4.3. Effect of the Autoclave Processing Parameters on the Sensors

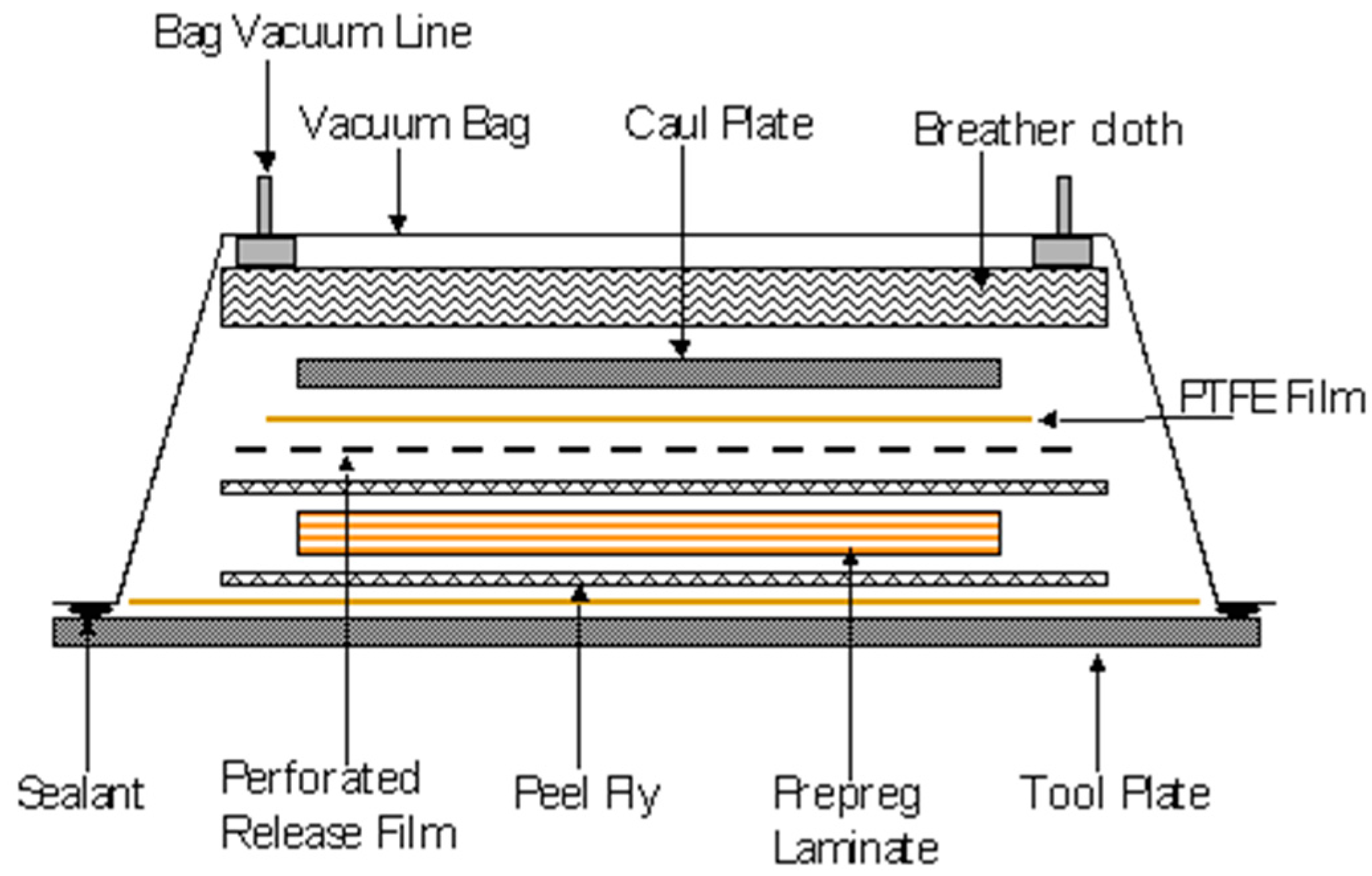

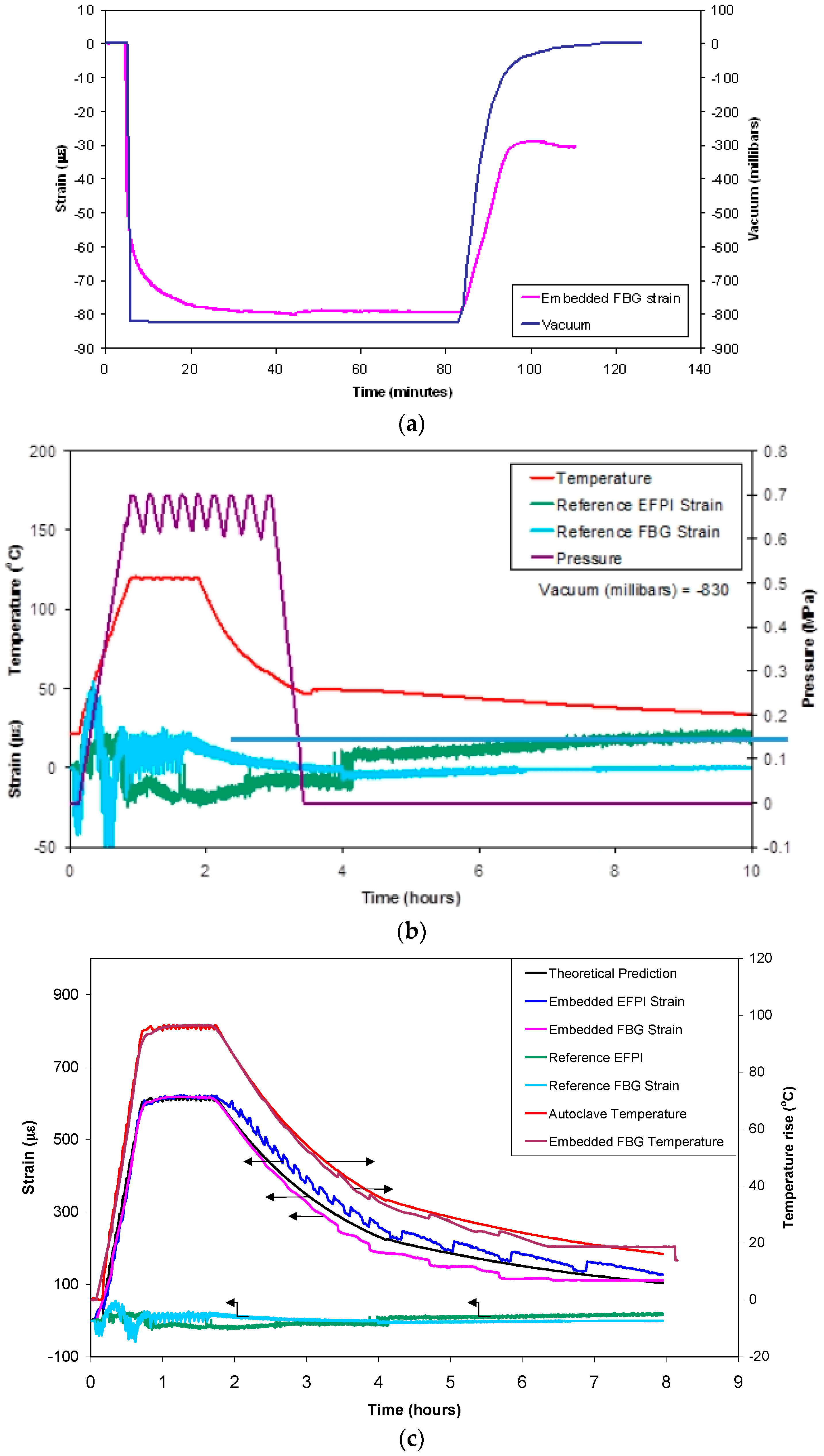

The effect of the applied vacuum (826 mbar (−0.084 MPa)), via the vacuum bag, on an FBG that was embedded in a unidirectional laminate is shown in

Figure 16a. A compressive strain of 80 µε was recorded for this applied vacuum. The interesting point to note is that the strain recorded by the FBG, when the vacuum bag was returned to atmospheric conditions, was approximately −35 µε.

The implication of the data presented in

Figure 16a is that due care and attention needs to be paid to maintaining the relative orientation of the embedded optical fibre sensor in specified substrates (resin, prepreg, fabric, concrete,

etc.). In the current paper, the alignment of the FBG and EFPI was controlled and assured because sections of the optical fibres, within the end-tabs, were pre-aligned and bonded to the matrix. The act of tensioning the end-tabbed preform, to apply the required pre-tension, ensured the alignment and the retention of the orientation of the optical fibre sensors during processing.

The issues associated with the retention of the relative orientation of embedded sensors was highlighted previously [

48]. The feasibility of measuring the residual strain using optical EFPI sensors was first demonstrated by Liu

et al. [

48] using a cross-ply carbon/epoxy composite. They embedded two temperature-compensated EFPI strain sensors between plies numbers 2 and 3 (sensor 1), and 8 and 9 (sensor 2) in a cross-ply (0, 90

2, 0

2, 90, 0, 90)

S carbon/epoxy laminate. They measured the cavity length of EFPI sensors before and after processing and reported the residual strain to be 90 µm and 550 µm in sensors 1 and 2 respectively. The authors proposed that the observed discrepancy may have been due to the relative orientations of the two sensors.

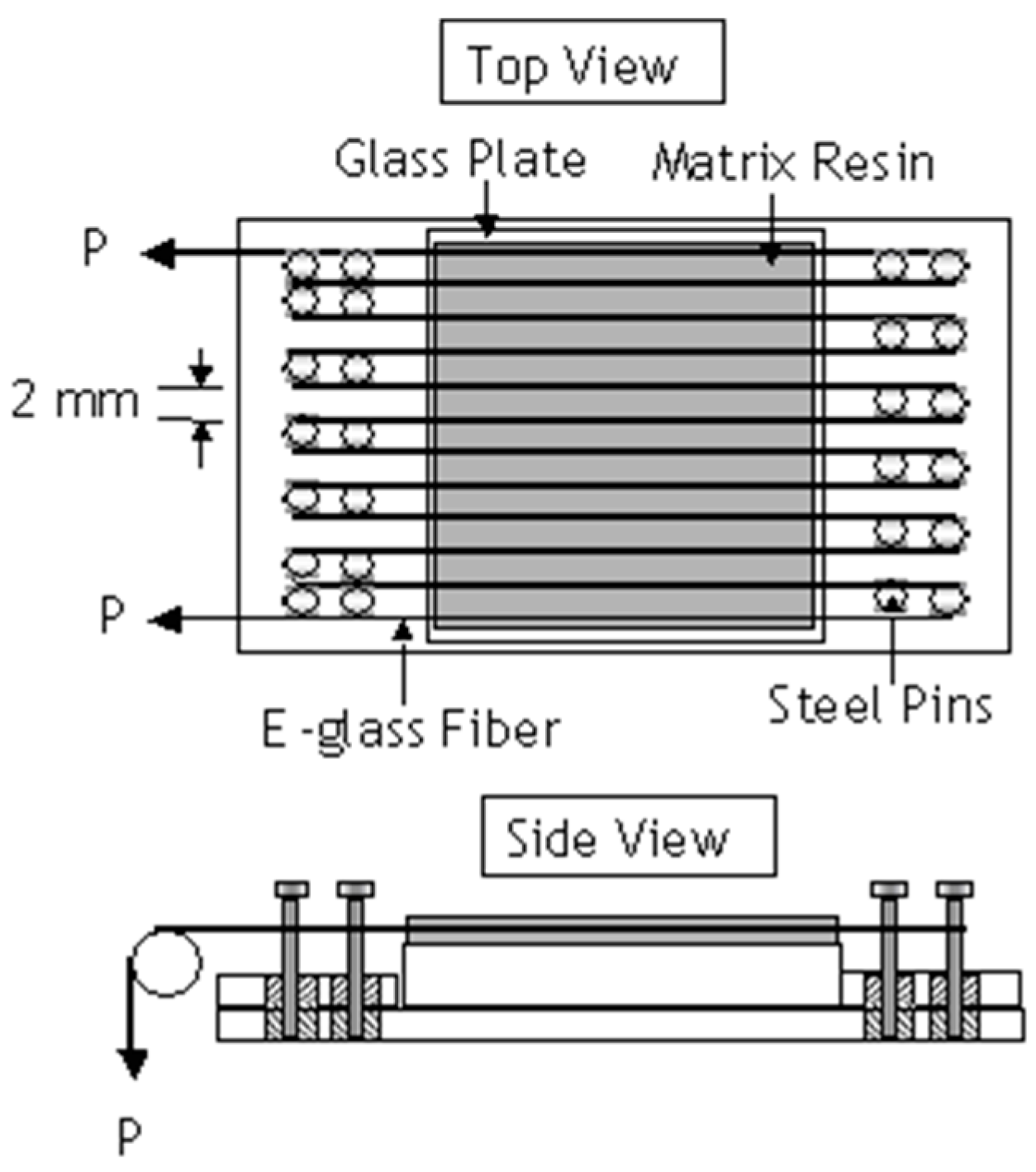

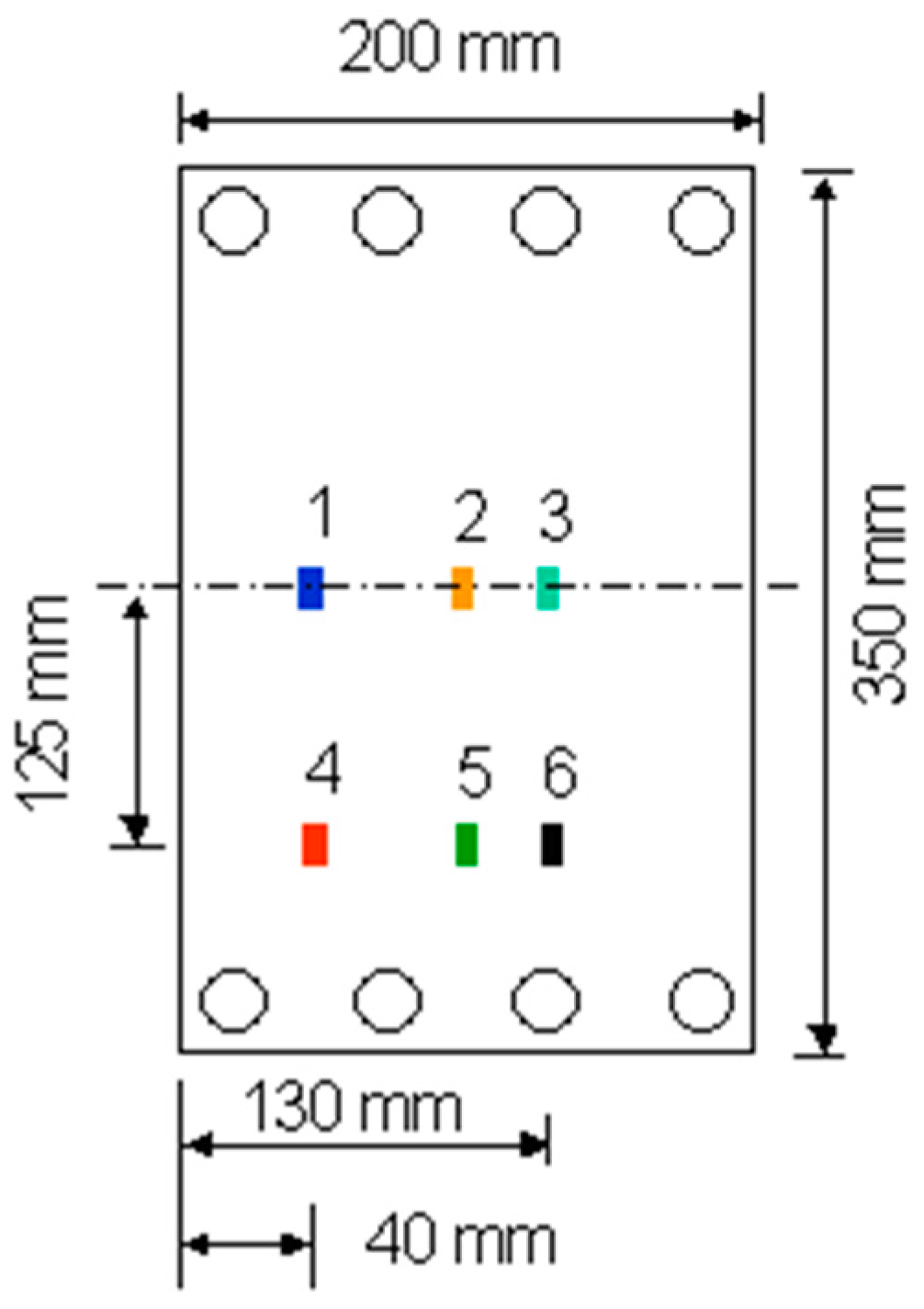

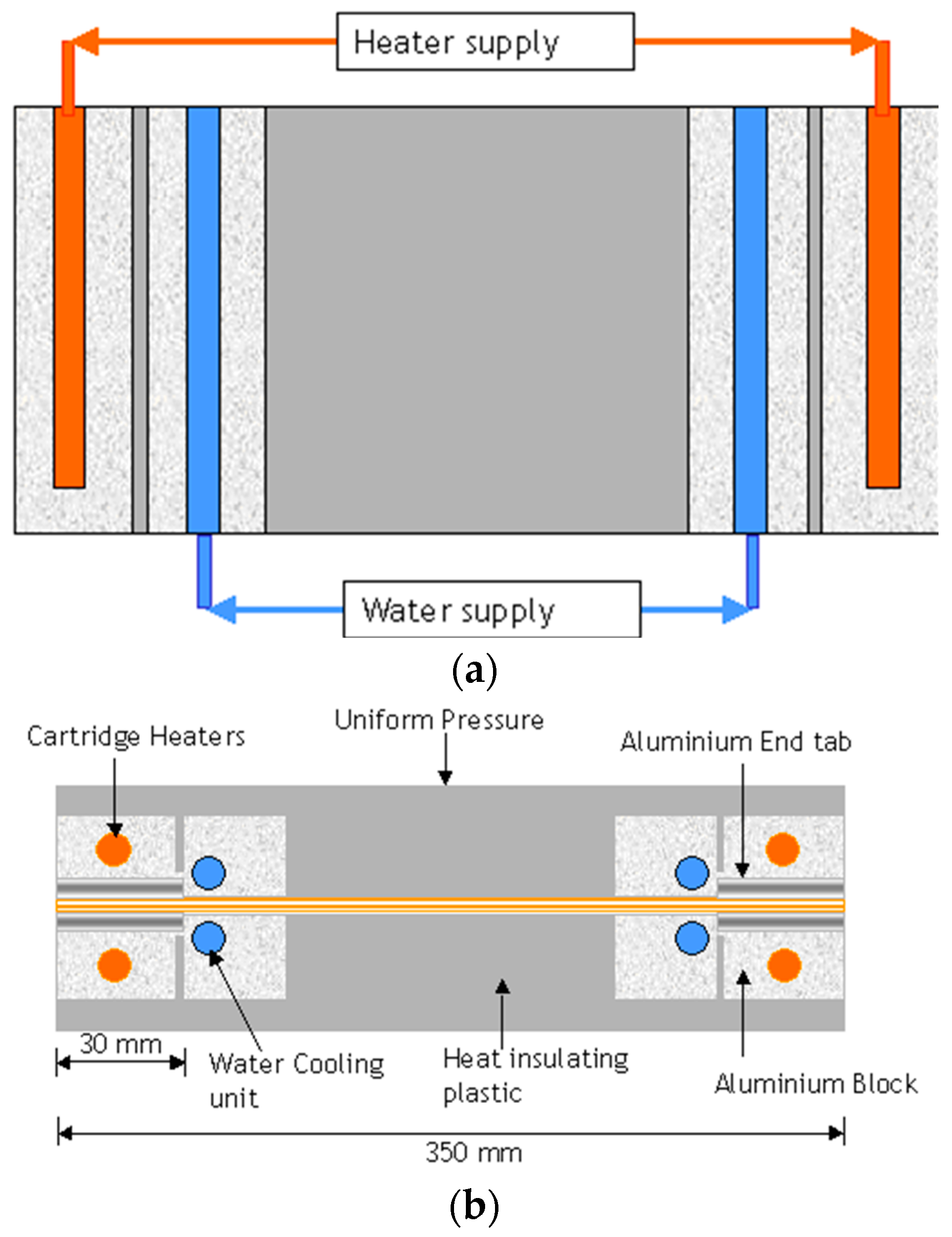

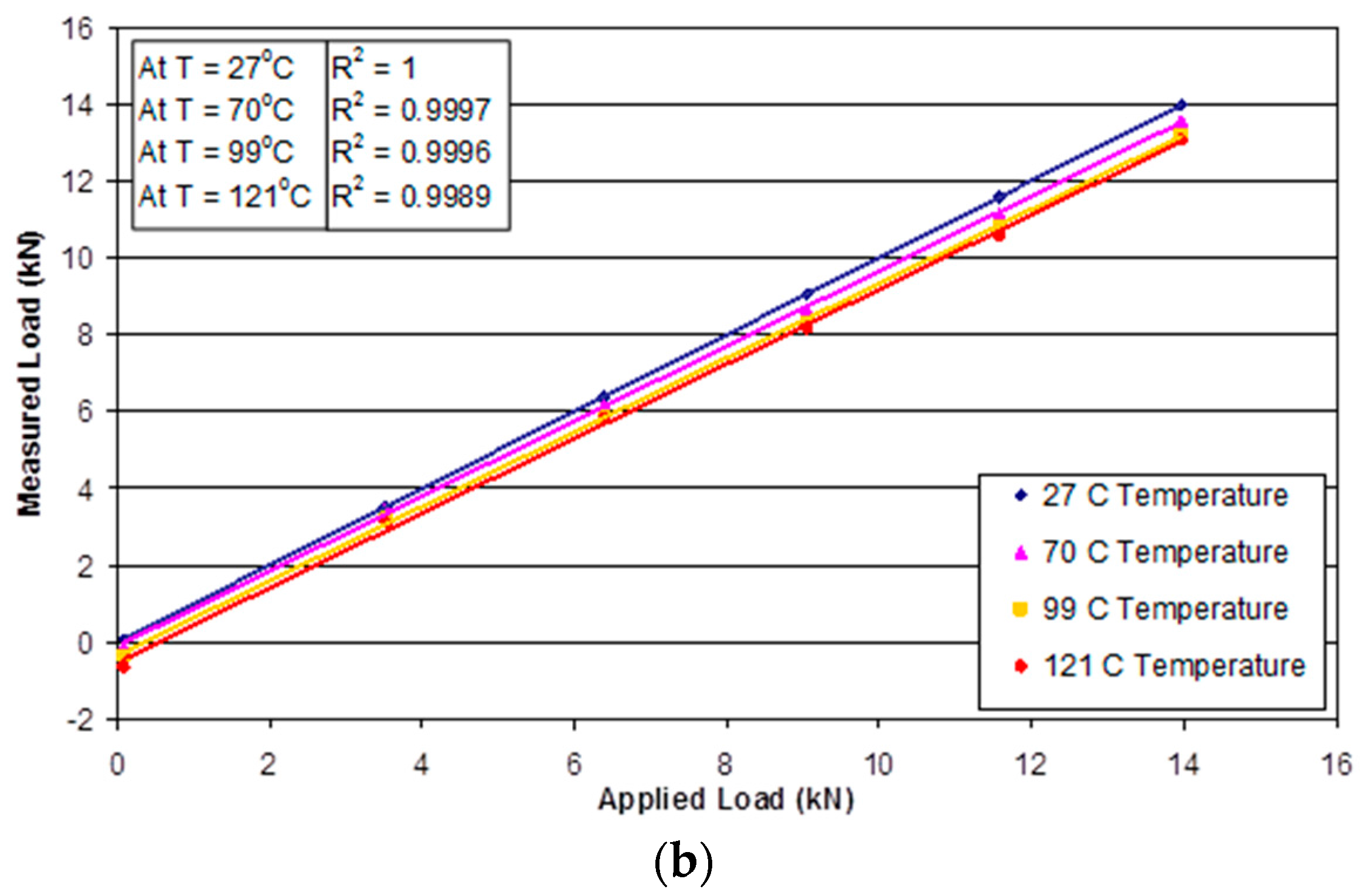

The effect of autoclave processing parameters on the output of the FBG and EFPI sensors (placed on the surface of the composite and embedded) was investigated using a pre-cured composite panel of dimensions 290 mm × 200 mm × 2 mm. The composite with the sensors was vacuum-bagged and subjected to a typical autoclave cure schedule.

Figure 16b shows the observed relationship between the cure cycle parameters on the output from the reference EFPI and FBG sensors (located on the surface of the cured composite panel but within the vacuum bag). The FBG sensor was influenced by temperature, pressure and the force exerted by the vacuum bag. The initial fluctuations in the FBG signal, reaching a maximum compressive strain of approximately 40 µε, is likely to have been caused by the lateral compression caused by the application of the vacuum in the vacuum bag and the applied external pressure. At around 50 °C, the strain recorded by the FBG decreases from approximately +50 µε to a minimum of −50 µε. However, the signal is noisy since the mode of operation of the autoclave pressure is cyclic once the target value has been reached. It is difficult to account for the change in magnitude of the FBG signal from +50 to −50 µm. However, it is possible that some form of relaxation occurring in the lateral forces experienced by the fibre along its length. A possible reason for this observation is the glass transition temperature of the acrylate coating on the optical fibre being approached and/or being exceeded. In the current experiment, the acrylate coating was retained on the optical fibre apart from the sensing regions in the EFPI and FBG sensors. The compressive strain is reversed at approximately 80 °C and the FBG signal is seen to oscillate with the applied autoclave pressure to around +20 and −20 µε. After 2-h of processing, the heater controller was turned off and the strain recorded by the FBG is seen to decay in tandem with the temperature.

The EFPI sensor is relatively insensitive to temperature because the coefficients of thermal expansion for the optical fibre and the capillary are similar [

45,

46]. However, the action of the vacuum bag will impress the EFPI sensor on to the surface of the pre-cured composite as the vacuum and pressure is applied. This may account for the initial rise in the measured strain (~15 µε) after approximately 15 min and it could be attributed to the bending induced by the vacuum bag acting on the ends of the capillary and the optical fibre. A decrease is observed in the recorded strain from approximately 15 µε to 25 µε at 85 °C. This coincides with the autoclave pressure reaching its set value. Since this small but detectable decrease in the stain was observed for the FBG and EFPI sensors, it is speculated that this may be attributed to the glass transition temperature of the acrylate coatings being exceeded on the two types of optical fibres. After the autoclave door was opened, a small increase in the strain was observed from the reference EFPI sensor. This may be attributed to the relaxation of the materials within the vacuum bagging materials. However, this ceases after approximately seven hours as the autoclave was permitted to cool naturally.

The thermal expansion of a pre-cured unidirectional composite was measured using the embedded optic fibre sensors. The cured composite with the surface-located and embedded sensors were subjected to a typical autoclave cure cycle. The composite was heated from ambient to 120 °C at 2 K·min−1 with a dwell of one hour. The pressure was ramped from atmospheric to 0.69 MPa at 0.015 MPa per minute and held at this pressure for one hour.

The thermal expansion of a unidirectional composite (α

c), in the fibre direction is given by:

where α, ν and E are the thermal expansion coefficient, volume fraction and modulus respectively. The subscript m and f denote the matrix and fibre respectively.

Figure 16c shows the output from the embedded, surface-located EFPI and FBG sensors and the thermocouple data as a function of the processing time and the autoclave temperature. In this instance, the strains recorded by the embedded EFPI and FBG sensors show a similar trend and magnitude during the heating and isothermal periods. During the cooling phase, a small divergence is seen between the EFPI and the FBG sensors.

Excellent correlation is seen in

Figure 16c between the embedded FBG temperature sensor and the output from the thermocouple. The outputs from the reference EFPI and FBG sensors that were located on the surface of the composite were discussed previously. A good correlation is observed between the outputs from the embedded EFPI and FBG sensors and that predicted using Equation (4). A summary of the relevant properties that were used for computing the thermal expansion of the unidirectional 16-ply composite is presented in

Table 1. The measured and the predicted values for the thermal expansions are presented in

Table 2.

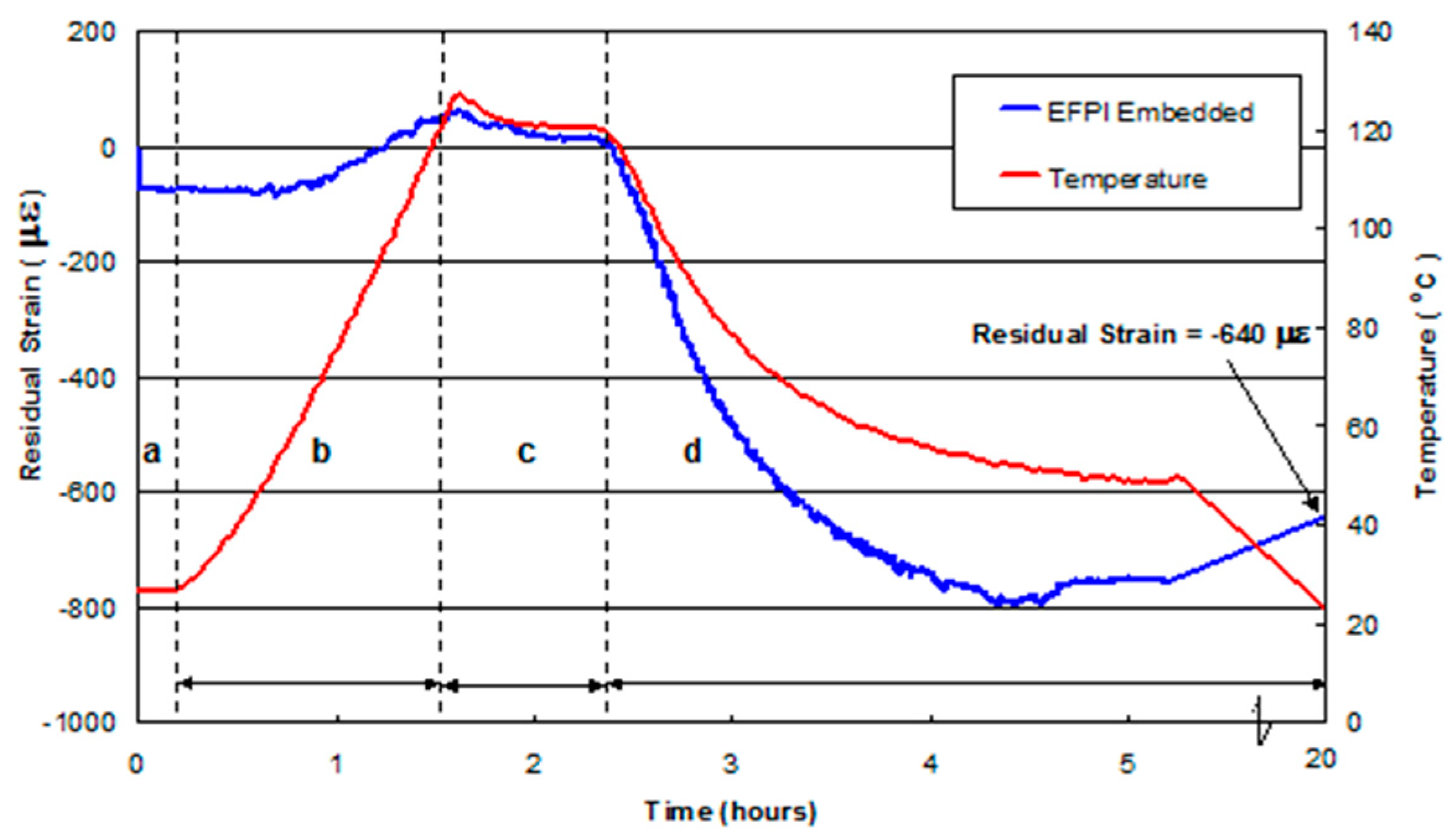

4.4. Residual Strain Monitoring in Composites without Pre-Stress

Figure 17 shows the output from an embedded EFPI sensor in a 16-ply UD E-glass/epoxy reference composite (manufactured without any pre-stress) during autoclave processing. A summary of the residual strains measured at specified stages of the cure cycle is presented in

Table 3. The general trends observed in

Figure 17 can be grouped into the following regions: (a) after embedding the EFPI sensor but before curing the laminated prepregs; (b) during the temperature ramp-up period; (c) during the isothermal dwell; and (d) cooling phase.

Region a: Subsequent to embedding the EFPI sensor, a compressive strain of approximately 50 µε was recorded. The origin of this compressive strain may be attributed to the manual procedures that were used to laminate and consolidate the prepregs with the aid of a roller. This action of consolidating the plies, layer-by-layer, is likely to have resulted in the EFPI with a capillary diameter of 300 µm, being impressed into the prepregs thus resulting in the observed compressive strain.

Region b: During the heating cycle, no significant changes were observed in the output of the EFPI sensor until approximately 60 °C when a positive strain was recorded. This increase may be attributed to a combination of the relaxation of the previously induced compressive strain due to the lamination process and thermal expansion of the various materials. During the heating phase, the viscosity of the resin initially decreases. Hence, it is reasonable to assume that any constraint or bending introduced on the optical fibre and sensor during lamination will relax from its constrained position. The viscosity/temperature profile for the Fiberdux 913 resin system reported by the manufacturer indicated that the minimum viscosity is reached between 120–130 °C. After this period, the viscosity of the resin increases as the cross-linking reactions become prominent. This cross-linking process is accompanied by shrinkage of the resin. However, as the temperature in the autoclave is increasing in region-b, and therefore, the constitutive materials in the composite and the pre-stressing rig undergo thermal expansion.

Region c: The observed excursion of approximately 7 °C at the end of the temperature ramp is possibly due to two factors. Firstly, it could be a consequence of the exothermic ring-opening cross-linking reaction between the epoxy resin and amine hardener. Secondly, it could be due to the temperature-controller in the autoclave overshooting the set isothermal value. On inspecting region-c in

Figure 17, it is apparent that preforms were above the set isothermal temperature for approximately 20 min from the end of the thermal ramp. This exothermic excursion was observed for all the prepregs processed in this study.

Region d: Here the heating was turned off and the composite was permitted to cool naturally.

With reference to

Table 3, the average residual strain measured from three UD reference composites, at ambient temperature, was –604 µε.

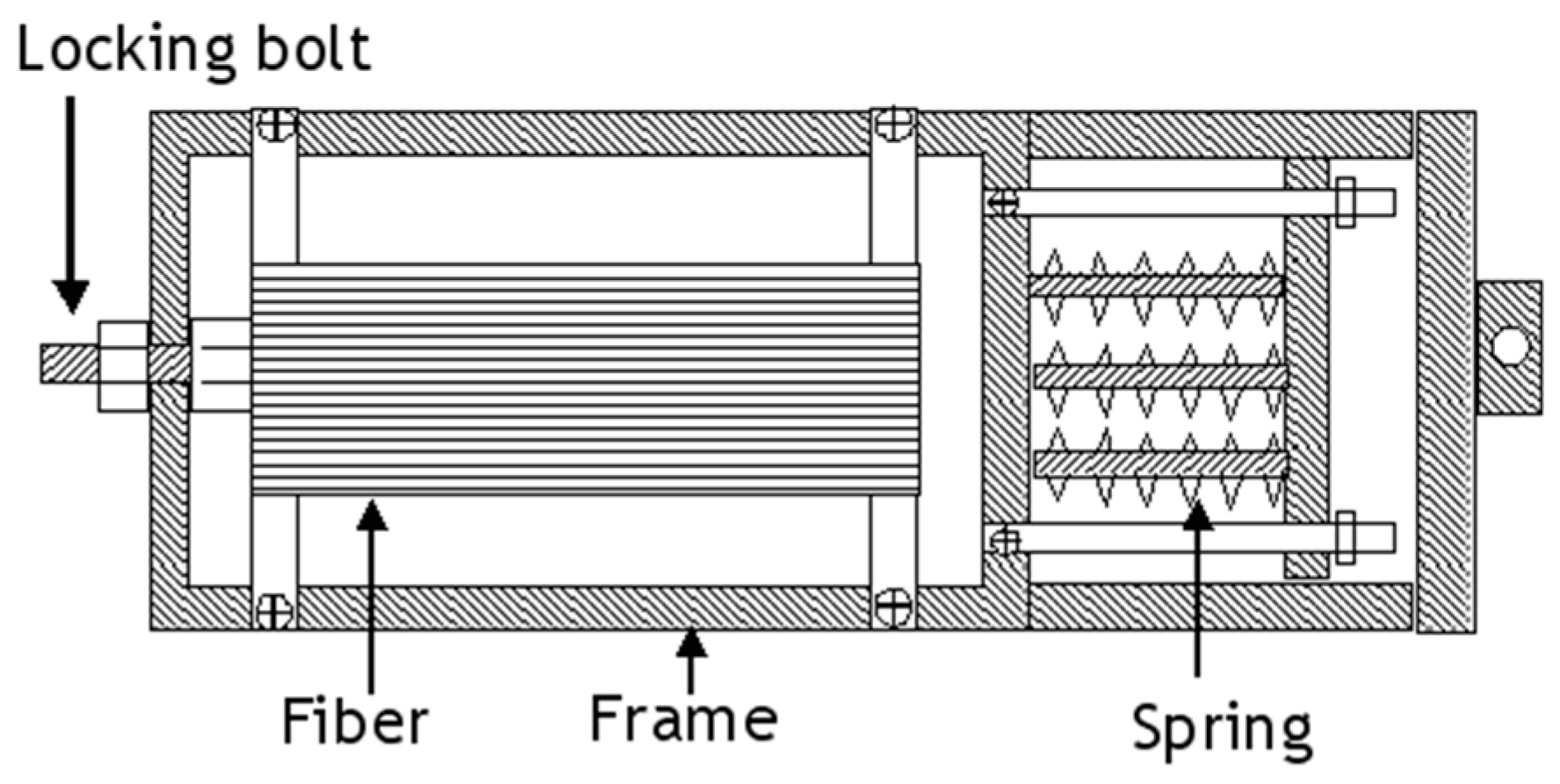

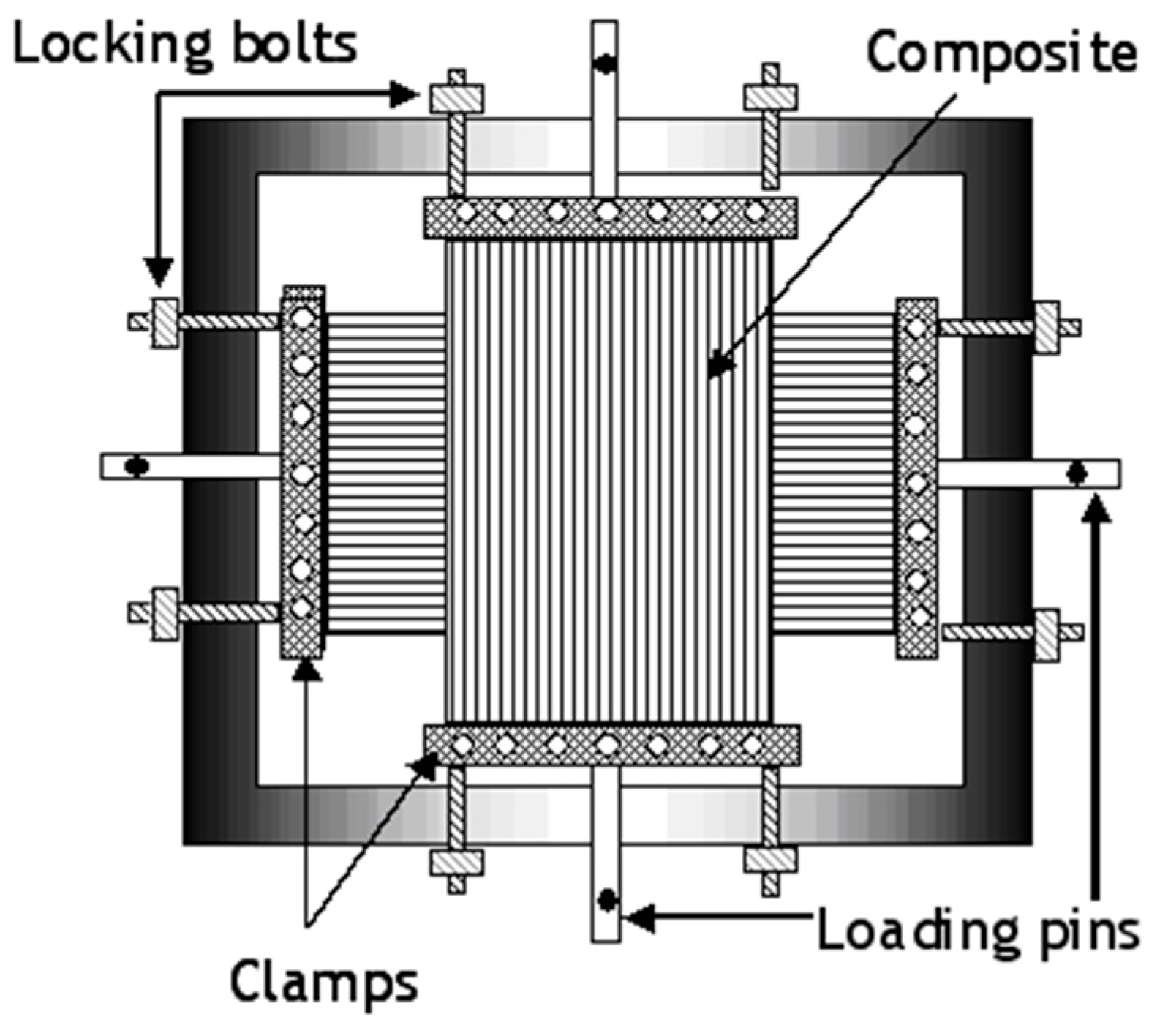

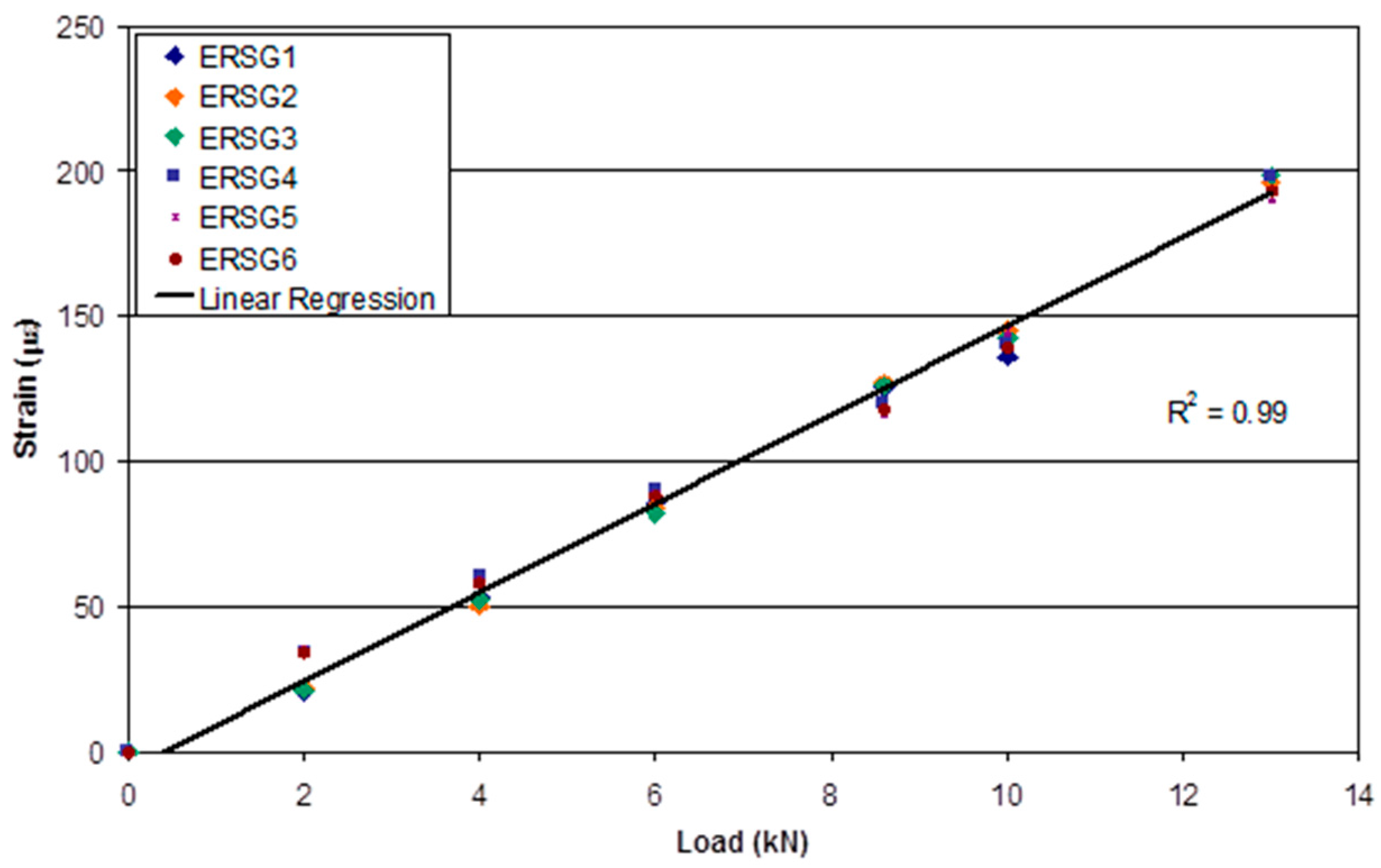

4.5. Residual Strain Development in a UD Pre-Stressed Composite

This section reports on the use of embedded EFPI sensors in unidirectional [0]16 E-glass epoxy composites where the preform was pre-stressed. The EFPI sensors were used to monitor the strain during and after processing. A limited number of experiments were also undertaken using embedded FBG sensors. In addition, electrical resistance strain gauges were surface-bonded on the composite after processing but before they were unclamped from the pre-stressing rig. The magnitude of the strain released, when the composite was unclamped from the pre-stressing rig, was recorded using the embedded optical fibre sensors and the surface-bonded ERSGs.

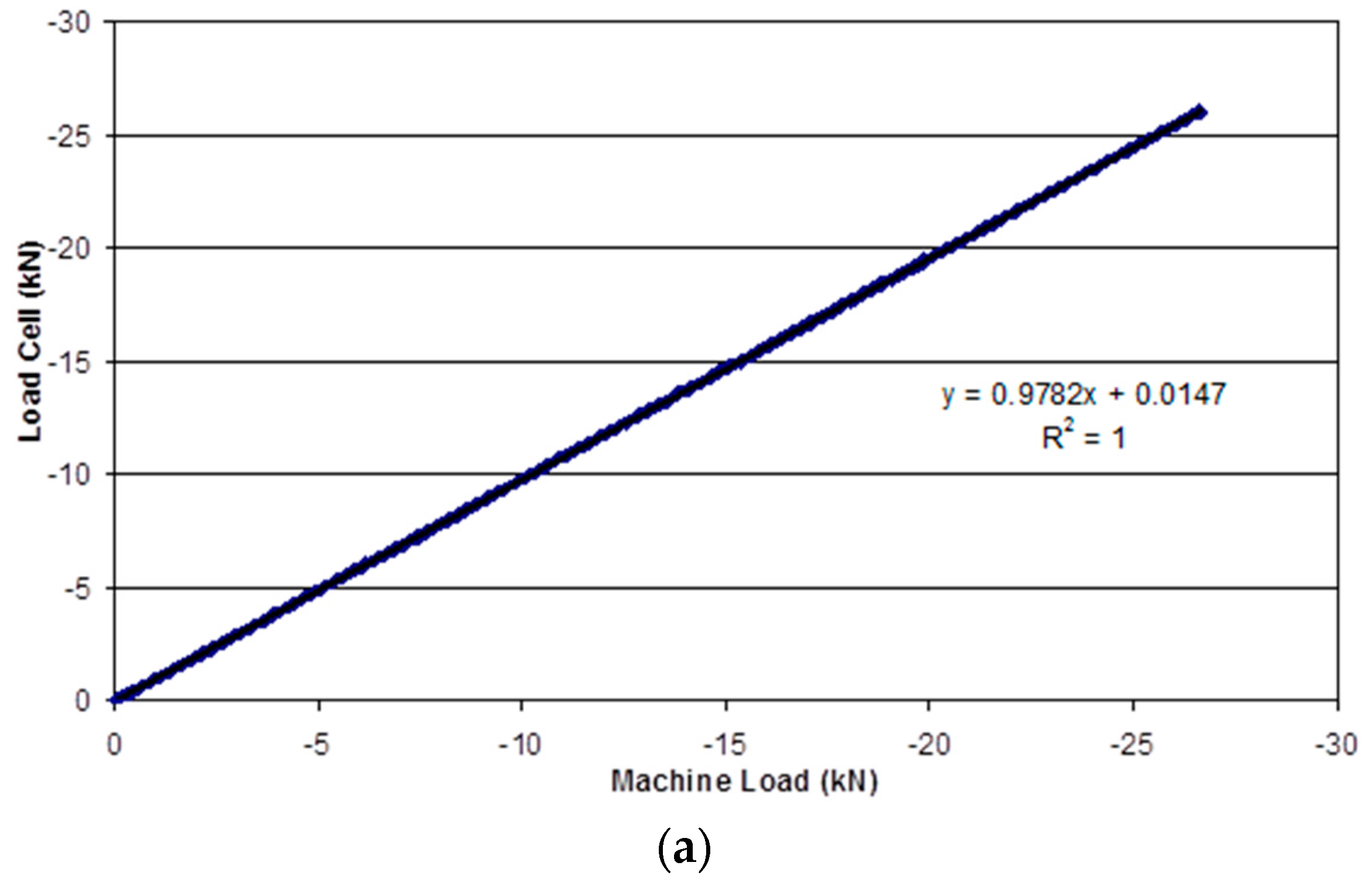

Figure 18 shows the outputs from the various sensors when the composite, with a previously applied pre-stress of 150 MPa, was unclamped from the pre-stressing rig. It can be seen that the applied pre-load was maintained throughout the curing process to within 1 kN. During the heating cycle, the load-cell did not record the pre-stress induced in the preform due to thermal expansion of the rig. This is because in the current set-up, there is no frame of reference for the load-cell to record the thermally-induced pre-stress experienced by the preform. During the heating phase, the pre-stressing rig assembly expands and this will induce a pre-stress on the preform. However, the load applied to the preform due to thermal expansion of the rig will not be recorded by the load-cell.

On inspecting the output from the EPPI sensor in

Figure 18, it is seen that a compressive strain of approximately 60 µε is induced in the preform prior to the application of the pre-load. As expected, the application of a pre-stress 150 MPa resulted in an increase in the strain recorded by the EFPI sensor. The residual strain and the magnitude of the strain that was released when the composite was unloaded from the pre-stressing rig, for four pre-stress levels, are summarised in

Table 4 and

Table 5 respectively.

With reference to

Table 5, the EFPI strain data from the repeat experiments, at pre-loads corresponding to 14 kN, were in the range −537 to −637. A reasonable agreement is observed between the datasets for the EFPIs and the ERSGs when they were embedded and surface-mounted respectively, at the centre of the composite. The ERSGs, when located 40 mm from the edge of the composite, recorded a higher value when compared to those located at the centre; this is presumably due to edge effects. Reasons for the variation in the FBGs were discussed previously.

Figure 19 shows the strains recorded by the EFPI, FBG and ERSG sensors when a composite (Panel code UP9_14kN), with a previously applied pre-stress of 108 MPa, was unloaded from the pre-stressing rig in a stepwise manner. The data recorded by the FBG sensor did not follow the stepwise pre-load release as observed with the EFPI and ERSG sensors. This is because the rate of data acquisition for FBG sensors was two measurements per minute, whereas that for the EFPI and ERSG sensors was 1 measurement per second. Initially, the strains measured from the EFPI, FBG and ERSG sensors are in agreement. However, as the composite was unloaded further, the EFPI sensor records a slightly lower compressive strain when compared to the FBG and ERSG sensors. On the other hand, the FBG and ERSG sensors are in good agreement.

Table 6 shows the average strain-release measured via the EFPI, FBG and ERSG sensors when the preform that was previously subjected to a pre-stress 108 MPa, was cured and then unloaded from the pre-stressing rig. The average strain-release measured with the FBG sensor is slightly higher than that obtained from the EFPI sensor. However, by considering the standard deviations and the number of samples that were evaluated, it can be concluded that the strain recorded from the optical fibre (EFPI and FBG) and ERSG sensors show a reasonable agreement. After releasing the pre-stress, the final residual strain in the composite, ε

final, can be expressed as:

where

εr is the residual strain measured before releasing the composite from the pre-stressing rig (this represents cure and thermally-induced residual stresses) and

εp is the strain measured when the pre-load is released.

Figure 20 shows the final residual strain measured for all the pre-stressed composites manufactured in this study. The compressive residual strain in the composites reduces as the previously applied pre-stress on the preforms increases. However, the application of a pre-stress to the preform of approximately 108 MPa results in the production of composites with a near-zero residual strain. Above an applied pre-stress of 108 MPa, the final residual strain is tensile. This demonstrates that the pre-stressing method reported here can be used to control the final residual strain in composites.

In

Figure 20, it is apparent that the strain gradient across the panel (middle and 40 mm from edge) increases with an increase in pre-stress. This variation in strain reaches a maximum of 14% at a 150 MPa pre-stress. It is proposed that this difference in the measured strain-release may be due to an edge effect caused by the variation in Poisson’s contraction at the unconstrained edge.