A Stimulated Raman Scattering CMOS Pixel Using a High-Speed Charge Modulator and Lock-in Amplifier

Abstract

:1. Introduction

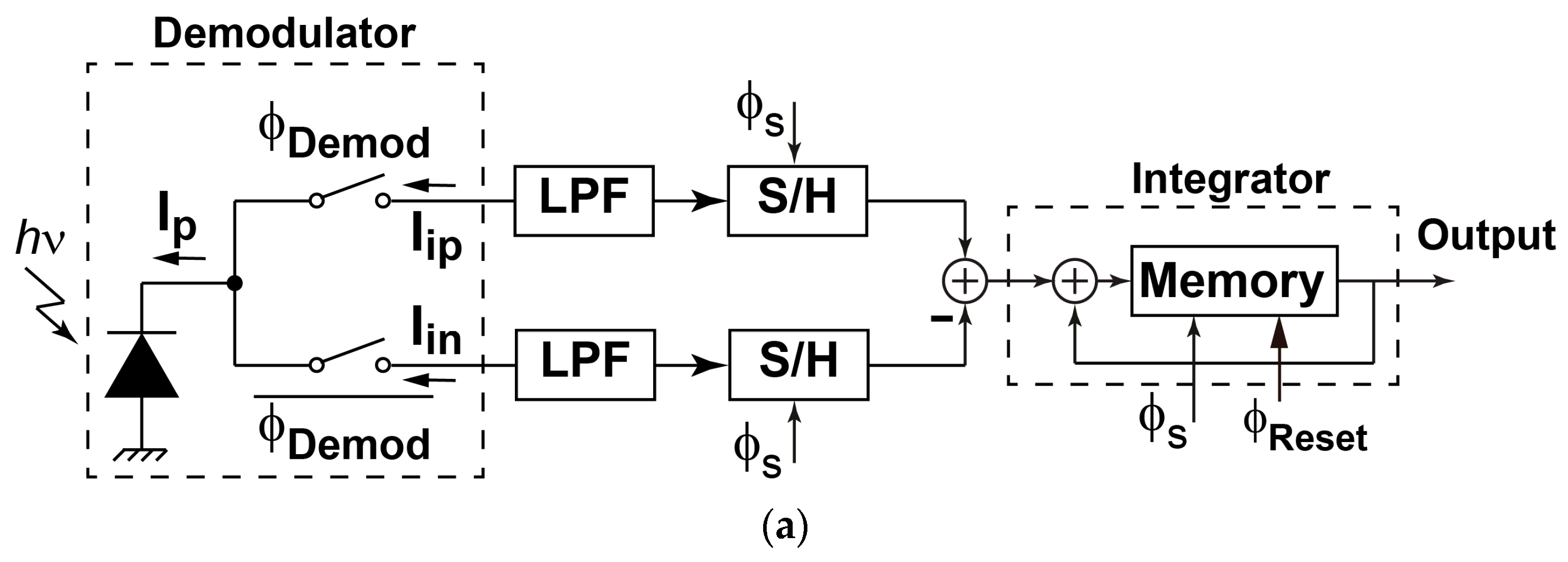

2. Demodulator and Readout Circuits in SRS Lock-in Pixels

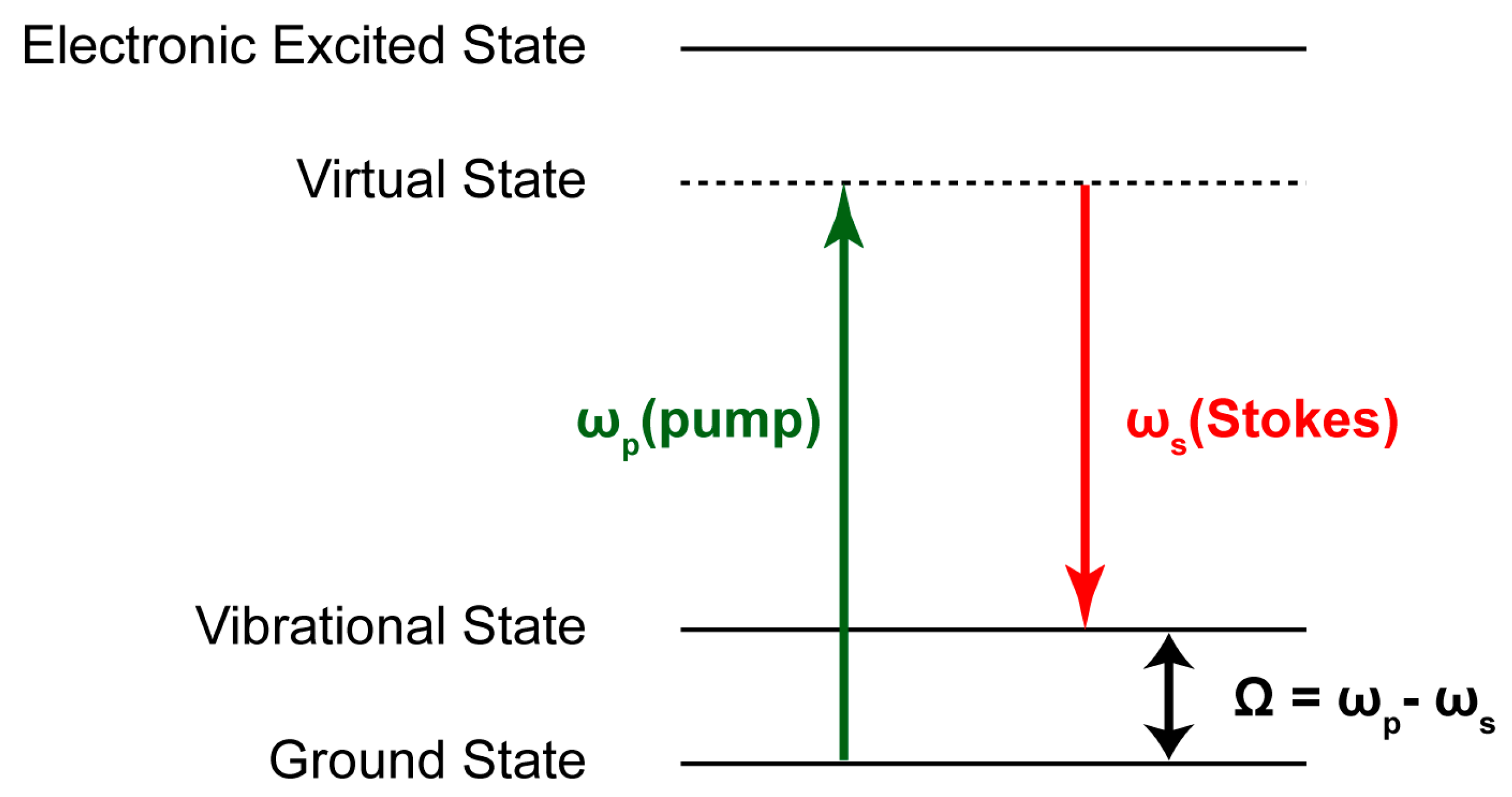

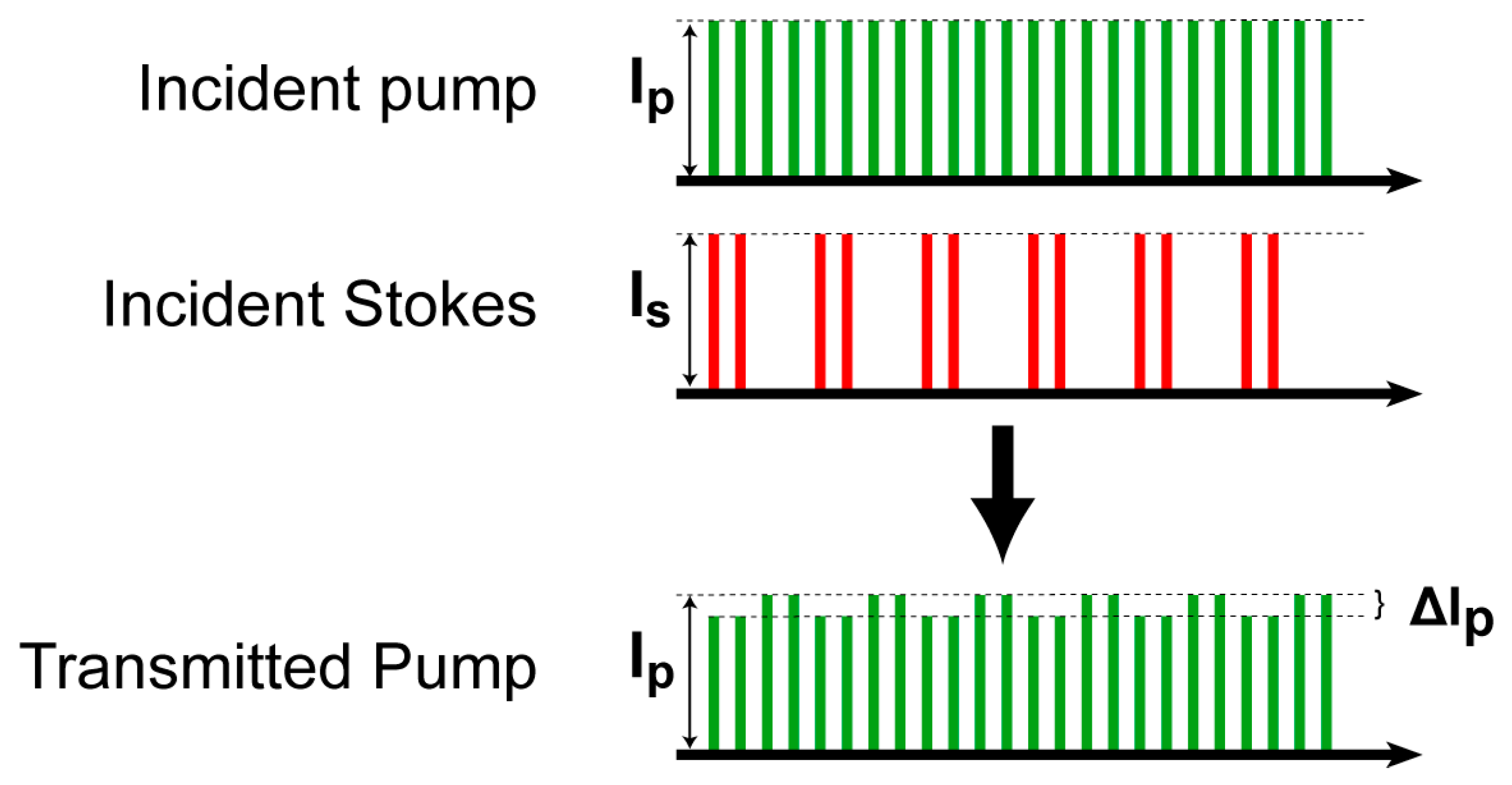

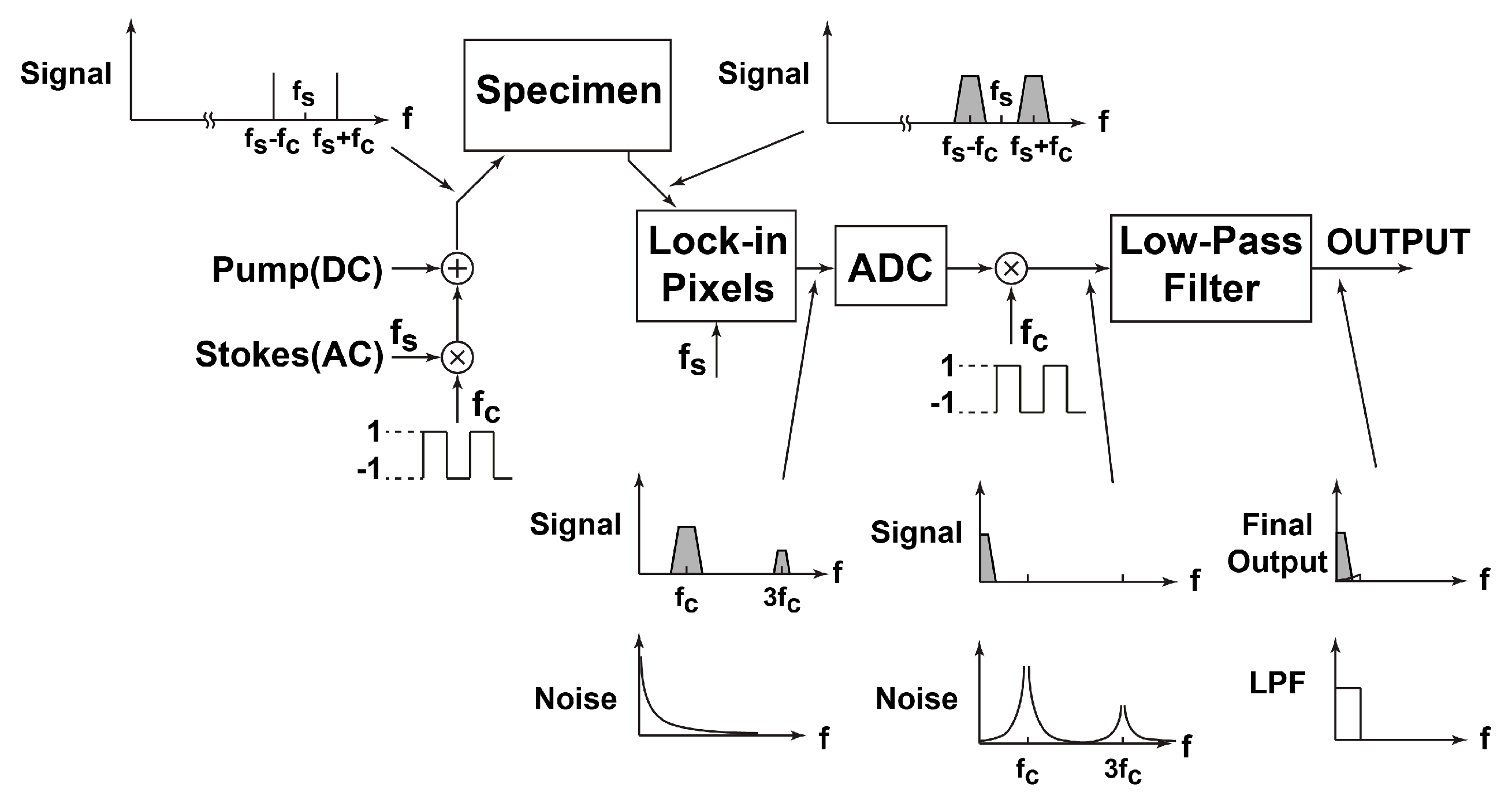

2.1. SRS Signal and Lock-in Pixel

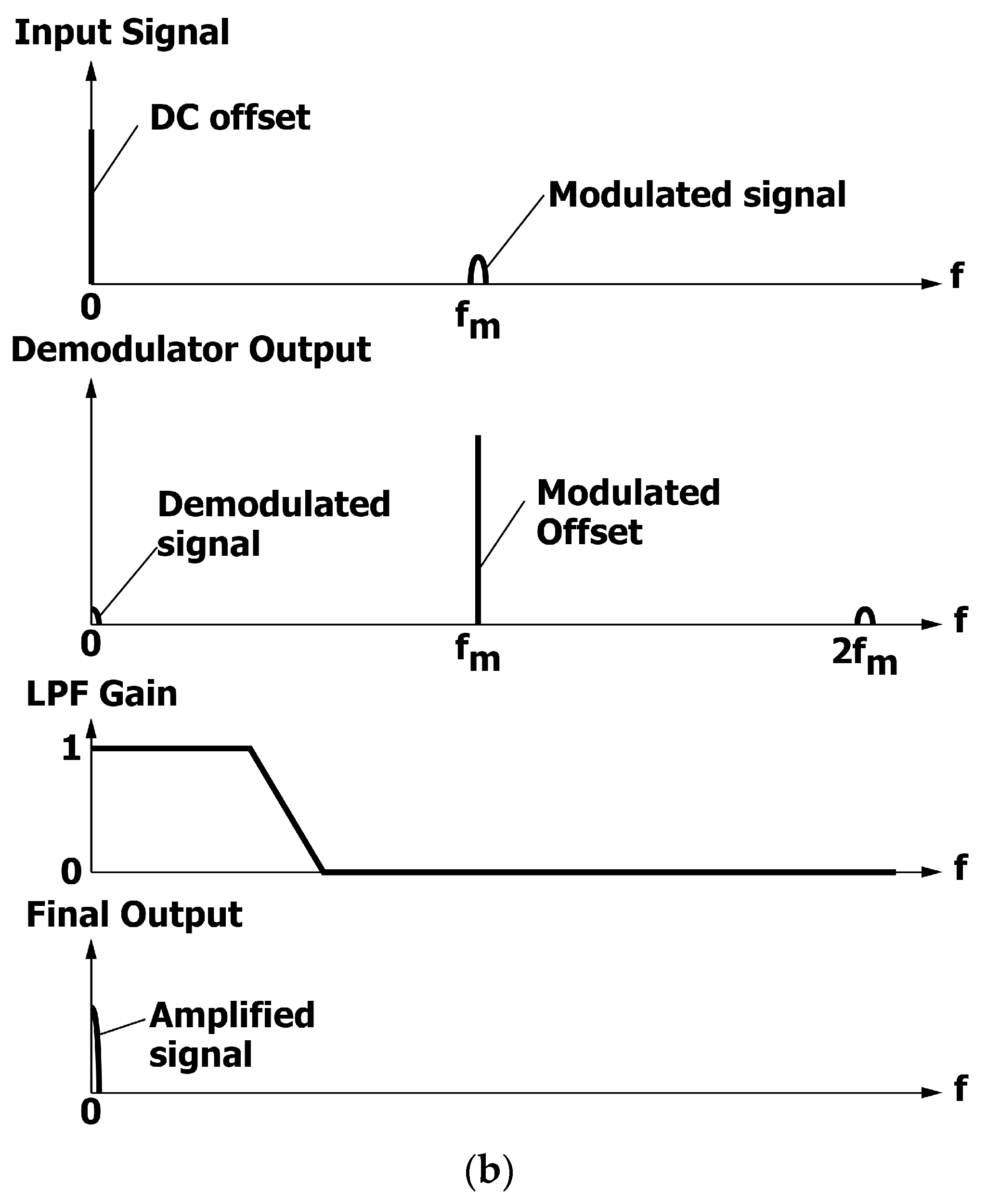

2.2. Lock-in Pixel Design for AC Signal Detection in Large DC Offset

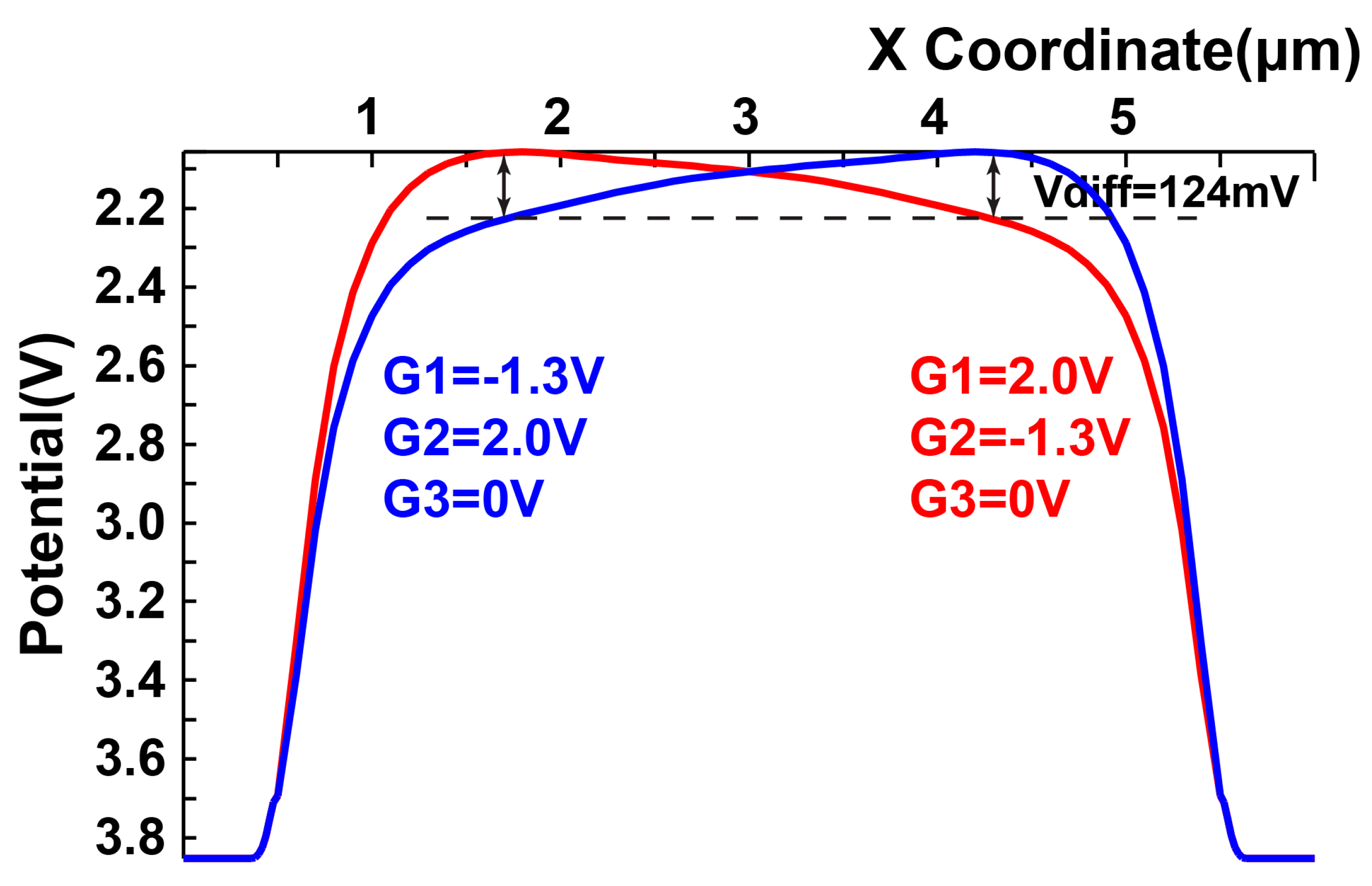

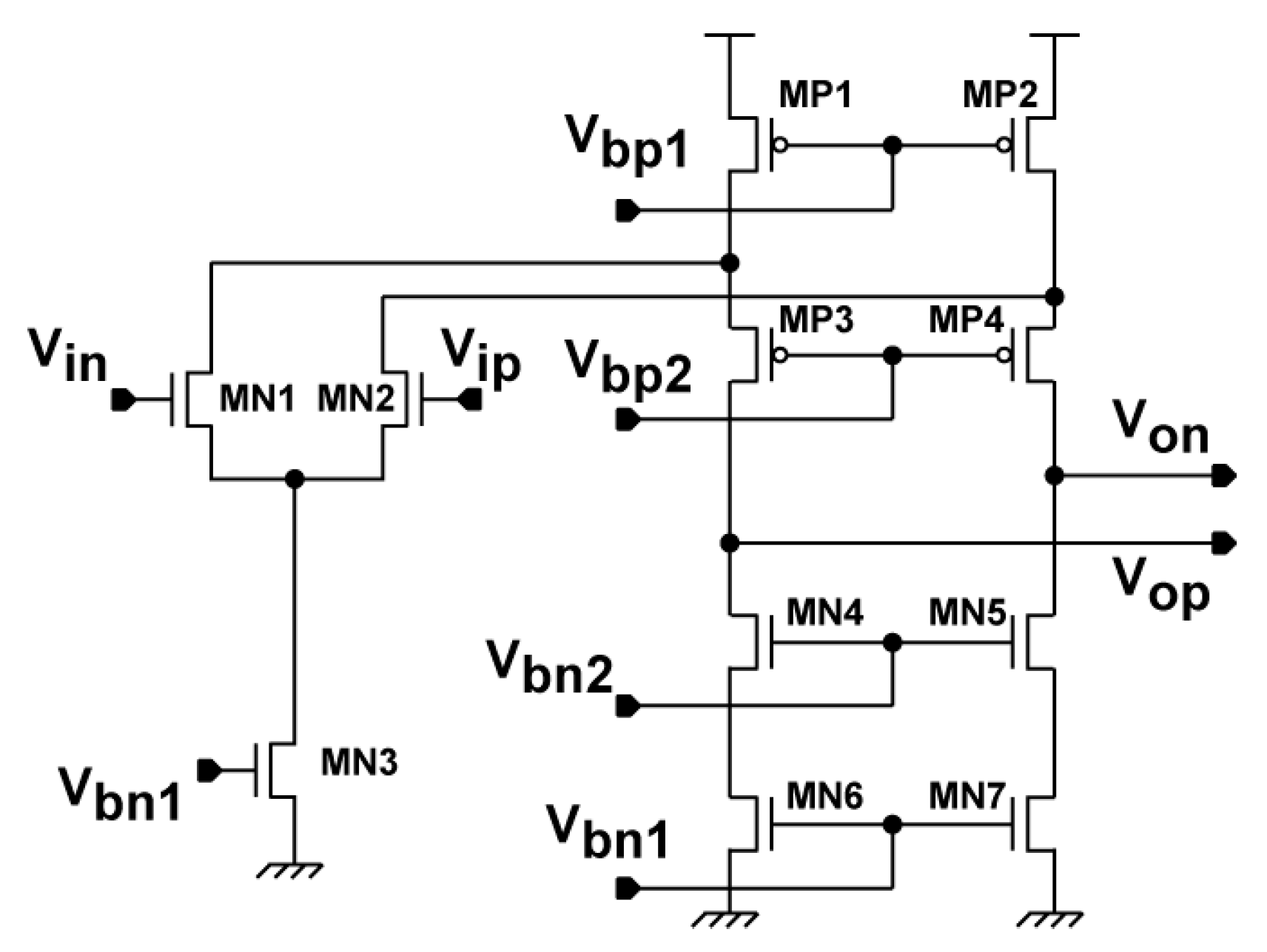

2.3. Demodulator Design

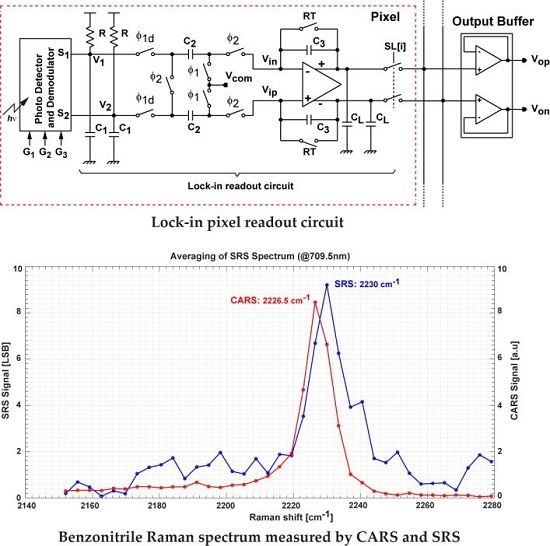

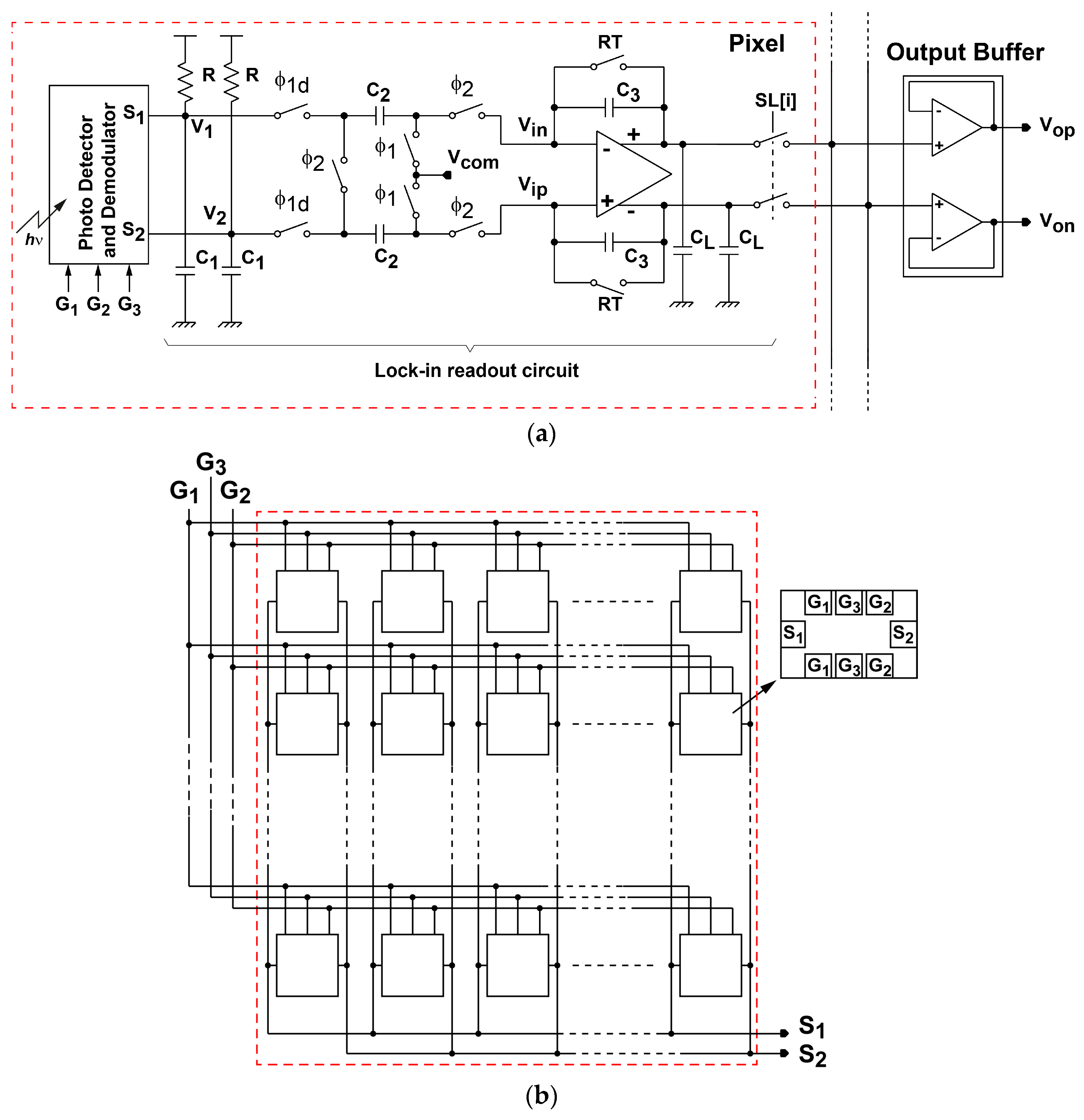

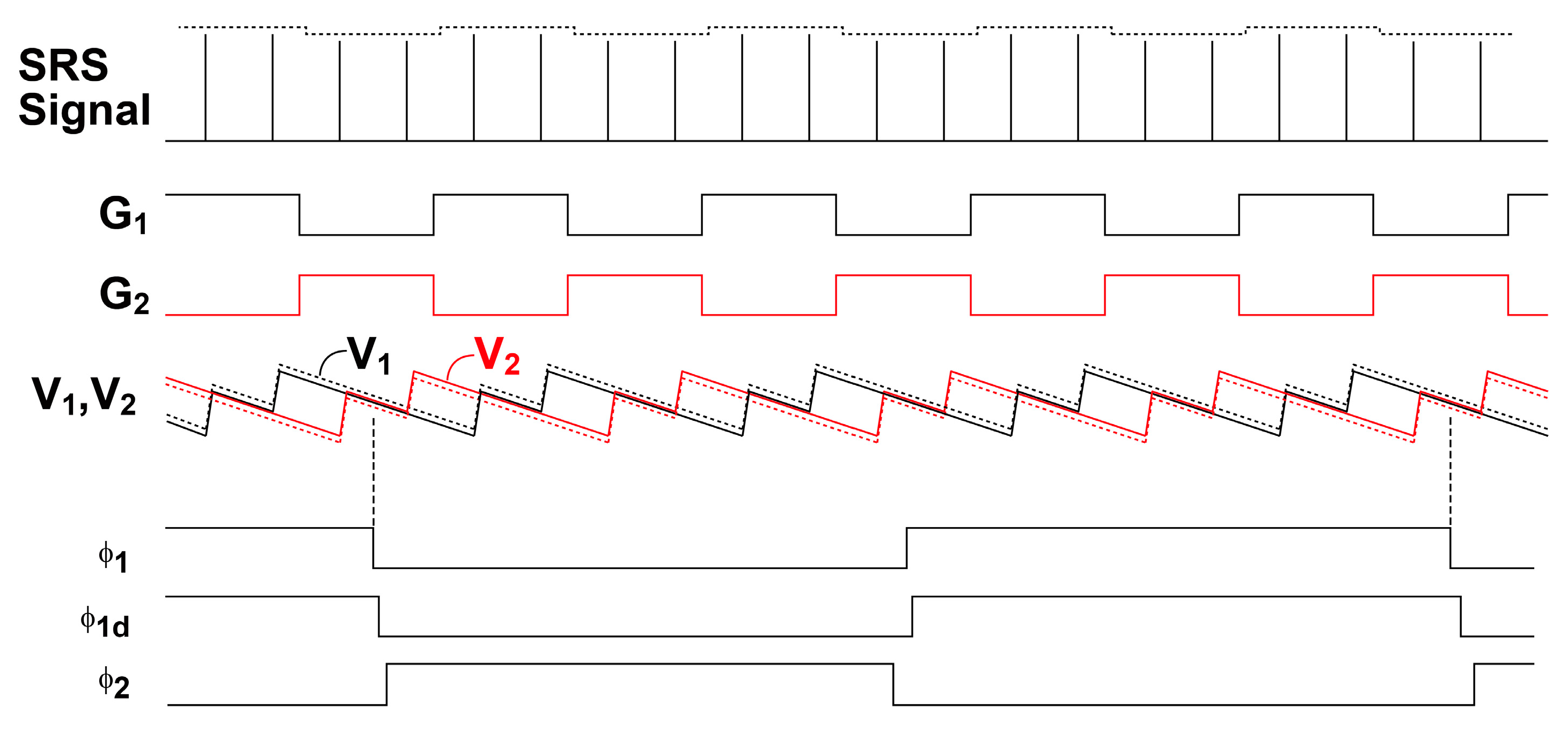

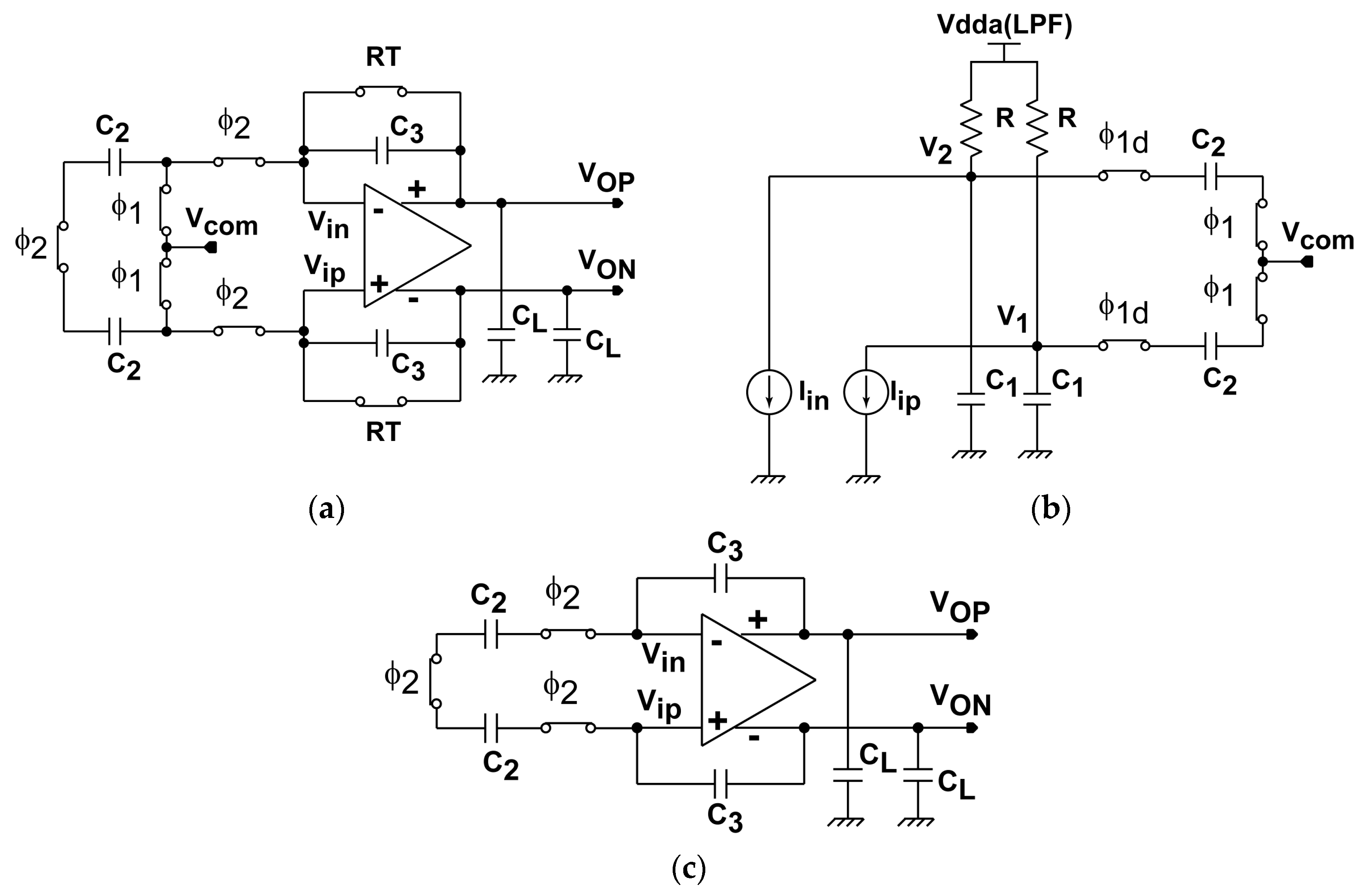

2.4. Pixel Readout Circuit Design and Operation

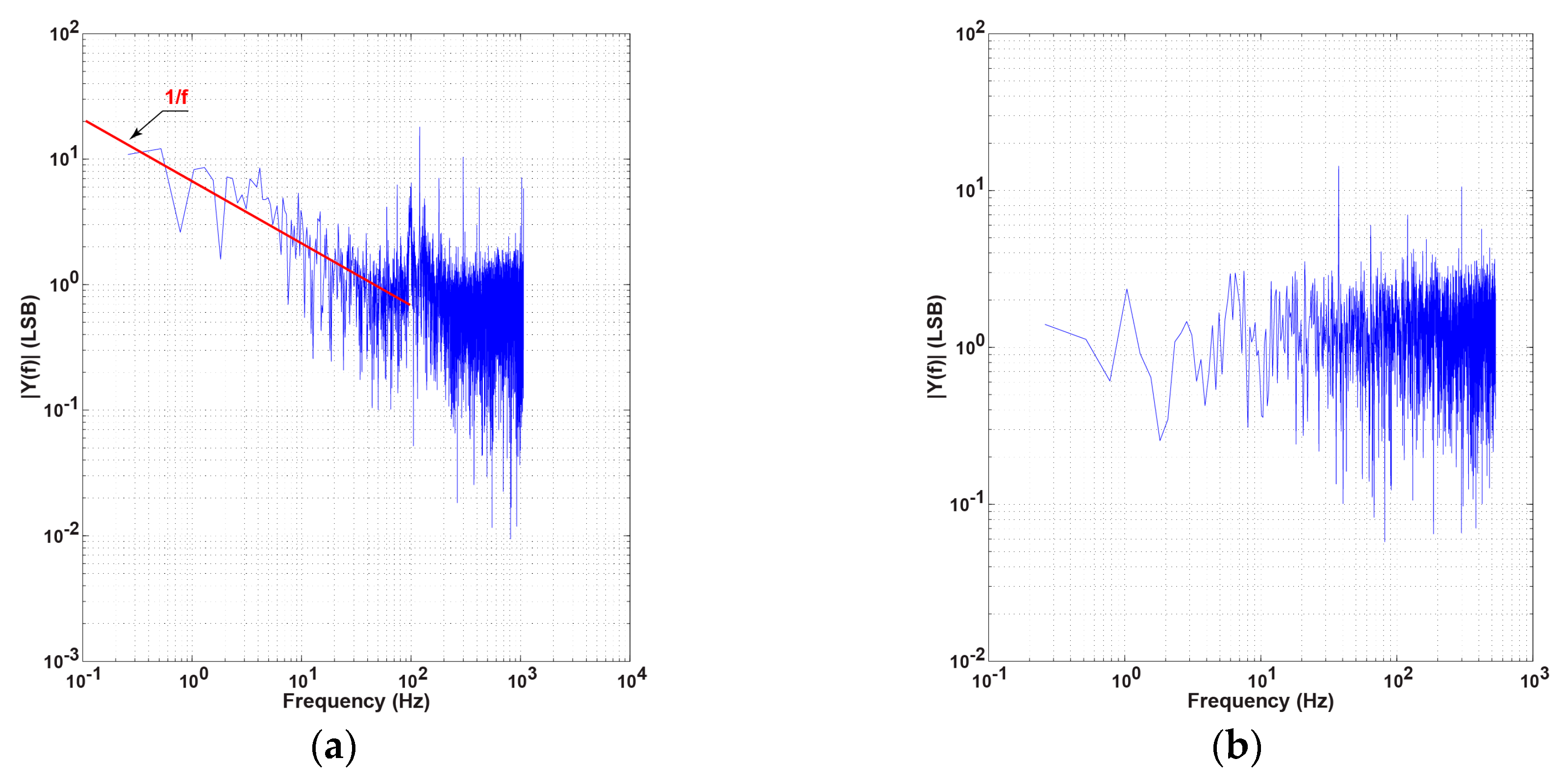

3. 1/f Noise Reduction of a Lock-in Amplifier

4. Implementation and Measurement Results

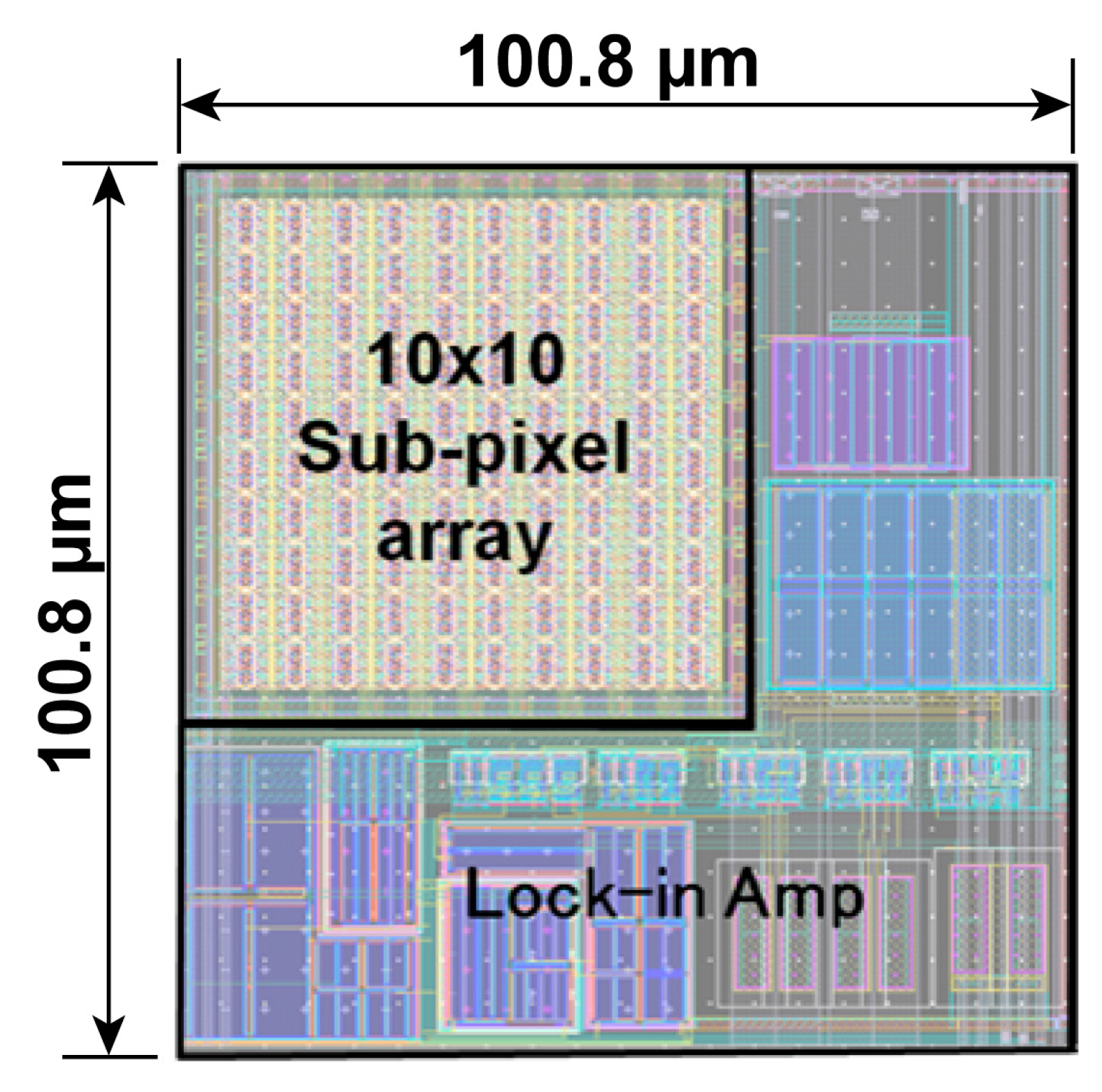

4.1. Implementation of CMOS SRS Pixel Array Chip

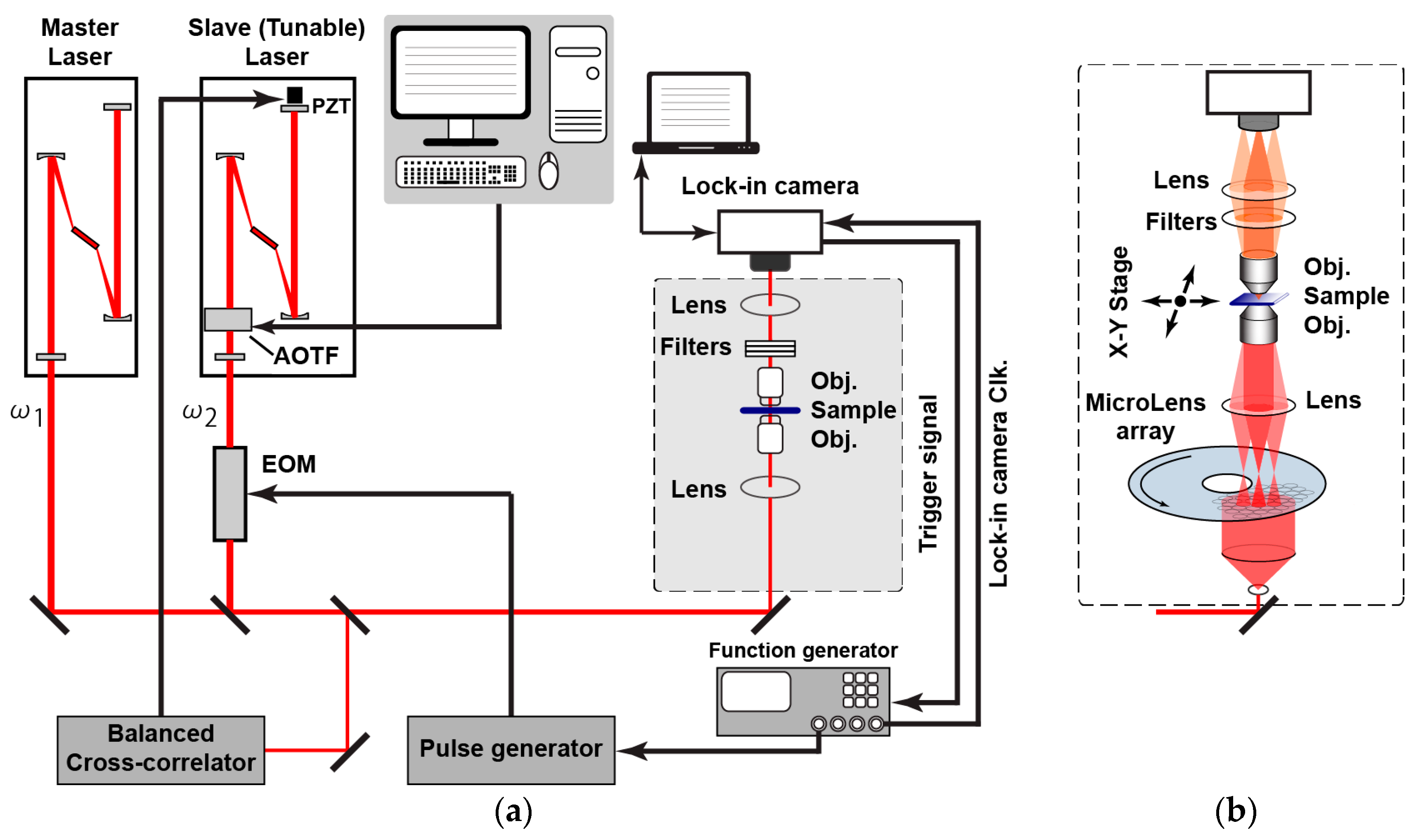

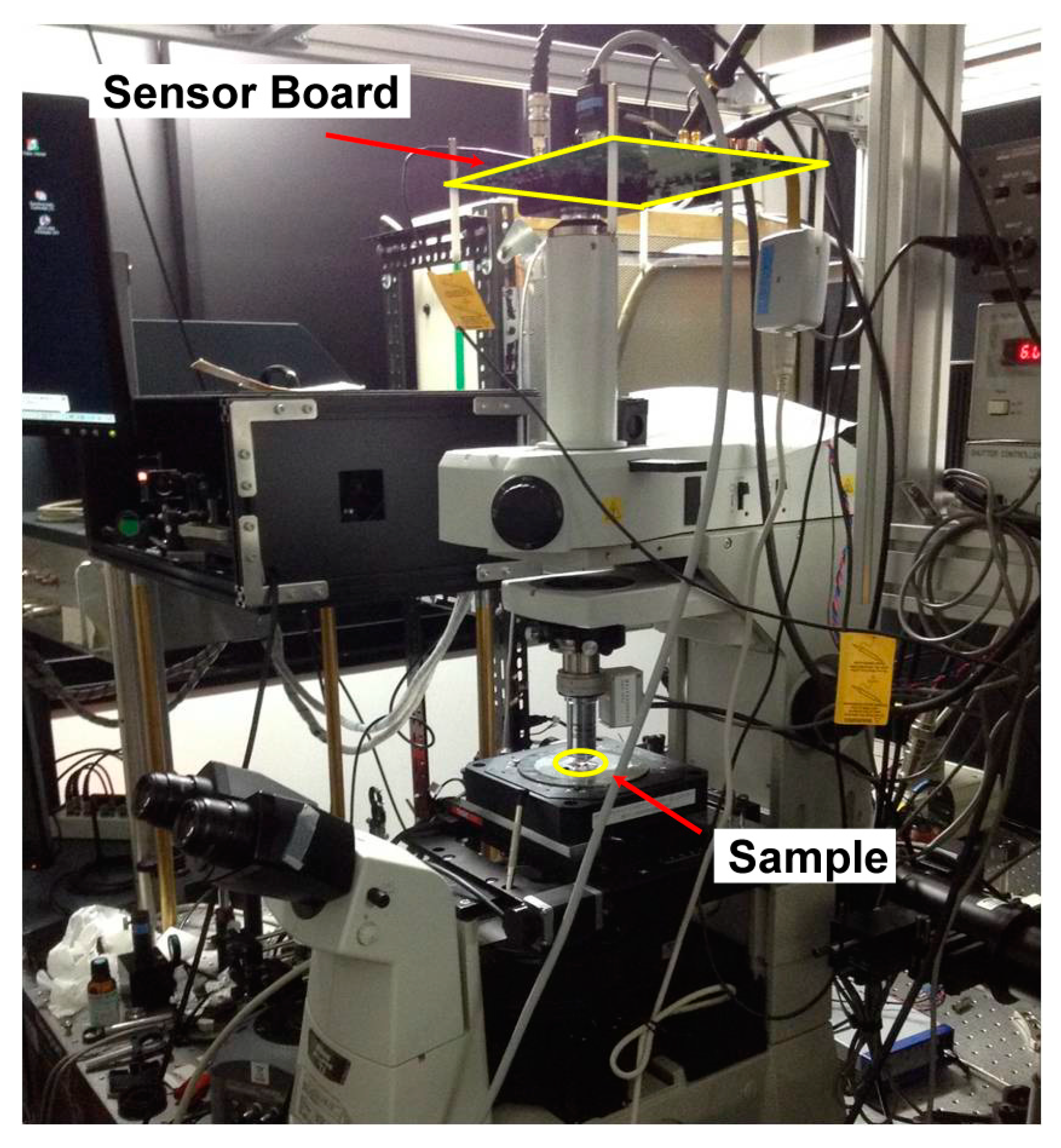

4.2. Experimental Setup and Measurement Conditions

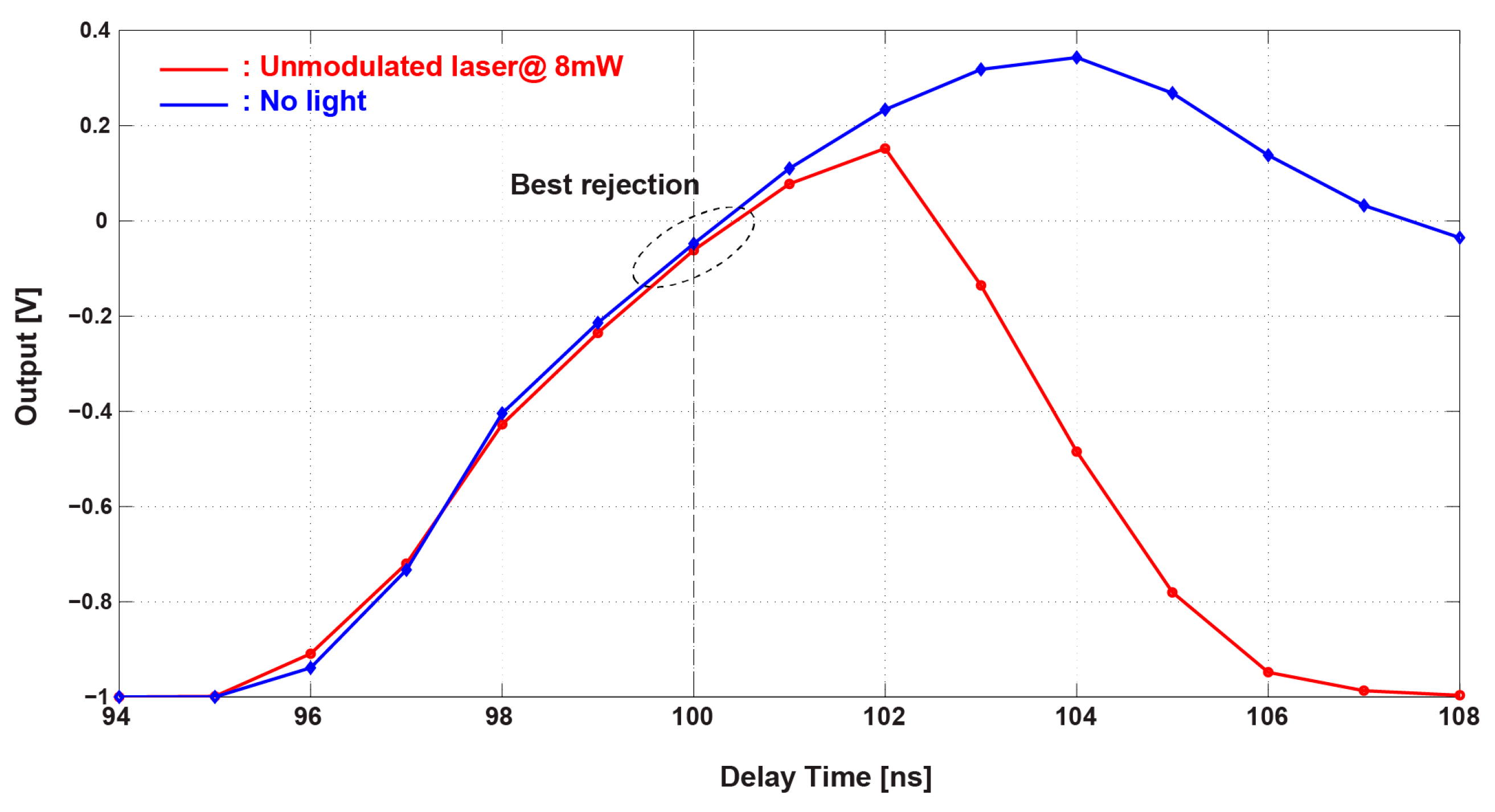

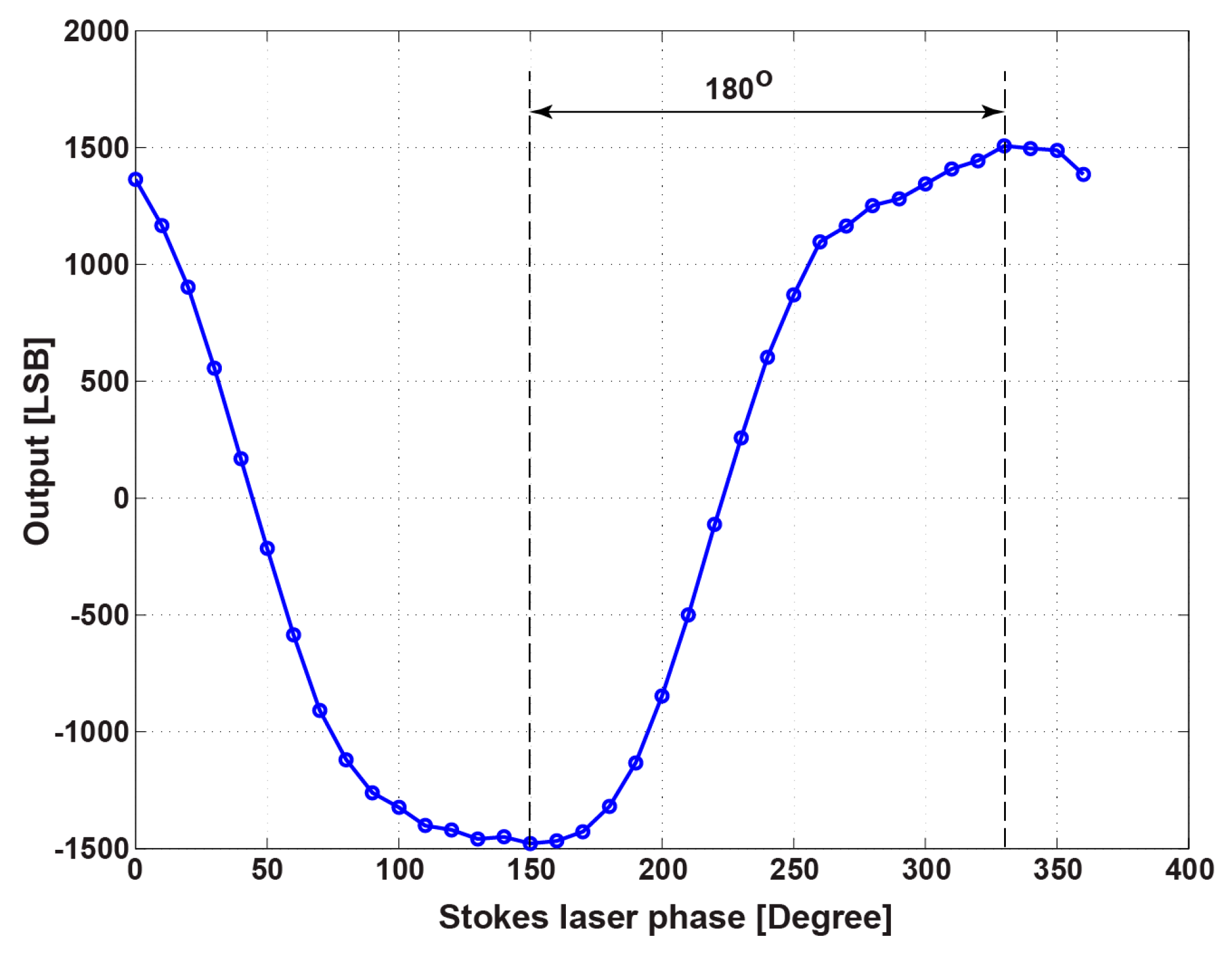

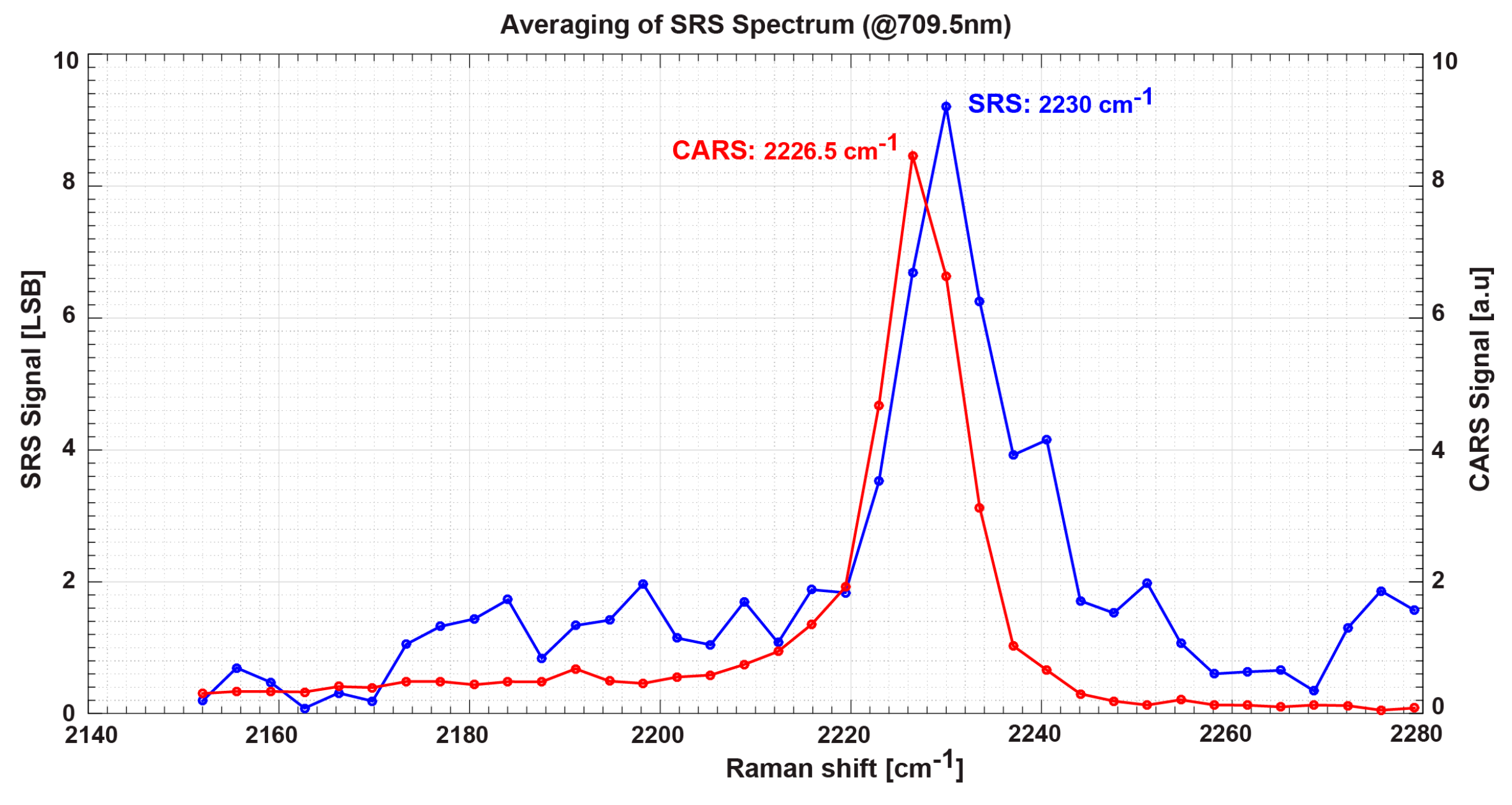

4.3. Measurement Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomas, G.J. Raman Spectroscopy of Protein and Nucleic Acid Assemblies. Annu. Rev. Biophys. Biomol. Struct. 1999, 28, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Chan, J.W.; Taylor, D.S.; Zwerdling, T.; Lane, S.M.; Ihara, K.; Huser, T. Micro-Raman spectroscopy detects individual neoplastic and normal hematopoietic cells. Biophys. J. 2006, 90, 648–656. [Google Scholar] [CrossRef] [PubMed]

- Van Manen, H.J.; Kraan, Y.M.; Roos, D.; Otto, C. Single-cell Raman and fluorescence microscopy reveal the association of lipid bodies with phagosomes in leukocytes. Proc. Natl. Acad. Sci. USA 2005, 102, 10159–10164. [Google Scholar] [CrossRef] [PubMed]

- Evans, C.L.; Xie, X.S. Coherent Anti-Stokes Raman Scattering Microscopy: Chemical Imaging for Biology and Medicine. Annu. Rev. Anal. Chem. 2008, 1, 883–909. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Ramachandran, P.V.; Wang, M.C. Shedding new light on lipid functions with CARS and SRS microscopy. Biochim. Biophys/ Acta (BBA) Mol. Cell Biol. Lipids 2014, 1841, 1120–1129. [Google Scholar] [CrossRef] [PubMed]

- Day, J.P.R.; Domke, K.F.; Rago, G.; Kano, H.; Hamaguchi, H.O.; Vartiainen, E.M.; Bonn, M. Quantitative Coherent Anti-Stokes Raman Scattering (CARS) Microscopy. J. Phys. Chem. B 2011, 115, 7713–7725. [Google Scholar] [CrossRef] [PubMed]

- Freudiger, C.W.; Min, W.; Saar, B.G.; Lu, S.; Holtom, G.R.; He, C.; Tsai, J.C.; Kang, J.X.; Xie, X.S. Label-Free Biomedical Imaging with High Sensitivity by Stimulated Raman Scattering Microscopy. Science 2008, 322, 1857–1861. [Google Scholar] [CrossRef] [PubMed]

- Nandakumar, P.; Kovalev, A.; Volkmer, A. Vibrational imaging based on stimulated Raman scattering microscopy. New J. Phys. 2009, 11, 033026. [Google Scholar] [CrossRef]

- Berto, P.; Andresen, E.R.; Rigneault, H. Background-Free Stimulated Raman Spectroscopy and Microscopy. Phys. Rev. Lett. 2014, 112, 053905. [Google Scholar] [CrossRef] [PubMed]

- Rock, W.; Bonn, M.; Parekh, S.H. Near shot-noise limited hyperspectral stimulated Raman scattering spectroscopy using low energy lasers and a fast CMOS array. Opt. Express 2013, 21, 15113–15120. [Google Scholar] [CrossRef] [PubMed]

- Spirig, T.; Seitz, P. The Lock-in CCD—Two-dimensional synchronous detection of light. IEEE J. Quantum Elec. 1995, 31, 1705–1705. [Google Scholar] [CrossRef]

- Kawahito, S.; Baek, G.; Li, Z.; Han, S.-M.; Seo, M.-W.; Yasutomi, K.; Kagawa, K. CMOS lock-in pixel image sensors with lateral electric field control for time-resolved imaging. In Proceedings of the International Image Sensor Workshop, Snowbird, UT, USA, June 2013; pp. 316–364.

- Cahydi, H.; Iwatsuka, J.; Minamikawa, T.; Niioka, H.; Araki, T.; Hashimoto, M. Fast spectral coherent anti-Stokes Raman scattering microscopy with high-speed tunable picosecond laser. J. BioMed. Opt. 2013, 18, 096009. [Google Scholar] [CrossRef] [PubMed]

- Minamikawa, T.; Hashimoto, M.; Fujita, K.; Kawata, S.; Araki, T. Multi-focus excitation coherent anti-Stokes Raman scattering (CARS) microscopy and its applications for real-time imaging. Opt. Express 2009, 17, 9526–9536. [Google Scholar] [CrossRef] [PubMed]

- Standard Spectra. Available online: http://www.chem.ualberta.ca/~mccreery/ramanmaterials.html (accessed on 15 October 2014).

| Parameter | Value |

|---|---|

| AC Power | 3.8 mW |

| DC Power | 8.0 mW |

| Pump laser wavelength | 709.5 nm |

| Stokes laser wavelength | 837~846 nm |

| Step size | 0.25 nm |

| Modulation frequency | 20 MHz |

| Integrator sampling frequency | 5 MHz |

| Integration time | 150 µs |

| Number of integration (Gain) | 750 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lioe, D.X.; Mars, K.; Kawahito, S.; Yasutomi, K.; Kagawa, K.; Yamada, T.; Hashimoto, M. A Stimulated Raman Scattering CMOS Pixel Using a High-Speed Charge Modulator and Lock-in Amplifier. Sensors 2016, 16, 532. https://doi.org/10.3390/s16040532

Lioe DX, Mars K, Kawahito S, Yasutomi K, Kagawa K, Yamada T, Hashimoto M. A Stimulated Raman Scattering CMOS Pixel Using a High-Speed Charge Modulator and Lock-in Amplifier. Sensors. 2016; 16(4):532. https://doi.org/10.3390/s16040532

Chicago/Turabian StyleLioe, De Xing, Kamel Mars, Shoji Kawahito, Keita Yasutomi, Keiichiro Kagawa, Takahiro Yamada, and Mamoru Hashimoto. 2016. "A Stimulated Raman Scattering CMOS Pixel Using a High-Speed Charge Modulator and Lock-in Amplifier" Sensors 16, no. 4: 532. https://doi.org/10.3390/s16040532

APA StyleLioe, D. X., Mars, K., Kawahito, S., Yasutomi, K., Kagawa, K., Yamada, T., & Hashimoto, M. (2016). A Stimulated Raman Scattering CMOS Pixel Using a High-Speed Charge Modulator and Lock-in Amplifier. Sensors, 16(4), 532. https://doi.org/10.3390/s16040532