An Optimized Air-Core Coil Sensor with a Magnetic Flux Compensation Structure Suitable to the Helicopter TEM System

Abstract

:1. Introduction

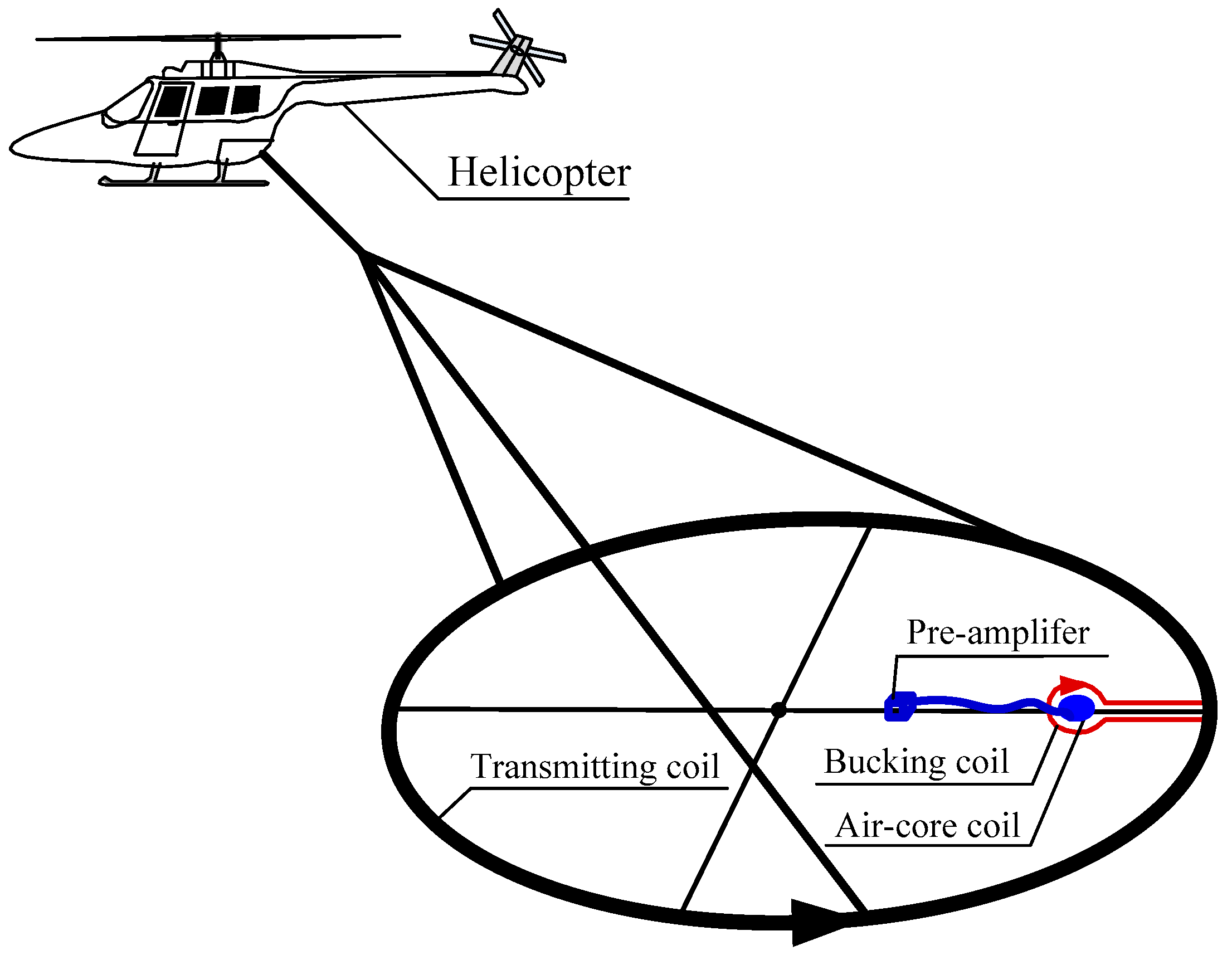

2. ACS Matched with Bucking Coil

2.1. Analysis of the Eccentric Bucking Coil

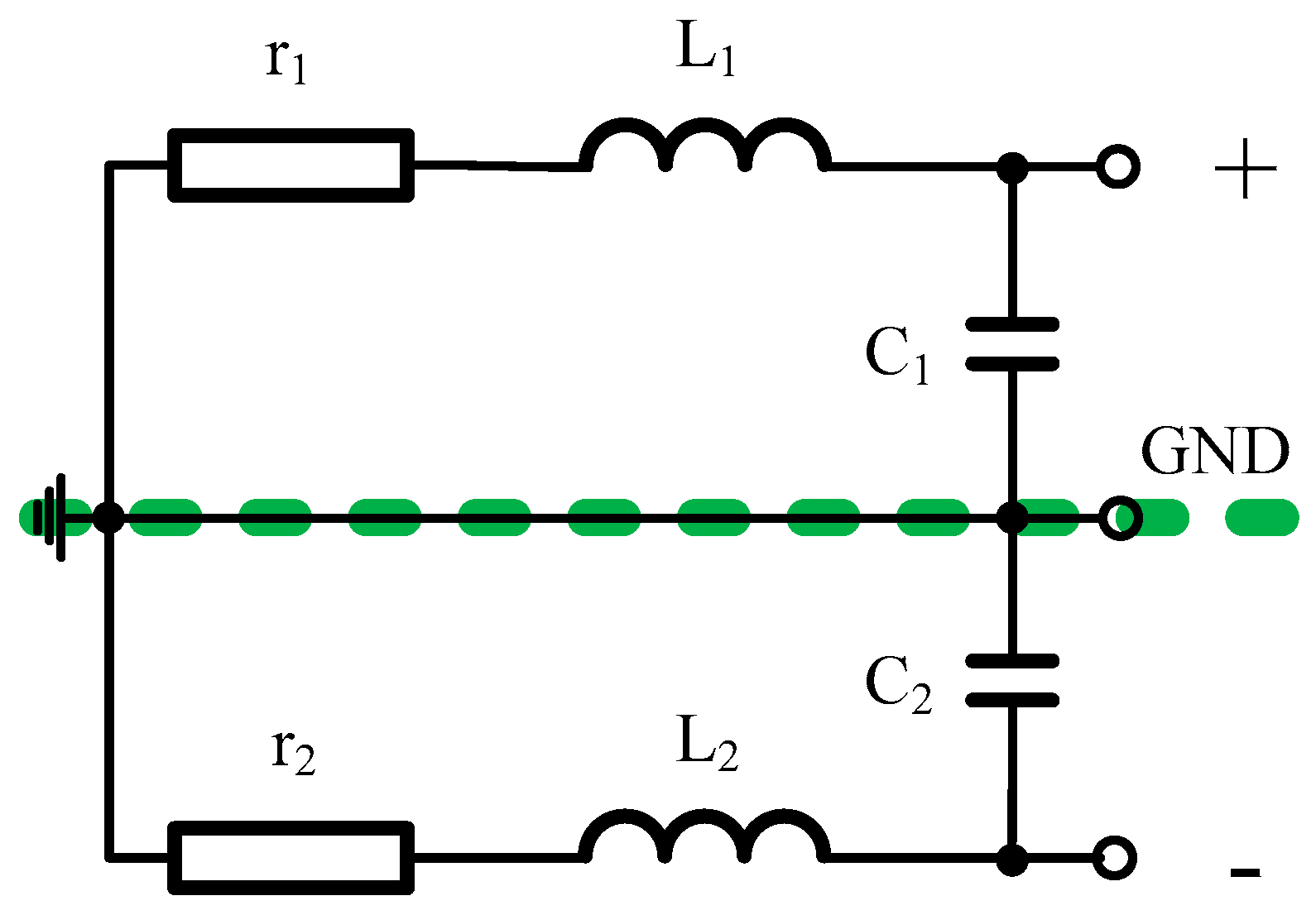

2.2. Equivalent Electrical Model of an Air-core Coil

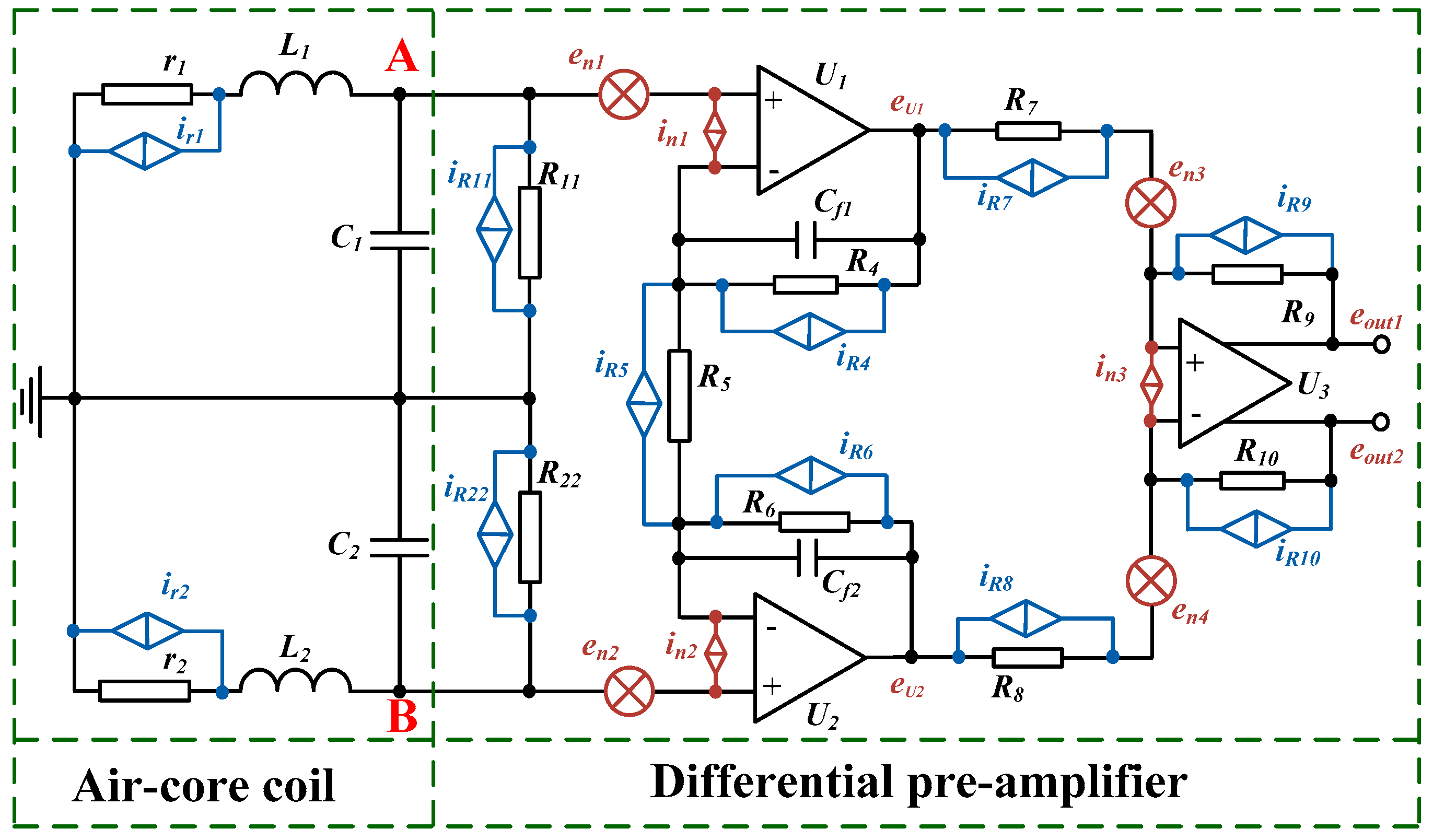

2.3. Equivalent Schematic of ACS with a Differential Pre-Amplifier Circuit

3. Specifications for the Optimization of the ACS

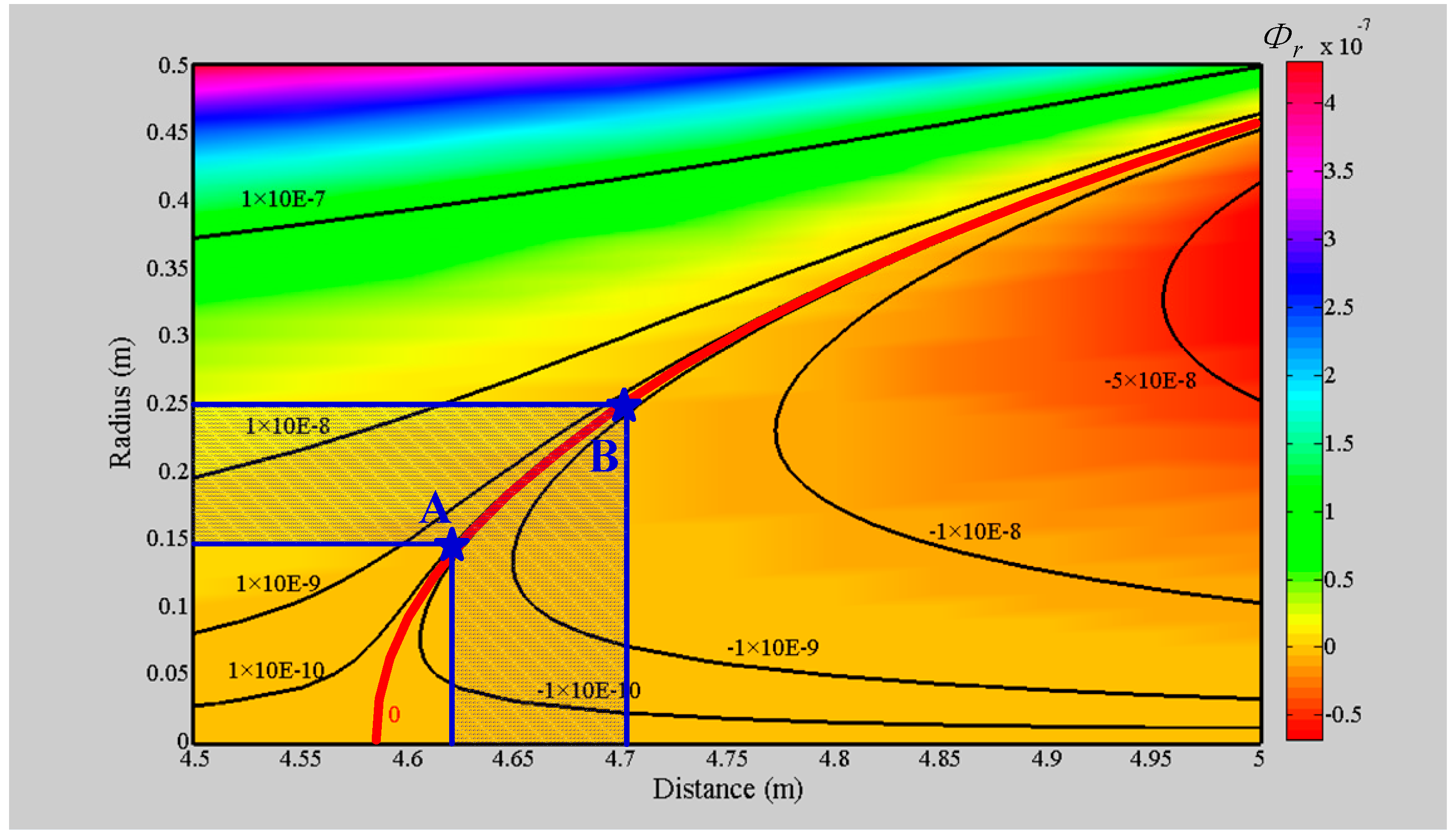

3.1. Optimization of the Geometric Location of the Bucking Coil

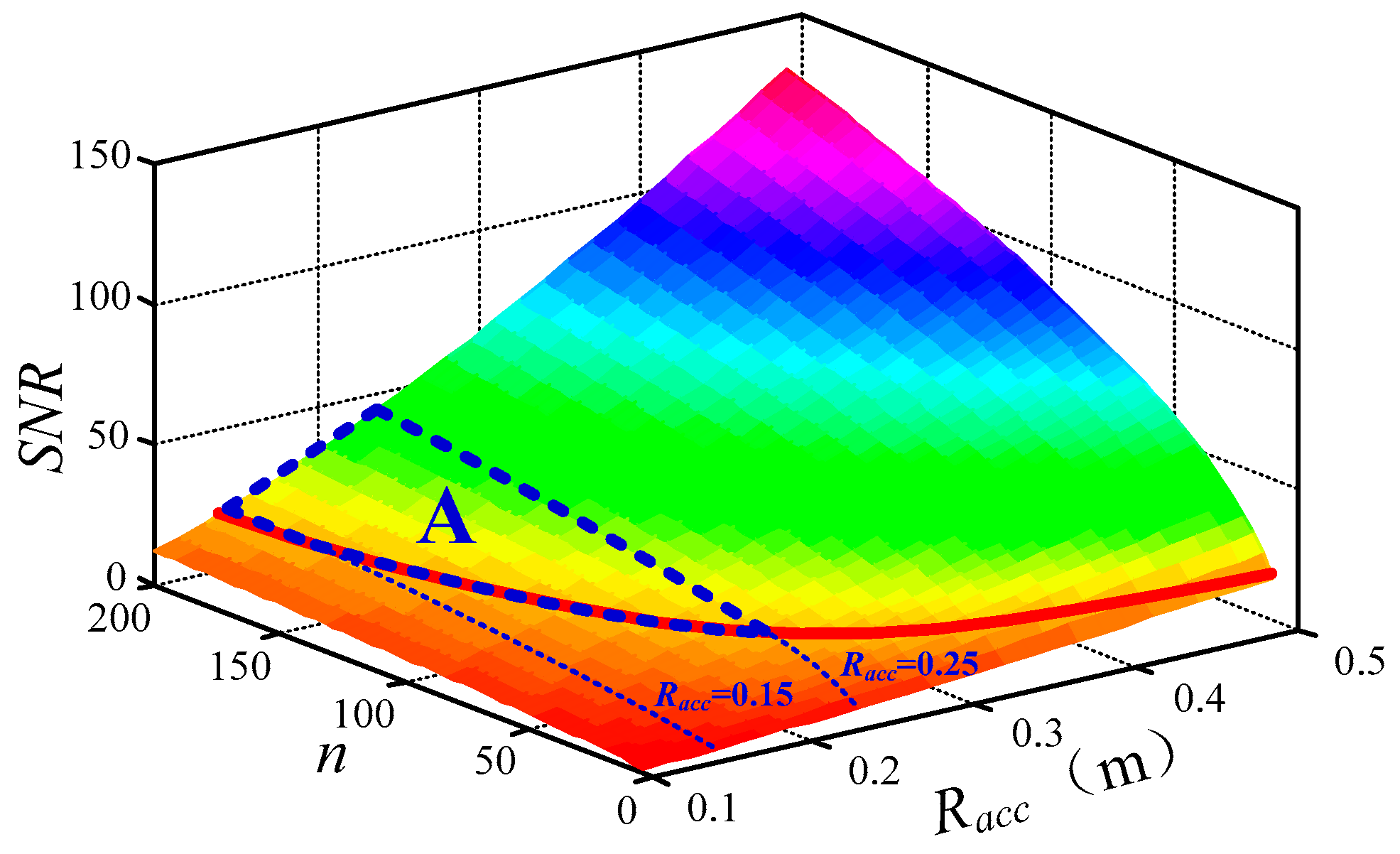

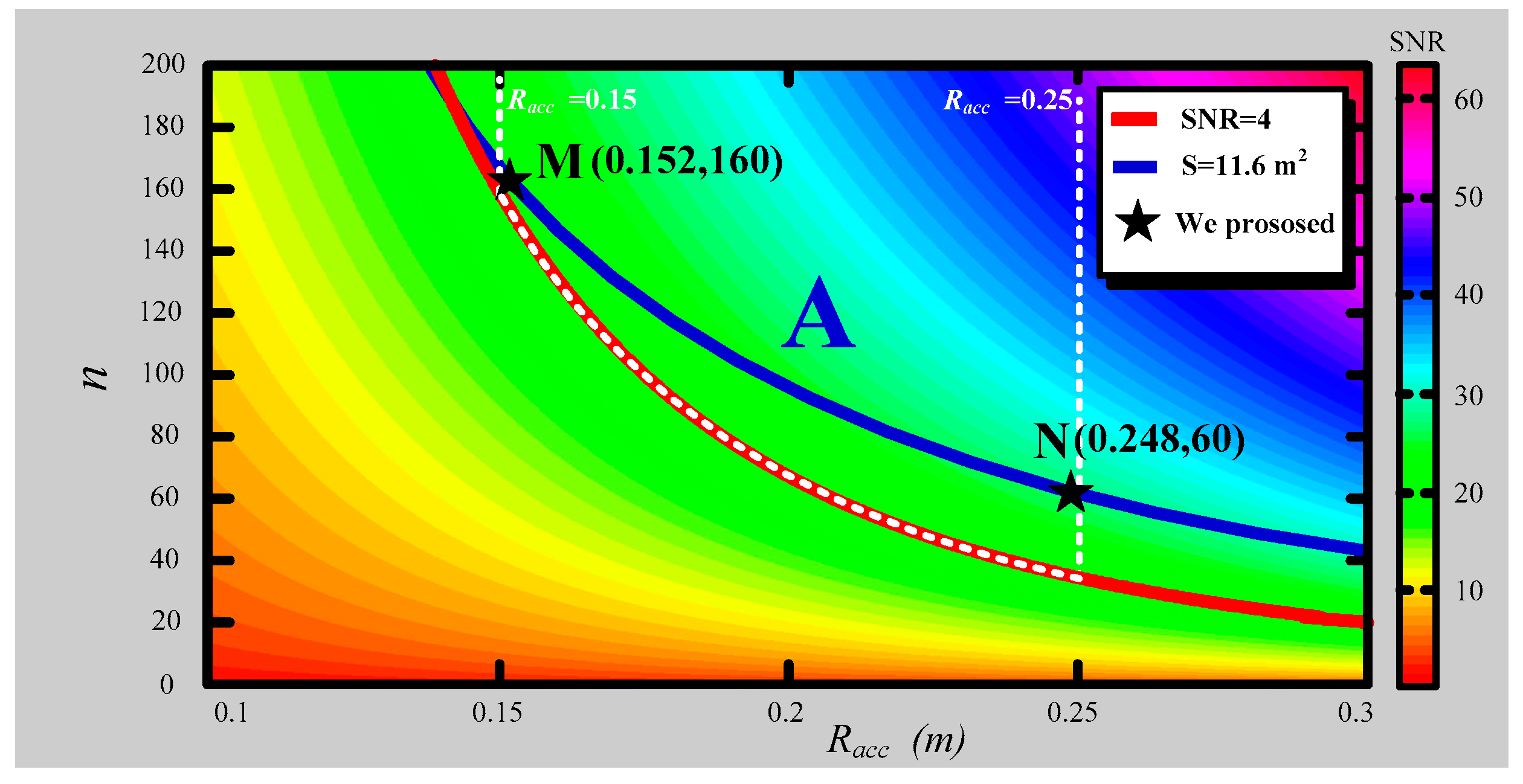

3.2. Geometric Optimization of the Air-Core Coil

3.3. Optimization of the Pre-Amplifier Circuit

4. Fabrication of ACS

4.1. Fabrication of the Air-Core Coil

4.2. Fabrication of the Pre-Amplifier Circuit

5. Electrical Performances of ACSs

5.1. Comparison of the Frequency Response of ACSs

5.2. Comparison of the Equivalent Input Noise of ACSs

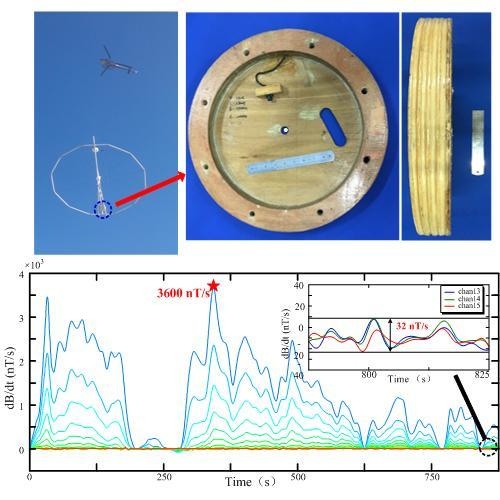

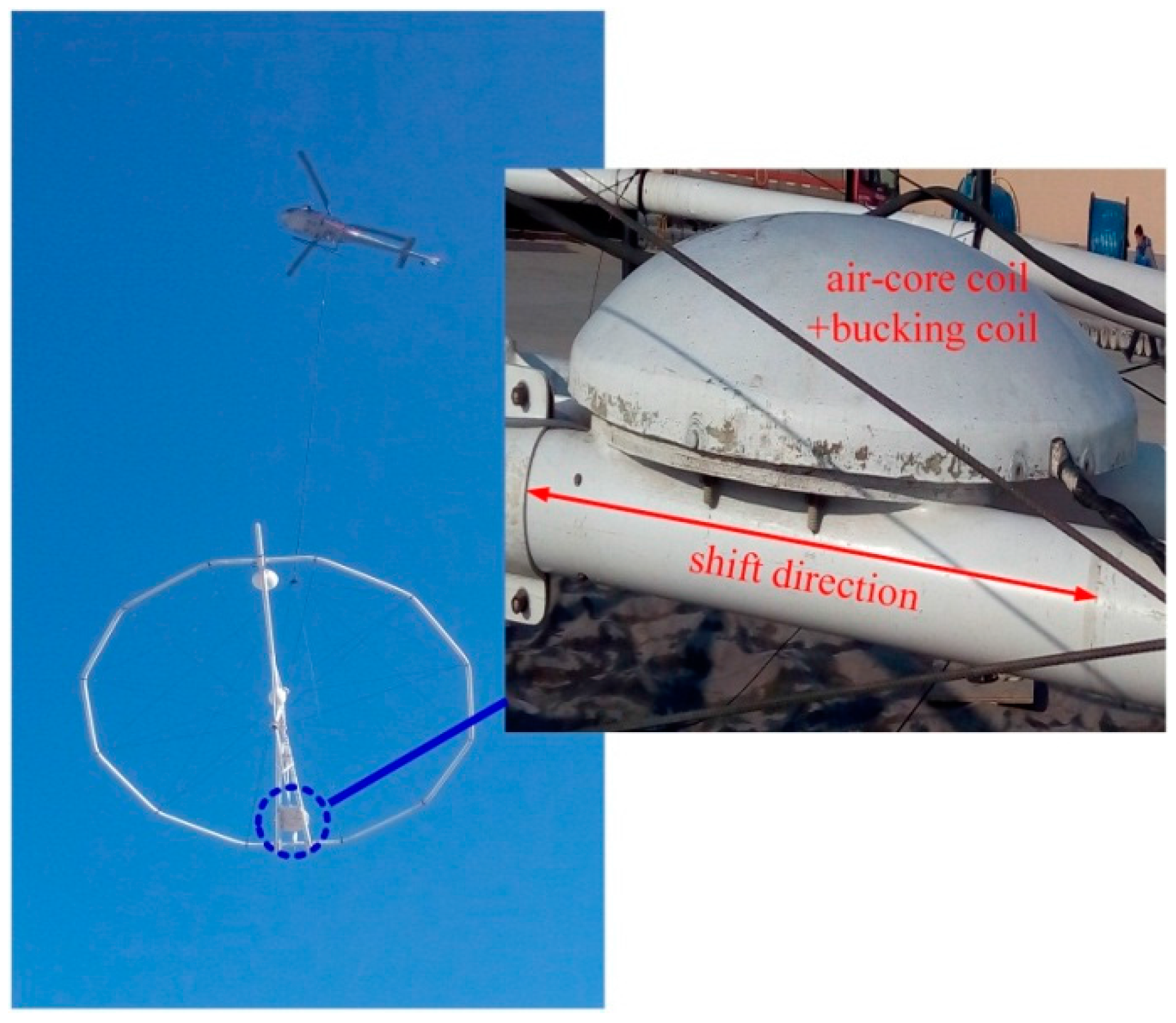

6. Field Experiments in Baoqing County

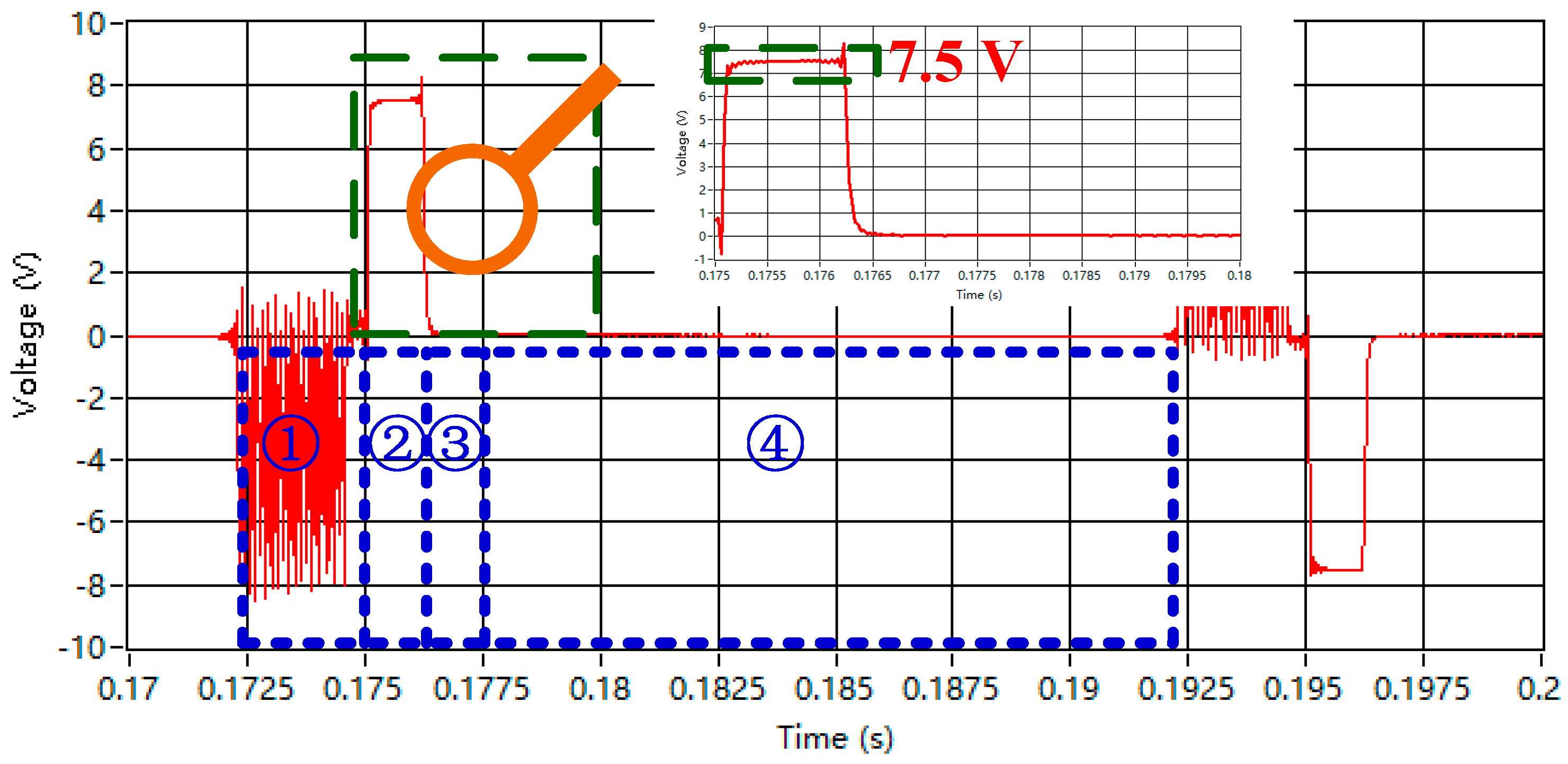

6.1. Ground Experiment Using the Magnetic Flux Compensation Structure

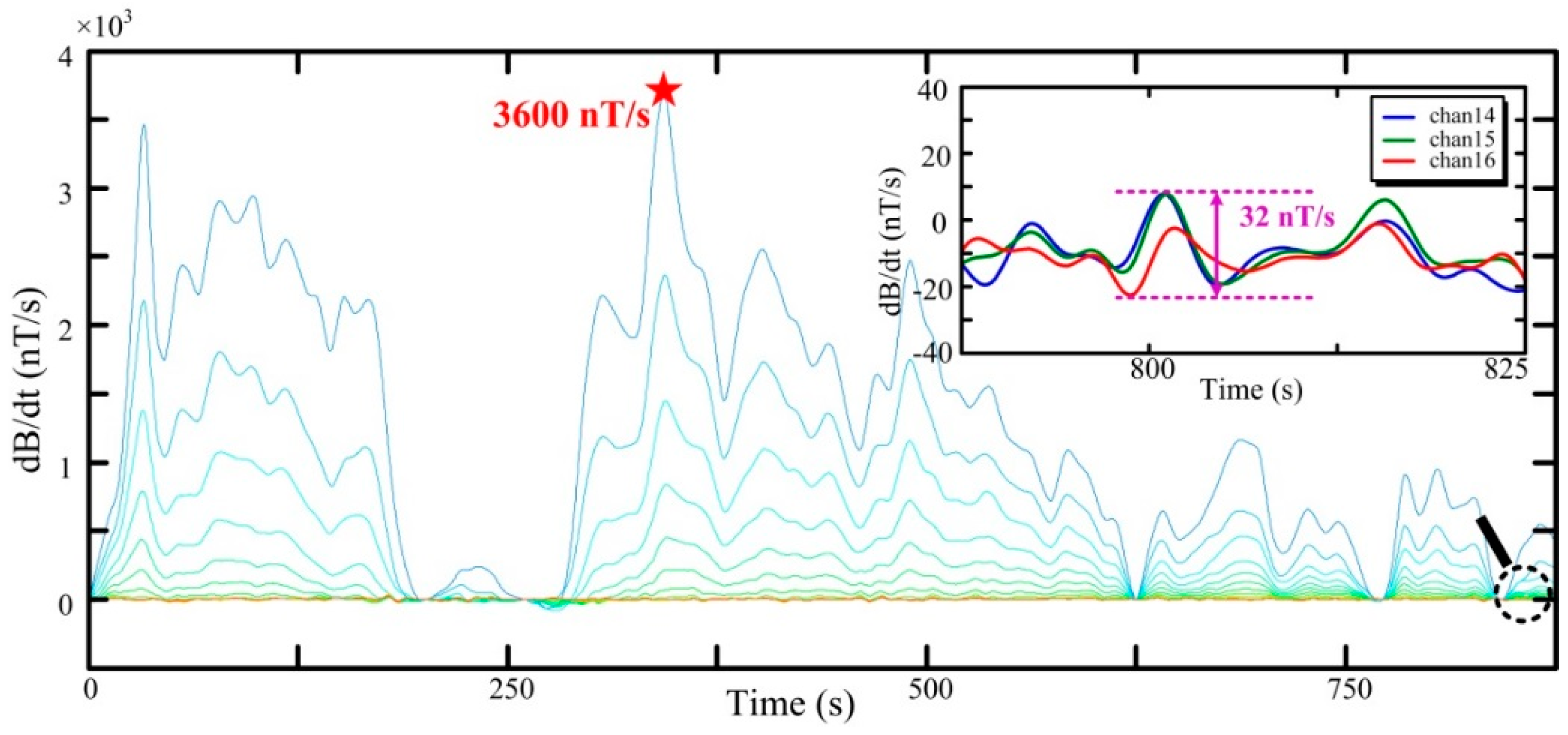

6.2. Field Experiments Using Two ACSs

7. Conclusions and Prospects

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sattel, D. A brief discussion of helicopter time-domain electromagnetic systems. SEG Int. Meet. Expand. Abstr. 2006, 25, 1268–1272. [Google Scholar]

- Siemon, B.; Anders, V.C.; Esben, A. A review of helicopter-borne electromagnetic methods for groundwater exploration. Near Sur. Geophys. 2009, 7, 629–646. [Google Scholar] [CrossRef]

- Balch, S.J.; Boyko, W.P.; Paterson, N.R. The AeroTEM airborne electromagnetic system. Lead. Edge 2003, 22, 562–566. [Google Scholar] [CrossRef]

- Scrivens, S. A Comparison between Helicopter and Fixed-Wing Time-Domain Electromagnetic Systems; Carleton University Ottawa: Ontario, ON, Canada, 2005. [Google Scholar]

- Christiansen, A.V.; Auken, E.; Sørensen, K. The transient electromagnetic method. In Groundwater Geophysics; Springer Berlin Heidelberg: Berlin, Germany, 2009; pp. 179–226. [Google Scholar]

- Allard, M. On the origin of the HTEM species. Proc. Exp. 2007, 7, 387–398. [Google Scholar]

- Tumanski, S. Induction coil sensors—A review. Measur. Sci. Technol. 2007, 18, R31–R46. [Google Scholar] [CrossRef]

- Korepanov, V.; Berkman, R.; Rakhlin, L.; Klymovych, Y.; Prystai, A.; Marussenokov, A.; Afanassenko, M. Advanced field magnetometers comparative study. Measurement 2001, 29, 137–146. [Google Scholar] [CrossRef]

- Chen, C.; Liu, F.; Lin, J.; Wang, Y. Investigation and Optimization of the Performance of an Air-Coil Sensor with a Differential Structure Suited to Helicopter TEM Exploration. Sensors 2015, 15, 23325–23340. [Google Scholar] [CrossRef] [PubMed]

- Grosz, A.; Paperno, E. Analytical optimization of low-frequency search coil magnetometers. IEEE Sens. 2012, 12, 2719–2723. [Google Scholar] [CrossRef]

- Fountain, D.; Smith, R.; Payne, T. A helicopter time-domain EM system applied to mineral exploration: System and data. First Break 2005, 23, 73–78. [Google Scholar]

- Chen, S.; Wang, Y.; Zhang, S. Bucking coil used in airborne transient electromagnetic survey. In Proceedings of the IEEE International Conference on Industrial Control and Electronics Engineering, Xi’an, China, 23–25 August 2012; pp. 478–481.

- Kuzmin, P.V.; Morrison, E.B. Bucking Coil and B-Field Measurement System and Apparatus for Time Domain Electromagnetic Measurements. U.S. Patent 8,400,157 B2, 19 March 2013. [Google Scholar]

- Phoenix Geosystem Corporate Brochure. Available online: http://www.phoenix-geosystem.com/ (accessed on 16 January 2015).

- Geophysical Instrumentation for Exploration & the Environment. Available online: http://www.geonics.com/ (accessed on 19 March 2015).

- Yan, B.; Zhu, W.; Liu, L.; Liu, K.; Fang, G. Equivalent input magnetic noise analysis for the induction magnetometer of 0.1 mHz to 1 Hz. IEEE Sens. J. 2014, 14, 4442–4449. [Google Scholar] [CrossRef]

- Lewis, S.; Sheingold, D. Noise and Operational Amplifier Circuits; Electrical Engineering University of Calgary: Alberta, AB, Canada, 1991; pp. 19–31. [Google Scholar]

| Parameters | Air-Core Coil A | Air-Core Coil B |

|---|---|---|

| Radius | 0.152 m | 0.248 m |

| Segments | 4 | 4 |

| Number of turns | 160 | 60 |

| Diameter of wire | 0.5 mm | 0.5 mm |

| Resistance of air-core coil | 10.46 Ω | 3.88 Ω |

| Inductance of air-core coil | 4.05 mH | 1.14 mH |

| Capacitance of air-core coil | 773 pF | 283 pF |

| Response frequency | 90 kHz | 280 kHz |

| Components | Parameters |

|---|---|

| R11 = R22 | 1.3 kΩ |

| R4 = R6 | 1.5 kΩ |

| R5 | 100 Ω |

| R7 = R8 | 1 kΩ |

| R9 = R10 | 20 kΩ |

| G | 620 |

| U1,U2 | AD797 |

| U3 | THS4131 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Liu, F.; Lin, J.; Zhu, K.; Wang, Y. An Optimized Air-Core Coil Sensor with a Magnetic Flux Compensation Structure Suitable to the Helicopter TEM System. Sensors 2016, 16, 508. https://doi.org/10.3390/s16040508

Chen C, Liu F, Lin J, Zhu K, Wang Y. An Optimized Air-Core Coil Sensor with a Magnetic Flux Compensation Structure Suitable to the Helicopter TEM System. Sensors. 2016; 16(4):508. https://doi.org/10.3390/s16040508

Chicago/Turabian StyleChen, Chen, Fei Liu, Jun Lin, Kaiguang Zhu, and Yanzhang Wang. 2016. "An Optimized Air-Core Coil Sensor with a Magnetic Flux Compensation Structure Suitable to the Helicopter TEM System" Sensors 16, no. 4: 508. https://doi.org/10.3390/s16040508