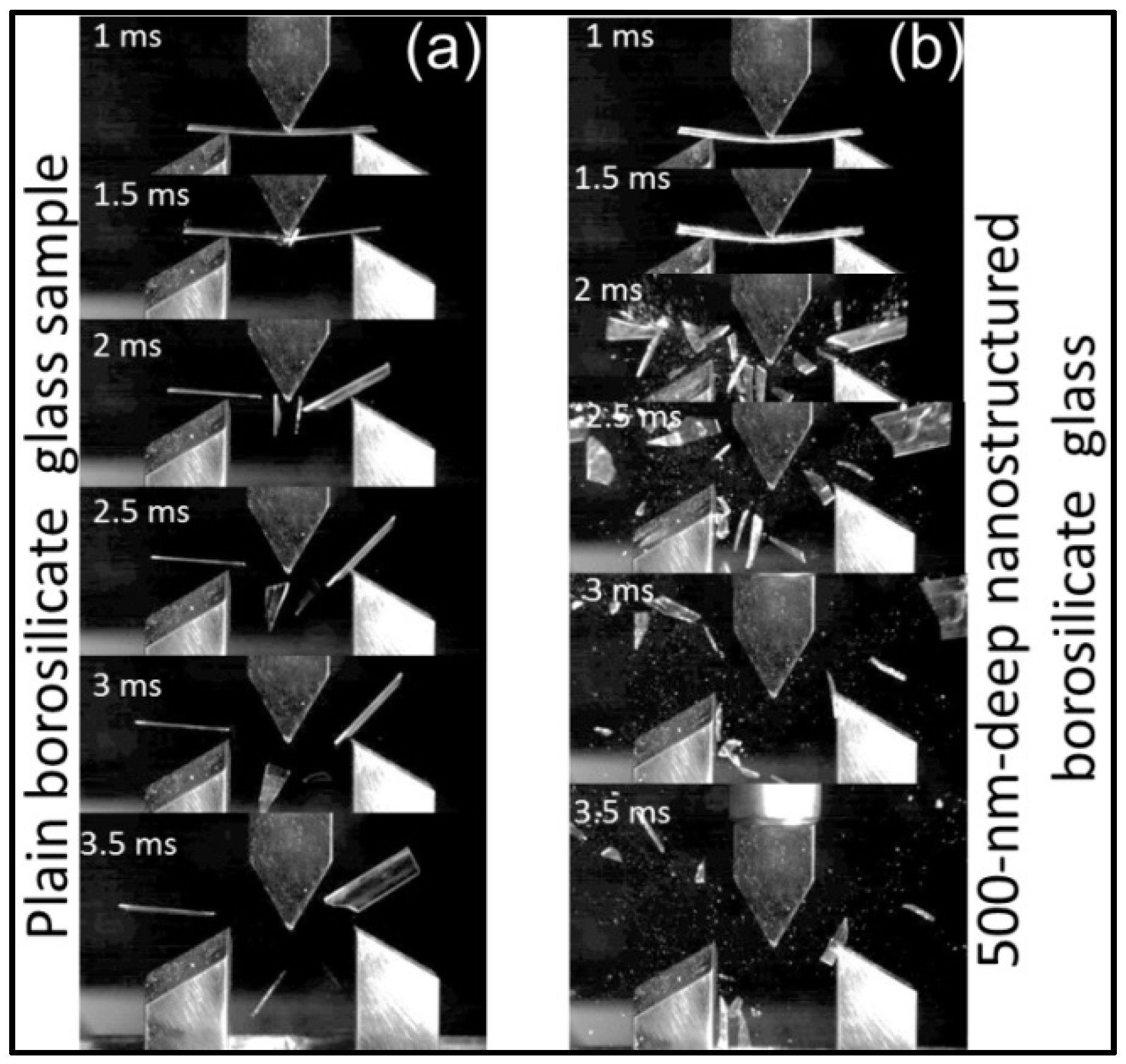

3.3. Fragmentation Analysis Before and After Nanostructure Fabrication

3.4. Transparency and Reflection Comparison for Different Depths of Nanostructured Borosilicate Glass

4. Discussion

4.1. Bending Strength Improvement by Nanostructure Fabrication

4.2. Unchanged Bulk Properties After Nanostructure Fabrication

4.3. Higher Strength Confirmation by Fragmentation Analysis

4.4. Transparency Improvement by Reduction in Reflection

4.5. Optimum Design Window for Enhancement of Strength and Transparency

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PV | Photovoltaic |

| LPCVD | Low pressure chemical vapor deposition |

| ICP-RIE | Inductively coupled plasma reactive ion etching |

| 3PB | Three-point bending |

References

- Brow, R.K.; Schmitt, M.L. A survey of energy and environmental applications of glass. J. Eur. Ceram. Soc. 2009, 29, 1193–1201. [Google Scholar] [CrossRef]

- Ramuz, M.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. Transparent, Optical, Pressure-Sensitive Artificial Skin for Large-Area Stretchable Electronics. Adv. Mater. 2012, 24, 3223–3227. [Google Scholar] [CrossRef] [PubMed]

- Belloy, E.; Sayah, A.; Gijs, M.A. Micromachining of glass inertial sensors. Microelectromech. Syst. J. 2002, 11, 85–90. [Google Scholar] [CrossRef]

- Rao, C.K. Safety of glass panels against wind loads. Eng. Struct. 1984, 6, 232–234. [Google Scholar]

- Liu, X.; Huang, W.; Fu, H.; Yao, A.; Wang, D.; Pan, H.; Lu, W.W. Bioactive borosilicate glass scaffolds: Improvement on the strength of glass-based scaffolds for tissue engineering. J. Mater. Sci. Mater. Med. 2009, 20, 365–372. [Google Scholar] [CrossRef] [PubMed]

- Ruan, Y.; Foo, T.C.; Warren-Smith, S.; Hoffmann, P.; Moore, R.C.; Ebendorff-Heidepriem, H.; Monro, T.M. Antibody immobilization within glass microstructured fibers: A route to sensitive and selective biosensors. Opt. Express 2008, 16, 18514–18523. [Google Scholar] [CrossRef] [PubMed]

- Haldimann, M. Fracture strength of structural glass elements. OAI 2006. [Google Scholar] [CrossRef]

- Lo, C.-M.; Wang, H.-B.; Dembo, M.; Wang, Y.-L. Cell movement is guided by the rigidity of the substrate. Biophys. J. 2000, 79, 144–152. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philosophical transactions of the royal society of london. Series A, containing papers of a mathematical or physical character. NASA 1921, 221, 163–198. [Google Scholar]

- Inglis, C. Stresses in a cracked plate due to the presence of cracks and sharp corners. Trans. Naval Arch. (Lond.) 1913, 60, 213. [Google Scholar]

- Varshneya, A.K. Chemical Strengthening of Glass: Lessons Learned and Yet To Be Learned. Int. J. Appl. Glass Sci. 2010, 1, 131–142. [Google Scholar] [CrossRef]

- Hoshide, T.; Nebu, A.; Hayashi, K. Bending strength of borosilicate glass coated with alumina and silicon carbide by RF magnetron sputtering. JSME Int. J. A Solid M 1998, 41, 332–337. [Google Scholar] [CrossRef]

- Gy, R. Ion exchange for glass strengthening. Mater. Sci. Eng. B 2008, 149, 159–165. [Google Scholar] [CrossRef]

- Shim, G.I.; Eom, H.W.; Kim, S.H.; Park, J.K.; Choi, S.Y. Fabrication of lightweight and thin bulletproof windows using borosilicate glass strengthened by ion exchange. Compos. Part B Eng. 2015, 69, 44–49. [Google Scholar] [CrossRef]

- Briggs, A.; Davidge, R.W. Borosilicate Glass Reinforced with Continuous Silicon-Carbide Fibers—A New Engineering Ceramic. Mater. Sci. Eng. A Struct. 1989, 109, 363–372. [Google Scholar] [CrossRef]

- Lampert, C.M. Large-area smart glass and integrated photovoltaics. Sol. Energy Mater. Sol. Cells 2003, 76, 489–499. [Google Scholar] [CrossRef]

- Ellison, A.; Cornejo, I.A. Glass substrates for liquid crystal displays. Int. J. Appl. Glass Sci. 2010, 1, 87–103. [Google Scholar] [CrossRef]

- Ji, S.; Song, K.; Nguyen, T.B.; Kim, N.; Lim, H. Optimal Moth Eye Nanostructure Array on Transparent Glass Towards Broadband Antireflection. ACS Appl. Mater. Int. 2013, 5, 10731–10737. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.W.; Bae, D.S.; Shin, H. Zinc-embedded silica nanoparticle layer in a multilayer coating on a glass substrate achieves broadband antireflection and high transparency. J. Appl. Phys. 2004, 96, 6766–6771. [Google Scholar] [CrossRef]

- Xi, J.Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.F.; Lin, S.Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photonics 2007, 1, 176–179. [Google Scholar]

- Dobrowolski, J.; Poitras, D.; Ma, P.; Vakil, H.; Acree, M. Toward perfect antireflection coatings: Numerical investigation. Appl. Opt. 2002, 41, 3075–3083. [Google Scholar] [CrossRef] [PubMed]

- Bernhard, C.G. Structural and Functional Adaptation in a Visual System. Endeavour 1967, 26, 79–84. [Google Scholar]

- Parker, A.R.; Townley, H.E. Biomimetics of photonic nanostructures. Nat. Nanotechnol. 2007, 2, 347–353. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.Y.; Zhang, X.A.; Bagal, A.; Guo, W.; Chang, C.H. Antireflection effects at nanostructured material interfaces and the suppression of thin-film interference. Nanotechnology 2013, 24, 235202. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, K.; Kumar, A.; Huang, C.T.; Lin, Y.Y.; Hou, M.T.; Yeh, J.A. Elimination of strength degrading effects caused by surface microdefect: A prevention achieved by silicon nanotexturing to avoid catastrophic brittle fracture. Sci. Rep. UK 2015, 5, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Kashyap, K.; Kumar, A.; Hou, M.T.; Yeh, J.A. Sidewall Nanotexturing for High Rupture Strength of Silicon Solar Cells. J. Microelectromech. S 2015, 24, 7–9. [Google Scholar] [CrossRef]

- Kashyap, K.; Zheng, L.C.; Lai, D.Y.; Hou, M.T.; Yeh, J.A. Rollable Silicon IC Wafers Achieved by Backside Nanotexturing. IEEE Electr. Device Lett. 2015, 36, 829–831. [Google Scholar] [CrossRef]

- Kermode, J.R.; Albaret, T.; Sherman, D.; Bernstein, N.; Gumbsch, P.; Payne, M.C.; Csanyi, G.; De Vita, A. Low-speed fracture instabilities in a brittle crystal. Nature 2008, 455, 1224–1227. [Google Scholar] [CrossRef]

- Arora, A.; Marshall, D.B.; Lawn, B.R. Indentation Deformation-Fracture of Normal and Anomalous Glasses. J. Non-Cryst. Solids 1979, 31, 415–428. [Google Scholar] [CrossRef]

- Leonhard, A.; Xing, L.Q.; Heilmaier, M.; Gebert, A.; Eckert, J.; Schultz, L. Effect of crystalline precipitations on the mechanical behavior of bulk glass forming Zr-based alloys. Nanostruct. Mater. 1998, 10, 805–817. [Google Scholar] [CrossRef]

- Cook, R.F.; Pharr, G.M. Direct Observation and Analysis of Indentation Cracking in Glasses and Ceramics. J. Am. Ceram. Soc. 1990, 73, 787–817. [Google Scholar] [CrossRef]

- Park, K.C.; Choi, H.J.; Chang, C.H.; Cohen, R.E.; McKinley, G.H.; Barbastathis, G. Nanotextured Silica Surfaces with Robust Superhydrophobicity and Omnidirectional Broadband Supertransmissivity. ACS Nano 2012, 6, 3789–3799. [Google Scholar] [CrossRef] [PubMed]

- Son, J.; Kundu, S.; Verma, L.K.; Sakhuja, M.; Danner, A.J.; Bhatia, C.S.; Yang, H. A practical superhydrophilic self cleaning and antireflective surface for outdoor photovoltaic applications. Sol. Energy Mater. Sol. Cells 2012, 98, 46–51. [Google Scholar] [CrossRef]

- Lee, J.-M.; Kim, B.-I. Thermal dewetting of Pt thin film: Etch-masks for the fabrication of semiconductor nanostructures. Mater. Sci. Eng. A 2007, 449, 769–773. [Google Scholar] [CrossRef]

- Morhard, C.; Pacholski, C.; Lehr, D.; Brunner, R.; Helgert, M.; Sundermann, M.; Spatz, J.P. Tailored antireflective biomimetic nanostructures for UV applications. Nanotechnology 2010, 21, 425301. [Google Scholar] [CrossRef] [PubMed]

- Nishioka, K.; Horita, S.; Ohdaira, K.; Matsumura, H. Antireflection subwavelength structure of silicon surface formed by wet process using catalysis of single nano-sized gold particle. Sol. Energy Mater. Sol. Cells 2008, 92, 919–922. [Google Scholar] [CrossRef]

- Peng, K.Q.; Yan, Y.J.; Gao, S.P.; Zhu, J. Synthesis of large-area silicon nanowire arrays via self-assembling nanoelectrochemistry. Adv. Mater. 2002, 14, 1164–1167. [Google Scholar]

- Designation E855-08, ASTM. Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Cook, R.F. Strength and sharp contact fracture of silicon. J. Mater. Sci. 2006, 41, 841–872. [Google Scholar] [CrossRef]

- Hong, S.-H.; Bae, B.-J.; Han, K.-S.; Hong, E.-J.; Lee, H.; Choi, K.-W. Imprinted moth-eye antireflection patterns on glass substrate. Electron. Mater. Lett. 2009, 5, 39–42. [Google Scholar] [CrossRef]

- Walheim, S.; Schäffer, E.; Mlynek, J.; Steiner, U. Nanophase-separated polymer films as high-performance antireflection coatings. Science 1999, 283, 520–522. [Google Scholar] [CrossRef] [PubMed]

- Wilson, S.; Hutley, M. The optical properties of'moth eye'antireflection surfaces. J. Mod. Opt. 1982, 29, 993–1009. [Google Scholar]

- Ji, S.; Park, J.; Lim, H. Improved antireflection properties of moth eye mimicking nanopillars on transparent glass: Flat antireflection and color tuning. Nanoscale 2012, 4, 4603–4610. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Kashyap, K.; Hou, M.T.; Yeh, J.A. Mechanical Strength and Broadband Transparency Improvement of Glass Wafers via Surface Nanostructures. Sensors 2016, 16, 902. https://doi.org/10.3390/s16060902

Kumar A, Kashyap K, Hou MT, Yeh JA. Mechanical Strength and Broadband Transparency Improvement of Glass Wafers via Surface Nanostructures. Sensors. 2016; 16(6):902. https://doi.org/10.3390/s16060902

Chicago/Turabian StyleKumar, Amarendra, Kunal Kashyap, Max T. Hou, and J. Andrew Yeh. 2016. "Mechanical Strength and Broadband Transparency Improvement of Glass Wafers via Surface Nanostructures" Sensors 16, no. 6: 902. https://doi.org/10.3390/s16060902