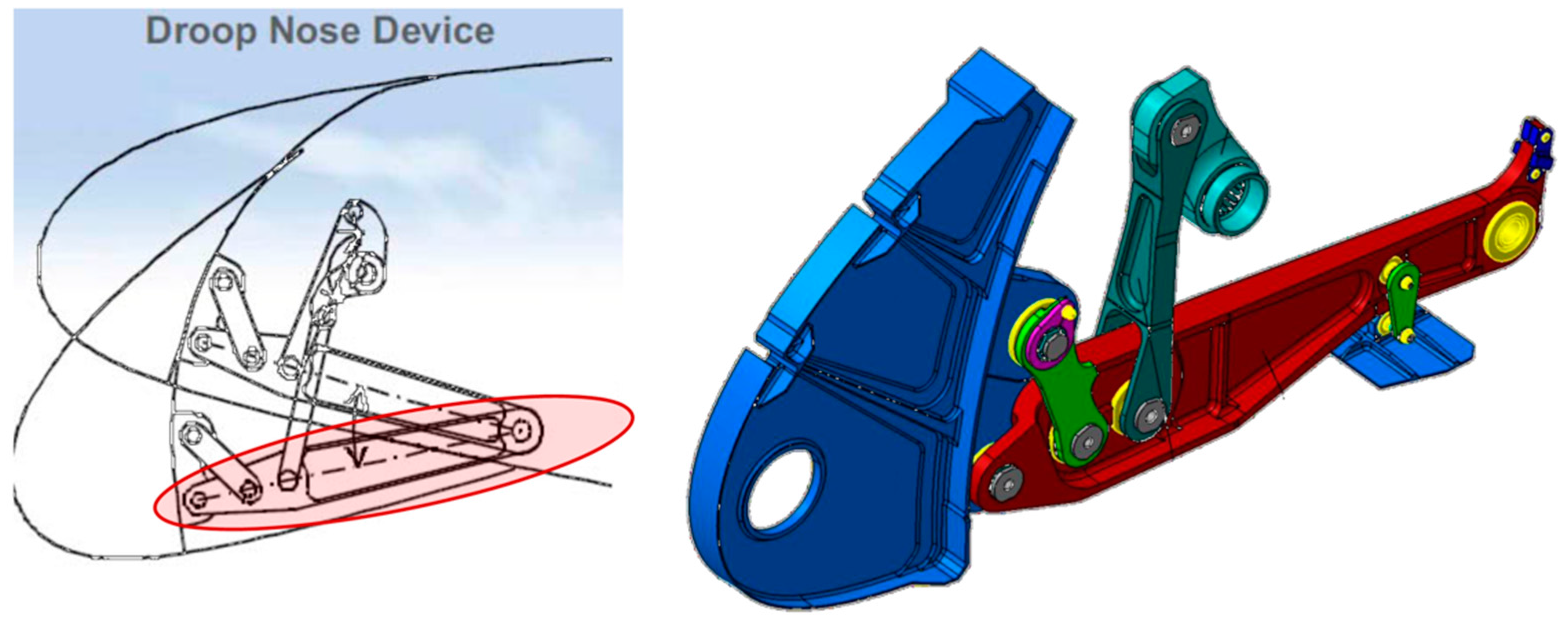

RTM Production Monitoring of the A380 Hinge Arm Droop Nose Mechanism: A Multi-Sensor Approach

Abstract

:1. Introduction

2. FBG Sensors for Residual Strain Measurements

2.1. Basics on FBGs

2.2. Temperature Compensation

2.3. Residual Strain Measurements

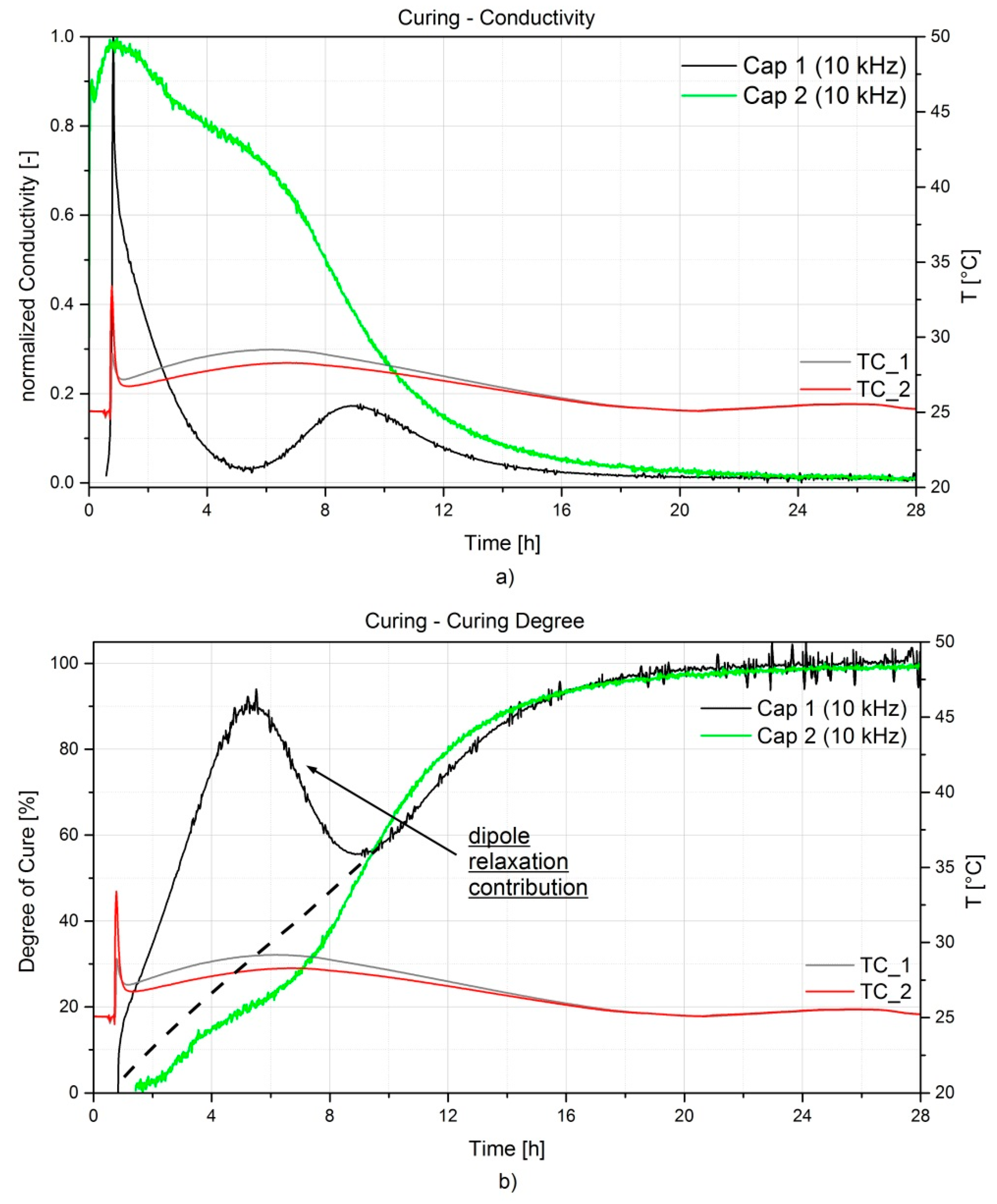

3. Use of Capacitive Sensors for Cure Monitoring

4. Experimental Setup

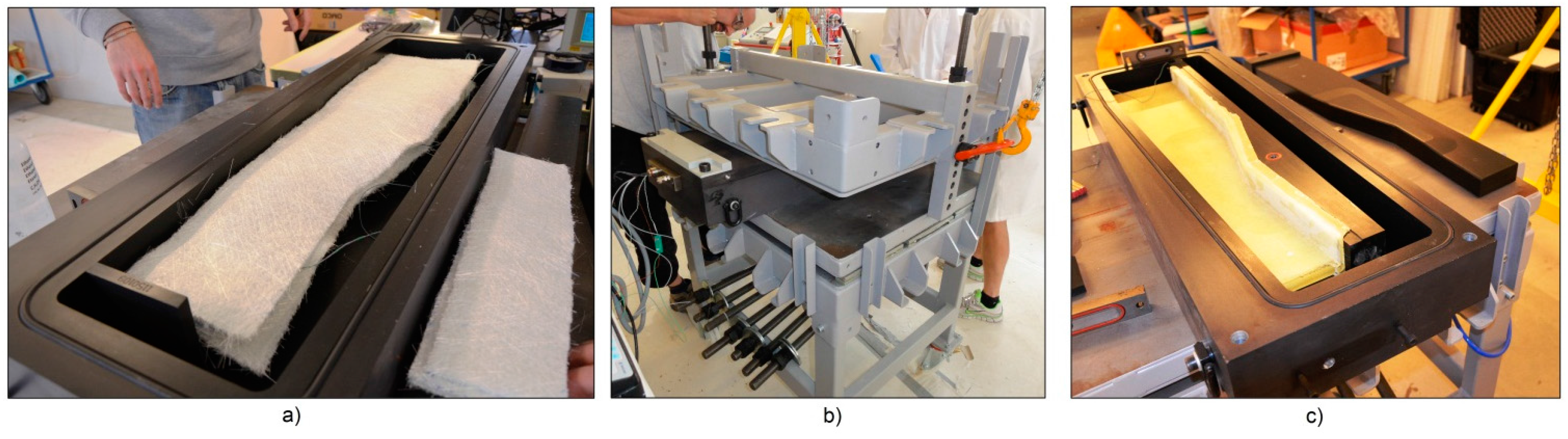

4.1. RTM Setup

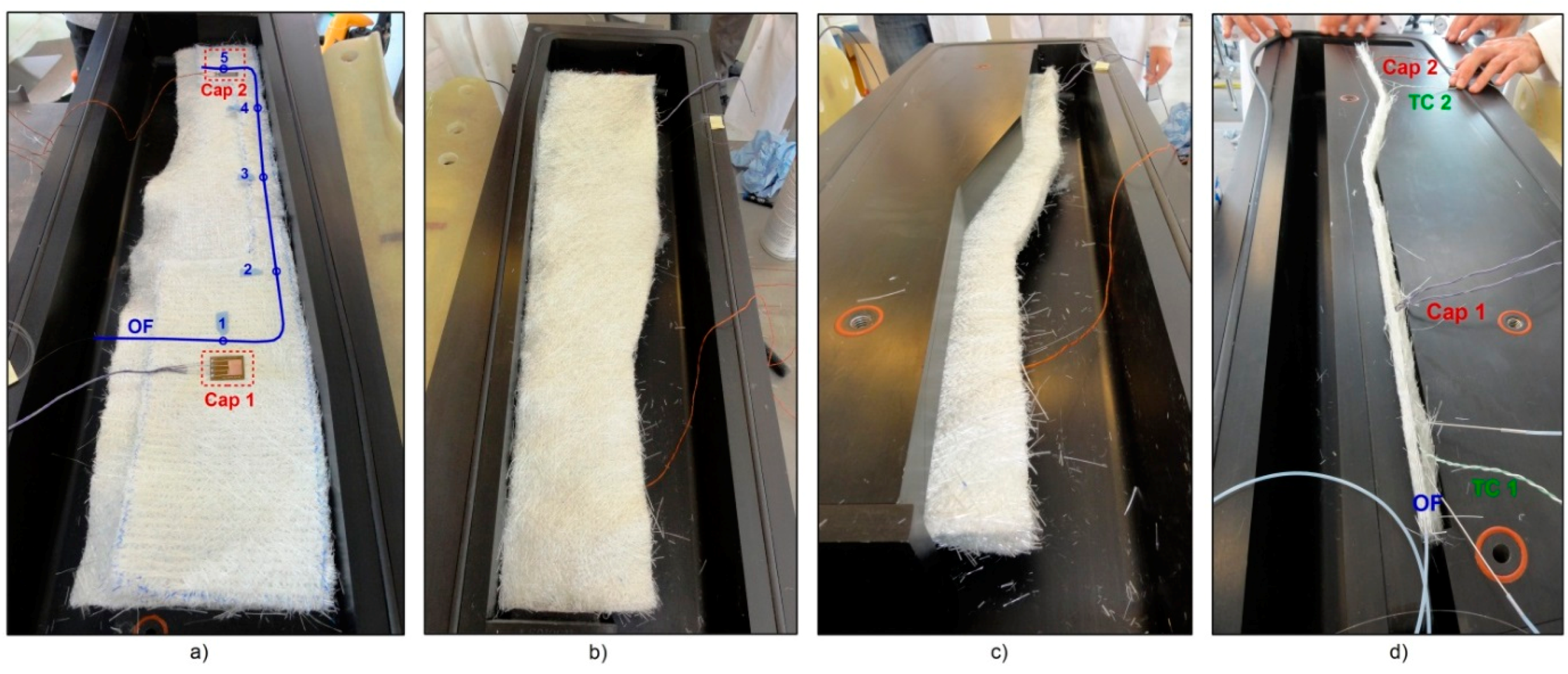

4.2. Strain Monitoring

4.3. Cure Monitoring

5. Sensors Embedding

6. Results and Discussion

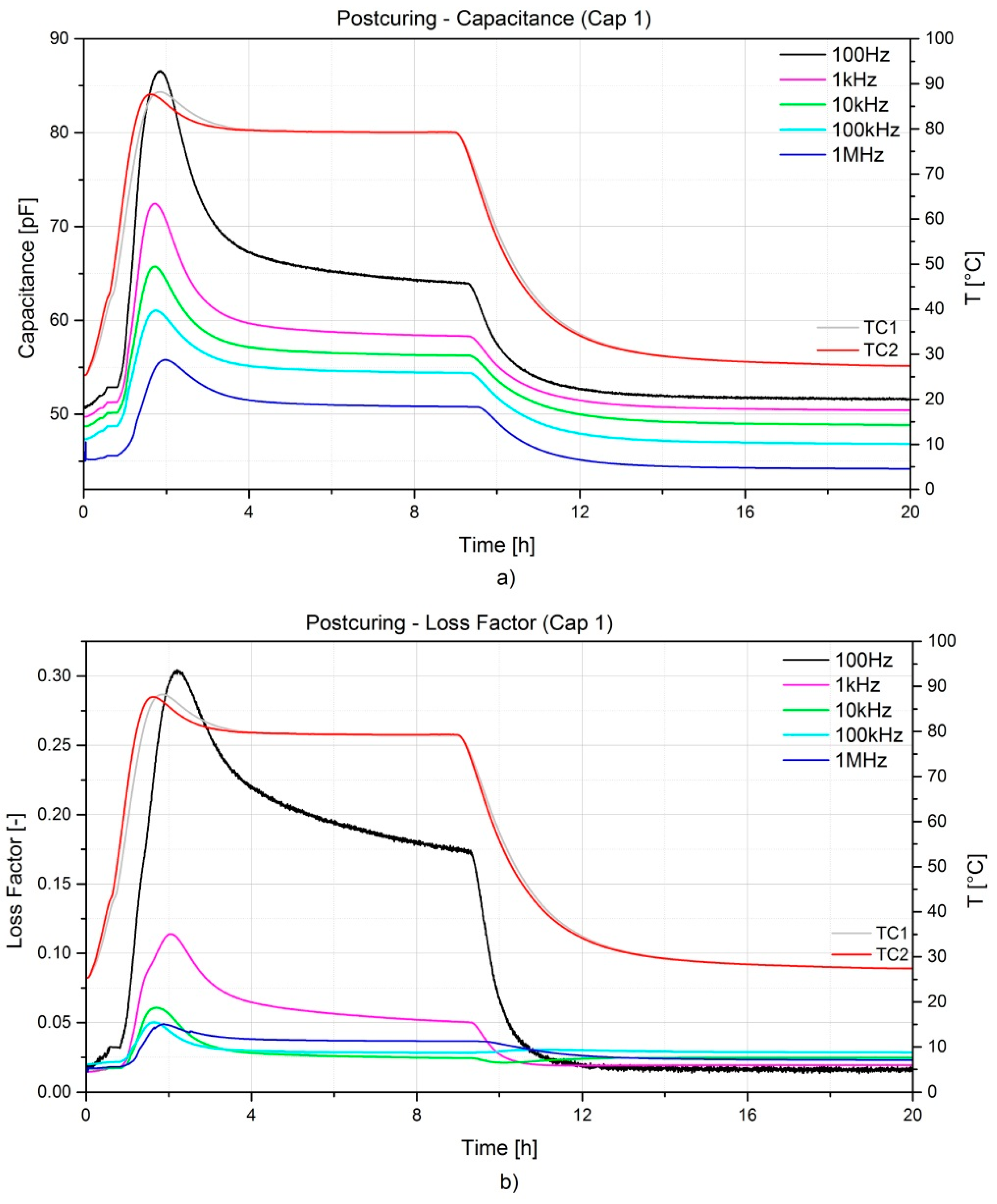

6.1. Cure Monitoring

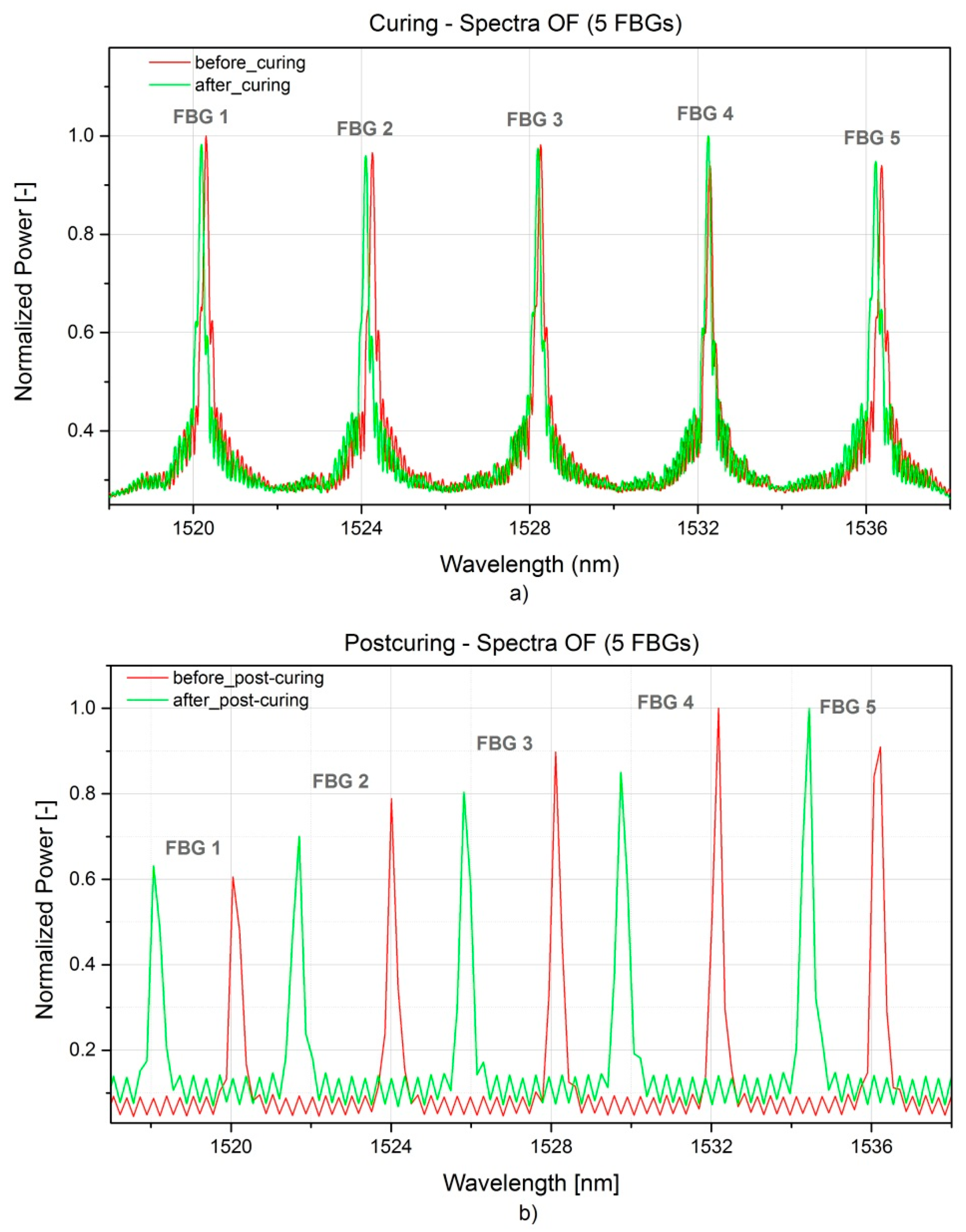

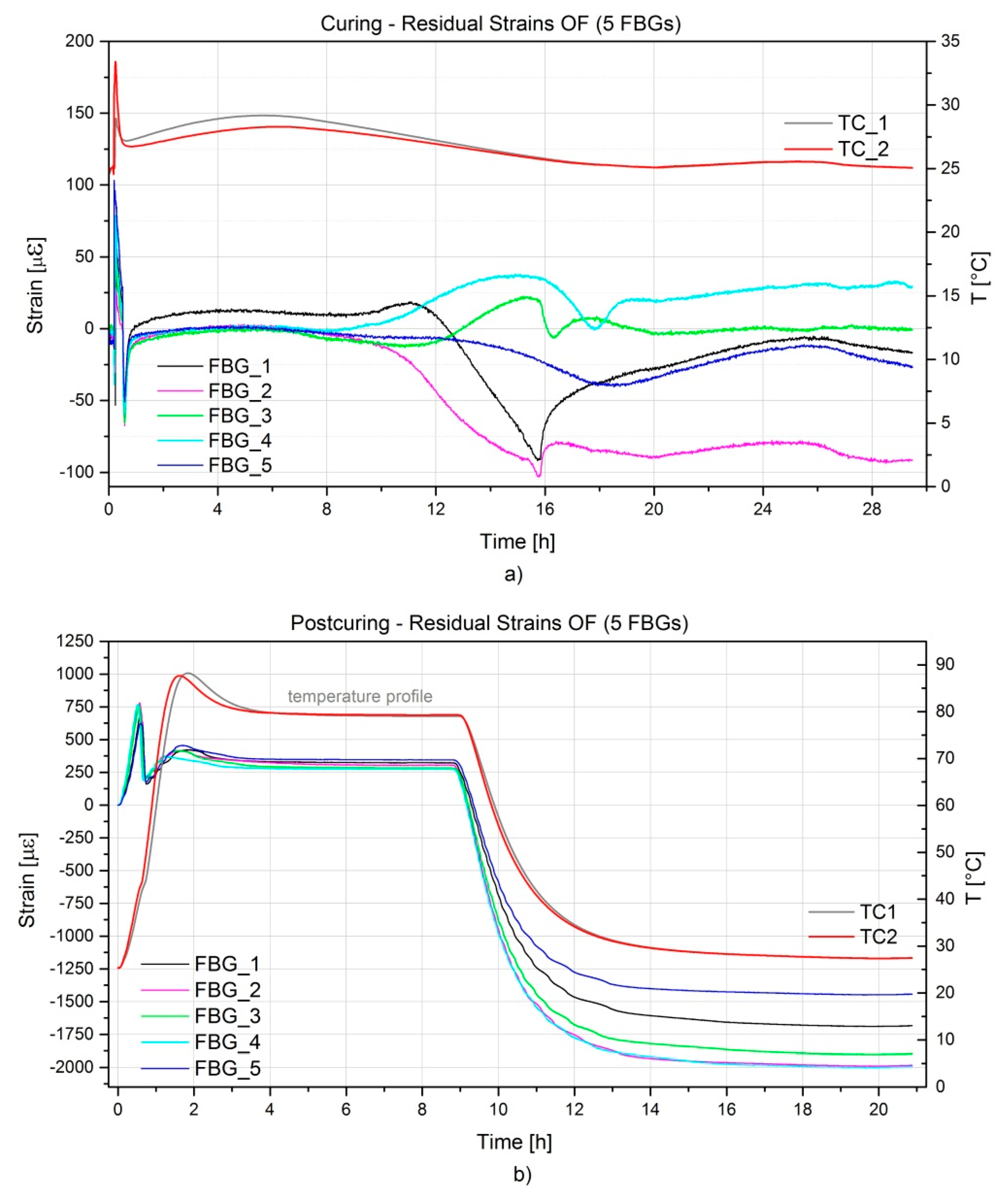

6.2. Residual Strains

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Composites Market Report 2014. Available online: http://www.eucia.eu/userfiles/files/20141008_market_report_grpcrp.pdf (accessed on 11 June 2016).

- Growth Opportunities in Global Composites Industry. Available online: http://www.speautomotive.com/SPEA_CD/SPEA2011/pdf/KEY/K4.pdf (accessed on 11 June 2016).

- Todd, M.; Nichols, J.; Trickey, S.; Seaver, M.; Nichols, C.; Virgin, L. Bragg grating-based fibre optic sensors in structural health monitoring. Phil. Trans. R. Soc. A 2007, 365, 317–343. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Xiao, G.; Mrad, N.; Yao, J. Fiber Optic Sensors for Structural Health Monitoring of Air Platforms. Sensors 2011, 11, 3687–3705. [Google Scholar] [CrossRef] [PubMed]

- Rippert, L.; Papy, J.; Wevers, M.; van Huffel, S. Fibre optic sensor for continuous health monitoring in CFRP composite materials. In Smart Structures and Materials; Proceedings of SPIE, San Diego, CA, USA, 10 March 2002; Volume 4693, pp. 312–323.

- Shanku, R.; Vaughan, J.G.; Roux, J.A. Rheological Characteristics and Cure Kinetics of EPON 862/W Epoxy Used in Pultrusion. Adv. Polym. Technol. 1997, 16, 297–311. [Google Scholar] [CrossRef]

- Parthasarathy, S.; Mantel, S.; Stelson, K.; Bickerton, S.; Advani, S. Real-time Sensing and Control of Resin Flow in Liquid Injection Molding Processes. In Proceedings of the American Control Conference, Philadelphia, PA, USA, 21–26 June 1998.

- Kikuchi, A. An Experimental Investigation of Real-Time Product Quality Sensing During Molding Processes. Master’s Thesis, Lehigh University, Bethlehem, PA, USA, 1993; p. 99. [Google Scholar]

- Yildiz, M.; Ozdemir, N.G.; Bektas, G. An Experimental Study on the Process Monitoring of Resin Transfer Molded Composite Structures Using Fiber Optic Sensor. J. Manuf. Sci. Eng. 2012, 134, 044502. [Google Scholar] [CrossRef]

- Dunkers, J.; Lenhart, J.; Kueh, S.; van Zanten, J.; Advani, S.; Parnas, R. Fiber optic flow and cure sensing for liquid composite molding. Opt. Lasers Eng. 2001, 35, 91–104. [Google Scholar] [CrossRef]

- Keulen, C.; Rocha, B.; Yildiz, M.; Suleman, A. Embedded fiber optic sensors for monitoring processing, quality and structural health of resin transfer molded components. J. Phys. Conf. Ser. 2011, 305, 012135. [Google Scholar] [CrossRef]

- Danisman, M.; Tuncol, G.; Kaynar, A.; Sozer, E.M. Monitoring of resin flow in the resin transfer molding (RTM) process using point-voltage sensors. Compos. Sci. Technol. 2007, 67, 367–379. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop, J.; Peters, F.; Kessler, M. Cure kinetics characterization and monitoring of an epoxy resin using DSC,Raman spectroscopy, and DEA. Compos. A 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Yenilmez, B.; Sozer, E. A grid of dielectric sensors to monitor mold filling and resin cure in resin transfer molding. Compos. A 2009, 40, 476–489. [Google Scholar] [CrossRef]

- O’Dwyer, M.; Maistros, G.; James, S.; Tatam, R.; Partridge, I. Relating the state of cure to the real-time internal strain development in a curing composite using in-fibre Bragg gratings and dielectric sensors. Meas. Sci. Technol. 1998, 9, 1153–1158. [Google Scholar] [CrossRef]

- Chiesura, G.; Luyckx, G.; Voet, E.; van Paepegem, W.; Degrieck, J.; Kaufmann, M.; Martens, T.; Lamberti, A.; Vanlanduit, S. Production monitoring of a RTM automotive control arm by means of fibre optic sensors. In Proceedings of the Optimess, Antwerp, Belgium, 8–9 April 2015; pp. 21–30.

- Final Report Summary. Available online: http://cordis.europa.eu/result/rcn/52805_en.html (accessed on 11 June 2016).

- Leading Edge A350. Available online: http://www.airliners.net/aviation-forums/general_aviation/print.main?id=5351043 (accessed on 11 June 2016).

- Haase, K. Strain sensors based on Bragg gratings. In Proceedings of the 20th IMEKO TC-3 International Conference on Measurement of Force, Mass and Torque, Merida, Mexico, 27 November–1 December 2007.

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef] [PubMed]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain Measurements of Composite Laminates with Embedded Fibre Bragg Gratings: Criticism and Opportunities for Research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- DTG 1550-125. Available online: http://www.fbgs.com/productsadv/be-en/6/detail/item/15/page/1/ (accessed on 11 June 2016).

- Bertholds, A.; Dandliker, R. Determination of the individual strain-optic coefficients in single-mode optical fibers. J. Lightwave Technol. 1988, 6, 17–20. [Google Scholar] [CrossRef]

- Zhou, Z.; Ou, J. Techniques of temperature compensation for FBG strain sensors used in long-term structural monitoring. In Proceedings of the Asian Pascifc Fundamental Problems of Opto- and Microelectronic, Khabarovsk, Russia, 13–16 September 2004.

- Pal, S.; Sun, T.; Grattan, K.; Wade, S.; Collins, S.; Baxter, G.; Dussardier, B.; Monnom, G. Non-linear temperature dependence of Bragg gratings written in different fibres, optimised for sensor applications over a wide range of temperatures. Sens. Actuators A Phys. 2004, 112, 211–219. [Google Scholar] [CrossRef]

- Chiesura, G.; Luyckx, G.; Voet, E.; Lammens, N.; van Paepegem, W.; Degrieck, J.; Dierick, M.; van Hoorebeke, L.; Vanderniepen, P.; Sulejmani, S.; et al. A Micro-Computed Tomography Technique to Study the Quality of Fibre Optics Embedded in Composite Materials. Sensors 2015, 15, 10852–10871. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, Y.; Kahrizi, M. Characterization of a FBG strain gage array embedded in composite structure. Sens. Actuators A Phys. 2005, 121, 297–305. [Google Scholar] [CrossRef]

- Zarrelli, M.; Skordos, A.A.; Partridge, I.K. Investigation of cure induced shrinkage in unreinforced epoxy resin. Plast. Rubber Compos. Process. Appl. 2002, 31, 377–384. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira, R.; Lavanchy, S.; Chatton, R.; Costantini, D.; Michaud, V.; Salathé, R.; Månson, J.-A.E. Experimental investigation of the effect of the mould thermal expansion on the development of internal stresses during carbon fibre composite processing. Compos. A 2008, 39, 1083–1090. [Google Scholar] [CrossRef]

- Yoon, H.; Costantini, D.; Limberger, H.; Salathé, R.; Kim, C.; Michaud, V. In-situ strain and temperature monitoring of adaptive composite materials. J. Intell. Mater. Struct. 2006, 17, 1059–1067. [Google Scholar] [CrossRef]

- Hussain, F.; Chen, J.; Hojjati, M. Epoxy-silicate nanocomposites: Cure monitoring and characterization. Mater. Sci. Eng. A 2007, 445–446, 467–476. [Google Scholar] [CrossRef]

- Hongkyeong, K.; Kookheon, C. Dielectric Changes During the Curing of Epoxy Resin Based on the Diglycidyl Ether of Bisphenol A (DGEBA) with Diamine. Bull. Korean Chem. Soc. 1999, 20, 1329–1334. [Google Scholar]

- Maffezoli, A.; Trivisano, A.; Opalicki, M.; Mijovic, J.; Kenny, J.M. Correlation between dielectric and chemorheological properties during cure of epoxy-based composites. J. Mater. Sci. 1994, 29, 800–808. [Google Scholar] [CrossRef]

- Sanchez, D.; Gresil, M.; Soutis, C. Distributed internal strain measurement during composite manufacturing using optical fibre sensors. Compos. Sci. Technol. 2015, 120, 49–57. [Google Scholar] [CrossRef]

- TDS Araldite LY 1564—Aradur XB 3486 Huntsman. Available online: http://www.swiss-composite.ch/pdf/t-Araldite-LY1564-Aradur3486-3487-e.pdf (accessed on 11 June 2016).

- Lamberti; Chiesura, G.; Luyckx, G.; Degrieck, J.; Kaufmann, M.; Vanlanduit, S. Dynamic Strain Measurements on Automotive and Aeronautic Composite Components by Means of Embedded Fiber Bragg Grating Sensors. Sensors 2015, 15, 27174–27200. [Google Scholar] [CrossRef] [PubMed]

| Grating | Initial λB (nm) | Final λB (nm) |

|---|---|---|

| Fbg1 | 1520.279 | 1518.165 |

| Fbg2 | 1524.255 | 1521.722 |

| Fbg3 | 1528.245 | 1525.915 |

| Fbg4 | 1532.262 | 1529.828 |

| Fbg5 | 1536.320 | 1534.467 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiesura, G.; Lamberti, A.; Yang, Y.; Luyckx, G.; Van Paepegem, W.; Vanlanduit, S.; Vanfleteren, J.; Degrieck, J. RTM Production Monitoring of the A380 Hinge Arm Droop Nose Mechanism: A Multi-Sensor Approach. Sensors 2016, 16, 866. https://doi.org/10.3390/s16060866

Chiesura G, Lamberti A, Yang Y, Luyckx G, Van Paepegem W, Vanlanduit S, Vanfleteren J, Degrieck J. RTM Production Monitoring of the A380 Hinge Arm Droop Nose Mechanism: A Multi-Sensor Approach. Sensors. 2016; 16(6):866. https://doi.org/10.3390/s16060866

Chicago/Turabian StyleChiesura, Gabriele, Alfredo Lamberti, Yang Yang, Geert Luyckx, Wim Van Paepegem, Steve Vanlanduit, Jan Vanfleteren, and Joris Degrieck. 2016. "RTM Production Monitoring of the A380 Hinge Arm Droop Nose Mechanism: A Multi-Sensor Approach" Sensors 16, no. 6: 866. https://doi.org/10.3390/s16060866