Measurement of Spray Drift with a Specifically Designed Lidar System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Lidar System

2.3. Meteorological Measurements

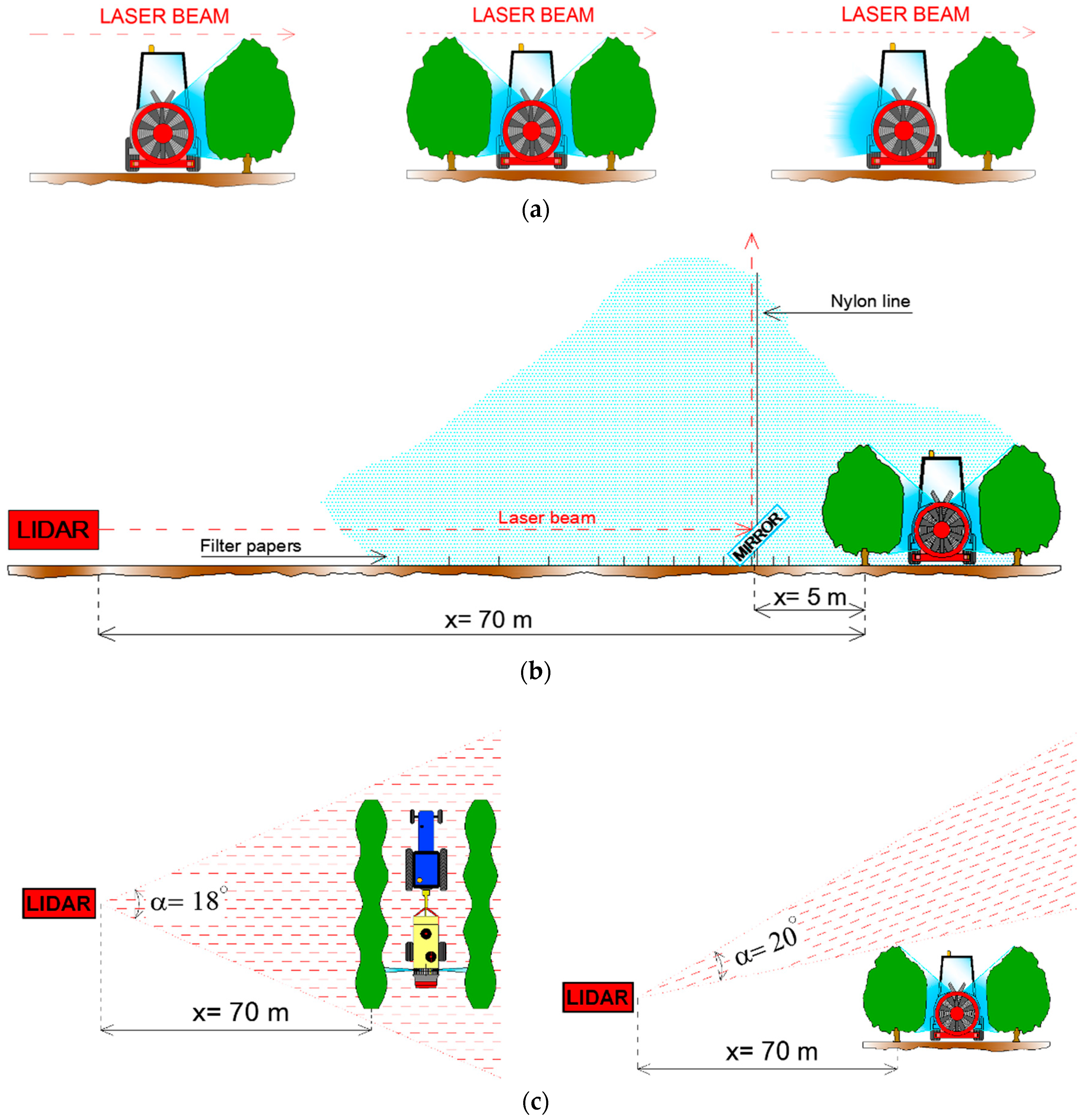

2.4. Lidar Measurement Configurations

2.5. Spray Flux Measurement over the Crop Canopy

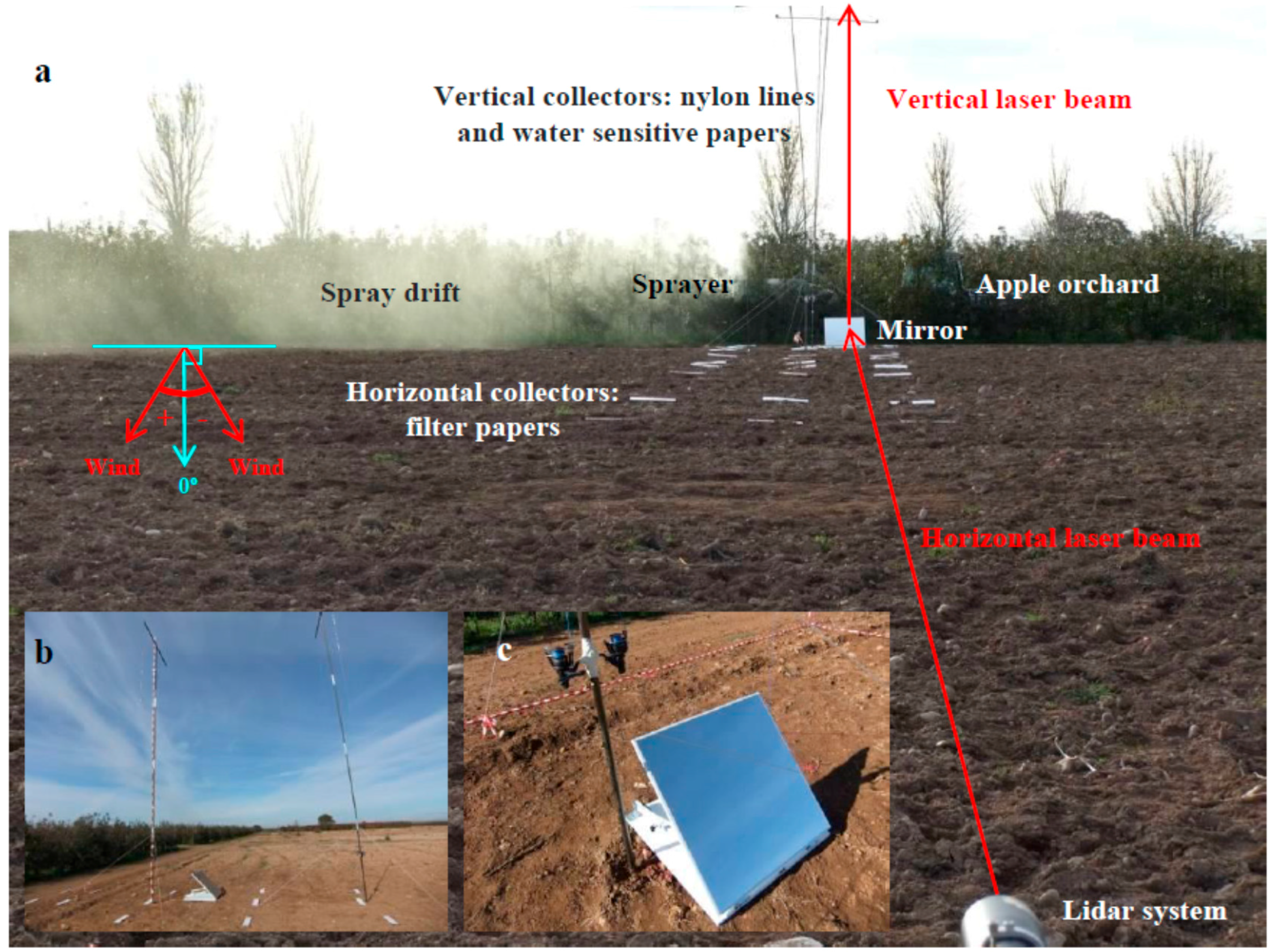

2.6. Comparison between Spray Drift Measurements Using the Lidar and the ISO 22866 Methodology

2.7. Lidar Scanning of the Spray Plume over the Crop Canopy

3. Results and Discussion

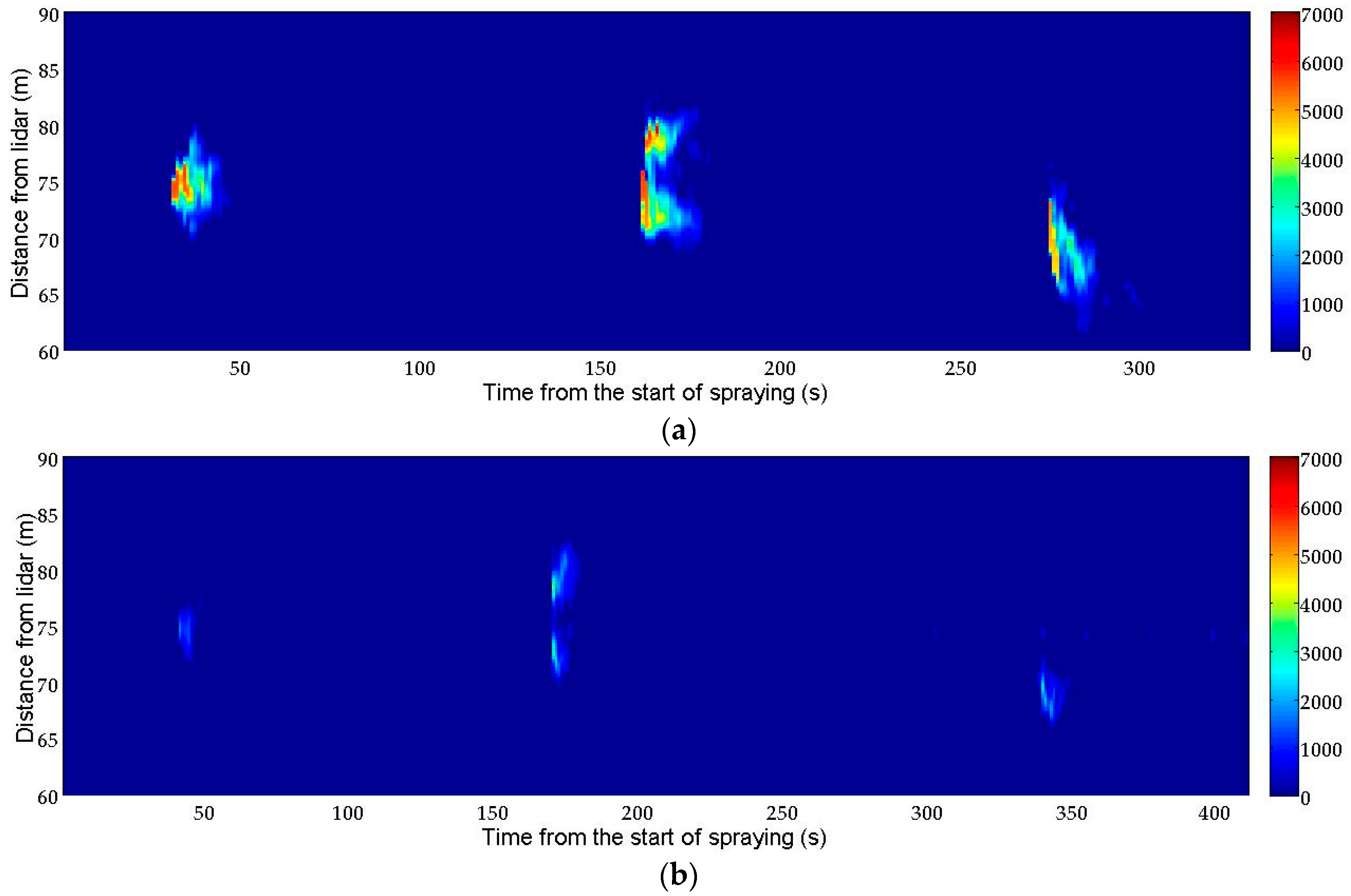

3.1. Spray Flux Measurement over the Crop Canopy

3.2. Comparison Between Spray Drift Measurements Using the Lidar and the ISO 22866 Methodology

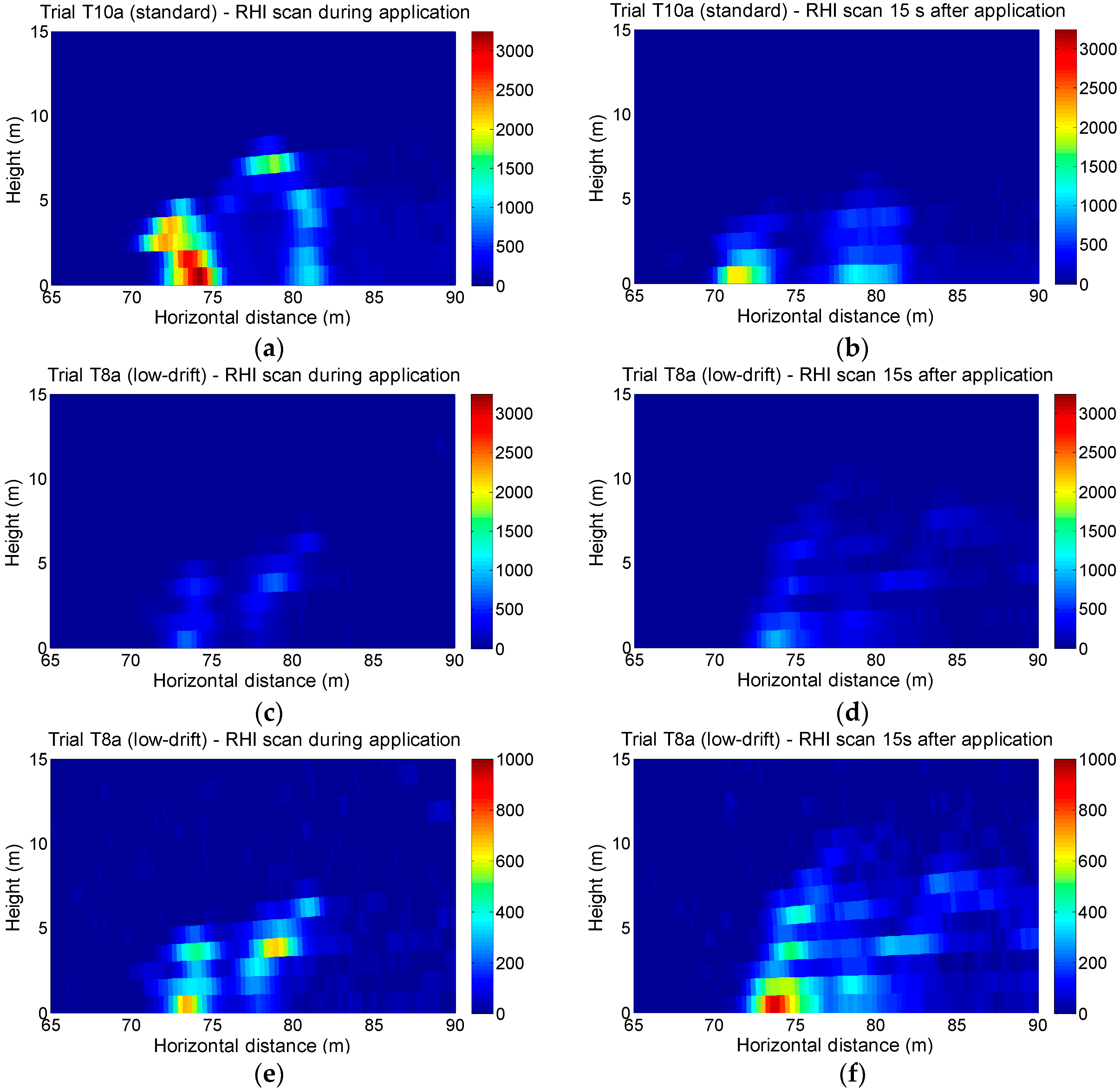

3.3. Lidar Scanning of the Spray Plume over the Crop Canopy

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| LIDAR | Light detection and ranging |

| RTI | Range-time intensity |

| DRP | Drift reduction potential |

| PPI | Plan position indicator |

| RHI | Range-height indicator |

References

- International Standard. Equipment for Crop Protection. Methods for Field Measurement of Spray Drift. ISO 22866. Available online: http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=35161 (accessed on 8 April 2016).

- Makarov, V.I.; Ankilov, A.N.; Koutsenogii, K.P.; Borodulin, A.I.; Samsonov, Y.N. Efficiency of the inertial wind capture of pesticide aerosols by vegetation species. J. Aerosol Sci. 1996, 27, S67–S68. [Google Scholar] [CrossRef]

- Unsworth, J.B.; Wauchope, R.D.; Klein, A.W.; Dorne, E.; Zeeh, B.; Yeh, S.M.; Akerblom, M.; Racke, K.D.; Rubin, B. Significance of the long range transport of pesticides in the atmosphere. Pure Appl. Chem. 1999, 71, 1359–1383. [Google Scholar] [CrossRef]

- Elliott, J.G.; Wilson, B.J. The Influence of Weather on the Efficiency and Safety of Pesticide Application: The Drift of Herbicides; The British Crop Protection Council: London, UK, 1983. [Google Scholar]

- Schulz, R. Field studies on exposure, effects and risk mitigation of aquatic nonpoint-source insecticide pollution: A review. J. Environ. Qual. 2004, 33, 419–448. [Google Scholar] [CrossRef] [PubMed]

- Cunha, J.P.; Chueca, P.; Garcerá, C.; Moltó, E. Risk assessment of pesticide spray drift form citrus applications with sir-blast sprayers in Spain. Crop Prot. 2012, 42, 116–123. [Google Scholar] [CrossRef]

- Butler-Ellis, M.C.; Lane, A.G.; O’Sullivan, C.M.; Miller, P.C.H.; Glass, C.R. Bystander exposure to pesticide spray drift: New data for model development and validation. Biosyst. Eng. 2010, 107, 162–168. [Google Scholar] [CrossRef]

- Ganzelmeier, H.; Rautmann, D.; Spangenberg, R.; Streloke, M.; Herrmann, M.; Wenzelburger, H.J.; Walter, H.F. Studies on spray drift of plant protection products. Mitt. Biol. Bundesanst. Land. Forstwirtsch. Berl. Dahl. 1995, 305, 1–111. [Google Scholar]

- Felsot, A.S.; Unsworth, J.B.; Linders, J.B.H.; Roberts, G.; Rautman, D.; Harris, C.; Carazo, E. Agrochemical spray drift; assessment and mitigation—A review. J. Eviron. Sci. Health B 2011, 46, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Miller, P.C.H. Spray drift and its measurement. In Application Technology for Crop Protection; Matthews, G.A., Hislop, E.C., Eds.; Centre for Agricultural Bioscience International: Wallingford, UK, 1993; pp. 101–122. [Google Scholar]

- Gregorio, E.; Rosell-Polo, J.R.; Sanz, R.; Rocadenbosch, F.; Solanelles, F.; Garcerá, C.; Chueca, P.; Arnó, J.; del Moral, I.; Masip, J.; et al. LIDAR as an alternative to passive collectors to measure pesticide spray drift. Atmos. Environ. 2014, 82, 83–93. [Google Scholar] [CrossRef]

- Llorens, J.; Gallart, M.; Llop, J.; Miranda-Fuentes, A.; Gil, E. Difficulties to apply ISO 22866 requirements for drift measurement. A particular case of traditional olive tree plantations. Asp. Appl. Biol. 2016, 132, 31–37. [Google Scholar]

- May, K.R.; Clifford, R. The impaction of aerosol particles on cylinders, spheres, ribbons and discs. Ann. Occup. Hyg. 1967, 10, 83–95. [Google Scholar] [CrossRef]

- Cooke, B.K.; Hislop, E.C. Spray tracing techniques. In Application Technology for Crop Protection; Matthews, G.A., Hislop, E.C., Eds.; Centre for Agricultural Bioscience International: Wallingford, UK, 1993; pp. 85–100. [Google Scholar]

- Gil, Y.; Sinfort, C. Emission of pesticides to the air during sprayer application: A bibliographic review. Atmos. Environ. 2005, 39, 5183–5193. [Google Scholar] [CrossRef]

- Derksen, R.C.; Ozkan, H.E.; Fox, R.D.; Brazee, R.D. Droplet spectra and wind tunnel evaluation of venture and pre-orifice nozzles. Trans. ASAE 1999, 42, 1573–1580. [Google Scholar] [CrossRef]

- Nuyttens, D.; Taylor, W.A.; De Schampheleire, M.; Verboven, P.; Dekeyser, D. Influence of nozzle type and size on drift potential by means of different tunnel evaluation methods. Biosyst. Eng. 2009, 103, 271–280. [Google Scholar] [CrossRef]

- Balsari, P.; Marucco, P.; Tamagnone, M. A test bench for the classification of boom sprayers according to drift risk. Crop Prot. 2007, 26, 1482–1489. [Google Scholar] [CrossRef]

- Gil, E.; Balsari, P.; Gallart, M.; Llorens, J.; Marucco, P.; Andersen, P.G.; Fàbregas, X.; Llop, J. Determination of drift potential of different flat fan nozzles on a boom sprayer using a test bench. Crop Prot. 2014, 56, 58–68. [Google Scholar] [CrossRef]

- Van de Zande, J.C.; Holterman, H.J.; Wenneker, M. Nozzle classification for drift reduction in orchard spraying: Identification of drift reduction class threshold nozzles. Agric. Eng. Int. CIGR J. 2008, 10, 1–12. [Google Scholar]

- Planas, S.; Solanelles, F.; Torrent, X.; Camp, F.; Gregorio, E.; Rosell, J.R. Comparing standardized methods for potential drift assessment. In Proceedings of the 12th Workshop on Spray Application Techniques in Fruit Growing, Valencia, Spain, 26–28 June 2013; pp. 112–115.

- Hoff, R.M.; Mickle, R.E.; Froude, F.A. A rapid acquisition lidar for aerial spray diagnostics. Trans. ASAE 1989, 32, 1523–1528. [Google Scholar] [CrossRef]

- Mickle, R.E. Utilizing vortex behaviour to minimize drift. J. Eviron. Sci. Health B 1994, 29, 621–645. [Google Scholar] [CrossRef]

- Mickle, R.E. Influence of aircraft vortices on spray cloud behaviour. J. Am. Mosq. Contr. 1996, 12, 372–379. [Google Scholar]

- Stoughton, T.E.; Miller, D.R.; Yang, Y.; Ducharme, K.M. A comparison of spray drift predictions to lidar data. Agric. For. Meteorol. 1997, 88, 15–18. [Google Scholar] [CrossRef]

- Miller, D.R.; Stoughton, T.E. Response of spray drift from aerial applications at forest edge to atmospheric stability. Agr. For. Meteorol. 2000, 100, 49–58. [Google Scholar] [CrossRef]

- Miller, D.R.; Khot, L.R.; Hiscox, A.L.; Salyani, M.; Walker, T.W.; Farooq, M. Effect of atmospheric conditions on coverage of fogger applications in a desert surface boundary layer. Trans. ASABE 2012, 55, 351–361. [Google Scholar] [CrossRef]

- Hiscox, A.L.; Miller, D.R.; Nappo, C.J.; Ross, J. Dispersion of fine spray from aerial applications in stable atmospheric conditions. Trans. ASABE 2006, 49, 1513–1520. [Google Scholar] [CrossRef]

- Khot, L.R.; Miller, D.R.; Hiscox, A.L.; Salyani, M.; Walker, T.W.; Farooq, M. Extrapolation of droplet catch measurements in aerosol application treatments. Atomization Spray 2011, 21, 149–158. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Gallart, M. Use of a terrestrial lidar sensor for drift detection in vineyard spraying. Sensors 2013, 13, 516–534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gregorio, E.; Rocadenbosch, F.; Sanz, R.; Rosell-Polo, J.R. Eye-safe lidar system for pesticide spray drift measurement. Sensors 2015, 15, 3650–3670. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Safety of Laser Products—Part 1: Equipment Classification and Requirements. IEC 60825-1. Available online: https://webstore.iec.ch/publication/3587 (accessed on 8 April 2016).

- Measures, R.M. Laser Remote Sensing: Fundamentals and Applications; Krieger Publishing Co.: Malabar, FL, USA, 1992. [Google Scholar]

- Collis, R.T.H.; Russell, P.B. Lidar measurement of particles and gases by elastic backscattering and differential absorption. In Laser Monitoring of the Atmosphere; Hinkley, E.D., Ed.; Springer: Berlin/Heidelberg, Germany, 1976; pp. 71–151. [Google Scholar]

- Gregorio, E.; Torrent, X.; Solanelles, F.; Sanz, R.; Rocadenbsch, F.; Masip, J.; Ribes-Dasi, M.; Planas, S.; Rosell-Polo, J.R. First measurements with a lidar systems specifically designed for spray drift monitoring. In Proceedings of the 13th Workshop on Spray Application Techniques in Fruit Growing, Lindau, Germany, 15–18 June 2015; pp. 36–37.

- Nuyttens, D.; De Schampheleire, M.; Baetens, B.; Sonck, B. The influence of operator controlled variables on spray drift from field crop sprayers. Trans. ASABE 2007, 50, 1128–1140. [Google Scholar] [CrossRef]

- Spuler, S.M.; Mayor, S.D. Scanning eye-safe elastic backscatter lidar at 1.54 μm. J. Atmos. Ocean. Technol. 2005, 22, 696–703. [Google Scholar] [CrossRef]

- Gregorio, E.; Rocadenbosch, F.; Tiana-Alsina, J.; Comerón, A.; Sanz, R.; Rosell, J.R. Parameter design of a biaxial lidar ceilometer. J. Appl. Remote Sens. 2012, 6, 063546. [Google Scholar]

- International Standard. Equipment for Crop Protection. Methods for the laboratory measurement of spray drift—Wind tunnels. ISO 22856. Available online: http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=41187 (accessed on 8 April 2016).

| Test | Date | Start Time (UTC) | Spraying Duration (s) | Lidar Operational Mode | Passive Collectors (ISO 22866 [1]) | Sprayer Operational Mode | Nozzles | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static with mirror 2 perpendicular directions | Static without mirror: measuring over the trees | Scanning over the trees: scanning plane | Filter paper (horizontal collectors) | Nylon lines (vertical collectors) | Water sensitive papers (vertical collectors) | Moving along crop alleys (# of alleys) | Stationary | Standard Albuz ATR 80 Grey | Low Drift Albuz TVI 8003 Blue | ||||

| T1 | 2014-11-13 | 16:15:31 | 330 | - | X | - | - | - | - | X(2) | - | X | - |

| T2 | 2014-11-13 | 16:38:23 | 409 | - | X | - | - | - | - | X(2) | - | - | X |

| T3 | 2014-11-18 | 13:29:54 | 802 | X | - | - | X | X | X | X(7) | - | - | X |

| T4 | 2014-11-18 | 15:10:51 | 883 | X | - | - | X | X | X | X(7) | - | X | - |

| T5 | 2014-11-19 | 11:50:05 | 935 | X | - | - | X | X | X | X(7) | - | X | - |

| T6 | 2014-11-19 | 14:20:21 | 823 | X | - | - | X | X | X | X(7) | - | - | X |

| T7a 1 | 2014-11-21 | 12:19:48 | 80 | - | - | PPI 2 | - | - | - | - | X | - | X |

| T7b 1 | 2014-11-21 | 12:26:18 | 65 | - | - | PPI | - | - | - | - | X | - | X |

| T8a | 2014-11-21 | 12:43:53 | 65 | - | - | RHI 2 (vertical) | - | - | - | - | X | - | X |

| T8b | 2014-11-21 | 12:46:17 | 65 | - | - | RHI (vertical) | - | - | - | - | X | - | X |

| T9a | 2014-11-21 | 14:35:33 | 65 | - | - | PPI | - | - | - | - | X | X | - |

| T9b | 2014-11-21 | 14:42:11 | 65 | - | - | PPI | - | - | - | - | X | X | - |

| T10a | 2014-11-21 | 14:54:07 | 65 | - | - | RHI (vertical) | - | - | - | - | X | X | - |

| T10b | 2014-11-21 | 15:00:27 | 65 | - | - | RHI (vertical) | - | - | - | - | X | X | - |

| Item | Specification |

|---|---|

| Wavelength | 1534 nm (Erbium glass laser) |

| Pulse energy | 3 mJ |

| Pulse duration | 6 ns |

| Repetition rate | Single shot-10 Hz (adjustable) |

| Beam divergence | 210 μrad (full angle) |

| Telescope aperture | 80 mm |

| Detector type | Avalanche photodiode |

| Sampling rate | 500 MS/s |

| Digitizer resolution | 12 bits |

| Spatial resolution | 2.4 m |

| Test | T (°C) Height = 4 m | T (°C) Height = 7 m | Relative Humidity (%) | Wind Speed (m·s−1) | Wind Direction (degrees 1) |

|---|---|---|---|---|---|

| T1 | 12.94 | 12.24 | 74.27 | 1.47 | −3.42 |

| T2 | 12.11 | 11.61 | 79.89 | 1.46 | −7.74 |

| T3 | 15.78 | 15.32 | 49.98 | 1.61 | −9.43 |

| T4 | 16.67 | 16.38 | 53.51 | 1.81 | −14.21 |

| T5 | 16.27 | 15.76 | 60.98 | 1.12 | −21.83 |

| T6 | 16.65 | 15.89 | 58.00 | 1.21 | −24.07 |

| T7a | 15.89 | 15.30 | 68.72 | 1.07 | 12.04 |

| T7b | 16.45 | 15.91 | 67.76 | 1.32 | 6.52 |

| T8a | 17.13 | 16.73 | 65.85 | 1.00 | −6.65 |

| T8b | 17.32 | 16.91 | 64.85 | 0.93 | −17.11 |

| T9a | 16.21 | 15.29 | 62.92 | 0.98 | 18.89 |

| T9b | 16.92 | 16.70 | 72.97 | 1.42 | −17.77 |

| T10a | 16.86 | 16.62 | 73.94 | 1.00 | 7.23 |

| T10b | 16.82 | 16.52 | 75.94 | 1.07 | 17.23 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gregorio, E.; Torrent, X.; Planas de Martí, S.; Solanelles, F.; Sanz, R.; Rocadenbosch, F.; Masip, J.; Ribes-Dasi, M.; Rosell-Polo, J.R. Measurement of Spray Drift with a Specifically Designed Lidar System. Sensors 2016, 16, 499. https://doi.org/10.3390/s16040499

Gregorio E, Torrent X, Planas de Martí S, Solanelles F, Sanz R, Rocadenbosch F, Masip J, Ribes-Dasi M, Rosell-Polo JR. Measurement of Spray Drift with a Specifically Designed Lidar System. Sensors. 2016; 16(4):499. https://doi.org/10.3390/s16040499

Chicago/Turabian StyleGregorio, Eduard, Xavier Torrent, Santiago Planas de Martí, Francesc Solanelles, Ricardo Sanz, Francesc Rocadenbosch, Joan Masip, Manel Ribes-Dasi, and Joan R. Rosell-Polo. 2016. "Measurement of Spray Drift with a Specifically Designed Lidar System" Sensors 16, no. 4: 499. https://doi.org/10.3390/s16040499